Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties

Abstract

1. Introduction

1.1. State of Research of Peat Substitution with Fibre

1.2. State of Research and Concept about Extrusion of Biomass

1.3. Hypotheses

- A small aperture opening leads to a larger fine-fraction and hereby increases the WHC.

- Fibre with an even particle size distribution (balanced ratio of fines and coarse particles) have the highest WHC.

- WHC varies between different raw materials at identical experimental setup, but also between batches of material for the same plant species, due to variation in characteristics such as chemical composition or moisture content during storage.

- To achieve a higher WHC, higher specific energy demand for extrusion is required.

2. Materials and Methods

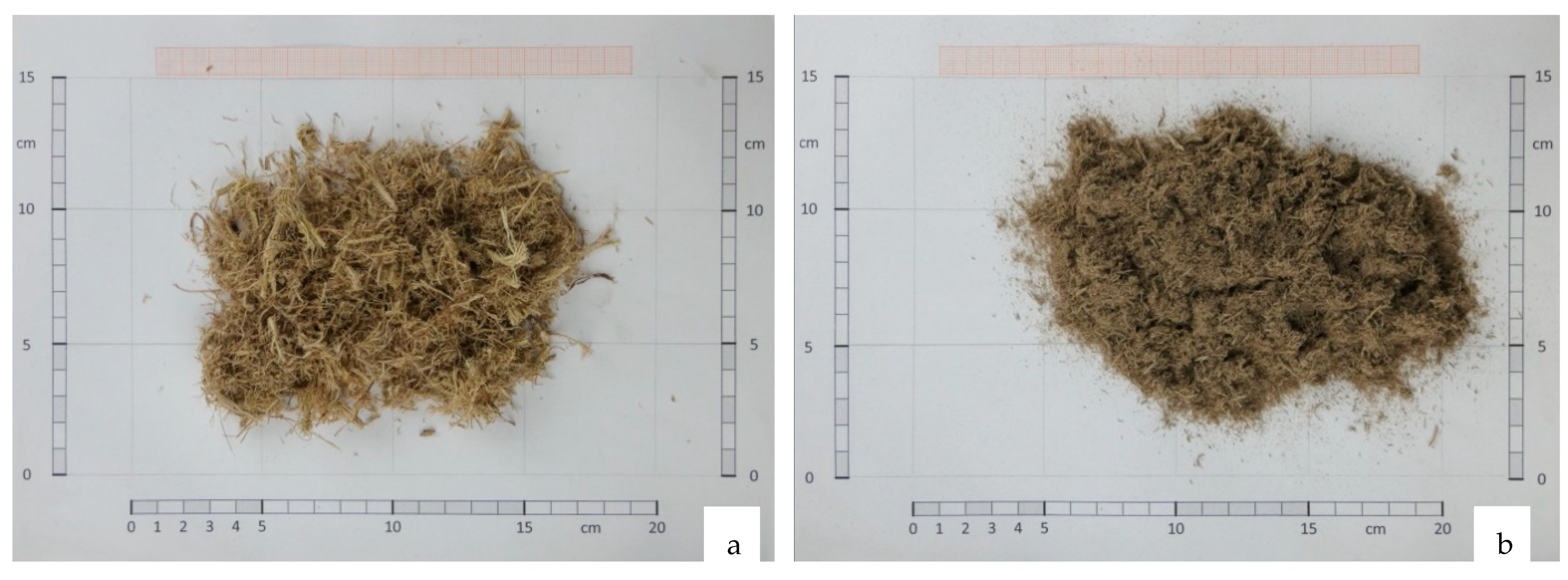

2.1. Procedure of Producing Fibre from Lignocellulosic Biomass

- mwa, mass of water to be added [kg]

- mWC, dry matter of chips/biomass [kg]

- mwp, mass of water present in chips/biomass before watering [kg]

- MCt, target moisture content [%], wet based.

2.2. Experimental Design of the Twin-Screw Extruder

- Wspec, specific energy demand for extruding on dry matter basis [kWh t−1];

- Pex, average power consumption during extrusion [kW];

- tex, time required for extruding of one batch of raw material [h];

- md, dry matter of the processed raw material batch [t].

2.3. Sample Preparation for Particle Size Analysis and Water Holding Capacity

2.4. Particle Size Analysis

2.5. Analysis of Water Holding Capacity with a Water Tension Measuring Box

2.6. Ash Content, Organic Matter and Particle Density

2.7. Statistical Analysis

3. Results

3.1. Specific Energy Demand

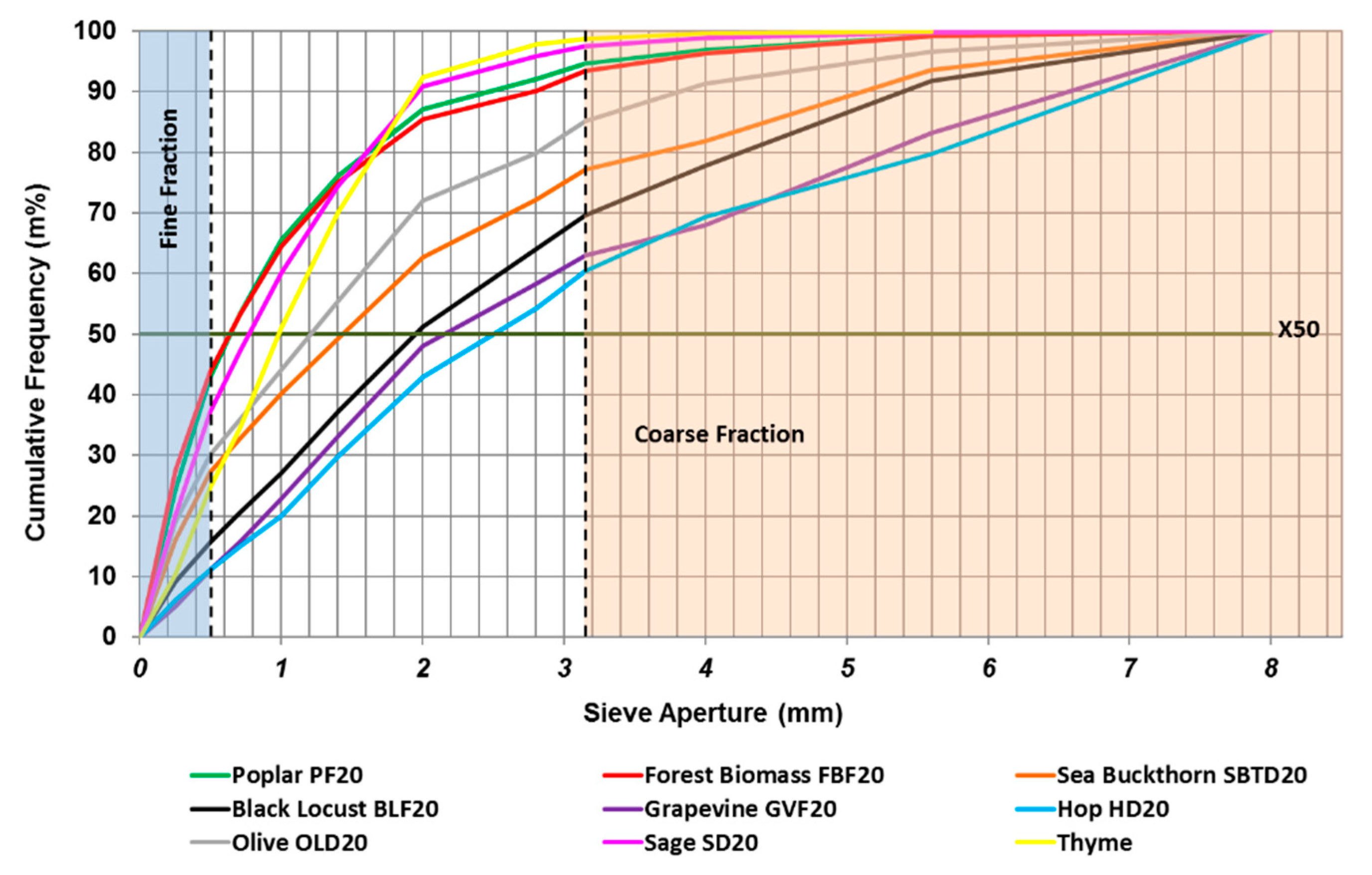

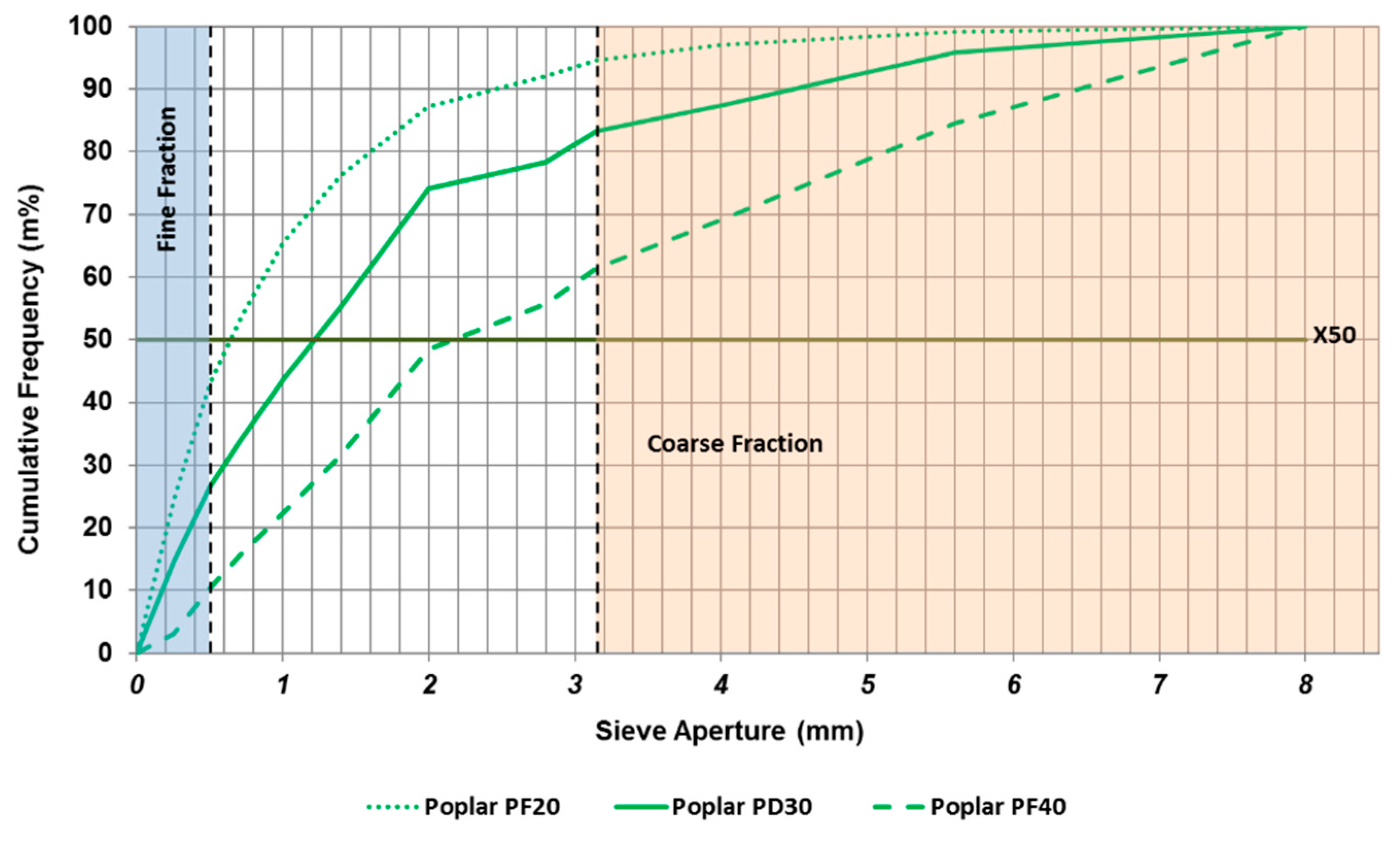

3.2. Particle Size Distribution

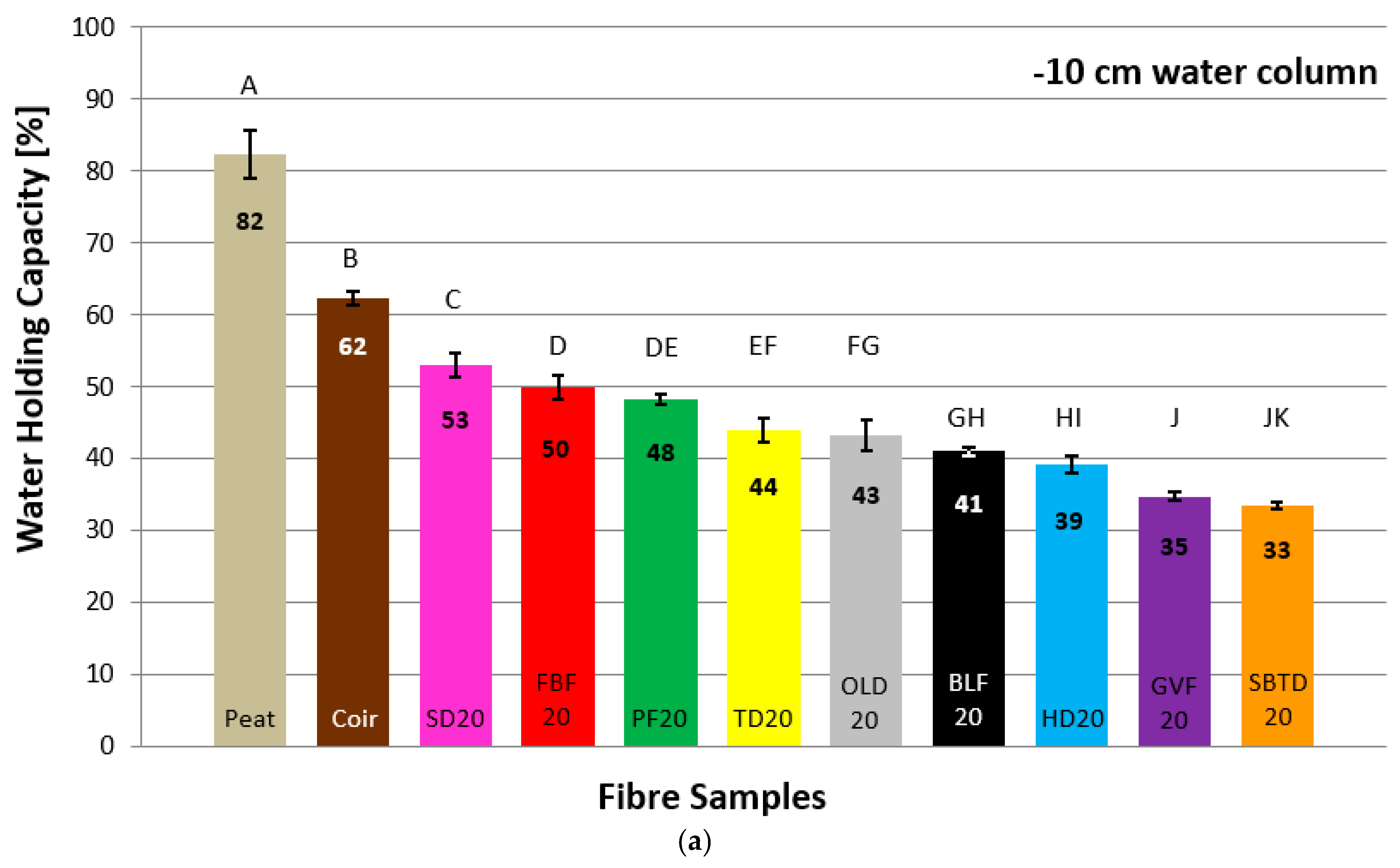

3.3. Influence of Raw Material on Water Holding Capacity

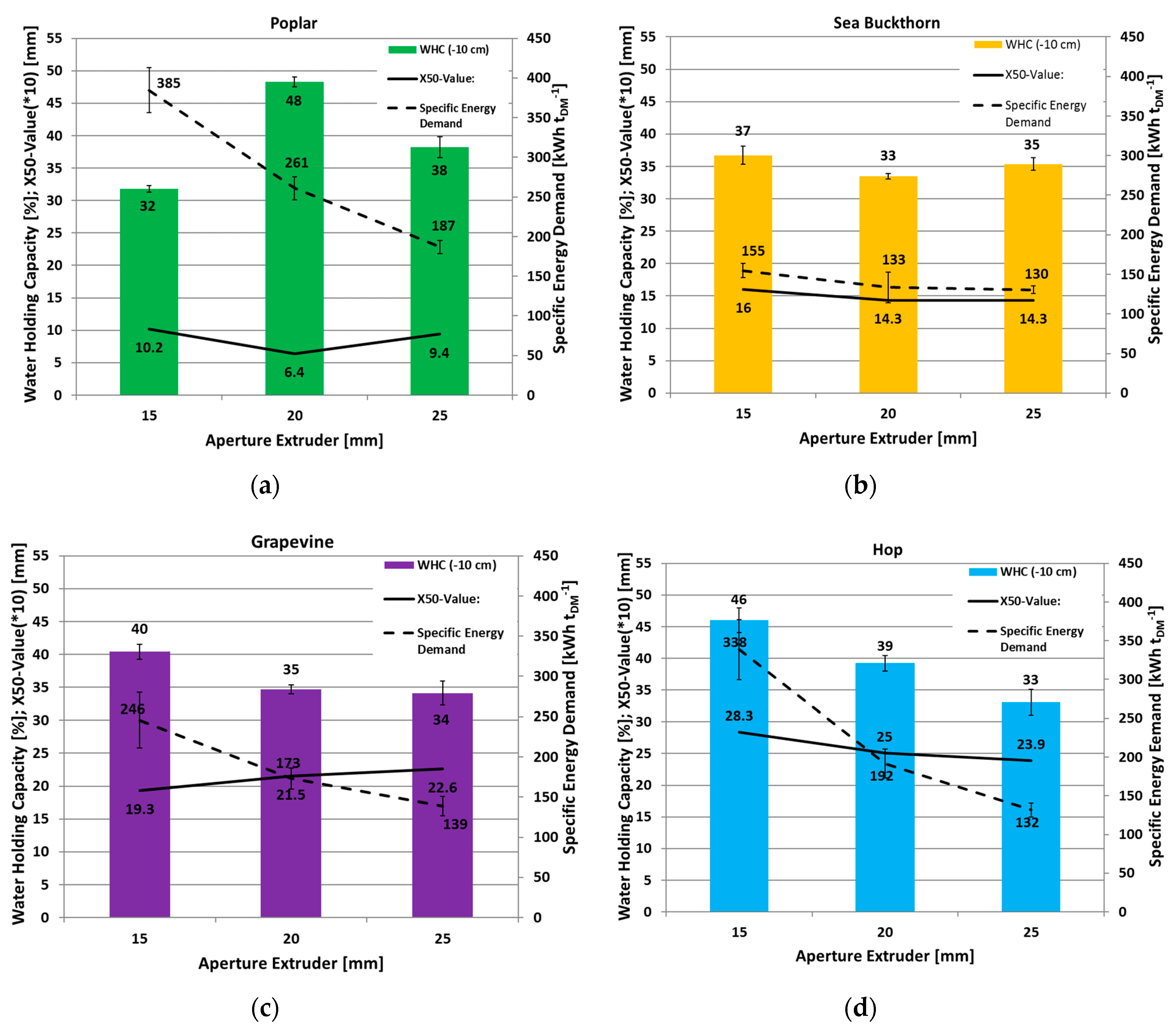

3.4. Interconnections of Water Holding Capacity, Aperture, X50-Value and Specific Energy Demand

3.5. Specific Energy Demand and Further Material Parameters in Dependence to Raw Material and Aperture Setting

4. Discussion

4.1. Water Holding Capacity and How It Is Affected

4.2. Energy Demand Influence Factors

4.3. Influences on Particle Size Distribution

4.4. Interactions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

| Sample Number | Specific Energy Demand [kWh t−1] * | WHC− 10 cm ** [%] | WHC− 50 cm ** [%] | X50-Value [mm] | Bulk Density [kg m−3] * | Shrinkage [%] | Particle Density [kg m−3] * | Total Pore Volume [%] | Ash Content * [%] |

|---|---|---|---|---|---|---|---|---|---|

| LD10 | 150 ± 17 | 34 ± 0.83 | 33 ± 0.62 | 1.17 | 124 ± 4.31 | 7.4 ± 1.80 | 1575 ± 2.33 | 92 ± 0.34 | 3.9 ± 0.35 |

| LD15 | 123 ± 35 | 35 ± 0.68 | 34 ± 0.73 | 1.54 | 120 ± 2.12 | 4.0 ± 0.70 | 1585 ± 3.03 | 92 ± 0.08 | 5.3 ± 0.45 |

| OLD10 | 156 | 42 ± 3.77 | 30 ± 1.31 | 0.98 | 165 ± 6.75 | 5.3 ± 0.84 | 1582 ± 0.94 | 90 ± 0.46 | 4.9 ± 0.14 |

| OLD15 | 90 | 43 ± 1.08 | 30 ± 0.35 | 1.34 | 192 ± 1.94 | 6.0 ± 1.00 | 1580 ± 1.75 | 88 ± 0.06 | 4.5 ± 0.26 |

| OLD20 | 93 | 43 ± 2.09 | 29 ± 0.83 | 1.21 | 182 ± 5.65 | 7.4 ± 0.48 | 1584 ± 1.05 | 89 ± 0.36 | 5.1 ± 0.16 |

| TD10 | 154 | 46 ± 1.11 | 38 ± 0.52 | 0.68 | 127 ± 2.39 | 5.8 ± 1.37 | 1575 ± 4.14 | 92 ± 0.14 | 3.8 ± 0.62 |

| TD15 | 154 | 45 ± 0.83 | 37 ± 0.90 | 0.76 | 123 ± 1.79 | 6.6 ± 0.86 | 1576 ± 0.88 | 92 ± 0.13 | 4.0 ± 0.13 |

| TD20 | 118 | 44 ± 1.67 | 37 ± 0.87 | 0.98 | 136 ± 1.81 | 5.2 ± 0.93 | 1573 ± 2.51 | 91 ± 0.09 | 3.5 ± 0.38 |

| TD25 | 105 | 35 ± 1.98 | 32 ± 1.43 | 0.73 | 131 ± 2.40 | 6.0 ± 0.32 | 1571 ± 0.81 | 92 ± 0.17 | 3.3 ± 0.12 |

| SD10 | 935 | 68 ± 1.17 | 53 ± 1.00 | 0.97 | 126 ± 2.61 | 13.3 ± 2.96 | 1571 ± 1.01 | 92 ± 0.18 | 3.2 ± 0.15 |

| SD15 | 391 | 60 ± 0.56 | 49 ± 0.64 | 0.77 | 125 ± 3.79 | 13.5 ± 2.58 | 1576 ± 0.74 | 92 ± 0.24 | 4.0 ± 0.11 |

| SD20 | 167 | 53 ± 1.67 | 46 ± 1.72 | 0.77 | 128 ± 8.08 | 7.1 ± 1.15 | 1573 ± 0.18 | 92 ± 0.63 | 3.5 ± 0.03 |

| SD25 | 131 | 43 ± 0.48 | 39 ± 0.70 | 1.04 | 113 ± 3.46 | 7.5 ± 1.79 | 1572 ± 0.67 | 93 ± 0.27 | 3.4 ± 0.10 |

| ORD6 | 100 | 44 ± 2.70 | 42 ± 2.15 | 0.69 | 170 ± 11.17 | 8.5 ± 0.24 | 1595 ± 1.68 | 89 ± 0.85 | 6.8 ± 0.25 |

| ORD10 | 89 | 43 ± 1.17 | 41 ± 0.84 | 0.84 | 168 ± 2.03 | 8.0 ± 0.58 | 1596 ± 1.13 | 89 ± 0.15 | 7.0 ± 0.17 |

| BLF 20 | 208 ± 14 | 41 ± 0.46 | 36 ± 0.76 | 1.95 | 116 ± 1.77 | 3.2 ± 0.70 | 1568 ± 1.14 | 93 ± 0.01 | 2.7 ± 0.17 |

| BLF 25 | 132 ± 3 | 37 ± 0.35 | 32 ± 0.39 | 2.46 | 120 ± 0.63 | 2.7 ± 1.80 | 1562 ± 1.96 | 92 ± 0.01 | 1.9 ± 0.30 |

| BLF 30 | 103 ± 15 | 37 ± 0.67 | 33 ± 0.44 | 2.97 | 131 ± 1.31 | 2.7 ± 1.04 | 1563 ± 2.95 | 92 ± 0.11 | 2.0 ± 0.45 |

| PF15 | 385 ± 28 | 32 ± 0.51 | 25 ± 1.19 | 1.02 | 74 ± 1.98 | 2.1 ± 0.64 | 1563 ± 0.21 | 95 ± 0.13 | 2.0 ± 0.03 |

| PF20 | 261 ± 15 | 48 ± 0.75 | 29 ± 1.04 | 0.64 | 93 ± 2.16 | 6.5 ± 1.87 | 1565 ± 0.30 | 94 ± 0.17 | 2.3 ± 0.05 |

| PF25 | 187 ± 8 | 38 ± 1.61 | 26 ± 0.88 | 0.94 | 90 ± 2.33 | 4.8 ± 1.86 | 1564 ± 0.34 | 94 ± 0.07 | 2.2 ± 0.05 |

| PF40 | 155 ± 10 | 35 ± 1.07 | 27 ± 0.77 | 2.17 | 75 ± 3.22 | 4.6 ± 1.96 | 1558 ± 0.36 | 95 ± 0.21 | 1.2 ± 0.06 |

| PD30 | 248 | 34 ± 0.96 | 24 ± 0.86 | 1.22 | 94 ± 2.85 | 6.2 ± 2.75 | 1565 ± 0.41 | 94 ± 0.15 | 2.3 ± 0.06 |

| PD35 | 260 | 25 ± 1.12 | 21 ± 0.66 | 1.12 | 85 ± 2.17 | 5.9 ± 1.15 | 1563 ± 0.26 | 95 ± 0.06 | 2.0 ± 0.04 |

| SBTF10 | 172 | 38 ± 2.36 | 28 ± 1.48 | 1.63 | 106 ± 5.08 | 7.0 ± 1.06 | 1557 ± 0.39 | 93 ± 0.12 | 1.2 ± 0.06 |

| SBTD15 | 151 ± 9 | 37 ± 1.38 | 31 ± 1.17 | 1.60 | 127 ± 4.96 | 5.6 ± 0.99 | 1564 ± 0.24 | 92 ± 0.30 | 2.1 ± 0.04 |

| SBTD20 | 133 ± 19 | 33 ± 0.40 | 29 ± 0.19 | 1.43 | 122 ± 2.87 | 5.9 ± 0.78 | 1560 ± 1.92 | 92 ± 0.08 | 1.5 ± 0.30 |

| SBTD25 | 130 ± 5 | 35 ± 0.99 | 34 ± 1.04 | 1.43 | 131 ± 3.95 | 6.7 ± 2.99 | 1560 ± 1.51 | 92 ± 0.28 | 1.5 ± 0.23 |

| HD15 | 338 ± 39 | 46 ± 1.94 | 41 ± 0.93 | 2.83 | 94 ± 1.28 | 7.2 ± 1.61 | 1573 ± 2.88 | 94 ± 0.06 | 3.5 ± 0.44 |

| HD20 | 192 ± 19 | 39 ± 1.22 | 36 ± 1.56 | 2.50 | 90 ± 2.60 | 6.8 ± 1.32 | 1570 ± 2.28 | 94 ± 0.17 | 3.0 ± 0.35 |

| HD25 | 132 ± 9 | 33 ± 2.06 | 31 ± 1.83 | 2.39 | 83 ± 3.78 | 8.4 ± 0.68 | 1582 ± 2.92 | 95 ± 0.20 | 4.8 ± 0.44 |

| GVF15 | 246 ± 35 | 40 ± 1.15 | 36 ± 1.18 | 1.93 | 89 ± 2.79 | 5.6 ± 0.65 | 1566 ± 0.34 | 94 ± 0.08 | 2.4 ± 0.05 |

| GVF20 | 173 ± 13 | 35 ± 0.65 | 32 ± 0.65 | 2.15 | 92 ± 1.16 | 2.5 ± 0.84 | 1563 ± 1.03 | 94 ± 0.07 | 2.1 ± 0.16 |

| GVF25 | 139 ± 12 | 34 ± 1.82 | 32 ± 1.66 | 2.26 | 91 ± 5.27 | 3.6 ± 1.28 | 1565 ± 0.77 | 94 ± 0.27 | 2.3 ± 0.12 |

| FBF20 | 215 ± 26 | 50 ± 1.63 | 32 ± 0.91 | 0.64 | 153 ± 3.90 | 9.4 ± 1.60 | 1578 ± 4.79 | 90 ± 0.08 | 4.3 ± 0.72 |

| FBF30 | 129 ± 13 | 57 ± 2.17 | 38 ± 0.60 | 0.84 | 212 ± 4.75 | 6.7 ± 0.75 | 1576 ± 4.71 | 87 ± 0.35 | 4.0 ± 0.71 |

| WP | not extruded | 82 ± 3.38 | 51 ± 1.72 | 1.30 | 110 ± 4.22 | 21.0 ± 1.18 | 1571 ± 0.96 | 93 ± 0.32 | 3.3 ± 0.15 |

| C | not extruded | 62 ± 0.94 | 38 ± 1.42 | 0.76 | 82 ± 0.61 | 6.6 ± 1.40 | 1662 ± 11.9 | 95 ± 0.03 | 16.2 ± 1.60 |

| S | not extruded | 42 ± 1.24 | 36 ± 0.95 | 0.23 | 1455 ± 21.0 | 8.0 ± 0.01 | 2597 ± 4.77 | 44 ± 0.89 | 97.1 ± 0.26 |

References

- Smith, L.; MacDonald, G.; Velichko, A.; Beilman, D.; Borisova, O.; Frey, K.; Kremenetski, K.; Sheng, Y. Siberian peatlands a net carbon sink and global methane source since the early holocene. Science 2004, 303, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Broder, T.; Blodau, C.; Biester, H.; Knorr, K.; Conant, R. Peat decomposition records in three pristine ombrotrophic bogs in southern patagonia. Biogeosciences 2012, 9, 1479–1491. [Google Scholar] [CrossRef]

- Hulatt, C.J.; Kaartokallio, H.; Asmala, E.; Autio, R.; Stedmon, C.A.; Sonninen, E.; Oinonen, M.; Thomas, D.N. Bioavailability and radiocarbon age of fluvial dissolved organic matter (dom) from a northern peatland-dominated catchment: Effect of land-use change. Aquat. Sci. 2014, 76, 393–404. [Google Scholar] [CrossRef]

- Gaudig, G. Sphagnum Growth and Its Perspectives for Sphagnum Farming; University Greifswald: Greifswald, Germany, 2020. [Google Scholar]

- Schmilewski, G. The role of peat in assuring the quality of growing media. Mires Peat 2008, 3, 1–8. [Google Scholar]

- Reinhofer, M. Torfersatz Durch Biogene Rest-und Abfallstoffe, Final Report; Institut für Nachhaltige Techniken und Systeme: Frohnleiten, Austria, 2006; p. 44. [Google Scholar]

- Gruda, N.; Schnitzler, W. Holzfasersubstrate als eine Torfalternative für die Gemüseproduktion. Holz Als Roh Und Werkst. 2006, 64, 347–350. [Google Scholar] [CrossRef]

- Grießer, S. Torfersatzsubstrate für den Erwerbsgartenbau-Ein Beitrag für Nachhaltige Landnutzung in Niedersachsen; University Vechta: Vechta, Germany, 2016. [Google Scholar]

- Meuser, F.; Meuser, S.; Wiedmann, W. Grundlagen des extrudierens. In Lebensmitteltechnologi; Springer: Berlin/Heidelberg, Germany, 2004; pp. 523–539. [Google Scholar]

- Cáceres, R.; Malińska, K.; Marfà, O. Nitrification within composting: A review. Waste Manag. 2018, 72, 119–137. [Google Scholar] [CrossRef] [PubMed]

- Dittrich, C.; Pecenka, R.; Løes, A.-K.; Schmutz, U. Technical Paper on Twin Screw Extruder Processing Technology for Fibres as Raw Material for Peat Substitution Organnic PLUS, Coventry 2019. Available online: https://orgprints.org/id/eprint/36844/ (accessed on 2 June 2021).

- Kiesewalter, S.; Riehl, G. Nutzungsalternativen von Grünlandaufwüchsen in Sächsischen Vorgebirgslagen–Ein Beitrag zur Erhaltung der Kulturlandschaft und des ländlichen Raums; Sächsische Landesanstalt für Landwirtschaft: Dresden, Germany, 2007. [Google Scholar]

- Bollen, G. Fungal recolonization of heat-treated glasshouse soils. Agro Ecosyst. 1974, 1, 139–155. [Google Scholar] [CrossRef]

- Landis, T.D.; Jacobs, D.F.; Wilkinson, K.M.; Luna, T. Growing media. Contain. Grow. Media 1990, 2, 41–85. [Google Scholar]

- Eymann, L.; Mathis, A.; Stucki, M.; Amrein, S. Torf und Torfersatzprodukte im Vergleich: Eigenschaften, Verfügbarkeit, Ökologische Nachhaltigkeit und Soziale Auswirkungen; Institut für Umwelt und Natürliche Ressourcen, Zürcher Hochschule für Angewandte Wissenschaften: Wädenswil, Switzerland, 2015. [Google Scholar]

- Schmutz, U.; Conroy, J. Pathways to Phase-Out Contentious Inputs from Organic Agriculture in Europe. Available online: https://organic-plus.net/ (accessed on 2 June 2021).

- Kir, A.; Løes, A.K.; Cetinel, B.; Turan, H.S.; Aydogdu, E.; Pecenka, R.; Dittrich, C.; Cáceres, R.; Lennartsson Turner, M.; Rayns, F. Testing peat-free growing media based on olive wood residues for olive saplings (Olea europaea L., cv. Gemlik). In Growing Media 2021; ISHS: Ghent, Belgium, 2021. [Google Scholar]

- König, U.J. Optimisation of Quality of Bio Substrates for Nursery Plants under Ecological Vegetable Production with Special Concern to Transformation to Praxis of Peat Ersatz by Fermented Wood Fibre; Forschungsring e.V.: Darmstadt, Germany, 2006. [Google Scholar]

- Kharazipour, A. Herstellung von Holzfasern als Torfersatzstoff; Büsgen-Institut: Göttingen, Germany, 2009. [Google Scholar]

- Makas, M.; Windeisen, E.; Wegener, G. Substitution von Torf durch Holz in Pflanzsubstraten. Eur. J. Wood Wood Prod. 2000, 58, 125–126. [Google Scholar] [CrossRef]

- White, J.L.; Potente, H. Screw Extrusion; Hanser Publishers: Munich, Germany, 2001; p. 464. [Google Scholar]

- Lehmann, T.; Gläser, S. Vorhabensbezeichnung: Innovative Biogaserzeugung mit gesteigertem Wirkungsgrad Durch Hydrothermale Aufbereitung-“Bioextrusion”-von Nawaro als Gärsubstrat und Verfahrensnachweis an Einer Versuchsanlage in Containerform mit 1 t/d Durchsatzleistung (ca. 20 kw el): Final Report; Lehmann Maschinenbau GmbH: Pöhl, Germany, 2009. [Google Scholar]

- Rauwendaal, C. Understanding Extrusion; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2018; p. 32. [Google Scholar]

- Kissel, R.; Henkelmann, G.; Seidel, J.; Koch, K.; Dollhofer, V.; Lebuhn, M. Substrataufbereitung; Biogas Forum Bayern: München, Germany, 2019. [Google Scholar]

- Kuschel, M. Veredlung von Holzhackschnitzeln Durch Aufschluss, Mdifizierung und Pressverdichtung; TU Freiberg: Freiberg, Germany, 2004. [Google Scholar]

- Irvine, G. The significance of the glass transition of lignin in thermomechanical pulping. Wood Sci. Technol. 1985, 19, 139–149. [Google Scholar] [CrossRef]

- Hietala, M.; Niinimäki, J.; Oksman, K. The use of twin-screw extrusion in processing of wood: The effect of processing parameters and pretreatment. BioResources 2011, 6, 4615–4625. [Google Scholar]

- Dietrich, T. Untersuchung zur Faserstoffherstellung aus Hanfschäben im Extruderverfahren an Einer Pilotanlage; TU Dresden: Dresden, Germany, 2008; p. 94. [Google Scholar]

- Wallot, G.; Gusovius, H.-J.; Pecenka, R.; Hoffmann, T. Herstellung von Faserwerkstoff aus Pflanzlichen Rohstoffen in einer Scheibenmühle. Agric. Eng. 2011, 66, 100–102. [Google Scholar]

- Pecenka, R.; Furll, C.; Idler, C.; Grundmann, P.; Radosavljevic, L. Fibre boards and composites from wet preserved hemp. Int. J. Mater. Prod. Technol. 2009, 36, 208–220. [Google Scholar] [CrossRef]

- EN ISO 18134-2:2017-05. Solid Biofuels-Determination of Moisture Content-Oven Dry Method-Part 2: Total Moisture-Simplified Method; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- EN ISO 14780:2020-02. Solid Biofuels-Sample Preparation; ISO: Geneva, Switzerland, 2020. [Google Scholar]

- EN DIN 13041:2012-01. Soil Improvers and Growing Media-Determination of Physical Properties-Dry Bulk Density, Air Volume, Water Volume, Shrinkage Value and Total Pore Space; DIN: Berlin, Germany, 2012. [Google Scholar]

- EN DIN 13039:2012-01. Soil Improvers and Growing Media-Determination of Organic Matter Content and Ash; DIN: Berlin, Germany, 2012. [Google Scholar]

- EN ISO 17827-1:2016-10. Solid Biofuels-Determination of Particle Size Distribution for Uncompressed Fuels-Part 1: Oscillating Screen Method Using Sieves with Apertures of 3,15 mm and Above; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Schubert, H. Handbuch der Mechanischen Verfahrenstechnik; John Wiley & Sons: New York, NY, USA, 2012; p. 1299. [Google Scholar]

- Pecenka, R.; Lenz, H.; Jekayinfa, S.O.; Hoffmann, T. Influence of tree species, harvesting method and storage on energy demand and wood chip quality when chipping poplar, willow and black locust. Agriculture 2020, 10, 116. [Google Scholar] [CrossRef]

- Gallardo, D.A.; Seymour, D. Rindenanteile und Aschegehalte von Pappel-und Weidenhybriden. Züchtung Und Ertragsleistung Schnellwachs. Baumarten Im Kurzumtrieb. 2012. Available online: https://www.nw-fva.de/fileadmin/user_upload/Verwaltung/Veranstaltungen/2011/10_AmthauerD_Rindenanteile_und_Aschegehalte_von_Pappel-_und_Weidenhybriden.pdf (accessed on 2 June 2021).

- Klasnja, B.; Kopitovic, S.; Orlovic, S. Wood and bark of some poplar and willow clones as fuelwood. Biomass Bioenergy 2002, 23, 427–432. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Sehlstedt-Persson, M. Impact of Drying and Heat Treatment on Physical Properties and Durability of Solid Wood; Luleå Tekniska Universitet: Luleå, Sweden, 2008. [Google Scholar]

- Badawy, M.; Faraj, H. Chemical composition and activity of bark and leaf extracts of pinus halepensis and olea europaea grown in al-jabel al-akhdar region, libya against some plant phytopathogens. J. Appl. Biotechnol. Bioeng. 2017, 3, 331–342. [Google Scholar] [CrossRef]

- Mohan Gupta, S.; Gupta, A.K.; Ahmed, Z. Antibacterial and antifungal activity in leaf, seed extract and seed oil of seabuckthorn (hippophae salicifolia d. Don) plant. J. Plant Pathol. Microbiol. 2011, 2, 393–401. [Google Scholar] [CrossRef]

- Wagenführ, R.; Scheiber, C. Holzatlas; Fachbuchverlag Leipzig: Leipzig, Germany, 1974; p. 816. [Google Scholar]

- Kießl, K.; Möller, U. Zur Berechnung des Feuchteverhaltens von Bauteilen aus Holz und Holzwerkstoffen. Holz Als Roh Und Werkst. 1989, 47, 317–322. [Google Scholar] [CrossRef]

- Zhao, H.; Jiang, Z.; Ma, J.; Cai, J. What causes the differences in cavitation resistance of two shrubs? Wood anatomical explanations and reliability testing of vulnerability curves. Physiol. Plant 2020, 169, 156–168. [Google Scholar] [CrossRef] [PubMed]

| Sample Code ** | Raw Material | Aperture [mm] | Number of Specific Energy Demand Measurements | ||||

|---|---|---|---|---|---|---|---|

| Common Name | Scientific Name | Origin | Condition at Delivery | Preparation | |||

| LD10 | Laurel | Laurus nobilis L. | Turkey | dry leaves and branches 12% MC * | moisten to 50% MC | 10 | 4 |

| LD15 | 15 | 3 | |||||

| OLD10 | Olive | Olea europaea L. | Turkey | dry chipped branches and leaves 11% MC | moisten to 50% MC | 10 | 1 |

| OLD15 | 15 | 1 | |||||

| OLD20 | 20 | 1 | |||||

| TD10 | Thyme | Thymus vulgaris L. | Turkey | dry leaves and small sticks 13% MC | moisten to 50% MC | 10 | 1 |

| TD15 | 15 | 1 | |||||

| TD20 | 20 | 1 | |||||

| TD25 | 25 | 1 | |||||

| SD10 | Sage | Salvia spp. L. | Turkey | dry branches 12% MC | moisten to 50% MC | 10 | 1 |

| SD15 | 15 | 1 | |||||

| SD20 | 20 | 1 | |||||

| SD25 | 25 | 1 | |||||

| ORD6 | Oregano | Origanum vulgare L. | Turkey | dry leaves 11% MC | moisten to 50% MC | 6 | 1 |

| ORD10 | 10 | 1 | |||||

| BLF 20 | Black locust | Robinia pseudoacacia L. | ATB plantation (SRC) | fresh whole trees 37% MC | chipping | 20 | 4 |

| BLF 25 | 25 | 4 | |||||

| BLF 30 | 30 | 4 | |||||

| PF15 | Poplar | Populus spp. L. | ATB plantation (SRC) | chipped fresh trees 50–57% MC | none | 15 | 5 |

| PF20 | 20 | 5 | |||||

| PF25 | 25 | 6 | |||||

| PF40 | 40 | 5 | |||||

| PD30 | chipped dry trees 10% MC | moisten to 50% MC | 30 | 1 | |||

| PD35 | 35 | 1 | |||||

| SBTF10 | Sea buckthorn | Hippophae rhamnoides L. | Germany, harvest residues | fresh sticks, branches, berries 44% MC | chipping | 10 | 1 |

| SBTD15 | dry chipped sticks, branches, berries and leaves 11% MC | moisten to 50% MC | 15 | 5 | |||

| SBTD20 | 20 | 5 | |||||

| SBTD25 | 25 | 4 | |||||

| HD15 | Hop | Humulus lupulus L. | Germany, harvest residues | dry vines 10% MC | moisten to 50% MC | 15 | 5 |

| HD20 | 20 | 5 | |||||

| HD25 | 25 | 6 | |||||

| GVF15 | Grape | Vitis vinifera L. | Germany, pruning residues | fresh vines 45% MC | chipping | 15 | 5 |

| GVF20 | 20 | 5 | |||||

| GVF25 | 25 | 5 | |||||

| FBF20 | Forest biomass Mainly Scots pine and holly oak | Pinus sylvestris, L. Quercus ilex L. | Residues from forest cleaning | fresh collected and chipped 42% MC | none | 20 | 5 |

| FBF30 | 30 | 5 | |||||

| WP | Floratorf white peat | none | hardware store | appears as substrate | none | not extruded | |

| C | Neudorf Kokohum Coir | pressed and dried in a block | |||||

| S | Sand | ATB plantation | |||||

| LD 10 | GVF15 |

| GV = grapevine | L = laurel |

| D = dry at delivery (remoistened prior to extrusion) | F = fresh at delivery (extruded fresh) |

| 10 = aperture setting 10 mm | 15 = aperture setting 15 mm |

| Parameter | Unit | Numbers of Samples per Batch | Methodology Specification |

|---|---|---|---|

| Moisture content (wet based) * | % | 3 | DIN EN ISO 18134–2 [31] |

| Sample preparation | - | 1 | DIN EN ISO 14780 [32] |

| WHC at all negative overpressures | % | 4 | DIN EN 13041 [33] |

| Shrinkage | % | 4 | DIN EN 13041 [33] |

| Bulk density (dry) | kg m−3 | 4 | DIN EN 13041 [33] |

| Particle density | kg m−3 | 4 | DIN EN 13041 [33] |

| Total Pore Volume | % | 4 | DIN EN 13041 [33] |

| Ash content | % | 3 | DIN EN 13039 [34] |

| Organic matter | % | 3 | DIN EN 13039 [34] |

| Specific energy demand (on dry matter basis, DM) | kWh t−1 | Continuous | Calculation with values collected from frequency converter and scale Equation no 2 |

| Particle size distribution | % | 3 | ISO 17827 [35] |

| X50 (average particle size) | Mm | 3 | [36] |

| Material Extruded at 20 mm Aperture | Fine Fraction [%] * (<0.5 mm) | X50 [mm] | Coarse Fraction [%] * (>3.15 mm) |

|---|---|---|---|

| Hop | 11 | 2.50 | 30.7 |

| Grapevine | 11 | 2.15 | 32.0 |

| Black locust | 16 | 1.95 | 22.2 |

| Sea buckthorn | 27 | 1.43 | 18.2 |

| Peat | 23 | 1.30 | 21.5 |

| Olive | 30 | 1.21 | 8.7 |

| Thyme | 25 | 0.98 | 0.4 |

| Sage | 37 | 0.77 | 1.2 |

| Coir | 31 | 0.76 | 1.7 |

| Poplar | 43 | 0.64 | 3.0 |

| Forest biomass | 44 | 0.64 | 3.7 |

| Sand | 82 | 0.23 | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dittrich, C.; Pecenka, R.; Løes, A.-K.; Cáceres, R.; Conroy, J.; Rayns, F.; Schmutz, U.; Kir, A.; Kruggel-Emden, H. Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy 2021, 11, 1185. https://doi.org/10.3390/agronomy11061185

Dittrich C, Pecenka R, Løes A-K, Cáceres R, Conroy J, Rayns F, Schmutz U, Kir A, Kruggel-Emden H. Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy. 2021; 11(6):1185. https://doi.org/10.3390/agronomy11061185

Chicago/Turabian StyleDittrich, Christian, Ralf Pecenka, Anne-Kristin Løes, Rafaela Cáceres, Judith Conroy, Francis Rayns, Ulrich Schmutz, Alev Kir, and Harald Kruggel-Emden. 2021. "Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties" Agronomy 11, no. 6: 1185. https://doi.org/10.3390/agronomy11061185

APA StyleDittrich, C., Pecenka, R., Løes, A.-K., Cáceres, R., Conroy, J., Rayns, F., Schmutz, U., Kir, A., & Kruggel-Emden, H. (2021). Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy, 11(6), 1185. https://doi.org/10.3390/agronomy11061185