Study on the Relationship between Fermentation-Accumulated Temperature and Nutrient Loss of Whole-Plant Corn Silage

Abstract

1. Introduction

2. Materials and Methods

2.1. Ensiling Conditions

2.2. Chemical Composition and Fermentation Profile Detection

2.3. Statistical Analysis

3. Results

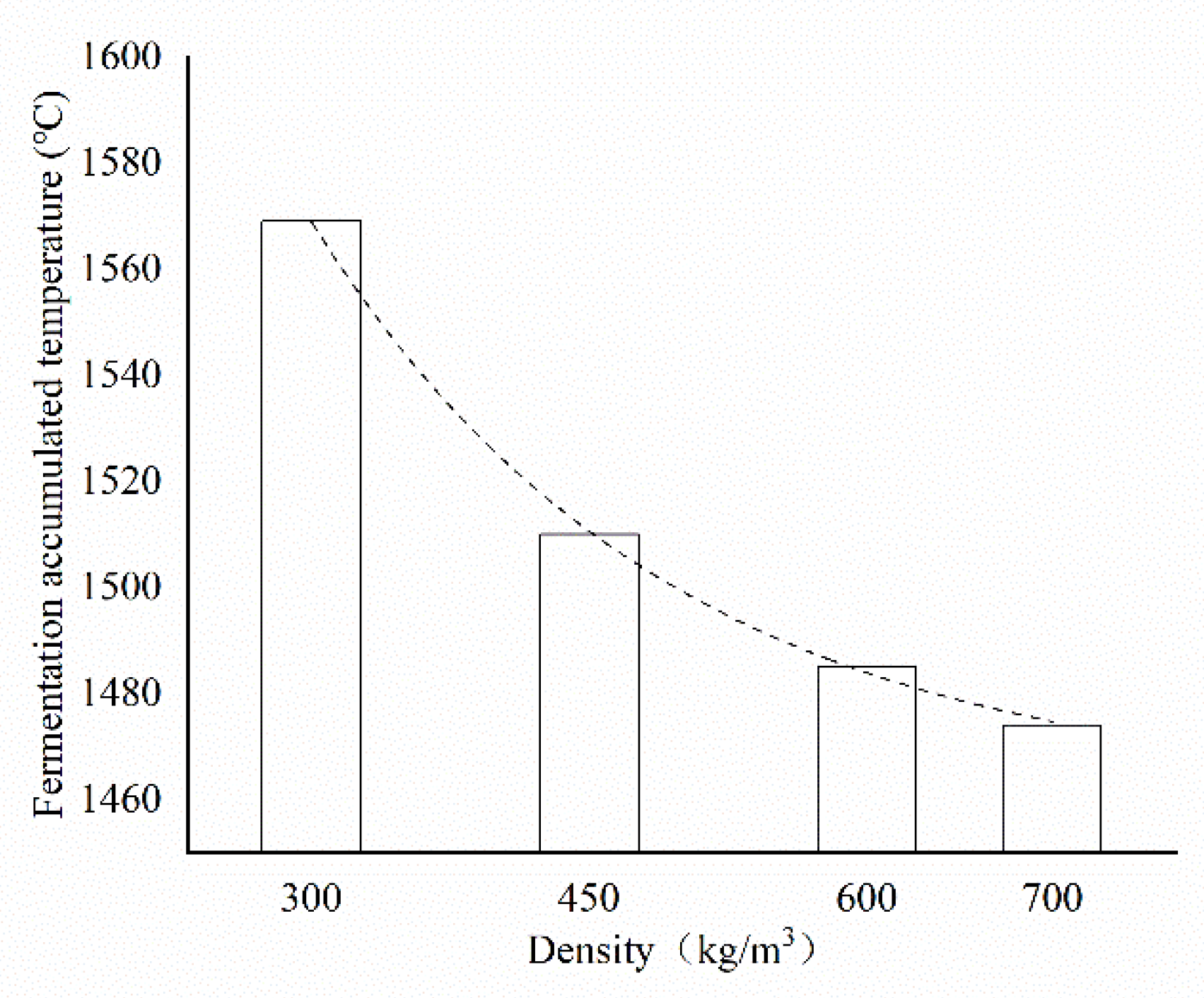

3.1. Comparison of Fermentation Temperature of Whole-Plant Corn Silage under Different Compaction Density

3.2. Changes in Fermentation Accumulated Temperature of Whole-Plant Corn Silage under Different Compaction Densities

3.3. Correlation Analysis of Various Indexes of Whole-Plant Corn Silage

3.4. Comparison of Nutritional Components of Whole-Plant Corn Silage under Different Compaction Density

3.5. Comparison of Fermentation Quality of Whole-Plant Corn Silage under Different Compaction Density

3.6. Correlation between Fermentation Accumulated Temperature and Nutritional Quality of Whole-Plant Corn Silage with Different Compaction Density

3.7. Correlation between Fermentation-Accumulated Temperature and Fermentation Quality of Whole-Plant Corn Silage with Different Compaction Density

3.8. Multiple Linear Regression Analysis of the Relationship between Accumulated Temperature, Compaction Density, Nutrition, and Fermentation Loss

4. Discussion

4.1. Effect of Compaction Density on the Accumulated Temperature of Whole-Plant Corn Silage Fermentation

4.2. Effect of Compaction Density on the Nutritional Quality of Whole-Plant Corn Silage

4.3. Effect of Compaction Density on Fermentation Quality of Whole-Plant Corn Silage

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, S.; Hoffmann, T. Metrological prerequisites for determination of silage density compacted in a bunker silo using a radiometric method. Agric. Eng. Int. CIGR J. 2012, 14, 134–143. [Google Scholar]

- Tavares, V.; Pinto, J.; Ricardo, E.; Figueiredo, H.; Ávila, C. Effects of different compaction degrees, inclusion of absorbent additive and wilting on the chemical composition of tanzania grass silages. Rev. Bras. De Zootec. 2009, 38, 40–49. [Google Scholar] [CrossRef][Green Version]

- Weiss, K.; Kroschewski, B.; Auerbach, H. Effects of air exposure, temperature and additives on fermentation characteristics, yeast count, aerobic stability and volatile organic compounds in corn silage. J. Dairy Sci. 2016, 99, 8053–8069. [Google Scholar] [CrossRef] [PubMed]

- Teixeira Franco, R.; Buffière, P.; Bayard, R. Ensiling for biogas production: Critical parameters. A review. Biomass Bioenergy 2016, 94, 94–104. [Google Scholar] [CrossRef]

- Gallo, A.; Giuberti, G.; Bruschi, S.; Fortunati, P.; Masoero, F. Use of principal factor analysis to generate a corn silage fermentative quality index to rank well- or poorly preserved forages. J. Sci. Food Agric. 2016, 96, 1686–1696. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.Y.; Che, X.R.; Chen, Y.Q.; He, Y.H.; Li, W.L. Feed Analysis and Quality Test Technology; China Agricultural University Press: Beijing, China, 2016. [Google Scholar]

- Murphy, R.P. A method for the extraction of plant samples and the determination of total soluble carbohydrates. J. Sci. Food Agric. 1958, 9, 714–717. [Google Scholar] [CrossRef]

- Ma, J.J.; Wang, J.Y.; Zhang, L.M.; Wang, S.X.; Huang, B.S.; Sun, Y.Z. Determination of the content of total starch in feed by colorimetric method with 3,5-dinitrosalicylic acid. China Feed 2010, 14, 38–40. [Google Scholar]

- Yuan, X.J.; Wen, A.Y.; Wang, J.; Desta, S.T.; Dong, Z.H.; Shao, T. Effects of four short-chain fatty acids or salts on fermentation characteristics and aerobic stability of alfalfa (Medicago sativa L.) silage. J. Sci. Food Agric. 2018, 98, 328–335. [Google Scholar] [CrossRef]

- Kim, S.C.; Adesogan, A.T. Influence of Ensiling Temperature, Simulated Rainfall, and Delayed Sealing on Fermentation Characteristics and Aerobic Stability of Corn Silage. J. Dairy Sci. 2006, 89, 3122–3132. [Google Scholar] [CrossRef]

- Guan, H.; Shuai, Y.; Yan, Y.; Ran, Q.; Wang, X.; Li, D.; Cai, Y.; Zhang, X. Microbial Community and FermentationDynamics of Corn Silage Prepared withHeat-Resistant Lactic Acid Bacteria in a HotEnvironment. Microorganisms 2020, 8, E719. [Google Scholar] [CrossRef]

- Gerlach, K.; Roß, F.; Weiß, K.; Buescher, W.; Südekum, K.-H. Aerobic exposure of grass silages and its impact on dry matter intake and preference by goats. Small Rumin. Res. 2014, 117, 131–141. [Google Scholar] [CrossRef]

- Guyader, J.; Baron, V.S.; Beauchemin, K.A. Corn Forage Yield and Quality for Silage in Short Growing Season Areas of the Canadian Prairies. Agronomy 2018, 8, 164. [Google Scholar] [CrossRef]

- Taylor, C.C.; Kung, L. The Effect of Lactobacillus buchneri 40788 on the Fermentation and Aerobic Stability of High Moisture Corn in Laboratory Silos1. J. Dairy Sci. 2002, 85, 1526–1532. [Google Scholar] [CrossRef]

- Hu, W.; Schmidt, R.J.; McDonell, E.E.; Klingerman, C.M.; Kung, L. The effect of Lactobacillus buchneri 40788 or Lactobacillus plantarum MTD-1 on the fermentation and aerobic stability of corn silages ensiled at two dry matter contents. J. Dairy Sci. 2009, 92, 3907–3914. [Google Scholar] [CrossRef] [PubMed]

- Moselhy, M.A.; Borba, J.P.; Borba, A.E.S. Improving the nutritive value, in vitro digestibility and aerobic stability of Hedychium gardnerianum silage through application of additives at ensiling time. Anim. Feed Sci. Technol. 2015, 206, 8–18. [Google Scholar] [CrossRef]

- Queiroz, O.C.M.; Arriola, K.G.; Daniel, J.L.P.; Adesogan, A.T. Effects of 8 chemical and bacterial additives on the quality of corn silage. J. Dairy Sci. 2013, 96, 5836–5843. [Google Scholar] [CrossRef] [PubMed]

- Wambacq, E.; Vanhoutte, I.; Audenaert, K.; Gelder, L.; Haesaert, G. Occurrence, prevention and remediation of toxigenic fungi and mycotoxins in silage: A review. J. Sci. Food Agric. 2015, 96, 2284–2302. [Google Scholar] [CrossRef]

- Kung, L.; Taylor, C.C.; Lynch, M.P.; Neylon, J.M. The effect of treating alfalfa with Lactobacillus buchneri 40788 on silage fermentation, aerobic stability, and nutritive value for lactating dairy cows. J. Dairy Sci. 2003, 86, 336–343. [Google Scholar] [CrossRef]

- Krüger, A.; de Mello Tavares Lima, P.; Abdalla Filho, A.; Moro, J.; Carvalho, I.; Abdalla, A.; Jobim, C. Dry matter concentration and corn silage density: Effects on forage quality. Trop. Grassl. Trop. 2020, 8, 20–27. [Google Scholar] [CrossRef]

- Guo, X.S.; Ke, W.C.; Ding, W.R.; Ding, L.M.; Xu, D.M.; Wang, W.W.; Zhang, P.; Yang, F.Y. Profiling of metabolome and bacterial community dynamics in ensiled Medicago sativa inoculated without or with Lactobacillus plantarum or Lactobacillus buchneri. Sci. Rep. 2018, 8, 357. [Google Scholar] [CrossRef]

- Pahlow, G.; Muck, R.; Driehuis, F.; Oude Elferink, S.; Spoelstra, S.F. Microbiology of Ensiling. Silage Sci. Technol. 2003, 42, 31–93. [Google Scholar]

- Shao, T.; Ohba, N.; Shimojo, M.; Masuda, Y. Dynamics of Early Fermentation of Italian Ryegrass (Lolium multiflorum Lam.)Silage. Asian-Australas. J. Anim. Sci. 2002, 15, 1606–1610. [Google Scholar] [CrossRef]

- Kung, L.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. J. Dairy Sci. 2018, 101, 4020–4033. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, X.; Zhao, M.; Yu, Z. Lactic acid bacteria strains for enhancing the fermentation quality and aerobic stability of Leymus chinensis silage. Grass Forage Sci. 2016, 71, 472–481. [Google Scholar] [CrossRef]

- Keshri, J.; Chen, Y.; Pinto, R.; Kroupitski, Y.; Weinberg, Z.; Sela, S. Microbiome dynamics during ensiling of corn with and without Lactobacillus plantarum inoculant. Appl. Microbiol. Biotechnol. 2018, 102, 4025–4037. [Google Scholar] [CrossRef] [PubMed]

- Dogi, C.; Pellegrino, M.; Poloni, V.; Poloni, L.; Pereyra, C.; Sanabria, A.; Pianzzola, M.; Dalcero, A.; Cavaglieri, L. Efficacy of corn silage inoculants on the fermentation quality under farm conditions and their influence on Aspergillus parasitucus, A. flavus and A. fumigatus determined by q-PCR. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess 2014, 32, 229–235. [Google Scholar] [CrossRef]

- Zheng, Y.; Yu, C.; Cheng, Y.-S.; Lee, C.; Simmons, C.W.; Dooley, T.M.; Zhang, R.; Jenkins, B.M.; VanderGheynst, J.S. Integrating sugar beet pulp storage, hydrolysis and fermentation for fuel ethanol production. Appl. Energy 2012, 93, 168–175. [Google Scholar] [CrossRef]

| Parameters | Value (%) |

|---|---|

| Dry matter (%) | 29.13 |

| Crude protein (%) | 8.05 |

| Acidic detergent insoluble proteins (%) | 0.57 |

| Neutral detergent insoluble proteins (%) | 1.02 |

| Crude fiber (%) | 21.19 |

| Acid detergent fiber (%) | 24.82 |

| Neutral detergent fiber (%) | 40.87 |

| Lignin (%) | 2.29 |

| Ash (%) | 4.84 |

| Fat (%) | 2.82 |

| Starch (%) | 29.33 |

| Water Soluble Carbohydrate (%) | 12.25 |

| Monosaccharide (%) | 7.52 |

| Lactic Acid (%) | 0.73 |

| Acetic Acid (%) | 0.58 |

| pH | 5.50 |

| DM | CP | ADICP | NDICP | CF | ADF | NDF | Lignin | Ash | Fat | Starch | WSC | LA | AA | BA | pH | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DM | 1 | |||||||||||||||

| CP | −0.351 | 1 | ||||||||||||||

| ADICP | −0.318 | −0.595 * | 1 | |||||||||||||

| NDICP | −0.453 | −0.469 | 0.884 ** | 1 | ||||||||||||

| CF | −0.497 | −0.267 | 0.826 ** | 0.764 ** | 1 | |||||||||||

| ADF | −0.489 | −0.307 | 0.828 ** | 0.753 ** | 0.969 ** | 1 | ||||||||||

| NDF | −0.546 | −0.232 | 0.816 ** | 0.794 ** | 0.975 ** | 0.988 ** | 1 | |||||||||

| Lignin | −0.135 | −0.123 | 0.386 | 0.249 | 0.665 * | 0.768 ** | 0.718 ** | 1 | ||||||||

| Ash | −0.276 | −0.298 | 0.759 ** | 0.716 ** | 0.925 ** | 0.868 ** | 0.875 ** | 0.574 | 1 | |||||||

| Fat | 0.586 * | −0.237 | −0.032 | −0.117 | −0.305 | −0.449 | −0.437 | −0.544 | −0.18 | 1 | ||||||

| Starch | 0.688 * | −0.635 * | −0.207 | −0.309 | −0.471 | −0.456 | −0.544 | −0.332 | −0.370 | 0.404 | 1 | |||||

| WSC | 0.261 | 0.368 | −0.354 | −0.098 | −0.331 | −0.437 | −0.332 | −0.371 | −0.230 | 0.545 | −0.186 | 1 | ||||

| LA | −0.015 | 0.617 * | −0.643 * | −0.497 | −0.415 | −0.288 | −0.264 | 0.141 | −0.390 | −0.581 * | −0.272 | 0.087 | 1 | |||

| AA | −0.082 | −0.427 | −0.027 | 0.171 | −0.261 | −0.211 | −0.221 | −0.440 | −0.260 | −0.160 | 0.540 | −0.280 | −0.06 | 1 | ||

| BA | 0.303 | −0.798 ** | 0.628 * | 0.610 * | 0.191 | 0.176 | 0.180 | −0.164 | 0.247 | 0.520 | 0.349 | 0.099 | −0.638 * | 0.275 | 1 | |

| pH | −0.294 | 0.213 | 0.268 | 0.210 | 0.586 * | 0.493 | 0.514 | 0.508 | 0.447 | 0.062 | −0.509 | 0.213 | −0.300 | −0.694 * | −0.190 | 1 |

| Parameters | Fresh Matter | Density | |||

|---|---|---|---|---|---|

| 300 kg/m 3 | 450 kg/m 3 | 600 kg/m 3 | 700 kg/m 3 | ||

| DM (%) | 29.13 ± 0.27 a | 26.09 ± 0.06 b | 26.54 ± 0.19 b | 26.47 ± 0.81 b | 26.71 ± 0.13 b |

| CP (%) | 8.05 ± 0.44 b | 8.68 ± 0.07 a | 8.04 ± 0.23 b | 8.24 ± 0.28 ab | 8.71 ± 0.32 a |

| ADICP (%) | 0.53 ± 0.09 c | 0.72 ± 0.03 ab | 0.83 ± 0.10 a | 0.70 ± 0.06 b | 0.49 ± 0.01 c |

| NDICP (%) | 1.02 ± 0.00 a | 1.01 ± 0.19 a | 1.18 ± 0.16 a | 0.95 ± 0.21 a | 0.67 ± 0.00 b |

| CF (%) | 21.19 ± 2.35 b | 24.9 ± 0.41 a | 23.91 ± 0.11 a | 22.88 ± 0.59 ab | 18.17 ± 0.66 c |

| ADF (%) | 24.82 ± 3.20 b | 31.64 ± 0.44 a | 29.49 ± 1.26 a | 29.92 ± 0.98 a | 22.09 ± 0.40 b |

| NDF (%) | 40.87 ± 3.78 b | 52.28 ± 1.56 a | 49.40 ± 1.52 a | 49.24 ± 2.06 a | 40.01 ± 1.37 b |

| Lignin (%) | 2.29 ± 0.32 b | 3.25 ± 0.00 a | 2.50 ± 0.26 b | 3.05 ± 0.37 a | 2.21 ± 0.05 b |

| Ash (%) | 4.84 ± 0.31 b | 5.87 ± 0.19 a | 5.96 ± 0.17 a | 5.64 ± 0.33 a | 4.42 ± 0.56 b |

| Fat (%) | 2.82 ± 0.09 c | 3.39 ± 0.07 b | 3.67 ± 0.02 a | 3.29 ± 0.15 b | 3.58 ± 0.03 a |

| Starch (%) | 29.33 ± 2.15 a | 23.01 ± 0.08 b | 27.66 ± 0.65 a | 27.44 ± 3.49 a | 27.55 ± 3.30 a |

| WSC (%) | 12.25 ± 1.13 a | 1.26 ± 0.31 b | 1.25 ± 0.13 b | 0.81 ± 0.11 b | 1.49 ± 0.26 b |

| Parameters | Fresh Matter | Density | |||

|---|---|---|---|---|---|

| 300 kg/m3 | 450 kg/m3 | 600 kg/m3 | 700 kg/m3 | ||

| LA (%) | 0.73 ± 0.33 c | 3.33 ± 0.45 a | 1.71 ± 0.19 b | 3.87 ± 0.21 a | 3.93 ± 0.71 a |

| AA (%) | 0.58 ± 0.22 b | 2.60 ± 0.26 a | 2.95 ± 0.08 a | 3.04 ± 0.20 a | 2.92 ± 0.33 a |

| BA (%) | ND | 0.07 ± 0.02 b | 0.18 ± 0.06 a | 0.10 ± 0.02 b | 0.09 ± 0.01 b |

| pH | 5.50 ± 0.10 a | 4.85 ± 0.05 b | 4.35 ± 0.05 c | 4.00 ± 0.17 d | 4.10 ± 0.00 d |

| Density (kg/m3) | Accumulated Fermentation Temperature (°C) | R2 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DM | CP | ADICP | NDICP | CF | ADF | NDF | Lignin | Ash | Fat | Starch | WSC | ||

| 300 | 1569.00 ± 20.00 | 0.512 | −0.466 | 0.866 | −0.5 | 0.554 | 0.564 | 0.546 | 0.574 | 0.547 | −0.402 | −0.462 | −0.544 |

| 450 | 1510.00 ± 12.00 | −0.548 | 0.461 | −0.267 | 0.5 | −0.554 | −0.564 | −0.546 | −0.597 | −0.537 | 0.46 | 0.461 | 0.529 |

| 600 | 1485.00 ± 17.00 | −0.16 | 0.91 | −0.609 | 0.266 | −0.447 | −0.429 | −0.403 | - | 0.522 | 0.06 | 0.145 | 0.458 |

| 700 | 1474.00 ± 16.00 | −0.16 | 0.91 | −0.609 | 0.266 | −0.447 | −0.429 | −0.403 | - | 0.522 | 0.06 | 0.145 | 0.458 |

| Density (kg/m3) | Accumulated Fermentation Temperature (°C) | R2 | |||

|---|---|---|---|---|---|

| LA | AA | BA | pH | ||

| 300 | 1569.00 ± 20.00 | −0.265 | 0.674 | −0.500 | −0.491 |

| 450 | 1510.00 ± 12.00 | 0.265 | −0.674 | 0.500 | 0.491 |

| 600 | 1485.00 ± 17.00 | 0.308 | −0.616 | −0.866 | 0.145 |

| 700 | 1474.00 ± 16.00 | 0.308 | −0.616 | −0.866 | 0.145 |

| Project | Linear Regression Model | R2 | P |

|---|---|---|---|

| DM | Y = 1618.983 − 0.230X1 + 0.897X2 | 0.820 | ** |

| CP | Y = 1623.105 − 0.235X1 − 1.414X2 | 0.846 | ** |

| ADICP | Y = 1657.357 − 0.269X1 + 0.340X2 | 0.852 | ** |

| NDICP | Y = 1643.033 − 0.266X1 + 0.382X2 | 0.850 | ** |

| CF | Y = 1632.185 − 0.238X1 + 0.067X2 | 0.820 | ** |

| ADF | Y = 1633.264 − 0.239X1 + 0.071X2 | 0.820 | ** |

| NDF | Y = 1629.428 − 0.234X1 + 0.003X2 | 0.819 | ** |

| Lignin | Y = 1618.922 − 0.220X1 − 0.166X2 | 0.825 | ** |

| Ash | Y = 1643.838 − 0.254X1 + 0.307X2 | 0.828 | ** |

| Fat | Y = 1641.133 − 0.232X1 + 0.549X2 | 0.828 | ** |

| Starch | Y = 1616.096 − 0.217X1 + 0.465X2 | 0.839 | ** |

| WSC | Y = 1843.806 − 0.236X1 − 2.364X2 | 0.843 | ** |

| LA | Y = 1625.707 − 0.238X1 − 0.014X2 | 0.827 | ** |

| AA | Y = 1623.850 − 0.236X1 − 0.015X2 | 0.824 | ** |

| BA | Y = 1645.660 − 0.236X1 − 0.016X2 | 0.856 | ** |

| pH | Y = 1634.287 − 0.167X1 − 1.825X2 | 0.839 | ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Luo, C.; Li, C.; Zhang, S.; Lu, N.; Yang, Z.; Yu, X.; Cao, Z.; Yang, H.; Li, S.; et al. Study on the Relationship between Fermentation-Accumulated Temperature and Nutrient Loss of Whole-Plant Corn Silage. Agronomy 2022, 12, 2752. https://doi.org/10.3390/agronomy12112752

Wang D, Luo C, Li C, Zhang S, Lu N, Yang Z, Yu X, Cao Z, Yang H, Li S, et al. Study on the Relationship between Fermentation-Accumulated Temperature and Nutrient Loss of Whole-Plant Corn Silage. Agronomy. 2022; 12(11):2752. https://doi.org/10.3390/agronomy12112752

Chicago/Turabian StyleWang, Donghai, Chenglong Luo, Chen Li, Shu Zhang, Na Lu, Zhuomeng Yang, Xiong Yu, Zhijun Cao, Hongjian Yang, Shengli Li, and et al. 2022. "Study on the Relationship between Fermentation-Accumulated Temperature and Nutrient Loss of Whole-Plant Corn Silage" Agronomy 12, no. 11: 2752. https://doi.org/10.3390/agronomy12112752

APA StyleWang, D., Luo, C., Li, C., Zhang, S., Lu, N., Yang, Z., Yu, X., Cao, Z., Yang, H., Li, S., Shao, W., & Wang, W. (2022). Study on the Relationship between Fermentation-Accumulated Temperature and Nutrient Loss of Whole-Plant Corn Silage. Agronomy, 12(11), 2752. https://doi.org/10.3390/agronomy12112752