Physical Clogging Characteristics of Labyrinth Emitters under Low-Quality (Sand-Laden Water) Irrigation

Abstract

:1. Introduction

2. Materials and Methods

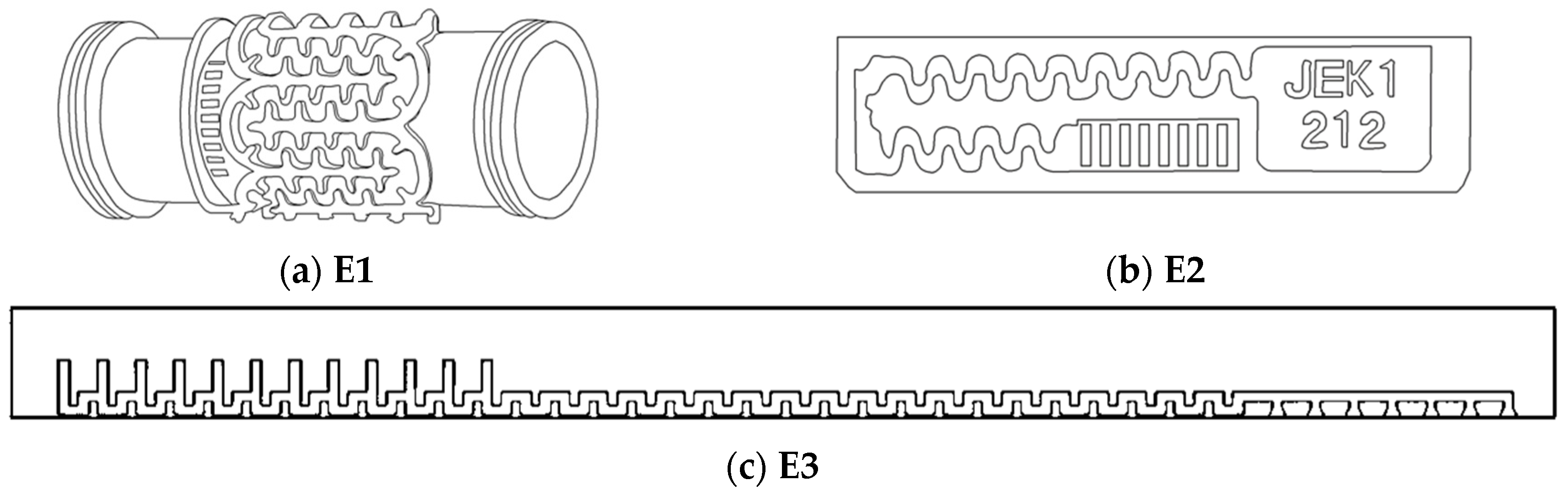

2.1. Emitters

2.2. Irrigation Source

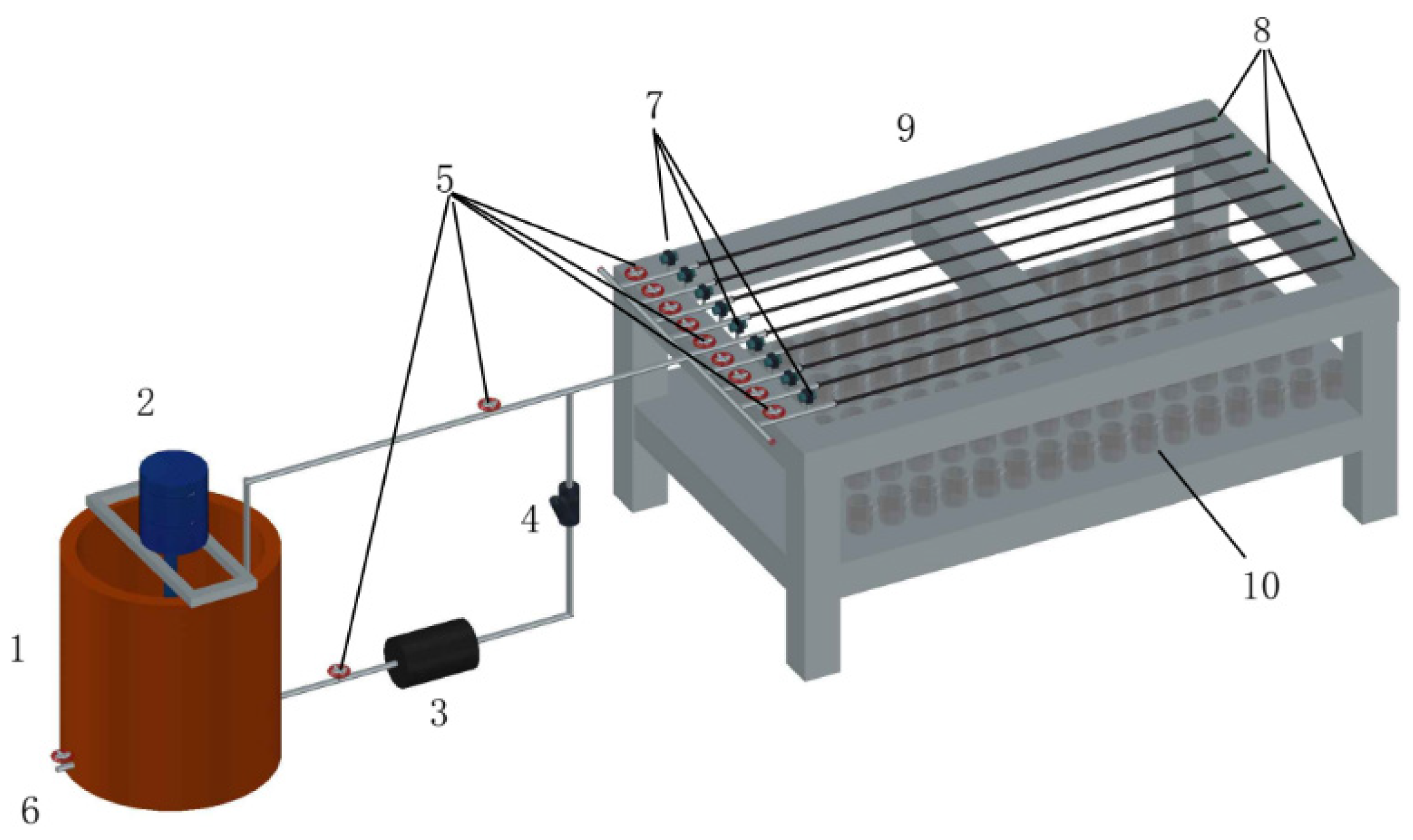

2.3. System Layout and Test Design

2.4. Flow Measurement and Clogging Matter Sampling

2.5. Evaluation Index and Determination Method

2.5.1. Relative Average Discharge

2.5.2. Christiansen Uniformity

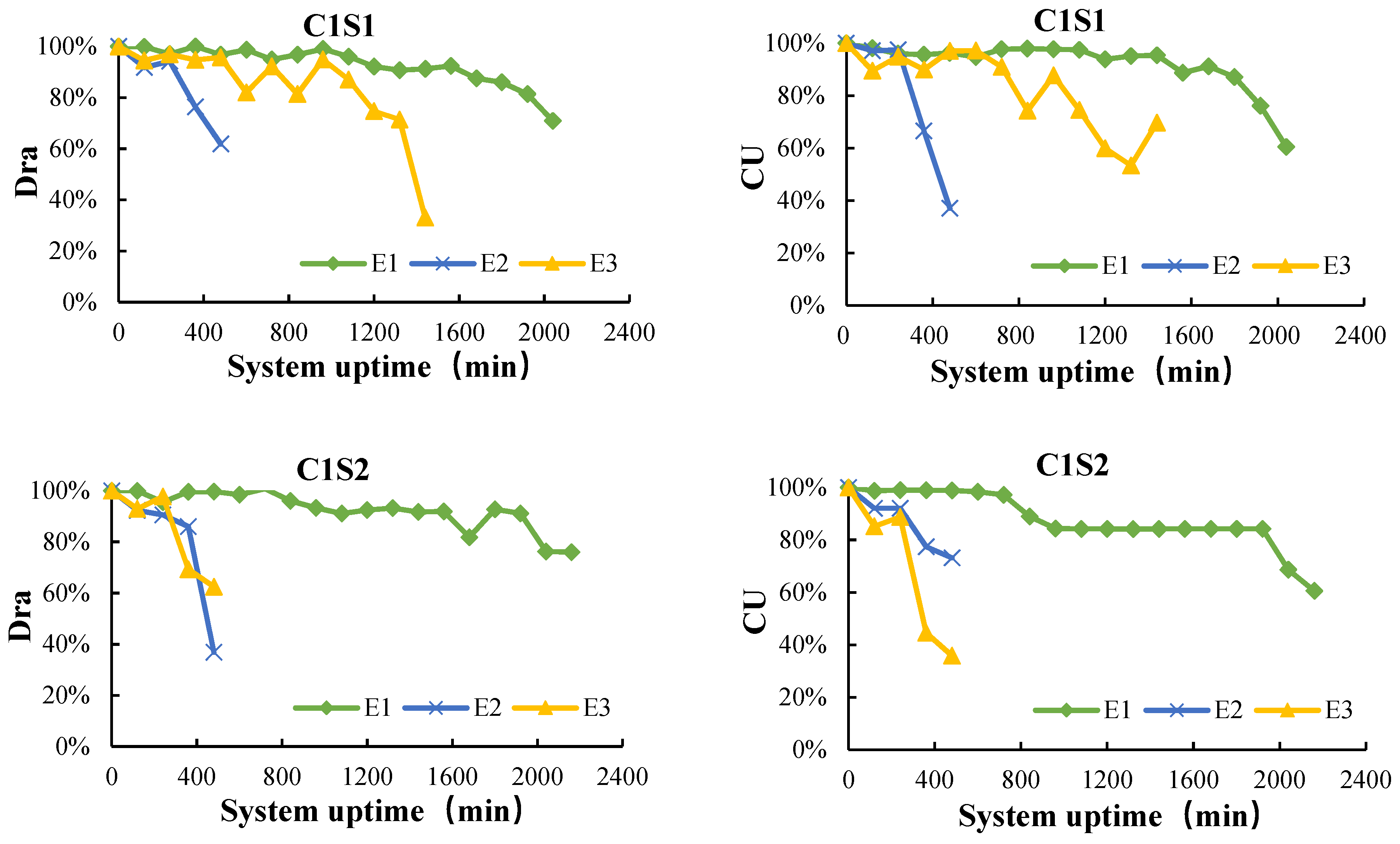

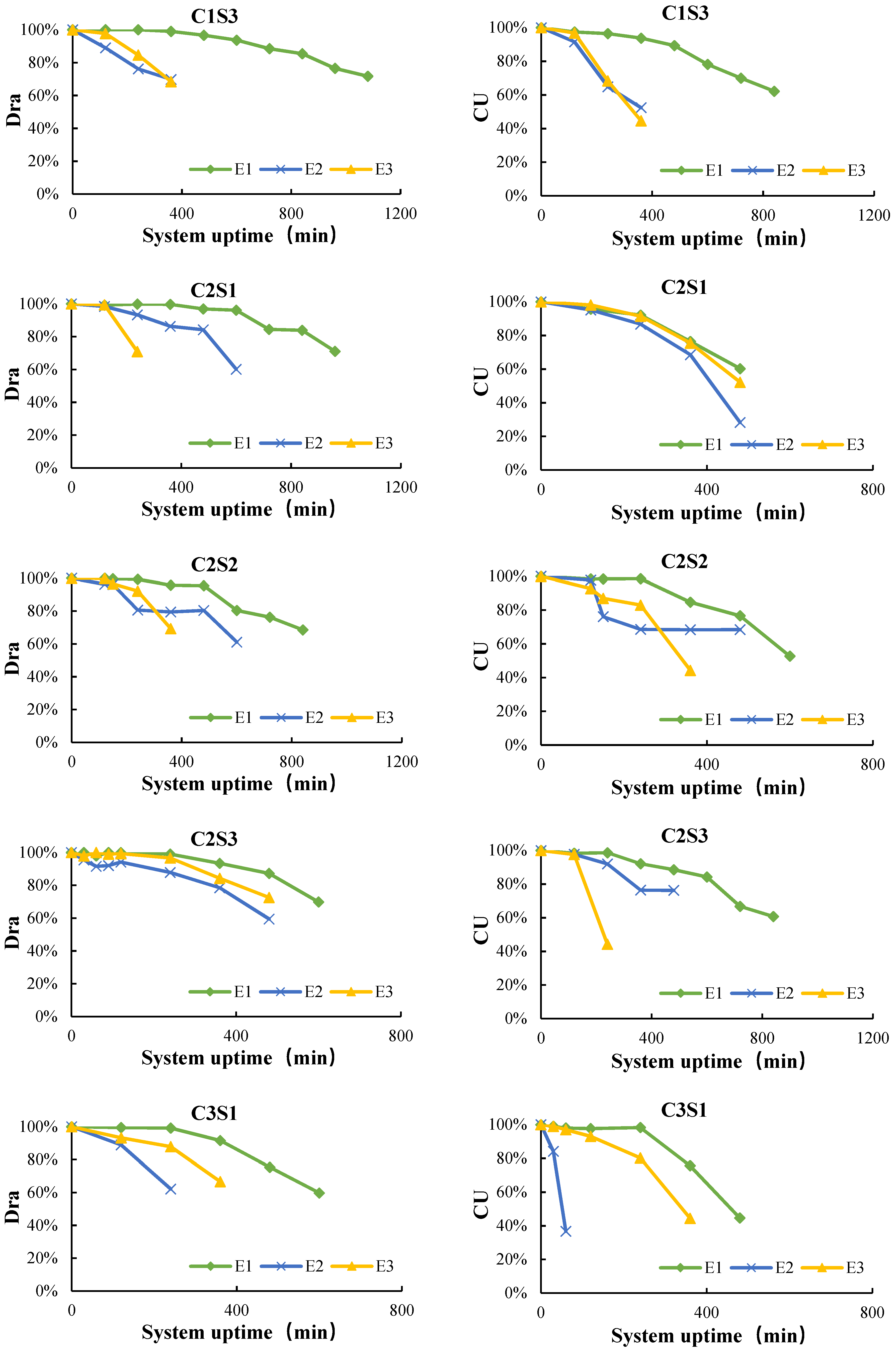

3. Results and Analysis

3.1. Physical Blockage Occurrence

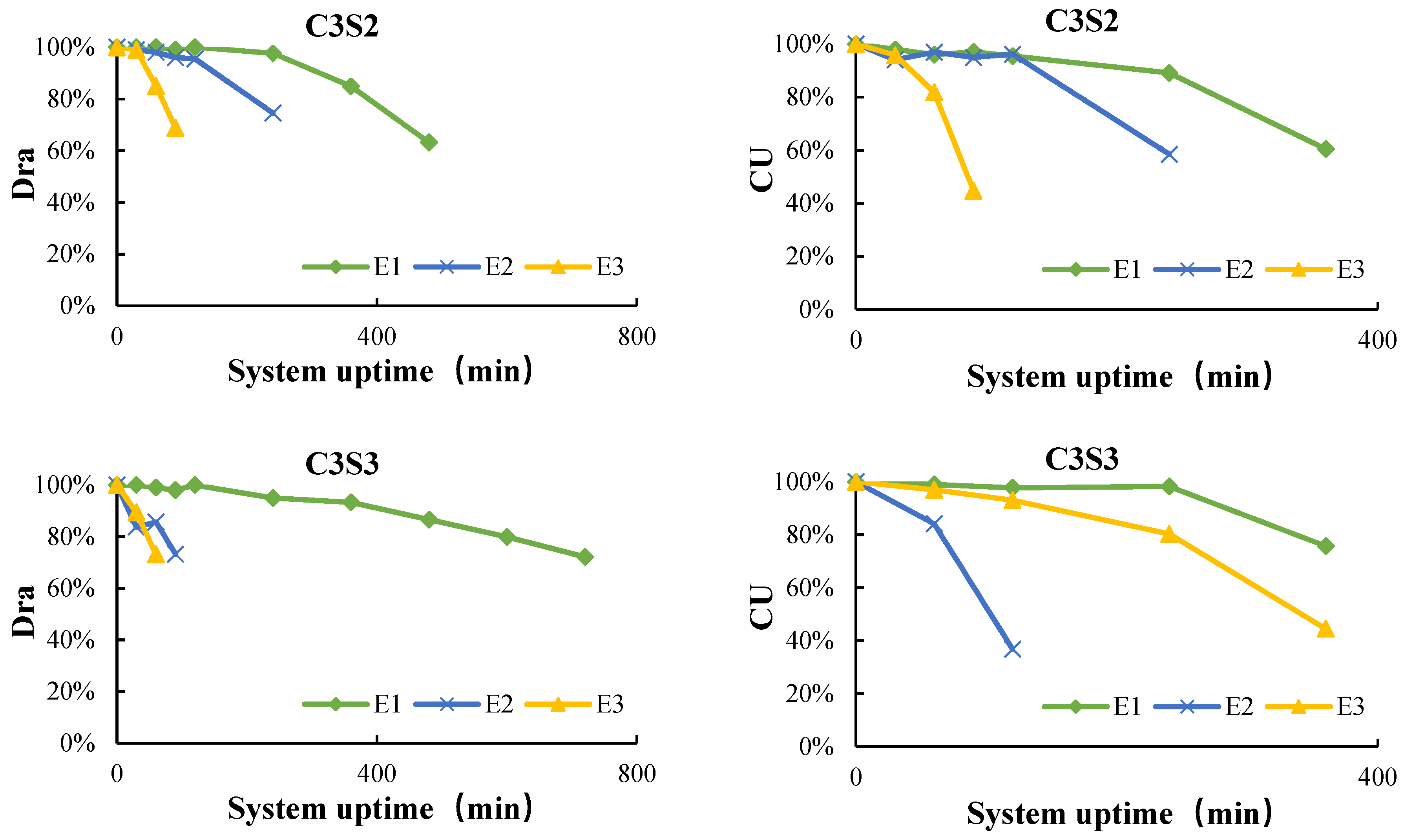

3.1.1. Whole Blockage Occurrence

3.1.2. Local Blockage Occurrence

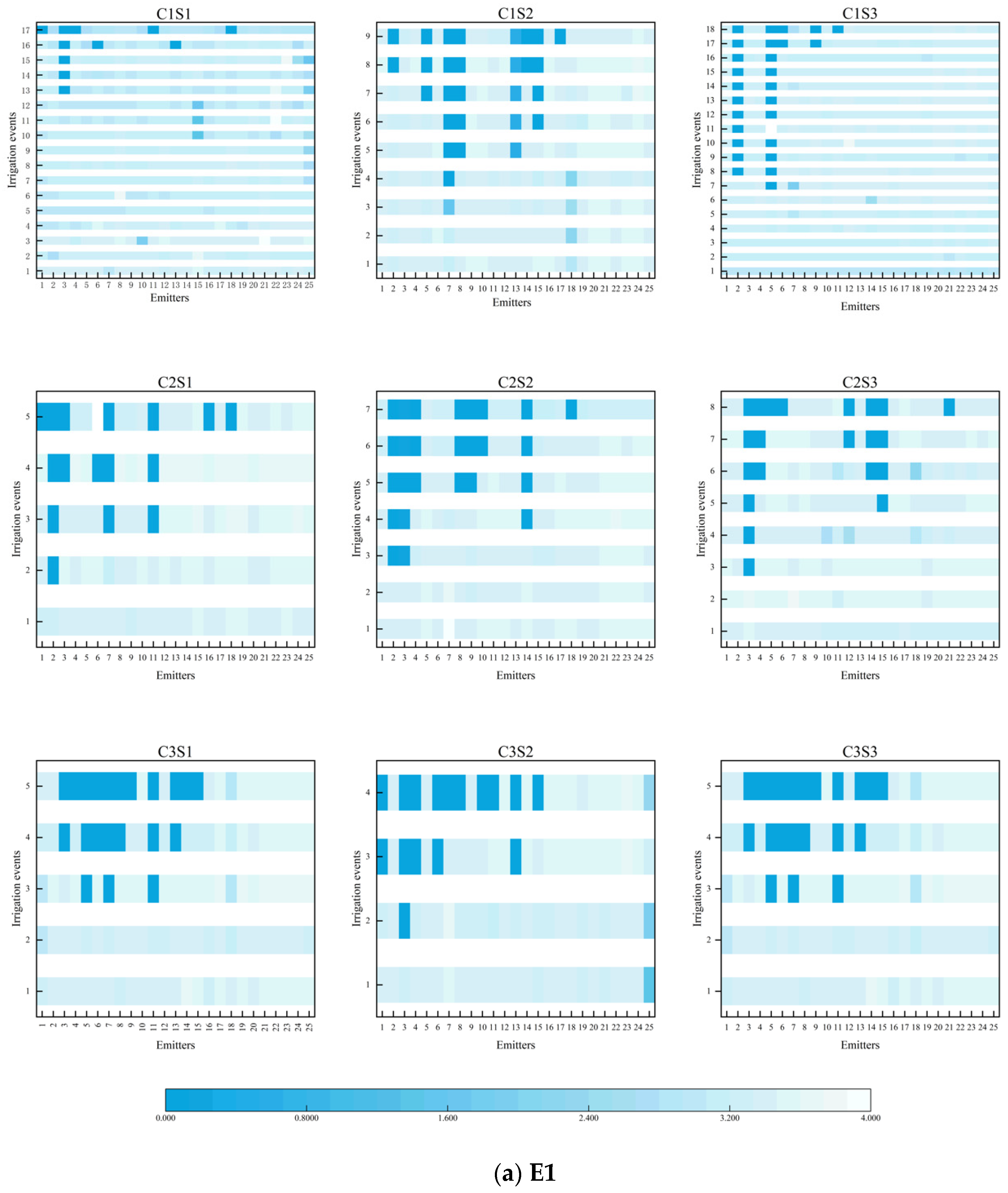

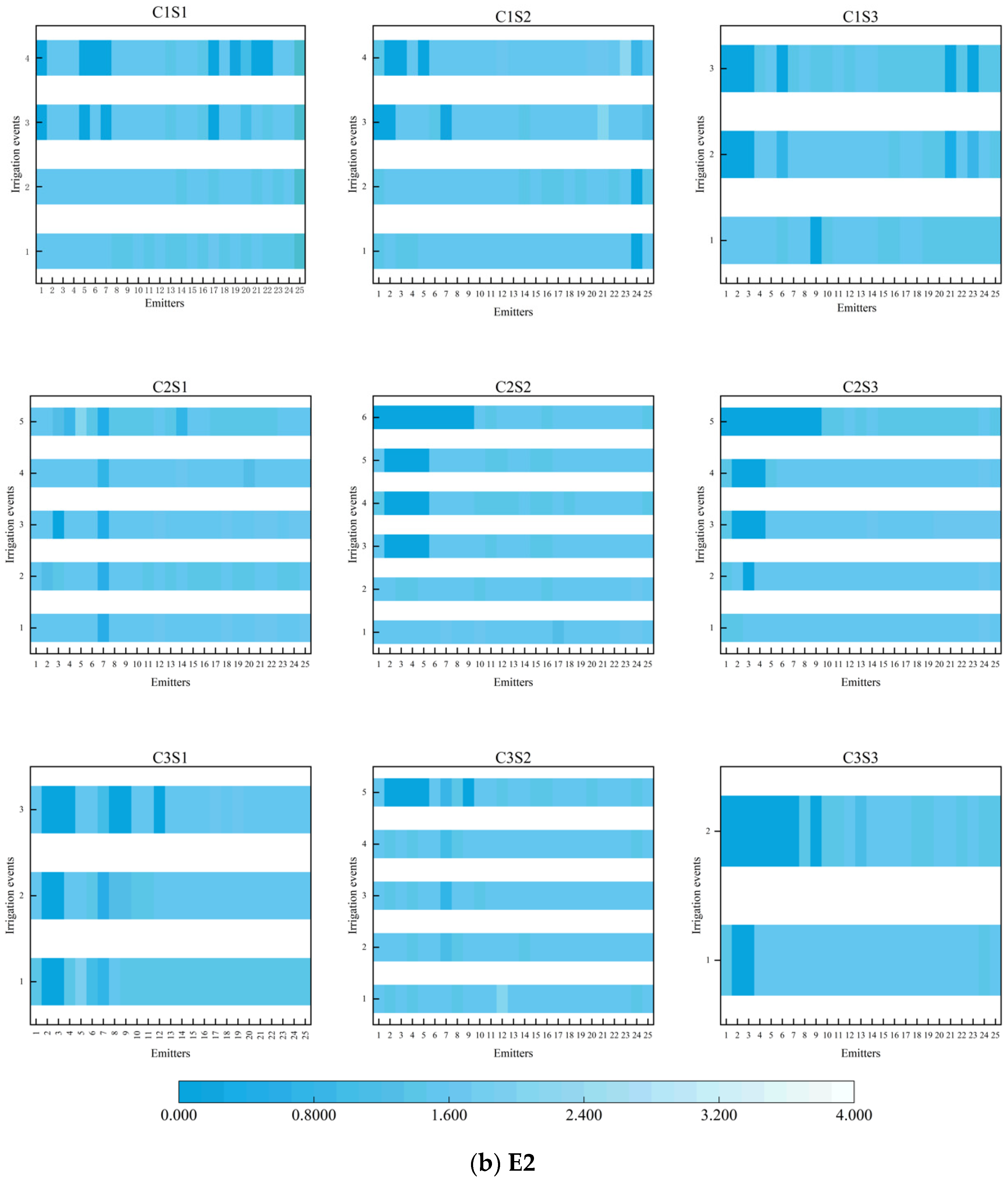

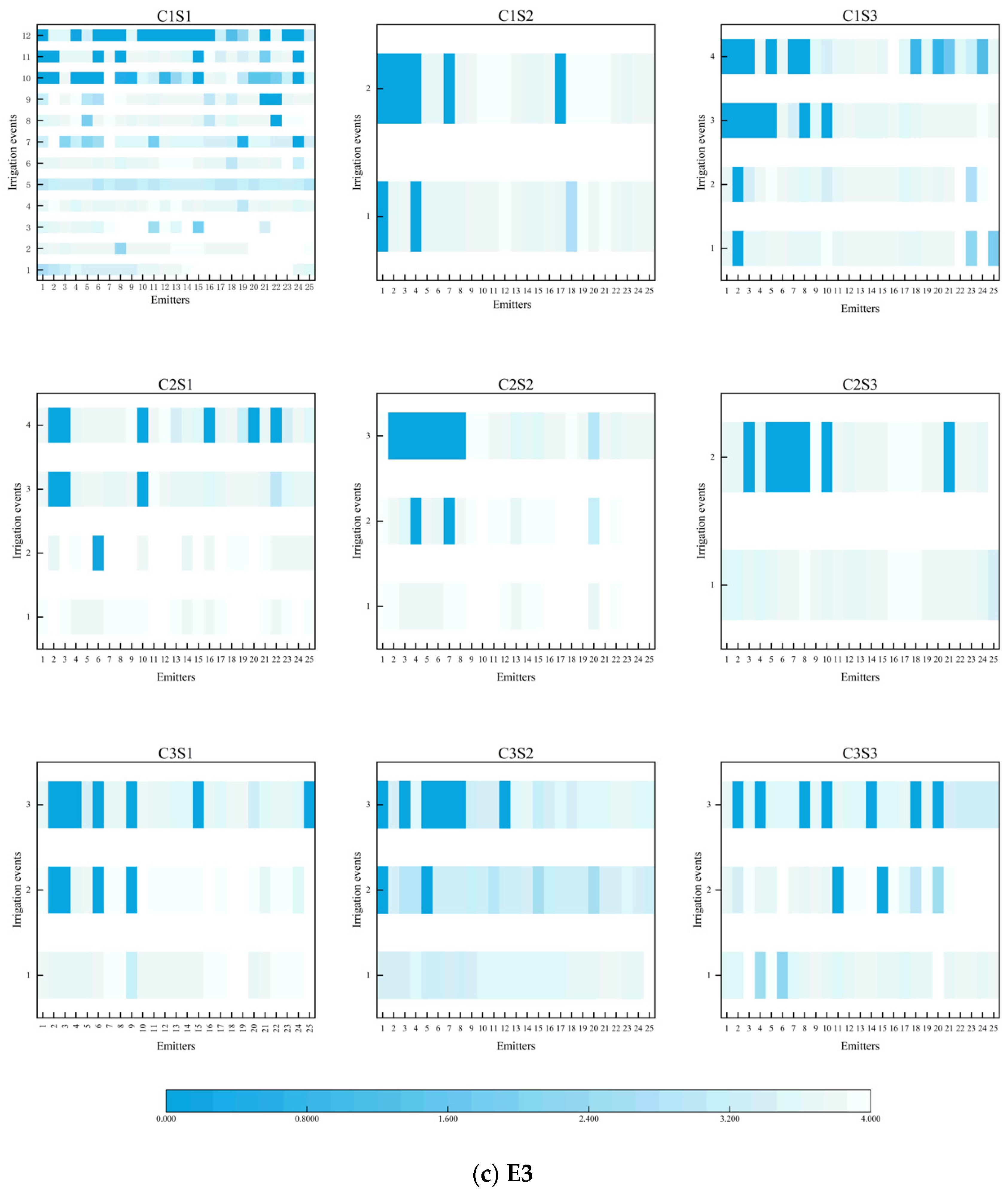

3.2. Physical Blockage Distribution

3.2.1. Whole Blockage Distribution

3.2.2. Local Blockage Distribution

3.3. Structure and Elemental Composition of Clogging Material

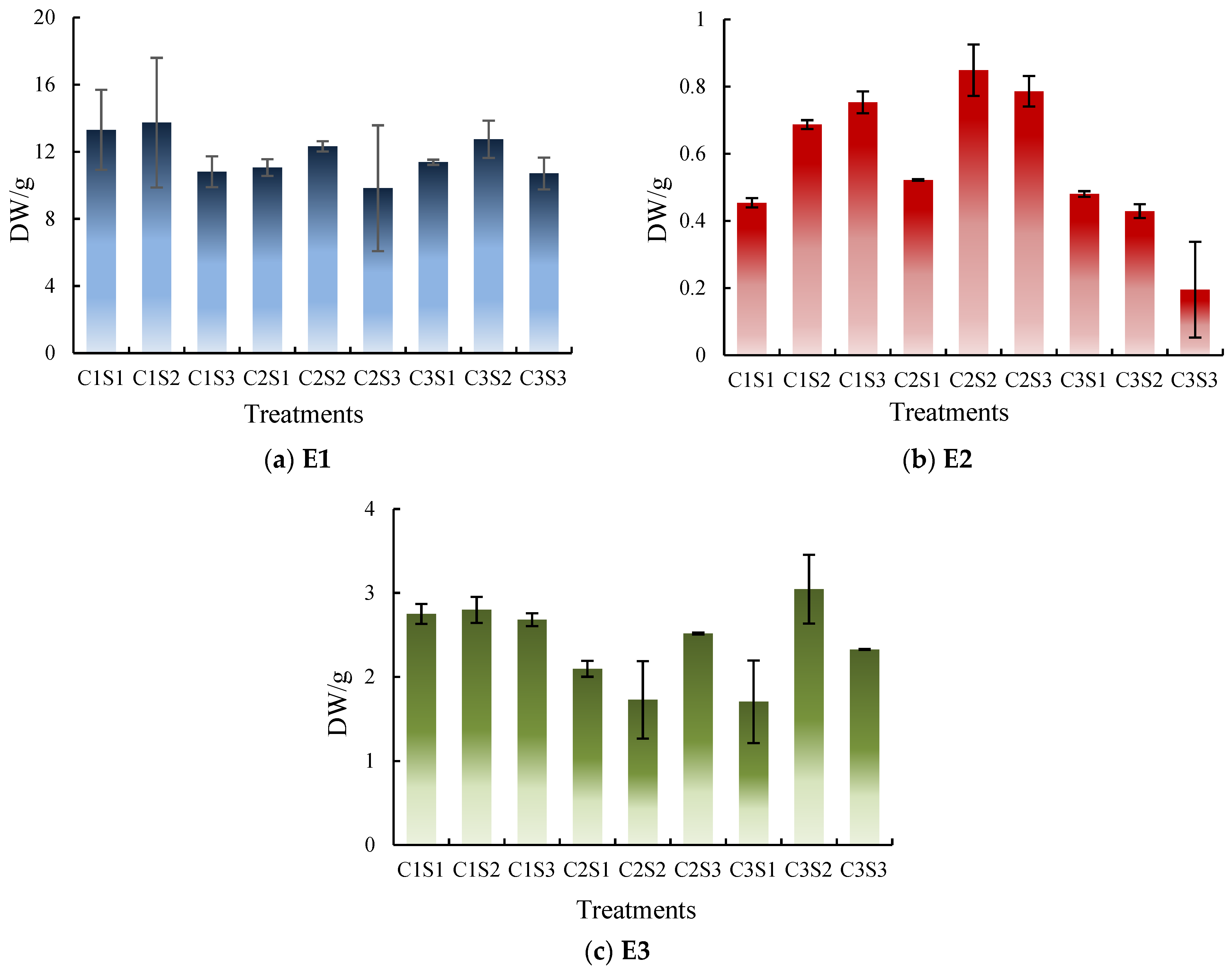

3.3.1. DW

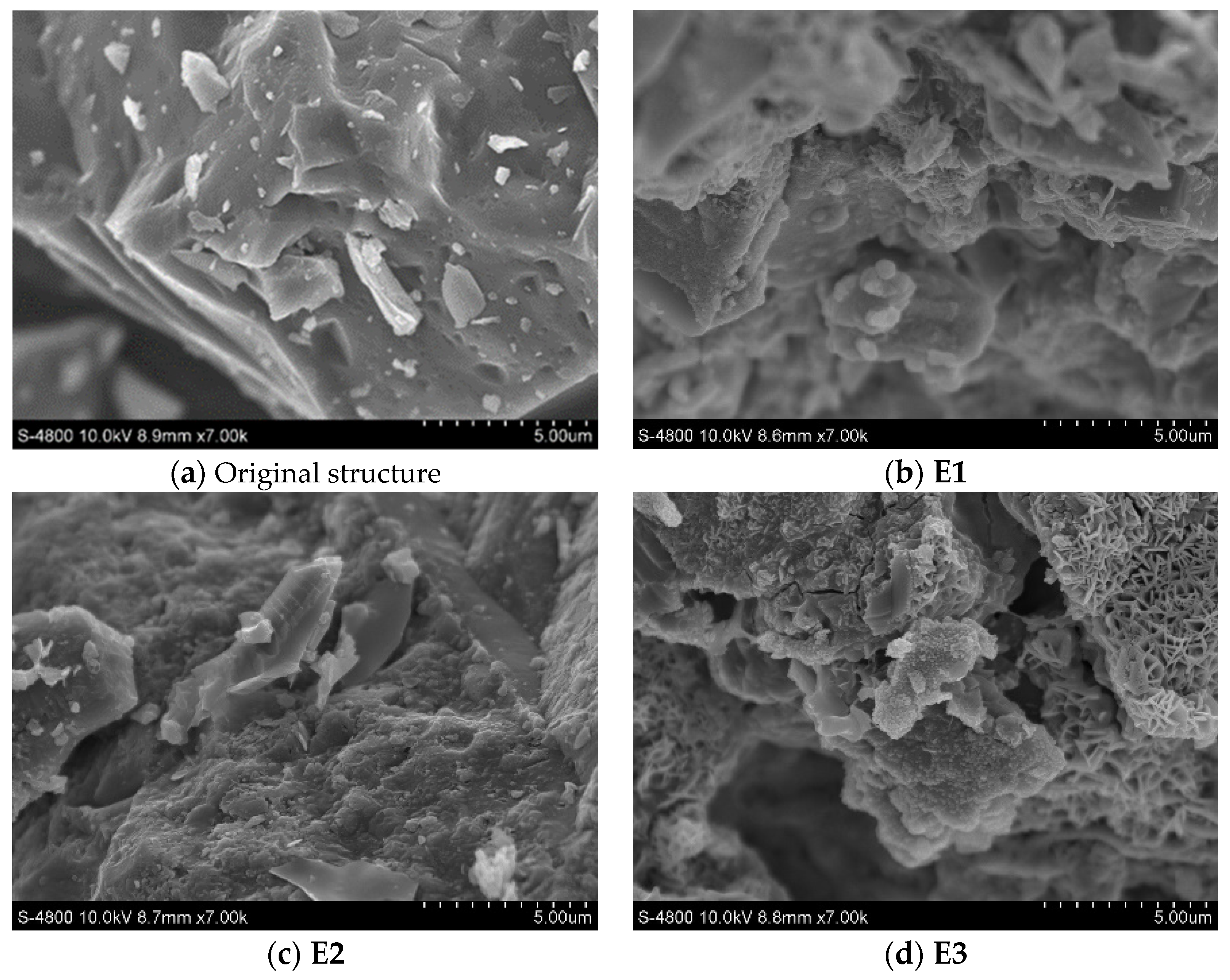

3.3.2. Surface Morphology

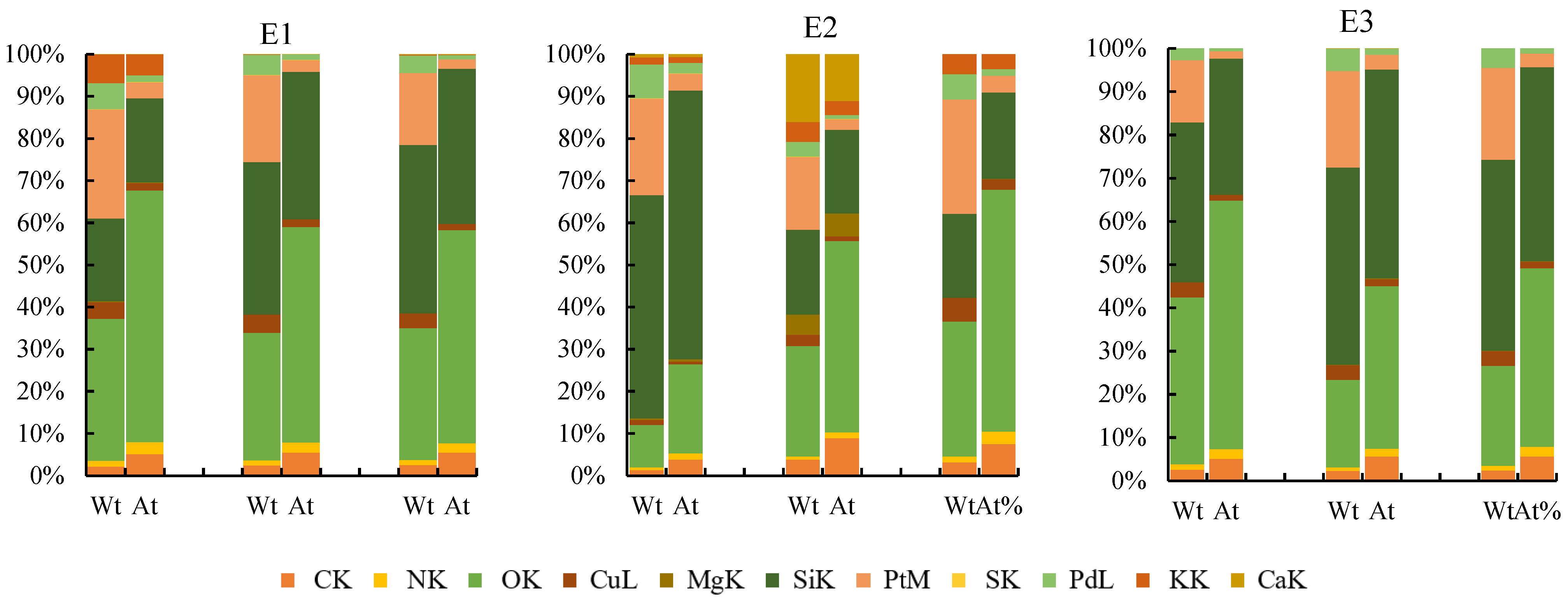

3.3.3. Elements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Kreij, C.; van der Burg, A.M.M.; Runi, W.T. Drip irrigation emitter clogging in Dutch greenhouses as affected by methane and organic acids. Agric. Water Manag. 2003, 60, 73–85. [Google Scholar] [CrossRef]

- Bounoua, S.; Tomas, S.; Labille, J.M.; Molle, B.; Granier, J.; Haldenwang, P.; Izzati, S.N. Understanding physical clogging in drip irrigation: In situ, in-lab and numerical approaches. Irrig. Sci. 2016, 34, 327–342. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Zhang, H. Tomato Yield and Quality and Emitter Clogging as Affected by Chlorination Schemes of Drip Irrigation Systems Applying Sewage Effluent. J. Integr. Agric. 2012, 11, 1744–1754. [Google Scholar] [CrossRef]

- Barragan, J.; Cots, L.; Monserrat, J.; Lopez, R.; Wu, I.P. Water distribution uniformity and scheduling in micro-irrigation systems for water saving and environmental protection. Biosyst. Eng. 2010, 107, 202–211. [Google Scholar] [CrossRef] [Green Version]

- Tao, R.; Hu, B.; Chu, G. Impacts of organic fertilization with a drip irrigation system on bacterial and fungal communities in cotton field. Agr. Syst. 2020, 182, 102820. [Google Scholar] [CrossRef]

- Gilbert, R.G.; Nakayama, F.S.; Bucks, D.A.; French, O.F.; Adamson, K.C. Trickle irrigation: Emitter clogging and other flow problems. Agric. Water Manag. 1981, 3, 159–178. [Google Scholar] [CrossRef]

- Jackson, R.C.; Kay, M.G. Use of pulse irrigation for reducing clogging problems in trickle emitters. J. Agric. Eng. Res. 1987, 37, 223–227. [Google Scholar] [CrossRef]

- Nakayama, F.S.; Bucks, D.A. Water quality in drip/trickle irrigation: A review. Irrig. Sci. 1991, 12, 187–192. [Google Scholar] [CrossRef]

- Juanico, M.; Azov, Y.; Teltsch, B.; Shelef, G. Effect of effluent addition to a freshwater reservoir on the filter clogging capacity of irrigation water. Water Res. 1995, 29, 1695–1702. [Google Scholar] [CrossRef]

- Leverenz, H.L.; Tchobanoglous, G.; Darby, J.L. Clogging in intermittently dosed sand filters used for wastewater treatment. Water Res. 2009, 43, 695–705. [Google Scholar] [CrossRef]

- Solé-Torres, C.; Puig-Bargués, J.; Duran-Ros, M.; Arbat, G.; Pujol, J.; Ramírez De Cartagena, F. Effect of different sand filter underdrain designs on emitter clogging using reclaimed effluents. Agric. Water Manag. 2019, 223, 105683. [Google Scholar] [CrossRef]

- Zhang, W.; Lv, C.; Zhao, X.; Dong, A.; Niu, W. The influence mechanism of the main suspended particles of Yellow River sand on the emitter clogging—An attempt to improve the irrigation water utilization efficiency in Yellow River basin. Agric. Water Manag. 2021, 258, 107202. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Xue, S.; Feng, J. Variation of microorganisms in drip irrigation systems using high-sand surface water. Agric. Water Manag. 2019, 218, 37–47. [Google Scholar] [CrossRef]

- Zhou, B.; Zhou, H.; Puig-Bargués, J.; Li, Y. Using an anti-clogging relative index (CRI) to assess emitters rapidly for drip irrigation systems with multiple low-quality water sources. Agric. Water Manag. 2019, 221, 270–278. [Google Scholar] [CrossRef]

- Zhangzhong, L.; Yang, P.; Zhen, W.; Zhang, X.; Wang, C. A kinetic model for the chemical clogging of drip irrigation system using saline water. Agric. Water Manag. 2019, 223, 105696. [Google Scholar] [CrossRef]

- Zhou, H.; Li, Y.; Wang, Y.; Zhou, B.; Bhattarai, R. Composite fouling of drip emitters applying surface water with high sand concentration: Dynamic variation and formation mechanism. Agric. Water Manag. 2019, 215, 25–43. [Google Scholar] [CrossRef]

- Cai, Y.; Zhao, X.; Wu, P.; Zhang, L.; Zhu, D.; Chen, J.; Lin, L. Ceramic patch type subsurface drip irrigation line: Construction and hydraulic properties. Biosyst. Eng. 2019, 182, 29–37. [Google Scholar] [CrossRef]

- Çolak, Y.B.; Yazar, A.; Gönen, E.; Eroğlu, E.Ç. Yield and quality response of surface and subsurface drip-irrigated eggplant and comparison of net returns. Agric. Water Manag. 2018, 206, 165–175. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Recycling of poor quality urban wastewater by drip irrigation systems. J. Clean. Prod. 2007, 15, 1529–1534. [Google Scholar] [CrossRef]

- Ravina, I.; Paz, E.; Sofer, Z.; Marm, A.; Schischa, A.; Sagi, G.; Yechialy, Z.; Lev, Y. Control of clogging in drip irrigation with stored treated municipal sewage effluent. Agric. Water Manag. 1997, 33, 127–137. [Google Scholar] [CrossRef]

- Taylor, H.D.; Bastos, R.K.X.; Pearson, H.W.; Mara, D.D. Drip irrigation with waste stabilisation pond effluents: Solving the problem of emitter fouling. Water Sci. Technol. 1995, 31, 417–424. [Google Scholar] [CrossRef]

- Pei, Y.T.; Li, Y.; Liu, Y.; Zhou, B.; Shi, Z.; Jiang, Y. Eight emitters clogging characteristics and its suitability under on-site reclaimed water drip irrigation. Irrig. Sci. 2014, 32, 141–157. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, T.; Li, Y.; Bralts, V. Effects of microbial community variation on bio-clogging in drip irrigation emitters using reclaimed water. Agric. Water Manag. 2017, 194, 139–149. [Google Scholar] [CrossRef]

- Chen, M.; Kang, Y.; Wan, S.; Liu, S. Drip irrigation with saline water for oleic sunflower (Helianthus annuus L.). Agric. Water Manag. 2009, 96, 1766–1772. [Google Scholar] [CrossRef]

- Chamba, D.; Zubelzu, S.; Juana, L. Determining hydraulic characteristics in laterals and drip irrigation systems. Agric. Water Manag. 2019, 226, 200–218. [Google Scholar] [CrossRef]

- Wang, Z.; Li, W.; Zhang, K.; Agrawal, Y.C.; Huang, H. Observations of the distribution and flocculation of suspended particulate matter in the North Yellow Sea cold water mass. Cont. Shelf Res. 2020, 204, 104187. [Google Scholar] [CrossRef]

- Pendergast, L.; Bhattarai, S.P.; Midmore, D.J. Evaluation of aerated subsurface drip irrigation on yield, dry weight partitioning and water use efficiency of a broad-acre chickpea (Cicer arietinum, L.) in a vertosol. Agr. Water Manag. 2019, 217, 38–46. [Google Scholar] [CrossRef]

- Puig-Bargués, J.; Arbat, G.; Elbana, M.; Duran-Ros, M.; Barragán, J.; de Cartagena, F.R.; Lamm, F.R. Effect of flushing frequency on emitter clogging in microirrigation with effluents. Agr. Water Manag. 2010, 97, 883–891. [Google Scholar] [CrossRef] [Green Version]

- Song, P.; Li, Y.; Zhou, B.; Zhou, C.; Zhang, Z.; Li, J. Controlling mechanism of chlorination on emitter bio-clogging for drip irrigation using reclaimed water. Agr. Water Manag. 2017, 184, 36–45. [Google Scholar] [CrossRef]

- Ait-Mouheb, N.; Schillings, J.; Al-Muhammad, J.; Bendoula, R.; Tomas, S.; Amielh, M.; Anselmet, F. Impact of hydrodynamics on clay particle deposition and biofilm development in a labyrinth-channel dripper. Irrig. Sci. 2019, 37, 1–10. [Google Scholar] [CrossRef]

- Li, G.B.; Li, Y.K.; Xu, T.W.; Liu, Y.Z.; Jin, H.; Yang, P.L.; Yan, D.Z.; Ren, S.M.; Tian, Z.F. Effects of average velocity on the growth and surface topography of biofilms attached to the reclaimed wastewater drip irrigation system laterals. Irrig. Sci. 2012, 30, 103–113. [Google Scholar] [CrossRef]

- Wu, D.; Li, Y.; Liu, H.; Yang, P.; Sun, H.; Liu, Y. Simulation of the flow characteristics of a drip irrigation emitter with large eddy methods. Math. Comput. Model. 2013, 58, 497–506. [Google Scholar] [CrossRef]

- Du, H.; Ma, T.; Yu, J.; Wang, L.; Lu, J.; Zhao, L. Experimental study on the clogging of drip irrigation system for Yellow River diversion. Yellow River 2019, 41, 149–151. [Google Scholar]

- Milstein, A.; Feldlite, M. Particle circulation in irrigation reservoirs: The role of filter backwash reject on filter clogging. Agric. Water Manag. 2015, 158, 139–144. [Google Scholar] [CrossRef]

- Bakke, R.; Trulear, M.G.; Robinson, J.A.; Characklis, W.G. Activity of Pseudomonas aeruginosa in biofilms: Steady state. Biotechnol. Bioeng. 1984, 26, 1418–1424. [Google Scholar] [CrossRef]

- Tay, J.H.; Liu, Q.S.; Liu, Y. The effects of shear force on the formation, structure and metabolism of aerobic granules. Appl. Microbiol. Biotechnol. 2001, 57, 227–233. [Google Scholar]

- Paul, E.; Ochoa, J.C.; Pechaud, Y.; Liu, Y.; Liné, A. Effect of shear stress and growth conditions on detachment and physical properties of biofilms. Water Res. 2012, 46, 5499–5508. [Google Scholar] [CrossRef]

| Types | Rated Pressure (kpa) | Rated Flow (L/h) | Length × Width × Depth (mm) | Flow Index/x | Discharge Coefficient/k | Manufacturing Deviation (%) |

|---|---|---|---|---|---|---|

| E1 | 100 | 3 | 224 × 0.63 × 1 | 0.5245 | 0.2909 | 4.07 |

| E2 | 100 | 1.5 | 100 × 0.68 × 0.33 | 0.4842 | 0.1687 | 4.63 |

| E3 | 100 | 3.5 | 170 × 1.2 × 0.5 | 0.5995 | 0.2433 | 3.21 |

| Levels | Sediment Grain Size | Sediment Concentration (g·L−1) | ||

|---|---|---|---|---|

| Combinations | Labels | Combinations | Labels | |

| 1 | 35% b–65% a | S1 | 1.8 | C1 |

| 2 | 35% c–65% a | S2 | 2.8 | C2 |

| 3 | 35% c–65% b | S3 | 3.8 | C3 |

| Parameter | Value | Parameter | Value | Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|---|---|---|---|

| pH | 7.89 | NH4+ (mg/L) | 0.22 | CO32− (mg/L) | 60.82 | K+ (mg/L) | 1.09 | Cl− (mg/L) | 11 |

| Conductivity (uS/cm) | 243 | Mg2+ (mg/L) | 2.89 | PO43− (mg/L) | 0.02 | Na+ (mg/L) | 5.70 | Ca2+ (mg/L) | 28.80 |

| Cu2+ (mg/L) | 0.03 | Zn+ (mg/L) | 0.03 | Total N (mg/L) | 1.33 | Fe2+ (mg/L) | 0.25 | Mn+ (mg/L) | 0.04 |

| Treatments | Clogged Emitter Number | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1S1 | E1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 4 | |

| E2 | 0 | 0 | 4 | 7 | |||||||||||||||

| E3 | 0 | 0 | 0 | 0 | 0 | 1 | 4 | 2 | 3 | 9 | 6 | 13 | |||||||

| C1S2 | E1 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 |

| E2 | 1 | 1 | 3 | 3 | |||||||||||||||

| E3 | 1 | 1 | 6 | 8 | |||||||||||||||

| C1S3 | E1 | 0 | 1 | 1 | 2 | 3 | 4 | 5 | 6 | 6 | |||||||||

| E2 | 0 | 3 | 3 | ||||||||||||||||

| E3 | 0 | 1 | 3 | ||||||||||||||||

| C2S1 | E1 | 0 | 1 | 3 | 3 | 6 | |||||||||||||

| E2 | 1 | 2 | 2 | 5 | |||||||||||||||

| E3 | 0 | 0 | 2 | 4 | |||||||||||||||

| C2S2 | E1 | 0 | 0 | 1 | 1 | 3 | 4 | 5 | |||||||||||

| E2 | 2 | 0 | 3 | 3 | 3 | 6 | |||||||||||||

| E3 | 0 | 2 | 5 | ||||||||||||||||

| C2S3 | E1 | 0 | 0 | 0 | 0 | 1 | 4 | 3 | 8 | ||||||||||

| E2 | 0 | 1 | 3 | 3 | 9 | ||||||||||||||

| E3 | 0 | 7 | |||||||||||||||||

| C3S1 | E1 | 0 | 0 | 3 | 6 | 6 | |||||||||||||

| E2 | 2(0.25) | 8(0.5) | |||||||||||||||||

| E3 | 1 | 4 | 7 | ||||||||||||||||

| C3S2 | E1 | 0 | 2 | 5 | 10 | ||||||||||||||

| E2 | 0(0.25) | 1(0.5) | 1(0.75) | 1 | 6(1.25) | ||||||||||||||

| E3 | 0(0.25) | 4(0.5) | 7(0.75) | ||||||||||||||||

| C3S3 | E1 | 0 | 0 | 3 | 7 | 10 | |||||||||||||

| E2 | 2(0.5) | 8 | |||||||||||||||||

| E3 | 2 | 3 | 7 | ||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Ling, G.; Hu, M.; Wang, W.; Hu, X. Physical Clogging Characteristics of Labyrinth Emitters under Low-Quality (Sand-Laden Water) Irrigation. Agronomy 2022, 12, 1615. https://doi.org/10.3390/agronomy12071615

Wang H, Ling G, Hu M, Wang W, Hu X. Physical Clogging Characteristics of Labyrinth Emitters under Low-Quality (Sand-Laden Water) Irrigation. Agronomy. 2022; 12(7):1615. https://doi.org/10.3390/agronomy12071615

Chicago/Turabian StyleWang, Hui, Gang Ling, Mingyu Hu, Wene Wang, and Xiaotao Hu. 2022. "Physical Clogging Characteristics of Labyrinth Emitters under Low-Quality (Sand-Laden Water) Irrigation" Agronomy 12, no. 7: 1615. https://doi.org/10.3390/agronomy12071615

APA StyleWang, H., Ling, G., Hu, M., Wang, W., & Hu, X. (2022). Physical Clogging Characteristics of Labyrinth Emitters under Low-Quality (Sand-Laden Water) Irrigation. Agronomy, 12(7), 1615. https://doi.org/10.3390/agronomy12071615