Estimating Tomato Transpiration Cultivated in a Sunken Solar Greenhouse with the Penman-Monteith, Shuttleworth-Wallace and Priestley-Taylor Models in the North China Plain

Abstract

1. Introduction

2. Materials and Methods

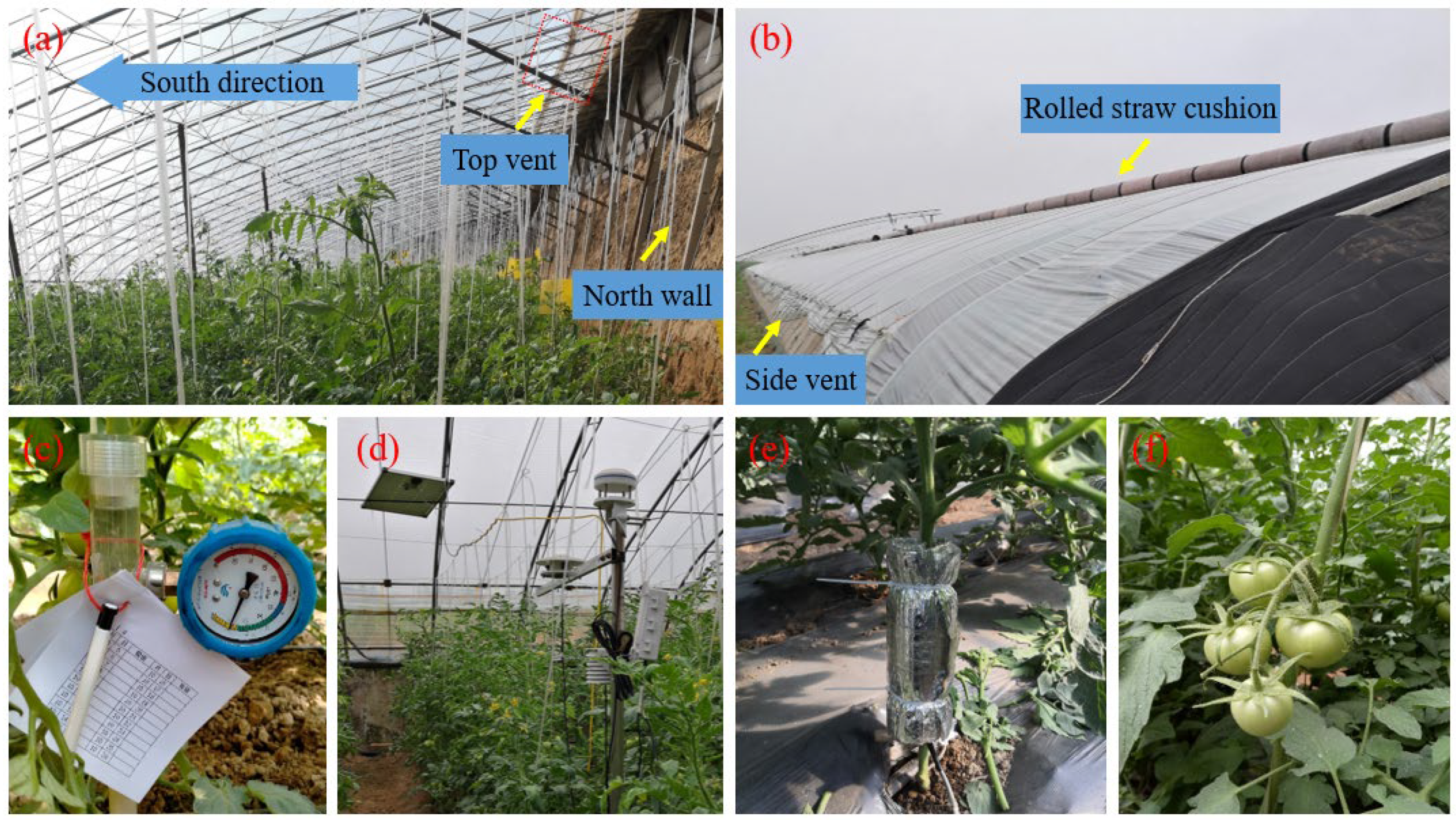

2.1. Experimental Site

2.2. Planting and Management

2.3. Measurements

3. Models and Parameters

3.1. Penman-Monteith Model

3.2. Shuttleworth-Wallace Model

3.2.1. Aerodynamic Resistances

3.2.2. Bulk Stomatal and Boundary Layer Resistances

3.2.3. Soil Surface Resistance

3.3. Priestley-Taylor Model

3.4. Evaluation of Model Performance

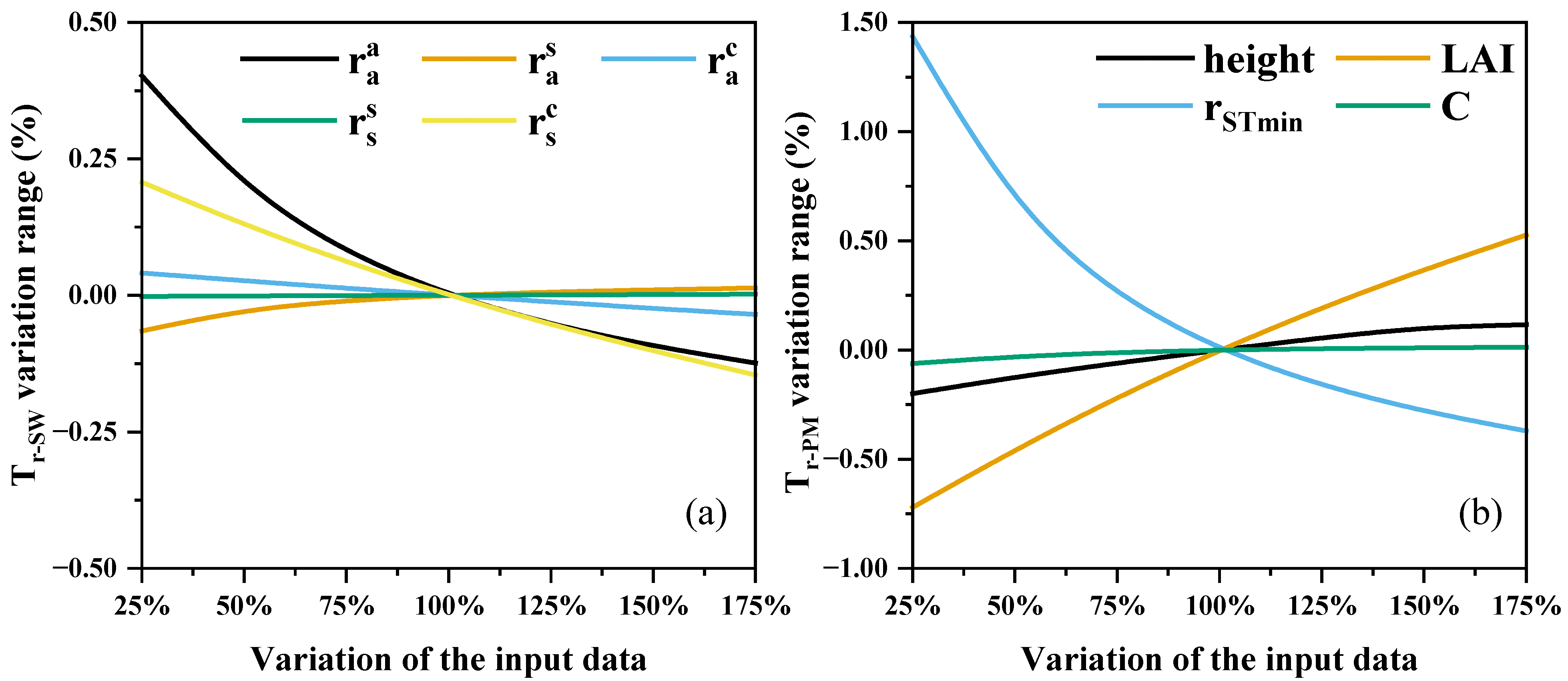

3.5. Models’ Sensitivity Analysis

3.6. Tomato Transpiration Estimation at Daily and Hourly Scale

4. Results

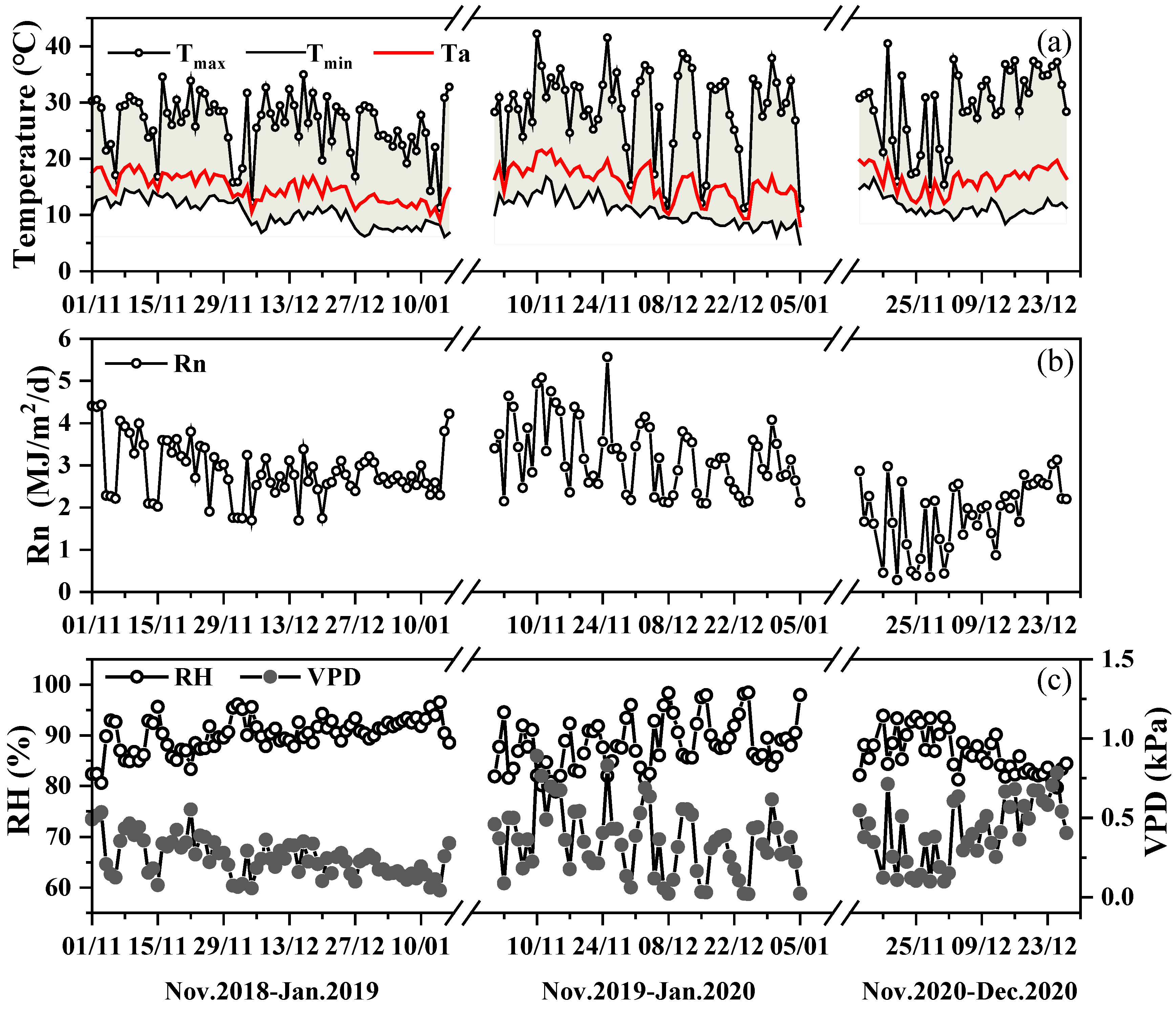

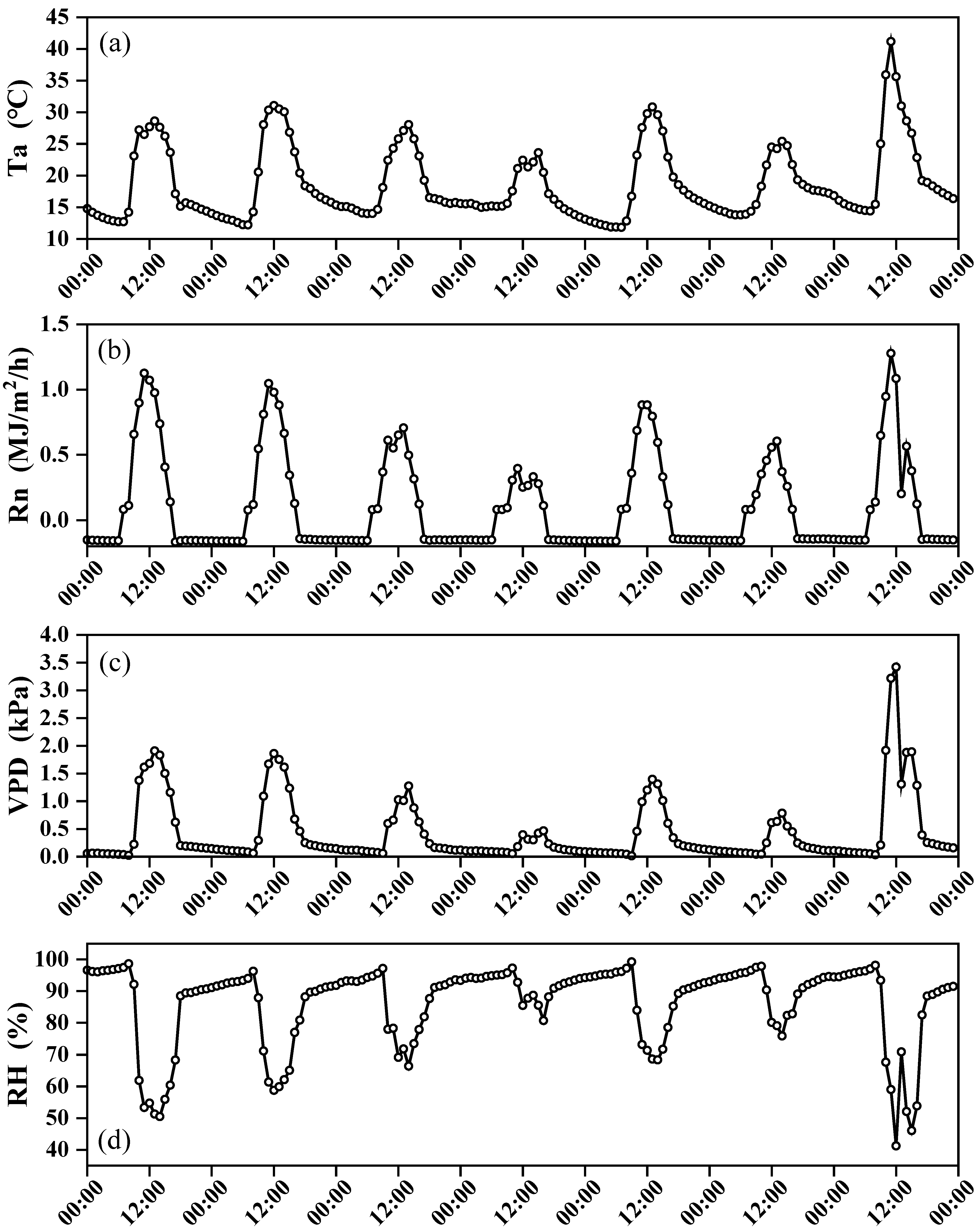

4.1. Microclimate Conditions, Tomato Growth and Yield in the Sunken Solar Greenhouse

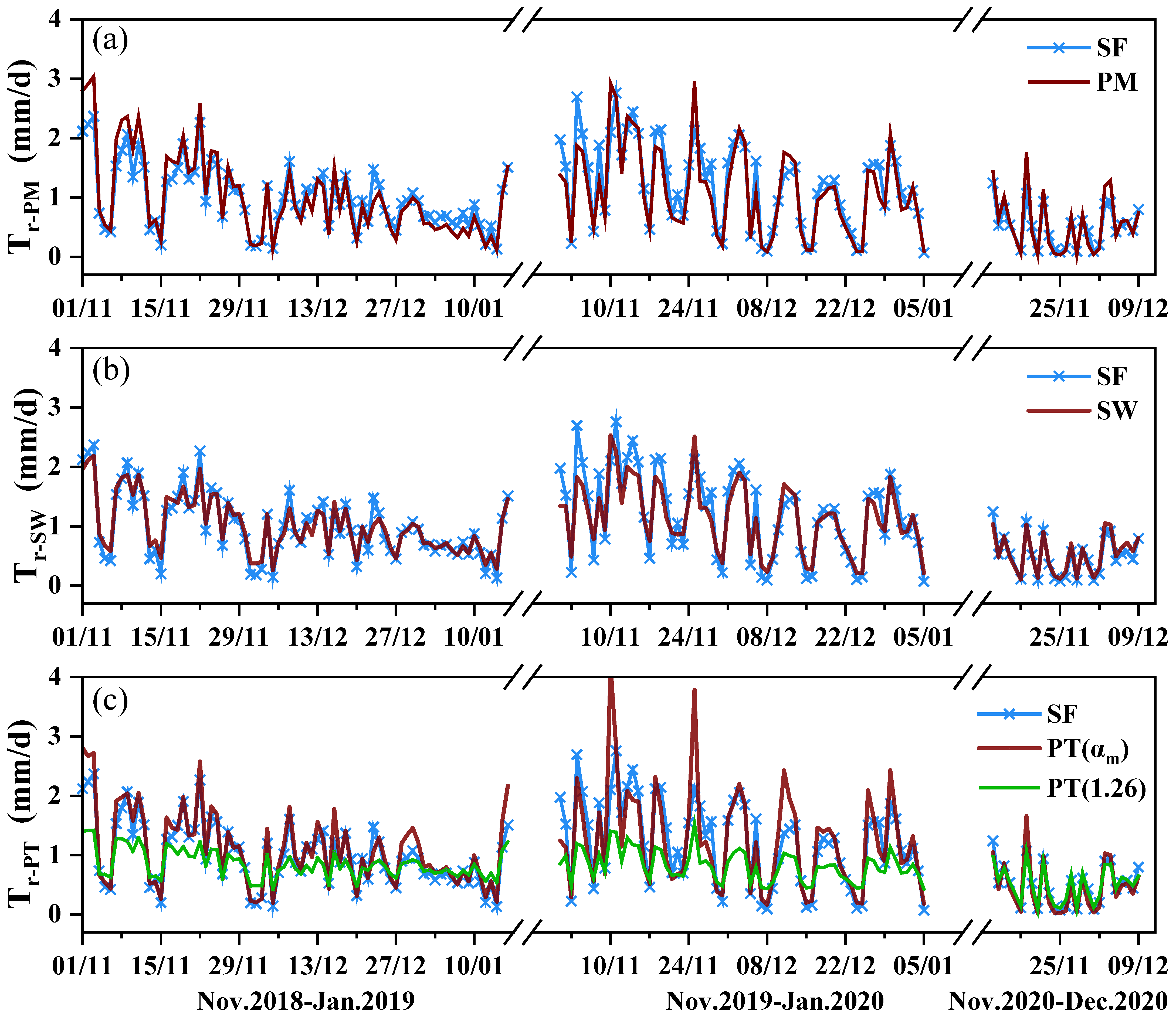

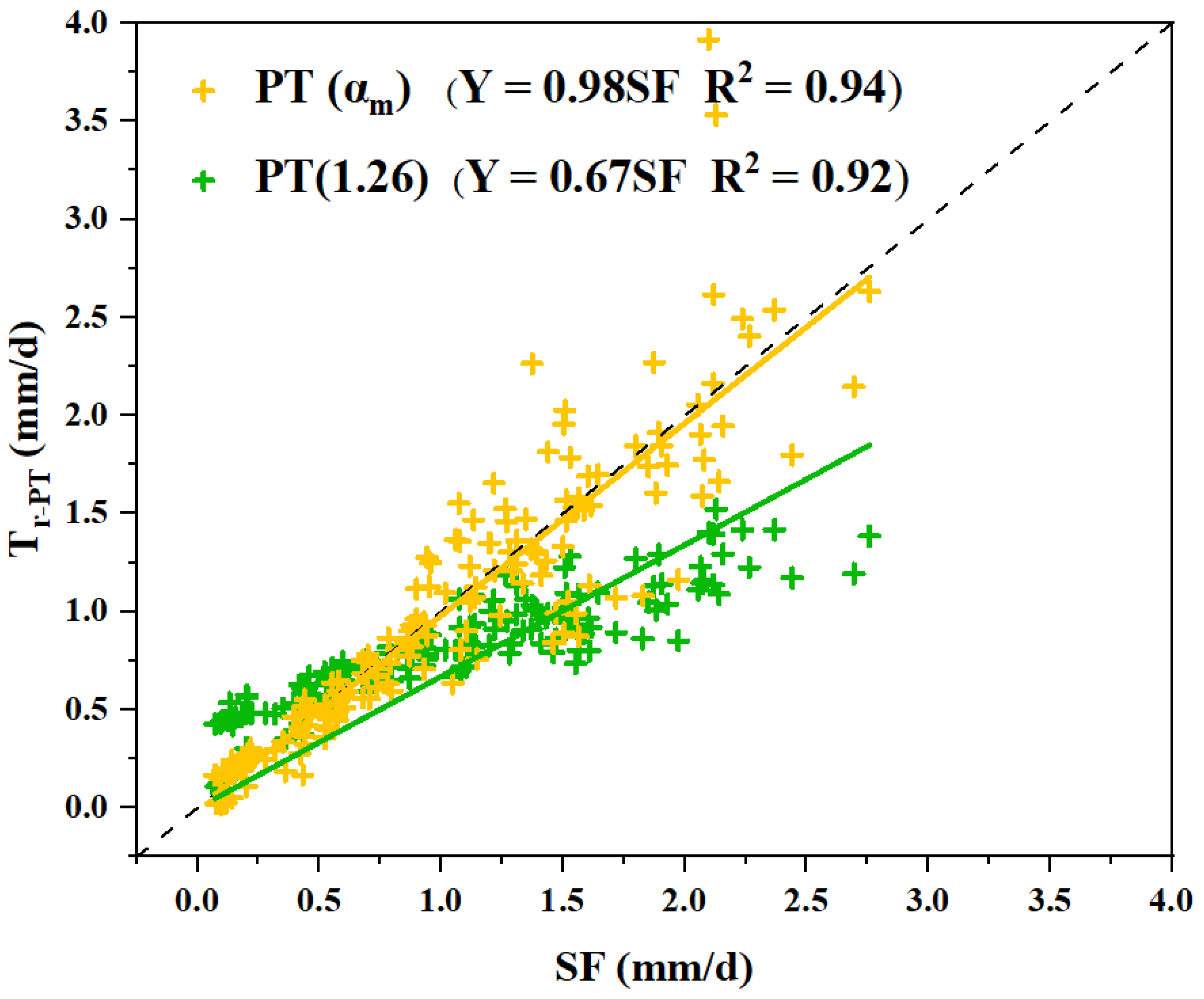

4.2. Comparison of the Estimated Daily Transpiration and Measured Sap Flow

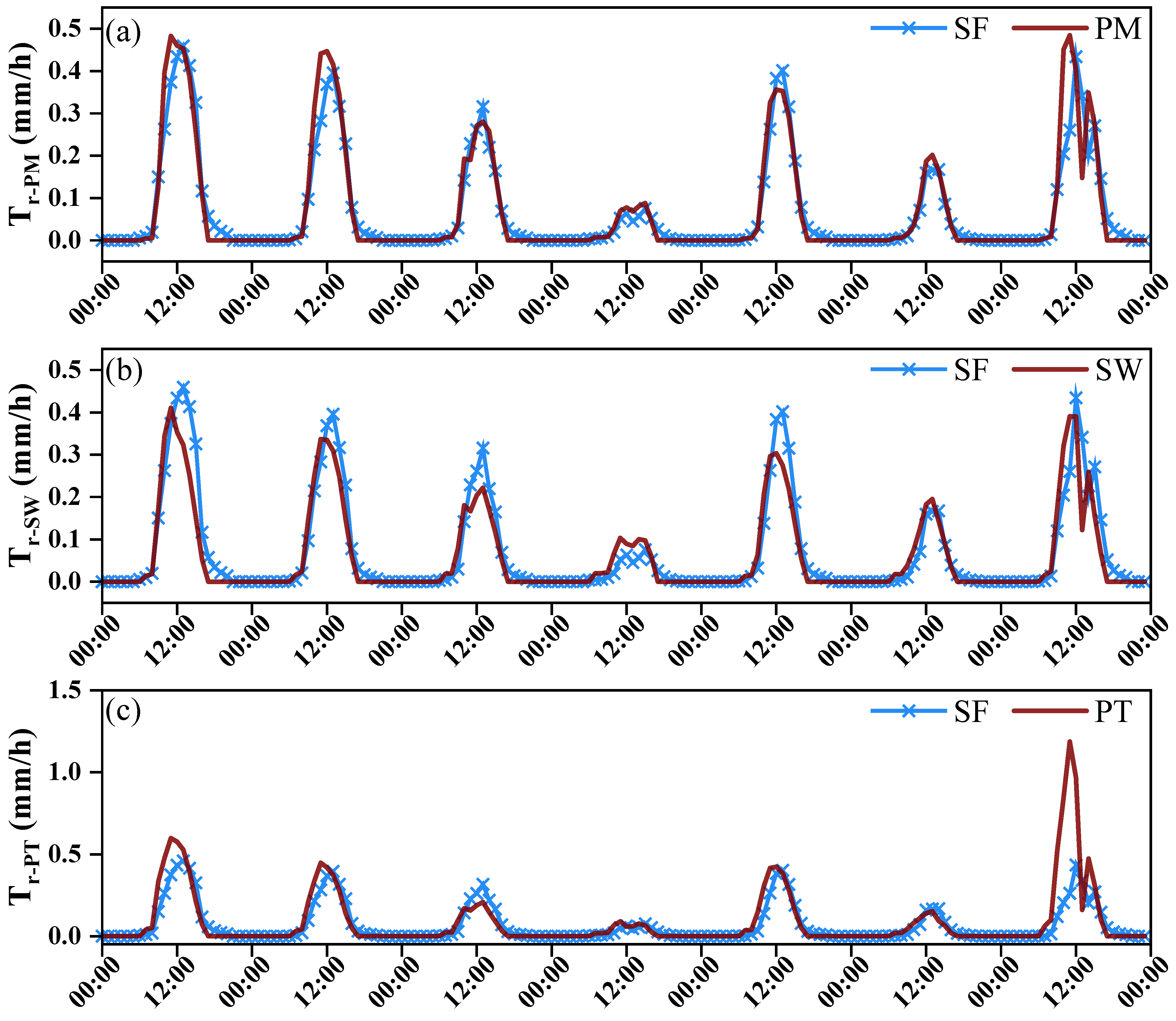

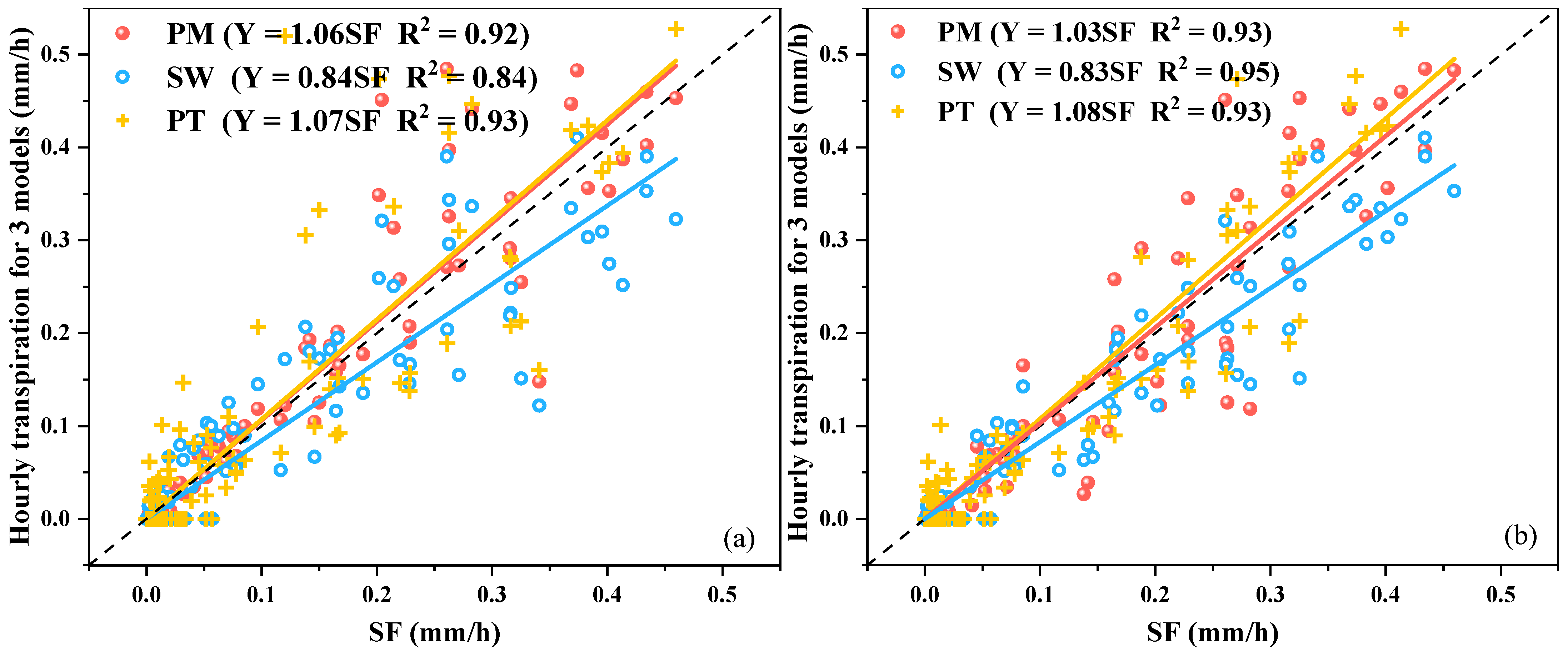

4.3. Comparison of Estimated Hourly Transpiration Rate and Measured Sap Flow

5. Discussion

5.1. Models’ Performance at Daily Scale

5.2. Models’ Performance at Hourly Scale

5.3. Models’ Uncertain with Parameter’s Sensitivity Analysis

6. Conclusions

- (1)

- The PM and SW models performed well in estimating the daily transpiration of greenhouse tomatoes. The original PT model, with a coefficient of 1.26, could underestimate tomato daily transpiration by approximately 30%. With a calibrated coefficient, the PT model perfectly estimated the tomato transpiration with an R2 of 0.94 and slope of 0.98.

- (2)

- The PM and calibrated PT models also did well in hourly transpiration estimation with an error of 3% and 8%, respectively; however, the SW model underestimated the hourly transpiration by approximately 17%. The SF lag time should be considered when it is used for transpiration analysis.

- (3)

- The PT model resulted in a large error when plants suffered from heat and water stress, while the PM and SW models performed well in this stressful situation because these situations were considered in the models’ parameters.

- (4)

- All three models could be used to estimate tomato transpiration in the SSG. The calibrated PT model is strongly recommended because it uses fewer parameters and a simple expression.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- China Statistical Publishing House. China Statistical Yearbook; China Statistical Publishing House: Beijing, China, 2021. [Google Scholar]

- Yang, L.; Liu, H.; Cohen, S.; Gao, Z. Microclimate and Plant Transpiration of Tomato (Solanum lycopersicum L.) in a Sunken Solar Greenhouse in North China. Agriculture 2022, 12, 260. [Google Scholar] [CrossRef]

- Liu, H.; Yin, C.; Hu, X.; Tanny, J.; Tang, X. Microclimate Characteristics and Evapotranspiration Estimates of Cucumber Plants in a Newly Developed Sunken Solar Greenhouse. Water 2020, 12, 2275. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. China Water Resources Bulletin; China WaterPower Press: Beijing, China, 2021.

- Liang, H.; Lv, H.; Batchelor, W.D.; Lian, X.; Wang, Z.; Lin, S.; Hu, K. Simulating nitrate and DON leaching to optimize water and N management practices for greenhouse vegetable production systems. Agric. Water Manag. 2020, 241, 106377. [Google Scholar] [CrossRef]

- Sun, Y.; Hu, K.; Fan, Z.; Wei, Y.; Lin, S.; Wang, J. Simulating the fate of nitrogen and optimizing water and nitrogen management of greenhouse tomato in North China using the EU-Rotate_N model. Agric. Water Manag. 2013, 128, 72–84. [Google Scholar] [CrossRef]

- Liu, H.; Yuan, B.; Hu, X.; Yin, C. Drip irrigation enhances water use efficiency without losses in cucumber yield and economic benefits in greenhouses in North China. Irrig. Sci. 2021, 40, 135–149. [Google Scholar] [CrossRef]

- Du, Y.-D.; Cao, H.-X.; Liu, S.-Q.; Gu, X.-B.; Cao, Y.-X. Response of yield, quality, water and nitrogen use efficiency of tomato to different levels of water and nitrogen under drip irrigation in Northwestern China. J. Integr. Agric. 2017, 16, 1153–1161. [Google Scholar] [CrossRef]

- Liang, H.; Hu, K.; Batchelor, W.D.; Qin, W.; Li, B. Developing a water and nitrogen management model for greenhouse vegetable production in China: Sensitivity analysis and evaluation. Ecol. Model. 2018, 367, 24–33. [Google Scholar] [CrossRef]

- Liu, H.; Li, H.; Ning, H.; Zhang, X.; Li, S.; Pang, J.; Wang, G.; Sun, J. Optimizing irrigation frequency and amount to balance yield, fruit quality and water use efficiency of greenhouse tomato. Agric. Water Manag. 2019, 226, 105787. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Gong, X.; Li, S.; Pang, J.; Chen, Z.; Sun, J. Optimizing irrigation and nitrogen management strategy to trade off yield, crop water productivity, nitrogen use efficiency and fruit quality of greenhouse grown tomato. Agric. Water Manag. 2021, 245, 106570. [Google Scholar] [CrossRef]

- Shock, C.; Wang, F.-X. Soil Water Tension, a Powerful Tool for Productivity and Stewardship. Am. Soc. Hortic. Sci. 2010, 46, 178–185. [Google Scholar]

- Kang, S.Z.; Liu, X.M.; Xiong, Y.Z. Theory of Water Transport in Soil-Plant-Atmosphere Continuum and Its Application; China Water Resources and Hydro-Power Press: Beijing, China, 1994. [Google Scholar]

- Evapotranspiration Basics and Estimating Actual Crop Evapotranspiration from Reference Evapotranspiration and Crop-Specific Coefficients. Available online: https://extensionpublications.unl.edu/assets/html/g1994/build/g1994.htm (accessed on 21 September 2022).

- Kang, S.; Gu, B.; Du, T.; Zhang, J. Crop coefficient and ratio of transpiration to evapotranspiration of winter wheat and maize in a semi-humid region. Agric. Water Manag. 2003, 59, 239–254. [Google Scholar] [CrossRef]

- Allan, R.; Pereira, L.; Smith, M. Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 1998. [Google Scholar]

- Montoro, A.; Torija, I.; Mañas, F.; López-Urrea, R. Lysimeter measurements of nocturnal and diurnal grapevine transpiration: Effect of soil water content, and phenology. Agric. Water Manag. 2020, 229, 105882. [Google Scholar] [CrossRef]

- Tfwala, C.M.; van Rensburg, L.D.; Bello, Z.A.; Green, S.R. Calibration of compensation heat pulse velocity technique for measuring transpiration of selected indigenous trees using weighing lysimeters. Agric. Water Manag. 2018, 200, 27–33. [Google Scholar] [CrossRef]

- Beslity, J.; Shaw, S.B.; Drake, J.E.; Fridley, J.; Stella, J.C.; Stark, J.; Singh, K. A low cost, low power sap flux device for distributed and intensive monitoring of tree transpiration. HardwareX 2022, 12, e00351. [Google Scholar] [CrossRef]

- Dix, M.J.; Aubrey, D.P. Calibration approach and range of observed sap flow influences transpiration estimates from thermal dissipation sensors. Agric. For. Meteorol. 2021, 307, 108534. [Google Scholar] [CrossRef]

- Zeggaf, A.T.; Takeuchi, S.; Dehghanisanij, H.; Anyoji, H.; Yano, T. A Bowen Ratio Technique for Partitioning Energy Fluxes between Maize Transpiration and Soil Surface Evaporation. Agron. J. 2008, 100, 988–996. [Google Scholar] [CrossRef]

- Wang, F.; Ma, D.; Zhao, W.; Lu, Y.; Zhou, D.; Zhang, J.; Chen, L.; Huang, P.; Naeth, M.A. A validation of eddy covariance technique for measuring crop evapotranspiration on different time scales in the North China Plain. Can. J. Soil Sci. 2021, 101, 134–146. [Google Scholar] [CrossRef]

- Shuttleworth, W.J.; Wallace, J.S. Evaporation from sparse crops—An energy combination theory. Q. J. R. Meteorol. Soc. 1985, 111, 839–855. [Google Scholar] [CrossRef]

- Priestley, C.H.B.; Taylor, R.J. On the Assessment of Surface Heat Flux and Evaporation Using Large-Scale Parameters. Mon. Weather. Rev. 1972, 100, 81–92. [Google Scholar] [CrossRef]

- López-Cruz, I.L.; Olivera-López, M.; Herrera-Ruiz, G. Simulation of greenhouse tomato crop transpiration by two theoretical models. International Workshop on Greenhouse Environmental Control and Crop Production in Semi-Arid Regions; International Society for Horticultural Science: Tucson, AZ, USA, 2008; pp. 145–150. [Google Scholar]

- Huang, S.; Yan, H.; Zhang, C.; Wang, G.; Acquah, S.J.; Yu, J.; Li, L.; Ma, J.; Opoku Darko, R. Modeling evapotranspiration for cucumber plants based on the Shuttleworth-Wallace model in a Venlo-type greenhouse. Agric. Water Manag. 2020, 228, 105861. [Google Scholar] [CrossRef]

- Guo, D.; Chen, Z.; Huang, D.; Zhang, J. Evapotranspiration Model-based Scheduling Strategy for Baby Pakchoi Irrigation in Greenhouse. HortScience 2021, 56, 204–209. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, T.; Wei, X. Estimating grapevine transpiration in greenhouse with three different methods in a Penman–Monteith model in Northeast China. Irrig. Sci. 2021, 40, 13–27. [Google Scholar] [CrossRef]

- Li, X.; Yang, P.; Ren, S.; Li, Y.; Xu, T.; Ren, L.; Wang, C. An improved canopy transpiration model and parameter uncertainty analysis by Bayesian approach. Math. Comput. Model. 2010, 51, 1368–1374. [Google Scholar] [CrossRef]

- Gong, X.; Liu, H.; Sun, J.; Gao, Y.; Zhang, X.; Jha, S.K.; Zhang, H.; Ma, X.; Wang, W. A proposed surface resistance model for the Penman-Monteith formula to estimate evapotranspiration in a solar greenhouse. J. Arid. Land 2017, 9, 530–546. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, C.; Wang, G.; Huang, S.; Zhang, H.; Zhao, B.; Wu, H. Energy partitioning of greenhouse cucumber based on the application of Penman-Monteith and Bulk Transfer models. Agric. Water Manag. 2019, 217, 201–211. [Google Scholar] [CrossRef]

- Brisson, N.; Itier, B.; L’Hotel, J.C.; Lorendeau, J.Y. Parameterisation of the Shuttleworth-Wallace model to estimate daily maximum transpiration for use in crop models. Ecol. Model. 1998, 107, 159–169. [Google Scholar] [CrossRef]

- Zhang, B.; Kang, S.; Zhang, L.; Tong, L.; Du, T.; Li, F.; Zhang, J. An evapotranspiration model for sparsely vegetated canopies under partial root-zone irrigation. Agric. For. Meteorol. 2009, 149, 2007–2011. [Google Scholar] [CrossRef]

- Li, S.; Kang, S.; Zhang, L.; Ortega-Farias, S.; Li, F.; Du, T.; Tong, L.; Wang, S.; Ingman, M.; Guo, W. Measuring and modeling maize evapotranspiration under plastic film-mulching condition. J. Hydrol. 2013, 503, 153–168. [Google Scholar] [CrossRef]

- Assouline, S.; Li, D.; Tyler, S.; Tanny, J.; Cohen, S.; Bou-Zeid, E.; Parlange, M.; Katul, G.G. On the variability of the Priestley-Taylor coefficient over water bodies. Water Resour. Res. 2016, 52, 150–163. [Google Scholar] [CrossRef]

- Engstrom, R.; Hope, A.; Stow, D.; Vourlitis, G.; Oechel, W. Priestley-Taylor Alpha Coefficient: Variability and Relationship to NDVI in Arctic Tundra Landscapes. J. Am. Water Resour. Assoc. 2007, 38, 1647–1659. [Google Scholar] [CrossRef]

- Qiu, R.; Liu, C.; Cui, N.; Wu, Y.; Wang, Z.; Li, G. Evapotranspiration estimation using a modified Priestley-Taylor model in a rice-wheat rotation system. Agric. Water Manag. 2019, 224, 105755. [Google Scholar] [CrossRef]

- Valdés-Gómez, H.; Ortega-Farías, S.; Argote, M. Evaluation of the Water Requirements for a Greenhouse Tomato Crop using the Priestley-Taylor Method Evaluación del Consumo de Agua de un Cultivo de Tomate en Invernadero Usando el Método de Priestley-Taylor. Chil. J. Agric. Res. 2009, 69, 3–11. [Google Scholar] [CrossRef][Green Version]

- Thom, A.; Oliver, H. On Penman’s Equation for Estimating Regional Evaporation. Q. J. R. Meteorol. Soc. 2006, 103, 345–357. [Google Scholar] [CrossRef]

- Gong, X.W.; Ge, J.K.; Li, Y.B.; Wang, S.S.; Zhang, H.; Zhang, L.; Liu, Y.F.; Liu, H. Evaluation of the dual source model to simulate transpiration and evaporation of tomato plants cultivated in a solar greenhouse. Eur. J. Hortic. Sci. 2020, 85, 362–371. [Google Scholar] [CrossRef]

- Nikolaou, G.; Neocleous, D.; Kitta, E.; Katsoulas, N. Assessment of the Priestley-Taylor coefficient and a modified potential evapotranspiration model. Smart Agric. Technol. 2023, 3, 100075. [Google Scholar] [CrossRef]

- Gong, X.; Qiu, R.; Ge, J.; Bo, G.; Ping, Y.; Xin, Q.; Wang, S. Evapotranspiration partitioning of greenhouse grown tomato using a modified Priestley–Taylor model. Agric. Water Manag. 2021, 247, 106709. [Google Scholar] [CrossRef]

- Zhou, M.C.; Ishidaira, H.; Hapuarachchi, H.P.; Magome, J.; Kiem, A.S.; Takeuchi, K. Estimating potential evapotranspiration using Shuttleworth–Wallace model and NOAA-AVHRR NDVI data to feed a distributed hydrological model over the Mekong River basin. J. Hydrol. 2006, 327, 151–173. [Google Scholar] [CrossRef]

- Moriasi, D.N.; Arnold, J.G.; Van Liew, M.W.; Bingner, R.L.; Harmel, R.D.; Veith, T.L. Model evaluation guidelines for systematic quantification of accuracy in watershed simulations. Trans. ASABE 2007, 50, 885–900. [Google Scholar] [CrossRef]

- Li, Y.; Xue, X.; Guo, W.; Wang, L.; Duan, M.; Chen, H.; Chen, F. Soil moisture and nitrate-nitrogen dynamics and economic yield in the greenhouse cultivation of tomato and cucumber under negative pressure irrigation in the North China Plain. Sci. Rep. 2019, 9, 4439. [Google Scholar]

- CAO, D. Effects of Alternative Root-Splitting Irrigation on Tomato Growth and Water Distribution; Heibei Agricultrual University: Hebei, China, 2020. [Google Scholar]

- Gong, X.; Wang, S.; Xu, C.; Zhang, H.; Ge, J. Evaluation of Several Reference Evapotranspiration Models and Determination of Crop Water Requirement for Tomato in a Solar Greenhouse. HortScience 2020, 55, 244–250. [Google Scholar] [CrossRef]

- Ghiat, I.; Mackey, H.R.; Al-Ansari, T. A Review of Evapotranspiration Measurement Models, Techniques and Methods for Open and Closed Agricultural Field Applications. Water 2021, 13, 2523. [Google Scholar] [CrossRef]

- Wang, L.; Iddio, E.; Ewers, B. Introductory overview: Evapotranspiration (ET) models for controlled environment agriculture (CEA). Comput. Electron. Agric. 2021, 190, 106447. [Google Scholar] [CrossRef]

- Katsoulas, N.; Stanghellini, C. Modelling Crop Transpiration in Greenhouses: Different Models for Different Applications. Agronomy 2019, 9, 392. [Google Scholar] [CrossRef]

- Villarreal-Guerrero, F.; Kacira, M.; Fitz-Rodríguez, E.; Linker, R.; Kubota, C.; Giacomelli, G.A.; Arbel, A. Simulated performance of a greenhouse cooling control strategy with natural ventilation and fog cooling. Biosyst. Eng. 2012, 111, 217–228. [Google Scholar] [CrossRef]

- Hobbins, M.T.; Ramírez, J.A.; Brown, T.C. The complementary relationship in estimation of regional evapotranspiration: An enhanced advection-aridity model. Water Resour. Res. 2001, 37, 1389–1403. [Google Scholar] [CrossRef]

- De Bruin, H.A.R. A Model for the Priestley-Taylor Parameter α. J. Clim. Appl. Meteorol. 1983, 22, 572–578. [Google Scholar] [CrossRef]

- Juhász, Á.; Hrotkó, K. Comparison of the transpiration part of two sources evapotranspiration model and the measurements of sap flow in the estimation of the transpiration of sweet cherry orchards. Agric. Water Manag. 2014, 143, 142–150. [Google Scholar] [CrossRef]

- Gong, X.; Liu, H.; Sun, J.; Gao, Y.; Zhang, H. Comparison of Shuttleworth-Wallace model and dual crop coefficient method for estimating evapotranspiration of tomato cultivated in a solar greenhouse. Agric. Water Manag. 2019, 217, 141–153. [Google Scholar] [CrossRef]

- Chen, Y.J.; Bongers, F.; Tomlinson, K.; Fan, Z.X.; Lin, H.; Zhang, S.B.; Zheng, Y.L.; Li, Y.P.; Cao, K.F.; Zhang, J.L. Time lags between crown and basal sap flows in tropical lianas and co-occurring trees. Tree Physiol. 2016, 36, 736–747. [Google Scholar] [CrossRef]

- Liu, H.-J.; Cohen, S.; Tanny, J.; Lemcoff, J.H.; Huang, G. Transpiration estimation of banana (Musa sp.) plants with the thermal dissipation method. Plant Soil 2008, 308, 227–238. [Google Scholar] [CrossRef]

| Planting Seasons | Fertilization | N kg ha−1 | P2O5 kg ha−1 | K2O kg ha−1 |

|---|---|---|---|---|

| 2018 winter | base fertilization | 114 | 114 | 114 |

| topdressing fertilization | 68 | 23 | 159 | |

| total | 182 | 137 | 273 | |

| 2019 winter | base fertilization | 114 | 114 | 114 |

| topdressing fertilization | 91 | 91 | 91 | |

| total | 205 | 205 | 205 | |

| 2020 winter | base fertilization | 171 | 171 | 171 |

| topdressing fertilization | 91 | 91 | 91 | |

| total | 262 | 262 | 262 |

| Planting Seasons | Total Irrigation Depth (mm) * | Sap Flow Measurement Period ** | ||

|---|---|---|---|---|

| Irrigation Depth (mm) | Irrigation Events | Irrigation Depth Per Time (mm) | ||

| 2018 winter | 516 | 255 | 6 | 42.5 |

| 2019 winter | 508 | 162 | 6 | 27.0 |

| 2020 winter | 461 | 250 | 5 | 50.0 |

| NSE | RSR | Performance Rating |

|---|---|---|

| 0.75 < NSE ≤ 1 | 0 ≤ RSR ≤ 0.5 | Very good |

| 0.65 < NSE < 0.75 | 0.5 < RSR < 0.6 | Good |

| 0.5 < NSE < 0.65 | 0.6 < RSR < 0.7 | Satisfactory |

| NSE ≤ 0.5 | RSR > 0.7 | Unsatisfactory |

| Date 2019 | RHmean % | Tmax °C | Ta °C | u m s−1 | VPD kPa | Rn MJ m−2 d−1 | LAI - | h m |

|---|---|---|---|---|---|---|---|---|

| 4 Nov | 81.62 | 28.90 | 18.32 | 0.29 | 0.50 | 4.65 | 1.60 | 1.21 |

| 5 Nov | 83.42 | 31.40 | 19.25 | 0.22 | 0.50 | 4.39 | 1.60 | 1.21 |

| 6 Nov | 86.88 | 28.80 | 18.40 | 0.20 | 0.36 | 3.43 | 1.59 | 1.21 |

| 7 Nov | 91.96 | 23.90 | 16.96 | 0.27 | 0.18 | 2.47 | 1.59 | 1.21 |

| 8 Nov | 87.72 | 31.20 | 18.33 | 0.32 | 0.36 | 3.89 | 1.59 | 1.21 |

| 9 Nov | 91.09 | 26.50 | 17.94 | 0.25 | 0.22 | 2.83 | 1.59 | 1.22 |

| 10 Nov | 82.06 | 42.20 | 21.21 | 0.31 | 0.89 | 4.94 | 1.58 | 1.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, M.; Liu, H.; Yang, L. Estimating Tomato Transpiration Cultivated in a Sunken Solar Greenhouse with the Penman-Monteith, Shuttleworth-Wallace and Priestley-Taylor Models in the North China Plain. Agronomy 2022, 12, 2382. https://doi.org/10.3390/agronomy12102382

Shao M, Liu H, Yang L. Estimating Tomato Transpiration Cultivated in a Sunken Solar Greenhouse with the Penman-Monteith, Shuttleworth-Wallace and Priestley-Taylor Models in the North China Plain. Agronomy. 2022; 12(10):2382. https://doi.org/10.3390/agronomy12102382

Chicago/Turabian StyleShao, Mengxuan, Haijun Liu, and Li Yang. 2022. "Estimating Tomato Transpiration Cultivated in a Sunken Solar Greenhouse with the Penman-Monteith, Shuttleworth-Wallace and Priestley-Taylor Models in the North China Plain" Agronomy 12, no. 10: 2382. https://doi.org/10.3390/agronomy12102382

APA StyleShao, M., Liu, H., & Yang, L. (2022). Estimating Tomato Transpiration Cultivated in a Sunken Solar Greenhouse with the Penman-Monteith, Shuttleworth-Wallace and Priestley-Taylor Models in the North China Plain. Agronomy, 12(10), 2382. https://doi.org/10.3390/agronomy12102382