Abstract

Enhancing vineyards sustainability and reducing herbicides usage is a crucial theme, thus alternative weed management methods are starting to be studied. Cover crops have been shown to provide for several environmental services such as performing an efficient weed control and promoting biodiversity, thus improving the sustainability of the overall management system. However, the use of cover crops is usually confined to the interrow area in order to avoid competition with vines. Under-trellis weed management in vineyards is an important challenge, conventionally fulfilled by cultivation or repeated herbicides applications. Autonomous mowers are small autonomous machines that have shown a great efficiency when employed in agricultural contexts. Due to their reduced size, they can easily prevent the excessive vertical growth of weeds both in the interrows and under trellis without the use of chemical applications. The aim of this trial was to evaluate if the combination of cover crop species and autonomous mowers management could improve vineyard sustainability. Vineyard floor cover that was managed with an autonomous mower had a shorter canopy height and a lower weed dry biomass compared to the conventionally managed vineyard floor cover. Vineyard floor management providing cover crops and autonomous mowing had a significantly lower weed cover percentage compared to conventional floor management, especially under-trellis. The results of this trial suggest that the combination of cover crops and autonomous mowers may be a sustainable and reliable technique to include in vineyards floor management.

1. Introduction

Viticulture is one of the most important economic and cultural activities of the Mediterranean region [1]. Increasing viticulture development is associated with several environmental issues [2] such as soil erosion [3], compaction [4], organic matter losses [5], pollution [6], biodiversity reduction [7] and other problems. Intensive agricultural practices are typical of vineyard management, thus it is crucial to find more sustainable production processes. The adoption of cover crops (CC) is a simple strategy of conservation agriculture that may improve vineyards sustainability [8,9,10]. Indeed, to date it is well known that CC enhances soil quality [3,4,5,8,9] and carbon sequestration [11], facilitating machinery passage [12] and increases microbial, vegetal and animal biodiversity [13,14,15,16]. CC have also proven to exploit a natural-based weed control effect [17,18]. Nevertheless, CC competition with grapevines is a major concern among farmers, so their management should always be arranged to avoid significant yield losses [19,20]. In general, under-trellis management of both CC and weeds represents an important challenge in viticulture [19,21]. For this reason, CC in vineyards are usually confined to the interrow and cultivation or herbicides applications are used to maintain a weed-free strip under vineyards trellis [22,23]. These under-trellis management techniques lead to a general decrease of soil quality [24], because bare soil is exposed to erosion. Furthermore, the root activity of vine plants reaches its maximum under-trellis, so it is important to perform a conservative soil management of the under-trellis area [25]. Using CC under-trellis in order to provide ground cover and protect this important area seems an appealing alternative in vineyards [24]. A complete floor cover practice is not frequent. Complete floor cover management is associated with lower vegetative vigor of vine plants compared to weed-free under-trellis systems [26,27]. While most of the trials concerning under-trellis cover cropped vineyards focused on competition with vines, few studies evaluated the potential of CC to perform under-trellis weeds control [24,25,28,29,30,31]. Under-trellis cover consisting of spontaneous species or annual CC did not significantly affects vines growth [24,25,29,30,31]. Furthermore, annual CC significantly suppressed under-trellis weed encroachment [24,29,30,31]. To the best of our knowledge, under-trellis perennial CC obtained the best weed control results [25,28], however their competition with vines may lead to important losses [25]. Moreover, particular interest is placed on weeds height in vineyards. This trait is linked with competition at both aboveground and underground levels [32,33]. Preventing weeds from growing tall inside vines canopy is another main goal of under-trellis management [23]. Very little is found in literature concerning under-trellis CC weed control and more research is needed to find suitable species and management options for this practice [19,34]. To improve management efficiency and sustainability, small autonomous machines have been employed in agriculture as a consequence of their high energy efficiency, low soil compaction and low cost [35]. Reiser et al. [36] developed a robotic rotary tiller weeder for under-trellis weed control in vineyards. Results from its application highlighted that autonomous intra-row weed management is a safe and reliable technique that helps to save energy. Magni et al. [28] obtained similar results by testing an autonomous mower to manage a perennial grass complete cover vineyard floor. In this trial, significant reductions of power consumption and CO2 emissions were observed compared to the ordinary technique. Despite designed for lawns mowing, autonomous mowers have shown promising results for agricultural purposes [28,37] due to their reduced size and high frequency of cut [38]. This last characteristic has the potential to exert a continuous mechanical control of both CC and weeds, preventing them from reaching an undesirable vertical growth [38].

The aim of this trial was to evaluate the potential of an autonomous mower managing a vineyard floor in terms of CC and weed control effects. Tests have been carried out on a CC based on Lolium perenne L., Trifolium repens L. and a spontaneous cover to study how the combination between species and management options could improve vineyard sustainability in terms of weed control and ground cover.

2. Materials and Methods

2.1. Experimental Design

A two year trial has been carried out at the Associazione Toscana Costitutori Viticoli (TOS.CO.VIT.), S. Piero a Grado, Pisa, Italy (43°39′ N, 10° 20′ E) from November 2018 to November 2020. The studied vineyard was established in 2004 (Vitis vinifera L. cv. Sangiovese N.) with a plant density of 4444 vines per hectare (0.9 × 2.5 m). Water was supplied from June to August using drip lines with 2 L h−1 drippers spaced at 0.5 m. Since 2006, conventional management (CM) of the vineyard floor consisted in multiple interrow flail mowing operations of spontaneous species and under-trellis weed control based on post emergence non-selective herbicide applications. A New Holland TN75F tractor (CNH Industrial, Turin, Italy) powered by a 57.8 kW diesel engine was employed. Herbicide treatments were applied under-trellis by means of a 480 L Amas sprayer (A.M.A.S. snc, Pistoia, Italy) with a 20 bar Comet BP 105 K pump (Comet spa, Reggio Emilia, Italy). During 2019, herbicide treatments were provided on 8 April and 12 July, while during 2020 herbicide treatments were provided on 6 April and 19 June. Mowing treatments were carried out by means of a Celli TCB/S mulcher (Celli, Forlì, Italy). During 2019, mowing treatments were provided 7 May, 26 June and 23 July, while during 2020 mowing treatments were provided on 15 April, 25 May, 24 June and 27 July. A list of management operations carried out during 2019 and 2020 is provided in Table 1. Four different management systems were studied for their effects on ground cover and weed control. The four management systems consisted of: cover crop 1 autonomously mowed (hereafter referred to as CC1-AM), cover crop 2 autonomously mowed (CC2-AM), spontaneous cover autonomously mowed (SC-AM) and spontaneous cover conventionally managed (SC-CM). Four replicates for a total of 16 experimental plots of 12 × 2.5 m (30 m2) were provided for this study.

Table 1.

List of operations carried out during 2019 and 2020 for the conventional managed (CM) plots.

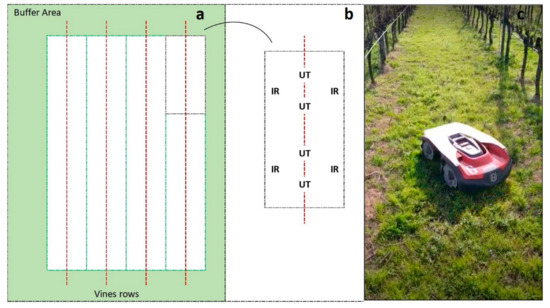

Autonomously mowed (AM) management was performed by a Husqvarna autonomous mower 535 AWD (Husqvarna, Stockholm, Sweden), from May to November 2019 and 2020. The size of the autonomous mower (length 93 cm × width 55 cm × height 29 cm) allowed it to move through the vines. A customized cowling was realized and installed on the autonomous mower to prevent it from getting stuck between vines. The autonomous mower was set to work 5 days per week. Mowing height was set at 5 cm. As the working capacity of the Husqvarna automower 535 AWD is 3500 (±20%) m2 d−1 (charging time included), mowing time was set at 4 h per day (charging time excluded) in order to manage the trial area of 740 m2 consisting of the AM plots and a buffer area surrounding the vines rows (Figure 1). Neighboring plots shared their edges between treatments.

Figure 1.

(a) Sketch map of the autonomously mowed (AM) area; (b) Detail of a single plot and measurements positions: IR (interrows) and UT (under-trellis); (c) Image of the autonomous mower operating during October 2019.

The two CC were directly sown on the plots in November 2018 and November 2019. Cover Crop 1 (CC1) consisted in a blend of perennial ryegrass cultivars (Lolium perenne L. cv Tetragreen 50% and Lolium perenne L. cv Dasher 3·50% with a seed rate of 50·g·m−2). Cover Crop 2 (CC2) consisted in a blend of clover cultivars (Trifolium repens L. cv Huia 95% and Trifolium repens L. cv Pertina 5% with a seed rate of 20 g m−2). Spontaneous Cover (SC) plots were covered by 35 different weed species. Major weeds were Erodium cicutarium (L.) L’Hèr., Matricaria chamomilla L., Malva sylvestris L., Conyza canadensis (L.) Cronquist, Aster squamatus (Spreng.) Hieron, Taraxacum officinale (L.) Weber. All these species were constantly present during all seasons. Major winter weeds were Poa annua L., Veronica persica Poir., Stellaria media (L.) Vill., Geranium molle L., Festuca arundinacea Schreb., Bellis perennis L., Capsella bursa-pastoris (L.) Medik. Major summer weeds were Euphorbia prostrata Aiton, Digitaria sanguinalis (L.) Scop., Cynodon dactylon (L.) Pers., Portulaca oleracea L., Paspalum distichum L. The soil was sandy (Sand 88.7%; Silt 7.9%; Clay 3.4%).

2.2. Assessment

During both 2019 and 2020, from May to October, ground cover percentage, weed cover percentage and average floor canopy height were monthly assessed in the interrow (IR) and under-trellis (UT) (Figure 1). Ground cover percentage was measured from digital images using the app Canopeo (Mathworks, Inc., Natick, MA, USA). The software measures the green cover percentage of a digital image. Pictures of each plot were taken using a Nikon Coolpix 7600 (Nikon corporation, Tokyo, Japan) digital camera from a quadrat of 0.25 m2 (50 × 50 cm), four in the IR and four UT. CC percentage of the quadrats was determined by visual assessment. The data acquired by the software and the data acquired from the visual assessment were subjected to a correlation test. In plots with established CC, weed cover was calculated detracting CC percentage (previously visually assessed) from the total green cover of the plot determined by the software. After taking pictures, the floor canopy height was assessed with a grass height meter within the same quadrats of 0.25 m2. At the end of the vines growing season (October 31, 2019 and November 3, 2020) aboveground weed biomass was collected in the same position of previous measurements and from the same quadrats. Weed dry biomass was measured after oven drying for 7 days at 70 °C (until weight was constant). Autonomous mower working path and mowed area over time were assessed in May, June, September, and October of both years. A remote sensing system consisting of two Emlid Reach RTK (Emlid Ltd., Hong Kong) devices along with two software packages to extract and display the data [39] was used. The custom-built software calculates the area mowed by the autonomous mower over a given period of time, based on the distance traveled and the cutting width. The mowed area data were recorded every 15 min and are reported as a percentage of the total area [37].

Primary energy consumption estimation was carried out for both management systems. The electric energy consumption of the autonomous mower was estimated from the data provided by the operator’s manual [40]. The fuel consumption of the tractor was estimated using the equation of the hourly consumption of a tractor performing a specific operation:

where Ch is the hourly consumption of the tractor (kg fuel h−1), W is the power of the tractor (kW), d is the effort percentage of the tractor engine due to a specific operation (1 = maximum power required) and Cs is the energetic efficiency of the tractor (kg fuel kWh−1). In this trial, considering the mechanical characteristics of the tractor, Cs was estimated at 0.25 kg fuel kWh−1), while d was assigned depending on the operation carried out. The primary energy requirement of the autonomous mower was calculated considering the efficiency of the Italian National Electric System equal to 0.546 [41]. To estimate the primary energy consumption of the tractor, a conversion factor of 12.03 kWh/kg of fuel [42] was used.

2.3. Statistical Analysis

The Shapiro–Wilk test was used to assess data normality and Breush–Pagan test was used for homoscedasticity. Statistical software SPSS (IBM Corp, Armonk, NY, USA) was used to analyze ground cover percentage, weed cover percentage, floor canopy height and weeds dry biomass data. To evaluate changes in ground cover percentage and weed cover percentage over time, treatments and position, repeated-measures analysis was performed using a generalized linear model (GENLIN) with a binomial distribution and a logit link function. Time (years and months) was included as a repeated factor in the model. To evaluate changes on floor canopy height over time, treatment and position, repeated-measures analysis was performed using a generalized linear model (GENLIN) with a gamma distribution and log link function. Time (years and months) was included as a repeated factor in the model. Weed dry biomass data were processed with general linear model one-way ANOVA (UNIANOVA). Pairwise comparisons were performed with a Bonferroni’s test. Autonomous mower working data were analyzed using statistical software R [43]. The extension package ‘drc’ (dose–response curve) of R [44] was used to analyze the percentage of area mowed by the autonomous with a two stage meta-analysis dose-response model and to estimate the parameters and the effective time values [37]. The non-linear function corresponded to a two-parameter asymptotic regression (Equation (2)):

Parameters d (the upper limit of the function for x going to infinity) and e (the steepness of the increase of the function) [45] were estimated from the model. All the graphs were plotted using the extension package ‘ggplot2′ (Elegant Graphics for Data Analysis) [46].

3. Results

3.1. Ground Cover Percentage and Weed Cover Percentage

Repeated-measures analysis revealed that ground cover percentage was significantly affected by treatment (p < 0.001), position (p < 0.001) and the interaction between treatments and positions (p < 0.001) (Table A1 in Appendix A). Over the two years, the highest ground cover percentage was recorded at the UT of CC2-AM plots with an average value of 39% and on the UT of SC-AM plots (36%) (Table 2). No significant differences between ground cover percentage values resulted at the IR and at the UT of the remaining plots (ranging from 31% to 33%).

Table 2.

Effect of the interaction between treatments (CC1-AM, CC2-AM, SC-AM, SC-CM) and positions (IR and UT) on ground cover percentage. CC1-AM: cover crop 1 autonomously mowed; CC2-AM: cover crop 2 autonomously mowed; SC-CM: spontaneous cover autonomously mowed, SC-AM: spontaneous cover conventionally managed.

The green cover percentage strongly correlated with CC percentage visually estimated for both CC types and positions. A correlation coefficient (r) of 0.70 and 0.71 resulted for CC1 at the IR and UT respectively. For CC2, a correlation coefficient (r) of 0.72 and 0.80 was produced at the IR and UT respectively. Repeated-measures analysis revealed that weed cover percentage was influenced by treatment (p < 0.001), position (p < 0.001), block (p < 0.01) and by the interaction between treatments and positions (p < 0.001) (Table A2 in Appendix A). Weed cover percentage at the UT of SC-AM plots and at the IR of SC-CM plots were similar (36% and 34%, respectively) and significantly higher compared to the values of the remaining plots (Table 3). Weed cover percentage resulted also similar at the IR of SC-AM plots and on the UT of SC-CM plots (32%). In plots where CC were established, weed cover percentage resulted significantly lower compared to plots with SC independent of the position. Furthermore, a significantly lower weed cover percentage was measured at the UT of plots provided with CC (18% for CC1-AM and 20% CC2-AM) with respect to the IR of the same plots (23% for CC1-AM and 25% CC2-AM).

Table 3.

Effect of the interaction between treatments (CC1-AM, CC2-AM, SC-AM, SC-CM) and positions (IR and UT) on weed cover percentage.

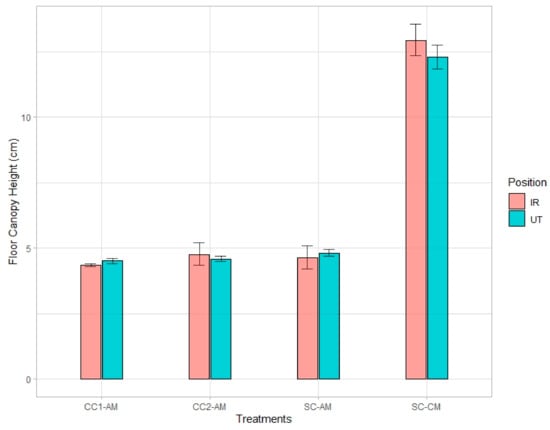

3.2. Floor Canopy Height

Repeated-measures analysis revealed a significant effect of the treatment and the interaction between treatments and positions (p < 0.001 and p < 0.05, respectively) on floor canopy height (Table A3 in Appendix A). Floor canopy height was significantly higher in CM plots (12.93 cm at the IR and 12.28 cm at the UT) compared to AM plots (ranging from 4.36 cm to 4.76 at the IR and from 4.51 cm to 4.81 cm UT) (Figure 2). Among the AM plots, significant differences were found only between floor canopy height at the UT of SC-AM plot (4.81 cm) compared to those measured on CC1-AM plots (4.51 cm at the UT and 4.36 cm at the IR). Figure 3 shows the different visual effects of different canopy heights.

Figure 2.

Effect of treatments (CC1-AM, CC2-AM, SC-AM, SC-CM) and positions (IR and UT) on floor canopy height. Error bar represents the upper and lower limits of the 95% confidence interval.

Figure 3.

Effects of different management systems on vineyard floor canopy height after two years of treatments. Left: AM plots; Right: conventional management (CM) plots.

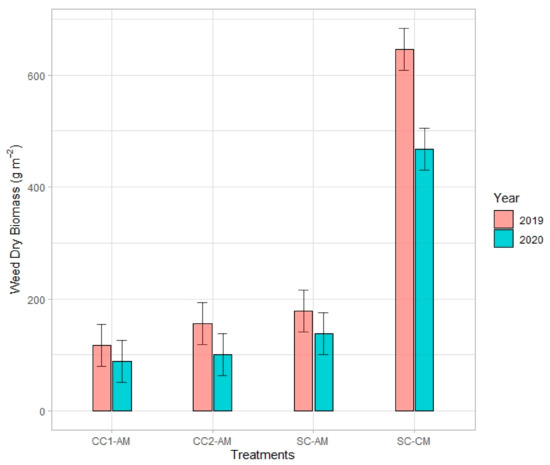

3.3. Weeds Dry Biomass

Weed dry biomass was affected by treatment (p < 0.001), year (p < 0.001) and by the interaction between treatments and years (p < 0.001) (Table A4 in Appendix A). Weed dry biomass collected in SC-CM plots resulted significantly higher compared to values obtained in AM plots for both years (646.53 g m−2 in 2019 and 467.62 g m−2 in 2020) (Figure 4). Weed dry biomass in SC-CM plots showed a significant difference between years. Instead, no significant differences resulted among weed dry biomass values in AM plots over the two years.

Figure 4.

Effect of treatments (CC1-AM, CC2-AM, SC-AM, SC-CM) and years on weed dry biomass. Error bar represents the upper and lower limits of the 95% confidence interval.

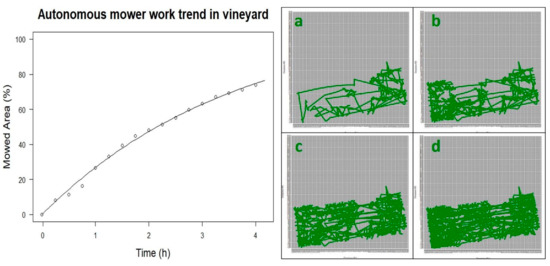

3.4. Autonomous Mower Working Data

Recorded data well fitted the asymptotic regression model (lack-of-fit test: p = 0.9888). Figure 5 shows the autonomous mower mowed area over time and the relative working path as resulted during the assessment of 30 June 2020.

Figure 5.

Left: Asymptotic regression curves with average points of the percentage of mowed area as a function of time (h). Right: Custom built software showing the working path of the autonomous mower managing vineyards on 30 June 2020. (a) Autonomous mower work after 60 min; (b) Autonomous mower work after 120 min; (c) Autonomous mower work after 180 min; (d) Autonomous mower work after 240 min.

The autonomous mower managed an area of 740 m2 consisting of the AM plots and a buffer area surrounding the vines rows (Figure 1). The autonomous mower managed approximately 26.62% (±5.07%) of the area after one hour, 48.18% (±2.82%) after two hours, 63.26% (±4.92%) after three hours and 73.93% (±4.95%) after 4 h of mowing (Figure 5). Table 4 shows the non-linear asymptotic regressions parameters (Equation (1)) and the effective times estimated from the two-stage meta-analysis dose-response model.

Table 4.

Parameters of the non-linear asymptotic regressions (Equation (1)) and effective times of the autonomous mower estimated from the two-stage meta-analysis dose-response model for an area of 740 m2.

According to the estimation, the autonomous mower was able to manage 90% of the area in 8.47 (±1.18) hours when working in vineyards. Assessments have been carried out in an area of 740 m2. Consequently, the autonomous mower work capacity ranges from 34.48 h to 45.64 h (40.06 ± 5.58 h) to manage the 90% of 3500 m2 (autonomous mower working capacity stated by manufacturer [40]).

3.5. Primary Energy Consumption

Table 5 shows the operative characteristics and the primary energy consumption estimation of the two management systems studied in this trial. The values shown in Table 5 are the average values of the two years of the trial. The primary energy estimation highlighted a difference of about 200 kWh per year between the two systems.

Table 5.

Operative characteristics and energy consumption estimation according to different vineyard floor management systems during the two years of the trial.

4. Discussion

4.1. Ground Cover Percentage

Over the two years, a higher ground cover percentage was achieved UT by CC2 (Trifolium repens) and spontaneous species, confirming the results obtained by Karl et al. [24]. The best results in terms of ground cover percentage were obtained in AM plots. The high ground cover percentage provides positive effects in terms of soil conservation [25], thus it is desirable both IR and UT. The total ground cover percentage was attributable to both weed and CC coverage. The high ground cover percentages of annual legume CC in humid and Mediterranean climates is correlated with their vigorous establishment during winter [25,29]. However, several authors observed that annual legume CC are characterized by a reduced persistence [24,29,30]. Abad et al. [31] used a perennial clover as UT CC, finding that over the two years there was an increasing persistence of the perennial clover. In this trial a blend of two T. repens cultivars (Huia and Pertina) was used. Despite that T. repens is a perennial clover, it showed a low persistence (dry-out during summer). The two cultivars were selected as turf-type clovers and their low persistence might be linked to the unsuitable field conditions. Moreover, the lack of persistence seems not to be related to the perennial or annual form of the clovers. Conversely, CC1 (Lolium perenne) reached a lower ground cover compared to CC2 both in the IR and UT. CC1 reached a high ground cover during winter, however it disappeared completely after the summer. Pornaro et al. [47] also confirm that L. perenne has a low drought tolerance and a slow recovery period after the summer. The SC consisted of different native species adapted to the specific environment of the studied vineyard and lasting for long periods as ground cover. SC persistence in vineyards leads to a higher water infiltration and conservation, suggesting that this type of cover is a reasonable choice for the drought conditions of Mediterranean vineyards [48]. SC showed high ground cover percentage UT of the SC-AM plots. The lower ground cover UT of the SC-CM plots compared to the ground cover UT of the SC-AM plots was due to the repeated glyphosate applications provided for the CM.

4.2. Weed Control

CC have proven to significantly decrease weed encroachment both in the IR and UT, corroborating the results of other authors [24,25,29,30,31]. In the present trial, the lowest weed cover percentage resulted in the UT of plots provided with CC. Water was supplied UT, allowing CC to grow and spread faster than weeds, so to avoid annual weeds germination and establishment. The higher CC weed control observed UT compared to the IR is probably linked to the UT water distribution that helped CC establishment. Furthermore, the AM management seems to efficiently control weed populations. Indeed, all the plots with AM management showed a significant lower weed dry biomass in both years compared to CM plots. Moreover, the combination of constant mowing and low cutting height resulted in an evident effect on therophyte species (i.e., Conyza canadensis and Digitaria sanguinalis) especially in the IR, compared to the UT. In fact, many authors state that mowing selects for short species and for species with a creeping habitus [32,38,49,50] and that management intensity can affect weed populations [50]. These findings may explain the higher weed cover percentage and the lower weed dry biomass in SC-AM plots compared to SC-CM plots. Because of the high cutting frequency and of the frequent overlapping, the studied autonomous mower has proven to be an optimal solution to manage a vineyard floor either covered by CC or by spontaneous species. A significant weed control effect was achieved in AM plots without herbicides applications, confirming findings obtained by Slaughter et al. [51].

4.3. Management System

The studied autonomous mower has proven to be a reliable machine for managing floor canopy height. The results shown in Figure 2 highlight that the autonomous mower kept the average floor canopy height close to its cutting height setting (5 cm). Maintaining a short floor canopy height is crucial to preserve the water and nutritional balance between the weeds and the vines [32,33]. Moreover, the high frequency of cut of the autonomous mower helps to reduce the size of the clippings [52]. Such small clippings are left in place by the autonomous mowers and are easily integrated into the soil thus recycling nutrients [53]. The results reported in Table 4 show that the autonomous mower working efficiency decreases when employed in vineyards because of the large number of obstacles, confirming the results obtained by Sportelli et al., [37]. Moreover, the working width of the studied autonomous mower (0.24 m) is significantly smaller than the width of the autonomous mowers cowling. This is a consequence of the fact that these machines are designed to manage ornamental lawns and safety regulations are more restricting in terms of safety. The distance between the cutting disc and the cowling allows the weeds to develop close to the vines trunks. A smaller distance between the cutting disc and the cowling may prevent weeds from growing tall close to the vines trunks and improve the overall working efficiency of the autonomous mower in terms of weed control. The results regarding the primary energy consumption estimation highlight that the AM system provides for a more sustainable vineyard floor management, corroborating findings reported by Magni et al. [28]. Moreover, vineyard floor management does not require daily mowing; thus, a single autonomous mower can be employed to manage different sectors of a vineyard, further improving autonomous mowers working efficiency and overall energy savings [10]. As shown in Table A5 and Table A6 (Appendix A), the summer drought strongly decreased both the floor canopy height and weed cover percentage, requiring a lower use of the autonomous mower. As the majority of economic costs related to the use of CC derive from their management [20], a more precise employment of autonomous mowers can also bring significant economic savings [54]. The findings of this trial highlight that the AM management system may be employed as a reliable vineyard floor management. Indeed, it is reasonable to say that autonomous mowers help to fill the gap between vines competition with UT CC or weeds by avoiding both CC and weeds from an undesirable excessive vertical growth.

5. Conclusions

This trial highlights that a complete vineyard floor cover represents a sustainable management practice, especially when coupled with small autonomous machines. An efficient floor management can benefit from the work of an autonomous mower, ensuring an acceptable ground cover together with a low floor canopy height. The results obtained in this trial suggest that autonomous mowers may be a sustainable choice when employed for agricultural purposes, especially for challenging operations such as managing UT CC and weeds. Moreover, in this trial autonomous mowers have shown to be an innovative method to control vertical growing weeds. To be further improved, these management techniques may benefit from higher energy and work efficiency and specifically selected CC species.

Author Contributions

Conceptualization, M.V. and M.F.; methodology, M.S., S.M. and L.C.; software, M.F. and M.S.; validation, M.F., M.P. and M.S.; formal analysis, C.F.; investigation, M.S.; resources, M.M.; data curation, C.F. and M.S.; writing—original draft preparation, M.S.; writing—review and editing, M.P., M.R. and A.P.; visualization, M.R.; supervision, M.M.; project administration, M.V.; funding acquisition, M.R. and A.P. All authors have read and agreed to the published version of the manuscript.

Funding

The present research was supported by the University of Pisa Project: “Gestione sostenibile del suolo del vigneto mediante inerbimento” (“Progetti di Ricerca di Ateneo 2018”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Husqvarna group for providing the autonomous mower and technical support; the Tuscany Association of Viticulture Producers (Tos.Sco.Vit) for their technical support.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on ground cover percentage.

Table A1.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on ground cover percentage.

| Source | Wald χ2 | DF | p-Value |

|---|---|---|---|

| Intercept | 3458.86 | 1 | *** |

| Treatment | 47.48 | 3 | *** |

| Position | 22.37 | 1 | *** |

| Treatment × Position | 28.55 | 3 | *** |

| Block | 6.03 | 3 | ns |

*** Significant at the 0.001 probability level respectively. ns, Not significant at the 0.05 probability level.

Table A2.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on weed cover percentage.

Table A2.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on weed cover percentage.

| Source | Wald χ2 | DF | p-Value |

|---|---|---|---|

| Intercept | 5465.09 | 1 | *** |

| Treatment | 645.25 | 3 | *** |

| Position | 18.60 | 1 | *** |

| Treatment × Position | 68.89 | 3 | *** |

| Block | 17.38 | 3 | ** |

**, *** Significant at the 0.01, and 0.001 probability level respectively.

Table A3.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on floor canopy height.

Table A3.

Results of repeated-measures analysis with generalized linear model testing the effects of the independent variables block, treatments, positions, and their interaction on floor canopy height.

| Source | Wald χ2 | DF | p-Value |

|---|---|---|---|

| Intercept | 33,577.06 | 1 | *** |

| Treatment | 3963.55 | 3 | *** |

| Position | 0.04 | 1 | ns |

| Treatment × Position | 8.24 | 3 | * |

| Block | 4.62 | 3 | ns |

*, *** Significant at the 0.05, and 0.001 probability level respectively. ns, Not significant at the 0.05 probability level.

Table A4.

Results of general linear model analysis (type III) testing the effects of the independent variable block, treatments, positions, years, and their interaction on weed dry biomass.

Table A4.

Results of general linear model analysis (type III) testing the effects of the independent variable block, treatments, positions, years, and their interaction on weed dry biomass.

| Source | Sum of Squares (Type III) | DF | Mean Squares | F | p-Value |

|---|---|---|---|---|---|

| Model | 2,380,330.05 | 18 | 132,240.56 | 47.81 | *** |

| Intercept | 3,583,477.24 | 1 | 3,583,477.24 | 1295.42 | *** |

| Treatment | 2,215,223.65 | 3 | 738,407.88 | 266.93 | *** |

| Position | 6343.50 | 1 | 6343.50 | 2.29 | ns |

| Year | 91,954.75 | 1 | 91,954.75 | 33.24 | *** |

| Position × Treatment | 1613.40 | 3 | 537.80 | 0.19 | ns |

| Position × Year | 1652.98 | 1 | 1652.98 | 0.60 | ns |

| Treatment × Year | 58,259.36 | 3 | 19,419.79 | 7.02 | *** |

| Position × Treatment x Year | 513.85 | 3 | 171.28 | 0.06 | ns |

| Block | 4768.58 | 3 | 1589.53 | 0.58 | ns |

| Error | 124,481.65 | 45 | 2766.26 | - | - |

| Total | 6,088,288.95 | 64 | - | - | - |

*** Significant at the 0.001 probability level. ns, Not significant at the 0.05 probability level.

Table A5.

Weed cover percentage monthly trend during vines growing season (May–October) during 2019 and 2020.

Table A5.

Weed cover percentage monthly trend during vines growing season (May–October) during 2019 and 2020.

| Month | Treatment | Position | 2019 | 2020 | ||

|---|---|---|---|---|---|---|

| Mean | Standard Error | Mean | Standard Error | |||

| May | CC1-AM | IR | 28 | 1.12228−2 | 31 | 1.15972−2 |

| UT | 21 | 1.01811−2 | 18 | 9.54982−3 | ||

| CC2-AM | IR | 40 | 1.22495−2 | 41 | 1.22865−2 | |

| UT | 25 | 1.07923−2 | 21 | 1.00929−2 | ||

| SC-AM | IR | 67 | 1.17666−2 | 72 | 1.11733−2 | |

| UT | 68 | 1.16890−2 | 79 | 1.01932−2 | ||

| SC-CM | IR | 38 | 1.21641−2 | 44 | 1.24221−2 | |

| UT | 43 | 1.23871−2 | 42 | 1.23545−2 | ||

| June | CC1-AM | IR | 26 | 1.09265−2 | 40 | 1.22393−2 |

| UT | 7 | 6.29899−3 | 18 | 9.55717−3 | ||

| CC2-AM | IR | 31 | 1.16037−2 | 48 | 1.24968−2 | |

| UT | 13 | 8.27811−3 | 23 | 1.04741−2 | ||

| SC-AM | IR | 34 | 1.18623−2 | 47 | 1.24841−2 | |

| UT | 43 | 1.23922−2 | 53 | 1.24804−2 | ||

| SC-CM | IR | 30 | 1.14179−2 | 56 | 1.24209−2 | |

| UT | 42 | 1.23556−2 | 51 | 1.25047−2 | ||

| July | CC1-AM | IR | 6 | 5.72908−3 | 0 | 1.38557−3 |

| UT | 12 | 8.08776−3 | 3 | 4.04448−3 | ||

| CC2-AM | IR | 5 | 5.62488−3 | 0 | 1.03521−3 | |

| UT | 16 | 9.26346−3 | 4 | 4.68945−3 | ||

| SC-AM | IR | 8 | 6.89101−3 | 0 | 1.42585−3 | |

| UT | 20 | 1.00515−2 | 2 | 3.81796−3 | ||

| SC-CM | IR | 24 | 1.07179−2 | 1 | 2.02633−3 | |

| UT | 54 | 1.24680−2 | 11 | 7.79528−3 | ||

| August | CC1-AM | IR | 1 | 2.37853−3 | 1 | 2.71709−3 |

| UT | 1 | 2.79713−3 | 2 | 3.26591−3 | ||

| CC2-AM | IR | 0 | 1.67688−3 | 1 | 2.41497−3 | |

| UT | 2 | 3.12943−3 | 2 | 3.70898−3 | ||

| SC-AM | IR | 1 | 2.07960−3 | 1 | 2.69244−3 | |

| UT | 1 | 2.79646−3 | 2 | 3.43543−3 | ||

| SC-CM | IR | 1 | 2.98750−3 | 2 | 3.62727−3 | |

| UT | 6 | 5.89924−3 | 7 | 6.45396−3 | ||

| September | CC1-AM | IR | 19 | 9.81953−3 | 18 | 9.59677−3 |

| UT | 16 | 9.27246−3 | 18 | 9.60061−3 | ||

| CC2-AM | IR | 18 | 9.55592−3 | 18 | 9.66802−3 | |

| UT | 20 | 1.00837−2 | 19 | 9.88409−3 | ||

| SC-AM | IR | 14 | 8.66408−3 | 19 | 9.87556−3 | |

| UT | 19 | 9.74000−3 | 25 | 1.08116−3 | ||

| SC-CM | IR | 35 | 1.19675−2 | 38 | 1.21256−2 | |

| UT | 32 | 1.16398−2 | 44 | 1.24240−2 | ||

| October | CC1-AM | IR | 49 | 1.25059−2 | 54 | 1.24711−2 |

| UT | 33 | 1.17318−2 | 70 | 1.15128−2 | ||

| CC2-AM | IR | 43 | 1.23906−2 | 51 | 1.25042−2 | |

| UT | 42 | 1.23305−2 | 50 | 1.25067−2 | ||

| SC-AM | IR | 52 | 1.24988−2 | 67 | 1.17286−2 | |

| UT | 39 | 1.21904−2 | 82 | 9.64860−3 | ||

| SC-CM | IR | 72 | 1.12375−2 | 65 | 1.19505−2 | |

| UT | 24 | 1.07046−2 | 30 | 1.14696−2 | ||

Table A6.

Floor canopy height monthly trend during vines growing season (May–October) during 2019 and 2020.

Table A6.

Floor canopy height monthly trend during vines growing season (May–October) during 2019 and 2020.

| Month | Treatment | Position | 2019 | 2020 | ||

|---|---|---|---|---|---|---|

| Mean | Standard Error | Mean | Standard Error | |||

| May | CC1-AM | IR | 4.76 | 0.44 | 4.43 | 0.26 |

| UT | 5.44 | 0.50 | 5.42 | 0.32 | ||

| CC2-AM | IR | 4.81 | 0.44 | 4.71 | 0.28 | |

| UT | 5.28 | 0.33 | 5.20 | 0.29 | ||

| SC-AM | IR | 4.90 | 0.45 | 4.70 | 0.28 | |

| UT | 5.59 | 0.52 | 5.61 | 0.33 | ||

| SC-CM | IR | 9.15 | 0.84 | 9.15 | 0.54 | |

| UT | 8.99 | 0.83 | 8.93 | 0.53 | ||

| June | CC1-AM | IR | 5.37 | 0.50 | 4.31 | 0.26 |

| UT | 5.15 | 0.48 | 4.62 | 0.27 | ||

| CC2-AM | IR | 4.94 | 0.46 | 4.56 | 0.27 | |

| UT | 5.08 | 0.32 | 5.00 | 0.28 | ||

| SC-AM | IR | 5.16 | 0.48 | 4.75 | 0.28 | |

| UT | 5.39 | 0.50 | 5.21 | 0.31 | ||

| SC-CM | IR | 13.20 | 1.22 | 12.01 | 0.71 | |

| UT | 11.26 | 1.04 | 11.85 | 0.70 | ||

| July | CC1-AM | IR | 3.65 | 0.34 | 3.56 | 0.21 |

| UT | 3.41 | 0.31 | 3.41 | 0.20 | ||

| CC2-AM | IR | 3.74 | 0.35 | 3.92 | 0.23 | |

| UT | 3.35 | 0.21 | 3.30 | 0.18 | ||

| SC-AM | IR | 3.81 | 0.35 | 3.47 | 0.21 | |

| UT | 3.68 | 0.34 | 3.87 | 0.23 | ||

| SC-CM | IR | 12.32 | 1.14 | 7.65 | 0.45 | |

| UT | 10.56 | 0.97 | 8.66 | 0.51 | ||

| August | CC1-AM | IR | 4.70 | 0.43 | 3.46 | 0.21 |

| UT | 5.39 | 0.50 | 4.23 | 0.25 | ||

| CC2-AM | IR | 5.83 | 0.54 | 4.03 | 0.24 | |

| UT | 5.08 | 0.32 | 5.00 | 0.28 | ||

| SC-AM | IR | 5.02 | 0.46 | 3.61 | 0.21 | |

| UT | 5.68 | 0.52 | 5.09 | 0.30 | ||

| SC-CM | IR | 14.27 | 1.32 | 9.77 | 0.58 | |

| UT | 11.88 | 1.10 | 9.34 | 0.56 | ||

| September | CC1-AM | IR | 4.59 | 0.27 | 4.47 | 0.27 |

| UT | 4.37 | 0.26 | 4.41 | 0.26 | ||

| CC2-AM | IR | 7.28 | 0.43 | 4.72 | 0.28 | |

| UT | 4.58 | 0.17 | 4.51 | 0.34 | ||

| SC-AM | IR | 4.37 | 0.26 | 4.26 | 0.25 | |

| UT | 4.47 | 0.27 | 4.75 | 0.28 | ||

| SC-CM | IR | 13.35 | 0.79 | 16.04 | 0.95 | |

| UT | 14.10 | 0.84 | 16.77 | 1.00 | ||

| October | CC1-AM | IR | 4.36 | 0.40 | 4.74 | 0.28 |

| UT | 4.21 | 0.39 | 4.36 | 0.26 | ||

| CC2-AM | IR | 4.19 | 0.39 | 4.55 | 0.27 | |

| UT | 4.44 | 0.28 | 4.37 | 0.24 | ||

| SC-AM | IR | 4.31 | 0.40 | 7.22 | 0.43 | |

| UT | 4.35 | 0.40 | 4.32 | 0.26 | ||

| SC-CM | IR | 20.67 | 1.91 | 17.50 | 1.04 | |

| UT | 15.57 | 1.44 | 18.73 | 1.11 | ||

References

- Jones, G.V.; White, M.A.; Cooper, O.R.; Storchmann, K. Climate Change and Global Wine Quality. Clim. Chang. 2005, 73, 319–343. [Google Scholar] [CrossRef]

- Christ, K.L.; Burritt, R.L. Critical environmental concerns in wine production: An integrative review. J. Clean. Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- García-Ruiz, J.M. The effects of land uses on soil erosion in Spain: A review. Catena 2010, 81, 1–11. [Google Scholar] [CrossRef]

- Polge de Combret-Champart, L.; Guilpart, N.; Merot, A.; Capillon, A.; Gary, C. Determinants of the degradation of soil structure in vineyards with a view to conversion to organic farming. Soil Use Manag. 2013, 29, 557–566. [Google Scholar] [CrossRef]

- Salome, C.; Coll, P.; Lardo, E.; Villenave, C.; Blanchart, E.; Hinsinger, P.; Marsden, C.; Le Cadre, E. Relevance of use-invariant soil properties to assess soil quality of vulnerable ecosystems: The case of Mediterranean vineyards. Ecol. Indic. 2014, 43, 83–93. [Google Scholar] [CrossRef]

- Chopin, E.; Marin, B.; Mkoungafoko, R.; Rigaux, A.; Hopgood, M.; Delannoy, E.; Cancès, B.; Laurain, M. Factors affecting distribution and mobility of trace elements (Cu, Pb, Zn) in a perennial grapevine (Vitis vinifera L.) in the Champagne region of France. Environ. Pollut. 2008, 156, 1092–1098. [Google Scholar] [CrossRef]

- Viers, J.H.; Williams, J.N.; Nicholas, K.A.; Barbosa, O.; Kotzé, I.; Spence, L.; Webb, L.B.; Merenlender, A.; Reynolds, M. Vinecology: Pairing wine with nature. Conserv. Lett. 2013, 6, 287–299. [Google Scholar] [CrossRef]

- Corbo, C.; Lamastra, L.; Capri, E. From Environmental to Sustainability Programs: A Review of Sustainability Initiatives in the Italian Wine Sector. Sustainability 2014, 6, 2133–2159. [Google Scholar] [CrossRef]

- Salomé, C.; Coll, P.; Lardo, E.; Metay, A.; Villenave, C.; Marsden, C.; Blanchart, E.; Hinsinger, P.; Le Cadre, E. The soil quality concept as a framework to assess management practices in vulnerable agroecosystems: A case study in Mediterranean vineyards. Ecol. Indic. 2016, 61, 456–465. [Google Scholar] [CrossRef]

- Failla, S.; Pirchio, M.; Sportelli, M.; Frasconi, C.; Fontanelli, M.; Raffaelli, M.; Peruzzi, A. Evolution of Smart Strategies and Machines Used for Conservative Management of Herbaceous and Horticultural Crops in the Mediterranean Basin: A Review. Agronomy 2021, 11, 106. [Google Scholar] [CrossRef]

- Nieto, O.M.; Castro, J.; Fernández-Ondoño, E. Conventional tillage versus cover crops in relation to carbon fixation in Mediterranean olive cultivation. Plant Soil 2012, 365, 321–335. [Google Scholar] [CrossRef]

- Guerra, B.; Steenwerth, K. Influence of Floor Management Technique on Grapevine Growth, Disease Pressure, and Juice and Wine Composition: A Review. Am. J. Enol. Vitic. 2012, 63, 149–164. [Google Scholar] [CrossRef]

- Hendgen, M.; Hoppe, B.; Döring, J.; Friedel, M.; Kauer, R.; Frisch, M.; Dahl, A.; Kellner, H. Effects of different management regimes on microbial biodiversity in vineyard soils. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef]

- Guzmán, G.; Cabezas, J.; Sánchez-Cuesta, R.; Lora, Á.; Bauer, T.; Strauss, P.; Winter, S.; Zaller, J.; Gómez, J. A field evaluation of the impact of temporary cover crops on soil properties and vegetation communities in southern Spain vineyards. Agric. Ecosyst. Environ. 2019, 272, 135–145. [Google Scholar] [CrossRef]

- Eckert, M.; Mathulwe, L.L.; Gaigher, R.; Der Merwe, L.J.-V.; Pryke, J.S. Native cover crops enhance arthropod diversity in vineyards of the Cape Floristic Region. J. Insect Conserv. 2019, 24, 133–149. [Google Scholar] [CrossRef]

- Wilson, H.; Wong, J.S.; Thorp, R.W.; Miles, A.F.; Daane, K.M.; A Altieri, M. Summer Flowering Cover Crops Support Wild Bees in Vineyards. Environ. Entomol. 2017, 47, 63–69. [Google Scholar] [CrossRef]

- Hartwig, N.L.; Ammon, H.U. Cover crops and living mulches. Weed Sci. 2002, 50, 688–699. [Google Scholar] [CrossRef]

- Kruidhof, H.M.; Bastiaans, L.; Kropff, M.J. Ecological weed management by cover cropping: Effects on weed growth in autumn and weed establishment in spring. Weed Res. 2008, 48, 492–502. [Google Scholar] [CrossRef]

- Garcia, L.; Celette, F.; Gary, C.; Ripoche, A.; Valdés-Gómez, H.; Metay, A. Management of service crops for the provision of eco-system services in vineyards: A review. Agric. Ecosyst. Environ. 2018, 251, 158–170. [Google Scholar] [CrossRef]

- Bergtold, J.S.; Ramsey, S.; Maddy, L.; Williams, J.R. A review of economic considerations for cover crops as a conservation practice. Renew. Agric. Food Syst. 2017, 34, 62–76. [Google Scholar] [CrossRef]

- Van Der Weide, R.Y.; O Bleeker, P.; Achten, V.T.J.M.; Lotz, L.A.P.; Fogelberg, F.; Melander, B. Innovation in mechanical weed control in crop rows. Weed Res. 2008, 48, 215–224. [Google Scholar] [CrossRef]

- Volaire, F.; Lelievre, F. Role of Summer Dormant Perennial Grasses as Intercrops in Rainfed Mediterranean Vineyards. Crop. Sci. 2010, 50, 2046–2054. [Google Scholar] [CrossRef]

- Baumgartner, K.; Steenwerth, K.L.; Veilleux, L. Cover-Crop Systems Affect Weed Communities in a California Vineyard. Weed Sci. 2008, 56, 596–605. [Google Scholar] [CrossRef]

- Karl, A.; Merwin, I.A.; Brown, M.G.; Hervieux, R.A.; Heuvel, J.E.V. Impact of Undervine Management on Vine Growth, Yield, Fruit Composition, and Wine Sensory Analyses of Cabernet franc. Am. J. Enol. Vitic. 2016, 67, 269–280. [Google Scholar] [CrossRef]

- Penfold, C.; Weckert, M.; Howie, J.; Nordblom, T.; Norton, M. Development of a Low-Input Under-Vine Floor Management System Which Improves Profitability without Compromising Yield or Quality; Final Report, Project Number: UA 1303; University of Adelaide Press: Adelaide, Australia, 2018; p. 98. [Google Scholar]

- Giese, G.; Velasco-Cruz, C.; Roberts, L.; Heitman, J.; Wolf, T.K. Complete vineyard floor cover crops favorably limit grapevine vegetative growth. Sci. Hortic. 2014, 170, 256–266. [Google Scholar] [CrossRef]

- Coniberti, A.; Ferrari, V.; Disegna, E.; García Petillo, M.; Lakso, A.N. Complete vineyard floor cover crop to reduce grapevine sus-ceptibility to bunch rot. Eur. J. Agron. 2018, 99, 167–176. [Google Scholar] [CrossRef]

- Magni, S.; Sportelli, M.; Grossi, N.; Volterrani, M.; Minelli, A.; Pirchio, M.; Fontanelli, M.; Frasconi, C.; Gaetani, M.; Martelloni, L.; et al. Autonomous Mowing and Turf-Type Bermudagrass as Innovations for An Environment-Friendly Floor Management of a Vineyard in Coastal Tuscany. Agriculture 2020, 10, 189. [Google Scholar] [CrossRef]

- Jordan, L.M.; Björkman, T.; Vanden Heuvel, J.E. Annual Under-vine Cover Crops Did Not Impact Vine Growth or Fruit Composi-tion of Mature Cool-climate ‘Riesling’ Grapevines. HortTechnology 2016, 26, 36–45. [Google Scholar] [CrossRef]

- Centinari, M. Impacts of under-trellis cover crops. Wines Vines Analytics. Available online: https://winesvinesanalytics.com/features/article/175449/Impacts-of-Under-Trellis-Cover-Crops (accessed on 20 January 2021).

- Abad, J.; Diana, M.L.; Gonzaga, S.; José Félix, C.; Ana, S. Under-vine cover crops: Impact on weed development, yield and grape composition. OENO One 2020, 54, 975–983. [Google Scholar] [CrossRef]

- MacLaren, C.; Bennett, J.; Dehnen-Schmutz, K. Management practices influence the competitive potential of weed communities and their value to biodiversity in South African vineyards. Weed Res. 2019, 59, 93–106. [Google Scholar] [CrossRef]

- Garnier, E.; Navas, M.-L. A trait-based approach to comparative functional plant ecology: Concepts, methods and applications for agroecology. A review. Agron. Sustain. Dev. 2012, 32, 365–399. [Google Scholar] [CrossRef]

- Novara, A.; Cerdà, A.; Gristina, L. Sustainable vineyard floor management: An equilibrium between water consumption and soil conservation. Curr. Opin. Environ. Sci. Heal. 2018, 5, 33–37. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations. Part 2: Operations and systems. Biosyst. Eng. 2017, 153, 110–128. [Google Scholar] [CrossRef]

- Reiser, D.; Sehsah, E.-S.; Bumann, O.; Morhard, J.; Griepentrog, H.W. Development of an Autonomous Electric Robot Implement for Intra-Row Weeding in Vineyards. Agriculture 2019, 9, 18. [Google Scholar] [CrossRef]

- Sportelli, M.; Pirchio, M.; Fontanelli, M.; Volterrani, M.; Frasconi, C.; Martelloni, L.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; et al. Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture? Agronomy 2020, 10, 553. [Google Scholar] [CrossRef]

- Pirchio, M.; Fontanelli, M.; Frasconi, C.; Martelloni, L.; Raffaelli, M.; Peruzzi, A.; Gaetani, M.; Magni, S.; Caturegli, L.; Volterrani, M.; et al. Autonomous Mower vs. Rotary Mower: Effects on Turf Quality and Weed Control in Tall Fescue Lawn. Agronomy 2018, 8, 15. [Google Scholar] [CrossRef]

- Emlid. A Reach RTK docs. Specification. Available online: https://docs.emlid.com/reach/specs/ (accessed on 20 January 2021).

- Husqvarna. Husqvarna automower 535 AWD Operator’s Manual. Available online: https://www.manualslib.com/manual/1579338/Husqvarna-Automower-535-Awd.html (accessed on 26 February 2021).

- Hoepli, Manuali Hoepli.it. Available online: http://www.manualihoepli.it/media/doc/pr243.pdf (accessed on 26 February 2021).

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale. Rapporti 280/2018. Available online: http://www.isprambiente.gov.it/it/pubblicazioni/rapporti/fattori-di-emissione-in-atmosfera-di-gasa-effetto-serra-e-altri-gas-nel-settore-elettrico (accessed on 26 February 2021).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2016; Available online: https://www.R-project.org/ (accessed on 20 January 2021).

- Gerhard, D.; Ritz, C. medrc: Mixed Effect Dose-Response Curves. R package version 1.1-0. Available online: https://rdrr.io/github/DoseResponse/medrc/man/metadrm.html (accessed on 20 January 2021).

- Ritz, C. Asymptotic regression model. In Analysis of Dose-Response Curves; Ritz, C., Strebig, J.C., Eds.; 2016; pp. 7–8. Available online: https://cran.r-project.org/web/packages/drc/drc.pdf (accessed on 20 January 2021).

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis, 3rd ed.; Springer International Publishing: New York, NY, USA, 2009. [Google Scholar]

- Pornaro, C.; Serena, M.; Macolino, S.; Leinauer, B. Drought Stress Response of Turf-Type Perennial Ryegrass Genotypes in a Medi-terranean Environment. Agronomy 2020, 10, 1810. [Google Scholar] [CrossRef]

- Sirera, À.P.; Antichi, D.; Raffa, D.W.; Rallo, G. Application of Remote Sensing Techniques to Discriminate the Effect of Different Soil Management Treatments over Rainfed Vineyards in Chianti Terroir. Remote. Sens. 2021, 13, 716. [Google Scholar] [CrossRef]

- Mainardis, M.; Boscutti, F.; Cebolla, M.D.M.R.; Pergher, G. Comparison between flaming, mowing and tillage weed control in the vineyard: Effects on plant community, diversity and abundance. PLoS ONE 2020, 15, e0238396. [Google Scholar] [CrossRef]

- Nascimbene, J.; Marini, L.; Ivan, D.; Zottini, M. Management Intensity and Topography Determined Plant Diversity in Vineyards. PLoS ONE 2013, 8, e76167. [Google Scholar] [CrossRef]

- Slaughter, D.; Giles, D.; Downey, D. Autonomous robotic weed control systems: A review. Comput. Electron. Agric. 2008, 61, 63–78. [Google Scholar] [CrossRef]

- Heckman, J.R.; Liu, H.; Hill, W.; DeMilia, M.; Anastasia, W.L. Kentucky Bluegrass Responses to Mowing Practice and Nitrogen Fertility Management. J. Sustain. Agric. 2000, 15, 25–33. [Google Scholar] [CrossRef]

- Brede, D. Turfgrass Maintenance Reduction Handbook: Sports, Lawns, and Golf, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000; p. 392. [Google Scholar]

- Sportelli, M.; Martelloni, L.; Orlandi, A.; Pirchio, M.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Peruzzi, A.; Consorti, S.B.; Vernieri, P. Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions. Agriculture 2019, 9, 115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).