Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device

Abstract

:1. Introduction

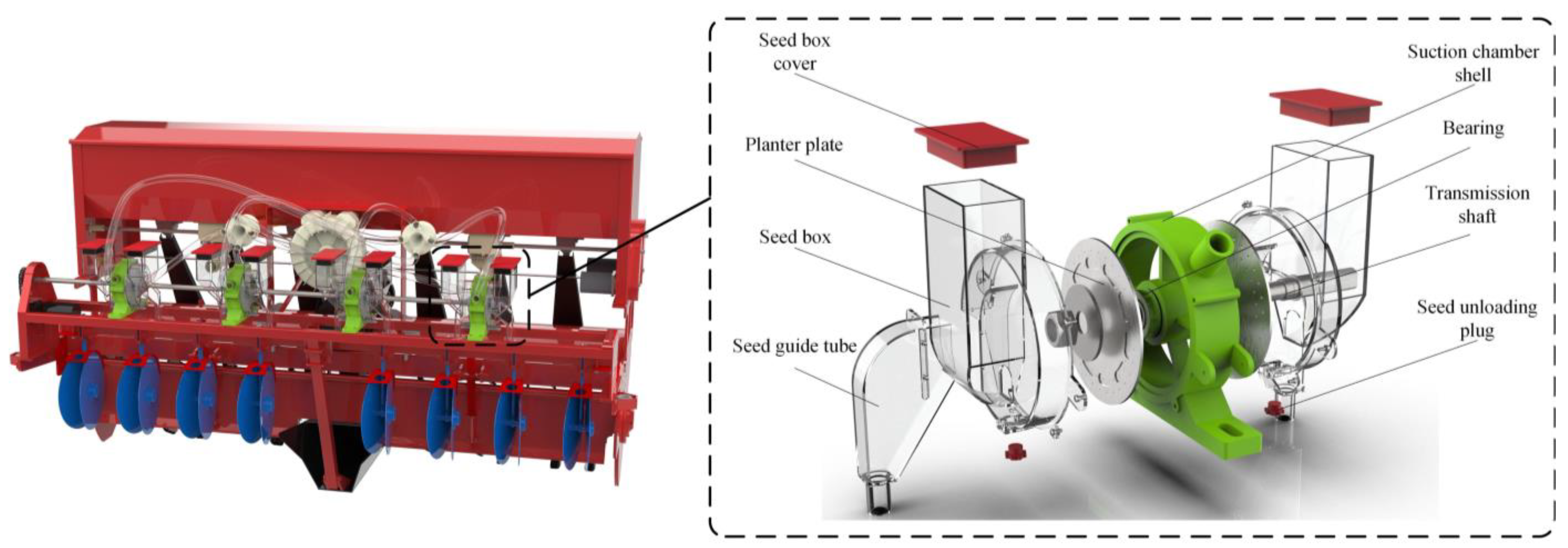

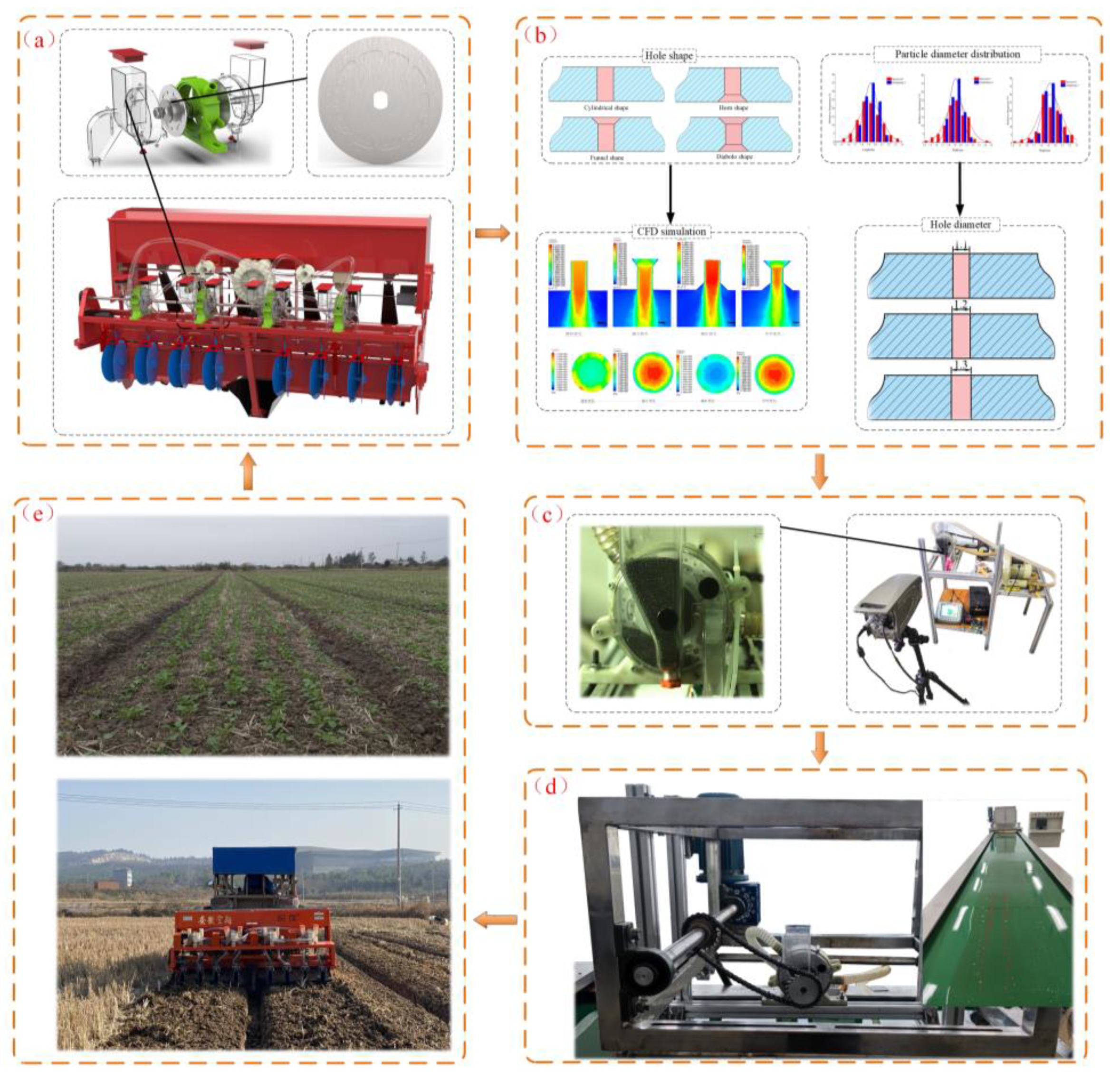

2. Structure and Working Principle of the Seed Metering Device

2.1. Structure of the Seed Metering Device

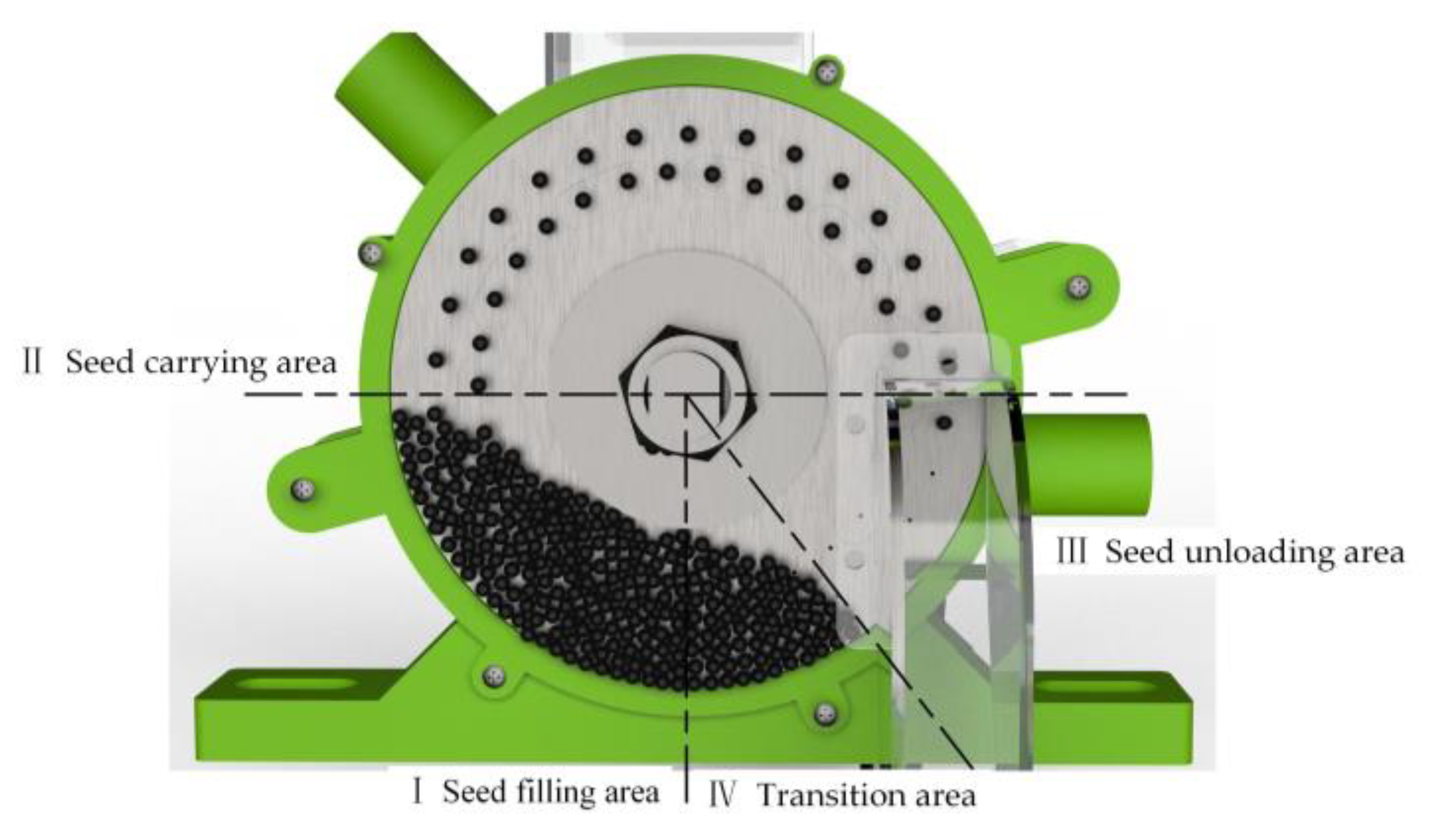

2.2. Working Principle of the Seed Metering Devic

3. Materials and Methods

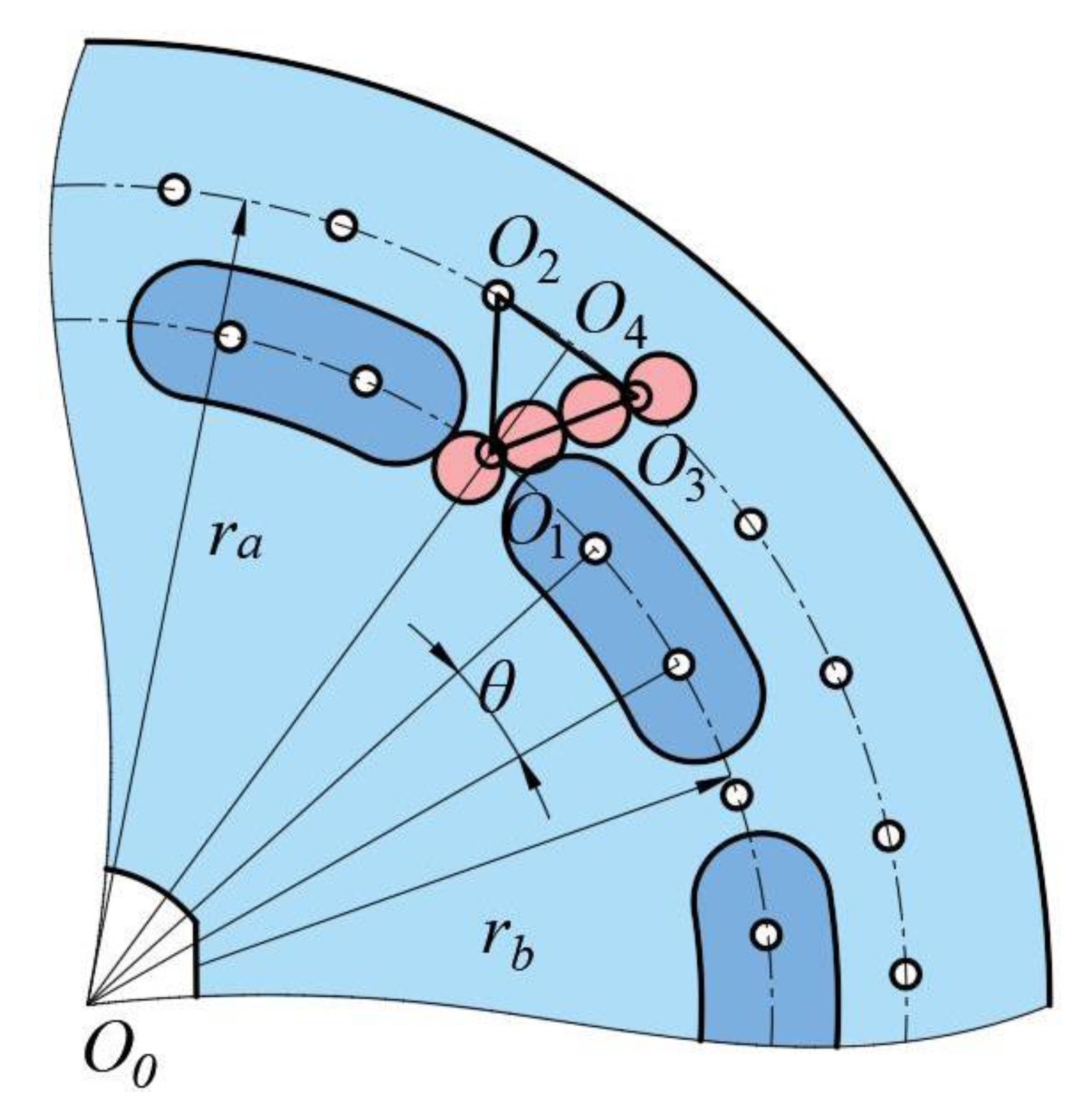

3.1. Key Parameter Design of the Planter Plate

3.1.1. Diameter of Planter Plate Design

3.1.2. Type of Hole Arrangement Form and Double Row Hole Spacing Design

3.1.3. Suction Hole Number Design

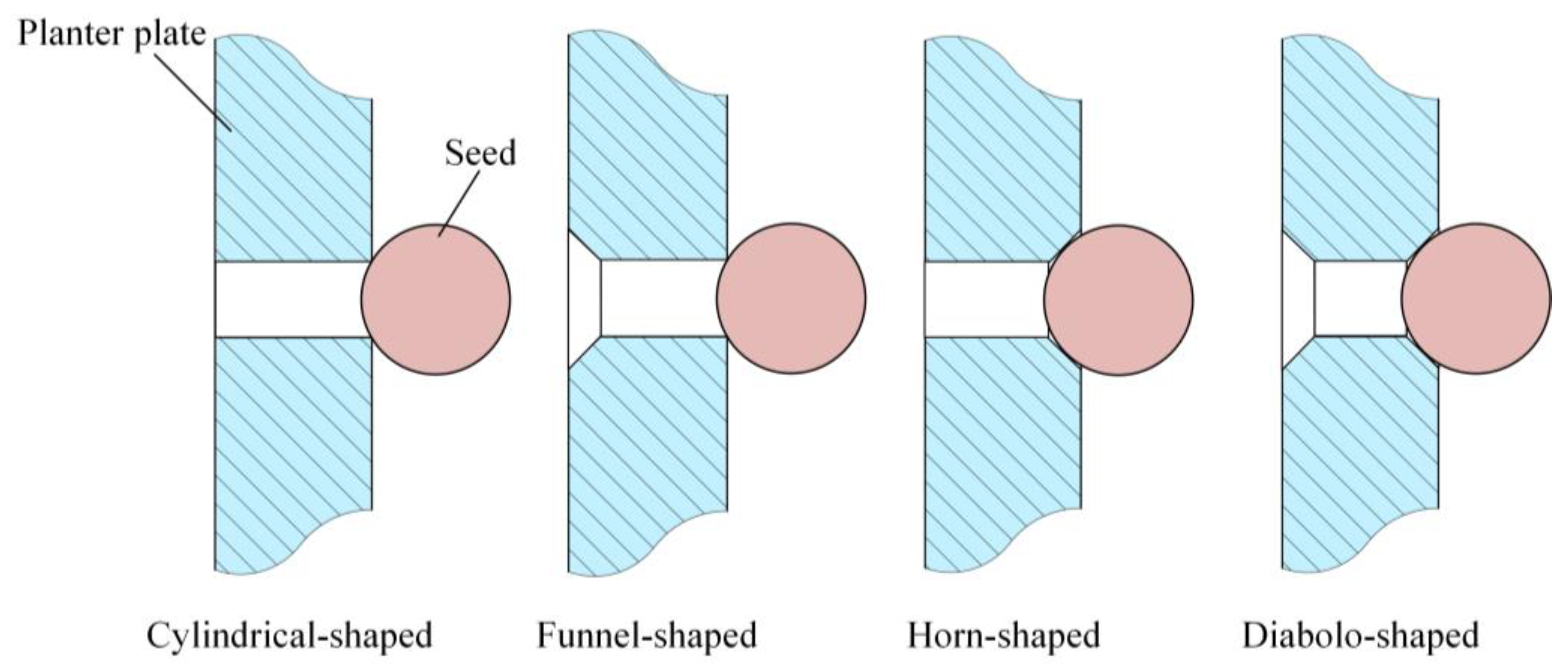

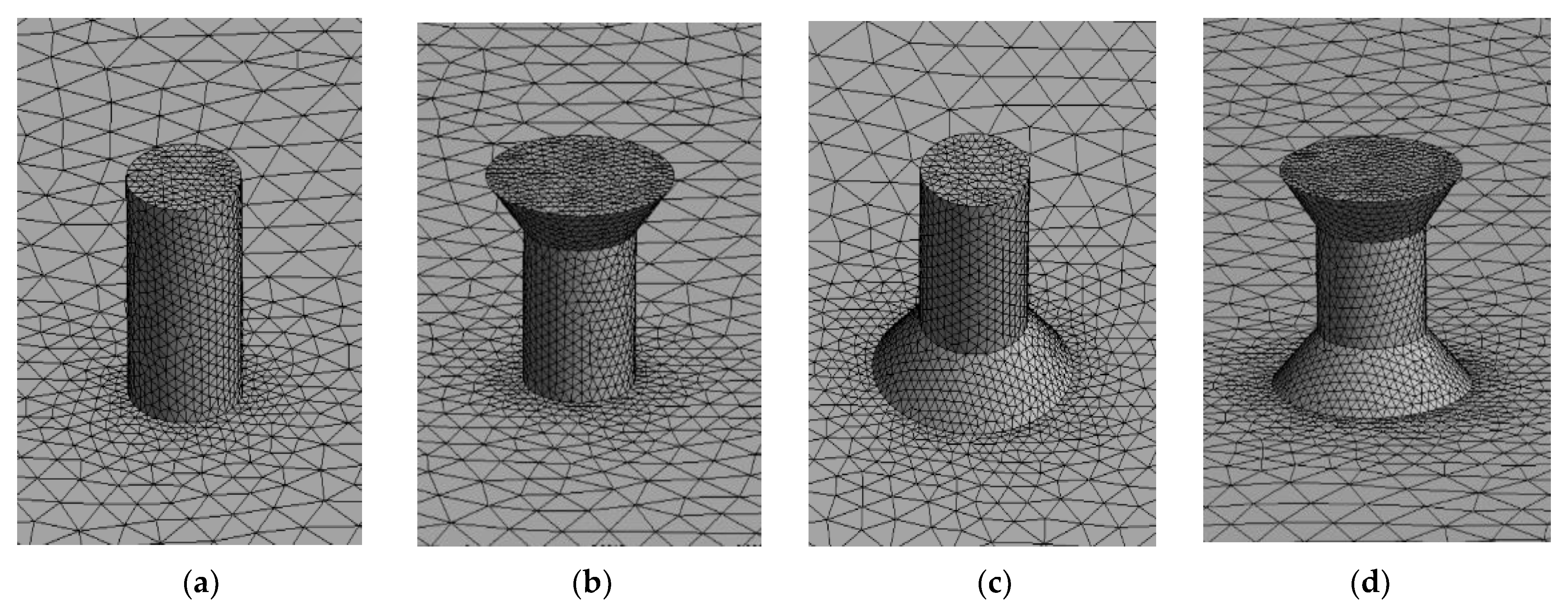

3.1.4. The Suction Hole Shape Design

3.2. Analysis of the Processes of Seed Filling and Seed Unloading

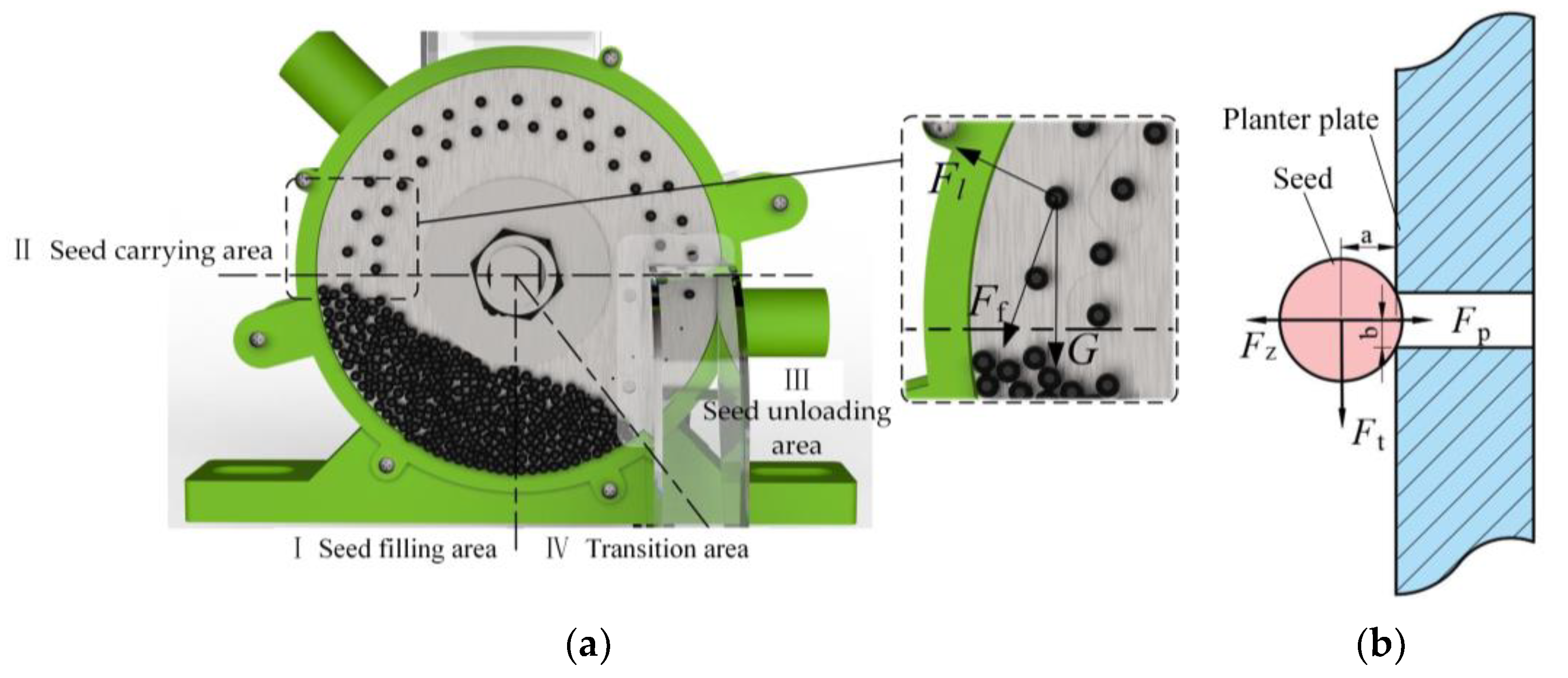

3.2.1. Analysis of the Seed Filling Process’s Kinetics

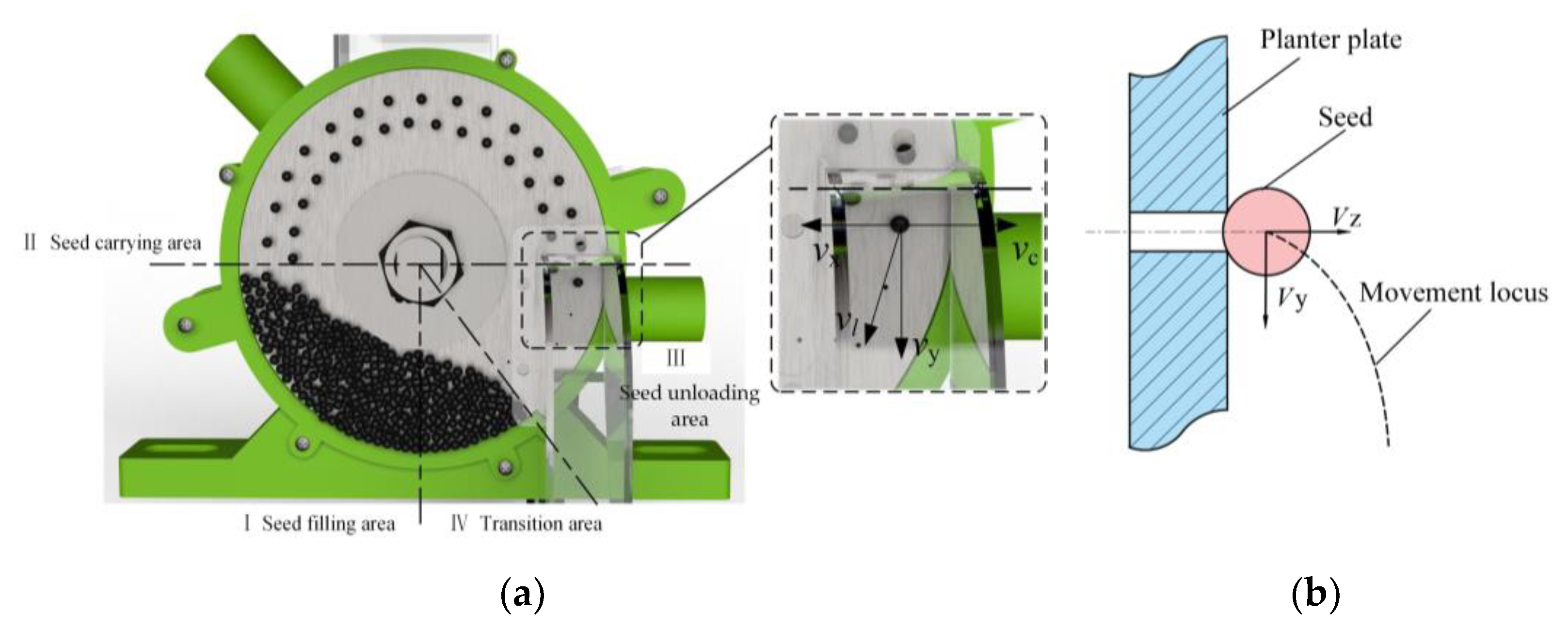

3.2.2. Analysis of the Seed Unloading Process’ Kinematics

3.3. Simulation Model and Parameter Setting

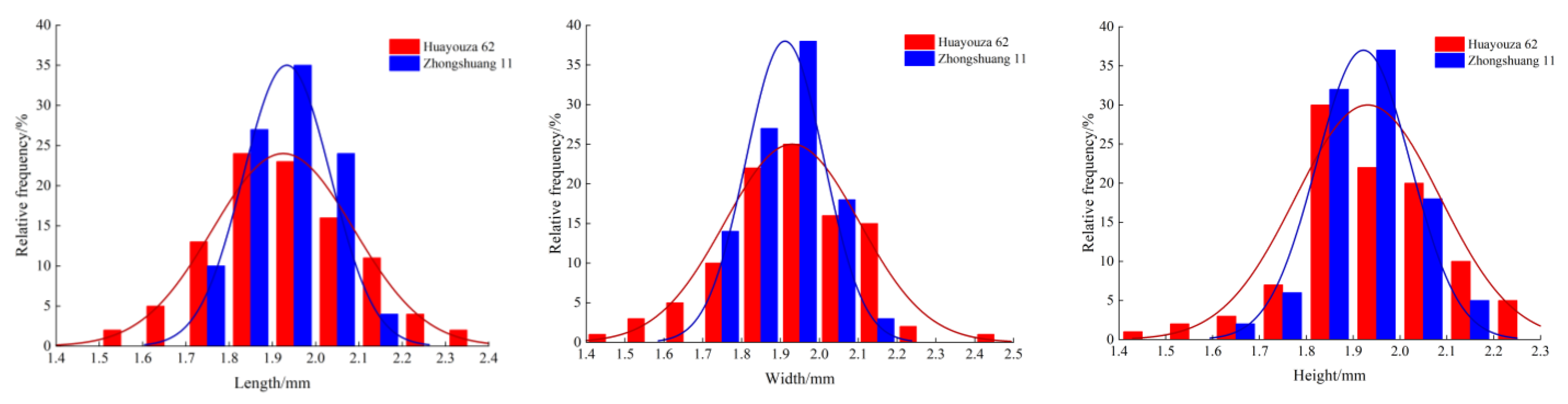

3.4. Test Materials and Equipment

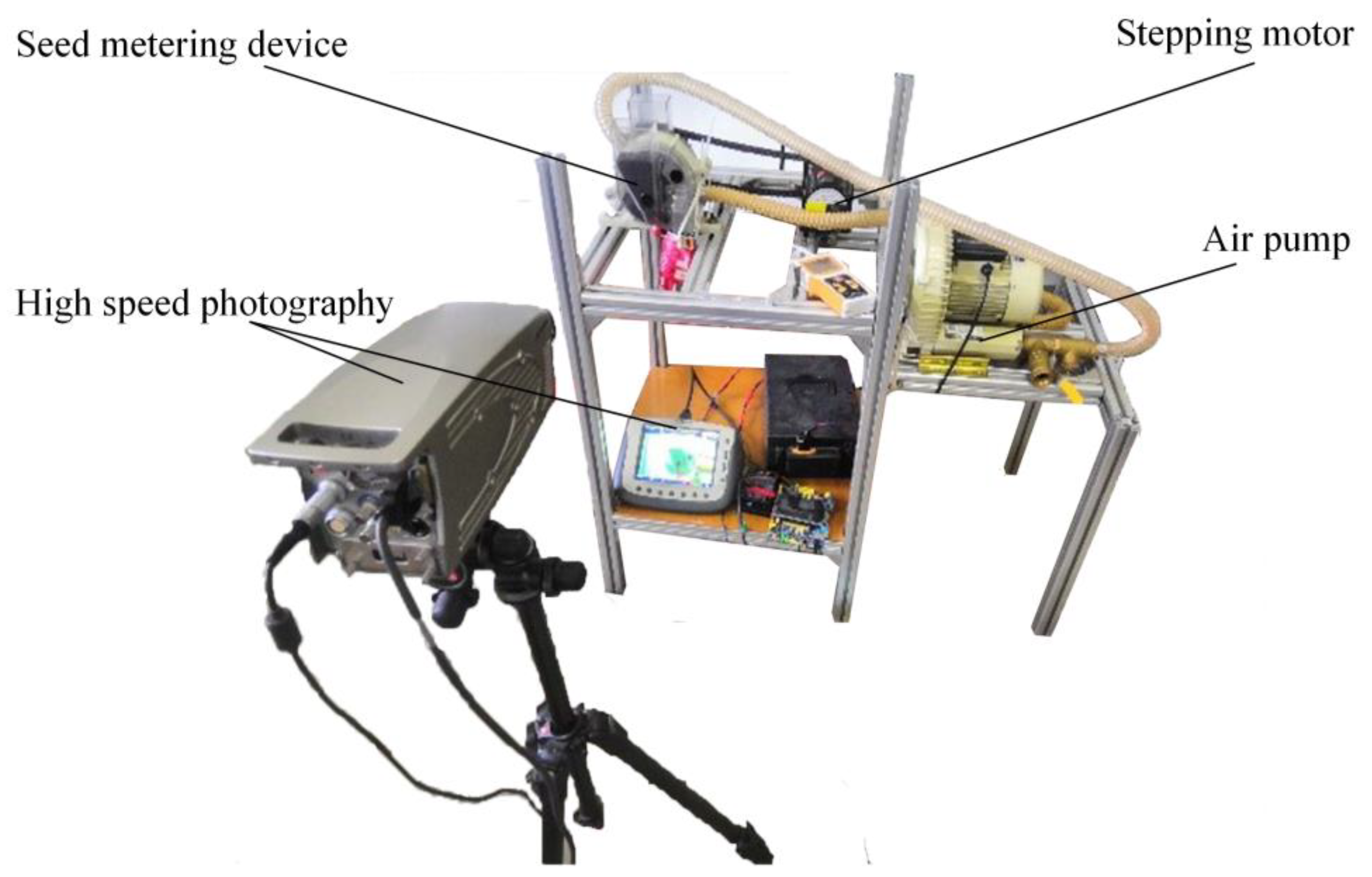

3.4.1. Equipment for Testing the Performance of Seed Filling

3.4.2. Equipment for Testing the Performance of Seed Arrangement

3.5. Index for Evaluating the Performance of the Seed Metering Device

3.5.1. Index for Evaluation of Seed Filling Effectiveness

3.5.2. Index for Evaluation of Seed Arrangement Effectiveness

3.6. Single-Factor Experimental Design

3.7. Seed Arrangement Performance Experimental Design

4. Results

4.1. Analysis of Fluent Simulation Results

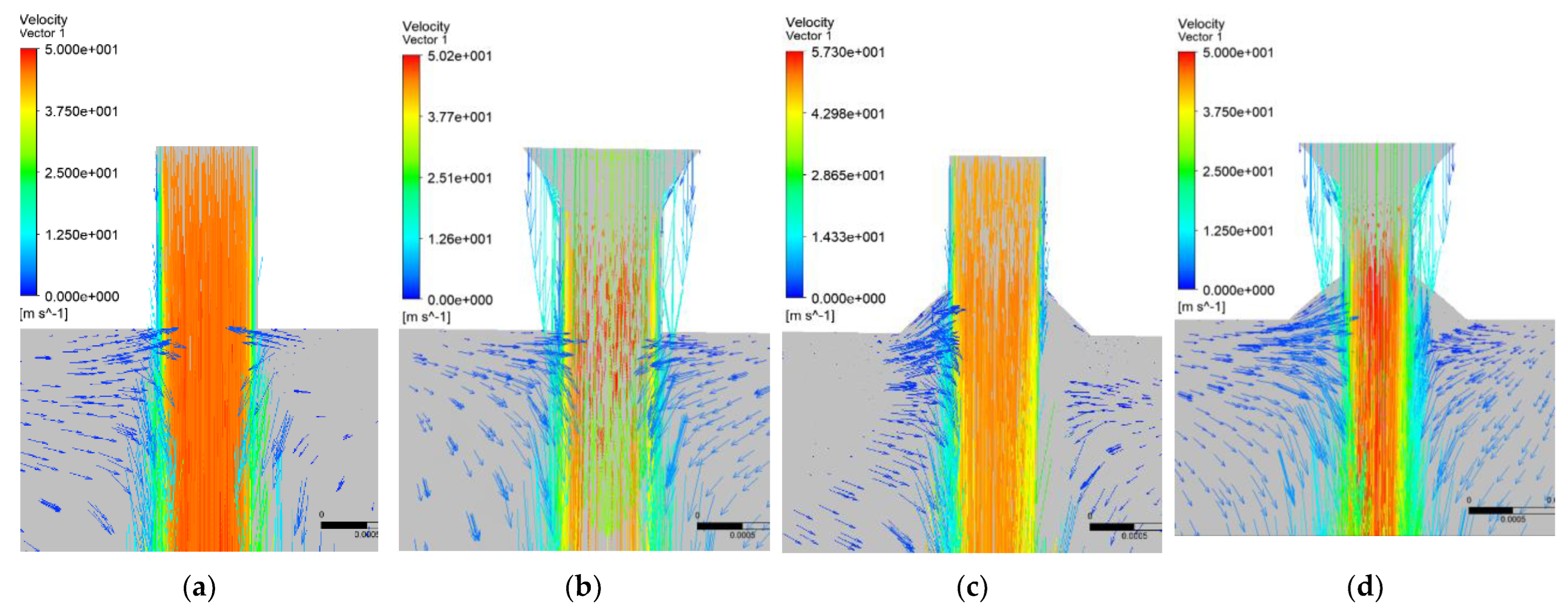

4.1.1. Influence of Suction Hole Shape on Velocity Flow Field

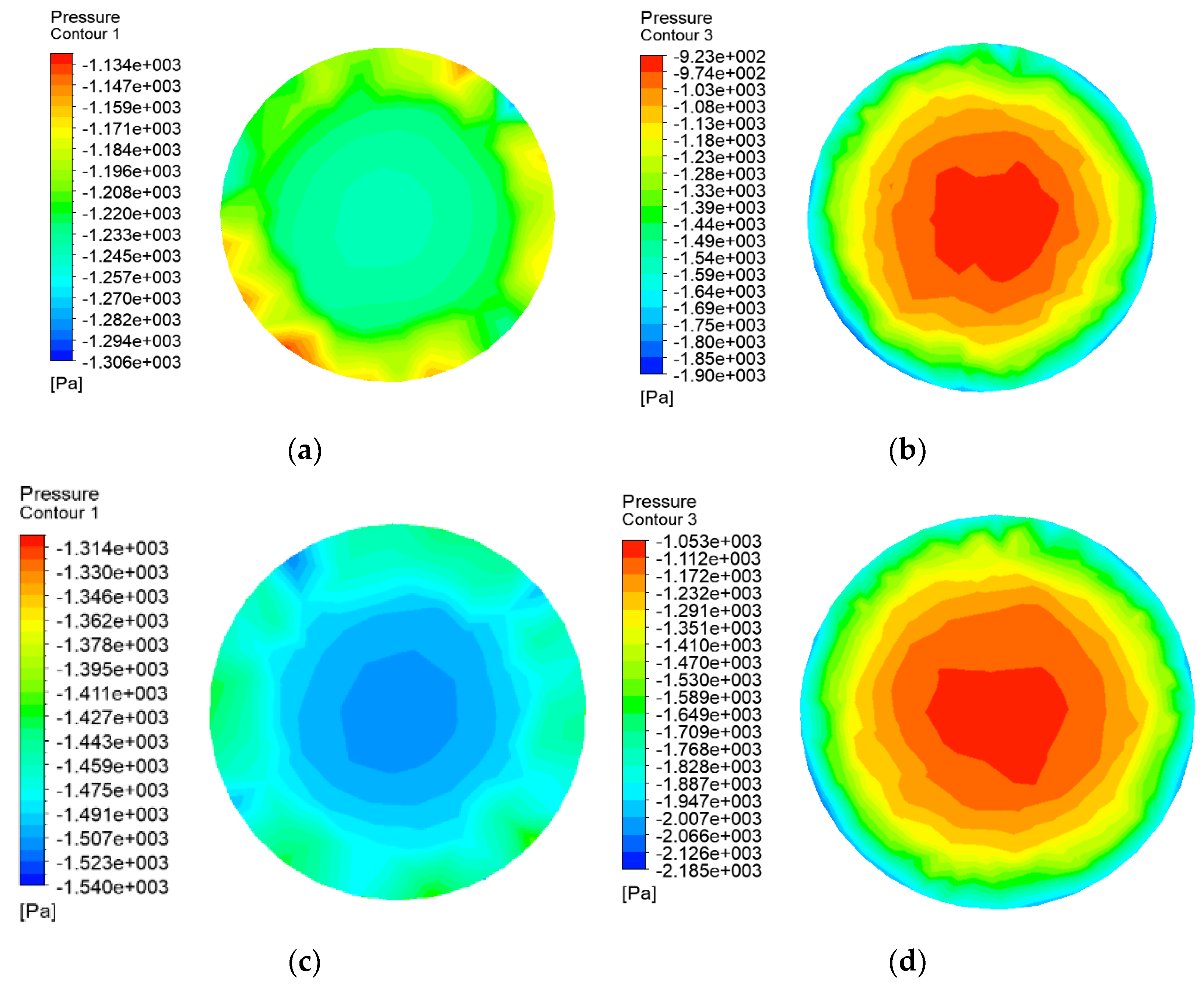

4.1.2. Influence of Suction Hole Shape on Pressure Flow Field

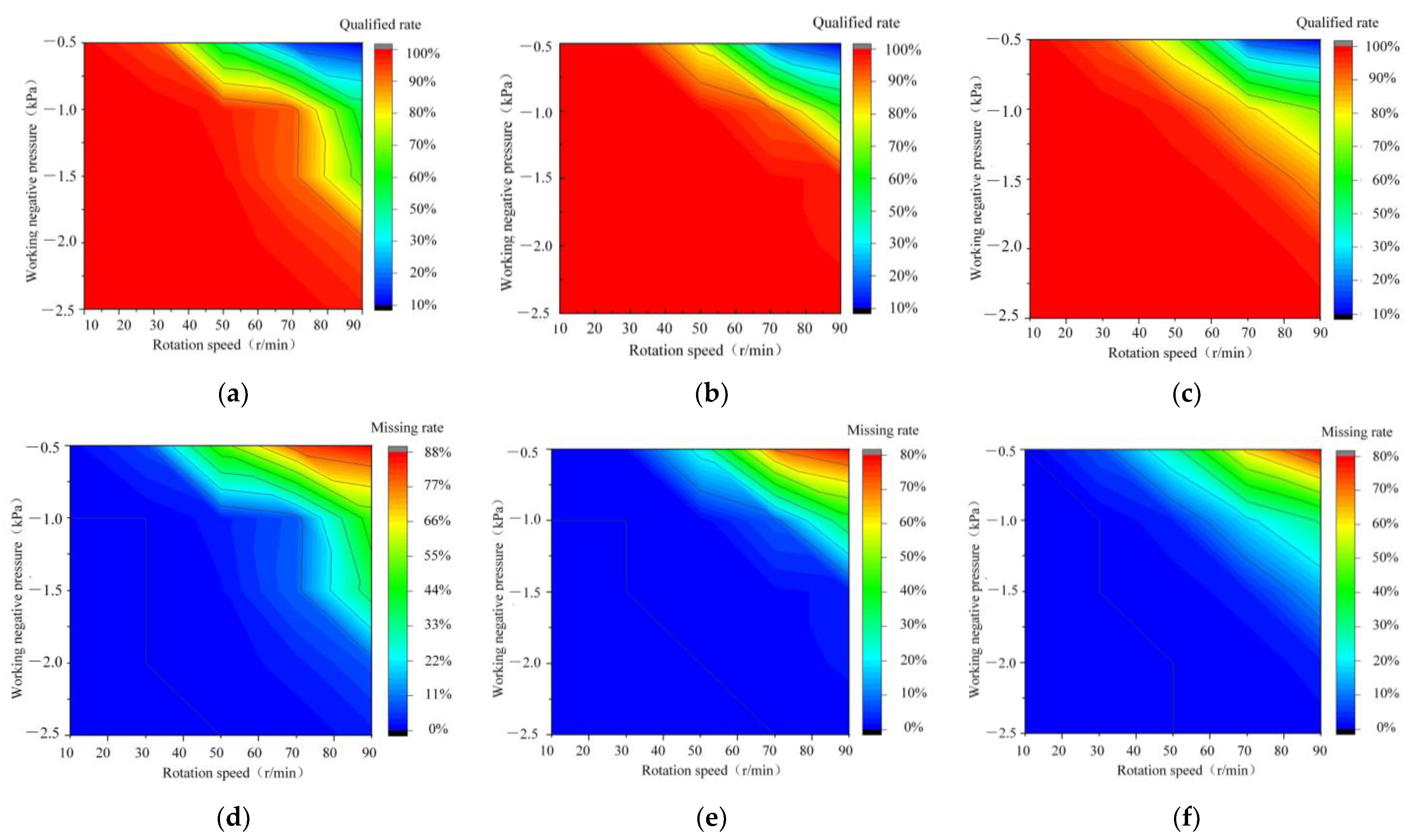

4.2. The Results of the Single Factor Test

4.2.1. Influence of Suction Hole Diameter on the Performance of Seed Filling

4.2.2. Influence of Suction Hole Shape on Seed Filling Performance

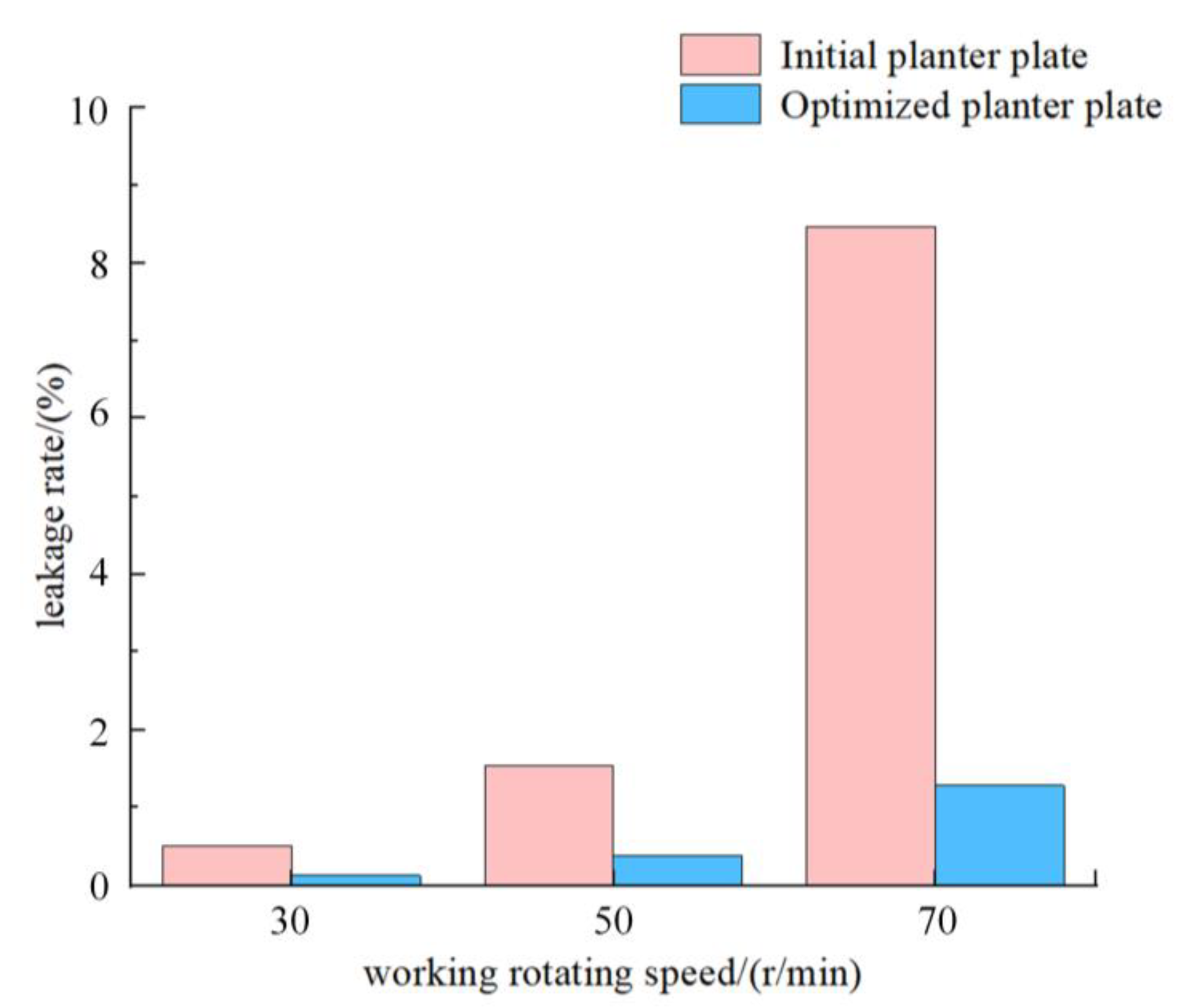

4.2.3. Comparison of Optimized and Original Planter Plates

4.3. The Results of the Seed Arrangement Performance Test

4.3.1. ANOVA Results of the Hole Number Qualified Rate

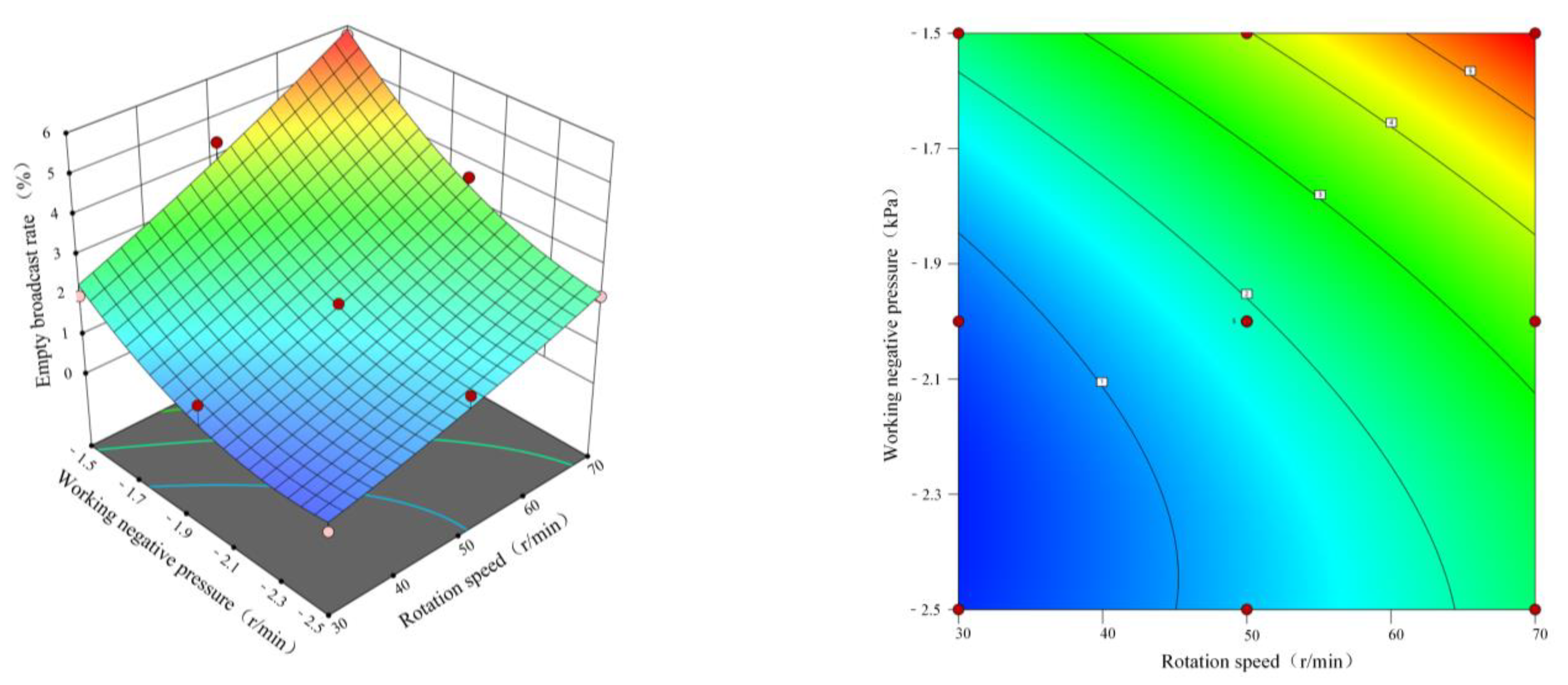

4.3.2. ANOVA Results of the Empty Broadcast Rate

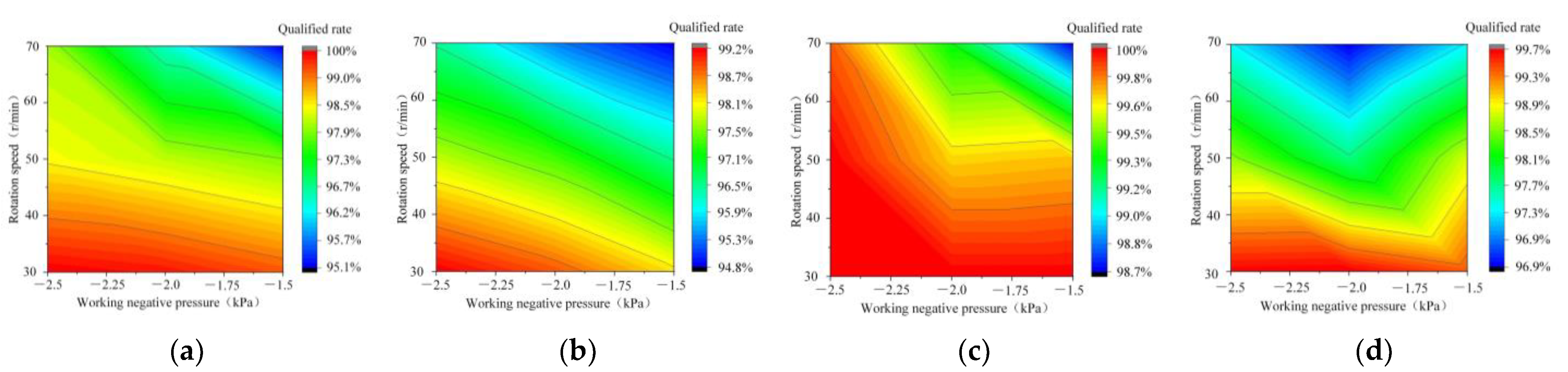

4.3.3. Results of Response Surface Methodology (RSM) for Experimental Evaluation Indicators

4.3.4. The Optimal Parameter Combination of Experimental Factors

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, Q.X.; Lei, X.L.; Liao, Y.T.; Ding, Y.C.; Zhang, Q.S.; Wang, L. Research Progress of Precision Seeding for Rapeseed. Trans. Chin. Soc. Agric. Mach. 2017, 48, 9. [Google Scholar]

- Xing, H.; Zang, Y.; Wang, Z.M.; Luo, X.W.; Pei, J.; He, S.Y.; Xu, P.; Liu, S.C. Design and parameter optimization of rice pneumatic seeding metering device with adjustable seeding rate. Trans. Chin. Soc. Agric. Eng. 2019, 35, 20–28. [Google Scholar]

- Li, Z.D.; Lei, X.L.; Cao, X.Y.; Liao, Y.T.; Liao, Q.X.; Li, S.S. Design and experiment of pneumatic-typed precision centralized metering device for rapeseed. Trans. Chin. Soc. Agric. Eng. 2015, 31, 9–17. [Google Scholar]

- Hu, M.J.; Xia, J.F.; Zheng, K.; Du, J.; Liu, Z.Y.; Zhou, M.K. Design and Experiment of Inside-filling Pneumatic High Speed Precision Seed-metering Device for Cotton. Trans. Chin. Soc. Agric. Mach. 2021, 52, 73–85. [Google Scholar]

- Zhang, Q.S.; Liao, Q.X.; Xiao, W.L.; Liu, X.P.; Wei, G.L.; Liu, L.C. Research process of tillage technology and equipment for rapeseed growing. Chin. J. Oil Crop Sci. 2018, 40, 702–711. [Google Scholar]

- Kuai, J.; Wang, J.J.; Zuo, Q.S.; Chen, H.L.; Gao, J.Q.; Wang, B.; Zhou, G.S.; Fu, T.D. Effects and Mechanism of Higher Plant Density on Directly-Sown Rapeseed in the Yangtze River Basin of China. Sci. Agric. Sin. 2018, 51, 4625–4632. [Google Scholar]

- Yin, W.Q.; Zhao, L.; Li, H.; Hu, F.; Yu, H.M. Design and Experiment on Suction Nozzle Type Hole of Pneumatic-sheave Combined Vegetable Precision Metering Device. Trans. Chin. Soc. Agric. Mach. 2019, 50, 68–76, 136. [Google Scholar]

- Liao, Q.X.; Zhang, M.; Yu, J.J.; Liu, X.H. Pneumatic Centralized Metering Device for Rapeseed. Trans. Chin. Soc. Agric. Mach. 2011, 42, 30–34. [Google Scholar]

- Li, J.H.; Lai, Q.H.; Zhang, H.; Zhang, Z.G.; Zhao, J.W.; Wang, T.T. Suction force on high-sphericity seeds in an air-suction seed-metering device. Biosyst. Eng. 2021, 211, 125–140. [Google Scholar] [CrossRef]

- Li, Z.D.; He, S.; Zhong, J.Y.; Han, J.F.; Chen, Y.X.; Song, Y. Parameter optimization and experiment of the disturbance pneumatic plate hole metering device for rapeseed. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–11. [Google Scholar]

- Jin, X.; Li, Q.W.; Zhao, K.X.; Zhao, B.; He, Z.T.; Qiu, Z.M. Development and test of an electric precision seeder for small-size vegetable seeds. Int. J. Agric. Biol. Eng. 2019, 12, 75–81. [Google Scholar] [CrossRef]

- Cheng, X.P.; Lu, C.Y.; Meng, Z.J.; Yu, J.Y. Design and parameter optimization on wheat precision seed meter with combination of pneumatic and type hole. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–9. [Google Scholar]

- Li, Z.H.; Wang, D.C.; Liu, G.L.; Yang, M.S.; Wang, Z.H. CFD simulation and improvement of air-stream distributive metering device. Trans. Chin. Soc. Agric. Mach. 2009, 40, 64–68. [Google Scholar]

- Lei, X.L.; Liao, Y.T.; Zhang, Q.S.; Wang, L.; Liao, Q.X. Numerical simulation of seed motion characteristics of distribution head for rapeseed and wheat. Comput. Electron. Agric. 2018, 150, 98–109. [Google Scholar] [CrossRef]

- Lei, X.L.; Hu, H.J.; Yang, W.H.; Liu, L.Y.; Liao, Q.X.; Ren, W.J. Seeding performance of air-assisted centralized seed-metering device for rapeseed. Int. J. Agric. Biol. Eng. 2021, 14, 79–87. [Google Scholar] [CrossRef]

- Ibrahim, E.J.; Liao, Q.X.; Wang, L.; Liao, Y.T.; Yao, L. Design and experiment of multi-row pneumatic precision metering device for rapeseed. Int. J. Agric. Biol. Eng. 2018, 11, 116–123. [Google Scholar]

- Gaikwad, B.B.; Sirohi, N.P.S. Design of a low-cost pneumatic seeder for nursery plug trays. Biosyst. Eng. 2008, 99, 322–329. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology. Biosyst. Eng. 2007, 97, 347–356. [Google Scholar] [CrossRef]

- Karayel, D.; Barut, Z.B.; Özmerzi, A. Mathematical Modelling of Vacuum Pressure on a Precision Seeder. Biosyst. Eng. 2004, 87, 437–444. [Google Scholar] [CrossRef]

- Yatskul, A.; Lemiere, J.; Cointault, F. Influence of the divider head functioning conditions and geometry on the seed’s distribution accuracy of the air-seeder. Biosyst. Eng. 2017, 161, 120–134. [Google Scholar] [CrossRef]

- Dai, Y.Z.; Luo, X.W.; Zhang, M.H.; Lan, F.; Zhou, Y.J.; Wang, Z.M. Design and experiments of the key components for centralized pneumatic rice dry direct seeding machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–8. [Google Scholar]

- Li, Y.H.; Yang, L.; Zhang, D.X.; Cui, T.; Zhang, K.L.; Xie, C.J.; Yang, R.M. Analysis and test of linear seeding process of maize high speed precision metering device with air suction. Trans. Chin. Soc. Agric. Eng. 2020, 36, 26–35. [Google Scholar]

- Liao, Y.T.; Liao, Q.X.; Wang, L.; Zheng, J.; Gao, L.P. Investigation on vacuum singulating effect influencing factors of pneumatic precision seed metering device for small particle size of seeds. Trans. Chin. Soc. Agric. Eng. 2018, 34, 10–17. [Google Scholar]

- Li, Z.D.; Yang, W.C.; Zhang, T.; Wang, W.W.; Zhang, S.; Chen, L.Q. Design and suction performance test of sucking-seed plate combined with groove-tooth structure on high speed precision metering device of rapeseed. Trans. Chin. Soc. Agric. Eng. 2019, 35, 12–22. [Google Scholar]

- Zhang, G.Z.; Luo, X.W.; Zang, Y.; Wang, Z.M.; Zeng, S.; Zhou, Z.Y. Experiment of sucking precision of sucking plate with group holes on rice pneumatic metering device. Trans. Chin. Soc. Agric. Eng. 2013, 29, 13–20. [Google Scholar]

- Li, Y.H.; Yang, L.; Zhang, D.X.; Cui, T.; Ding, L.; Wei, Y.N. Design and Experiment of Pneumatic Precision Seed-metering Device with Single Seed-metering Plate for Double-row. Trans. Chin. Soc. Agric. Mach. 2019, 50, 61–73. [Google Scholar]

- Liu, H.; Liao, Y.T.; Wang, L.; Wang, B.S.; Du, Z.; Liao, Q.X. Design and Experiment of Positive and Negative Pressure Combination Precision Metering Device for Pakchoi. Trans. Chin. Soc. Agric. Mach. 2022, 53, 54–65. [Google Scholar]

- Chinese Academy of Agricultural Machinery. Agricultural Machinery Design Manual; Agricultural Science and Technology Press: Beijing, China, 2007; Volume 1, p. 358. [Google Scholar]

- Xu, J.; Hou, J.; Wu, W.; Han, C.; Wang, X.; Tang, T.; Sun, S. Key Structure Design and Experiment of Air-Suction Vegetable Seed-Metering Device. Agronomy 2022, 12, 675. [Google Scholar] [CrossRef]

- Zhao, X.B. Engineering Fluid Mechanics, 3rd ed.; Southeast University Press: Nanjing, China, 2012. [Google Scholar]

- Department of Theoretical Mechanics, Harbin Institute of Technology. Theoretical Mechanics (I); Higher Education Press: Beijing, China, 2016; p. 317. [Google Scholar]

- Yan, B.X.; Zhang, D.X.; Yang, L.; Cui, T.; Zhong, X.J.; Li, Y.H. Performance Analysis of Gravity Assist Filling Precision Seed-metering Device with Synchronously Rotating Seed Plate and Vacuum Chamber. Trans. Chin. Soc. Agric. Mach. 2018, 49, 117–124. [Google Scholar]

- Zhang, K.X.; Li, J.F.; Song, Z.H.; Liu, X.X.; Liu, L. Optimum Design and Test of Variable Diameter Double Disc Air Suction Precision Seeder. Trans. Chin. Soc. Agric. Mach. 2019, 50, 52–63. [Google Scholar]

- GB/T 6973-2005; Single Seed (Precision) Planter Test Method. General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2006.

- NY/T 1143-2006; Technical Specification for Quality Evaluation of Planter. Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2006.

- He, S. Analysis and Experiment on the Adsorption Mechanism of the Perturbation Pneumatic Precision Seed Metering Device for Rapeseed; Anhui Agricultural University: Hefei, China, 2021. [Google Scholar]

- Li, Z.; Zhang, H.; Xie, R.; Gu, X.; Du, J.; Chen, Y. Evaluation on the Performance of Airflow Distribution Device of Pneumatic Seeder for Rapeseed through CFD Simulations. Agriculture 2022, 12, 1781. [Google Scholar] [CrossRef]

| Level Code | Experimental Factors | |

|---|---|---|

| Suction Hole Diameter/mm | Suction Hole Shape | |

| 1 | 1.3 | Cylindrical-shaped |

| 2 | 1.2 | Horn-shaped |

| 3 | 1.1 | Funnel-shaped |

| 4 | Diabolo-shaped | |

| Level Code | Experimental Factors | |

|---|---|---|

| Rotation Speed (r/min) | Negative Pressure (Pa) | |

| −1 | 30 | −2.5 |

| 0 | 50 | −2.0 |

| 1 | 70 | −1.5 |

| NO. | Experimental Factors | Empty Broadcast Rate (%) | Qualified Rate (%) | |

|---|---|---|---|---|

| Rotation Speed A (r/min) | Negative Pressure B (Pa) | |||

| 1 | 70 | −2 | 3.6 | 95.32 |

| 2 | 50 | −2 | 1.67 | 95.95 |

| 3 | 50 | −2 | 1.574 | 96.22 |

| 4 | 50 | −2 | 1.83 | 96.66 |

| 5 | 30 | −2 | 1.16 | 97.74 |

| 6 | 70 | −1.5 | 5.77 | 93.81 |

| 7 | 50 | −2 | 1.68 | 96.74 |

| 8 | 50 | −2 | 1.95 | 96.53 |

| 9 | 30 | −2.5 | 0.16 | 98.04 |

| 10 | 50 | −2.5 | 1.54 | 97.86 |

| 11 | 70 | −2.5 | 2.26 | 97.13 |

| 12 | 30 | −1.5 | 2.02 | 97.18 |

| 13 | 50 | −1.5 | 4.38 | 95.36 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1.38 | 5 | 0.2758 | 30.47 | <0.0001 |

| A-rotation | 0.6437 | 1 | 0.6437 | 71.10 | <0.0001 |

| B-pressure | 0.6536 | 1 | 0.6506 | 71.87 | <0.0001 |

| AB | 0.0464 | 1 | 0.0464 | 5.13 | 0.0180 |

| A2 | 0.0065 | 1 | 0.0065 | 0.7216 | 0.4237 |

| B2 | 0.0181 | 1 | 0.0181 | 2.0 | 0.1999 |

| Residual | 0.0634 | 7 | 0.0091 | ||

| Lack of Fit | 0.0282 | 3 | 0.0094 | 1.07 | 0.4564 |

| Pure Error | 0.0352 | 4 | 0.0088 | ||

| Cor Total | 1.44 | 12 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8.30 | 5 | 1.66 | 15.11 | <0.0001 |

| A-rotation | 4.03 | 1 | 4.03 | 36.66 | <0.0001 |

| B-pressure | 3.53 | 1 | 3.53 | 32.14 | <0.0001 |

| AB | 0.6246 | 1 | 0.6246 | 5.69 | 0.0581 |

| A2 | 0.1119 | 1 | 0.1119 | 1.02 | 0.5609 |

| B2 | 0.0055 | 1 | 0.0055 | 0.0497 | 0.0140 |

| Residual | 0.7690 | 7 | 0.1099 | ||

| Lack of Fit | 0.8420 | 3 | 0.2465 | 33.43 | 0.0527 |

| Pure Error | 0.7395 | 4 | 0.0074 | ||

| Cor Total | 9.07 | 12 |

| Rotation Speed (r/min) | Negative Pressure (kPa) | Theoretical Value | Test Value | ||

|---|---|---|---|---|---|

| Empty Broadcast Rate/% | Hole Number Qualified Rate/% | Empty Broadcast Rate/% | Hole Number Qualified Rate/% | ||

| 30 | 2.39 | 0.33 | 98.04 | 0.47 | 98.56 |

| 50 | 2.5 | 1.23 | 97.66 | 1.72 | 97.65 |

| 70 | 2.5 | 2.33 | 97.18 | 2.66 | 96.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wu, J.; Du, J.; Duan, D.; Zhang, T.; Chen, Y. Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device. Agronomy 2023, 13, 141. https://doi.org/10.3390/agronomy13010141

Li Z, Wu J, Du J, Duan D, Zhang T, Chen Y. Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device. Agronomy. 2023; 13(1):141. https://doi.org/10.3390/agronomy13010141

Chicago/Turabian StyleLi, Zhaodong, Jiajie Wu, Juanhui Du, Delong Duan, Tian Zhang, and Yongxin Chen. 2023. "Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device" Agronomy 13, no. 1: 141. https://doi.org/10.3390/agronomy13010141

APA StyleLi, Z., Wu, J., Du, J., Duan, D., Zhang, T., & Chen, Y. (2023). Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device. Agronomy, 13(1), 141. https://doi.org/10.3390/agronomy13010141