Fluid Movement Law and Influencing Factors of Shredding on Rice Straw Briquetting Machines

Abstract

:1. Introduction

2. Materials and Methods

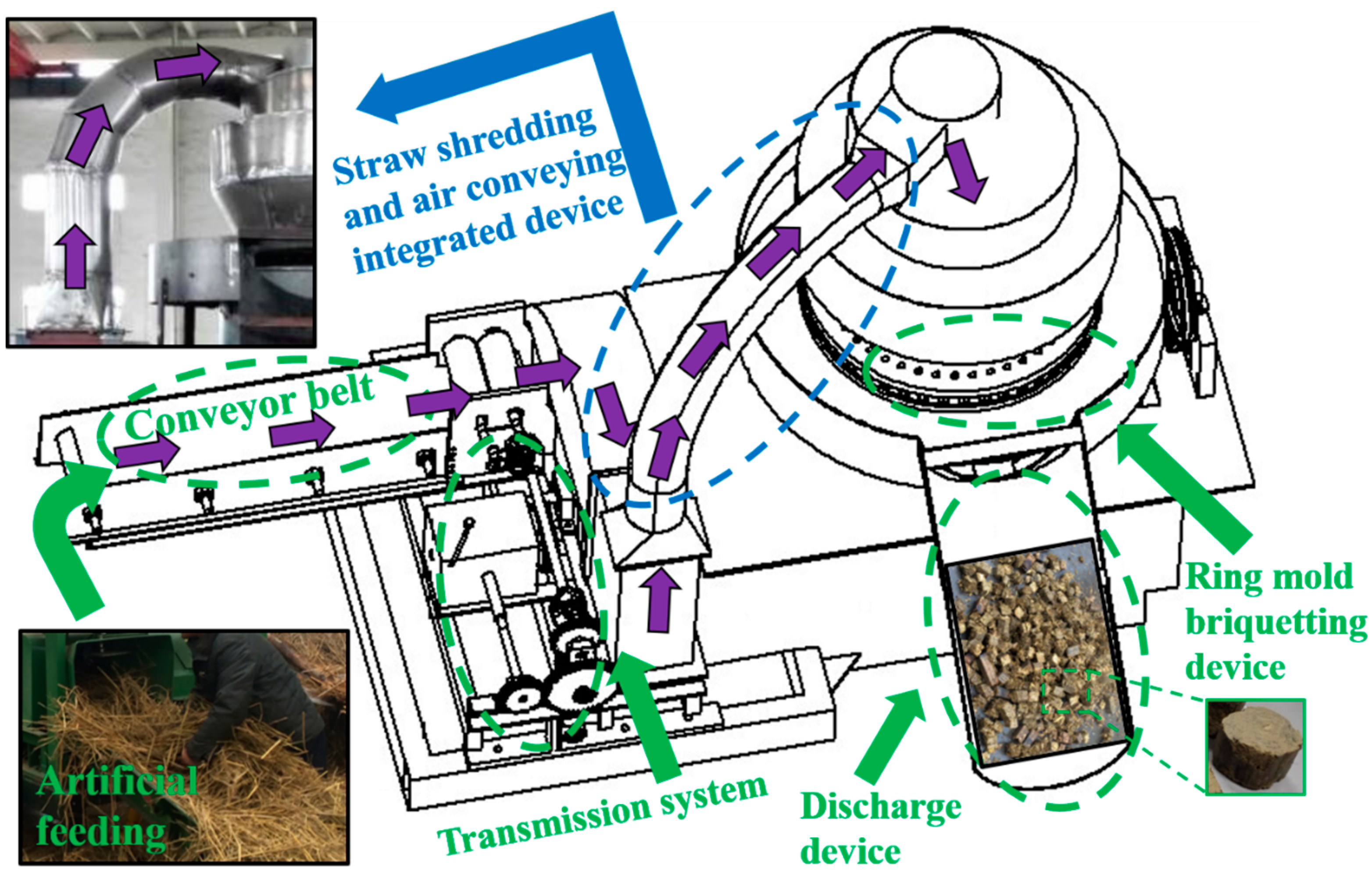

2.1. Structure Description of Straw Briquetting Machine

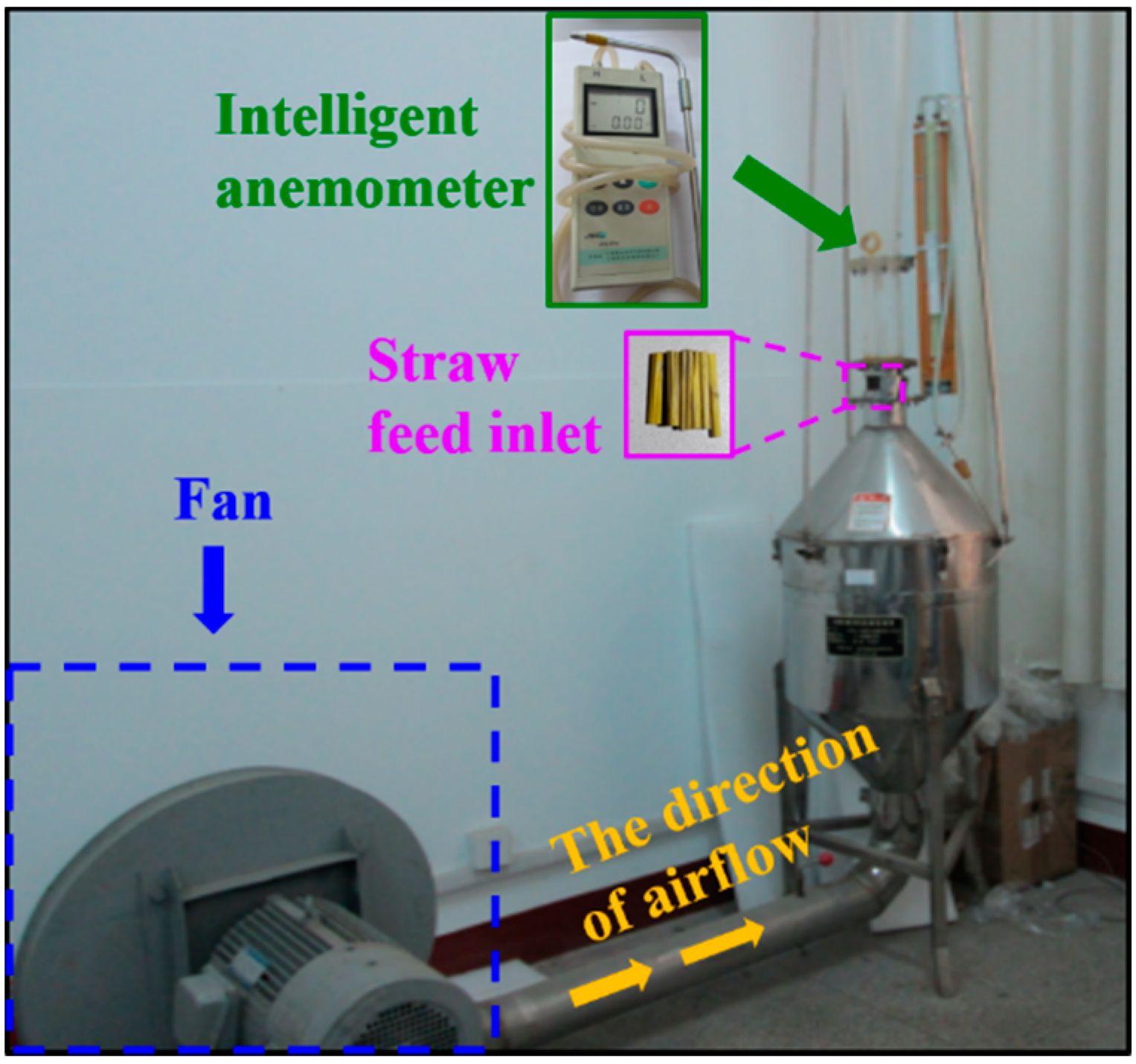

2.2. Experiment on the Air Blowing Speed of Straw

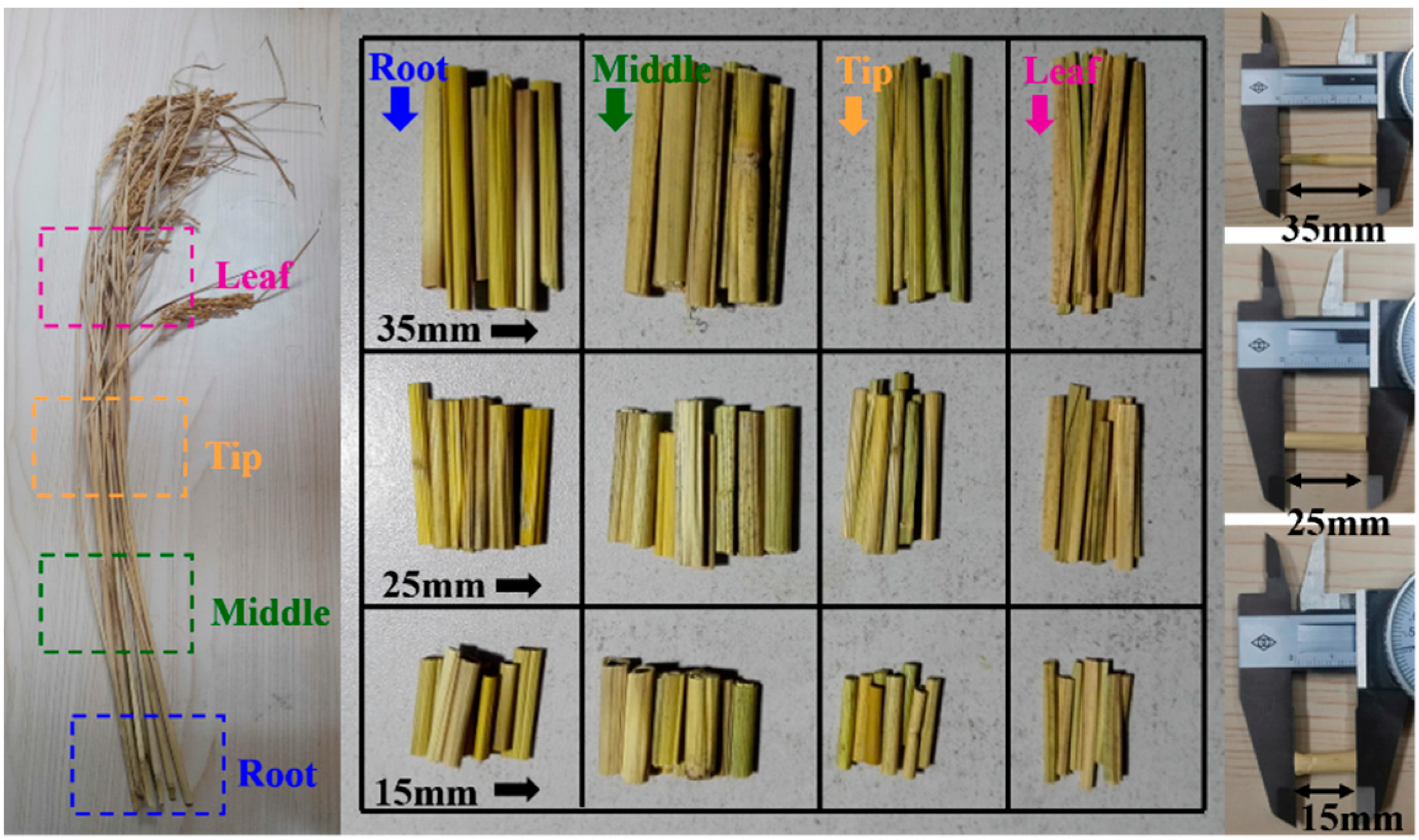

2.2.1. Straw Suspension Experiment Material

2.2.2. Straw Suspension Experiment Methods

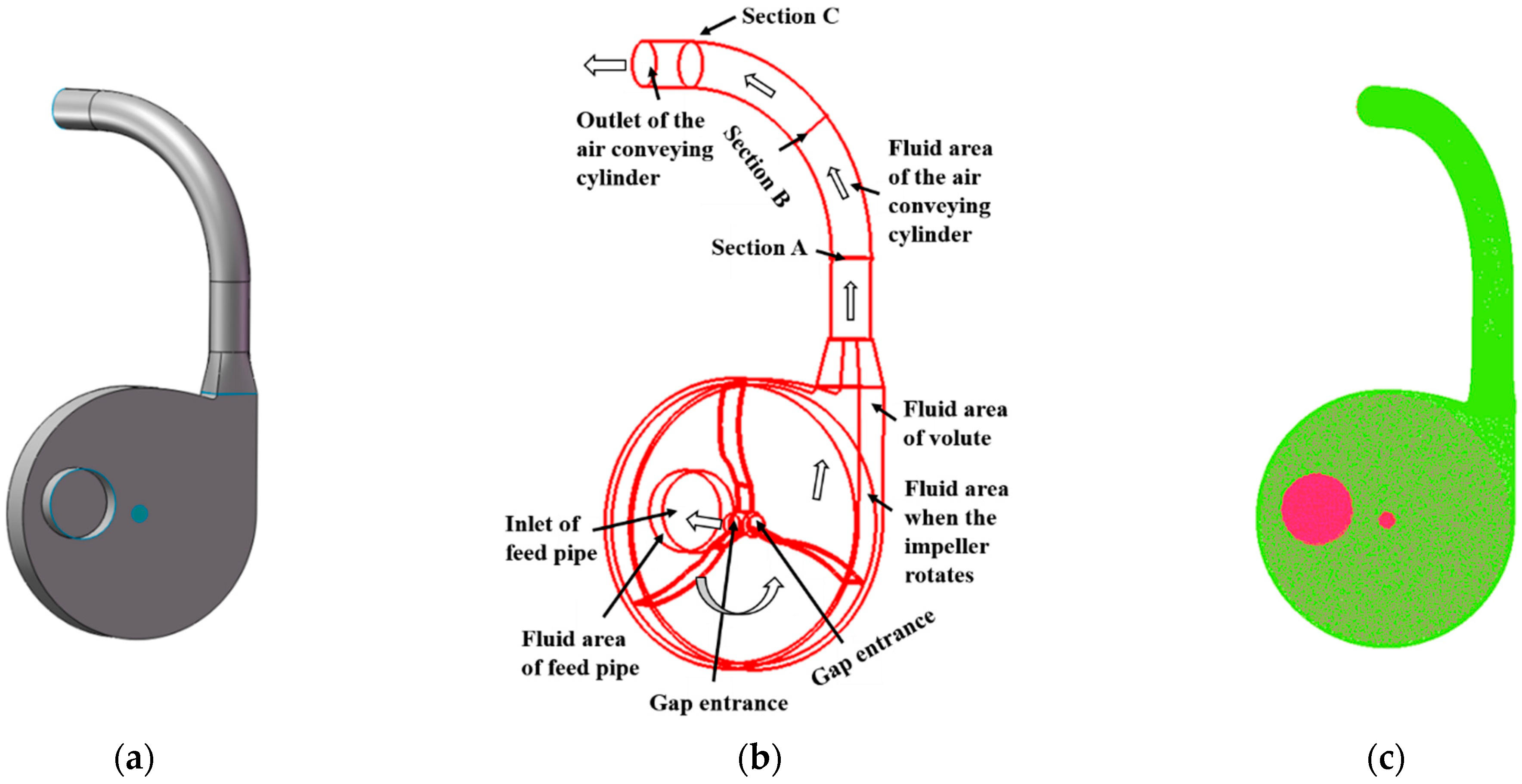

2.3. Establishing Method of the Overall Flow Channel Model

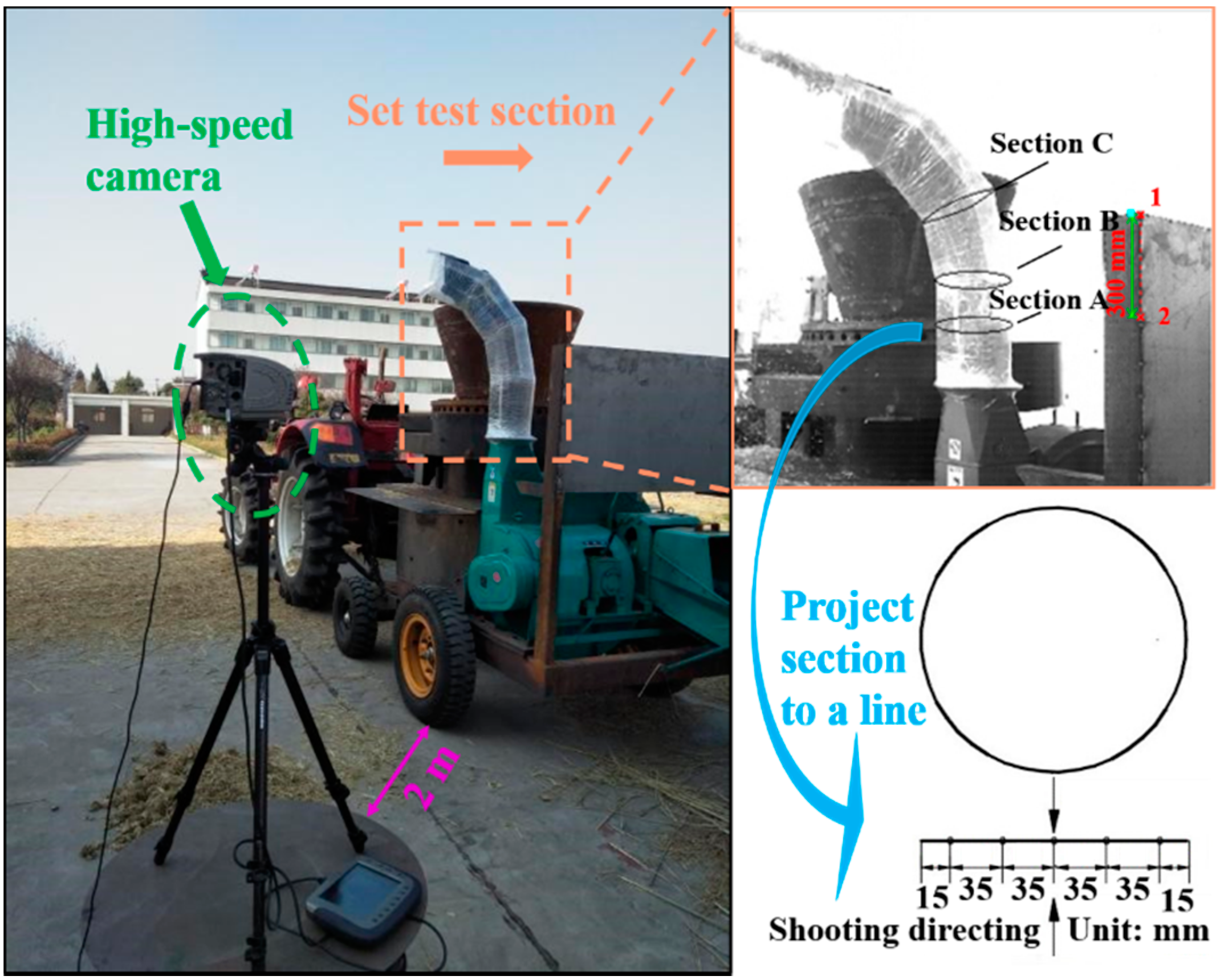

2.4. High-Speed Photography Experiment of Rice Straw Suspension Speed

2.5. Test Verification of the Improved Whole Straw Briquetting Machine

3. Results and Discussion

3.1. Analysis of the Experiment Results of the Straw Materials’ Suspension Speed

3.2. Analysis of the Simulation Results of the Overall Flow Channel Model

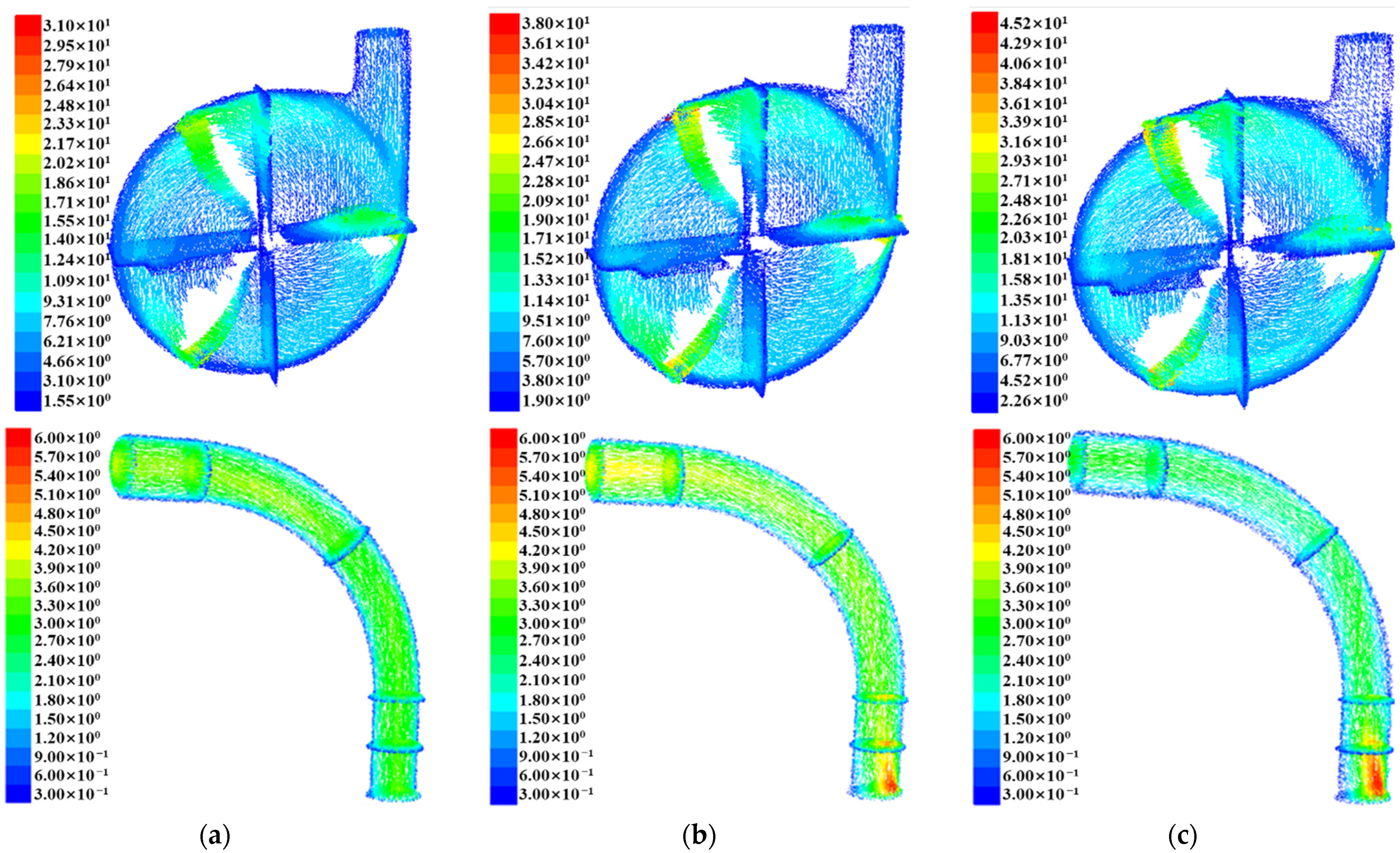

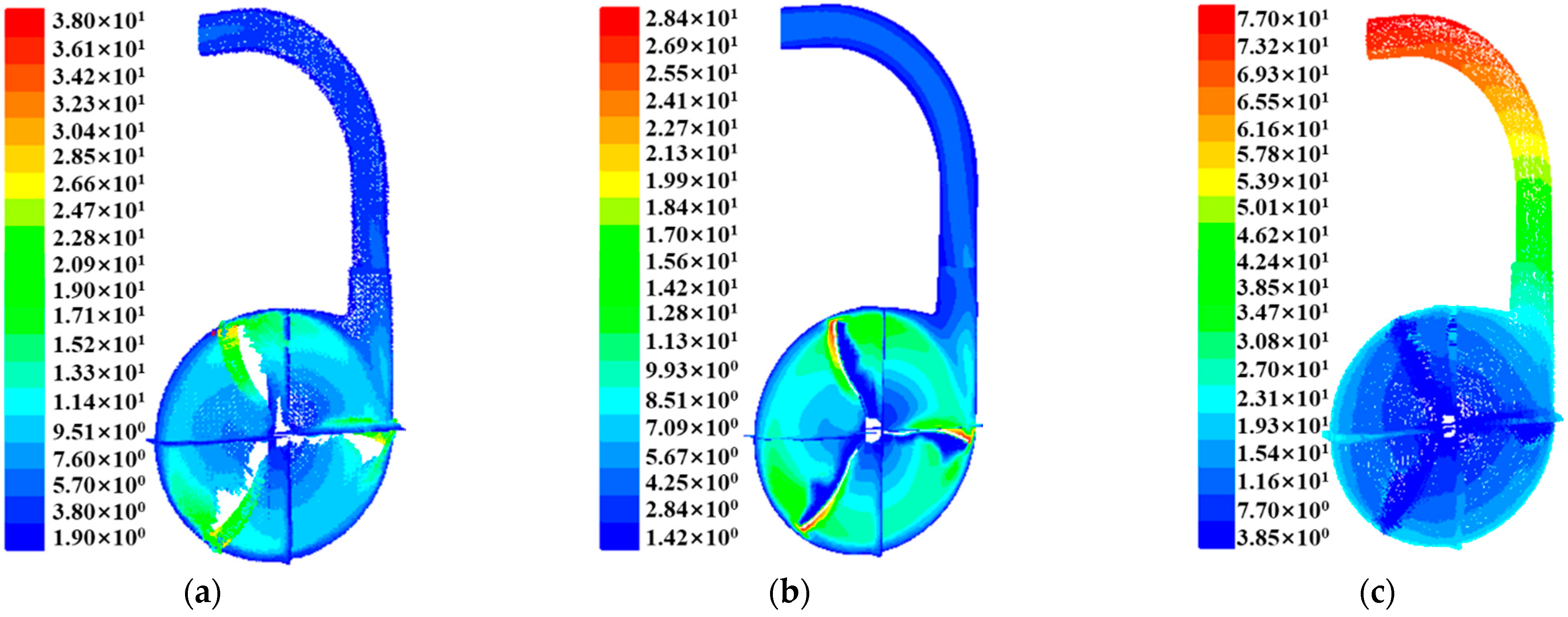

3.2.1. Influence of Impeller Speed

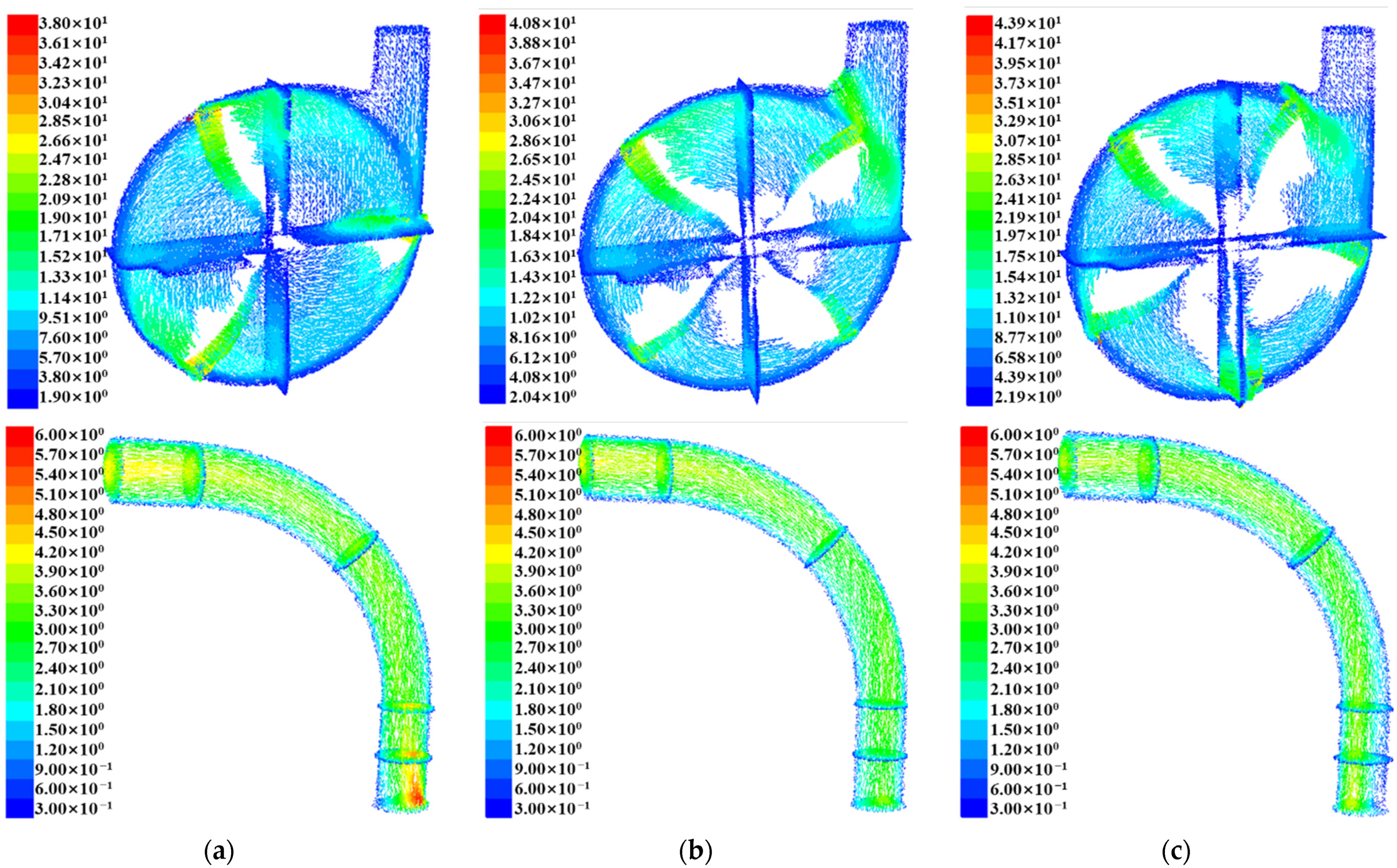

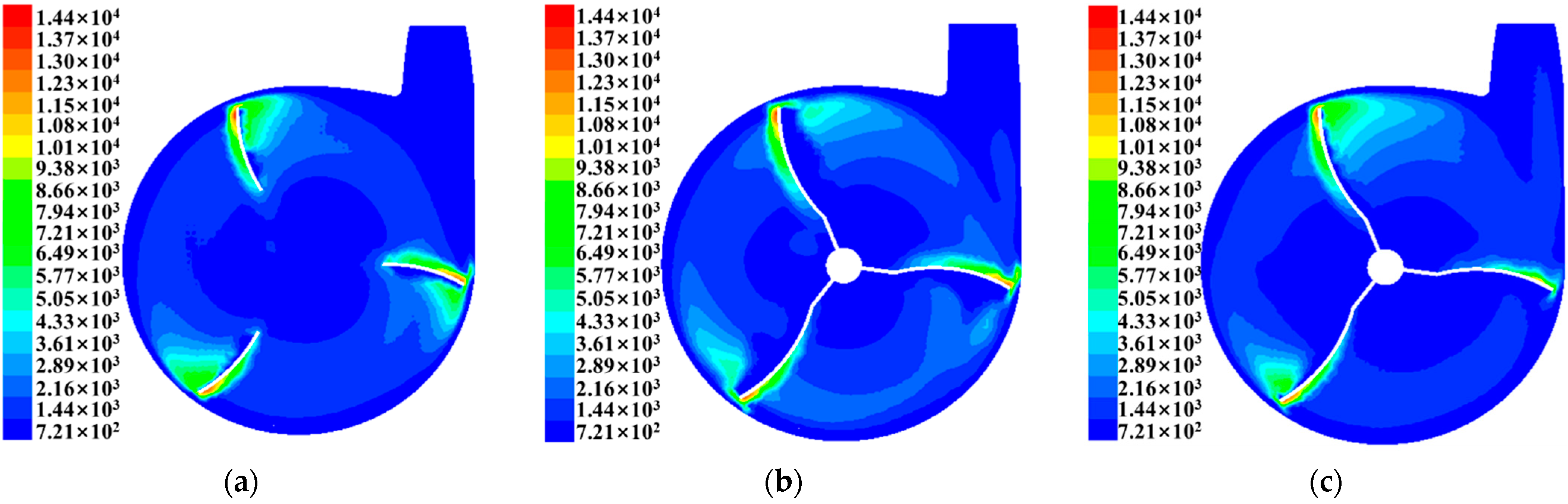

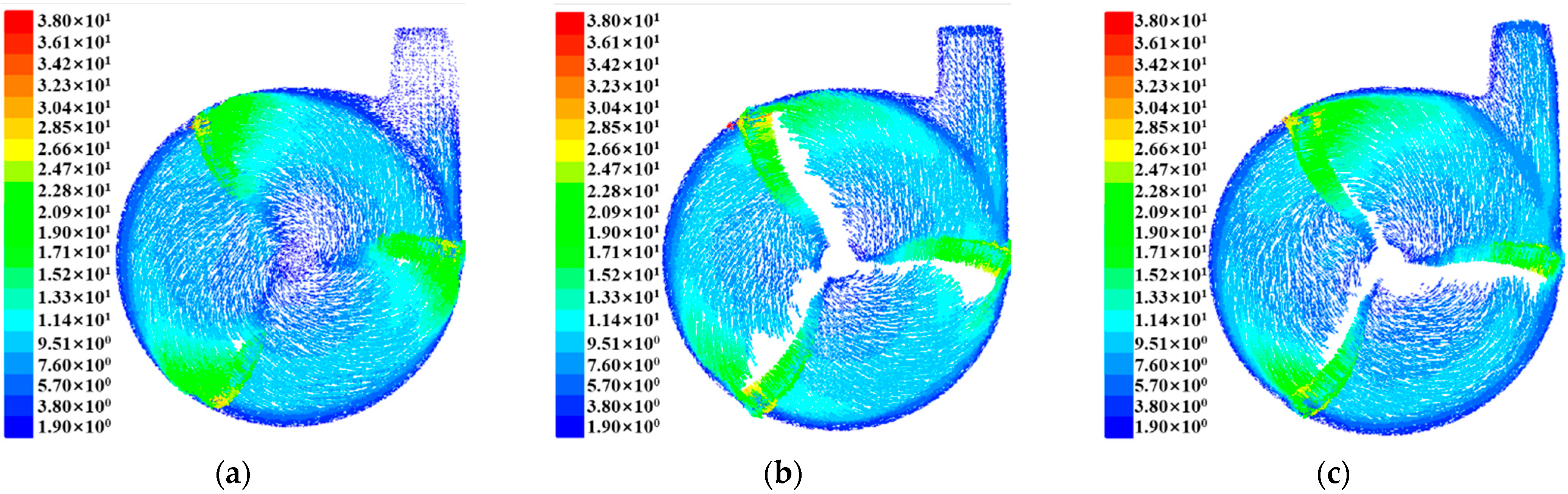

3.2.2. Effect of the Number of Blades

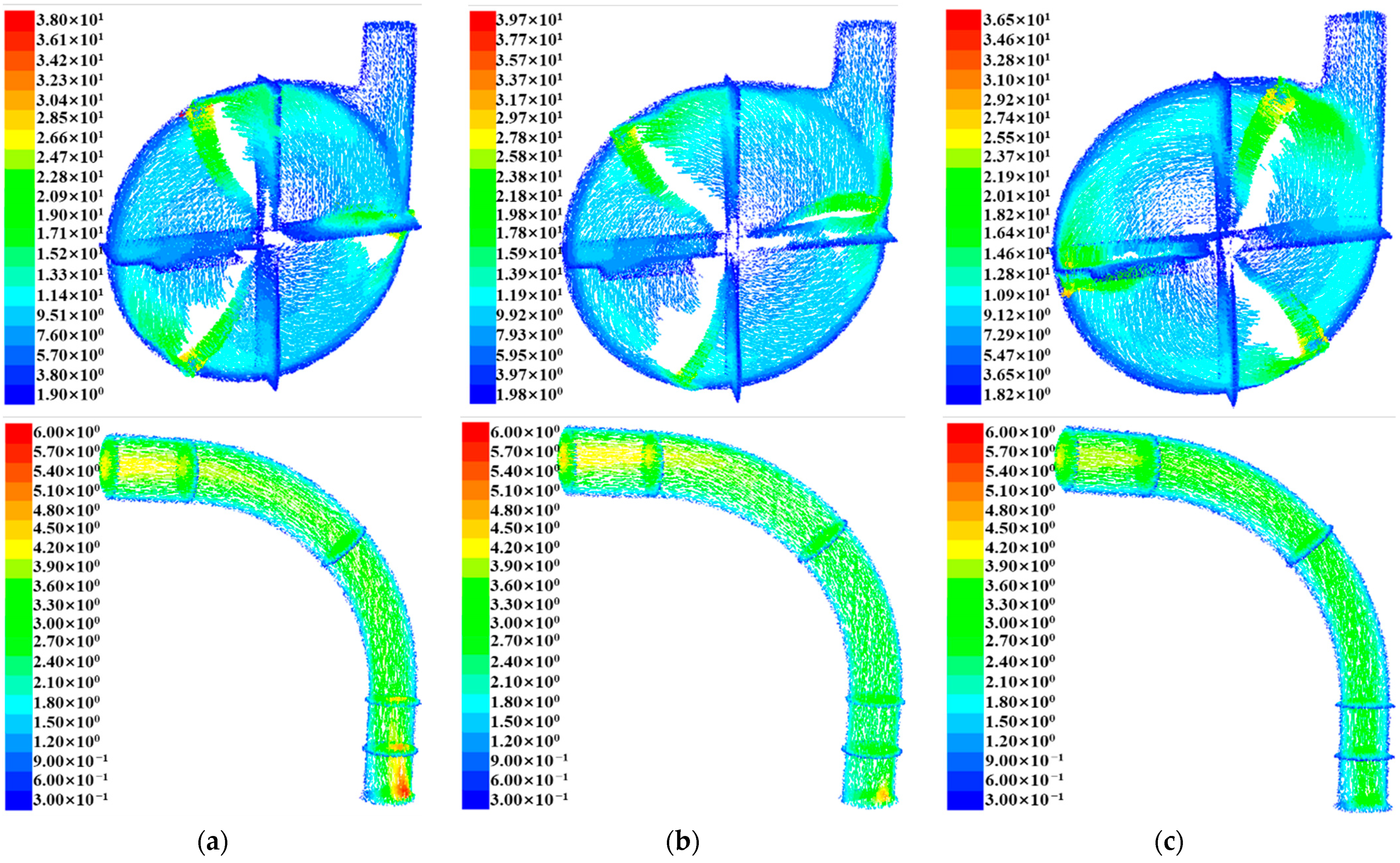

3.2.3. Effect of Blade Pitch

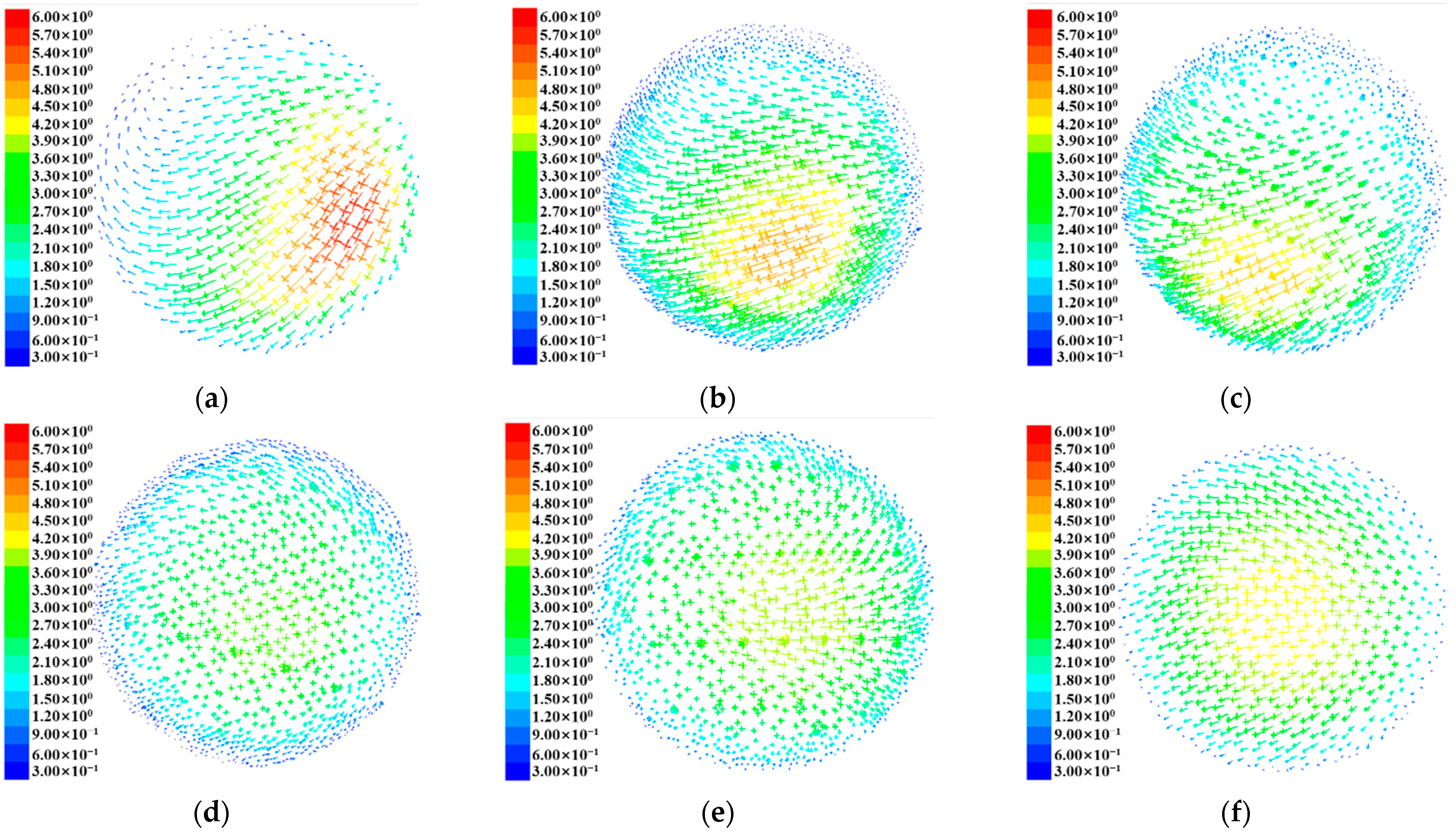

3.3. Simulation Results and Discussion of the Flow Field in the Integrated Device

3.3.1. Flow Field Pressure Distribution

3.3.2. Flow Field Velocity Distribution

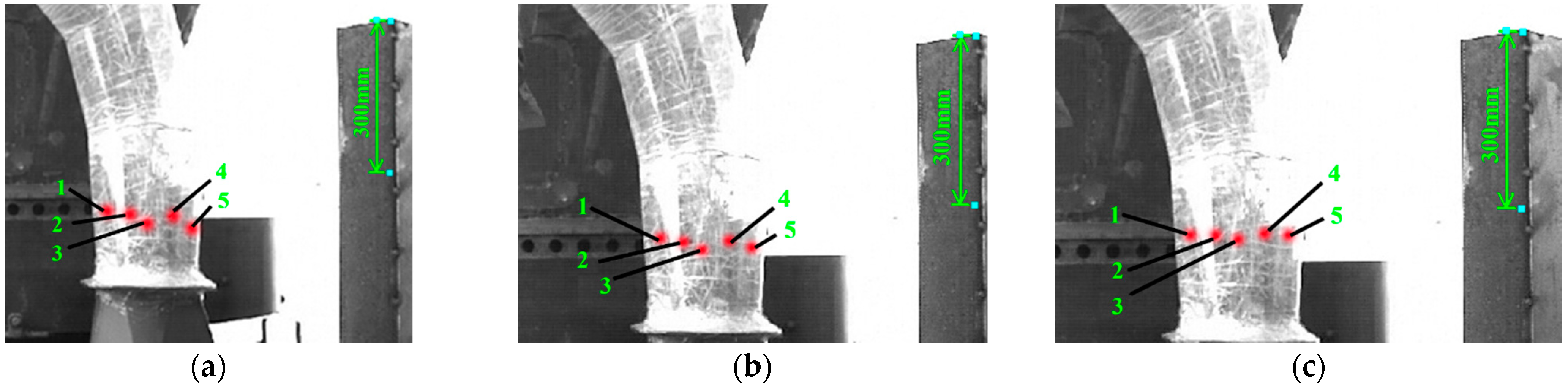

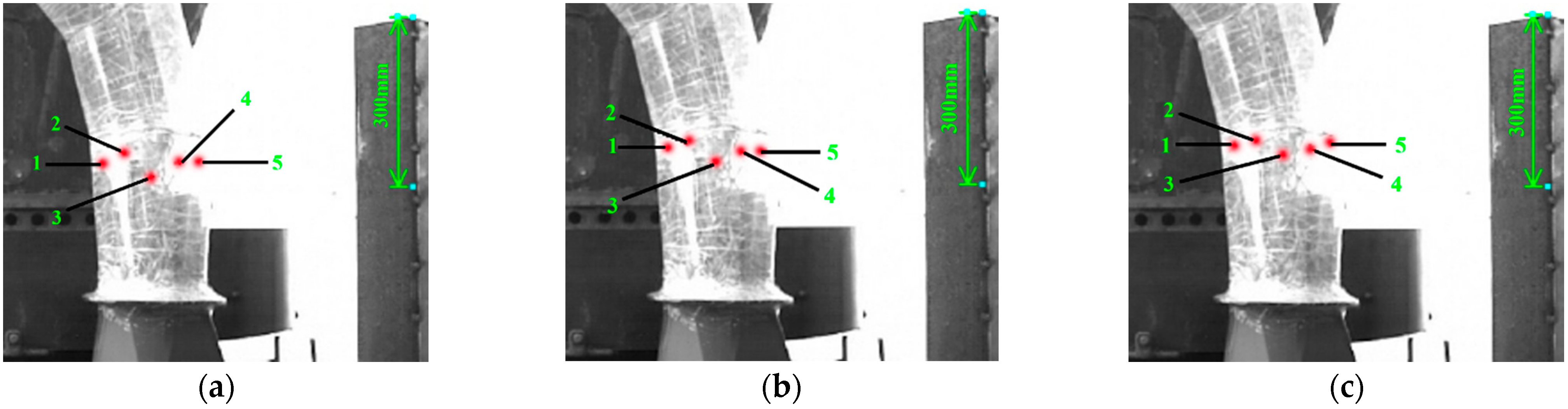

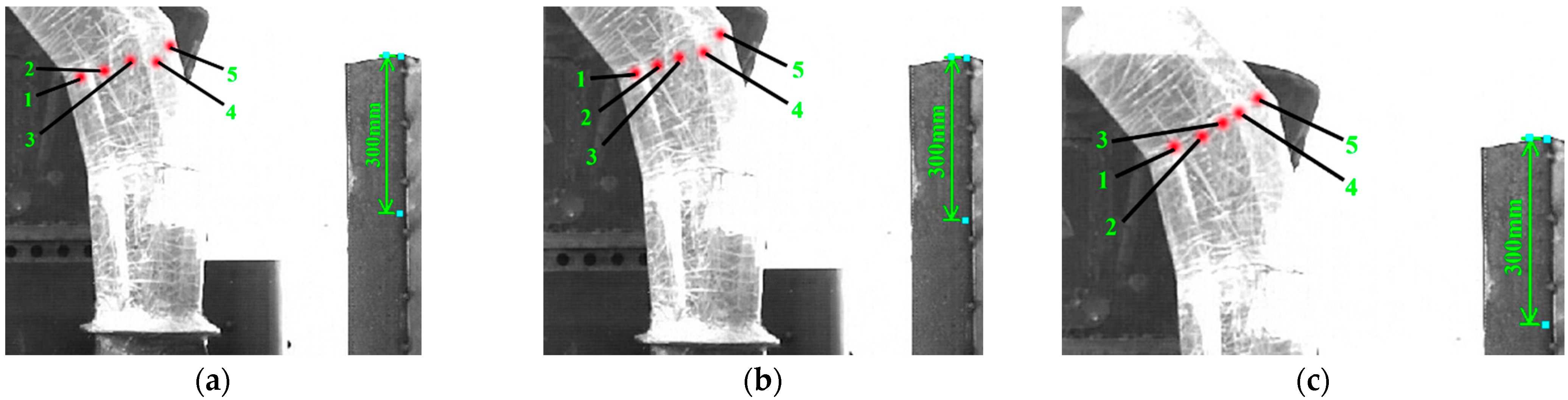

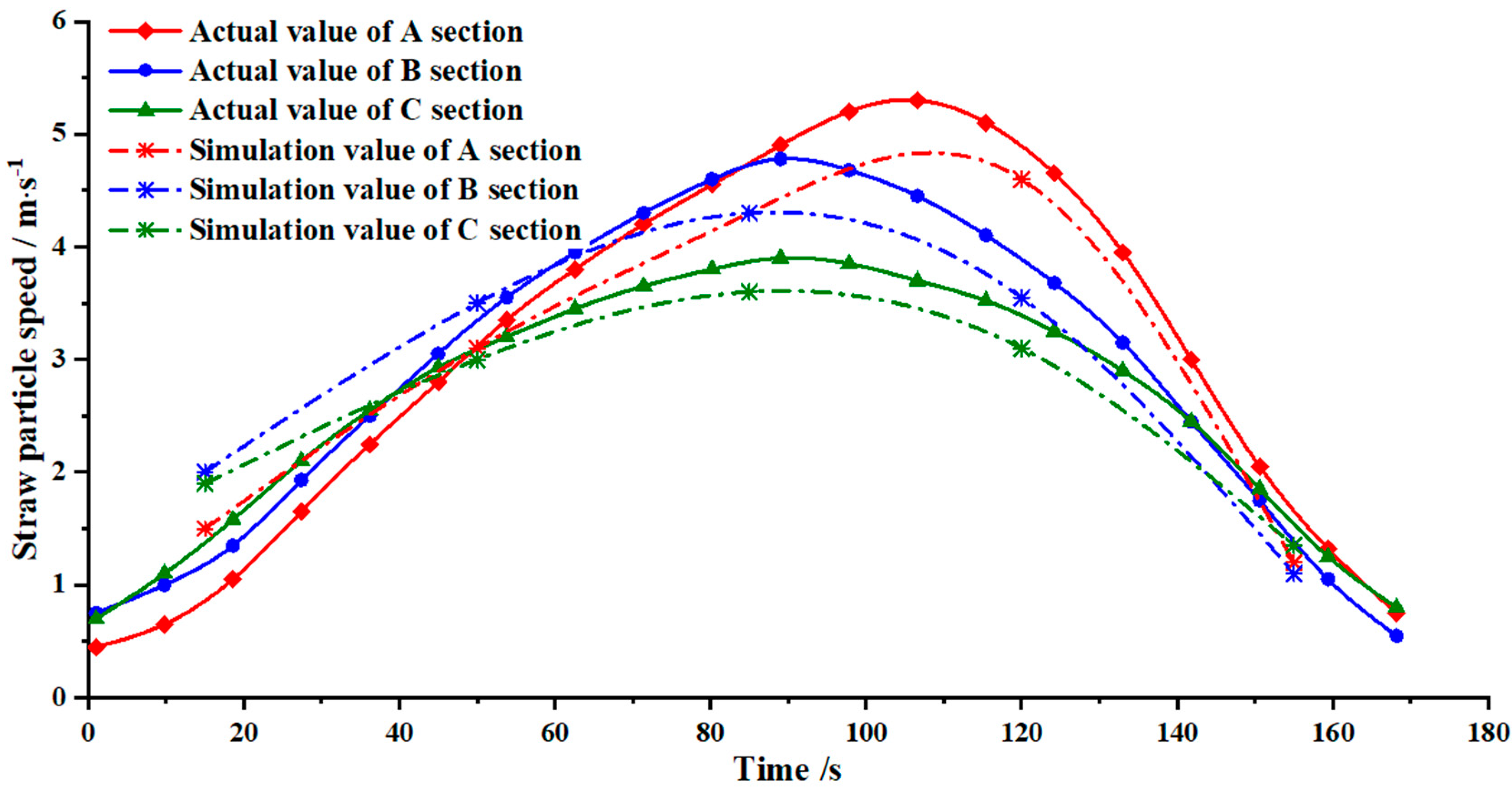

3.4. High-Speed Photography Experiment Results and Discussion

3.5. Results of Briquetting Production on the Whole Machine

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beňová, D.; Mareš, K.; Hutla, P.; Ivanova, T.; Banout, J.; Kolaříková, M. Energy Potential of Agri Residual Biomass in Southeast Asia with the Focus on Vietnam. Agronomy 2021, 11, 169. [Google Scholar] [CrossRef]

- Zhao, X.; Yuan, G.; Wang, H.; Lu, D.; Chen, X.; Zhou, J. Effects of Full Straw Incorporation on Soil Fertility and Crop Yield in Rice-Wheat Rotation for Silty Clay Loamy Cropland. Agronomy 2019, 9, 133. [Google Scholar] [CrossRef] [Green Version]

- Tsapekos, P.; Kougias, P.G.; Vasileiou, S.A.; Treu, L.; Campanaro, S.; Lyberatos, G.; Angelidaki, I. Bioaugmentation with hydrolytic microbes to improve the anaerobic biodegradability of lignocellulosic agricultural residues. Bioresour. Technol. 2017, 234, 350–359. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Li, Y.; Li, X.; Xu, T. Structural damage modes for rice stalks undergoing threshing. Biosyst. Eng. 2019, 186, 323–336. [Google Scholar] [CrossRef]

- Luo, Z.; Song, H.; Huang, M.; Zhang, Z.; Peng, Z.; Zi, T.; Tian, C.; Eissa, M.A. Nitrogen-Reduction in Intensive Cultivation Improved Nitrogen Fertilizer Utilization Efficiency and Soil Nitrogen Mineralization of Double-Cropped Rice. Agronomy 2022, 12, 1103. [Google Scholar] [CrossRef]

- Ai, P.; Zhang, X.; Ran, Y.; Meng, L.; Elsayed, M.; Fan, Q.; Abomohra, A.E. Biomass briquetting reduces the energy loss during long-term ensiling and enhances anaerobic digestion: A case study on rice straw. Bioresour. Technol. 2019, 292, 121912. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Briquetting characteristics of bean straw-maize cob blend. Biomass Bioenergy 2019, 126, 150–158. [Google Scholar] [CrossRef]

- Xie, M.; Shen, G.; Holder, A.L.; Hays, M.D.; Jetter, J.J. Light absorption of organic carbon emitted from burning wood, charcoal, and kerosene in household cookstoves. Environ. Pollut. 2018, 240, 60–67. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Zhi, D.; Lin, Y.; He, K.; Liu, B.; Mao, H. Assessment of combustion and emission behavior of corn straw biochar briquette fuels under different temperatures. J. Environ. Manag. 2019, 250, 109399. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, X.; Tang, Z.; Zhang, Y.; Huang, K. Effects of Rice Stra-w Combined with Inorganic Fertilizer on Grain Filling and Yield of Comm-on Buckwheat. Agronomy 2022, 12, 1287. [Google Scholar] [CrossRef]

- Díaz, M.J.; Moya, M.; Castro, E. Bioethanol Production from Steam-Exploded Barley Straw by Co-Fermentation with Escherichia coli SL100. Agronomy 2022, 12, 874. [Google Scholar] [CrossRef]

- Bedő, S.; Fehér, A.; Khunnonkwao, P.; Jantama, K.; Fehér, C. Optimized Bioconversion of Xylose Derived from Pre-Treated Crop Residues into Xyli-tol by Using Candida boidinii. Agronomy 2021, 11, 79. [Google Scholar] [CrossRef]

- Feng, C.; Yu, X.; Tan, H.; Liu, T.; Hu, T.; Zhang, Z.; Qiu, S.; Chen, L. The economic feasibility of a crop-residue densification plant: A case study for the city of Jinzhou in China. Renew. Sustain. Energy Rev. 2013, 24, 172–180. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Gu, F.; Zhao, Y.; Wu, F.; Hu, Z.; Shi, L. Simulation analysis and experimental validation of conveying device in uniform rushed straw throwing and seed-sowing Machines usi-ng CFD-DEM coupled approach. Comput. Electron. Agric. 2022, 193, 106720. [Google Scholar] [CrossRef]

- Li, K.; Li, H.; Li, S.; Chen, Z. Fully Convolutional Neural Network Prediction Method for Aerostatic Performance of Bluff Bodies Based on Consistent Shape Description. Appl. Sci. 2022, 12, 3147. [Google Scholar] [CrossRef]

- Mannini, C.; Sbragi, G.; Schewe, G. Analysis of self-excited forces for a box-girder bridge deck through unsteady RANS simulations. J. Fluids Struct. 2016, 63, 57–76. [Google Scholar] [CrossRef]

- Xu, F.Y.; Wu, T.; Ying, X.Y.; Kareem, A. Higher-order self-excited drag forces on bridge decks. J. Eng. Mech. 2016, 142, 06015007. [Google Scholar] [CrossRef]

- Zaripov, T.S.; Rybdylova, O.; Sazhin, S.S. A model for heating and evaporation of a droplet cloud and its implementation into ANSYS Fluent. Int. Commun. Heat Mass 2018, 97, 85–91. [Google Scholar] [CrossRef]

- Golshan, S.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N.; Blais, B.; Kuipers, J.A.M. Review and implementation of CFD-DEM applied to che-mical process systems. Chem. Eng. Sci. 2020, 221, 115646. [Google Scholar] [CrossRef]

- Norouzi, H.R.; Mostoufi, N.; Mansourpour, Z.; Sotudeh-Gharebagh, R.; Cha-ouki, J. Characterization of solids mixing patterns in bubbling fluidized be-ds. Chem. Eng. Res. Des. 2011, 89, 817–826. [Google Scholar] [CrossRef]

- Yao, L.; Liu, Y.; Liu, J.; Xiao, Z.; Xie, K.; Cao, H.; Zhang, H. An optim-ized CFD-DEM method for particle collision and retention analysis of two-phase flow in a reduced-diameter pipe. Powder Technol. 2022, 405, 117547. [Google Scholar] [CrossRef]

- Gautam, A.; Agrawal, Y.; Phaldessai, G.; Guha, M.; Warudkar, V.; Bhagoria, J.L. Computational investigation of blast furnace internal phenomenon having different zones using fluent. Mater. Today Proc. 2022, 60, 2124–2131. [Google Scholar] [CrossRef]

- Hiroyasu, M. Verification of neutronics and thermal-hydraulics coupling method for FLUENT code using the MSRE pump startup, trip data. Nucl. Eng. Des. 2021, 378, 111191. [Google Scholar] [CrossRef]

- Ozbek, A.S.; Weerheijm, J.; Breugel, K. High speed photography technique for measuring impact strength of porous concrete. Constr. Build. Mater. 2018, 186, 1092–1104. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, S.; Yang, L.; Zhao, S.; Liu, Y.; Shi, Y. Defect detection during laser welding using electrical signals and high-speed photography. J. Mater. Process. Technol. 2019, 271, 394–403. [Google Scholar] [CrossRef]

- Liu, J.N.; Gao, M.; Zhang, L.S.; Zhang, L.X. A laser interference/high-speed photography method for the study of triple phase contact-line movements and lateral rewetting flow during single bubble growth on a small hydrophilic heated surface. Int. Commun. Heat. Mass 2019, 100, 111–117. [Google Scholar] [CrossRef]

- Du, X.; Ji, J.; Jin, X.; Li, C.; Yang, X. Research on divider losses with high-speed photography for foxtail millet harvesting. Future Gener. Comput. Syst. 2018, 88, 55–60. [Google Scholar] [CrossRef]

- Ghazanfari, H.S.; Ali, A.M.; Roy, P.; Shamsaiee, M.; Shafiee, M.; Saffari, H.; Valiño, L.; Andersson, R. An experimental investigation on bubbles departure characteristics during sub-cooled flow boiling in a vertical U-shaped channel utilizing high-speed photography. Therm. Sci. Eng. Prog. 2021, 22, 2451–9049. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Y.; Lam, K.P.; Archer, D.H. A prototype mesh generation tool for CFD simulations in architecture domain. Build. Environ. 2010, 45, 2253–2262. [Google Scholar] [CrossRef]

- Arastoopour, H. Numerical simulation and experimental analysis of gas/solid flow systems: 1999 fluor-daniel plenary lecture. Powder Technol. 2001, 119, 59–67. [Google Scholar] [CrossRef]

- Lisowski, A.; Świątek, K.; Klonowski, J.; Sypuła, M.; Chlebowski, J.; Nowakowski, T.; Kostyra, K.; Strużyk, A. Movement of chopped material in the discharge spout of forage harvester with a flywheel chopping unit: Measurements using maize and numerical simulation. Biosyst. Eng. 2012, 111, 381–391. [Google Scholar] [CrossRef]

| Number | Variables | Parameters | Number | Variables | Parameters |

|---|---|---|---|---|---|

| 1 | Outer diameter of impeller | 850 mm | 8 | Feeding pipe diameter | 260 mm |

| 2 | Blade width | 150 mm | 9 | Feeding straight pipe height | 400 mm |

| 3 | Number of blades | 3 | 10 | Curvature radius of elbow | 700 mm |

| 4 | Blade angle | 0° | 11 | Length of straight pipe | 200 mm |

| 5 | Impeller speed | 630 r/min | 12 | Diameter of air-conveying cylinder | 160 mm |

| 6 | Volute width | 184 mm | 13 | Average straw size | 5 mm |

| 7 | Distance between blade and the front wall | 15 mm | 14 | Average density of straw | 35 kg/m3 |

| Number | Straw Part | Straw Size/mm | Single Grain Quality/g | Suspension Speed /m·s−1 | Minimum Air Blowing Speed/m·s−1 |

|---|---|---|---|---|---|

| 1 | Root | 15 | 0.018 | 2.26~4.16 | 10.82 |

| 2 | 25 | 0.025 | 2.45~4.53 | 11.78 | |

| 3 | 35 | 0.041 | 2.67~4.89 | 12.71 | |

| 4 | Middle | 15 | 0.037 | 2.85~4.78 | 12.43 |

| 5 | 25 | 0.051 | 3.12~5.09 | 13.23 | |

| 6 | 35 | 0.091 | 3.46~5.98 | 15.55 | |

| 7 | Tip | 15 | 0.016 | 3.11~5.22 | 13.57 |

| 8 | 25 | 0.030 | 3.53~5.94 | 15.44 | |

| 9 | 35 | 0.044 | 3.76~6.26 | 16.28 | |

| 10 | Leaf | 15 | 0.008 | 2.14~3.61 | 9.39 |

| 11 | 25 | 0.013 | 2.53~4.06 | 10.56 | |

| 12 | 35 | 0.016 | 2.81~4.72 | 12.27 |

| Number | Briquette Density/(g·cm−3) | Increase Rate/f (%) | Number | Briquetting Productivity/(Pieces·h−1) | Increase Rate/f (%) | ||

|---|---|---|---|---|---|---|---|

| Before Optimization/e | After Optimization/e | Before Optimization/e | After Optimization/e | ||||

| 1 | 1.085 | 1.119 | 3.04 | 1 | 1061 | 1098 | 3.37 |

| 2 | 1.151 | 1.195 | 3.64 | 2 | 1136 | 1154 | 1.56 |

| 3 | 1.127 | 1.140 | 1.14 | 3 | 1077 | 1106 | 2.62 |

| Mean | 1.121 | 1.151 | 2.61 | Mean | 1091 | 1119 | 2.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Ding, H.; Tang, Z.; Zhao, Y.; Ding, Z.; Su, Z. Fluid Movement Law and Influencing Factors of Shredding on Rice Straw Briquetting Machines. Agronomy 2022, 12, 1439. https://doi.org/10.3390/agronomy12061439

Chen S, Ding H, Tang Z, Zhao Y, Ding Z, Su Z. Fluid Movement Law and Influencing Factors of Shredding on Rice Straw Briquetting Machines. Agronomy. 2022; 12(6):1439. https://doi.org/10.3390/agronomy12061439

Chicago/Turabian StyleChen, Shuren, Hantao Ding, Zhong Tang, Yunfei Zhao, Zhao Ding, and Zhan Su. 2022. "Fluid Movement Law and Influencing Factors of Shredding on Rice Straw Briquetting Machines" Agronomy 12, no. 6: 1439. https://doi.org/10.3390/agronomy12061439

APA StyleChen, S., Ding, H., Tang, Z., Zhao, Y., Ding, Z., & Su, Z. (2022). Fluid Movement Law and Influencing Factors of Shredding on Rice Straw Briquetting Machines. Agronomy, 12(6), 1439. https://doi.org/10.3390/agronomy12061439