Utilisation of Oil Palm’s Empty Fruit Bunch Spikelets for Oil-Spill Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Laboratory Scale Set Up and Sorbents Selection

2.3. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

2.4. Statistical Experimental Design

2.4.1. One-Factor-at-a-Time (OFAT)

2.4.2. Response Surface Methodology (RSM)

Plackett–Burman Design

Central Composite Design (CCD)

3. Results and Discussion

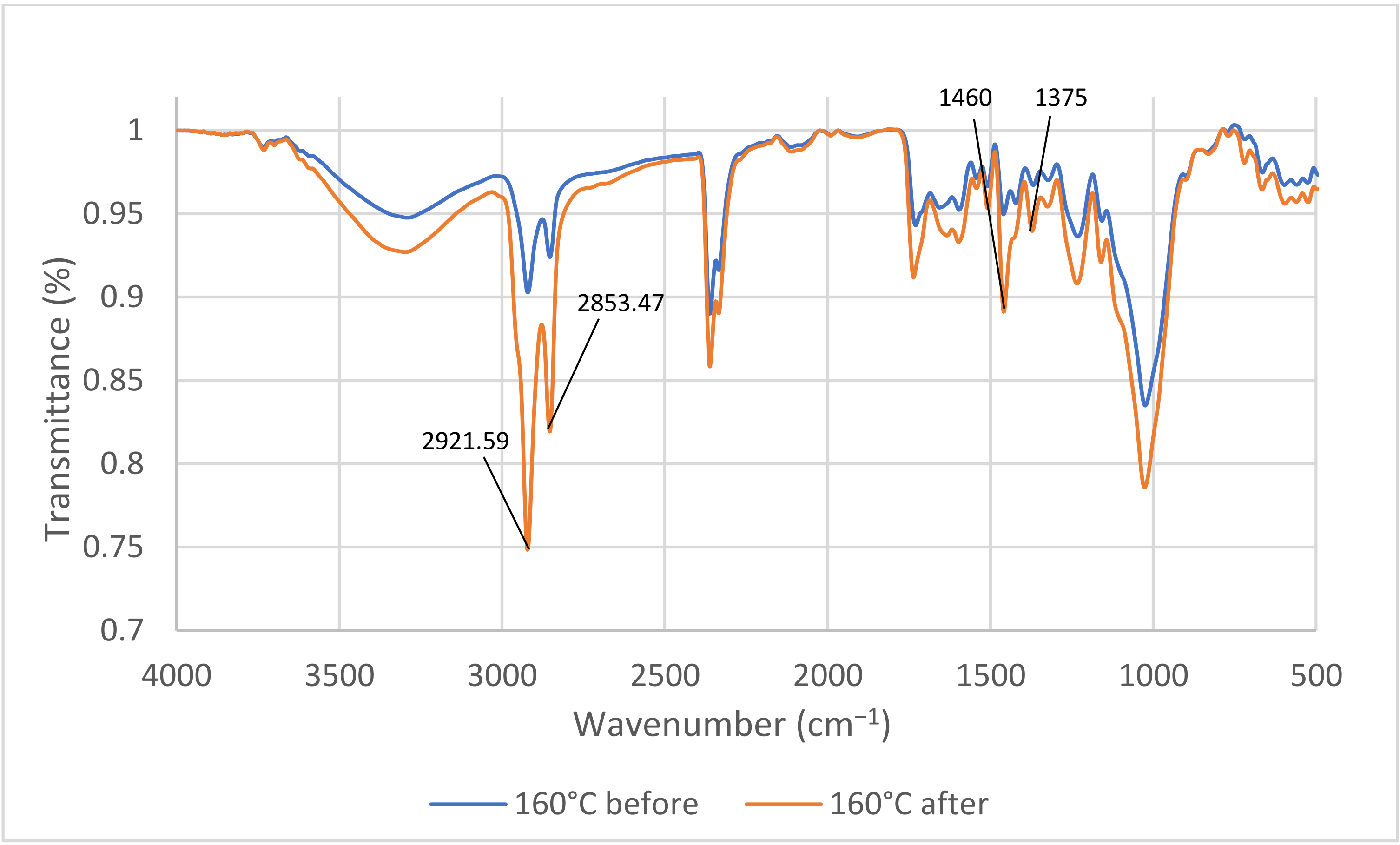

3.1. EFB Spikelets Profile

3.2. Optimisation of Oil Absorbed Using OFAT

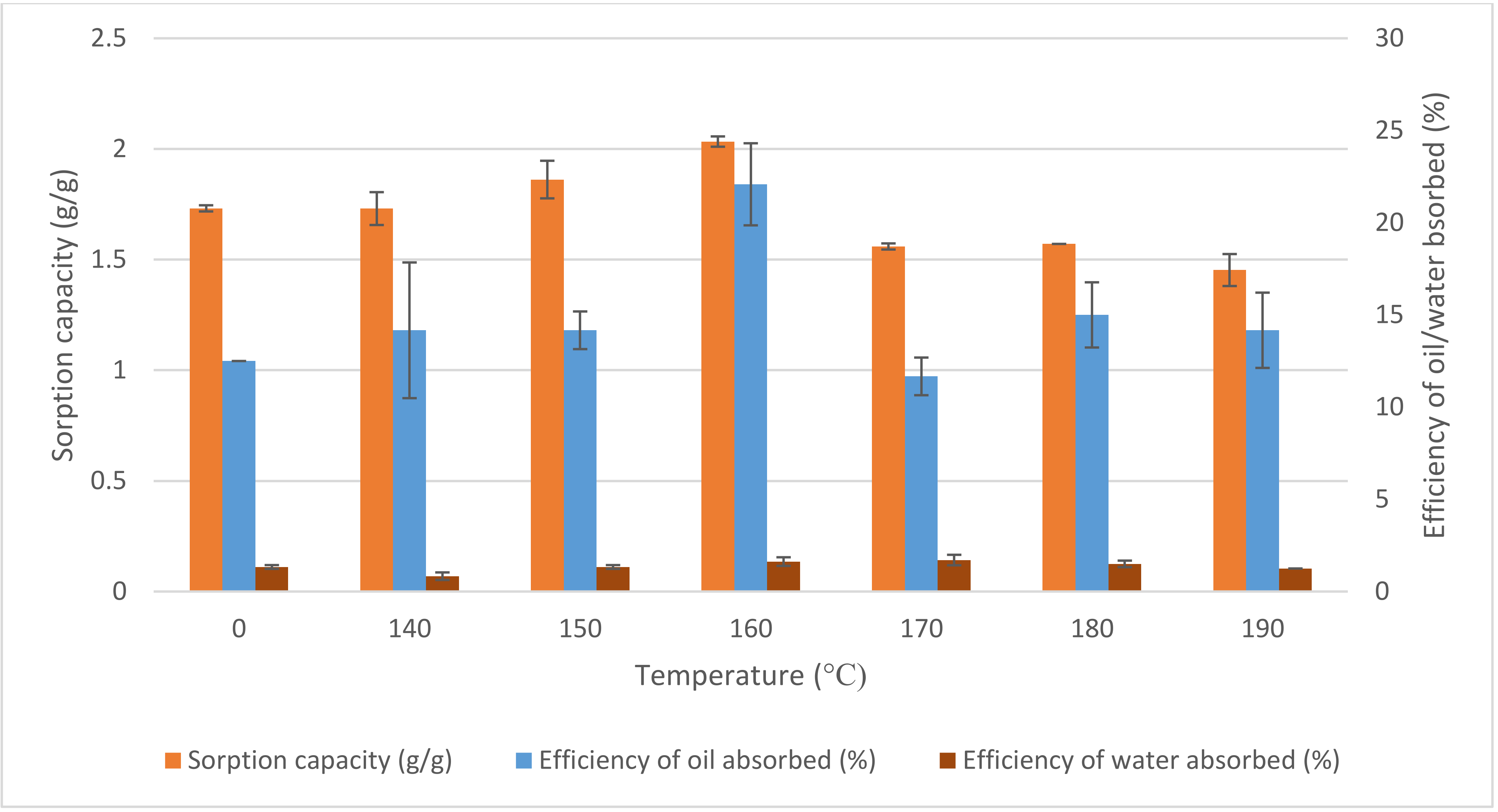

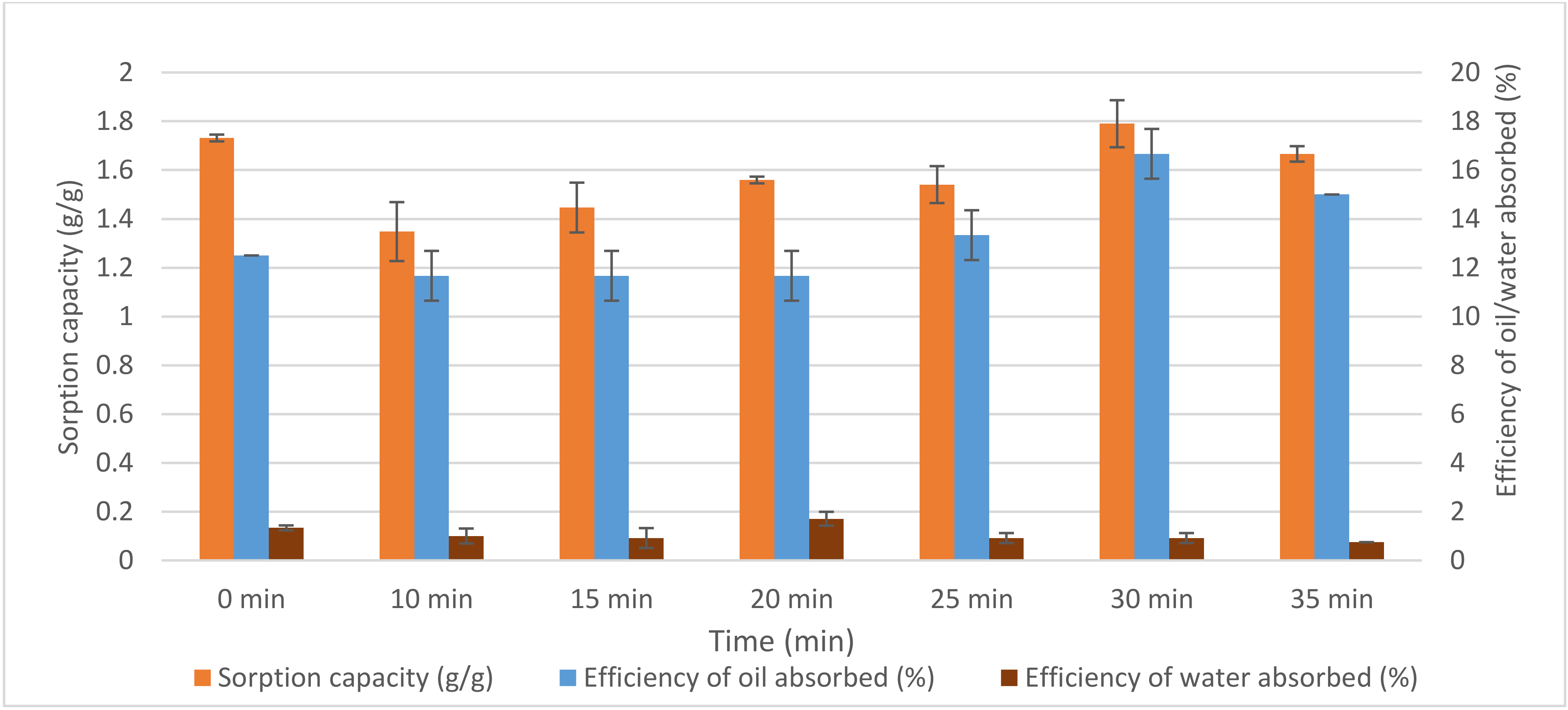

3.2.1. Effects of Temperature and Time on Treated EFB Spikelets

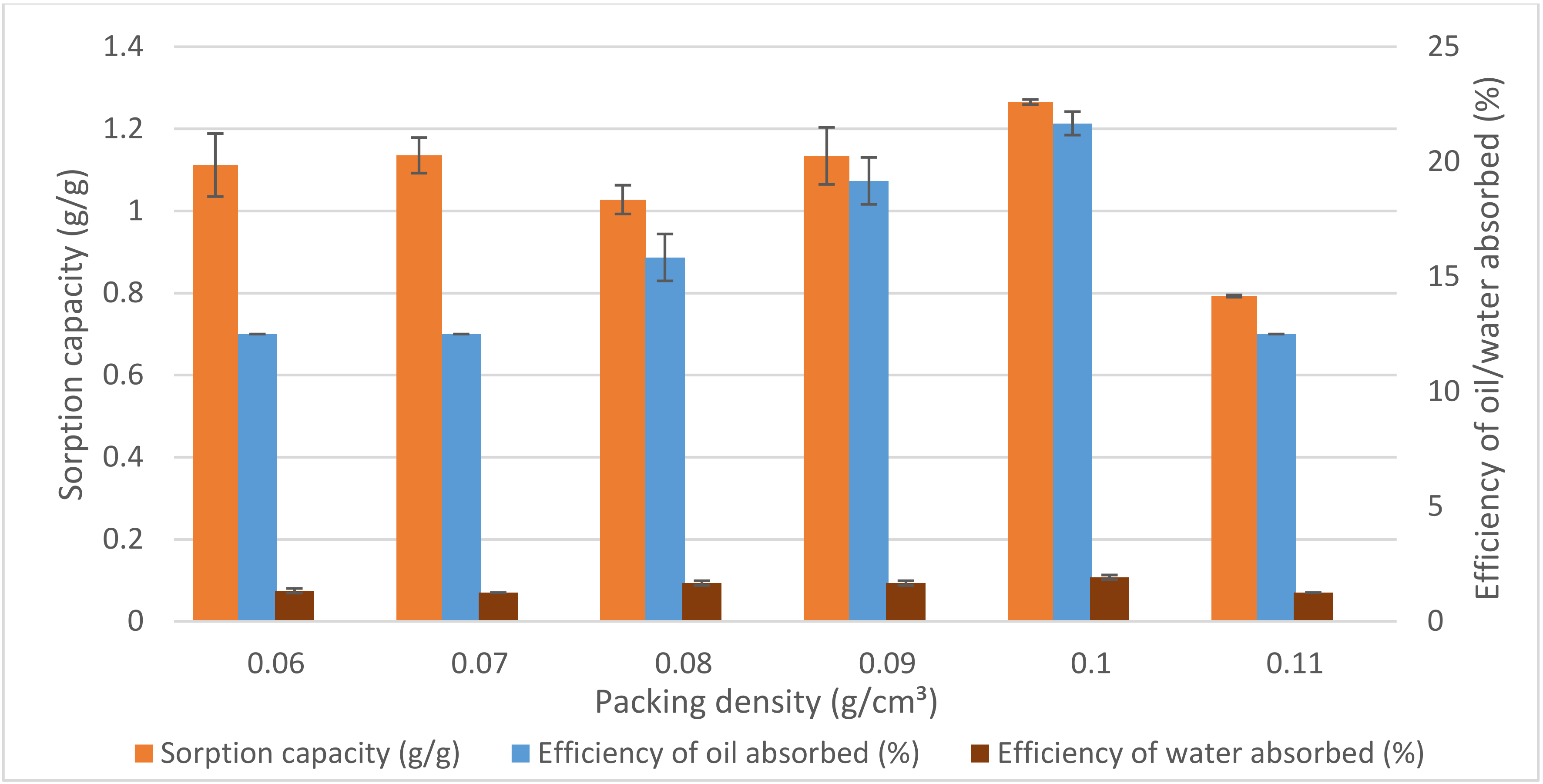

3.2.2. Effects of Packing Density on Treated EFB Spikelets

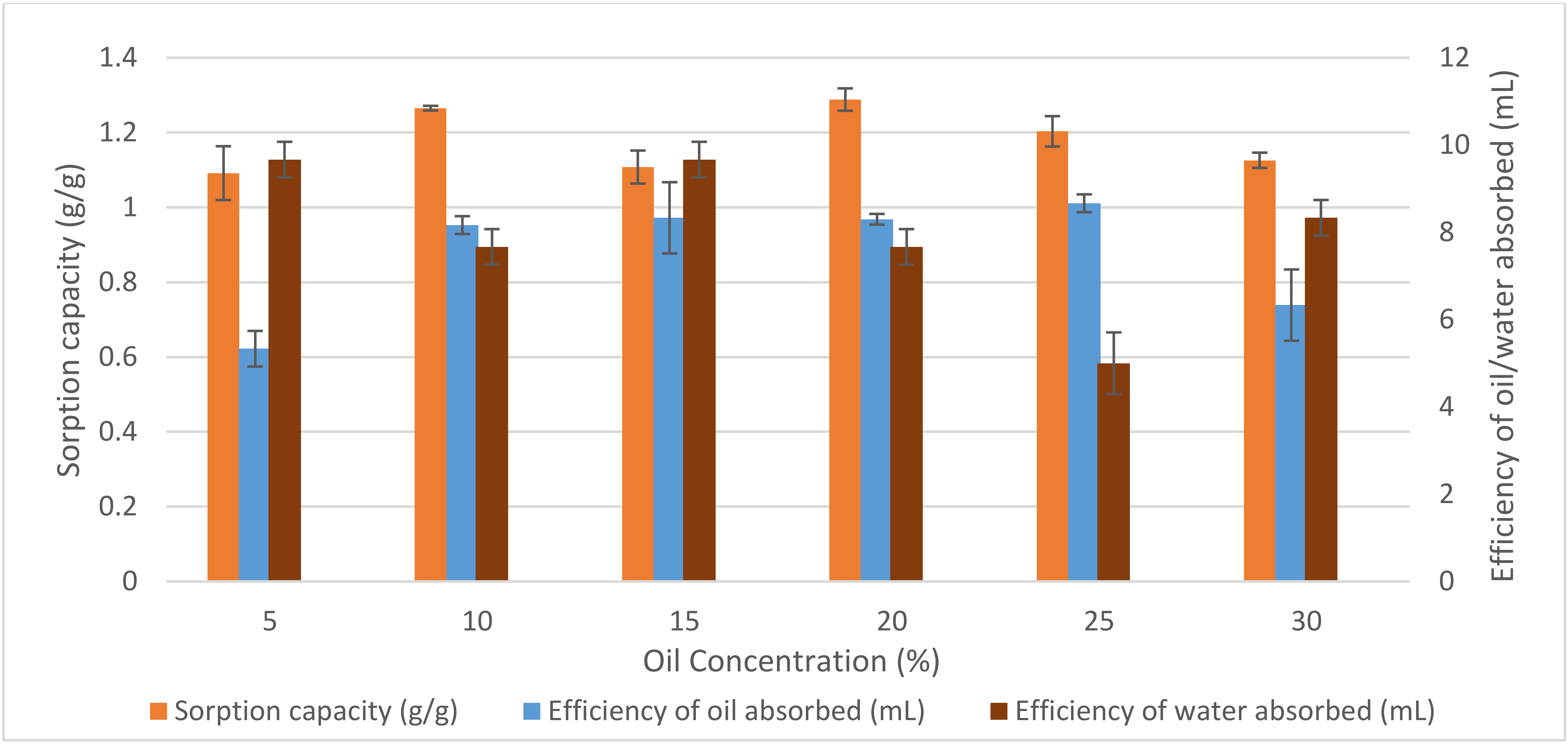

3.2.3. Effects of Oil Concentration on Treated EFB Spikelets

3.3. Optimisation of Oil Absorbed Using Response Surface Methodology (RSM)

3.3.1. Plackett–Burman Design

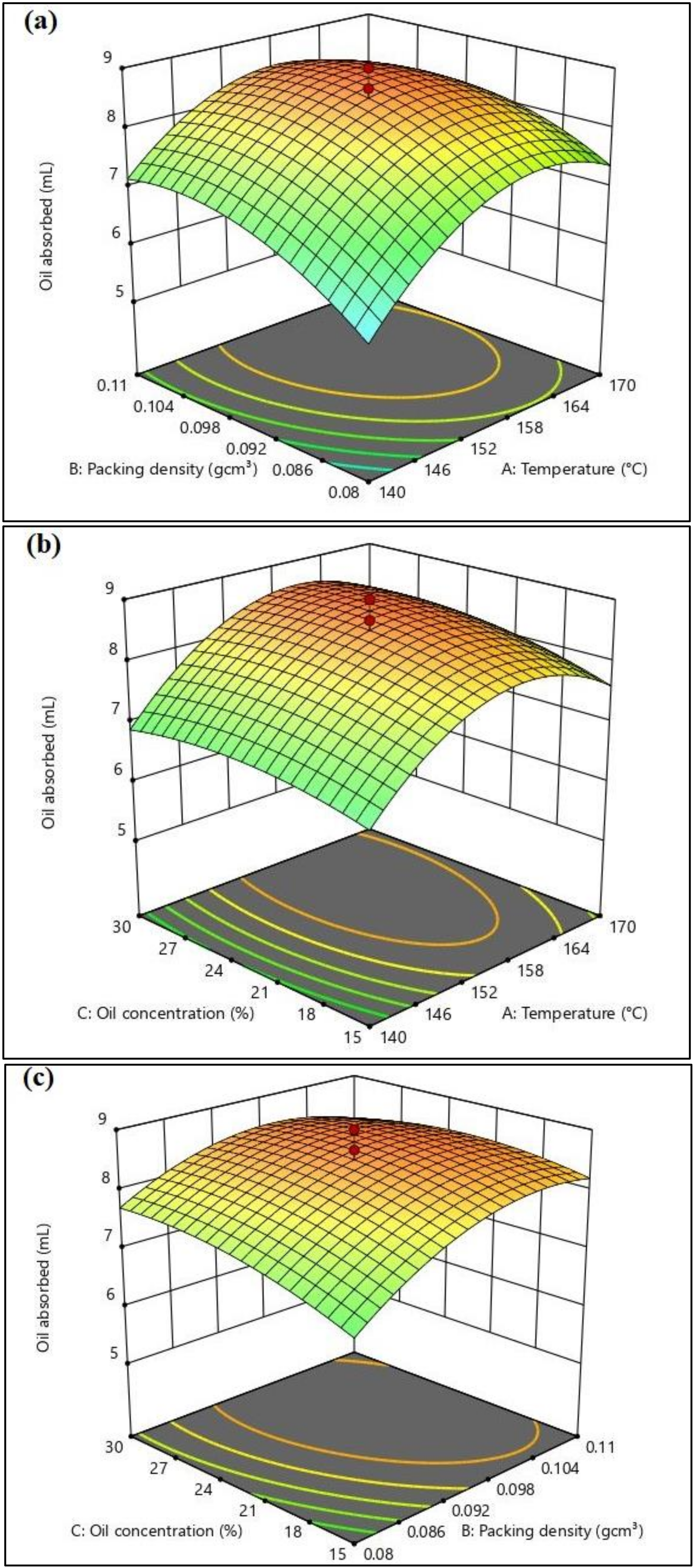

3.3.2. Central Composite Design (CCD)

3.3.3. Model Validation Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Errington, I.; King, C.K.; Wilkins, D.; Spedding, T.; Hose, G.C. Ecosystem effects and the management of petroleum-contaminated soils on sub-Antarctic islands. Chemosphere 2018, 194, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Nikkhah, A.A.; Zilouei, H.; Asadinezhad, A.; Keshavarz, A. Removal of oil from water using polyurethane foam modified with nanoclay. Chem. Eng. J. 2015, 262, 278–285. [Google Scholar] [CrossRef]

- Australia State of the Environment Report: Remediation and Re-Use of Soil from a Fuel Spill Near Lake. Available online: https://soe.environment.gov.au/case-study/antarctic-environment/box-ant8-remediation-and-re-use-soil-fuel-spill-near-lake-dingle (accessed on 17 May 2021).

- Lim, Z.S.; Wong, R.R.; Wong, C.; Zulkharnain, A.; Shaharuddin, N.A.; Ahmad, S.A. Bibliometric analysis of research on diesel pollution in Antarctica and a review on remediation techniques. Appl. Sci. 2021, 11, 1123. [Google Scholar] [CrossRef]

- Neuman, S. Oil Spill Reported off China Coast After Tanker, Bulk Carrier Collide. 2021. Available online: https://www.npr.org/2021/04/27/991144729/oil-spill-reported-off-china-coast-after-tanker-bulk-carrier-collide (accessed on 14 September 2021).

- Macoustra, G.K.; King, C.K.; Wasley, J.; Robinson, S.A.; Jolley, D.F. Impact of hydrocarbons from a diesel fuel on the germination and early growth of subantarctic plants. Environ. Sci. Process Impacts 2015, 17, 1238–1248. [Google Scholar] [CrossRef][Green Version]

- Verasoundarapandian, G.; Zakaria, N.N.; Shaharuddin, N.A.; Khalil, K.A.; Puasa, N.A.; Azmi, A.A.; Gomez-Fuentes, C.; Zulkharnain, A.; Wong, C.Y.; Rahman, M.F.; et al. Coco peat as agricultural waste sorbent for sustainable diesel-filter system. Plants 2021, 10, 2468. [Google Scholar] [CrossRef]

- Zamparas, M.; Tzivras, D.; Dracopoulos, V.; Ioannides, T. Application of Sorbents for Oil Spill Cleanup Focusing on Natural-Based Modified Materials: A Review. Molecules 2020, 25, 4522. [Google Scholar] [CrossRef]

- Cao, S.; Dong, T.; Xu, G.; Wang, F. Oil Spill Cleanup by Hydrophobic Natural Fibers. J. Nat. Fibers 2017, 14, 727–735. [Google Scholar] [CrossRef]

- Abdelwahab, O.; Nasr, S.M.; Thabet, W.M. Palm fibers and modified palm fibers adsorbents for different oils. Alex. Eng. J. 2017, 56, 749–755. [Google Scholar] [CrossRef]

- Taufik, S.H.; Ahmad, S.A.; Zakaria, N.N.; Shaharuddin, N.A.; Azmi, A.A.; Khalid, F.E.; Merican, F.; Convey, P.; Zulkharnain, A.; Abdul Khalil, K. Rice straw as a natural sorbent in a filter system as an approach to bioremediate diesel pollution. Water 2021, 13, 3317. [Google Scholar] [CrossRef]

- International Tanker Owners Pollution Federation Limited (ITOPF). Oil Tanker Spill Statistics 2019; International Tanker Owners Pollution Federation Limited (ITOPF): London, UK, 2020. [Google Scholar]

- Abdullah, N.; Sulaim, F. The Oil Palm Wastes in Malaysia. Biomass Now Sustain. Growth Use 2013, 1, 75–93. [Google Scholar] [CrossRef]

- Mba, O.I.; Dumont, M.; Ngadi, M. Palm oil: Processing, characterization and utilization in the food industry—A review. Food Biosc. 2015, 10, 26–41. [Google Scholar] [CrossRef]

- Thoe, J.M.; Surugau, N.; Chong, H.L. Application of Oil Palm Empty Fruit Bunch as Adsorbent: A Review. Trans. Sci. Technol. 2019, 6, 9–26. [Google Scholar] [CrossRef]

- Alam, F.A.S.A.; Begum, H. Malaysian oil palm industry: Prospect and problem. J. Food Agric. Environ. 2015, 13, 143–148. [Google Scholar]

- Elias, M.A.; Hadibarata, T.; Sathishkumar, P. Modified oil palm industry solid waste as a potential adsorbent for lead removal. Environ. Chem. Ecotoxicol. 2021, 3, 1–7. [Google Scholar] [CrossRef]

- Idris, S.S.; Rahman, N.A.; Ismail, K.; Alias, A.B.; Rashid, Z.A.; Aris, M.J. Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour. Technol. 2010, 101, 4584–4592. [Google Scholar] [CrossRef]

- Mohammed, M.A.A.; Salmiaton, A.; Wan Azlina, W.A.K.G.; Mohamad Amran, M.S. Gasification of oil palm empty fruit bunches: A characterisation and kinetic study. Bioresour. Technol. 2012, 110, 628–636. [Google Scholar] [CrossRef]

- Shariff, A.; Aziz, N.S.M.; Abdullah, N. Slow pyrolysis of oil palm empty fruit bunches for biochar production and characterisation. J. Phys. Sci. 2014, 25, 7–112. [Google Scholar]

- Abdullah, N.; Sulaiman, F. The thermal properties of the washed empty fruit bunches of oil palm. J. Phys. Sci. 2013, 24, 117–137. [Google Scholar]

- Hameed, B.H.; Tan, I.A.W.; Ahmad, A.L. Preparation of oil palm empty fruit bunch-based activated carbon for removal of 2,4,6-trichlorophenol: Optimisation using response surface methodology. J. Hazard. Mater. 2009, 164, 1316–1324. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Sreekala, M.S.; George, J.; Kumaran, M.G.; Thomas, S. Watersorption kinetics in oil palm fibers. J. Polym. Sci. 2001, 39, 1215–1223. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Ibrahim, S.; Baharuddin, S.N.I.B.; Ariffin, B.; Hanafiah, M.A.K.M.; Kantasamy, N. Cogon grass for oil sorption: Characterization and sorption studies. Key Eng. Mater. 2018, 775, 359–364. [Google Scholar] [CrossRef]

- Onwuka, J.C.; Agbaji, E.B.; Ajibola, V.O.; Okibe, F.G. Treatment of crude oil-contaminated water with chemically modified natural fiber. Appl. Water Sci. 2018, 8, 1–10. [Google Scholar] [CrossRef]

- Zakaria, N.N.; Gomez-Fuentes, C.; Abdul Khalil, K.; Convey, P.; Roslee, A.F.A.; Zulkharnain, A.; Sabri, S.; Shaharuddin, N.A.; Cardenas, L.; Ahmad, S.A. Statistical optimisation of diesel biodegradation at low temperatures by an Antarctic marine bacterial consortium isolated from non-contaminated seawater. Microorganisms 2021, 9, 1213. [Google Scholar] [CrossRef]

- Haron, M.J.; Tiansih, M.; Ibrahim, N.A.; Kassim, A.; Wan Yunus, W.M.Z. Sorption of cu(II) by polyhydroxamic acid chelating exchanger prepared from polymethyl acrylate grafted oil palm empty fruit bunch (OPEFB). Bioresources 2009, 4, 1305–1318. [Google Scholar]

- Johari, I.S.; Yusof, N.A.; Haron, M.J.; Mohd Nor, S.M. Preparation and characterization of polyethyl hydrazide grafted oil palm empty fruit bunch for removal of Ni(II) ion in aqueous environment. Polymers 2013, 5, 1056–1067. [Google Scholar] [CrossRef]

- Xiao, X.; Bian, J.; Li, M.F.; Xu, H.; Xiao, B.; Sun, R.C. Enhanced enzymatic hydrolysis of bamboo (Dendrocalamus gigantus munro) culm by hydrothermal pretreatment. Biores. Technol. 2014, 159, 41–47. [Google Scholar] [CrossRef]

- Hao, Y.; Pan, Y.; Du, R.; Wang, Y.; Chen, Z.; Zhang, X.; Wang, X. The influence of a thermal treatment on the decay resistance of wood via FTIR Analysis. Adv. Mater. Sci. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Rosli, N.S.; Harun, S.; Jahim, J.M.; Othaman, R. Chemical and physical characterization of oil palm empty fruit bunch. Malays. J. Anal. Sci. 2017, 21, 188–196. [Google Scholar] [CrossRef]

- Ahmad, I.; Sohail, S.M.; Khan, H.; Khan, R.; Ahmad, W. Characterization of petroleum crude oils by Fourier transform infrared (FT-IR) and Gas Chromatography-Mass Spectrometerys. J. Pet. Sci. Eng. 2018, 2, 1–7. [Google Scholar] [CrossRef]

- Ibrahim, S.; Ha-Ming, A.; Wang, S. Removal of emulsifed food and mineral oils from wastewater using surfactant modifed barley straw. Biores. Technol. 2009, 100, 5744–5749. [Google Scholar] [CrossRef] [PubMed]

- Isroi, C.A.; Panji, T.; Wibowo, N.A.; Syamsu, K. Bioplastic production from cellulose of oil palm empty fruit bunch. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012011. [Google Scholar] [CrossRef]

- Puasa, N.A.; Ahmad, S.A.; Zakaria, N.N.; Khalil, K.A.; Taufik, S.H.; Zulkharnain, A.; Azmi, A.A.; Gomez-Fuentes, C.; Wong, C.-Y.; Shaharuddin, N.A. Oil palm’s empty fruit bunch as a sorbent material in filter system for oil-spill clean up. Plants 2022, 11, 127. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, R.; Hamid, R.; Osman, S.A. Physical and chemical modifications of plant fibres for reinforcement in cementitious composites. Adv. Civ. Eng. 2019, 2019, 1–18. [Google Scholar] [CrossRef]

- Khalid, F.E.; Ahmad, S.A.; Zakaria, N.N.; Shaharuddin, N.A.; Sabri, S.; Azmi, A.A.; Khalil, K.A.; Verasoundarapandian, G.; Gomez-Fuentes, C.; Zulkharnain, A. Application of cogon grass (Imperata cylindrica) as Biosorbent in diesel-filter system for oil spill removal. Agronomy 2021, 11, 2273. [Google Scholar] [CrossRef]

- Husseien, M.; Amer, A.A.; El-Maghraby, A.; Taha, N.A. Experimental investigation of thermal modification influence on sorption qualities of barley straw. J. Appl. Sci. Res. 2008, 4, 652–657. [Google Scholar]

- Kudaybergenov, K.K.; Ongarbayev, E.K.; Mansurov, Z.A. Thermally treated rice husks for petroleum adsorption. Int. J. Biol. Chem. 2012, 1, 3–12. [Google Scholar]

- Kudaybergenov, K.K.; Ongarbayev, E.K.; Mansurov, Z.A. Carbonaceous composites from agricultural wastes for adsorption of hydrocarbon contamination in water. Eurasian Chem. J. 2010, 12, 151. [Google Scholar] [CrossRef]

- Sreekumar, P.A.; Thomas, S.P.; Saiter, J.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1777–1784. [Google Scholar] [CrossRef]

- George, J.; Bhagawan, S.S.; Thomas, S. Effects of Environment on the Properties of Low-Density Polyethylene Composites Reinforced with Pineapple-Leaf Fibre. Compos. Sci. Technol. 1998, 58, 1471–1485. [Google Scholar] [CrossRef]

- El Gheriany, I.A.; Ahmad El Saqa, F.; Abd El Razek Amer, A.; Hussein, M. Oil spill sorption capacity of raw and thermally modified orange peel waste. Alex. Eng. J. 2020, 59, 925–932. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Wang, A. Effect of kapok fiber treated with various solvents on oil absorbency. Ind. Crops Prod. 2012, 40, 178–184. [Google Scholar] [CrossRef]

- Reneta Nafu, Y.; Foba-Tendo, J.; Njeugna, E.; Oliver, G.; Omar Cooke, K. Extraction and characterization of fibres from the stalk and spikelets of empty fruit bunch. J. Appl. Chem. 2015, 2015, 750818. [Google Scholar] [CrossRef]

- Xu, Y.; Shen, H.; Xu, G. Evaluation of oil sorption kinetics behavior and wetting characteristic of cattail fiber. Cellulose 2019, 27, 1531–1541. [Google Scholar] [CrossRef]

- Abel, U.A.; Habor, G.R.; Oseribho, O.I. Adsorption studies of oil spill clean-up using coconut coir activated carbon (CCAC). Am. J. Chem. Eng. 2020, 8, 36. [Google Scholar] [CrossRef]

- Zhu, L.; Perwuelz, A.; Lewandowski, M.; Campagne, C. Static and dynamic aspects of liquid capillary flow in thermally bonded polyester nonwoven fabrics. J. Adhes. Sci. Technol. 2008, 22, 745–760. [Google Scholar]

- Thompson, N.E.; Emmanuel, G.C.; Adagadzu, K.J.; Yusuf, N.B. Sorption studies of crude oil on acetylated rice husks. Arch. Appl. Sci. Res. 2010, 2, 142–151. [Google Scholar]

| Variables | Code | Unit | Experimental Range | |

|---|---|---|---|---|

| Low (−1) | High (+1) | |||

| Temperature | A | °C | 140 | 170 |

| Time | B | min | 20 | 35 |

| Packing density | C | g/cm3 | 0.08 | 0.11 |

| Oil concentration | D | % (v/v) | 15 | 30 |

| Symbol | Unit | Experimental Values | |||||

|---|---|---|---|---|---|---|---|

| −2 | −1 | 0 | +1 | +2 | |||

| Temperature | A | °C | 129.773 | 140 | 155 | 170 | 180.227 |

| Packing density | B | g/cm3 | 0.069773 | 0.08 | 0.095 | 0.11 | 0.120227 |

| Oil concentration | C | % (v/v) | 9.88655 | 15 | 22.5 | 30 | 35.1134 |

| Run | A | B | C | D | Oil Absorbed | Water Absorbed |

|---|---|---|---|---|---|---|

| 1 | 140 | 20 | 0.11 | 15 | 8 | 8 |

| 2 | 155 | 27.5 | 0.095 | 22.5 | 9.06667 | 5 |

| 3 | 140 | 35 | 0.11 | 30 | 9.33333 | 5.33333 |

| 4 | 155 | 27.5 | 0.095 | 22.5 | 9.16667 | 5.33333 |

| 5 | 155 | 27.5 | 0.095 | 22.5 | 9 | 5 |

| 6 | 140 | 35 | 0.11 | 15 | 8.3333 | 9.3333 |

| 7 | 155 | 27.5 | 0.095 | 22.5 | 9.33333 | 5 |

| 8 | 170 | 20 | 0.11 | 30 | 10.6667 | 5.33333 |

| 9 | 140 | 35 | 0.08 | 30 | 8 | 6 |

| 10 | 155 | 27.5 | 0.095 | 22.5 | 9.06667 | 5.33333 |

| 11 | 140 | 20 | 0.08 | 15 | 7.66667 | 6.33333 |

| 12 | 140 | 20 | 0.08 | 30 | 7.66667 | 5.33333 |

| 13 | 170 | 35 | 0.08 | 30 | 9.83333 | 4.33333 |

| 14 | 155 | 27.5 | 0.095 | 22.5 | 10 | 5 |

| 15 | 170 | 35 | 0.08 | 15 | 8 | 6 |

| 16 | 170 | 20 | 0.11 | 30 | 10.3333 | 5.16667 |

| 17 | 170 | 35 | 0.11 | 15 | 9 | 9.66667 |

| 18 | 170 | 20 | 0.08 | 15 | 9 | 7 |

| Source | Sum of Squares | DF | Mean Square | F Value | p Value |

|---|---|---|---|---|---|

| Model | 10.53 | 4 | 2.63 | 14.72 | 0.0001 |

| A | 5.11 | 1 | 5.11 | 28.60 | 0.0002 |

| B | 0.0579 | 1 | 0.0579 | 0.3237 | 0.5799 |

| C | 2.52 | 1 | 2.52 | 14.10 | 0.0027 |

| D | 2.84 | 1 | 2.84 | 15.86 | 0.0018 |

| Residual | 2.15 | 12 | 0.1788 | ||

| Cor Total | 13.49 | 17 | |||

| Std. Dev. | 0.4228 | R2 | 0.8307 | ||

| Mean | 8.97 | Adjusted R2 | 0.7743 | ||

| C.V. | 4.71 | Predicted R2 | 0.5857 | ||

| Adequate Precision | 13.0860 |

| Run Order | A | B | C | Oil Absorbed (mL) | |

|---|---|---|---|---|---|

| Experimental Value | Predicted Value | ||||

| 1 | 155 | 0.095 | 22.5 | 8.5 | 5 |

| 2 | 129.773 | 0.095 | 22.5 | 5 | 6 |

| 3 | 140 | 0.11 | 30 | 6.33333 | 6.66667 |

| 4 | 140 | 0.08 | 15 | 5.33333 | 3.33333 |

| 5 | 140 | 0.11 | 15 | 7.33333 | 6 |

| 6 | 155 | 0.095 | 22.5 | 8.33333 | 4 |

| 7 | 155 | 0.0697731 | 22.5 | 6.33333 | 2.66667 |

| 8 | 155 | 0.120227 | 22.5 | 8 | 9 |

| 9 | 170 | 0.08 | 15 | 7 | 7.33333 |

| 10 | 155 | 0.095 | 22.5 | 8.33333 | 5.16667 |

| 11 | 170 | 0.08 | 30 | 7.16667 | 5 |

| 12 | 155 | 0.095 | 22.5 | 8.66667 | 4.33333 |

| 13 | 155 | 0.095 | 9.88655 | 7.22667 | 7.77333 |

| 14 | 155 | 0.095 | 22.5 | 8.16667 | 4.5 |

| 15 | 170 | 0.11 | 30 | 7.66667 | 5.33333 |

| 16 | 155 | 0.095 | 22.5 | 9 | 5 |

| 17 | 140 | 0.08 | 30 | 6 | 4.83333 |

| 18 | 170 | 0.11 | 15 | 7.33333 | 7.66667 |

| 19 | 155 | 0.095 | 35.1134 | 8.66667 | 8.83333 |

| 20 | 180.227 | 0.095 | 22.5 | 7 | 5.33333 |

| Source | Sum of Squares | df | Mean Square | F-value | p Value | |

|---|---|---|---|---|---|---|

| Model | 22.83 | 9 | 2.54 | 16.19 | <0.0001 | significant |

| A | 4.15 | 1 | 4.15 | 26.50 | 0.0004 | |

| B | 2.61 | 1 | 2.61 | 16.66 | 0.0022 | |

| C | 0.4906 | 1 | 0.4906 | 3.13 | 0.1072 | |

| AB | 0.2813 | 1 | 0.2813 | 1.80 | 0.2099 | |

| AC | 0.0868 | 1 | 0.0868 | 0.5541 | 0.4738 | |

| BC | 0.2813 | 1 | 0.2813 | 1.80 | 0.2099 | |

| A2 | 12.24 | 1 | 12.24 | 78.11 | <0.0001 | |

| B2 | 3.73 | 1 | 3.73 | 23.83 | 0.0006 | |

| C2 | 0.7840 | 1 | 0.7840 | 5.00 | 0.0492 | |

| Residual | 1.57 | 10 | 0.1567 | |||

| Lack of Fit | 1.12 | 5 | 0.2244 | 2.53 | 0.1662 | not significant |

| Pure Error | 0.4444 | 5 | 0.0889 | |||

| Cor Total | 24.40 | 19 | ||||

| R2 | 0.9358 | |||||

| Std. Dev. | 0.3958 | Adjusted R2 | 0.8780 | |||

| Mean | 7.37 | Predicted R2 | 0.5975 | |||

| C.V.% | 5.37 | Adequate Precision | 12.6257 | |||

| Optimised Parameters | Predicted OFAT | Predicted RSM | Experimental RSM |

|---|---|---|---|

| Temperature (°C) | 160 | 159.660 | 159.660 |

| Packing density (g/cm3) | 0.1 | 0.098 | 0.098 |

| Oil concentration (%) | 25 | 26.998 | 26.998 |

| Oil absorbed (mL) | 8.667 | 8.805 | 9 |

| Water absorbed (mL) | 5 | 5.213 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puasa, N.A.; Ahmad, S.A.; Zakaria, N.N.; Shaharuddin, N.A.; Khalil, K.A.; Azmi, A.A.; Gomez-Fuentes, C.; Merican, F.; Zulkharnain, A.; Kok, Y.-Y.; et al. Utilisation of Oil Palm’s Empty Fruit Bunch Spikelets for Oil-Spill Removal. Agronomy 2022, 12, 535. https://doi.org/10.3390/agronomy12020535

Puasa NA, Ahmad SA, Zakaria NN, Shaharuddin NA, Khalil KA, Azmi AA, Gomez-Fuentes C, Merican F, Zulkharnain A, Kok Y-Y, et al. Utilisation of Oil Palm’s Empty Fruit Bunch Spikelets for Oil-Spill Removal. Agronomy. 2022; 12(2):535. https://doi.org/10.3390/agronomy12020535

Chicago/Turabian StylePuasa, Nurul Aini, Siti Aqlima Ahmad, Nur Nadhirah Zakaria, Noor Azmi Shaharuddin, Khalilah Abdul Khalil, Alyza Azzura Azmi, Claudio Gomez-Fuentes, Faradina Merican, Azham Zulkharnain, Yih-Yih Kok, and et al. 2022. "Utilisation of Oil Palm’s Empty Fruit Bunch Spikelets for Oil-Spill Removal" Agronomy 12, no. 2: 535. https://doi.org/10.3390/agronomy12020535

APA StylePuasa, N. A., Ahmad, S. A., Zakaria, N. N., Shaharuddin, N. A., Khalil, K. A., Azmi, A. A., Gomez-Fuentes, C., Merican, F., Zulkharnain, A., Kok, Y.-Y., & Wong, C.-Y. (2022). Utilisation of Oil Palm’s Empty Fruit Bunch Spikelets for Oil-Spill Removal. Agronomy, 12(2), 535. https://doi.org/10.3390/agronomy12020535