A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions

Abstract

:1. Introduction

- Section 2 reports the reference equations that were chosen, the variables they contain, the way the MCS algorithm was developed, and the experimental trials carried out for the validation activity.

- Section 3 shows the MCS output, how it relates to the random input variables, and their importance, as determined by the linear regression analysis. Section 3.2 and Section 3.3 show the results of the experimental trials and the validation process entered when compared with the MCS output.

2. Materials and Methods

2.1. The Reference Equations

- Pdb is the power at the drawbar (kW);

- PPTO is the maximum engine power measured at power take-off [1] (kW);

- Pvd is the power used for the vehicle’s displacement (kW);

- Ps is the power lost due to slippage (kW);

- α is the driveline efficiency coefficient (dimensionless).

- PPTO is the maximum power of the engine measured at power take-off [1] (kW)

- M is the dynamic wheel load, in force units, normal to the soil surface ();

- is the forward velocity (m s−1);

- s is the wheel slip (dimensionless).

- hha are the worked hours required for 1 hectare (hours ha−1, from Equation (5));

- SFCkW is the specific fuel consumption of the engine (gfuel kWh−1);

- PPTO is the power provided by the vehicle’s engine (kW).

- W is the working width of the implement (m);

- is the forward velocity (m s−1).

- F, taken from the ASAE standard (fixed as it refers to a given plow);

- Tr, taken from the ASAE standard (Bn = 55);

- , which is fixed (1.94 m s−1);

- S, which is variable;

- SFCkW, which is variable;

- A, which is fixed (0.92);

- The motion resistance ratio coefficient, which is fixed (0.07);

- Grip, which is variable.

2.2. Random Independent Variables

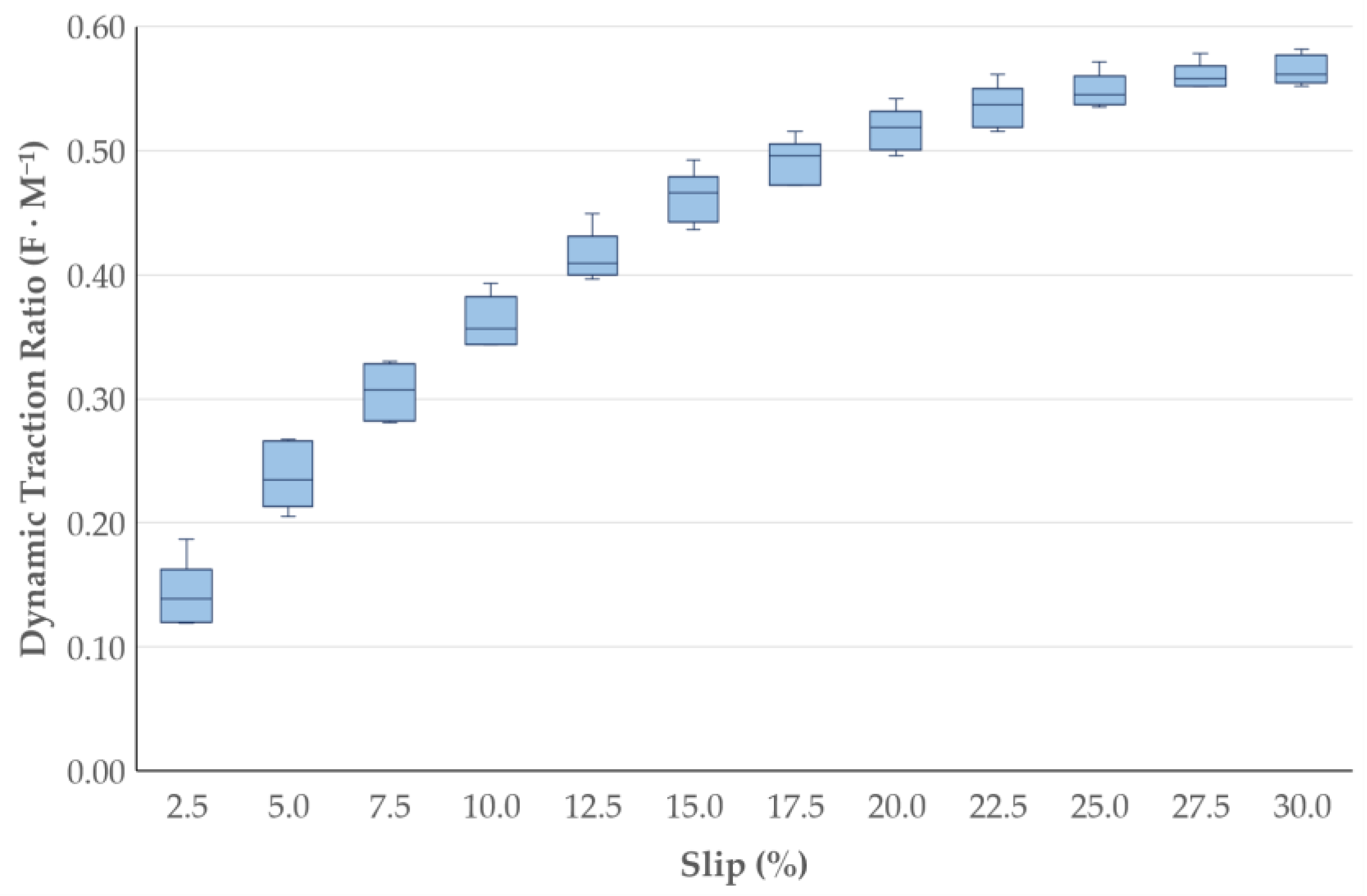

2.2.1. Tire Grip

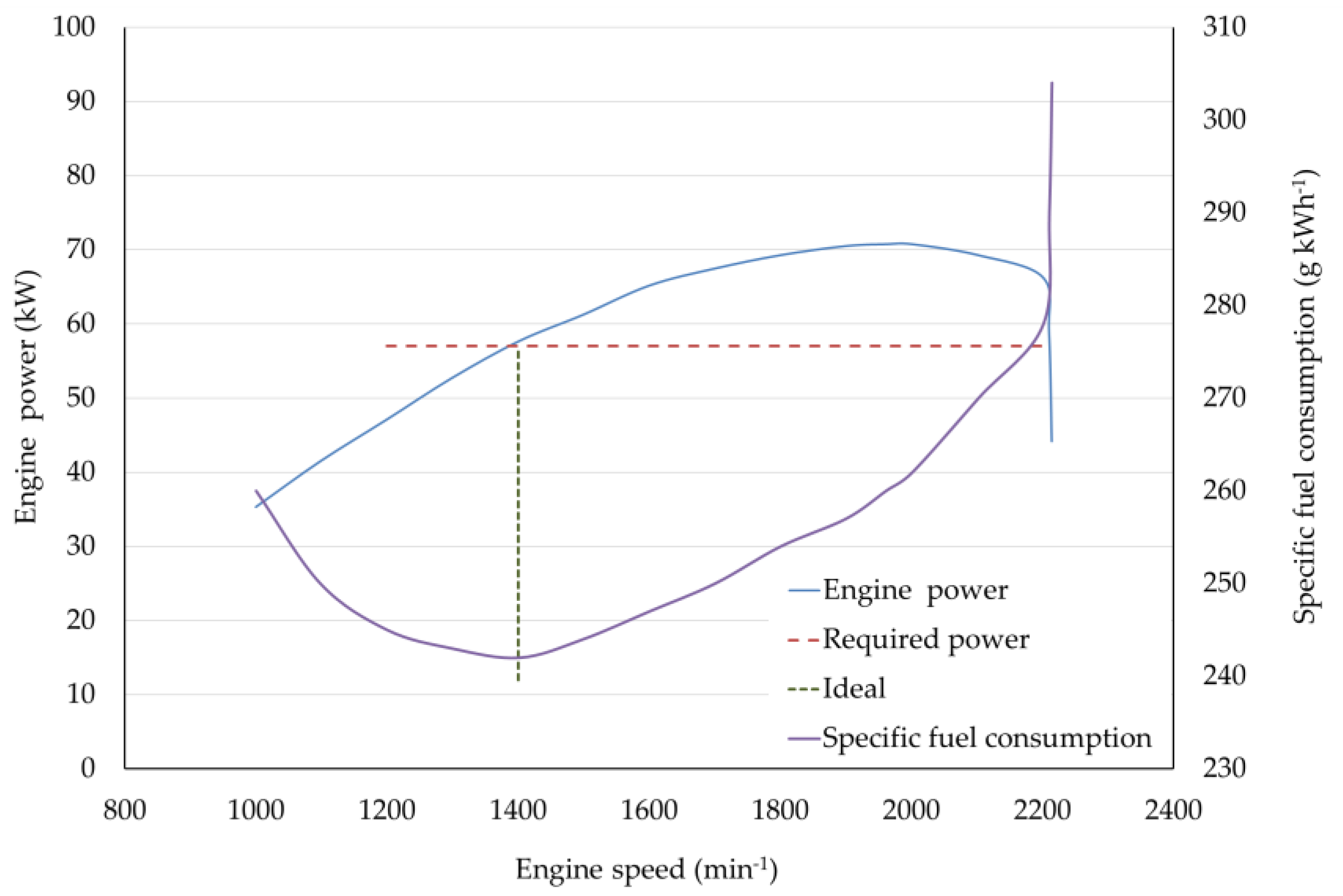

2.2.2. The Specific Fuel Consumption of the Engine (

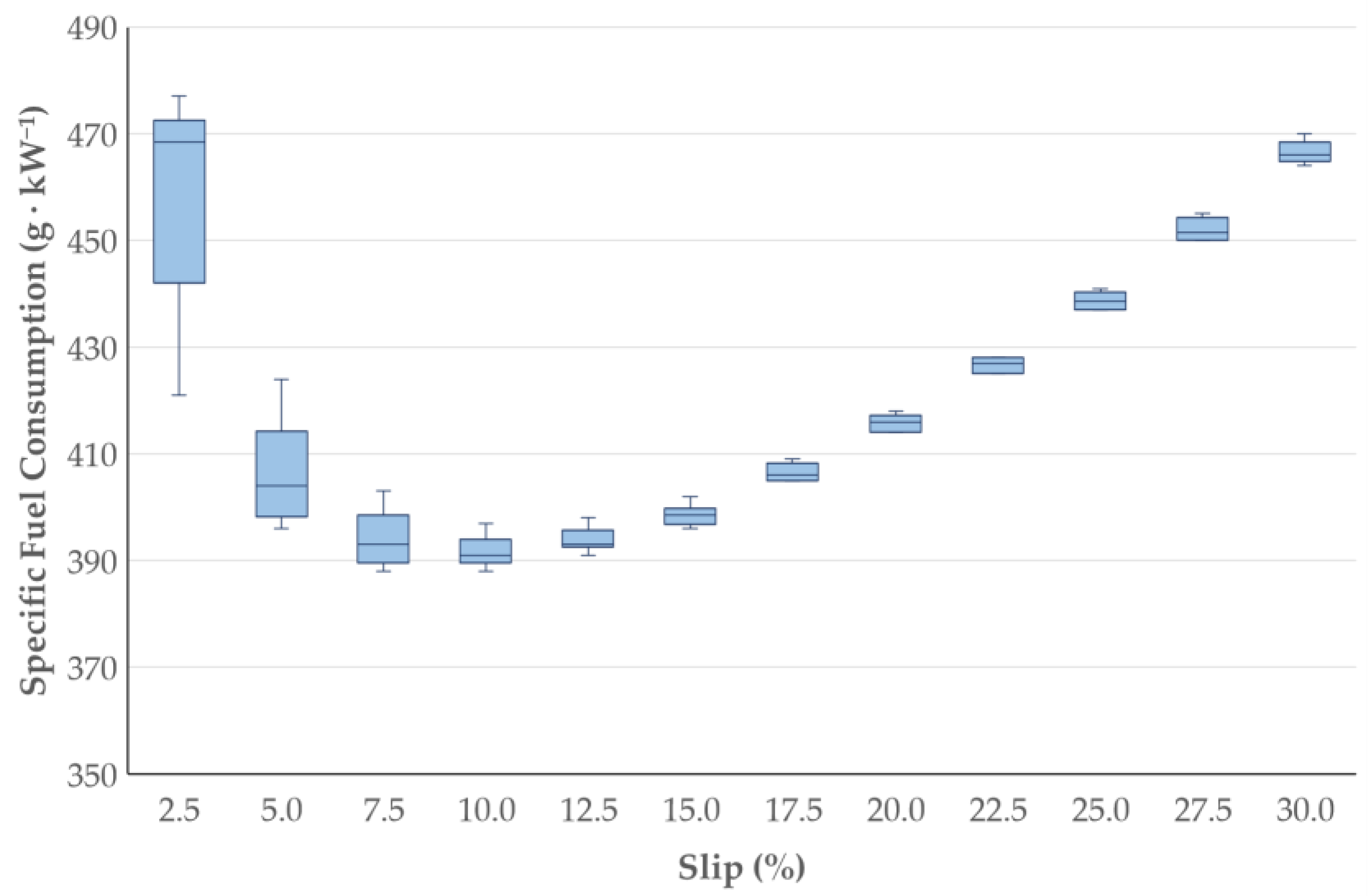

2.2.3. Wheel Slip (s)

- Slip: 3–30%;

- Tire grip: ±15%;

- Specific fuel consumption: 245–293 g kWh−1.

2.3. Monte Carlo Analysis

2.4. Experimental Trials

- s is the slip (%);

- An is the advance under no-load conditions per wheel revolution (m);

- A1 is the advance under load conditions per wheel revolution (m).

- SFCdb is the specific fuel consumption of the drawbar power (g kWh−1);

- SFCkW is the specific fuel consumption of the engine, which is constant (269 g kWh−1);

- PPTO was taken from Equation (3);

- Pdb was taken from Equation (1) after the field trials.

- is the specific fuel consumption of the drawbar power (kg ha−1);

- SFCdb is the specific fuel consumption at the drawbar (g kWh−1);

- hha are the hours of work required for one hectare;

- Pdb was taken from Equation (1) after the field trials.

3. Results

3.1. Linear Regression and Monte Carlo Analysis

3.2. The Experimental Trials: Effects of Different Tires on the Traction Efficiency

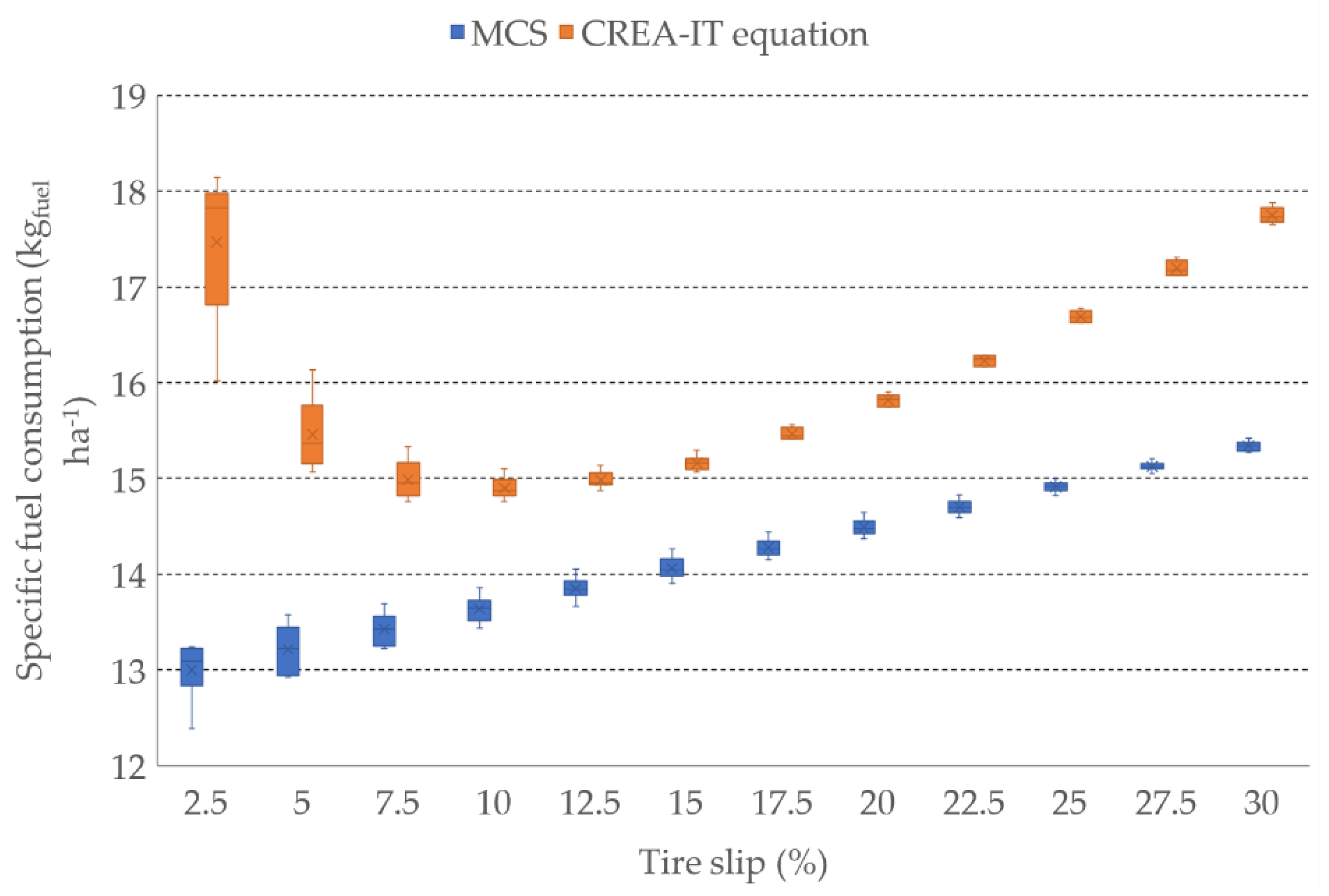

3.3. Validation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OECD—Organisation for Economic Co-Operation and Development. Code 2: OECD Standard Codes for the Official Testing of Agricultural and Forestry Tractors Performance; OECD: Paris, France, 2018. [Google Scholar]

- Molari, G.; Sedoni, E. Experimental evaluation of power losses in a power-shift agricultural tractor transmission. Biosyst. Eng. 2008, 100, 177–183. [Google Scholar] [CrossRef]

- Harris, B.J.; Rethmel, B.R. Comparison of IF and standard marked metric radial ply tires. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting, ASABE, Louisville, KY, USA, 7–10 August 2011; Volume 7, pp. 5461–5472. [Google Scholar]

- Smerda, T.; Cupera, J. Tire inflation and its influence on drawbar characteristics and performance—Energetic indicators of a tractor set. J. Terramechanics 2010, 47, 395–400. [Google Scholar] [CrossRef]

- Monteiro, L.A.; Albiero, D.; De Souza, F.H.; Melo, R.P.; Cordeiro, I.M. Tractor efficiency at different weight and power ratios. Rev. Cienc. Agron. 2013, 44, 70–75. [Google Scholar] [CrossRef]

- Gil-Sierra, J.; Ortiz-Canavate, J.; Gil-Quiros, V.; Casanova-Kindelan, J. Energy efficiency in agricultural tractors: A methodology for their classification. Appl. Eng. Agric. 2007, 23, 145–150. [Google Scholar] [CrossRef]

- Turker, U.; Ergul, I.; Eroglu, M.C. Energy efficiency classification of agricultural tractors in Turkey based on OECD tests. Energy Educ. Sci. Tecnol. Part A Energy Sci. Res. 2012, 28, 917–924. [Google Scholar]

- Grisso, R.D.; Kocher, M.F.; Vaughan, D.H. Predicting tractor fuel consumption. Appl. Eng. Agric. 2004, 20, 553–561. [Google Scholar] [CrossRef]

- Lacour, S.; Burgun, C.; Perilhon, C.; Descombes, G.; Doyen, V. A model to assess tractor operational efficiency from bench test data. J. Terramechanics 2014, 54, 1–18. [Google Scholar] [CrossRef]

- Tiwari, V.K.; Pandey, K.P.; Pranav, P.K. A review on traction prediction equations. J. Terramechanics 2010, 47, 191–199. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Pagano, M.; Grilli, R.; Fedrizzi, M.; Fornaciari, L. Dynamic-energetic balance of agricultural tractors: Active systems for the measurement of the power requirements in static tests and under field conditions. J. Agric. Eng. 2013, 44, 415–420. [Google Scholar] [CrossRef]

- Zoz, F.M.; Grisso, D.R. Tractor and Traction Performance. In Proceedings of the 2003 Agricultural Equipment Technology Conference, Louisville, KY, USA, 9–11 February 2003; ASAE Distinguished Lecture # 27; ASAE Publication Number 913C0403. ASAE: St. Joseph, MI, USA, 2003. [Google Scholar]

- Lyasko, M.I. How to calculate the effect of soil conditions on tractive performance. J. Terramechanics 2010, 47, 423–445. [Google Scholar] [CrossRef]

- Filho, A.G.; Lancas, K.P.; Leite, F.; Acosta, J.J.B.; Jesuino, P.R. Performance of agricultural tractor on three different soil surfaces and four forward speeds. Rev. Bras. Eng. Agrícola Ambient. 2010, 14, 333–339. [Google Scholar]

- Cutini, M.; Brambilla, M.; Bisaglia, C. Tractor Drive Line Efficiency Evaluation taking into account Power Lost in Slippage. In Proceedings of the “New Engineering Concepts for Valued Agriculture”, Wageningen, The Netherlands, 8–12 July 2018; pp. 533–538. [Google Scholar]

- Cutini, M.; Bisaglia, C. Development of a dynamometric vehicle to assess the drawbar performances of high-powered agricultural tractors. J. Terramechanics 2016, 65, 73–84. [Google Scholar] [CrossRef]

- Prairie Agricultural Machinery Institute (PAMI). Research Update, Standardised Tractor Performance Testing. What It Is—And Isn’t; Prairie Agricultural Machinery Institute: Humboldt, SK, Canada, 1996. [Google Scholar]

- ASAE D497.7; Agricultural Machinery Management Data. ASABE: St. Joseph, MI, USA, 2011.

- Cutini, M.; Brambilla, M.; Bisaglia, C.; Pochi, D.; Fanigliulo, R. Efficiency of Tractor Drawbar Power Taking into account Soil-Tire Slippage. Lect. Notes Civ. Eng. 2020, 67, 409–417. [Google Scholar] [CrossRef]

- Grisso, R.D. Gear Up and Throttle Down; Publication 442-450 (BSE-326P); Virginia Cooperative Extension, Virginia Tech: Blacksburg, VA, USA, 2001. [Google Scholar]

- ASABE Standards S296.5 W/Corr. 1 DEC2003 (R2013); General Terminology for Traction of Agricultural Traction and Transport Devices and Vehicles. ASABE: St. Joseph, MI, USA, 2015.

- EP496.3 FEB2006 (R2015); Agricultural Machinery Management. ASABE: St. Joseph, MI, USA, 2015.

- Metropolis, N. The beginning of Monte Carlo methods. Los Alamos Sci. 1987, 15, 125–130. [Google Scholar]

- Buc, D.; Màsàrova, G. Application of Monte Carlo simulation in the field of mechanical engineering. AD ALTA J. Interdiscip. Res. 2013, 3, 31–34. [Google Scholar]

- Osaki, M.; Aparecido Alves, L.R.; Lima, F.F.; Garcia Ribeiro, R.; Sant’Ana de Camargo Barros, G. Risks associated with a double-cropping production system—A case study in southern Brazil. Sci. Agric. 2017, 76, 130–138. [Google Scholar] [CrossRef]

- Colantoni, A.; Villarini, M.; Monarca, D.; Carlini, M.; Mosconi, E.M.; Bocci, E.; Hamedani, S.R. Economic analysis and risk assessment of biomass gasification CHP systems of different sizes through Monte Carlo simulation. Energy Rep. 2021, 7, 1954–1961. [Google Scholar] [CrossRef]

- Briggs, A.; Goeree, R.; Blackhouse, G.; O’Brien, B. Probabilistic Analysis of Cost-Effectiveness Models: Choosing between Treatment Strategies for Gastro-Esophogeal Reflux Disease; Research Working Paper; McMaster University Centre for Health Economics and Policy Analysis: Hamilton, ON, Canada, 2001. [Google Scholar]

- Qin, F.; Zhao, Y.; Shi, X.; Xu, S.; Yu, D. Sensitivity and uncertainty analysis for the DeNitrification–DeComposition model, a case study of modeling soil organic carbon dynamics at a long-term observation site with a rice–bean rotation. Comput. Electron. Agric. 2016, 124, 263–272. [Google Scholar] [CrossRef]

- Clark, C.E. The PERT Model for the Distribution of an Activity Time. Oper. Res. 1962, 10, 405–406. [Google Scholar] [CrossRef] [Green Version]

- Minitab, version 17; Statistical Software; Minitab: State College, PA, USA, 2010.

- Campolongo, F.; Saltelli, A.; Sørensen, T.; Tarantola, S. Hitchhiker’s guide to Sensitivity Analysis. In Sensitivity Analysis; Saltelli, A., Chan, K., Scott, E.M., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2000; pp. 16–45. [Google Scholar]

- ENAMA Protocol n. 41. Pneumatici Per Ruote Motrici e Direttrici; ENAMA: Rome, Italy, 2000.

- Saltelli, A.; Tarantola, F.; Campolongo, F.; Ratto, M. Sensitivity Analysis in Practice; Wiley: Hoboken, NJ, USA, 2004; ISBN 978-0-470-87093-8. Available online:http://www.andreasaltelli.eu/file/repository/SALTELLI_2004_Sensitivity_Analysis_in_Practice.pdf (accessed on 13 March 2022).

| Value | Grip (% Net Traction) | Slip (%) | SFCkW (gfuel kWh−1) |

|---|---|---|---|

| Minimum (a) | 0.85 | 5 | 245 |

| Most likely (b) | 1.00 | 15 | 269 |

| Maximum (c) | 1.15 | 29 | 293 |

| Instrument or Material | Make and Model | Scope |

|---|---|---|

| Test tractor | 208 kW, MFWD type | Drawbar pull |

| Dynamometric vehicle | 234 kW, MFWD type | Braking force and wheel slip measurement |

| Weighing platform | Bulgari 20 t (Adda Bilance, Milan, Italy) | Mass measurement (max 20 t; division 5 kg) |

| 450 m soil test track | CREA-IT, Bergamo, Italy | Drawbar pull test surface |

| Force transducer | AEP T20-C2/10T (Modena, Italy) | Drawbar pull force measurement (±0.02% combined error) |

| GPS | DS-IMU 1 (Wetzlar, Germany) | Forward speed measurement (Accuracy: ±0.05 m s−1) |

| Rotation optical sensors | Mod. 63L 3000B, Comp srl (Milan, Italy) | Wheel slip measurement |

| Fixed | Measured | Calculated | Dependent |

|---|---|---|---|

| Driveline efficiency (α) | Slip (s) | Power used for the vehicle’s displacement (Pvd) | Specific fuel consumption of the drawbar power (SFCdb) |

| Specific fuel consumption of the engine (SFCkW) | Forward speed () | Drawbar power (Pdb) | |

| Vehicle’s mass (M) | Engine power (PPTO) | ||

| Drawbar force (F) | Dynamic traction ratio (Tr) |

| Input Variable | Corr. Coeff. (r) | SRC |

|---|---|---|

| Grip (% net traction) | −0.15 | −0.14 |

| Wheel Slip (%) | 0.73 | 0.60 |

| SFCkW (gfuel kWh−1) | 0.57 | 0.74 |

| Slip% | Squared Error |

|---|---|

| 2.5 | 19.96 |

| 5 | 5.04 |

| 7.5 | 2.44 |

| 10 | 1.59 |

| 12.5 | 1.28 |

| 15 | 1.20 |

| 17.5 | 1.41 |

| 20 | 1.77 |

| 22.5 | 2.34 |

| 25 | 3.15 |

| 27.5 | 4.28 |

| 30 | 5.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cutini, M.; Brambilla, M.; Pochi, D.; Fanigliulo, R.; Bisaglia, C. A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions. Agronomy 2022, 12, 1017. https://doi.org/10.3390/agronomy12051017

Cutini M, Brambilla M, Pochi D, Fanigliulo R, Bisaglia C. A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions. Agronomy. 2022; 12(5):1017. https://doi.org/10.3390/agronomy12051017

Chicago/Turabian StyleCutini, Maurizio, Massimo Brambilla, Daniele Pochi, Roberto Fanigliulo, and Carlo Bisaglia. 2022. "A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions" Agronomy 12, no. 5: 1017. https://doi.org/10.3390/agronomy12051017

APA StyleCutini, M., Brambilla, M., Pochi, D., Fanigliulo, R., & Bisaglia, C. (2022). A Simplified Approach to the Evaluation of the Influences of Key Factors on Agricultural Tractor Fuel Consumption during Heavy Drawbar Tasks under Field Conditions. Agronomy, 12(5), 1017. https://doi.org/10.3390/agronomy12051017