Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

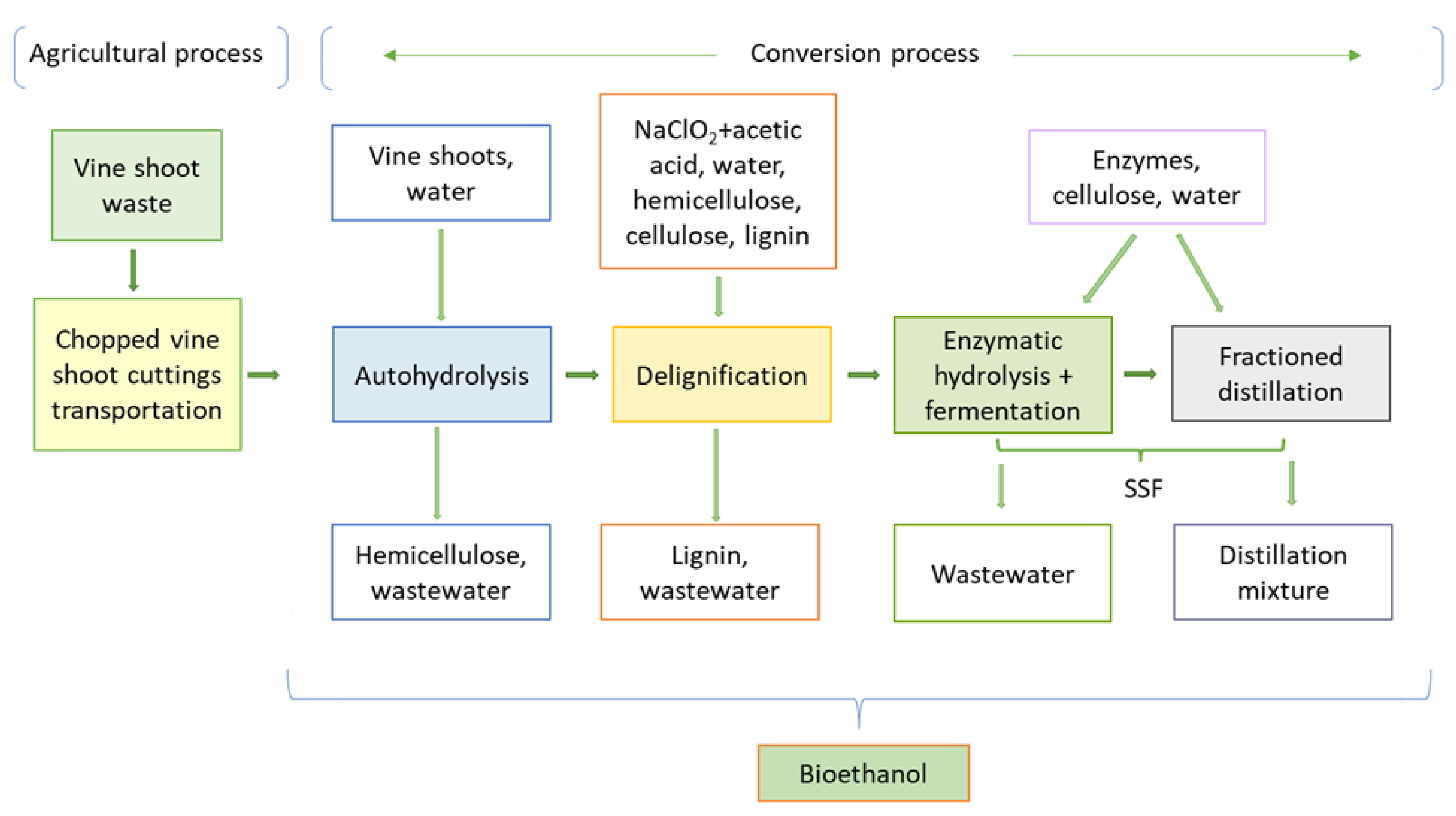

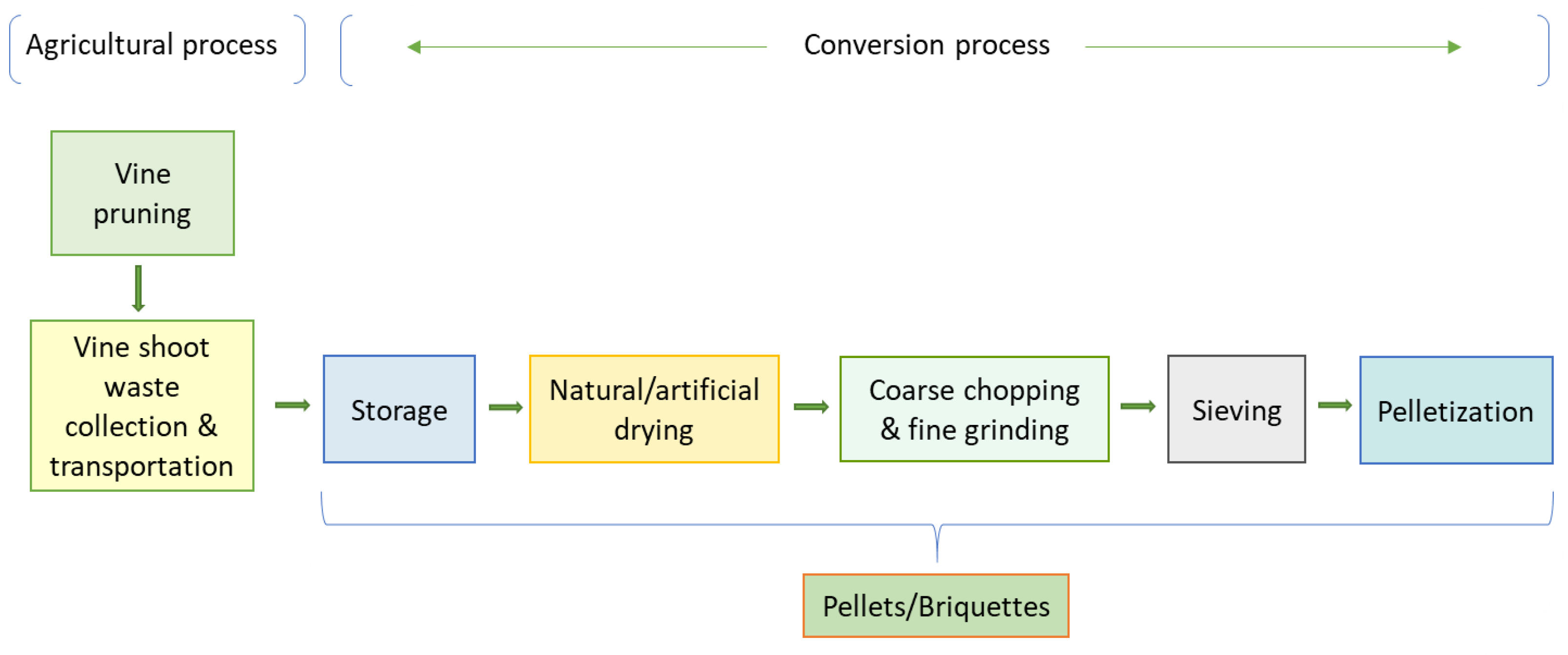

2.2. Life Cycle Inventory (LCI)

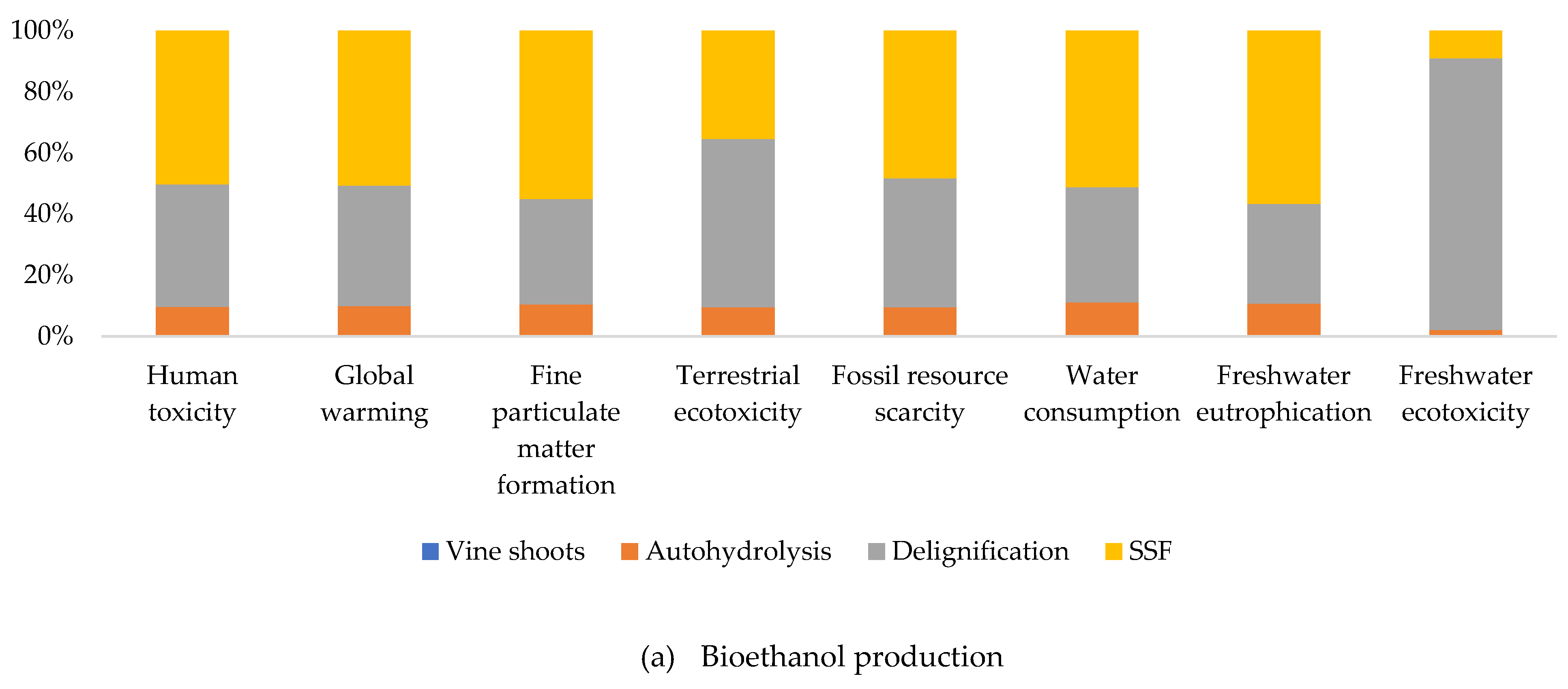

2.3. Life Cycle Impact Assessment (LCIA)

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEA World Energy Outlook 2021. Available online: https://www.iea.org/reports/world-energy-outlook-2021 (accessed on 7 January 2022).

- Morone, P.; Strzalkowski, A.; Tani, A. Biofuel transitions: An overview of regulations and standards for a more sustainable framework. In Biofuels for a More Sustainable Future; Ren, J., Scipioni, A., Manzardo, A., Lian, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; Chapter 3; pp. 21–46. [Google Scholar]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Moving towards the second generation of lignocellulosic biorefineries in the EU: Drivers, challenges, and opportunities. Renew. Sust. Energ. Rev. 2019, 101, 590–599. [Google Scholar] [CrossRef] [Green Version]

- Banu, J.R.; Preethi; Kavitha, S.; Tyagi, V.K.; Gunasekaran, M.; Karthikeyan, O.P.; Kumar, G. Lignocellulosic biomass based biorefinery: A successful platform towards circular bioeconomy. Fuel 2021, 302, 1–18. [Google Scholar]

- Benetto, E.; Jury, C.; Kneip, G.; Vazquez-Rowe, I.; Huck, V.; Minette, F. Life cycle assessment of heat production from grape marc pellets. J. Clean. Prod. 2015, 87, 149–158. [Google Scholar] [CrossRef]

- Dávila, I.; Gordobil, O.; Labidi, J.; Gullón, P. Assessment of suitability of vine shoots for hemicellulosic oligosaccharides production through aqueous processing. Bioresour. Technol. 2016, 211, 636–644. [Google Scholar] [CrossRef]

- OIV State of the World Vitivinicultural Sector in 2020. Available online: https://www.oiv.int/public/medias/7909/oiv-state-of-the-world-vitivinicultural-sector-in-2020.pdf (accessed on 7 January 2022).

- Bisaglia, C.; Romano, E. Utilization of vineyard prunings: A new mechanization system from residues harvest to CHIPS production. Biomass Bioenergy 2018, 115, 136–142. [Google Scholar] [CrossRef]

- Manzone, M.; Paravidino, E.; Bonifacino, G.; Balsari, P. Biomass availability and quality produced by vineyard management during a period of 15 years. Renew. Energy 2016, 99, 465–471. [Google Scholar] [CrossRef]

- Pizzi, A.; Pedretti, E.F.; Duca, D.; Rossini, G.; Mengarelli, C.; Ilari, A.; Mancini, M. Emissions of heating appliances fuelled with agropellet produced from vine pruning residues and environmental aspects. Renew. Energy 2018, 121, 513–520. [Google Scholar] [CrossRef]

- Sánchez-Gómez, R.; Zalacain, A.; Alonso, G.L.; Salinas, M.R. Effect of vine-shoots toasting on the generation of high added value volatiles. Flavour Fragr. J. 2016, 31, 293–301. [Google Scholar] [CrossRef]

- Sańchez-Gόmez, R.; Zalacain, A.; Alonso, G.L.; Salinas, M.R. Vine-Shoot Waste Aqueous Extracts for Re-use in Agriculture Obtained by Different Extraction Techniques: Phenolic, Volatile, and Mineral Compounds. J. Agric. Food Chem. 2014, 62, 10861–10872. [Google Scholar] [CrossRef]

- Gullón, P.; Gullón, B.; Davila, I.; Labidi, J.; Gonzalez-Garcia, S. Comparative environmental Life Cycle Assessment of integral revalorization of vine shoots from a biorefinery perspective. Sci. Total Environ. 2018, 624, 225–240. [Google Scholar] [CrossRef] [Green Version]

- Stegmann, P.; Londo, M.; Junginger, M. The circular bioeconomy: Its elements and role in European bioeconomy clusters. Resour. Conserv. Recycl. 2020, 6, 1–17. [Google Scholar] [CrossRef]

- Velasco-Munoz, J.F.; Mendoza, J.M.F.; Aznar-Sanchez, J.A. Circular economy implementation in the agricultural sector: Definition, strategies and indicators. Resour. Conserv. Recycl. 2021, 170, 1–15. [Google Scholar] [CrossRef]

- Sherwood, J. The significance of biomass in a circular economy. Bioresour. Technol. 2020, 300, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zanetti, M.; Brandelet, B.; Marini, D.; Sgabrossa, A.; Girorio, C.; Badocco, D.; Tapparo, A.; Grigolato, S.; Rogaume, C.; Rogaume, Y.; et al. Vineyard pruning residues pellets for use in domestic appliances: A quality assessment according to the EN ISO 17225. J. Agric. Eng. 2017, 48, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Duranay, N.D.; Akkus, G. Solid fuel production with torrefaction from vineyard pruning waste. Biomass Convers. Biorefin. 2021, 11, 2335–2346. [Google Scholar] [CrossRef]

- Hamedani, S.R.; Colantoni, A.; Gallucci, F.; Salerno, M.; Silvestri, C.; Villarini, M. Comparative energy and environmental analysis of agro-pellet production from orchard woody biomass. Biomass Bioenergy 2019, 129, 105334. [Google Scholar] [CrossRef]

- Picchi, G.; Silvestri, S.; Cristoforetti, A. Vineyard residues as a fuel for domestic boilers in Trento Province (Italy): Comparison to wood chips and means of polluting emissions control. Fuel 2013, 113, 43–49. [Google Scholar] [CrossRef]

- Fernandez-Puratich, H.; Hernandez, D.; Tenreiro, C. Analysis of energetic performance of vine biomass residues as an alternative fuel for Chilean wine industry. Renew. Energy 2015, 83, 1260–1267. [Google Scholar] [CrossRef]

- Tenu, I.; Roman, C.; Senila, L.; Rosca, R.; Carlescu, I.; Baetu, M.; Arsenoaia, V.; Dumitrachi, E.P.; Corduneanu, O.R. Valorization of vine tendrils resulted from pruning as densified solid biomass fuel (Briquettes). Processes 2021, 9, 1409. [Google Scholar] [CrossRef]

- Muzikant, M.; Havrland, B.; Hutla, P.; Vechetova, S. Properties of heat briquettes produced from vine cane waste—case study Republic of Moldova. ATS 2010, 43, 1–8. [Google Scholar]

- Senila, L.; Kovacs, E.; Scurtu, D.A.; Cadar, O.; Becze, A.; Senila, M.; Levei, E.A.; Dumitras, D.E.; Tenu, I.; Roman, C. Bioethanol Production from Vineyard Waste by Autohydrolysis Pretreatment and Chlorite Delignification via Simultaneous Saccharification and Fermentation. Molecules 2020, 25, 2026. [Google Scholar] [CrossRef] [PubMed]

- Basaglia, M.; D’Ambra, M.; Piubello, G.; Zanconato, V.; Favaro, L.; Casella, S. Agro-Food Residues and Bioethanol Potential: A Study for a Specific Area. Processes 2021, 9, 344. [Google Scholar] [CrossRef]

- Dávila, I.; Gullón, B.; Labidi, J.; Gullón, P. Multiproduct biorefinery from vine shoots: Bio-ethanol and lignin production. Renew. Energy 2019, 142, 612–623. [Google Scholar] [CrossRef]

- Buratti, C.; Barbanera, M.; Lascaro, E. Ethanol Production from Vineyard Pruning Residues with Steam Explosion Pretreatment. Environ. Prog. Sustain. Energy 2015, 34, 802–809. [Google Scholar] [CrossRef]

- Bjorn, A.; Owsianiak, M.; Molin, C.; Laurent, A. Main characteristics of LCA. In Life Cycle Assessment: Theory and Practice, 1st ed.; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 9–16. [Google Scholar]

- Zucaro, A.; Forte, A.; Fierro, A. Life cycle assessment of wheat straw lignocellulosic bio-ethanol fuel in a local biorefinery prospective. J. Clean. Prod. 2018, 194, 138–149. [Google Scholar] [CrossRef]

- Wang, L.; Littlewood, J.; Murphy, R.J. Environmental sustainability of bioethanol production from wheat straw in the UK. Renew. Sustain. Energy Rev. 2013, 28, 715–725. [Google Scholar] [CrossRef] [Green Version]

- Dias, M.O.S.; Junqueira, T.L.; Cavalett, O.; Cunha, M.P.; Jesus, C.D.F.; Rossell, C.E.V.; Filho, R.M.; Bonomi, A. Integrated versus stand-alone second generation ethanol production from sugarcane bagasse and trash. Bioresour. Technol. 2012, 103, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Muazu, R.I.; Borrion, A.L.; Stegemann, J.A. Life Cycle Assessment Model for Biomass Fuel Briquetting. Waste Biomass Valorization 2022, 13, 2461–2476. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Sevda, S.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef]

- Thornely, P.; Gilbert, P.; Shackley, S.; Hammond, J. Maximizing the greenhouse gas reductions from biomass: The role of life cycle assessment. Biomass Bioenergy 2015, 81, 35–43. [Google Scholar] [CrossRef]

- Neri, E.; Cespi, D.; Setti, L.; Gombi, E.; Bernardi, E.; Vassura, I.; Passarini, F. Biomass Residues to Renewable Energy: A Life Cycle Perspective Applied at a Local Scale. Energies 2016, 9, 922. [Google Scholar] [CrossRef] [Green Version]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polymer Chemistry 2015, 6, 4497–4559. [Google Scholar] [CrossRef] [Green Version]

- Sindhu, R.; Binod, P.; Pandey, A. Biological pretreatment of lignocellulosic biomass – An overview. Bioresour. Technol. 2016, 199, 76–82. [Google Scholar] [CrossRef] [PubMed]

- Bilal, M.; Iqbal, H.M.N. Recent Advancements in the Life Cycle Analysis of Lignocellulosic Biomass. Curr. Sustain. /Renew. Energy Rep. 2020, 7, 100–107. [Google Scholar] [CrossRef]

- Pachón, E.R.; Mandade, P.; Gnansounou, E. Conversion of vine shoots into bioethanol and chemicals: Prospective LCA of biorefinery concept. Bioresour. Technol. 2020, 303, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ilari, A.; Toscano, G.; Pedretti, E.F.; Fabrizi, S.F.; Duca, D. Environmental Sustainability of Heating Systems Based on Pellets Produced in Mobile and Stationary Plants from Vineyard Pruning Residues. Resources 2020, 9, 94. [Google Scholar] [CrossRef]

- Hauschild, M.Z. Introduction to LCA Methodology. In Life Cycle Assessment: Theory and Practice, 1st ed.; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 59–66. [Google Scholar]

- Klöpffer, W. Introducing Life Cycle Assessment and its presentation in “LCA Compendium”. In Background and Future Prospects in Life Cycle Assessment; Klöpffer, W., Ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 1–37. [Google Scholar]

- Heijungs, R.; Guinee, J.B. An overview of the life cycle assessment method—Past, present, and future. In Life Cycle Assessment Handbook; Curran, M.A., Ed.; Scrivener Publishing: Beverly, MA, USA, 2012; pp. 15–41. [Google Scholar]

- Muralikrishna, I.V.; Manickam, V. Life cycle assessment. In Environmental Management: Science and Engineering for Industry; Butterworth-Heinemann Elsevier: Oxford, UK, 2017; pp. 57–75. [Google Scholar]

- ISO. ISO 14040:2006: Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/74/37456.html (accessed on 17 January 2022).

- ISO. ISO 14044:2006: Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/84/38498.html (accessed on 17 January 2022).

- Senila, L.; Tenu, I.; Carlescu, P.; Corduneanu, O.R.; Dumitrachi, E.P.; Kovacs, E.; Scurtu, D.A.; Cadar, O.; Becze, A.; Senila, M.; et al. Sustainable biomass pellets production using vineyard wastes. Agriculture 2020, 10, 501. [Google Scholar] [CrossRef]

- Senila, L.; Tenu, I.; Carlescu, P.; Scurtu, D.A.; Kovacs, E.; Senila, M.; Cadar, O.; Roman, M.; Dumitras, D.E.; Roman, C. Characterization of biobriquettes produced from vineyard wastes as a solid biofuel resource. Agriculture 2022, 12, 341. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, O.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Pergola, M.; Gialdini, A.; Celano, G.; Basile, M.; Caniani, D.; Cozzi, M.; Gentilesca, T.; Mancini, I.M.; Pastore, V.; Romano, S.; et al. An environmental and economic analysis of the wood-pellet chain: Two case studies in Southern Italy. Int. J. Life Cycle Assess. 2018, 23, 1675–1684. [Google Scholar] [CrossRef]

- Soam, S.; Borjesson, P.; Sharma, P.K.; Gupta, R.P.; Tuli, D.K.; Kumar, R. Life cycle assessment of rice straw utilization practices in India. Bioresour. Technol. 2017, 228, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Cen, K.; Chen, F.; Chen, D.; Gan, Z.; Zhuang, X.; Zhang, H. Life cycle assessment of torrefied cornstalk pellets combustion heating system. Fuel 2022, 320, 1–8. [Google Scholar] [CrossRef]

- Jiang, L.; Xue, B.; Ma, Z.; Yu, L.; Huang, B.; Chen, X. A life-cycle based co-benefits analysis of biomass pellet production in China. Renew. Energy 2020, 154, 445–452. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Foakides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Mata, T.M.; Rodrigues, S.; Caetano, N.S.; Martins, A.A. Life cycle assessment of bioethanol from corn stover from soil phytoremediation. Energy Rep. 2022, 8, 468–474. [Google Scholar] [CrossRef]

- Rathnayake, M.; Chaireongsirikul, T.; Svangariyaskul, A.; Lawtrakul, L.; Toochinda, P. Process simulation based life cycle assessment for bioethanol production from cassava, cane molasses, and rice straw. J. Clean. Prod. 2018, 190, 24–35. [Google Scholar] [CrossRef]

- Gonzales-Garcia, S.; Moreira, M.T.; Feijoo, G. Comparative environmental performance of lignocellulosic ethanol from different feedstocks. Renew. Sustain. Energy Rev. 2010, 14, 2077–2085. [Google Scholar] [CrossRef]

- Khaire, K.C.; Moholkar, V.S.; Goyal, A. Bioconversion of sugarcane tops to bioethanol and other value added products: An overview. Mater. Sci. Energy Technol. 2021, 4, 54–68. [Google Scholar] [CrossRef]

- Jesus, M.S.; Romani, A.; Genisheva, Z.; Teixeira, J.A.; Domingues, L. Integral valorization of vine pruning residue by sequential autohydrolysis stages. J. Clean. Prod. 2017, 168, 74–86. [Google Scholar] [CrossRef] [Green Version]

- Dávila, I.; Gullón, P.; Labidi, J.; Budarin, V. Assessment of the influence of the temperature in the microwave-assisted alkaline delignification of vine shoots. Chem. Eng. Trans. 2018, 1687–1692. [Google Scholar]

- Ellen McArthur Foundation 2013 towards the Circular Economy: Opportunities for the Consumers Goods Sector. 2013. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-2-opportunities-for-the-consumer-goods (accessed on 9 February 2022).

- Stigsson, C.; Furusjö, E.; Börjesson, P. A model of an integrated hydrothermal liquefaction, gasification and Fischer-Tropsch synthesis process for converting lignocellulosic forest residues into hydrocarbons. Bioresour. Technol. 2022, 353, 126070. [Google Scholar] [CrossRef] [PubMed]

| LCI Stage | Process | Amount | Unit |

|---|---|---|---|

| Input | |||

| Vine shoots | Transportation, freight, lorry 16–32 | 7185 | kg/km |

| Autohydrolysis | Water | 130 | L |

| Cellulose | 6.73 | kg | |

| Hemicellulose | 3.35 | kg | |

| Lignin | 4.73 | kg | |

| Electricity [Parr reactor] | 74.0 | kWh | |

| Delignification | Cellulose | 5.96 | kg |

| Hemicellulose | 0.17 | kg | |

| Lignin | 4.32 | kg | |

| Sodium chlorite | 19.1 | kg | |

| Water | 77 | kg | |

| Electricity | 165 | kWh | |

| Simultaneous Saccharification and Fermentation (SSF) | Cellulose | 4.52 | kg |

| Lignin | 0.33 | kg | |

| Enzymes | 0.06 | kg | |

| Water | 50 | L | |

| Electricity | 390 | kWh | |

| Output | |||

| Autohydrolysis (solid phase) | Cellulose | 5.93 | kg |

| Hemicellulose | 0.17 | kg | |

| Lignin | 4.27 | kg | |

| Autohydrolysis (liquid phase) | Hemicellulose | 1.26 | kg |

| By-products | 2.79 | kg | |

| Water | 130 | L | |

| Delignification (solid phase) | Cellulose | 4.12 | kg |

| Lignin | 0.32 | kg | |

| Delignification (liquid phase) | Lignin + Water | 80 | kg |

| Simultaneous Saccharification and Fermentation (SSF) | Water + by-products | 53.9 | kg |

| LCI Stage | Process | Amount | Unit |

|---|---|---|---|

| S1-Baling shoots between rows | Diesel | 9.3 × 10−3 | kg |

| S2-Loading shoots in the trailer | Diesel | 7.3 × 10−4 | kg |

| S3-Transporting shoots at the end of the row | Diesel | 1.7 × 10−3 | kg |

| S4-Transport of shoots to the storage base | Diesel | 1.3 × 10−3 | kg |

| S5-Uploading shoots from the trailer | Diesel | 7.3 × 10−4 | kg |

| S6-Stacking shoots in the primary dryer | Diesel | 6.3 × 10−4 | kg |

| S7-Dehydration of the shoots | Electricity | 1.89 | kWh |

| S8-Chopping and grinding shoots | Electricity | 2.3 × 10−2 | kWh |

| S9-Pelletizing the wood material | Electricity | 0.11 | kWh |

| Impact Category | Global Warming | Fine Particulate Matter Formation | Freshwater Eutrophication | Terrestrial Ecotoxicity | Freshwater Ecotoxicity | Fossil Resource Scarcity | Water Consumption | Human Toxicity |

|---|---|---|---|---|---|---|---|---|

| Unit | kg CO2 eq | kg PM2.5 eq | kg P eq | kg 1,4-DCB | kg 1,4-DCB | kg oil eq | m3 | kg 1,4-DCB |

| S1 | 4.9 × 10−3 | 1.4 × 10−5 | 8.4 × 10−8 | 6.6 × 10−3 | 1.1 × 10−5 | 1.1 × 10−2 | 5.6 × 10−5 | 6.2 × 10−4 |

| S2 | 3.9 × 10−4 | 1.1 × 10−6 | 6.6 × 10−9 | 5.2 × 10−4 | 8.5 × 10−7 | 9.0 × 10−4 | 4.4 × 10−6 | 4.8 × 10−5 |

| S3 | 9.3 × 10−4 | 2.7 × 10−6 | 1.6 × 10−8 | 1.2 × 10−3 | 2.0 × 10−6 | 2.2 × 10−3 | 1.1 × 10−5 | 1.2 × 10−4 |

| S4 | 6.7 × 10−4 | 1.9 × 10−6 | 1.1 × 10−8 | 8.9 × 10−4 | 1.5 × 10−6 | 1.5 × 10−3 | 7.6 × 10−6 | 8.3 × 10−5 |

| S5 | 3.8 × 10−4 | 1.1 × 10−6 | 6.6 × 10−9 | 5.2 × 10−4 | 8.5 × 10−7 | 9.0 × 10−4 | 4.4 × 10−6 | 4.8 × 10−5 |

| S6 | 3.3 × 10−4 | 9.6 × 10−7 | 5.7 × 10−9 | 4.5 × 10−4 | 7.3 × 10−7 | 7.7 × 10−4 | 3.8 × 10−6 | 4.2 × 10−5 |

| S7 | 8.4 × 10−1 | 2.7 × 10−3 | 1.8 × 10−4 | 9.4 × 10−1 | 1.9 × 10−4 | 2.2 × 10−1 | 1.9 × 10−2 | 2.7 × 10−2 |

| S8 | 1.0 × 10−2 | 3.3 × 10−5 | 2.2 × 10−6 | 1.1 × 10−2 | 2.3 × 10−6 | 2.6 × 10−3 | 2.4 × 10−4 | 3.3 × 10−4 |

| S9 | 4.9 × 10−2 | 1.6 × 10−4 | 1.0 × 10−5 | 5.4 × 10−2 | 1.1 × 10−5 | 1.3 × 10−2 | 1.1 × 10−3 | 1.6 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovacs, E.; Hoaghia, M.-A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. https://doi.org/10.3390/agronomy12061320

Kovacs E, Hoaghia M-A, Senila L, Scurtu DA, Varaticeanu C, Roman C, Dumitras DE. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy. 2022; 12(6):1320. https://doi.org/10.3390/agronomy12061320

Chicago/Turabian StyleKovacs, Eniko, Maria-Alexandra Hoaghia, Lacrimioara Senila, Daniela Alexandra Scurtu, Cerasel Varaticeanu, Cecilia Roman, and Diana Elena Dumitras. 2022. "Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy" Agronomy 12, no. 6: 1320. https://doi.org/10.3390/agronomy12061320

APA StyleKovacs, E., Hoaghia, M.-A., Senila, L., Scurtu, D. A., Varaticeanu, C., Roman, C., & Dumitras, D. E. (2022). Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy, 12(6), 1320. https://doi.org/10.3390/agronomy12061320