Study of the Potential for Agricultural Reuse of Urban Wastewater with Membrane Bioreactor Technology in the Circular Economy Framework

Abstract

:1. Introduction

2. Materials and Methods

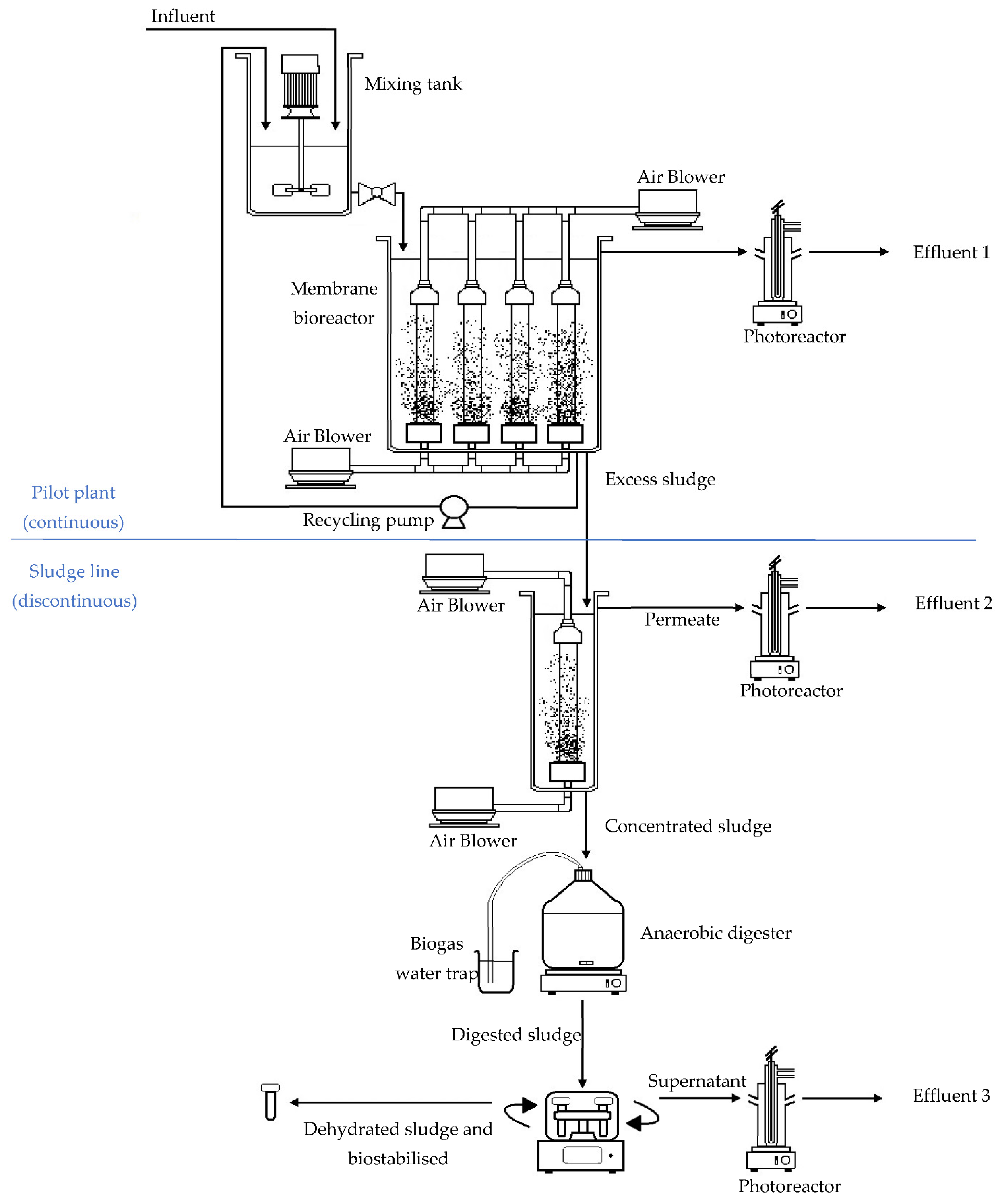

2.1. Description of the Pilot Plant

2.2. Analytical Methods

2.3. Advanced Oxidation Processes

2.4. Biological Dephosphatation Potential Indicator (IBDP)

- COD: chemical oxygen demand concentration in the influent (mg/L)

- TP: total phosphorous concentration in the influent (mg/L)

2.5. Indicators of Circular Economy

2.5.1. Indicators of Circular Economy for Water

Recovery of Water in the Treatment Process Indicator (IW,R)

- Qw: wastewater flow rate (L/day)

- Qeff: effluent flow rate (L/day)

- Qp: permeate from the sludge thickener flow rate (L/day)

- Qs: supernatant from digester sludge centrifugation flow rate (L/day)

Organic Matter Removal Efficiency Indicator (IRECOD)

- Qw: wastewater flow rate (L/day)

- CODin: chemical oxygen demand concentration in the influent (mg/L)

- CODeff: chemical oxygen demand concentration in the effluent (mg/L)

Effluent Inorganic Content Indicator (IEIC)

- Ni: inorganic nitrogen concentration in the effluent, (mg/L)

- Pi: inorganic phosphorus concentration in the effluent, (mg/L)

- Qd: daily average effluent flow, (L/day)

2.5.2. Indicators of Circular Economy for Sludge

Indicator of Technological Nutrient Performance for Recovered Sludge (ISG,R)

- mSG,R: sludge flow rate recovered during the water treatment process (kg/day)

- Qeff: effluent flow (L/day)

Indicator of the Amount of Sludge Recovered as a Function of Sludge Produced (ISG,%R)

- mSG,R: sludge flow rate recovered during the water treatment process (kg/day)

- mSG,T: sludge flow rate produced during the water treatment process (kg/day)

2.5.3. Indicator of Circular Economy for Biogas Produced

Indicator of Efficiency of Biogas Transformation into Electric Energy

- Eb: energy obtained from biogas

- Qb: volumetric flow of biogas obtained by the anaerobic digestion

3. Results and Discussion

3.1. Characterisation of the Operating Cycles

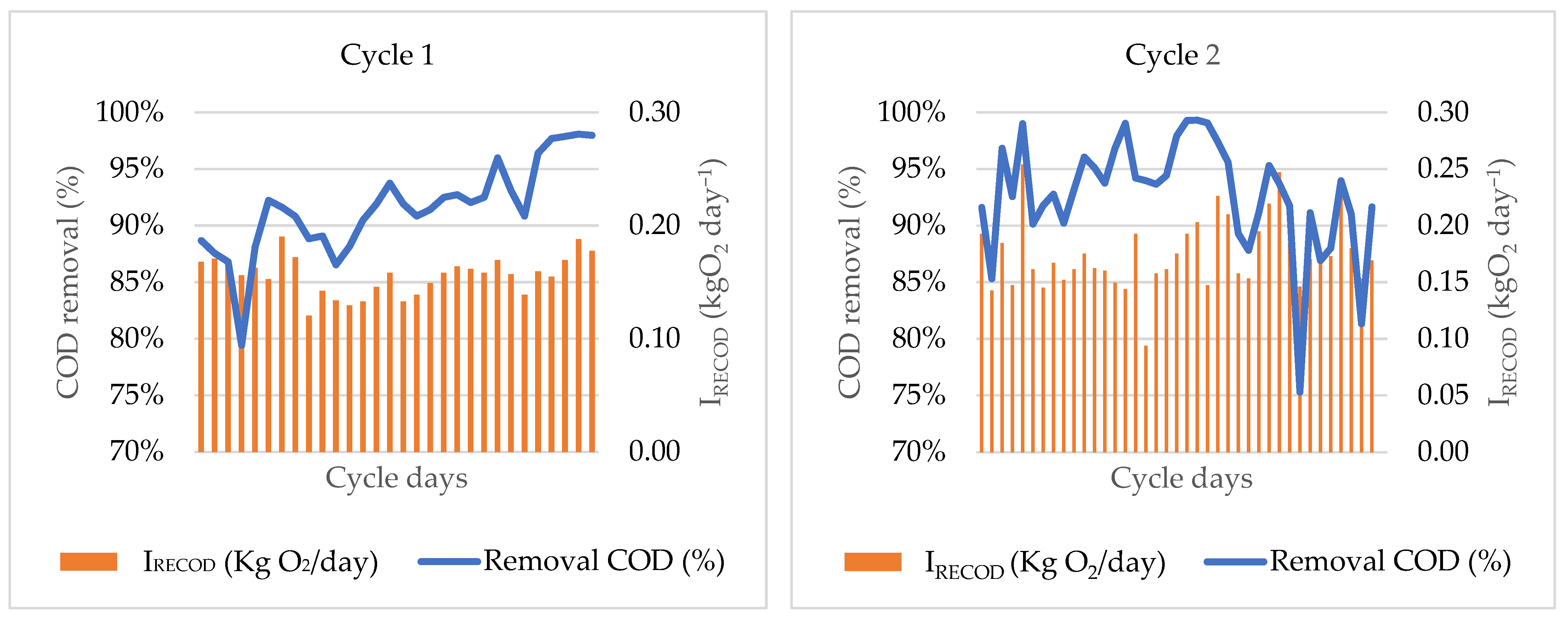

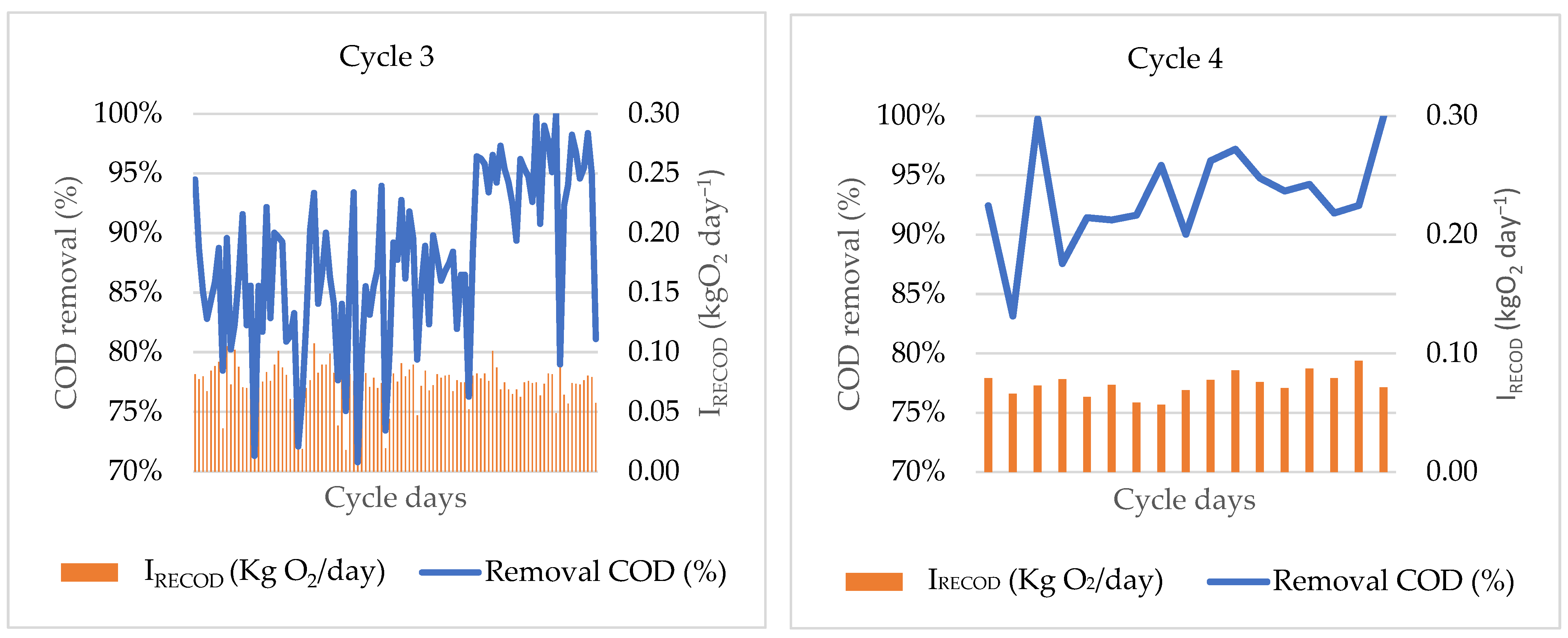

3.2. Water Pollution Removal

3.3. Biogas Production during Anaerobic Digestion

3.4. Turbidity and E.coli Measurements

3.5. Indicators of Circular Economy

3.5.1. Indicators of Circular Economy for Water

3.5.2. Indicators of Circular Economy for Sludge

3.5.3. Indicator of Circular Economy for Biogas

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Yakovleva, N.; Camacho-Ferre, F. Analysis of the circular economic production models and their approach in agriculture and agricultural waste biomass management. Int. J. Environ. Res. Public Health 2020, 17, 9549. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, C.; Cruz-Jesus, F.; Oliveira, T.; Damásio, B. Leveraging the circular economy: Investment and innovation as drivers. J. Clean. Prod. 2022, 360, 132146. [Google Scholar] [CrossRef]

- Connor, R. The United Nations World Water Development Report 2015: Water for a Sustainable World; UNESCO Publishing: Paris, France, 2015; Volume 1. [Google Scholar]

- Aznar-Sánchez, J.A.; Belmonte-Ureña, L.J.; Velasco-Muñoz, J.F.; Valera, D.L. Farmers’ profiles and behaviours toward desalinated seawater for irrigation: Insights from South-east Spain. J. Clean. Prod. 2021, 296, 126568. [Google Scholar] [CrossRef]

- Bonetta, S.; Pignata, C.; Lorenzi, E.; De Ceglia, M.; Meucci, L.; Bonetta, S.; Gilli, G.; Carraro, E. Detection of pathogenic Campylobacter, E. coli O157:H7 and Salmonella spp. in wastewater by PCR assay. Environ. Sci. Pollut. Res. 2016, 23, 15302–15309. [Google Scholar] [CrossRef]

- Farhadkhani, M.; Nikaeen, M.; Hadi, M.; Gholipour, S.; Yadegarfar, G. Campylobacter risk for the consumers of wastewater-irrigated vegetables based on field experiments. Chemosphere 2020, 251, 126408. [Google Scholar] [CrossRef]

- Hai, F.I.; Riley, T.; Shawkat, S.; Magram, S.F.; Yamamoto, K. Removal of Pathogens by Membrane Bioreactors: A Review of the Mechanisms, Influencing Factors and Reduction in Chemical Disinfectant Dosing. Water 2014, 6, 3603–3630. [Google Scholar] [CrossRef]

- Bonetta, S.; Pignata, C.; Gasparro, E.; Richiardi, L.; Bonetta, S.; Carraro, E. Impact of wastewater treatment plants on microbiological contamination for evaluating the risks of wastewater reuse n.d. Environ. Sci. Eur. 2022, 34, 20. [Google Scholar] [CrossRef]

- Judd, S.J. The status of industrial and municipal effluent treatment with membrane bioreactor technology. Chem. Eng. J. 2016, 305, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Kundan, S.; Rupam, B.; Dash, R.R. Biological Treatment of Contaminants of Emerging Concern in Wastewater: A Review. J. Hazard. Toxic Radioact. Waste 2022, 26, 4022002. [Google Scholar] [CrossRef]

- Antiñolo Bermúdez, L.; Pascual, J.M.; del Mar Muñio Martínez, M.; Manuel, J.; Capilla, P. Effectiveness of Advanced Oxidation Processes in Wastewater Treatment: State of the Art. Water 2021, 13, 2094. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Fuwad, A.; Choi, Y. Current advances in treatment technologies for removal of emerging contaminants from water–A critical review. Coord. Chem. Rev. 2021, 442, 213993. [Google Scholar] [CrossRef]

- Asai, M.; Hayashi, T.; Yamamoto, M. Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community. Sustainability 2019, 11, 225. [Google Scholar] [CrossRef] [Green Version]

- Martínez Patiño, J.; Hernández Figueroa, M.A.; Picón Núñez, M.; Ireta Moreno, F.; Merced Lozano García, J. Assessing the power quality of internal combustion engines operating with different fuels. Electr. Eng. 2017, 99, 899–905. [Google Scholar] [CrossRef]

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- Qyyum, A.; D’adamo, I.; Sassanelli, C. Biomethane Community: A Research Agenda towards Sustainability. Sustainability 2022, 14, 4735. [Google Scholar] [CrossRef]

- Ahmad, T.; Ahmad, K.; Alam, M. Sludge quantification at water treatment plant and its management scenario. Environ. Monit. Assess. 2017, 189, 453. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Thomas, M.; Surapaneni, A.; Moon, E.M.; Milne, N.A. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 2022, 28, 102651. [Google Scholar] [CrossRef]

- Fijalkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The presence of contaminations in sewage sludge–The current situation. J. Environ. Manag. 2017, 203, 1126–1136. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; de Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Horttanainen, M.; Deviatkin, I.; Havukainen, J.; Klavins, M.; Ozola-Davidane, R.; Kruopienė, J.; Szatkowska, B.; Appels, L.; et al. Indicators for resource recovery monitoring within the circular economy model implementation in the wastewater sector. J. Environ. Manag. 2022, 304, 114261. [Google Scholar] [CrossRef] [PubMed]

- Andrade, E.P.; Bonmati, A.; Esteller, L.J.; Brunn, S.; Jensen, L.S.; Meers, E.; Anton, A. Selection and application of agri-environmental indicators to assess potential technologies for nutrient recovery in agriculture. Ecol. Indic. 2022, 134, 108471. [Google Scholar] [CrossRef]

- Metcalf, L.; Eddy, H.P.; Tchobanoglous, G. Wastewater Energy: Treatment and Reuse; McGraw-Hill: New York, NY, USA, 2004; pp. 42–48. [Google Scholar]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standar Methods for Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA; American Water Works Association: Denver, CO, USA; Water Environment Federation: Wythe, VA, USA, 2022. [Google Scholar]

- Monteoliva-García, A.; Martín-Pascual, J.; Muñío, M.; Poyatos, J. Removal of carbamazepine, ciprofloxacin and ibuprofen in real urban wastewater by using light-driven advanced oxidation processes. Int. J. Environ. Sci. Technol. 2019, 16, 6005–6018. [Google Scholar] [CrossRef]

- Ibáñez, M.; Gracia-Lor, E.; Bijlsma, L.; Morales, E.; Pastor, L.; Hernández, F. Removal of emerging contaminants in sewage water subjected to advanced oxidation with ozone. J. Hazard. Mater. 2013, 260, 389–398. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; de Toledo, R.A.; Shim, H. Effect of COD/TP ratio on biological nutrient removal in A2O and SBR processes coupled with microfiltration and effluent reuse potential. Environ. Technol. 2016, 37, 1461–1466. [Google Scholar] [CrossRef]

- Meena, R.A.A.; Kannah, R.Y.; Sindhu, J.; Ragavi, J.; Kumar, G.; Gunasekaran, M.; Banu, J.R. Trends and resource recovery in biological wastewater treatment system. Bioresour. Technol. Rep. 2019, 7, 100235. [Google Scholar] [CrossRef]

- Aboulhassan, M.A.; Souabi, S.; Yaacoubi, A.; Baudu, M. Removal of surfactant from industrial wastewaters by coagulation flocculation process. Int. J. Environ. Sci. Technol. 2006, 3, 327–332. [Google Scholar] [CrossRef] [Green Version]

- Sikosana, M.K.L.N.; Randall, D.G.; von Blottnitz, H. A technological and economic exploration of phosphate recovery from centralised sewage treatment in a transitioning economy context. Water SA 2017, 43, 343–353. [Google Scholar] [CrossRef] [Green Version]

- Yan, P.; Qin, R.C.; Guo, J.S.; Yu, Q.; Li, Z.; Chen, Y.P.; Shen, Y.; Fang, F. Net-zero-energy model for sustainable wastewater treatment. Environ. Sci. Technol. 2017, 51, 1017–1023. [Google Scholar] [CrossRef]

- Fenech, C.; Rock, L.; Nolan, K.; Tobin, J.; Morrissey, A. The potential for a suite of isotope and chemical markers to differentiate sources of nitrate contamination: A review. Water Res. 2012, 46, 2023–2041. [Google Scholar] [CrossRef]

- Cao, M.; Hu, A.; Gad, M.; Adyari, B.; Qin, D.; Zhang, L.; Sun, Q.; Yu, C.P. Domestic wastewater causes nitrate pollution in an agricultural watershed, China. Sci. Total Environ. 2022, 823, 153680. [Google Scholar] [CrossRef] [PubMed]

- Zaragüeta, M.; Acebes, P. Controlling Eutrophication in A Mediterranean Shallow Reservoir by Phosphorus Loading Reduction: The Need for an Integrated Management Approach. Environ. Manag. 2017, 59, 635–651. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Song, C.; Ji, L.; Liu, Y.; Xiao, J.; Cao, X.; Zhou, Y. Cause and effect of N/P ratio decline with eutrophication aggravation in shallow lakes. Sci. Total Environ. 2018, 627, 1294–1302. [Google Scholar] [CrossRef] [PubMed]

- Preisner, M.; Neverova-Dziopak, E.; Kowalewski, Z. Analysis of eutrophication potential of municipal wastewater. Water Sci. Technol. 2020, 81, 1994–2003. [Google Scholar] [CrossRef]

- Li, B.; Brett, M.T. The relationship between operational and bioavailable phosphorus fractions in effluents from advanced nutrient removal systems. Int. J. Environ. Sci. Technol. 2015, 12, 3317–3328. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Brett, M.T. The impact of alum based advanced nutrient removal processes on phosphorus bioavailability. Water Res. 2012, 46, 837–844. [Google Scholar] [CrossRef]

- Molina-Sánchez, E.; Leyva-Díaz, J.C.; Cortés-García, F.J.; Molina-Moreno, V. Proposal of Sustainability Indicators for the Waste Management from the Paper Industry within the Circular Economy Model. Water 2018, 10, 1014. [Google Scholar] [CrossRef] [Green Version]

- Salguero-Puerta, L.; Leyva-Díaz, J.C.; Cortés-García, F.J.; Molina-Moreno, V. Sustainability Indicators Concerning Waste Management for Implementation of the Circular Economy Model on the University of Lome (Togo) Campus. Int. J. Environ. Res. Public Health 2019, 16, 2234. [Google Scholar] [CrossRef] [Green Version]

- Do, K.U.; Chu, X.Q. Performances of membrane bioreactor technology for treating domestic wastewater operated at different sludge retention time. In Development in Wastewater Treatment Research and Processes: Removal of Emerging Contaminants from Wastewater through Bio-Nanotechnology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 107–122. [Google Scholar] [CrossRef]

- Monteoliva-García, A.; Martín-Pascual, J.J.; Muñío, M.M.; Poyatos, J.M. Removal of a Pharmaceutical Mix from Urban Wastewater Coupling Membrane Bioreactor with Advanced Oxidation Processes. J. Environ. Eng. 2019, 145, 04019055. [Google Scholar] [CrossRef]

- Calero-Díaz, G.; Monteoliva-García, A.; Leyva-Díaz, J.C.; López-López, C.; Martín-Pascual, J.; Torres, J.C.; Poyatos, J.M. Impact of ciprofloxacin, carbamazepine and ibuprofen on a membrane bioreactor system: Kinetic study and biodegradation capacity. J. Chem. Technol. Biotechnol. 2017, 92, 2944–2951. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of Indicators of Circular Economy as Instruments for the Evaluation of Sustainability and Efficiency in Wastewater from Pig Farming Industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- Zhang, L.; De Vrieze, J.; Hendrickx, T.L.; Wei, W.; Temmink, H.; Rijnaarts, H.; Zeeman, G. Anaerobic treatment of raw domestic wastewater in a UASB-digester at 10 °C and microbial community dynamics. Chem. Eng. J. 2018, 334, 2088–2097. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Gypakis, A.; Kyriakou, A.; Lasaridi, K.; Manios, T. Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag. 2017, 59, 362–370. [Google Scholar] [CrossRef] [PubMed]

- Monteoliva-García, A.; Martín-Pascual, J.; Muñío, M.M.; Poyatos, J.M. Effects of carrier addition on water quality and pharmaceutical removal capacity of a membrane bioreactor–Advanced oxidation process combined treatment. Sci. Total Environ. 2020, 708, 135104. [Google Scholar] [CrossRef] [PubMed]

| Cycle | Duration (day) | HRT (h) | MLSS (mg L−1) | Temperature (°C) | SRT (day) |

|---|---|---|---|---|---|

| 1 | 40 | 6 | 4919 ± 1124 | 20.8 ± 1.6 | 22.3 |

| 2 | 23 | 6 | 6696 ± 2472 | 20.2 ± 2.9 | 10.7 |

| 3 | 164 | 12 | 4771 ± 1436 | 12.6 ± 2.8 | 38.5 |

| 4 | 58 | 12 | 2429 ± 768 | 20.1 ± 1.4 | 36.5 |

| Cycle | TSS (mg/L) | Conductivity (µS/cm) | pH | BOD5 (mgO2/L) | COD (mgO2/L) |

|---|---|---|---|---|---|

| Influent | |||||

| 1 | 106 ± 17 | 1157.2 ± 135.7 | 7.9 ± 0.2 | 292 ± 45 | 496 ± 52 |

| 2 | 116 ± 40 | 1184.3 ± 219.6 | 7.8 ± 0.3 | 277 ± 56 | 541 ± 92 |

| 3 | 108 ± 23 | 1106.2 ± 215.4 | 8.1 ± 0.1 | 256 ± 63 | 484 ± 110 |

| 4 | 171 ± 85 | 1114.6 ± 153.2 | 7.6 ± 0.1 | 271 ± 24 | 462 ± 61 |

| Effluent | |||||

| 1 | 3 ± 2 | 871.4 ± 68.8 | 7.4 ± 0.4 | 9 ± 7 | 42 ± 22 |

| 2 | 3 ± 2 | 862.8 ± 142.5 | 7.9 ± 0.3 | 5 ± 6 | 37 ± 27 |

| 3 | 3 ± 3 | 834.0 ± 134.9 | 7.0 ± 0.9 | 7 ± 9 | 57 ± 31 |

| 4 | 3 ± 2 | 787.9 ± 33.6 | 7.2 ± 0.3 | 7 ± 5 | 32 ± 20 |

| Bioreactor | |||||

| 1 | 4919 ± 1124 | 894.9 ± 95.2 | 7.4 ± 0.4 | - | - |

| 2 | 6696 ± 2472 | 859.5 ± 117.2 | 7.7 ± 0.3 | - | - |

| 3 | 4771 ± 1436 | 802.3 ± 144.8 | 7.0 ± 0.7 | - | - |

| 4 | 2429 ± 768 | 784.9 ± 27.5 | 6.6 ± 0.6 | - | - |

| Anaerobic Digester | ||||

|---|---|---|---|---|

| Cycle | Conductivity (µS/cm) | pH | Total Alkalinity (mg/L CaCO3) | Volatile Fatty Acids (mg/L CaCO3) |

| 1 | 1784.2 ± 561.3 | 7.5 ± 0.1 | 612.5 ± 213.5 | 35.4 ± 15.6 |

| 2 | 2278.3 ± 619.6 | 7.4 ± 0.1 | 825.6 ± 256.8 | 39.5 ± 9.9 |

| 3 | 2406.2 ± 361.9 | 7.0 ± 0.2 | 900.0 ± 228.9 | 127.2 ± 37.2 |

| 4 | 974.6 ± 132.8 | 7.3 ± 0.2 | 490.6 ± 272.7 | 104.5 ± 95.5 |

| Cycle | BOD5 Removal (%) | COD Removal (%) | TSS Removal (%) |

|---|---|---|---|

| 1 | 96.9 ± 2.5 | 91.5 ± 4.0 | 97.8 ± 1.8 |

| 2 | 97.9 ± 3.3 | 92.8 ± 4.9 | 97.1 ± 2.3 |

| 3 | 97.0 ± 3.4 | 87.9 ± 6.8 | 96.8 ± 4.3 |

| 4 | 97.3 ± 1.8 | 93.1 ± 4.2 | 97.7 ± 2.8 |

| Cycle | Maximum CH4 Flow Rate (L biogas Kg−1 sludge day−1) | Total CH4 Volume (L) |

|---|---|---|

| 1 | 0.257 | 1.633 |

| 2 | 0.793 | 4.410 |

| 3 | 0.198 | 2.952 |

| 4 | 0.117 | 1.447 |

| Cycle | Turbidity (NTU) Influent | Turbidity (NTU) Effluent | Microbiological Count (CFU/100 mL) |

|---|---|---|---|

| 1 | 193.36 ± 36.75 | 4.13 ± 0.33 | 6.91 ± 0.48 |

| 2 | 205.34 ± 41.42 | 6.26 ± 0.67 | 7.13 ± 0.57 |

| 3 | 226.87 ± 47.33 | 8.12 ± 0.51 | 7.06 ± 0.53 |

| 4 | 174.37 ± 31.33 | 10.62 ± 0.78 | 6.17 ± 0.39 |

| Cycle | IW,R (%) | IEIC(N) (mg/day) | IEIC(P) (mg/day) |

|---|---|---|---|

| 1 | 99.99 | 4284.0 | 13,640.5 |

| 2 | 99.98 | 2485.7 | 11,952.0 |

| 3 | 99.99 | 12,948.9 | 851.9 |

| 4 | 99.99 | 16,276.1 | 7694.7 |

| Cycle | mSG,R (kg/day) | mSG,T (kg/day) | ISG,%R (%) |

|---|---|---|---|

| 1 | 0.026 | 3.800 | 0.682 |

| 2 | 0.054 | 7.980 | 0.682 |

| 3 | 0.015 | 2.210 | 0.682 |

| 4 | 0.016 | 2.330 | 0.682 |

| Cycle | mSG,R (kg/day) | Qeff (L/day) | ISG,R |

|---|---|---|---|

| 1 | 0.026 | 343.80 | 7.55 × 10−5 |

| 2 | 0.054 | 347.98 | 1.56 × 10−4 |

| 3 | 0.015 | 172.21 | 8.75 × 10−5 |

| 4 | 0.016 | 172.33 | 9.22 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antiñolo Bermúdez, L.; Leyva Díaz, J.C.; Martín Pascual, J.; Muñío Martínez, M.d.M.; Poyatos Capilla, J.M. Study of the Potential for Agricultural Reuse of Urban Wastewater with Membrane Bioreactor Technology in the Circular Economy Framework. Agronomy 2022, 12, 1877. https://doi.org/10.3390/agronomy12081877

Antiñolo Bermúdez L, Leyva Díaz JC, Martín Pascual J, Muñío Martínez MdM, Poyatos Capilla JM. Study of the Potential for Agricultural Reuse of Urban Wastewater with Membrane Bioreactor Technology in the Circular Economy Framework. Agronomy. 2022; 12(8):1877. https://doi.org/10.3390/agronomy12081877

Chicago/Turabian StyleAntiñolo Bermúdez, Laura, Juan Carlos Leyva Díaz, Jaime Martín Pascual, María del Mar Muñío Martínez, and José Manuel Poyatos Capilla. 2022. "Study of the Potential for Agricultural Reuse of Urban Wastewater with Membrane Bioreactor Technology in the Circular Economy Framework" Agronomy 12, no. 8: 1877. https://doi.org/10.3390/agronomy12081877

APA StyleAntiñolo Bermúdez, L., Leyva Díaz, J. C., Martín Pascual, J., Muñío Martínez, M. d. M., & Poyatos Capilla, J. M. (2022). Study of the Potential for Agricultural Reuse of Urban Wastewater with Membrane Bioreactor Technology in the Circular Economy Framework. Agronomy, 12(8), 1877. https://doi.org/10.3390/agronomy12081877