Use of Active Sensors in Coffee Cultivation for Monitoring Crop Yield

Abstract

:1. Introduction

2. Materials and Methods

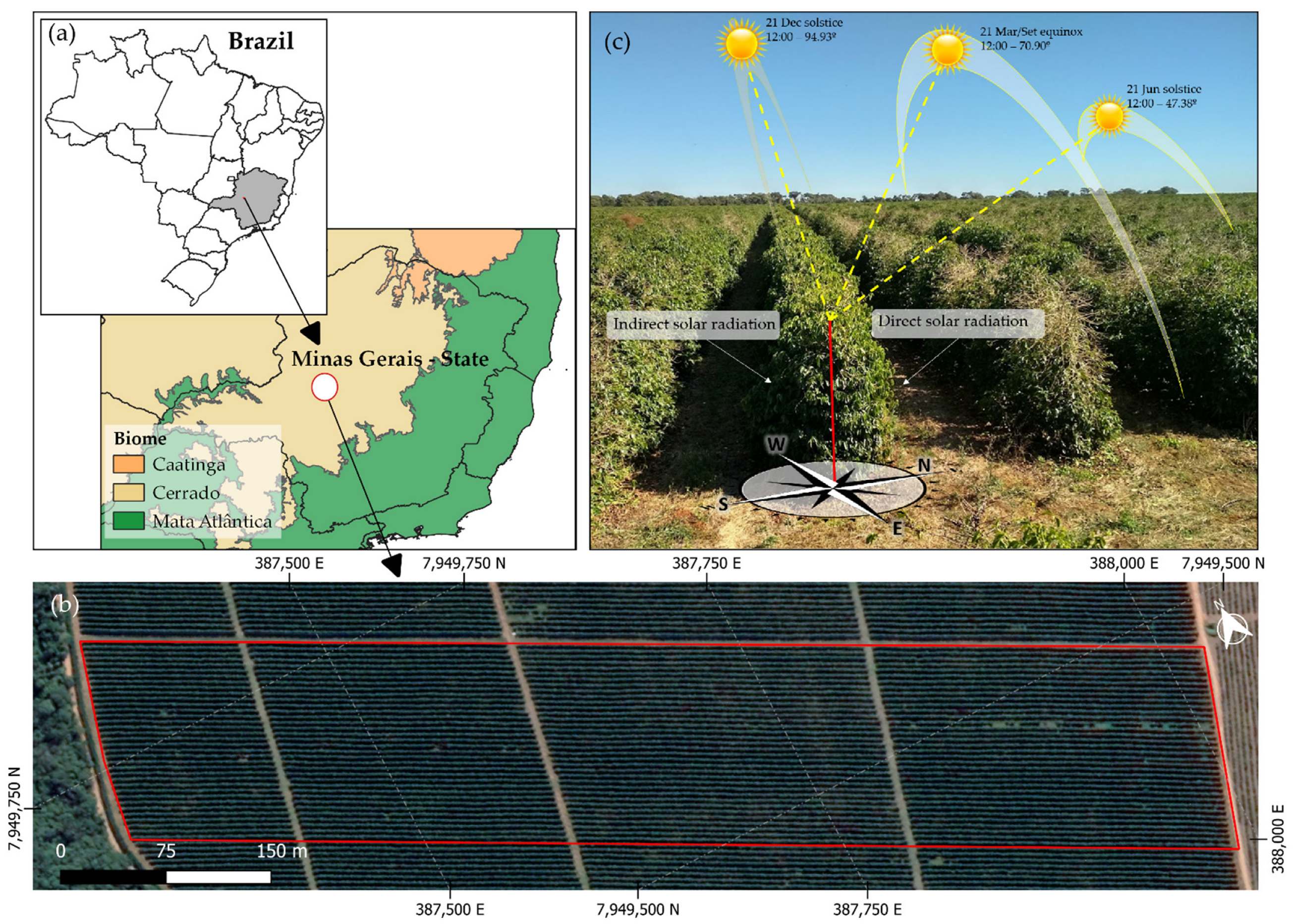

2.1. Study Area

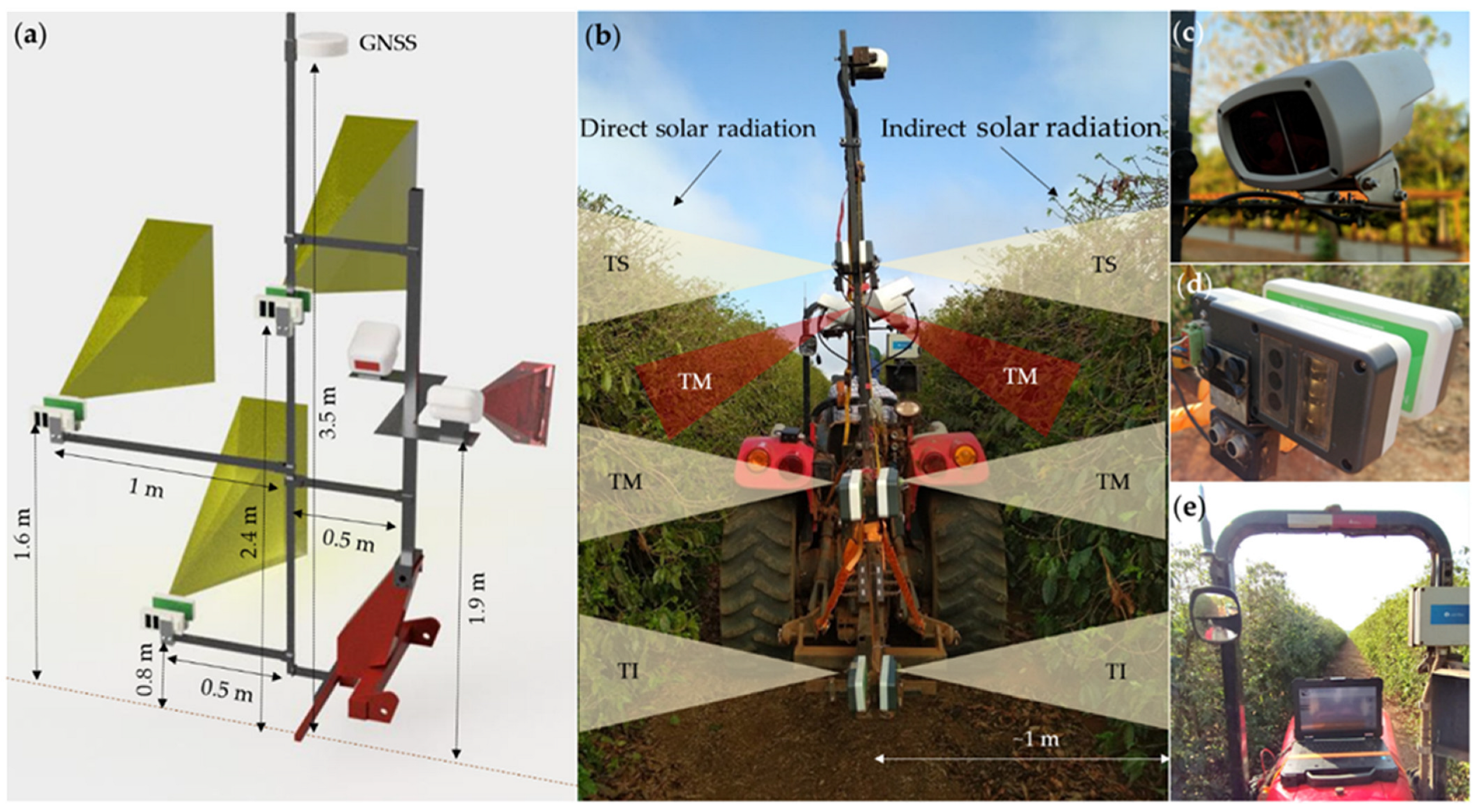

2.2. Tractor Instrumentation with AOS

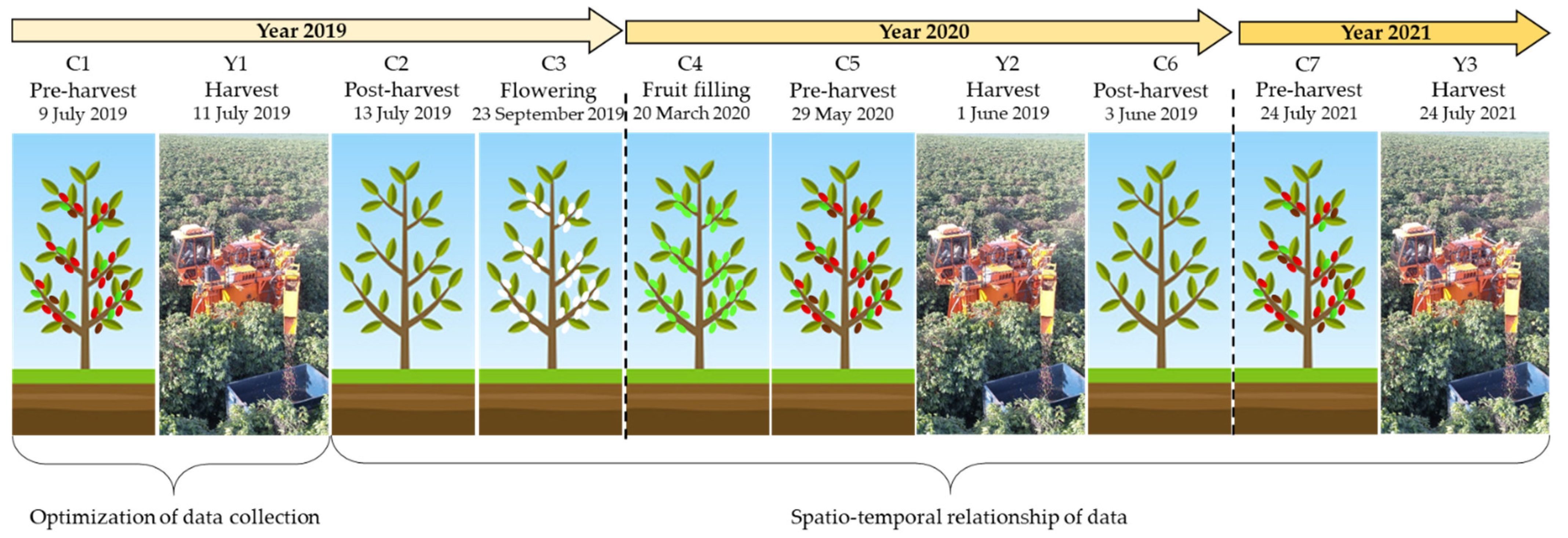

2.3. Data Acquisition with AOS and Yield Measurement

2.4. Data Analysis

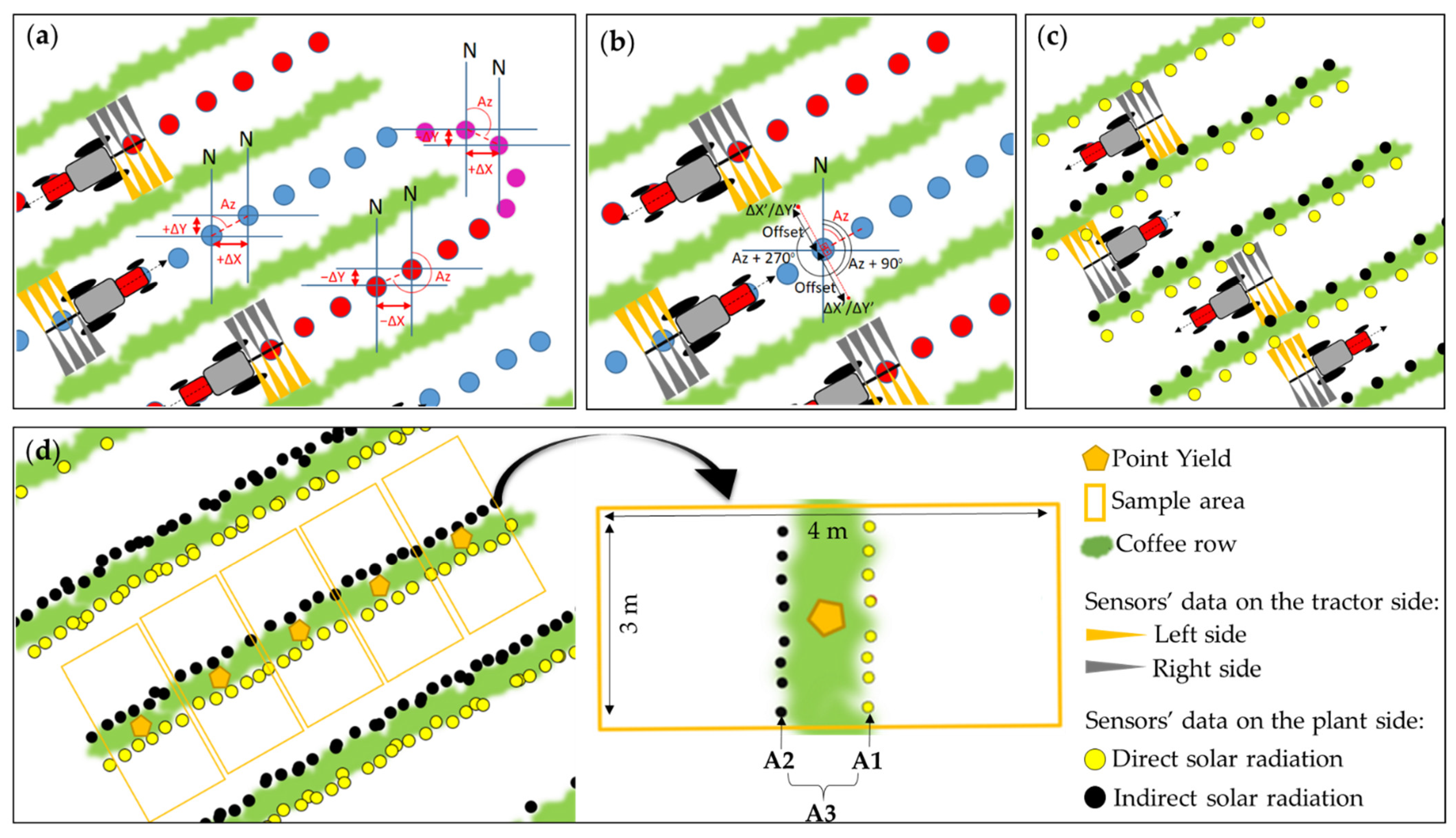

2.4.1. Optimizing AOS Positioning on the Side of a Coffee Plant to Infer Its Yield

2.4.2. Spatio-Temporal Relationship of AOS Data to Coffee Crop Yield

3. Results

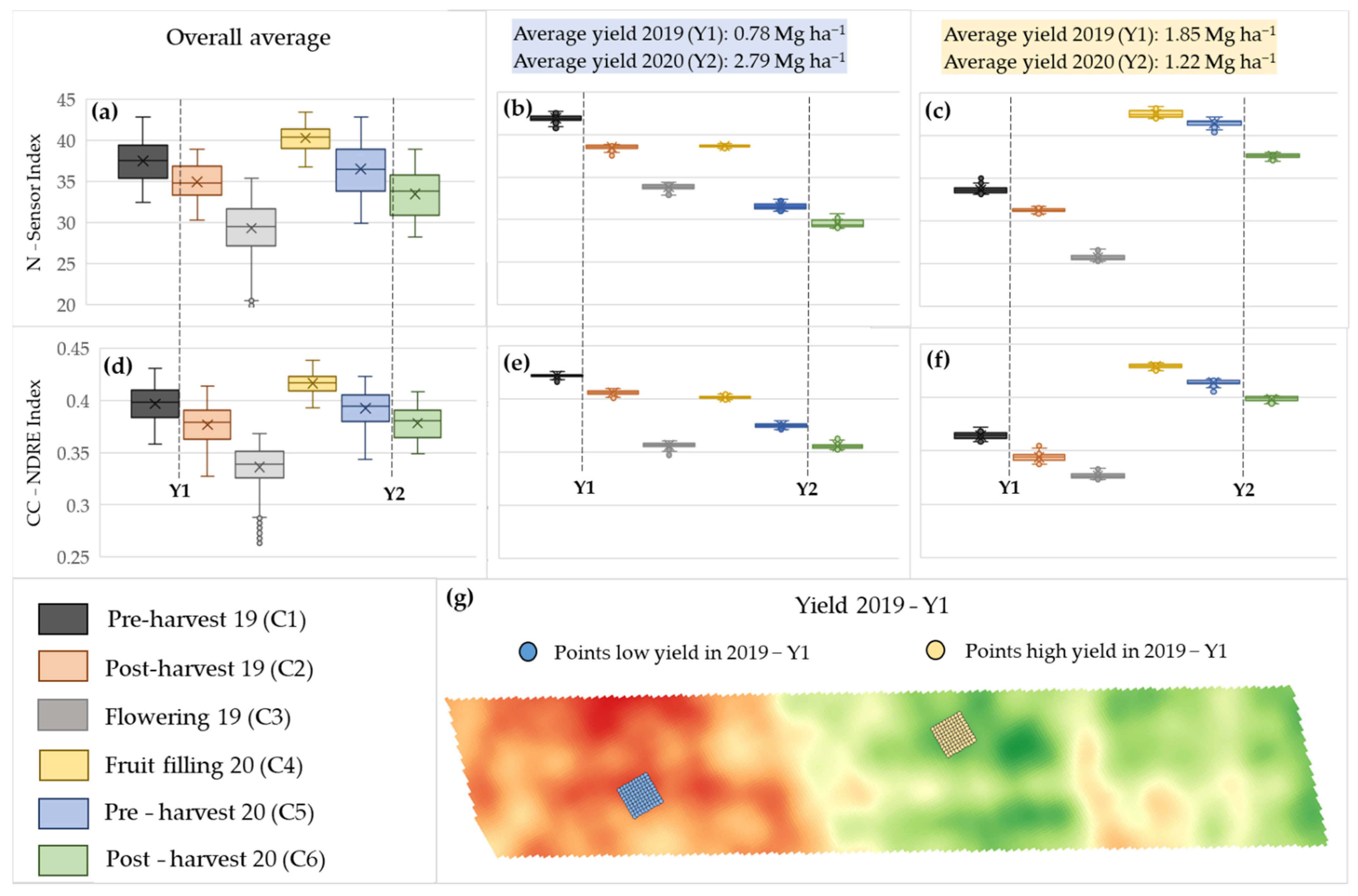

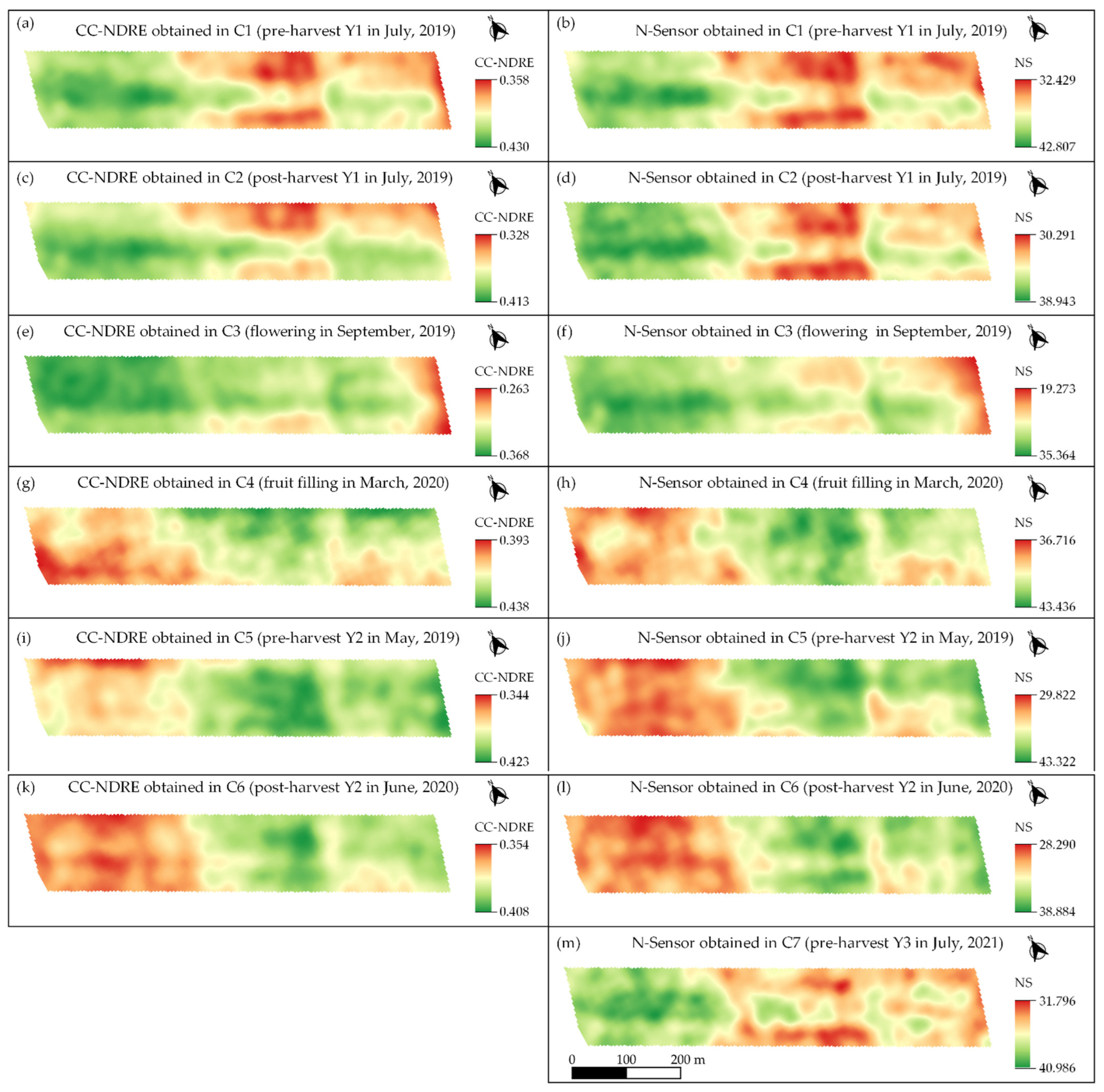

3.1. Optimizing AOS Positioning on the Side of the Coffee Plant for Yield Inference

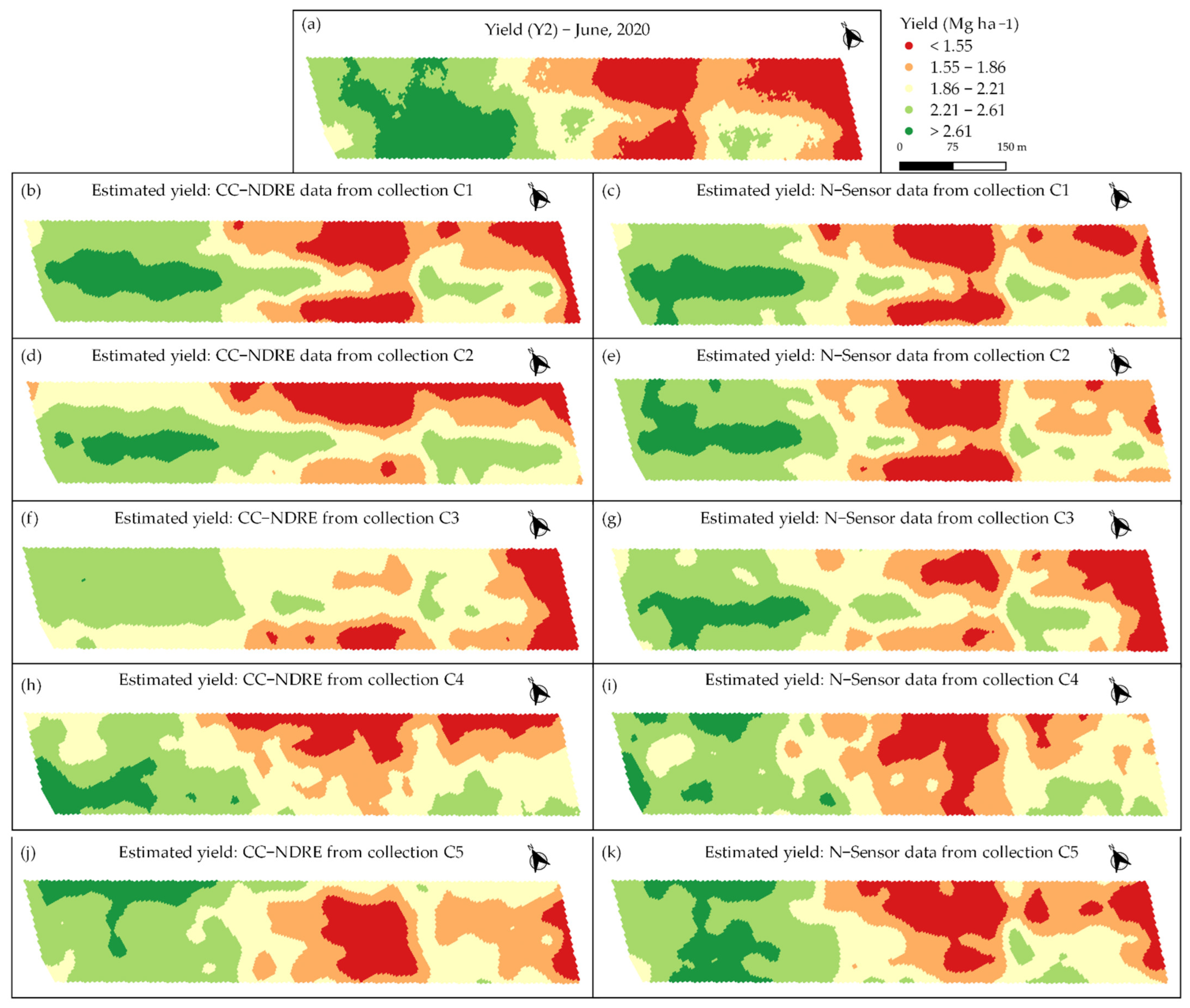

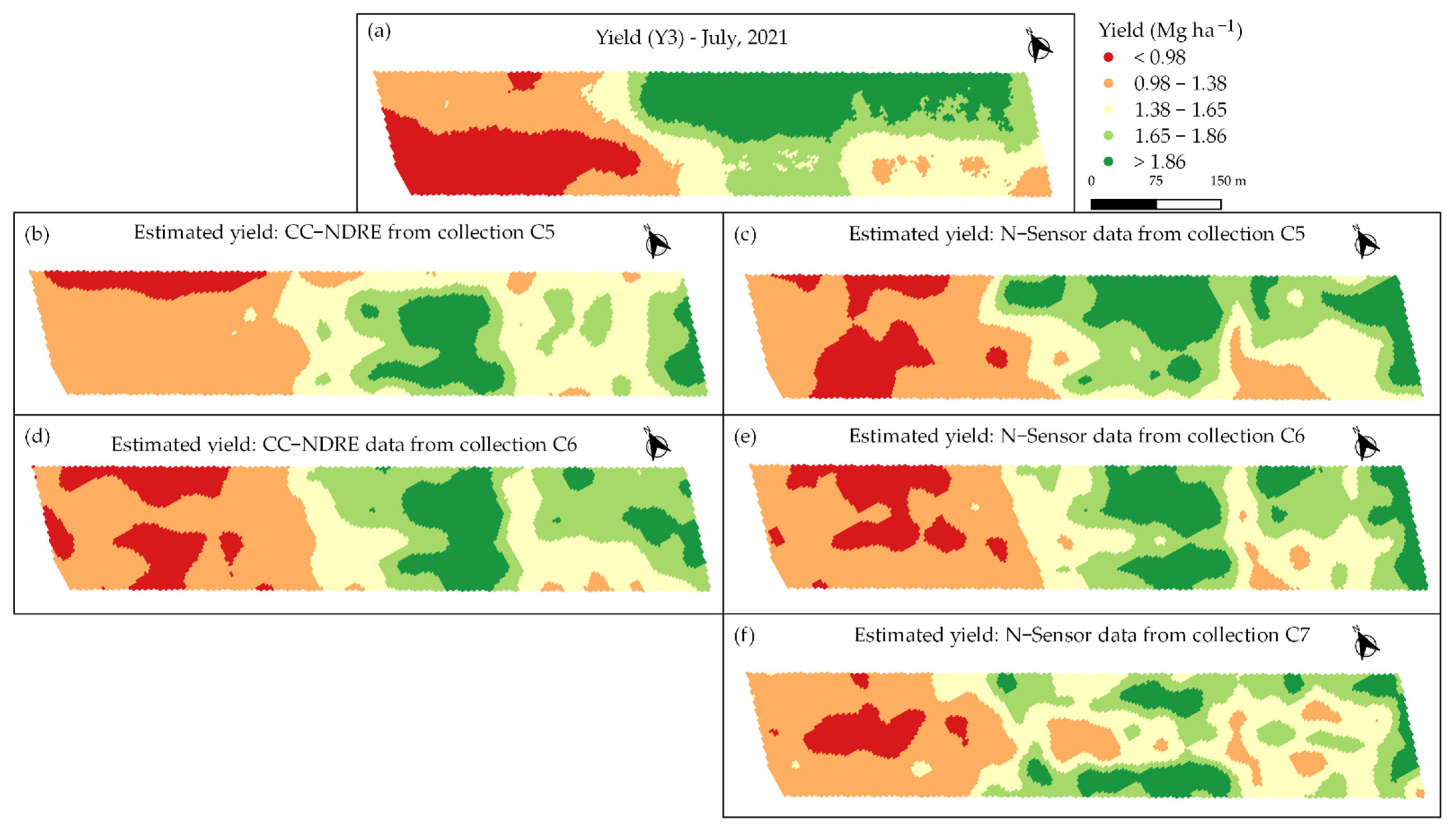

3.2. Spatio-Temporal Relationship of AOS Data to Coffee Yield

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef] [PubMed]

- Aula, L.; Omara, P.; Nambi, E.; Oyebiyi, F.B.; Raun, W.R. Review of active optical sensors for improving winter wheat nitrogen use efficiency. Agronomy 2020, 10, 1157. [Google Scholar] [CrossRef]

- Pallottino, F.; Antonucci, F.; Costa, C.; Bisaglia, C.; Figorilli, S.; Menesatti, P. Optoelectronic Proximal Sensing Vehicle-Mounted Technologies in Precision Agriculture: A Review. Comput. Electron. Agric. 2019, 162, 859–873. [Google Scholar] [CrossRef]

- Kitchen, N.R.; Sudduth, K.A.; Drummond, S.T.; Scharf, P.C.; Palm, H.L.; Roberts, D.F.; Vories, E.D. Ground-based canopy reflectance sensing for variable-rate nitrogen corn fertilization. Agron. J. 2010, 102, 71–84. [Google Scholar] [CrossRef]

- Schmidt, J.; Beegle, D.; Zhu, Q.; Sripada, R. Improving in-season nitrogen recommendations for maize using an active sensor. Field Crops Res. 2011, 120, 94–101. [Google Scholar] [CrossRef]

- Solari, F.; Shanahan, J.F.; Ferguson, R.B.; Adamchuk, V.I. An active sensor algorithm for corn nitrogen recommendations based on a chlorophyll meter algorithm. Agron. J. 2010, 102, 1090–1098. [Google Scholar] [CrossRef]

- Teal, R.K.; Tubana, B.; Girma, K.; Freeman, K.W.; Arnall, B.D.; Walsh, O.; Raun, W.R. In-Season prediction of corn grain yield potential using Normalized Difference Vegetation Index. Agron. J. 2006, 98, 1488–1494. [Google Scholar] [CrossRef]

- Berntsen, J.; Thomsen, A.; Schelde, K.; Hansen, O.M.; Knudsen, L.; Broge, N.; Hougaard, H.; Hørfarter, R. Algorithms for sensor-based redistribution of nitrogen fertilizer in winter wheat. Precis. Agric. 2006, 7, 65–83. [Google Scholar] [CrossRef]

- Girma, K.; Martin, K.L.; Anderson, R.H.; Arnall, D.B.; Brixey, K.D.; Casillas, M.A.; Chung, B.; Dobey, B.C.; Kamenidou, S.K.; Kariuki, S.K.; et al. Mid-season prediction of wheat-grain yield potential using plant, soil, and sensor measurements. J. Plant Nutr. 2006, 29, 873–897. [Google Scholar] [CrossRef]

- Grohs, D.S.; Bredemeier, C.; Mundstock, C.M.; Poletto, N. Model for yield potential estimation in wheat and barley using the GreenSeeker sensor. Eng. Agrícola 2009, 29, 101–112. [Google Scholar] [CrossRef] [Green Version]

- Raun, W.R.; Solie, J.B.; Johnson, G.V.; Stone, M.L.; Lukina, E.V.; Thomason, W.E.; Schepers, J.S. In-season prediction of potential grain yield in winter wheat using canopy reflectance. Agron. J. 2001, 93, 131–138. [Google Scholar] [CrossRef]

- Xue, L.; Li, G.; Qin, X.; Yang, L.; ZhanG, H. Topdressing nitrogen recommendation for early rice with an active sensor in south China. Precis. Agric. 2014, 15, 95–110. [Google Scholar] [CrossRef]

- Trevisan, R.G.; Vilanova Júnior, N.S.; Eitelwein, M.T.; Molin, J.P. Management of plant growth regulators in cotton using active crop canopy sensors. Agriculture 2018, 8, 101. [Google Scholar] [CrossRef]

- Amaral, L.R.; Molin, J.P.; Schepers, J.S. Algorithm for Variable-Rate Nitrogen Application in Sugarcane Based On Active Crop Canopy Sensor. Agron. J. 2015, 107, 1513–1523. [Google Scholar] [CrossRef]

- Amaral, L.R.; Trevisan, R.G.; Molin, J.P. Canopy sensor placement for variable-rate nitrogen application in sugarcane fields. Precis. Agric. 2017, 19, 147–160. [Google Scholar] [CrossRef]

- Portz, G.; Molin, J.P.; Jasper, J. Active crop sensor to detect variability of nitrogen supply and biomass on sugarcane fields. Precis. Agric. 2012, 13, 33–44. [Google Scholar] [CrossRef]

- Putra, B.T.W.; Soni, P.; Morimoto, E.; Pujiyanto, P. Estimating biophysical properties of coffee (Coffea canephora) plants withabove-canopy field measurements, using CropSpec. Int. Agrophys. 2018, 32, 183–191. [Google Scholar] [CrossRef]

- Oliveira, M.F.; Santos, A.F.; Kazama, E.H.; Rolim, G.S.; Silva, R.P. Determination of application volume for coffee plantations using artificial neural networks and remote sensing. Comput. Electron. Agric. 2021, 184, 106096. [Google Scholar] [CrossRef]

- Anastasiou, E.; Balafoutis, A.; Darra, N.; Psiroukis, V.; Biniari, A.; Xanthopoulos, G.; Fountas, S. Satellite and proximal sensing to estimate the yield and quality of table grapes. Agriculture 2018, 8, 94. [Google Scholar] [CrossRef]

- Darra, N.; Psomiadis, E.; Kasimati, A.; Anastasiou, A.; Anastasiou, E.; Fountas, S. Remote and proximal sensing-derived spectral indices and biophysical variables for spatial variation determination in vineyards. Agronomy 2021, 11, 741. [Google Scholar] [CrossRef]

- Yu, R.; Brillante, L.; Torres, N.; Kurtural, S.K. Proximal sensing of vineyard soil and canopy vegetation for determining vineyard spatial variability in plant physiology and berry chemistry. OENO One 2021, 55, 315–333. [Google Scholar] [CrossRef]

- Santini, P.T.; Almeida, L.G.; de Souza, K.R.D.; Barbosa, J.P.R.A.D.; Alves, J.D. Spatio-temporal variability of carbohydrate and chlorophyll content in the coffee canopy. Coffee Sci. 2019, 14, 366–372. [Google Scholar] [CrossRef]

- Chaves, A.R.; Martins, S.C.; Batista, K.D.; Celin, E.F.; Damatta, F.M. Varying leaf-to-fruit ratios affect branch growth and dieback, with little to no effect on photosynthesis, carbohydrate or mineral pools, in different canopy positions of field-grown coffee trees. Environ. Exp. Bot. 2012, 77, 207–218. [Google Scholar] [CrossRef]

- Damatta, F.M. Ecophysiological constraints on the production of shaded and unshaded coffee: A review. Field Crop Res. 2004, 86, 99–114. [Google Scholar] [CrossRef]

- Cannell, M.G.R. Crop physiological aspects of coffee bean yield—A review. Kenya Coffee 1976, 41, 245–253. [Google Scholar]

- Montoya, L.A.; Sylvain, P.G.; Umanã, R. Effect of light intensity and nitrogen fertilization upon growth differentiation balance in Coffea arabica L. Coffee (Turrialba) 1961, 3, 97–104. [Google Scholar]

- Castillo, Z.J.; Lopez, A.R. Nota sobre el efecto de la intensidad de la luz en la floracion del café. Cenicafe 1966, 17, 51–60. [Google Scholar]

- Alvares, A.C.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.L.M.; Sparovek, G. Koppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Rouse, J.W.; Haas, R.H.; Schell, J.A.; Deering, D.W. Monitoring vegetation systems in the great plains with ERTS. In Proceedings of the Earth Resources Technology Satellite—1 Symposium, Washington, DC, USA, 10–14 December 1974; pp. 309–317. [Google Scholar]

- Barnes, E.M.; Clarke, T.R.; Richards, S.E.; Colaizzi, P.D.; Haberland, J.; Kostrzewski, M.; Waller, P.; Choi, C.; Riley, E.; Thompson, T.; et al. Coincident detection of crop water stress, nitrogen status and canopy density using ground-based multispectral data. In Proceedings of the 5th International Conference on Precision Agriculture, Bloomington, MN, USA, 16–19 July 2000. [Google Scholar]

- Maldaner, L.F.; Canata, T.F.; Dias, C.T.S.; Molin, J.P. A statistical approach to static and dynamic tests for Global Navigation Satellite Systems receivers used in agricultural operations. Sci. Agric. 2021, 78, e20190252. [Google Scholar] [CrossRef]

- Martello, M.; Molin, J.P.; Bazame, H.C. Obtaining and Validating High-Density Coffee Yield Data. Horticulturae 2022, 8, 421. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Canata, T.F.; Molin, J.P. An approach to sugarcane yield estimation using sensors in the harvester and zigbee technology. Sugar Tech 2022, 24, 813–821. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Molin, J.P. Data processing within rows for sugarcane yield mapping. Sci. Agric. 2020, 77, e20180391. [Google Scholar] [CrossRef]

- Chang, C.-W.; Laird, D.A.; Mausbach, M.J.; Hurburgh, C.R. Near-Infrared Reflectance Spectroscopy–Principal Components Regression Analyses of Soil Properties. Soil Sci. Soc. Am. J. 2001, 65, 480–490. [Google Scholar] [CrossRef] [Green Version]

- Morlin Carneiro, F.; Angeli Furlani, C.E.; Zerbato, C.; Candida de Menezes, P.; da Silva Gírio, L.A.; Freire de Oliveira, M. Comparison between vegetation indices for detecting spatial and temporal variabilities in soybean crop using canopy sensors. Precis. Agric. 2020, 21, 979–1007. [Google Scholar] [CrossRef]

- Lu, J.; Miao, Y.; Shi, W.; Li, J.; Yuan, F. Evaluating different approaches to non-destructive nitrogen status diagnosis of rice using portable RapidSCAN active canopy sensor. Sci. Rep. 2017, 7, 14073. [Google Scholar] [CrossRef]

- Junges, A.H.; Fontana, D.C.; Anzanello, R.; Bremm, C. Normalized difference vegetation index obtained by ground-based remote sensing to characterize vine cycle in Rio Grande do Sul, Brazil. Ciênc. E Agrotecnol. 2017, 41, 543–553. [Google Scholar] [CrossRef]

- Taskos, D.G.; Koundouras, S.; Stamatiadis, S.; Zioziou, E.; Nikolaou, N.; Karakioulakis, K.; Theodorou, N. Using active canopy sensors and chlorophyll meters to estimate grapevine nitrogen status and productivity. Precis. Agric. 2014, 16, 77–98. [Google Scholar] [CrossRef]

- Pereira, S.O.; Bartholo, G.F.; Baliza, D.P.; Sogreira, F.M.; Guimarães, R.J. Productivity and coffee biannuality depending on the crop spacing. Pesqui. Agropecuária Bras. 2011, 46, 152–160. [Google Scholar] [CrossRef]

- Valadares, S.V.; Neves, J.C.L.; Rosa, G.N.G.P.; Martinez, H.E.P.; Venegas, V.H.A.; Lima, P.C. Productivity and biennial production of dense coffee plantations under different doses of N and K. Pesqui. Agropecuária Bras. 2013, 48, 296–303. [Google Scholar] [CrossRef] [Green Version]

| Specification | Crop Circle ACS 430 | N-Sensor NG |

|---|---|---|

| Light source * | Polychromatic modulated LED | LED (light-emitting diodes) |

| Spectral Bands ** | 670 nm (RED) 730 nm (RedEdge) 780 nm (NIR) | 730 nm (RedEdge) 770 nm (NIR) |

| Sensor | VI | Optimization of the Acquisition Scenario | Optimization of Sensor Positioning | ||||

|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | TI | TM | TS | ||

| Crop Circle | CC-NDVI | −0.17 | −0.15 | −0.21 | −0.07 | −0.21 | −0.07 |

| CC-NDRE | −0.33 | −0.27 | −0.34 | −0.11 | −0.34 | −0.26 | |

| N-Sensor | NS | −0.34 | −0.27 | −0.34 | |||

| In Comparison with Y2 | In Comparison with Y3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sensor | Pre-Harvest Y1 | Post-Harvest Y1 | Flowering | Fruit Filling | Pre-Harvest Y2 | Pre-Harvest Y2 | Post-Harvest Y2 | Pre-Harvest Y3 | |

| C1 | C2 | C3 | C4 | C5 | C5 | C6 | C7 | ||

| Crop Circle (CC-NDRE) | r | 0.91 | 0.82 | 0.73 | −0.77 | −0.81 | 0.72 | 0.88 | * |

| R2 | 0.84 | 0.68 | 0.54 | 0.59 | 0.65 | 0.52 | 0.77 | * | |

| RMSE | 0.20 | 0.28 | 0.34 | 0.32 | 0.29 | 0.30 | 0.21 | * | |

| RMSE% | 9.96 | 13.96 | 16.78 | 15.74 | 14.50 | 20.38 | 13.99 | * | |

| RPD | 2.47 | 1.76 | 1.47 | 1.56 | 1.70 | 1.45 | 2.11 | * | |

| N-Sensor | r | 0.88 | 0.87 | 0.89 | −0.77 | −0.93 | 0.90 | 0.85 | −0.71 |

| R2 | 0.77 | 0.75 | 0.79 | 0.59 | 0.86 | 0.81 | 0.72 | 0.50 | |

| RMSE | 0.24 | 0.25 | 0.23 | 0.32 | 0.19 | 0.19 | 0.23 | 0.31 | |

| RMSE% | 11.68 | 12.20 | 11.38 | 15.78 | 9.19 | 12.93 | 15.45 | 20.84 | |

| RPD | 2.11 | 2.02 | 2.16 | 1.56 | 2.68 | 2.28 | 1.91 | 1.41 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martello, M.; Molin, J.P.; Bazame, H.C.; Tavares, T.R.; Maldaner, L.F. Use of Active Sensors in Coffee Cultivation for Monitoring Crop Yield. Agronomy 2022, 12, 2118. https://doi.org/10.3390/agronomy12092118

Martello M, Molin JP, Bazame HC, Tavares TR, Maldaner LF. Use of Active Sensors in Coffee Cultivation for Monitoring Crop Yield. Agronomy. 2022; 12(9):2118. https://doi.org/10.3390/agronomy12092118

Chicago/Turabian StyleMartello, Maurício, José Paulo Molin, Helizani Couto Bazame, Tiago Rodrigues Tavares, and Leonardo Felipe Maldaner. 2022. "Use of Active Sensors in Coffee Cultivation for Monitoring Crop Yield" Agronomy 12, no. 9: 2118. https://doi.org/10.3390/agronomy12092118

APA StyleMartello, M., Molin, J. P., Bazame, H. C., Tavares, T. R., & Maldaner, L. F. (2022). Use of Active Sensors in Coffee Cultivation for Monitoring Crop Yield. Agronomy, 12(9), 2118. https://doi.org/10.3390/agronomy12092118