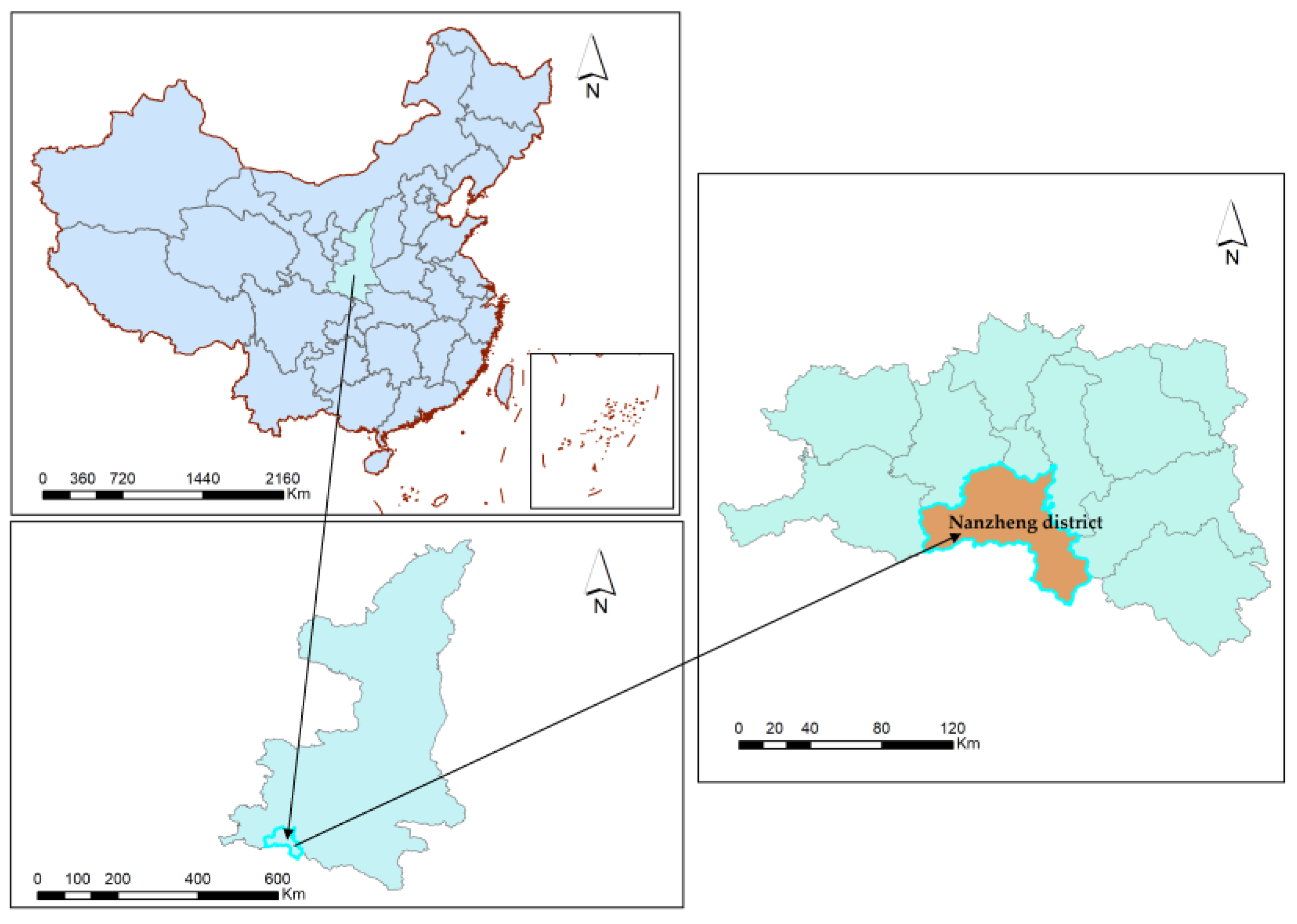

Life Cycle Assessment of Carbon Footprint of Green Tea Produced by Smallholder Farmers in Shaanxi Province of China

Abstract

1. Introduction

2. Materials and Methods

2.1. System Boundary

- (1)

- Cultivation: Emissions from the upstream production of fertilizer and pesticide, as well as emissions from fertilizer application in the field and the use of agricultural machinery in the pruning and harvesting period.

- (2)

- Processing: Emissions from electricity, coal, and pellets consumed by mechanical equipment in the processing stage.

- (3)

- Packaging and transportation: Emissions from the production of packaging materials and energy consumption during transportation.

- (4)

- Consumption and disposal: Emissions from boiling water and tea residue treatment.

2.2. Data Inventory

2.2.1. Cultivation

2.2.2. Processing

2.2.3. Packaging and Transport

2.2.4. Consumption and Disposal

2.3. Carbon Footprint Calculation Method

2.3.1. CO2 Emissions

2.3.2. N2O Emissions

2.3.3. Carbon Storage of Tea Plants

2.3.4. Carbon Emissions of Tea per Unit

3. Results

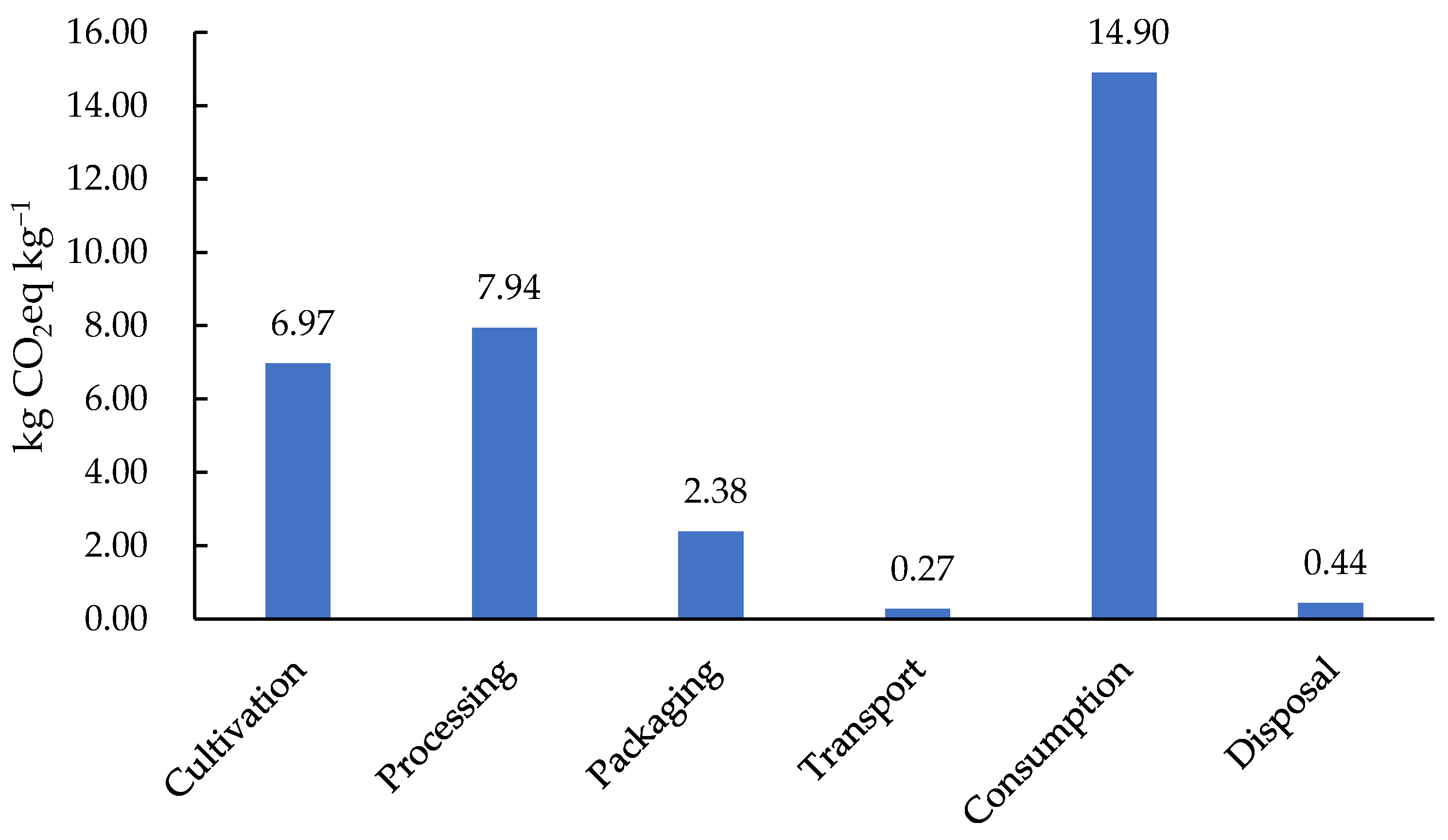

3.1. Carbon Emissions from Each Stage

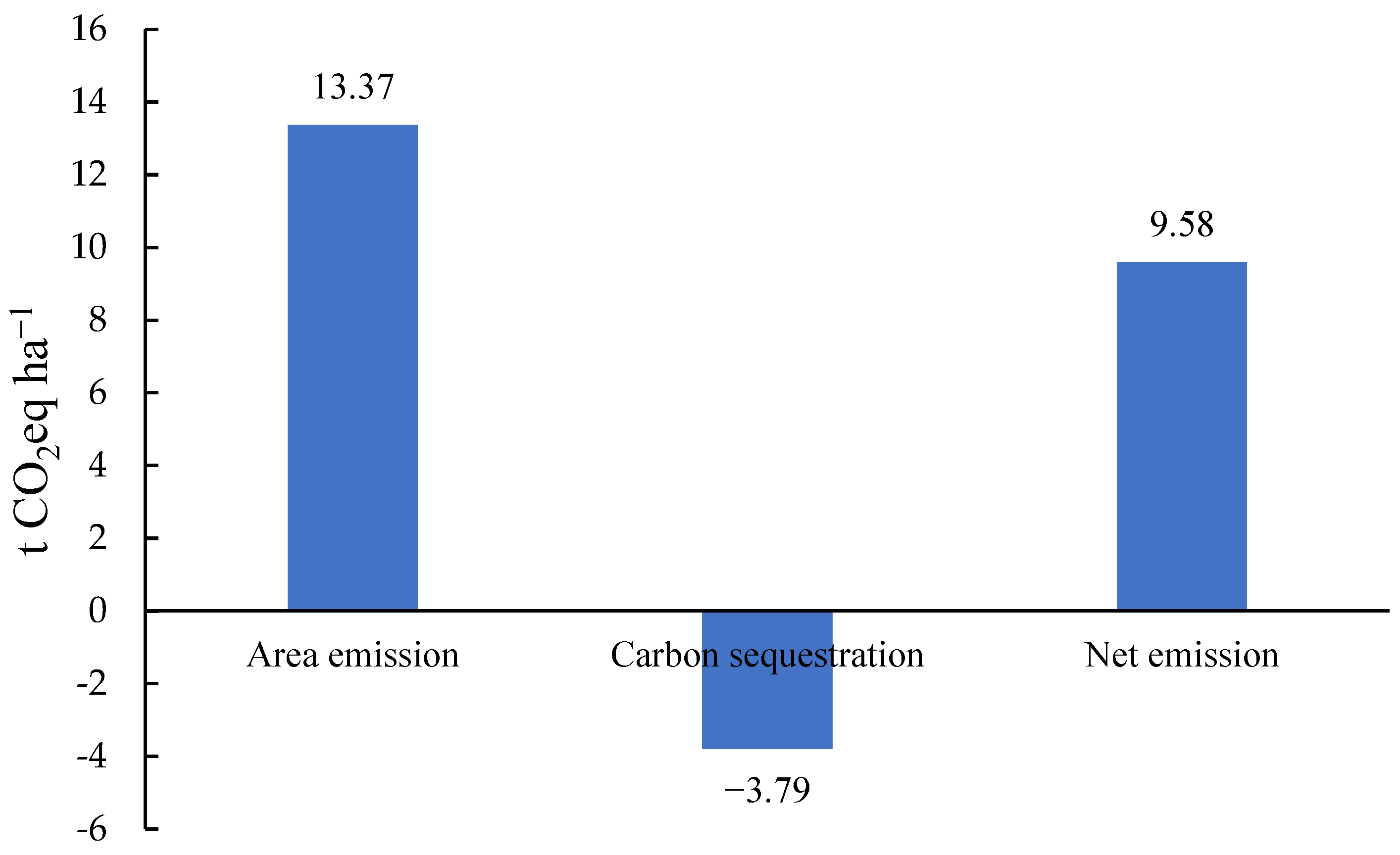

3.2. Carbon Footprint of the Cultivation Stage

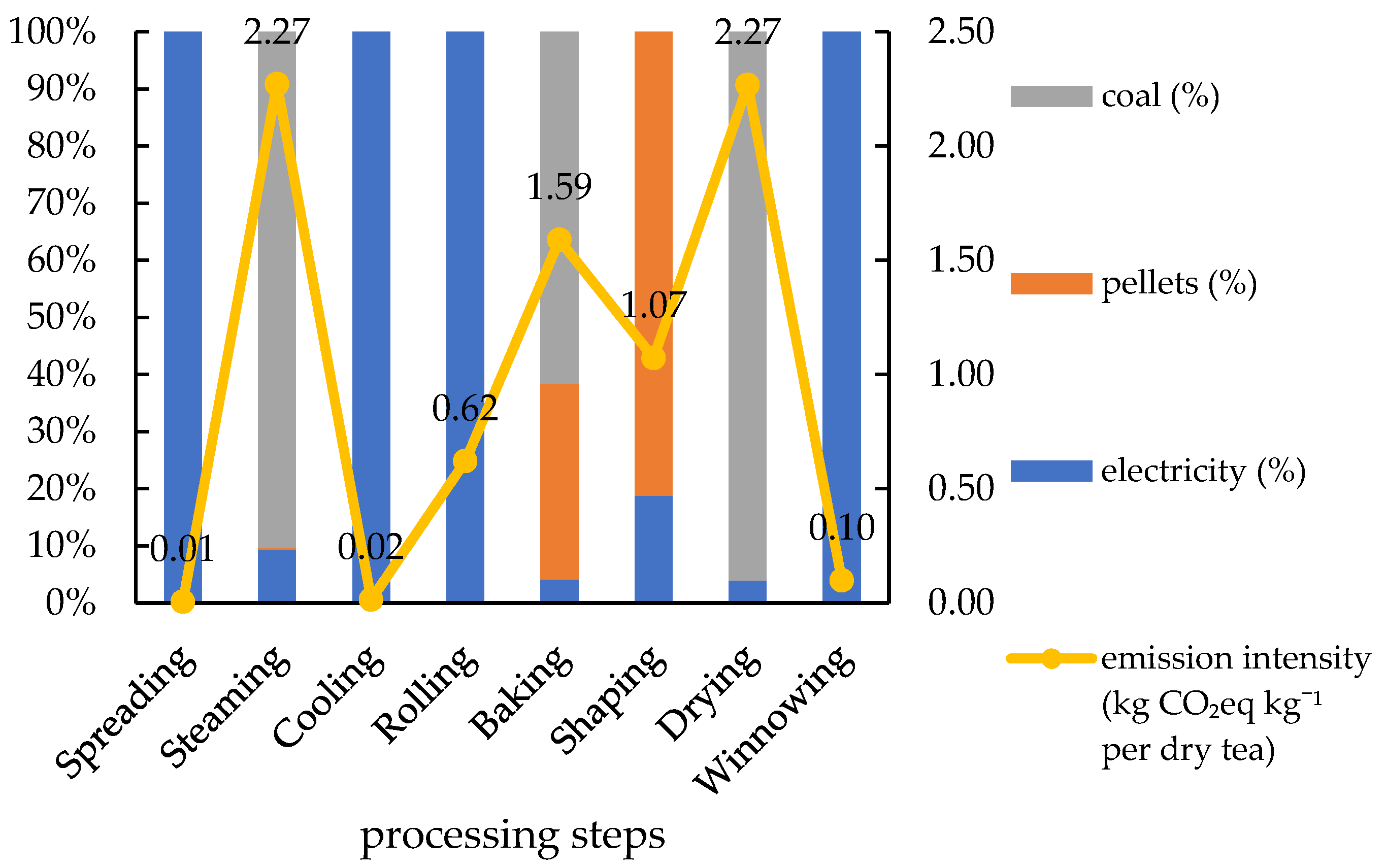

3.3. Carbon Footprint of the Processing Stage

4. Discussion

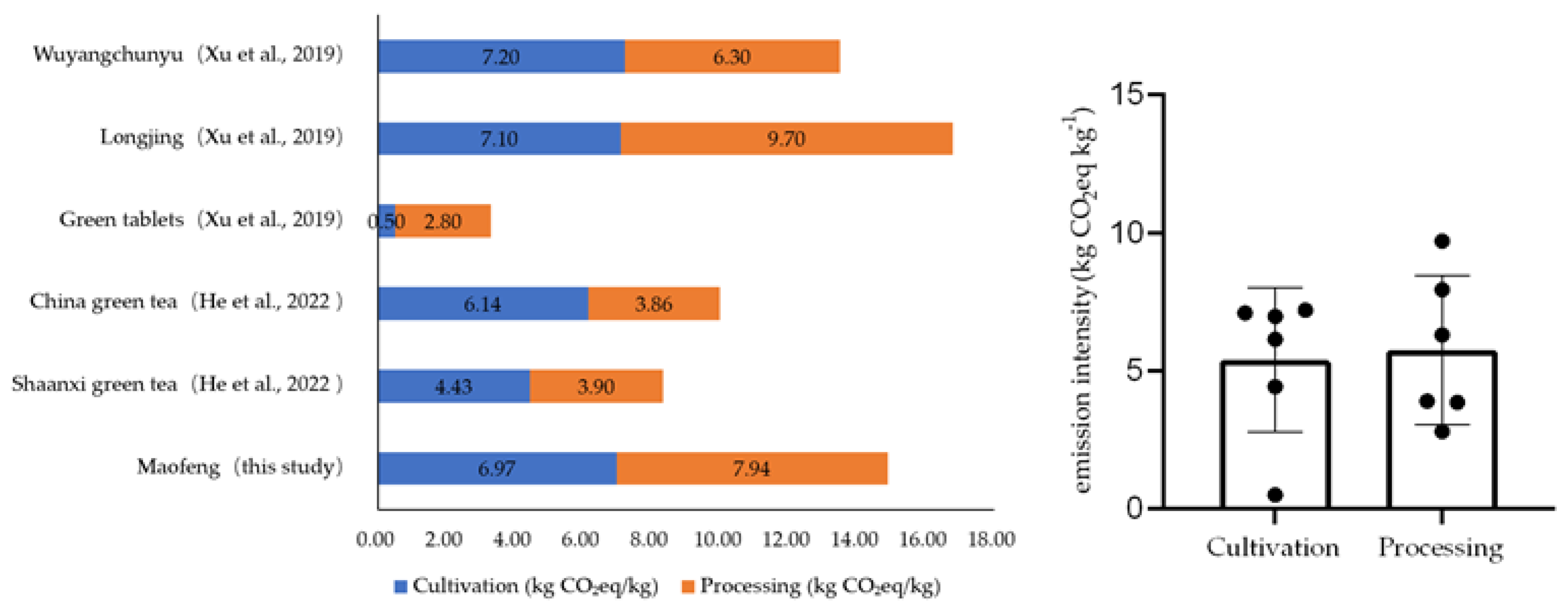

4.1. Carbon Footprint of the Production System

4.2. Carbon Footprint of the Consumer System

4.3. Limitations of This Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Voora, V.; Bermúdez, S.; Larrea, C. Global Market Report: Tea; International Institute for Sustainable Development (IISD): Winnipeg, MB, Canada, 2019. [Google Scholar]

- Su, S.; Wan, C.; Li, J.; Jin, X.; Pi, J.; Zhang, Q.; Weng, M. Economic Benefit and Ecological Cost of Enlarging Tea Cultivation in Subtropical China: Characterizing the Trade-off for Policy Implications. Land Use Policy 2017, 66, 183–195. [Google Scholar] [CrossRef]

- Fang, Q.; Shi, Q. Research on the Impact of Cooperatives on the Production Benefits of Small Farmers: Based on the Investigation and Analysis of Anhui Tea Industry. J. Yunnan Agric. Univ. Soc. Sci. 2021, 15, 55–60. [Google Scholar]

- Zhang, W.; Qiao, Y.; Lakshmanan, P.; Yuan, L.; Liu, J.; Zhong, C.; Chen, X. Combing Public-Private Partnership and Large-Scale Farming Increased Net Ecosystem Carbon Budget and Reduced Carbon Footprint of Maize Production. Resour. Conserv. Recycl. 2022, 184, 106411. [Google Scholar] [CrossRef]

- Deka, N.; Goswami, K. Economic Sustainability of Organic Cultivation of Assam Tea Produced by Small-Scale Growers. Sustain. Prod. Consum. 2021, 26, 111–125. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, W. An Empirical Study on China’s Tea Export, tea Industry Development Andcounty Economic Growth from the Perspective of Rural Revitalization—An Empirical Study Based on 27 Counties in 7 Provinces. J. Tea 2019, 45, 205–211. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. China Rural Statistical Yearbook; National Bureau of Statistics of China: Beijing, China, 2021. [Google Scholar]

- Rondoni, A.; Grasso, S. Consumers Behaviour towards Carbon Footprint Labels on Food: A Review of the Literature and Discussion of Industry Implications. J. Clean. Prod. 2021, 301, 127031. [Google Scholar] [CrossRef]

- He, M.-B.; Zong, S.-X.; Li, Y.-C.; Ma, M.-M.; Ma, X.; Li, K.; Han, X.; Zhao, M.-Y.; Guo, L.-P.; Xu, Y.-L. Carbon Footprint and Carbon Neutrality Pathway of Green Tea in China. Adv. Clim. Change Res. 2022, 13, 443–453. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Y.; Wu, Z.; Jiang, F.; Zhang, W.; Weng, B.; You, Z. Estimation of Greenhouse Gas Emissions from Fertilization, Production and Transportation of Synthetic Nitrogen for Tea Garden in Typical Region of China. J. Tea Sci. 2020, 40, 205–214. [Google Scholar]

- Zou, Z.; Shen, C.; Li, X.; Zhang, L.; Zhang, L.; Han, W.; Yan, P. State Quo of Nitrogen Fertilizer Application and Loss in Tea Garden in China. J. Plant Nutr. Fertil. 2021, 27, 153–160. [Google Scholar]

- Wang, Z.; Geng, Y.; Liang, T. Optimization of Reduced Chemical Fertilizer Use in Tea Gardens Based on the Assessment of Related Environmental and Economic Benefits. Sci. Total Environ. 2020, 713, 136439. [Google Scholar] [CrossRef]

- Li, F. Thinking on the Development of Mechanization of Tea Primary Processing in Yidu City. Hubei Agric. Mech. 2019, 10, 3–4. [Google Scholar]

- Zhang, Q.; Cui, Q.; Wang, Y.; Luo, H.; Dai, J.; Liang, J. Energy Consumption Status and Energy Substitution Countermeasures of Tea Processing Enterprises in Enshi Prefecture. China Tea 2018, 40, 48–52. [Google Scholar]

- Zeng, X.; Long, J.; Yan, Y.; Huang, C.; Peng, X. Preliminary Report on the Use of Clean Energy in the Primary Processing of Tea in Yiling District. Hubei Agric. Mech. 2018, 47–48. [Google Scholar]

- Shi, S.; Yin, J. Global Research on Carbon Footprint: A Scientometric Review. Environ. Impact Assess. Rev. 2021, 89, 106571. [Google Scholar] [CrossRef]

- Wu, R.; Xie, Y.; Wang, Y.; Li, Z.; Hou, L. The Comparative Landscape of Chinese and Foreign Articles on the Carbon Footprint Using Bibliometric Analysis. Environ. Sci. Pollut. Res. 2022, 29, 35471–35483. [Google Scholar] [CrossRef] [PubMed]

- ISO 14067:2018(E); Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- Matthews, H.S.; Hendrickson, C.T.; Matthews, D. Life Cycle Assessment: Quantitative Approaches for Decisions That Matter; Carnegie Mellon University: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Liang, L.; Ridoutt, B.G.; Wang, L.; Xie, B.; Li, M.; Li, Z. China’s Tea Industry: Net Greenhouse Gas Emissions and Mitigation Potential. Agriculture 2021, 11, 363. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, Q. Analysis on Carbon Emissions of Green Tea Production According to PAS2050. Hubei Agric. Sci. 2016, 55, 608–611. [Google Scholar]

- Xu, Q.; Hu, K.; Wang, X.; Wang, D.; Knudsen, M.T. Carbon Footprint and Primary Energy Demand of Organic Tea in China Using a Life Cycle Assessment Approach. J. Clean. Prod. 2019, 233, 782–792. [Google Scholar] [CrossRef]

- Azapagic, A.; Bore, J.; Cheserek, B.; Kamunya, S.; Elbehri, A. The Global Warming Potential of Production and Consumption of Kenyan Tea. J. Clean. Prod. 2016, 112, 4031–4040. [Google Scholar] [CrossRef]

- Cichorowski, G.; Joa, B.; Hottenroth, H.; Schmidt, M. Scenario Analysis of Life Cycle Greenhouse Gas Emissions of Darjeeling Tea. Int. J. Life Cycle Assess. 2015, 20, 426–439. [Google Scholar] [CrossRef]

- Doublet, G.; Jungbluth, N. Life Cycle Assessment of Drinking Darjeeling Tea. In Conventional and Organic Darjeeling Tea; ESU-Services Ltd.: Uster, Switzerland, 2010. [Google Scholar]

- Munasinghe, M.; Deraniyagala, Y.; Dassanayake, N.; Karunarathna, H. Economic, Social and Environmental Impacts and Overall Sustainability of the Tea Sector in Sri Lanka. Sustain. Prod. Consum. 2017, 12, 155–169. [Google Scholar] [CrossRef]

- Vidanagama, J.; Lokupitiya, E. Energy Usage and Greenhouse Gas Emissions Associated with Tea and Rubber Manufacturing Processes in Sri Lanka. Environ. Dev. 2018, 26, 43–54. [Google Scholar] [CrossRef]

- Taulo, J.L.; Sebitosi, A.B. Material and Energy Flow Analysis of the Malawian Tea Industry. Renew. Sustain. Energy Rev. 2016, 56, 1337–1350. [Google Scholar] [CrossRef]

- Zhao, X. Research on the Development of Tea Industry in Shaanxi Province. Ph.D. Thesis, Northwest A & F University, Xianyang, China, 2013. [Google Scholar]

- Ju, Y. Development Status and Countermeasures of Shaanxi Tea Industry. Northwest Hortic. 2018, 39–41. [Google Scholar]

- Wang, D.; Wang, H. Problems and Countermeasures in the Development of Hanzhong Tea Industry. Shaanxi J. Agric. Sci. 2008, 118–120. [Google Scholar]

- Chen, S.; Lu, F.; Wang, X. Estimation of Greenhouse Gases Emission Factors for China’s Nitrogen, phosphate, and Potash Fertilizers. Acta Ecol. Sin. 2015, 35, 6371–6383. [Google Scholar]

- Yao, Z.; Wang, Y.; Wang, R.; Liu, C.; Zheng, X. Nitrous Oxide Emissions and Controlling Factors of Tea Plantations in China. J. Agro-Environ. Sci. 2020, 39, 715–725. [Google Scholar]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories Volume 4 Agriculture, Forestry and Other Land Use; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Zhang, G.; Lu, F.; Huang, Z.; Chen, S.; Wang, X. Estimations of Application Dosage and Greenhouse Gas Emission of Chemical Pesticides in Staple Crops in China. Chin. J. Appl. Ecol. 2016, 27, 2875–2883. [Google Scholar]

- National Development and Reform Commission (NDRC) of China. Methods and Guidelines for Accounting for Greenhouse Gas Emissions by Food, Tobacco, Alcohol, Beverage and Tea Enterprises; NDRC: Beijing, China, 2015; pp. 1–28. [Google Scholar]

- National Development and Reform Commission (NDRC) of China. Average CO2 Emission Factors for China’s Regional Grids in 2011 and 2012; NDRC: Beijing, China, 2014. [Google Scholar]

- National Development and Reform Commission (NDRC) of China. Guidelines for the Preparation of Provincial GHG Inventories; NDRC: Beijing, China, 2010. [Google Scholar]

- Ma, X.; Li, C.; Li, B. Carbon Emissions of China’s Cement Packaging: Life Cycle Assessment. Sustainability 2019, 11, 5554. [Google Scholar] [CrossRef]

- Han, Y. Life Cycle Analysis of Water Consumption, Energy Consumption, and GHG Emissions and Sustainable Production Pathways Investigation for Papermaking Industry in China. Master’s Thesis, South China University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Energy-Saving and Green-Development Assessment Center for Automobile Industrial. China Automobile Low Carbon Action Plan (CALCP) Research Report 2021; Energy-Saving and Green-Development Assessment Center for Automobile Industrial: Beijing, China, 2021. [Google Scholar]

- Guan, X.; Yang, J.; Xie, X.; Lin, C.; Li, J. Research on the Behavior of Tea Consumption in China with the CKB Data. J. Tea Sci. 2018, 38, 287–295. [Google Scholar]

- Gallego-Schmid, A.; Jeswani, H.K.; Mendoza, J.M.F.; Azapagic, A. Life Cycle Environmental Evaluation of Kettles: Recommendations for the Development of Eco-Design Regulations in the European Union. Sci. Total Environ. 2018, 625, 135–146. [Google Scholar] [CrossRef] [PubMed]

- Bian, R.; Zhang, T.; Zhao, F.; Chen, J.; Liang, C.; Li, W.; Sun, Y.; Chai, X.; Fang, X.; Yuan, L. Greenhouse Gas Emissions from Waste Sectors in China during 2006–2019: Implications for Carbon Mitigation. Process Saf. Environ. Prot. 2022, 161, 488–497. [Google Scholar] [CrossRef]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories Volume 4 Agriculture, Forestry and Other Land Use; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- IPCC. IPCC, 2014: Climate Change 2014: Synthesis Report; Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Zhang, M.; Chen, Y.; Yu, C.; Pan, Z.; Fan, D.; Luo, Y.; Wang, X. Dynamic Assessment of Plant Biomass and Carbon Storage during the Production Cycle of the Gardens. J. Zhejiang Univ. Agric. Life Sci. 2013, 39, 687–694. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, Y.; Fan, D.; Zhu, Q.; Pan, Z.; Fan, K.; Wang, X. Temporal Evolution of Carbon Storage in Chinese Tea Plantations from 1950 to 2010. Pedosphere 2017, 27, 121–128. [Google Scholar] [CrossRef]

- Wang, S.; Li, T.; Zheng, Z.; Zhang, X.; Chen, H.Y.H. Soil Organic Carbon and Nutrients Associated with Aggregate Fractions in a Chronosequence of Tea Plantations. Ecol. Indic. 2019, 101, 444–452. [Google Scholar] [CrossRef]

- Ruan, J. Carbon Sequestration Potential of Tea Plantation Ecosystems and Low-Carbon Tea Production Technologies. China Tea 2010, 32, 6–9. [Google Scholar]

- Chen, J.; Jiang, J.; Chen, Y.; Guo, G. Research on Energy-Saving Tea Processing Line. Tea Fujian 2022, 44, 13–16. [Google Scholar]

- Chen, X.; Ma, C.; Zhou, H.; Liu, Y.; Huang, X.; Wang, M.; Cai, Y.; Su, D.; Muneer, M.A.; Guo, M.; et al. Identifying the Main Crops and Key Factors Determining the Carbon Footprint of Crop Production in China, 2001–2018. Resour. Conserv. Recycl. 2021, 172, 105661. [Google Scholar] [CrossRef]

- Wang, J.; Tu, X.; Zhang, H.; Cui, J.; Ni, K.; Chen, J.; Cheng, Y.; Zhang, J.; Chang, S.X. Effects of Ammonium-Based Nitrogen Addition on Soil Nitrification and Nitrogen Gas Emissions Depend on Fertilizer-Induced Changes in PH in a Tea Plantation Soil. Sci. Total Environ. 2020, 747, 141340. [Google Scholar] [CrossRef]

- IPCC. Global Warming of 1.5 °C: An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Boehm, R.; Cash, S.; Anderson, B.; Ahmed, S.; Griffin, T.; Robbat, A.; Stepp, J.; Han, W.; Hazel, M.; Orians, C. Association between Empirically Estimated Monsoon Dynamics and Other Weather Factors and Historical Tea Yields in China: Results from a Yield Response Model. Climate 2016, 4, 20. [Google Scholar] [CrossRef]

- FAO. Carbon Neutral Tea Production in China—Three Pilot Case Studies; FAO: Rome, Italy, 2021; ISBN 978-92-5-134373-9. [Google Scholar]

- Xie, S.; Yang, F.; Feng, H.; Yu, Z.; Liu, C.; Wei, C.; Liang, T. Organic Fertilizer Reduced Carbon and Nitrogen in Runoff and Buffered Soil Acidification in Tea Plantations: Evidence in Nutrient Contents and Isotope Fractionations. Sci. Total Environ. 2021, 762, 143059. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; Cai, T.; Feng, X.; You, L.; Yang, X.; Huang, C.; Chen, Y.; Cui, Z. Effects of New Fertilizers on the Yield and Soil Biological Activity of Threemajor Food Crops: A Global Meta-Analysis. J. Plant Nutr. Fertil. 2021, 27, 1496–1505. [Google Scholar]

- Qiao, Y.; Halberg, N.; Vaheesan, S.; Scott, S. Assessing the Social and Economic Benefits of Organic and Fair Trade Tea Production for Small-Scale Farmers in Asia: A Comparative Case Study of China and Sri Lanka. Renew. Agric. Food Syst. 2016, 31, 246–257. [Google Scholar] [CrossRef]

- Xu, Q.; Yang, Y.; Hu, K.; Chen, J.; Djomo, S.N.; Yang, X.; Knudsen, M.T. Economic, Environmental, and Emergy Analysis of China’s Green Tea Production. Sustain. Prod. Consum. 2021, 28, 269–280. [Google Scholar] [CrossRef]

- Antón, A.; Torrellas, M.; Núñez, M.; Sevigné, E.; Amores, M.J.; Muñoz, P.; Montero, J.I. Improvement of Agricultural Life Cycle Assessment Studies through Spatial Differentiation and New Impact Categories: Case Study on Greenhouse Tomato Production. Environ. Sci. Technol. 2014, 48, 9454–9462. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC Toxicity Model: Recommended Characterisation Factors for Human Toxicity and Freshwater Ecotoxicity in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2008, 13, 532. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.A. Modelling the Long-Term Atmospheric Behaviour of Pollutants on Various Spatial Scales; RIVM: Utrecht, The Netherlands, 1995; ISBN 90-393-0950-7. [Google Scholar]

| Stage | Carbon Emissions Source | Activity Data (AD) | Emission Factors (EF) | Reference | |

|---|---|---|---|---|---|

| Cultivation | Practices one (upstream) | Diammonium phosphate | 517.5 kg P2O5 ha−1 | 4.07 kg CO2eq (kg P2O5)−1 | [32] |

| Urea | 517.5 kg N ha−1 | 7.48 kg CO2eq (kg N)−1 | |||

| Practices two (upstream) | Ammonium carbonate | 510 kg N ha−1 | 7.07 kg CO2eq (kg N)−1 | ||

| Phosphate fertilizer | 690 kg P2O5 ha−1 | 2.33 kg CO2eq (kg P2O5)−1 | |||

| Urea | 690 kg N ha−1 | 7.48 kg CO2eq (kg N)−1 | |||

| Nitrogen fertilizer application | Direct emissions of N2O | 517.5 kg N ha−1 (Practices one); 1200 kg N ha−1 (Practices two) | 1.92% | [33] | |

| Nitrogen deposition | 1% | [34] | |||

| Leaching runoff | 1% | ||||

| Chemical pesticide (upstream) | Pesticide (Cypermethrin, 100%) | Twice a year | 54.27 kg CO2eq ha−1 | [35] | |

| Germicide (Carbendazim, 60%) | Twice a year | 57.57 kg CO2eq ha−1 | |||

| Machinery | Pruning (90%) | 37.5 L ha−1 (once) | 2.925 kg CO2eq kWh−1 | [36] | |

| Picking (50%) | 30 L ha−1 (twice) | ||||

| Processing | Energy Input and Tea-Processing Capacity of Each Procedure | |||

|---|---|---|---|---|

| Electricity (kwh) | Coal (kg h−1) | Pellets (kg h−1) | Tea-Processing Capacity (kg h−1) | |

| 1. Spreading | 0.175 | / | / | 75–100 |

| 2. Steaming | 24 | 83.33–100 | 0.83 | 300–400 |

| 3. Cooling | 2.5 | / | / | 400–600 |

| 4. Rolling | 30 | / | / | 145 |

| 5. Baking | 13 | 66.67–83.33 | 75 | 600 |

| 6. Shaping | 5 | / | 15 | 75 |

| 7. Drying | 4.5 | 41.67 | / | 150 |

| 8. Winnowing | 2.5 | / | / | 75 |

| Energy | EF | Unit | Reference |

|---|---|---|---|

| Electricity | 0.667 | kg CO2eq kWh−1 | [37] |

| Coal | 1.74 | kg CO2eq kg−1 | [36,38] |

| Pellets | 0.968 | kg CO2eq kg−1 |

| Packaging Category | AD | EF | Reference |

|---|---|---|---|

| Primary packaging | 45 kg tea per bag | 0.37 kg CO2eq per bag | [39] |

| Transportation packaging | 25 kg tea per box | 1.90 kg CO2eq per box | [40] |

| Product packaging | 1 kg per tea | 2.30 kg CO2eq kg−1 per kg tea | [22] |

| Destination (Province) | Bazhong (Sichuan) | Hanzhong (Shaanxi) | Ankang (Shaanxi) | Xi’an (Shaanxi) | Longnan (Gansu) |

|---|---|---|---|---|---|

| Freight volume | 40% | 20% | 10% | 20% | 10% |

| Haul distance | 156.10 km | 28.30 km | 241.70 km | 312.20 km | 315.50 km |

| EF | 0.29 kg CO2eq km−1 [41] | ||||

| Category | Value | Unit |

| Consumption per instance | 4 | g |

| Amount of hot water | 800 | mL |

| Electricity consumption | 0.122 | Kwh L−1 |

| Emission sources | Value | Unit |

| Northwest Regional Power Grid (Shaanxi, Gansu) | 0.667 | kg CO2eq kWh−1 |

| Central China Regional Power Grid (Sichuan) | 0.526 | kg CO2eq kWh−1 |

| Landfill | 0.674 | kg CO2eq kg−1 |

| Incineration | 0.229 | kg CO2eq kg−1 |

| Input | Carbon Emission Source | Emissions | Total |

|---|---|---|---|

| Fertilizer | Practice one (upstream) | 5977.13 | 10,920.74 |

| N2O emissions | 9887.22 | ||

| Practice two (upstream) | 4943.61 | 15,159.47 | |

| N2O emissions | 8167.71 | ||

| Upstream (average) | 6484.45 | 13,040.10 | |

| N2O emissions (average) | 6555.66 | ||

| Chemical pesticide | Cypermethrin | 108.53 | 174.35 |

| Carbendazim | 65.81 | ||

| Machinery | Pruning (90%) | 74.04 | 156.30 |

| Picking (50%) | 82.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, M.; Li, Y.; Zong, S.; Li, K.; Han, X.; Zhao, M. Life Cycle Assessment of Carbon Footprint of Green Tea Produced by Smallholder Farmers in Shaanxi Province of China. Agronomy 2023, 13, 364. https://doi.org/10.3390/agronomy13020364

He M, Li Y, Zong S, Li K, Han X, Zhao M. Life Cycle Assessment of Carbon Footprint of Green Tea Produced by Smallholder Farmers in Shaanxi Province of China. Agronomy. 2023; 13(2):364. https://doi.org/10.3390/agronomy13020364

Chicago/Turabian StyleHe, Mingbao, Yingchun Li, Shixiang Zong, Kuo Li, Xue Han, and Mingyue Zhao. 2023. "Life Cycle Assessment of Carbon Footprint of Green Tea Produced by Smallholder Farmers in Shaanxi Province of China" Agronomy 13, no. 2: 364. https://doi.org/10.3390/agronomy13020364

APA StyleHe, M., Li, Y., Zong, S., Li, K., Han, X., & Zhao, M. (2023). Life Cycle Assessment of Carbon Footprint of Green Tea Produced by Smallholder Farmers in Shaanxi Province of China. Agronomy, 13(2), 364. https://doi.org/10.3390/agronomy13020364