The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

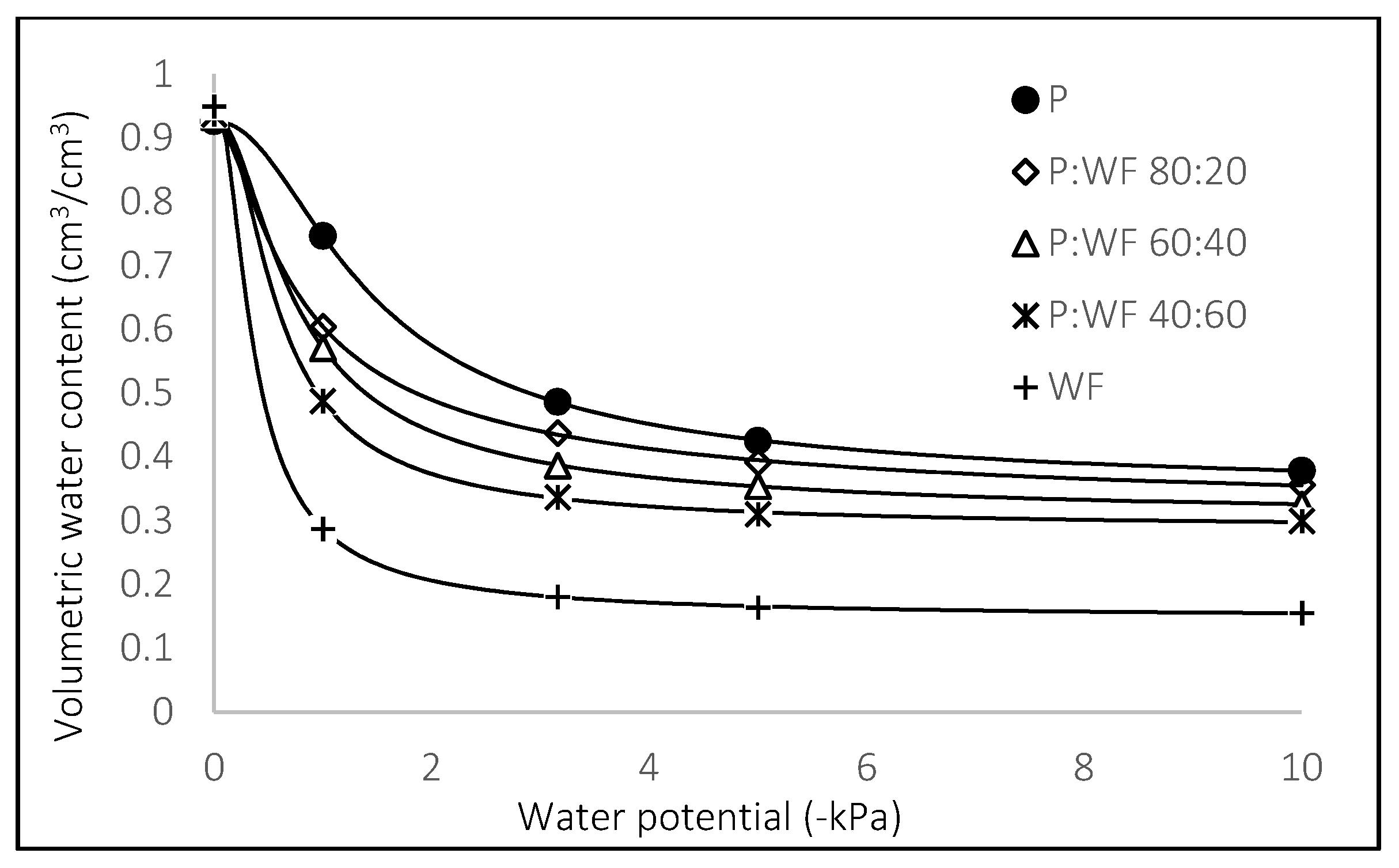

2.2.1. Water Retention Properties

2.2.2. Wettability Measurements: Two Complementary Approaches

Preparation of the Materials

Contact Angle Measurements

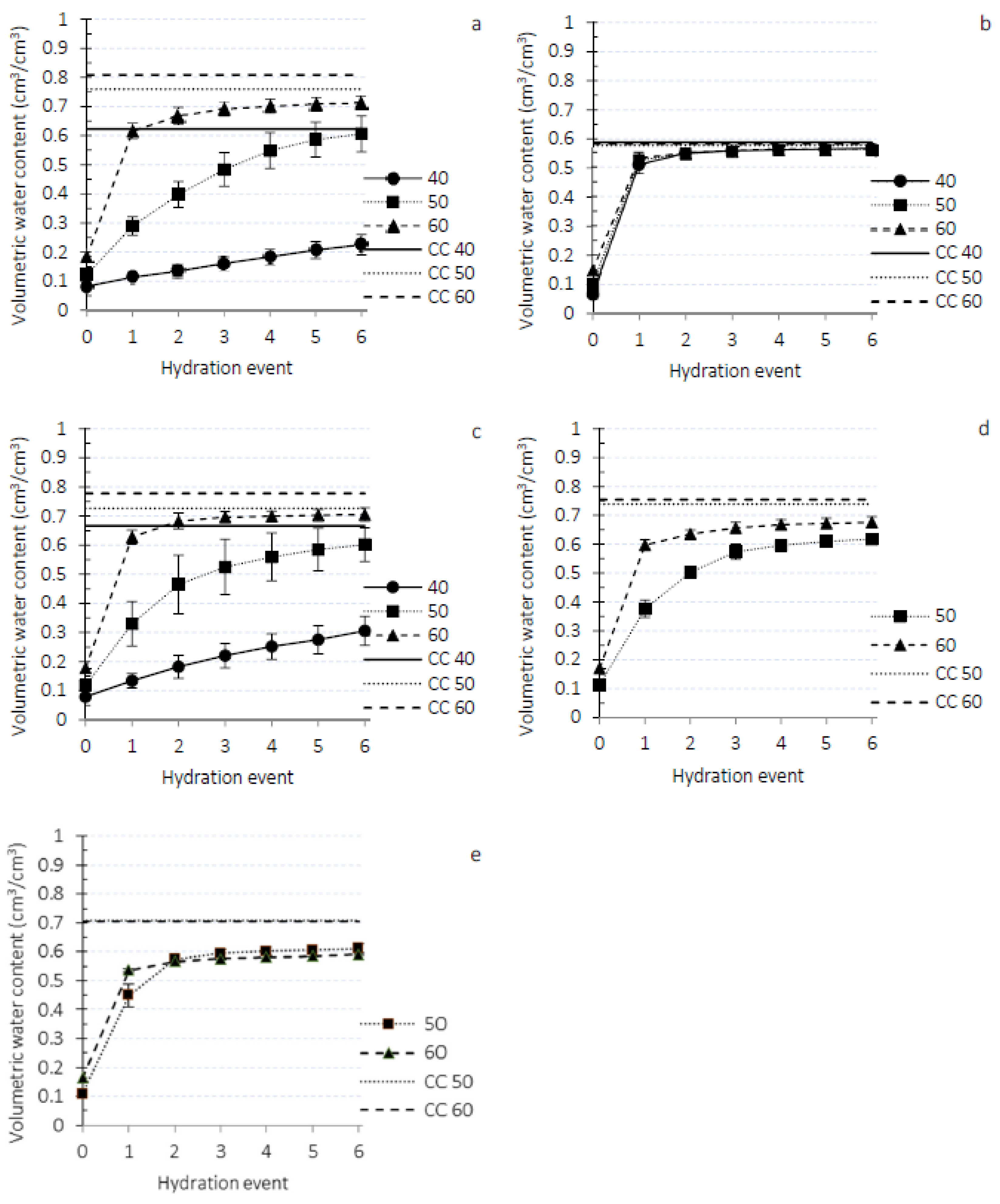

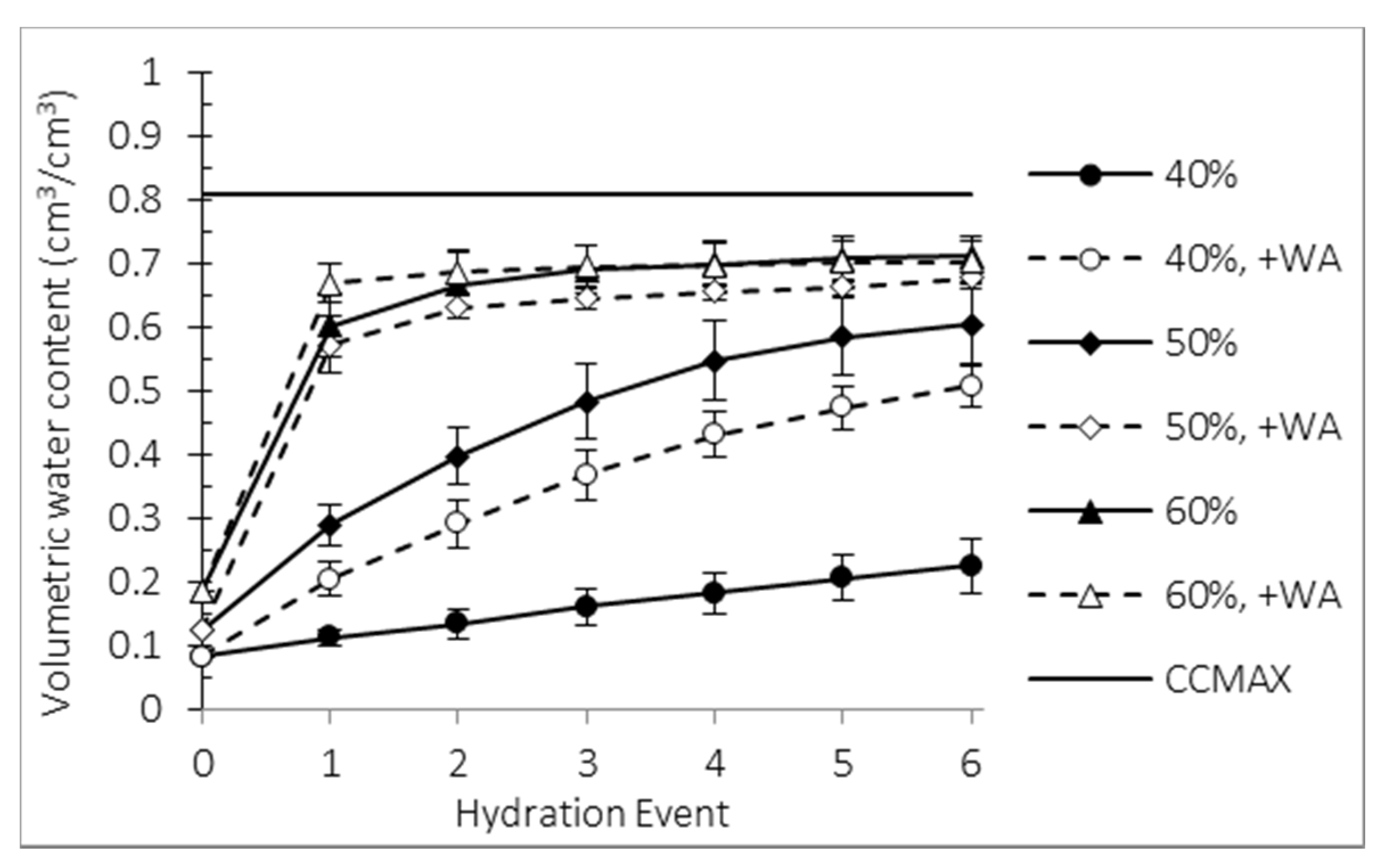

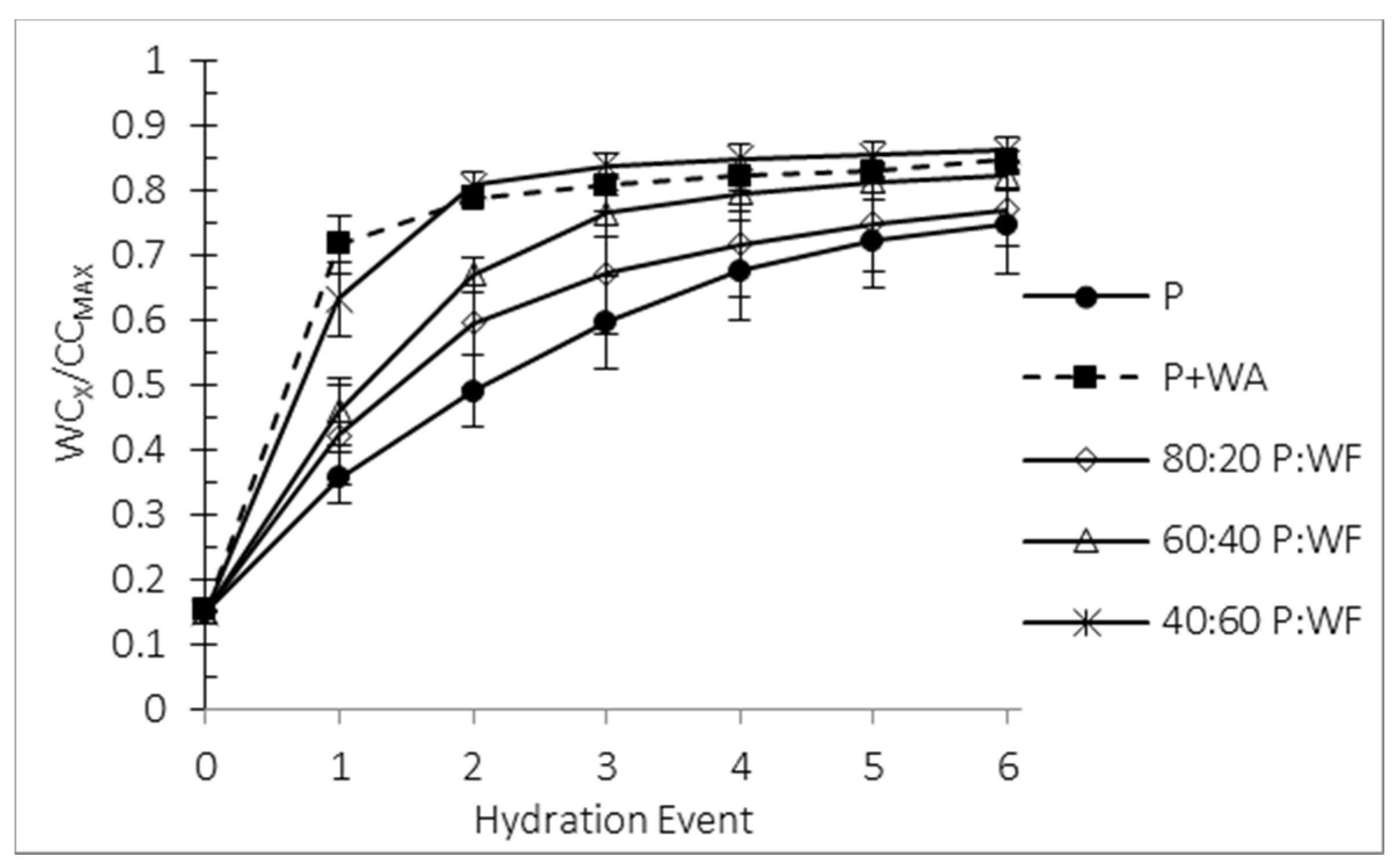

Hydration Curves

- -

- The water volumes retained (v/v) by the substrate column after 1 and 3 irrigations, «WC1» and «WC3», i.e., after 5-min and 15-min irrigation (5-min irrigation corresponding to a usual time of watering; and 15 min to a maximum);

- -

- The container capacity (CCX), corresponding to the maximum water content (v/v) recovered by the substrate initially equilibrated at initial MC of 40% (CC40), 50% (CC50), and 60% (CC60) w/w;

- -

- The maximum container capacity (CCMAX), considered as the CC value (v/v) for a substrate prepared at the 60% w/w MC, i.e., when the substrate was fully hydrophilic and quickly rewetted.

2.2.3. Statistical Analysis

3. Results

3.1. Wettability Measurements

3.1.1. Contact Angles

3.1.2. Hydration Curves

Raw Materials and Mixes

Effects of Wetting Agent Addition in Peat and Comparison with Peat:Wood Fiber Mixes

3.2. Water Retention Properties

4. Discussion

4.1. Validity and Robustness of Methods and Results

4.2. Respective Weights of Peat vs. Wood Fiber Regarding the Ability to Rewet for Mixes

4.3. Wood Fiber and Other Peat Alternatives for Reducing Risks of Hydrophobicity—Consequences on Other Physical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmilewski, G. Growing media constituents used in the EU in 2013. Acta Hortic. 2017, 1168, 85–92. [Google Scholar] [CrossRef]

- Alexander, P.D.; Bragg, N.C.; Meade, R.; Padelopoulos, G.; Watts, O. Peat in horticulture and conservation: The UK response to a changing world. Mires Peat 2008, 3, 8. [Google Scholar]

- Parish, F.; Sirin, A.A.; Charman, D.; Joosten, H.; Minaeva, T.Y.; Silvius, M. Assessment on Peatlands, Biodiversity and Climate Change; Global Environment Centre, Kuala Lumpur & Wetlands International: Wageningen, The Netherland, 2008; 46p, ISBN 978-983-43751-0-2. [Google Scholar]

- Peters, J.; Unger, M. Peatlands in the EU regulatory environment: Survey with case studies on Poland and Estonia. Bonn Bad Godesberg: Bundesamt für Naturschutz. BfN-Skripten 2017, 454, 103. [Google Scholar]

- Michel, J.-C. Wettability of Organic Growing Media Used in Horticulture: A Review. Vadose Zone J. 2015, 14. [Google Scholar] [CrossRef]

- Michel, J.; Jackson, B.; Fonteno, W. The use of coir for reducing risks of peat-based substrate hydrophobicity. Acta Hortic. 2021, 1305, 449–454. [Google Scholar] [CrossRef]

- Michel, J.C.; Riviere, L.M.; Bellon-Fontaine, M.N. Measurement of the wettability of organic materials in relation to water content by the capillary rise method. Eur. J. Soil Sci. 2001, 52, 459–467. [Google Scholar] [CrossRef]

- Fields, J.S.; Fonteno, W.C.; Jackson, B.E. Hydration Efficiency of Traditional and Alternative Greenhouse Substrate Components. HortScience 2014, 49, 336–342. [Google Scholar] [CrossRef]

- Michel, J.-C.; Jackson, B.; Fonteno, W. Classification of organic substrates’ wettability from contact angle measurements and hydration efficiency tests. Acta Hortic. 2017, 1168, 199–206. [Google Scholar] [CrossRef]

- Jackson, B.E. Wood substrates in horticulture: Past, present, and future. In Proceedings of the ISHS Symposium on Growing Media, Composting and Substrate Analysis, Milan, Italy, 24–28 June 2019. [Google Scholar]

- Jackson, B.E. The role of wood substrates in controlled environment vegetable and fruit production systems. Prod. Grow. 2018, 38, 24–25. [Google Scholar]

- Domeño, I.; Irigoyen, I.; Muro, J. New wood fibre substrates characterization and evaluation in hydroponic tomato culture. Eur. J. Hortic. Sci. 2010, 75, 89–94. [Google Scholar]

- Lemaire, F.; Dartigues, A.; Riviere, L.M.; Charpentier, S. Cultures en pots et Conteneurs: Principes Agronomiques et Applications, 1st ed.; INRA: Paris, France, 1989; ISBN 2-7380-0157-2. [Google Scholar]

- Jackson, B.E. Substrates on Trial: Wood Fiber in the Spotlight. Greenh. Manag. 2018, 38, 52–56. [Google Scholar]

- NF EN 13041. Amendements du sol et Supports de Culture—Détermination des Propriétés Physiques—Masse Volumique Apparente Sèche, Volume d’air, Volume d’eau, Valeur de Rétraction et Porosité Totale; Association Française de Normalisation: Paris, France, 2000. [Google Scholar]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Schulker, B.A.; Jackson, B.E.; Fonteno, W.C.; Heitman, J.L.; Albano, J.P. Comparison of Water Capture Efficiency through Two Irrigation Techniques of Three Common Greenhouse Soilless Substrate Components. Agronomy 2020, 10, 1389. [Google Scholar] [CrossRef]

- van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Morel, P.; Poncelet, L.; Riviere, L.M. Les Supports de Culture Horticoles; Editions Quae: Versailles, France, 2000; ISBN 9782738009074. [Google Scholar]

- Michel, J.C. The physical properties of peat: A key factor for modern growing media. Mires Peat 2010, 6, 2. [Google Scholar]

- de Boodt, M.; Verdonck, O. The physical properties of the substrates in horticulture. Acta Hortic 1972, 26, 37–42. [Google Scholar] [CrossRef]

- Donners, M.P.J.; Verhoeven, J.; Michel, J.-C. Potential use of recycled stone wool substrate granulates as substrate component. Acta Hortic 2019, 1266, 323–330. [Google Scholar] [CrossRef]

- Michel, J.C.; Kerloch, E. Evolution of hydraulic properties and wettability of organic growing media during cultivation according to irrigation strategies. Sci. Hort. 2017, 217, 28–35. [Google Scholar] [CrossRef][Green Version]

| Substrates | Bulk Density (g·cm−3) | Initial Moisture Content in Weight (%) a | ||

|---|---|---|---|---|

| 40% | 50% | 60% | ||

| Initial Volumetric Water Content (%) for both Contact Angle Measurements and Hydration Curves b | ||||

| P c | 0.13 | 0.08 | 0.12 | 0.19 |

| 80:20 d P:WF | 0.12 | 0.08 | 0.12 | 0.18 |

| 60:40 d P:WF | 0.12 | 0.08 | 0.11 | 0.17 |

| 40:60 d P:WF | 0.11 | 0.07 | 0.11 | 0.16 |

| WF e | 0.10 | 0.07 | 0.10 | 0.15 |

| MC = 40% a | MC = 50% a | MC = 60% a | |

|---|---|---|---|

| P b | 90.0° a e A f | 90.0° a A | 87.0° b A |

| 80:20 c P:WF | 90.0° a A | 89.4° b B | 86.9° c A |

| 60:40 c P:WF | 89.7° a B | 88.5° b C | 86.0° c B |

| 40:60 c P:WF | 89.5° a C | 88.1° b D | 85.7° c B |

| WF d | 86.1° a D | 85.8° ab E | 85.5° b B |

| WC1/CCMAX a | WC3/CCMAX b | CC/CCMAX c | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MC = 40%d | MC = 50%d | MC = 60%d | MC = 40% | MC = 50% | MC = 60% | MC = 40% | MC = 50% | MC = 60% | |

| Pe | 0.14 a h A i | 0.36 b A | 0.77 c A | 0.20 a A | 0.60 b A | 0.85 c A | 0.77 a A | 0.94 b A | 1 b A |

| 80:20 f P:WF | 0.17 a A | 0.42 b AB | 0.81 c A | 0.28 a B | 0.67 b AB | 0.89 c AB | 0.86 a B | 0.95 ab A | 1 b A |

| 60:40 f P:WF | ND j | 0.46 a B | 0.80 b A | ND | 0.76 a BC | 0.88 b AB | ND | 1 a A | 1 a A |

| 40:60 f P:WF | ND | 0.63 a C | 0.77 b A | ND | 0.83 a C | 0.85 a A | ND | 1 a A | 1 a A |

| WF g | 0.88 a B | 0.90 a D | 0.91 a B | 0.96 a C | 0.96 a D | 0.96 a B | 1 a C | 1 a A | 1 a A |

| Bulk Density (BD) a | Total Porosity (TP) b | Air-Filled Porosity (AFP) b | Water Holding Capacity (WHC) b | Available Water (AW) b | |

|---|---|---|---|---|---|

| Pc | 0.12 a f | 0.93 a | 0.18 a | 0.75 a | 0.37 a |

| 80:20 d P:WF | 0.11 ab | 0.93 ab | 0.33 b | 0.60 b | 0.25 b |

| 60:40 d P:WF | 0.11 b | 0.93 b | 0.36 c | 0.57 c | 0.24 b |

| 40:60 d P:WF | 0.10 c | 0.94 c | 0.45 d | 0.49 d | 0.19 c |

| WF e | 0.08 d | 0.95 d | 0.66 e | 0.29 e | 0.13 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durand, S.; Jackson, B.E.; Fonteno, W.C.; Michel, J.-C. The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates. Agronomy 2021, 11, 907. https://doi.org/10.3390/agronomy11050907

Durand S, Jackson BE, Fonteno WC, Michel J-C. The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates. Agronomy. 2021; 11(5):907. https://doi.org/10.3390/agronomy11050907

Chicago/Turabian StyleDurand, Stan, Brian E. Jackson, William C. Fonteno, and Jean-Charles Michel. 2021. "The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates" Agronomy 11, no. 5: 907. https://doi.org/10.3390/agronomy11050907

APA StyleDurand, S., Jackson, B. E., Fonteno, W. C., & Michel, J.-C. (2021). The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates. Agronomy, 11(5), 907. https://doi.org/10.3390/agronomy11050907