Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter

Abstract

:1. Introduction

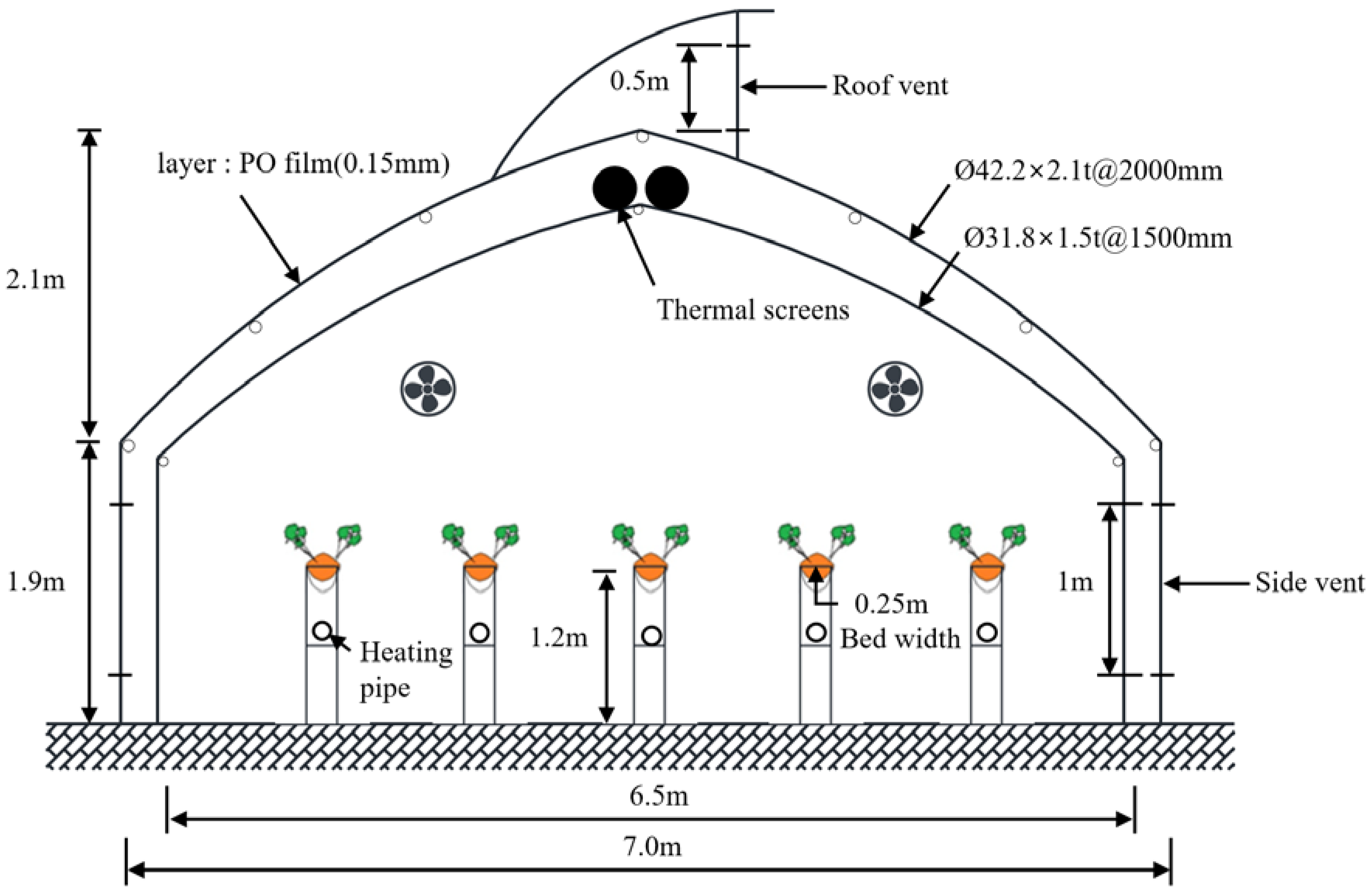

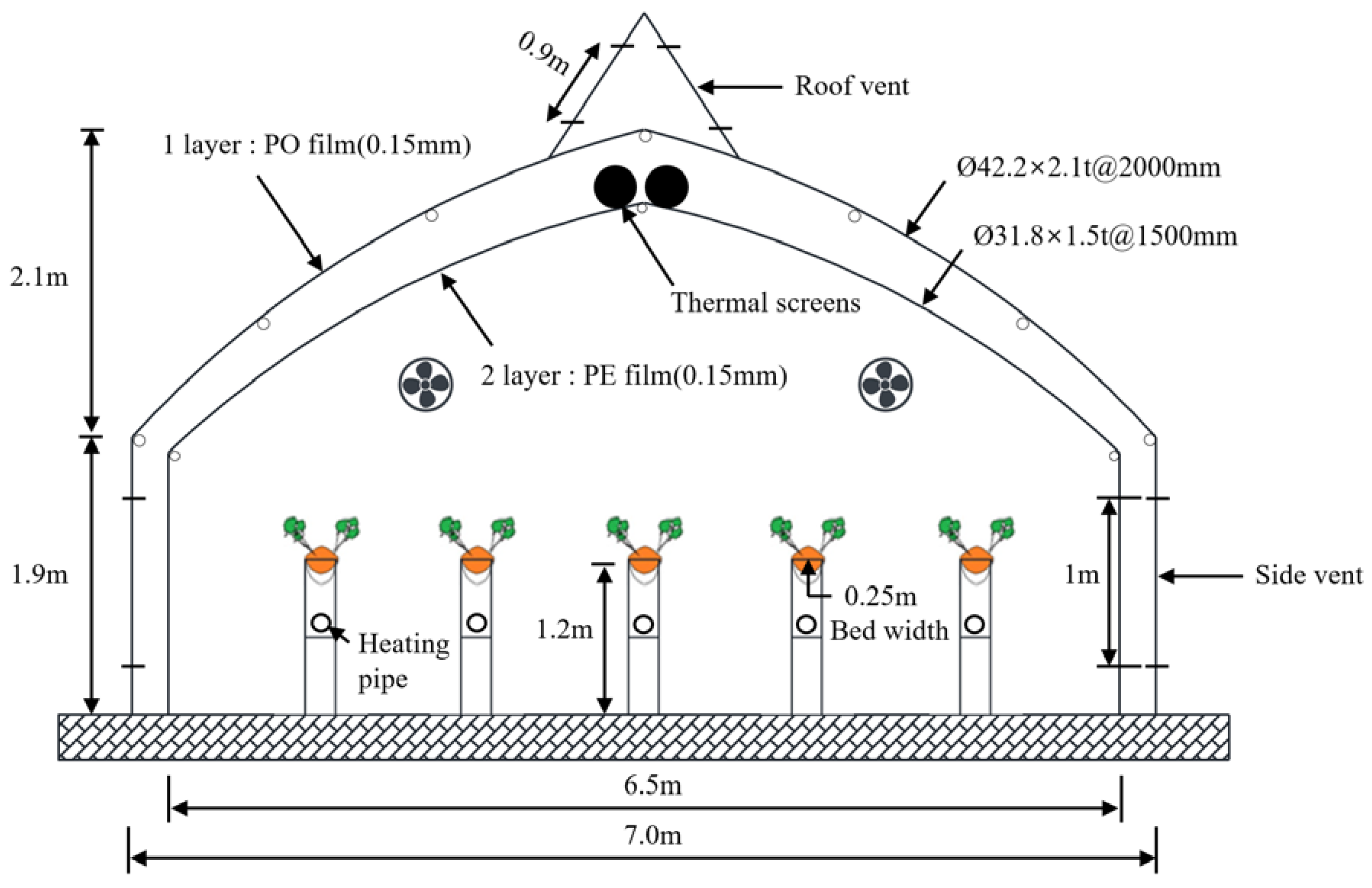

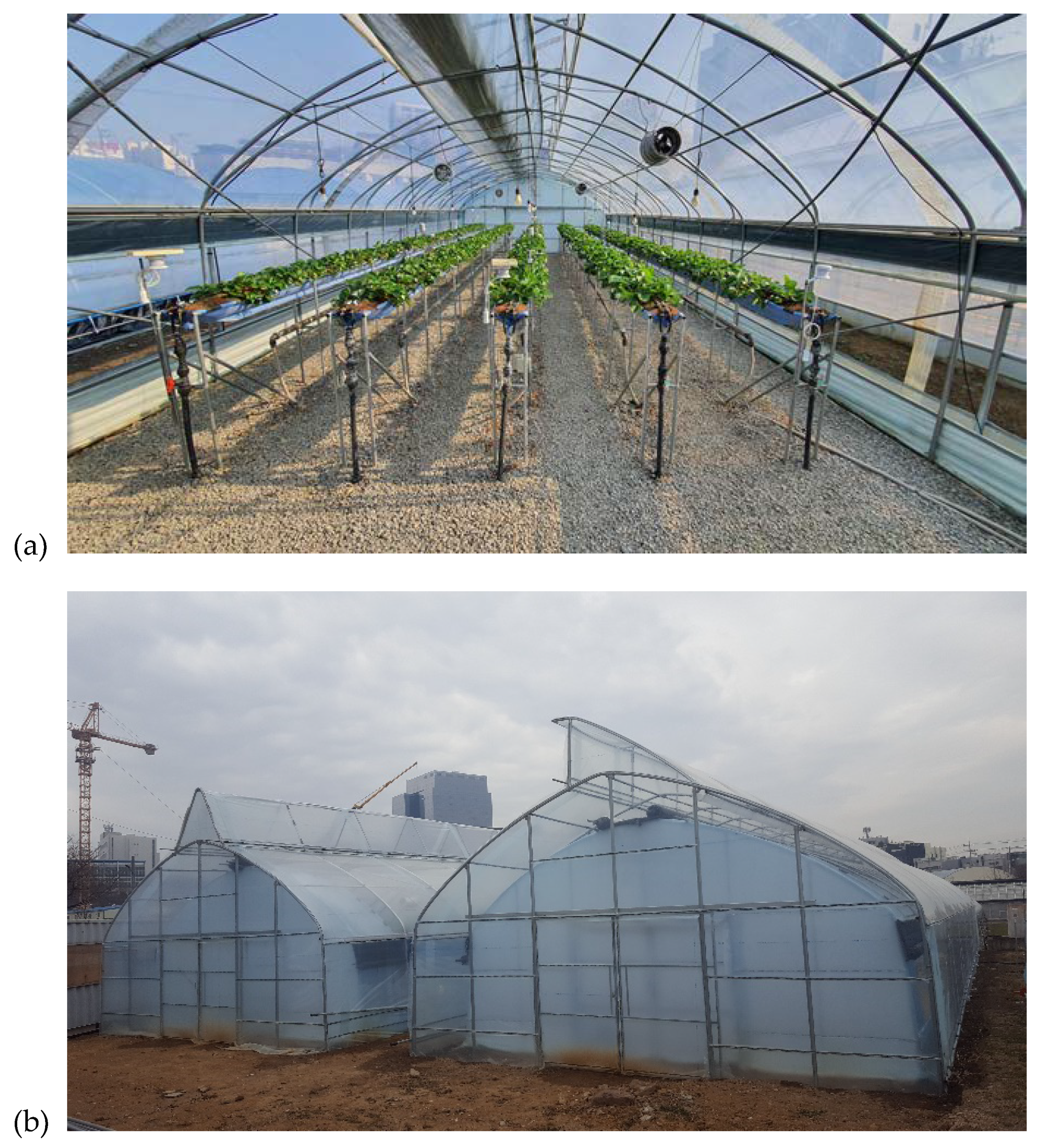

2. Materials and Methods

2.1. Experimental Site and Procedure

2.2. Instrumentation and Data Collection

2.3. Statistical and Sensitivity Analysis

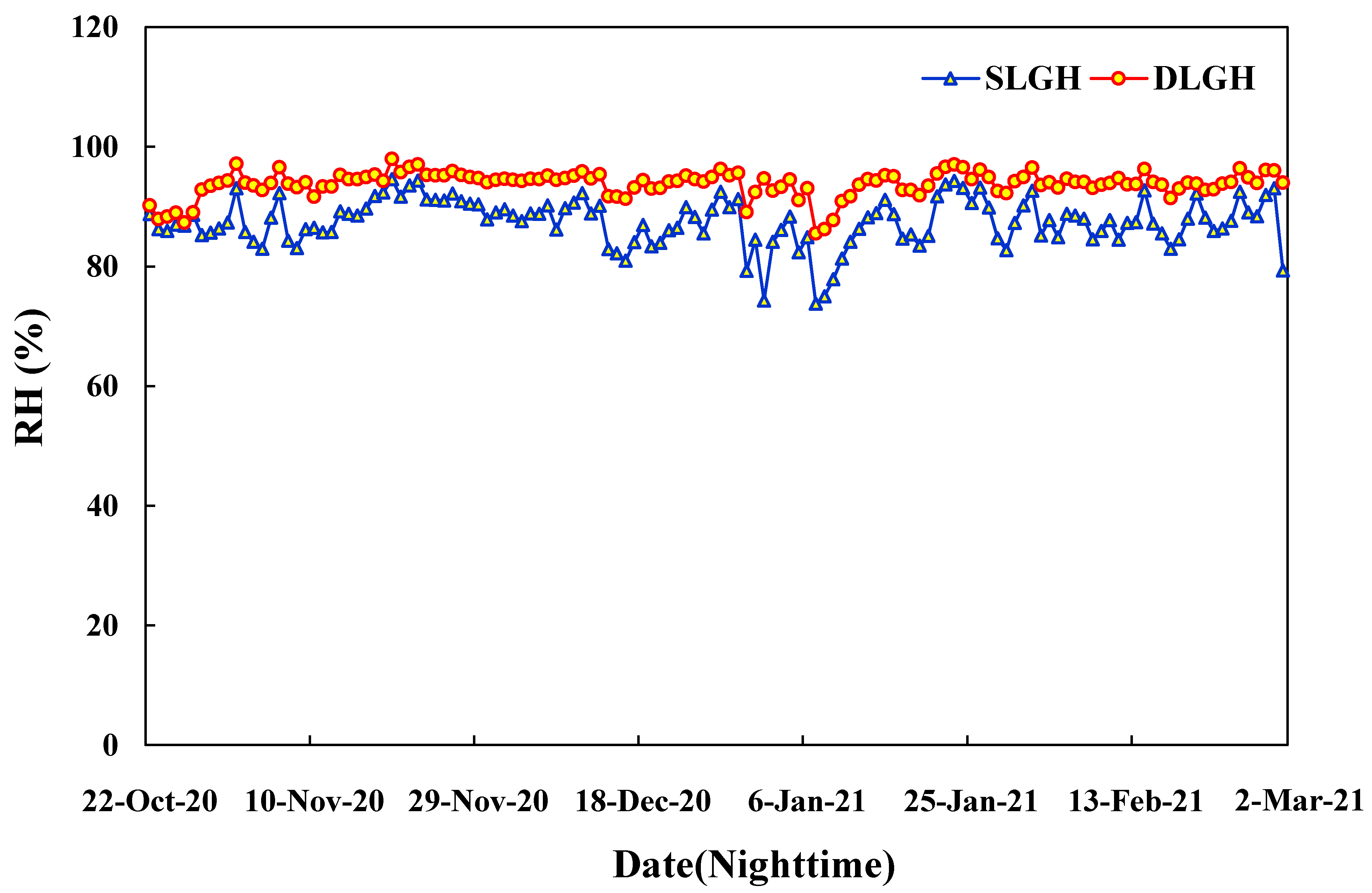

3. Results

4. Discussion

5. Conclusions

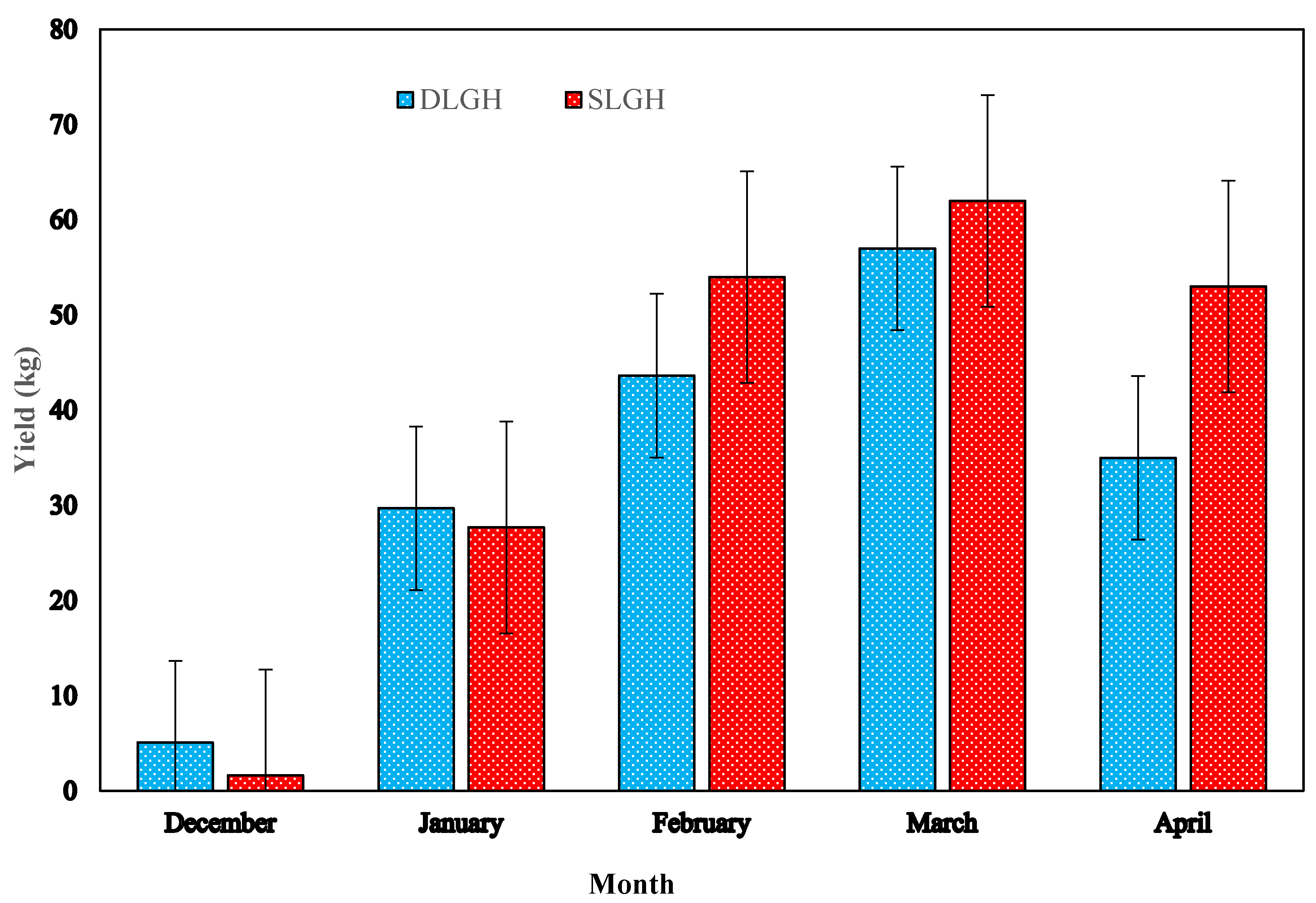

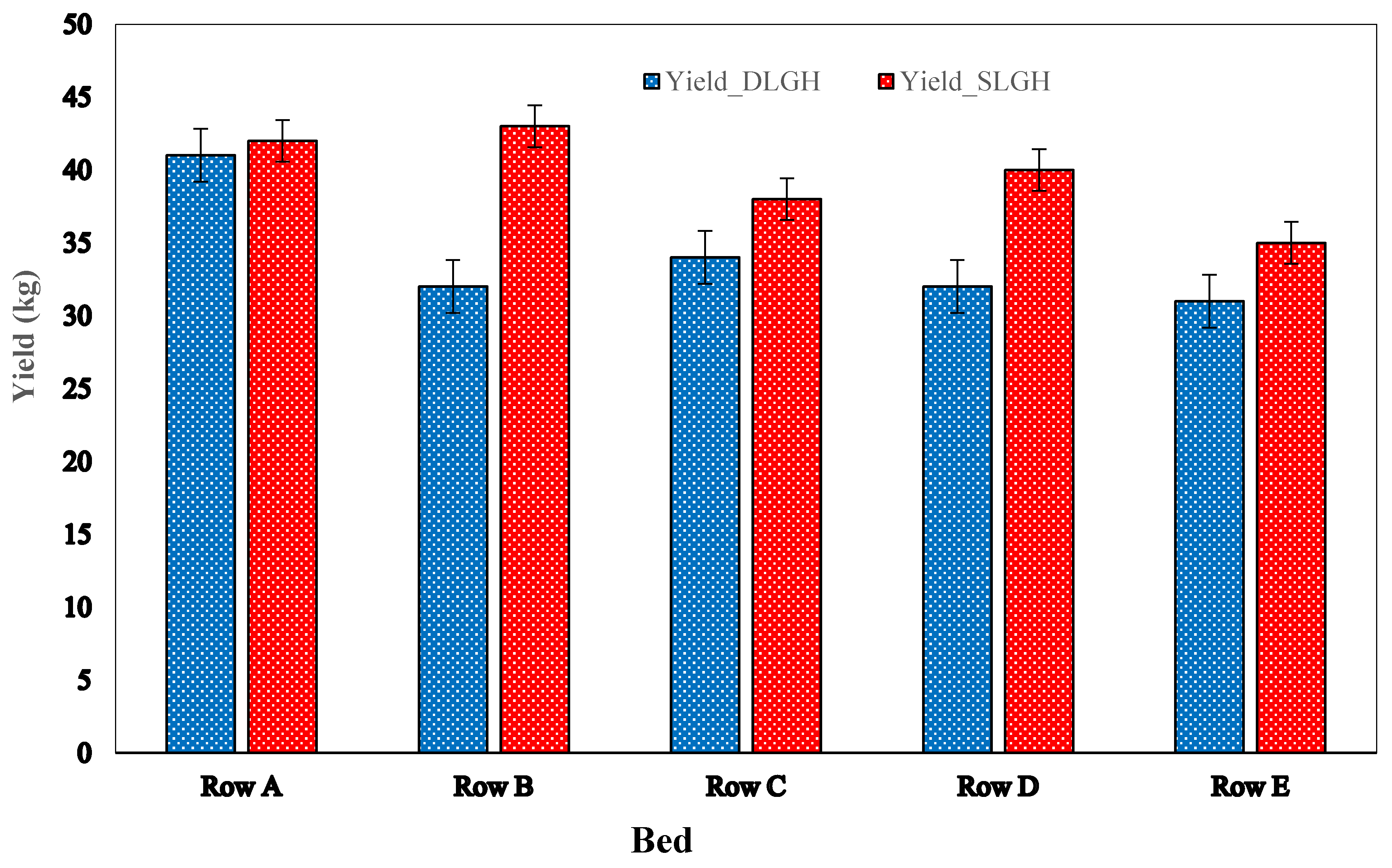

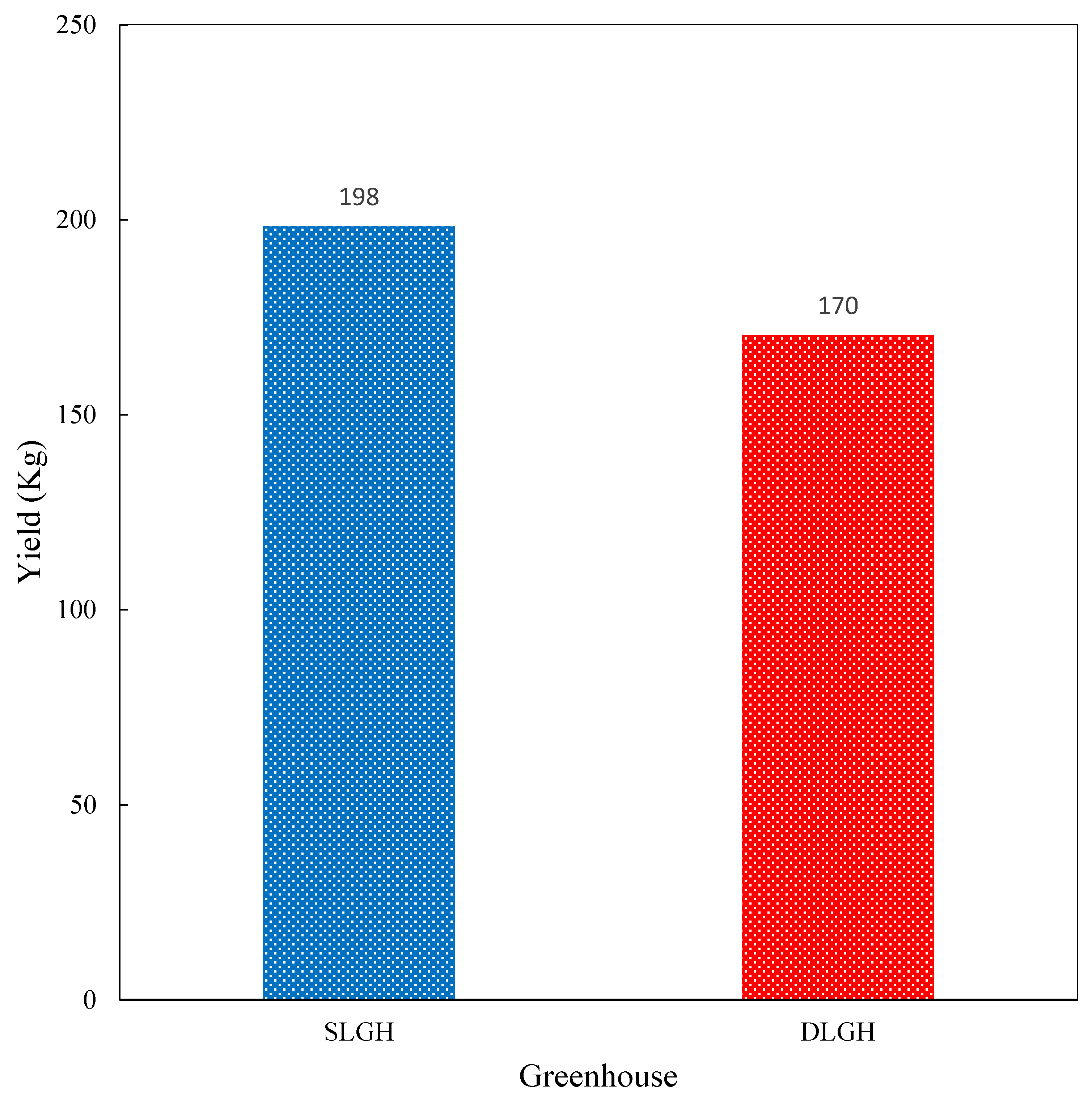

- The yield obtained in both greenhouses was insignificantly different; however, the yield in SLGH was 14% higher than the yield in DLGH;

- The VPD percentage within the recommended range was more in the SLGH than the DLGH;

- The SLGH can be used instead of the DLGH, saving construction costs regarding installing the second layer; however, the operating cost of the SLGH system was higher.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jayasekara, S.N.; Na, W.H.; Owolabi, A.B.; Lee, J.W.; Rasheed, A.; Kim, H.T.; Lee, H.W. Comparison of Environmental Conditions and Insulation Effect between Air Inflated and Conventional Double Layer Greenhouse. Prot. Hortic. Plant Fact. 2018, 27, 46–53. [Google Scholar] [CrossRef]

- Gruda, N. Impact of Environmental Factors on Product Quality of Greenhouse Vegetables for Fresh Consumption. Plant Sci. 2007, 24, 227–247. [Google Scholar] [CrossRef]

- Taki, M.; Rohani, A.; Rahmati-Joneidabad, M. Solar thermal simulation and applications in greenhouse. Inf. Process. Agric. 2018, 5, 83–113. [Google Scholar] [CrossRef]

- Frantz, J.M.; Ritchie, G.; Cometti, N.N.; Robinson, J.; Bugbee, B. Exploring the limits of crop productivity. Beyond the limits of tipburn in lettuce. J. Am. Soc. Hortic. Sci. 2004, 129, 331–338. [Google Scholar] [CrossRef] [Green Version]

- Akpenpuun, T.D.; Na, W.H.; Ogunlowo, Q.O.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.T.; Lee, H.-W. Effect of glazing configuration as an energy-saving strategy in naturally ventilated greenhouses for strawberry (“Seolhyang” sp.) cultivation. J. Agric. Eng. 2021, 52, 1–8. [Google Scholar] [CrossRef]

- Casierra-Posada, F.; Torres, I.D.; Blanke, M.M. Fruit Quality and Yield in Partially Defoliated Strawberry Plants in the Tropical Highlands. Gesunde Pflanz. 2013, 65, 107–112. [Google Scholar] [CrossRef]

- Martinez-Ferri, E.; Ariza, M.T.; Dominguez, P.; Medina, J.J.; Miranda, L.; Muriel, J.L.; Montesinos, P.; Rodriguez-Diaz, J.A.; Soria, C. Cropping Strawberry for Improving Productivity and Environment Sustainability. In Strawberries: Cultivation, Antioxidant Properties and Health Benefit Nutrition and Diet Reseach Progress; Malone, N., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2014; pp. 1–20. [Google Scholar]

- Ogunlowo, Q.O.; Akpenpuun, T.D.; Na, W.H.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.T.; Lee, H.-W. Analysis of heat and mass distribution in a single- and multi-span greenhouse microclimate. Agriculture 2021, 11, 891. [Google Scholar] [CrossRef]

- American Society of Agricultural Engineers. Heating, Ventilating and Cooling Greenhouses ANSI/ASAE Standard EP406.3; American Society of Agricultural and Biological Engineers (ASABE): St. Joseph, MI, USA, 2003. [Google Scholar]

- Harel, D.; Fadida, H.; Slepoy, A.; Gantz, S.; Shilo, K. The Effect of Mean Daily Temperature and Relative Humidity on Pollen, Fruit Set and Yield of Tomato Grown in Commercial Protected Cultivation. Agronomy 2014, 4, 167–177. [Google Scholar] [CrossRef]

- Wang, S.Y.; Lin, H. Effect of plant growth temperature on membrane lipids in strawberry (Fragaria x ananassa Duch.). Sci. Hortic. 2006, 108, 35–42. [Google Scholar] [CrossRef]

- Li, H.; Li, T.; Gordon, R.J.; Asiedu, S.K.; Hu, K. Strawberry plant fruiting efficiency and its correlation with solar irradiance, temperature and reflectance water index variation. Environ. Exp. Bot. 2010, 68, 165–174. [Google Scholar] [CrossRef]

- Shamshiri, R.; Ismail, W.I.W. A Review of Greenhouse Climate Control and Automation Systems in Tropical Regions. J. Agric. Sci. Appl. 2013, 2, 175–183. [Google Scholar] [CrossRef]

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 2020, 181, 115979. [Google Scholar] [CrossRef]

- Lieten, P. The effect of humidity on the performance of greenhouse grown strawberry. Acta Hortic. 2002, 567, 479–482. [Google Scholar] [CrossRef]

- Khalid, S.; Qureshi, K.M.; Hafiz, I.A.; Khan, K.S.; Qureshi, U.S. Effect of organic amendments on vegetative growth, fruit and yield quality of strawberry. Pak. J. Agric. Resour. 2013, 26, 104–112. [Google Scholar]

- Palencia, P.; Martinez, F.; Medina, J.J.; Vazquez, E.; Flores, F.; Lopez-Medina, J. Effect of climate change on strawberry production. Acta Hortic. 2009, 838, 51–54. [Google Scholar] [CrossRef]

- Cayli, A. Temperature and relative humidity spatial variability: An assessment of the environmental conditions inside greenhouses. Fresenius Environ. Bull. 2020, 29, 4954–4962. [Google Scholar]

- Baeza, E.; Hemming, S.; Stanghellini, C. Materials with switchable radiometric properties: Could they become the perfect greenhouse cover? Biosyst. Eng. 2020, 193, 157–173. [Google Scholar] [CrossRef]

- Frangi, P.; Piatti, R.; Amoroso, G. Evaluation of different screens for energy saving in the greenhouse. Acta Hortic. 2011, 893, 275–280. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Evaluation of Overall Heat Transfer Coefficient of Different Greenhouse Thermal Screens Using Building Energy Simulation. Prot. Hortic. Plant Fact. 2018, 27, 294–301. [Google Scholar] [CrossRef]

- Yano, A.; Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sustain. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Bakar, N.N.A.; Hassan, M.Y.; Abdullah, H.; Rahman, H.A.; Abdullah, M.P.; Hussin, F.; Bandi, M. Energy efficiency index as an indicator for measuring building energy performance: A review. Renew. Sustain. Energy Rev. 2015, 44, 1–11. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Development of a model to calculate the overall heat transfer coefficient of greenhouse covers. Span. J. Agric. Res. 2018, 15, e0208. [Google Scholar] [CrossRef] [Green Version]

- Bradford, E.; Hancock, J.F.; Warner, R.M. Interactions of Temperature and Photoperiod Determine Expression of Repeat Flowering in Strawberry. Hortic. Sci. 2010, 135, 102–107. [Google Scholar] [CrossRef] [Green Version]

- Fernandez, G.; Butler, L.; Louws, F. Strawberry Growth and Development in an Annual Plasticulture System. Hortic. Sci. 2001, 36, 1219–1223. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Ma, X.; Li, M.; Wang, Y. The effect of temperature and light on strawberry production in a solar greenhouse. Sol. Energy 2020, 195, 318–328. [Google Scholar] [CrossRef]

- Kim, S.K.; Jeong, M.S.; Park, S.W.; Kim, M.J.; Na, H.Y.; Chun, C.H. Improvement of runner plant production by increasing photosynthetic photon flux during strawberry transplant propagation in a closed transplant production system. Korean J. Hortic. Sci. 2010, 28, 535–539. [Google Scholar]

- Kacira, M.; Sase, S.; Okushima, L. Optimization of vent configuration by evaluating the greenhouse and plant canopy ventilation rates under wind induced ventilation. Trans. Am. Soc. Agric. Eng. 2004, 47, 2059–2067. [Google Scholar] [CrossRef]

- Rouphaela, Y.; Kyriacoub, M.C.; Petropoulosc, S.A.; Pascalea, S.D.; Collad, G. Improving vegetable quality in controlled environments. Sci. Hortic. 2018, 234, 275–289. [Google Scholar] [CrossRef]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Sabir, N.; Singh, B. Protected cultivation of vegetables in global arena: A review. Indian J. Agric. Sci. 2013, 83, 123–135. [Google Scholar]

- Kroggel, M.; Kubota, C. Controlled environment strategies for tipburn management in greenhouse strawberry production. Acta Hortic. 2017, 1156, 529–536. [Google Scholar] [CrossRef]

- Katsoulas, N.; Kittas, C. Impact of Greenhouse Microclimate on Plant Growth and Development with Special Reference to the Solanaceae. Eur. J. Plant Sci. Biotechnol. 2008, 2, 31–444. [Google Scholar]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Che Man, H.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Rosales, M.A.; Cervilla, L.M.; Eva, S.; Juan, J.R.; Rubio-Wilhelmi, M.; Soriano, T. The effect of environmental conditions on nutritional quality of cherry tomato fruits: Evaluation of two experimental Mediterranean greenhouses. J. Sci. Food Agric. 2011, 91, 152–162. [Google Scholar] [CrossRef] [PubMed]

- Quinn, M.J.; May, M.L.; Dilorenzo, N.; Ponce, C.H.; Smith, D.R.; Parr, S.L.; Galyean, M.L. Effects of roughage source and distillers grain concentration on beef cattle fnishing performance, carcass characteristics, and in vitro fermentation. J. Anim. Sci. 2011, 89, 2631–2642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Speetjens, B.; Hemming, S.; Wang, D.; Tsay, J. Design of a Vegetable Greenhouse System for Subtropical Conditions in Taiwan; Wageningen UR Greenhouse Horticulture: Wageningen, The Netherlands, 2012; Available online: https://edepot.wur.nl/238571 (accessed on 3 December 2021).

- Iraqi, D.; Gagnon, S.; Dubé, S.; Gosselin, A. Vapour pressure deficit (VPD) effects on the physiology and yield of greenhouse tomato. Hortic. Sci. 1995, 30, 846. [Google Scholar]

- Zolnier, S.; Gates, R.S.; Buxton, J.; Mach, C. Psychrometric and Ventilation Constraints for Vapor Pressure Deficit Control. Comput. Electron. Agric. 2000, 26, 343–359. [Google Scholar] [CrossRef]

- Ting, K.C.; Giacomelli, G.A. Availability of Solar Photosynthetically Active Radiation. Trans. ASAE 1987, 30, 1453–1457. [Google Scholar] [CrossRef]

- Yoshida, H.; Mizuta, D.; Fukua, N.; Hikosaka, S.; Goto, E. Effects of varying light quality from single-peak blue and red light-emitting diodes during nursery period on flowering, photosynthesis, growth, and fruit yield of everbearing strawberry. Plant Biotechnol. 2016, 33, 267–276. [Google Scholar] [CrossRef] [Green Version]

- Hidaka, K.; Dan, K.; Imamura, H.; Miyoshi, Y.; Takayama, T.; Sameshima, K.; Kitano, M.; Okimura, M. Effect of Supplemental Lighting from Different Light Sources on Growth and Yield of Strawberry. Environ. Control Biol. 2013, 51, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Faust, J.E.; Holcombe, V.; Rajapakse, N.C.; Layne, D.R. The Effect of Daily Light Integral on Bedding Plant Growth and Flowering. Hortic. Sci. 2005, 40, 645–649. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Teitel, M.; Barak, M. Vertical temperature and humidity gradients in a naturally ventilated greenhouse. J. Agric. Eng. Res. 2001, 78, 431–436. [Google Scholar] [CrossRef]

- Akpenpuun, T.D.; Mijinyawa, Y. Evaluation of a Greenhouse Under Tropical Conditions Using Irish Potato (Solanum tuberosum L.) as the Test Crop. ACTA Technol. Agric. 2018, 21, 56–62. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Mean | Standard Deviation | Minimum | Maximum | Range |

|---|---|---|---|---|---|

| SLGH | |||||

| Temperature, °C | 15.70 | 2.50 | 9.27 | 21.78 | 12.51 |

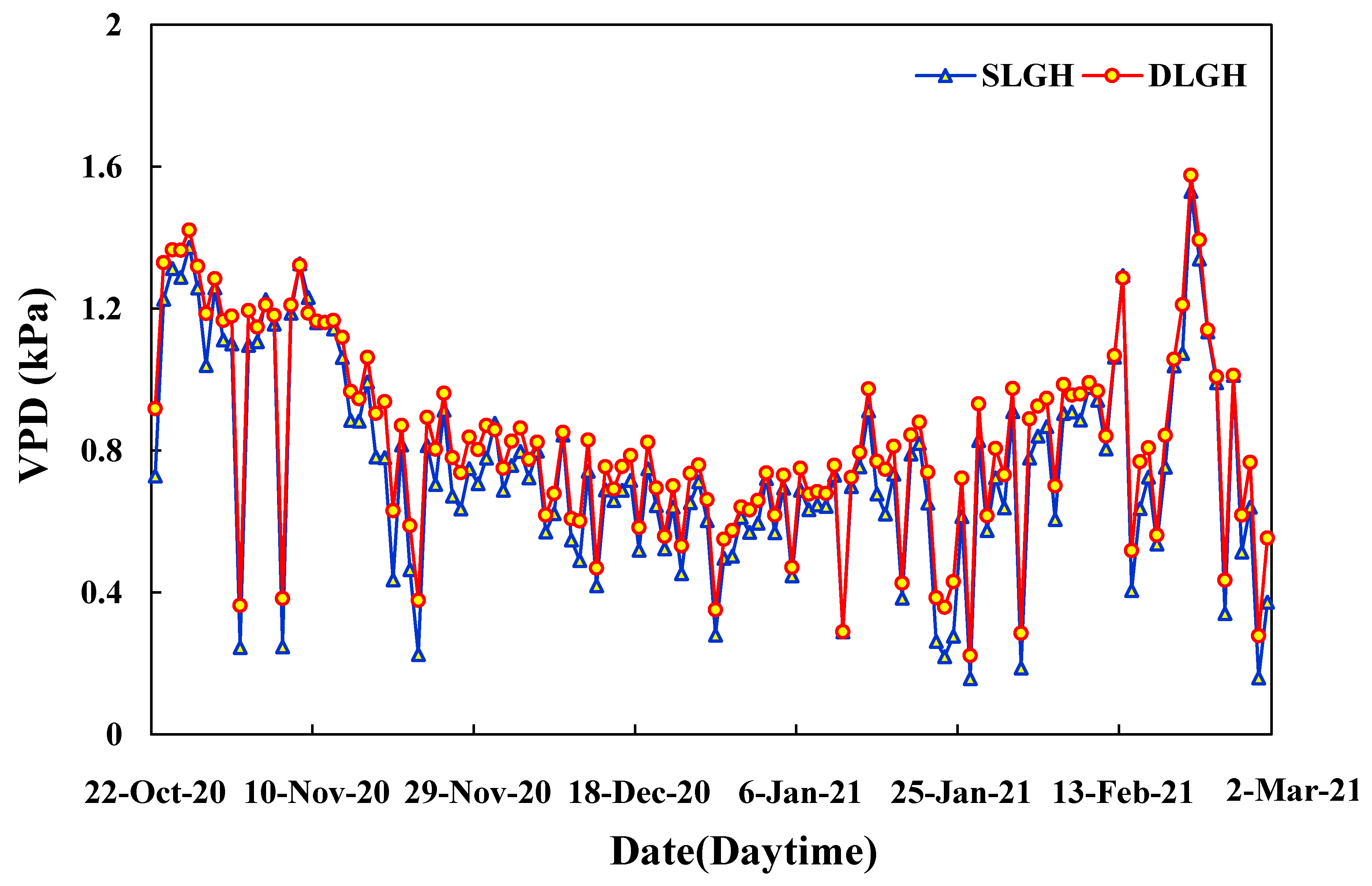

| Relative Humidity (RH), % | 64.13 | 10.71 | 46.60 | 91.74 | 45.14 |

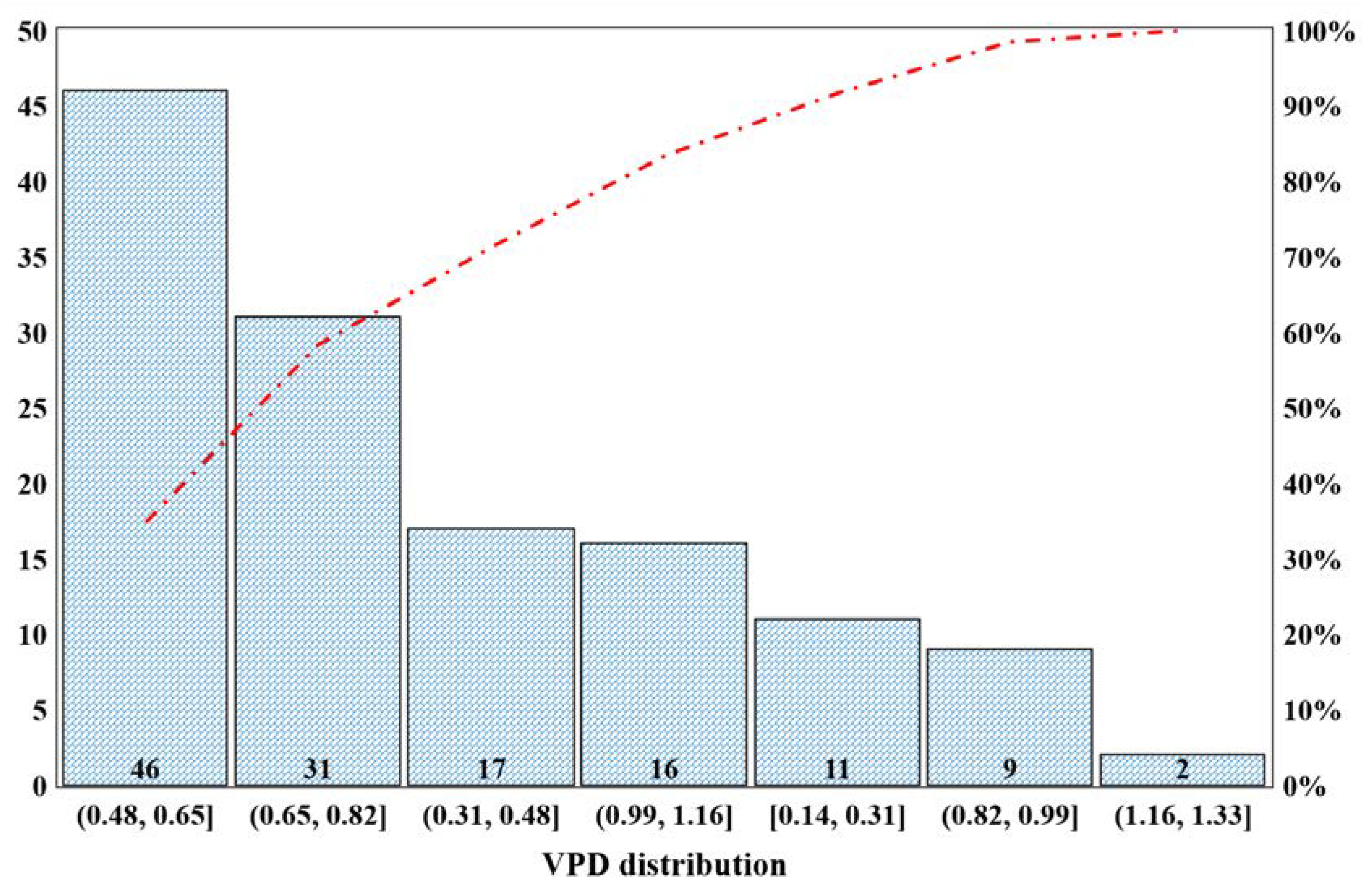

| Vapor Pressure Deficit (VPD), kPa | 0.76 | 0.29 | 0.16 | 1.53 | 1.37 |

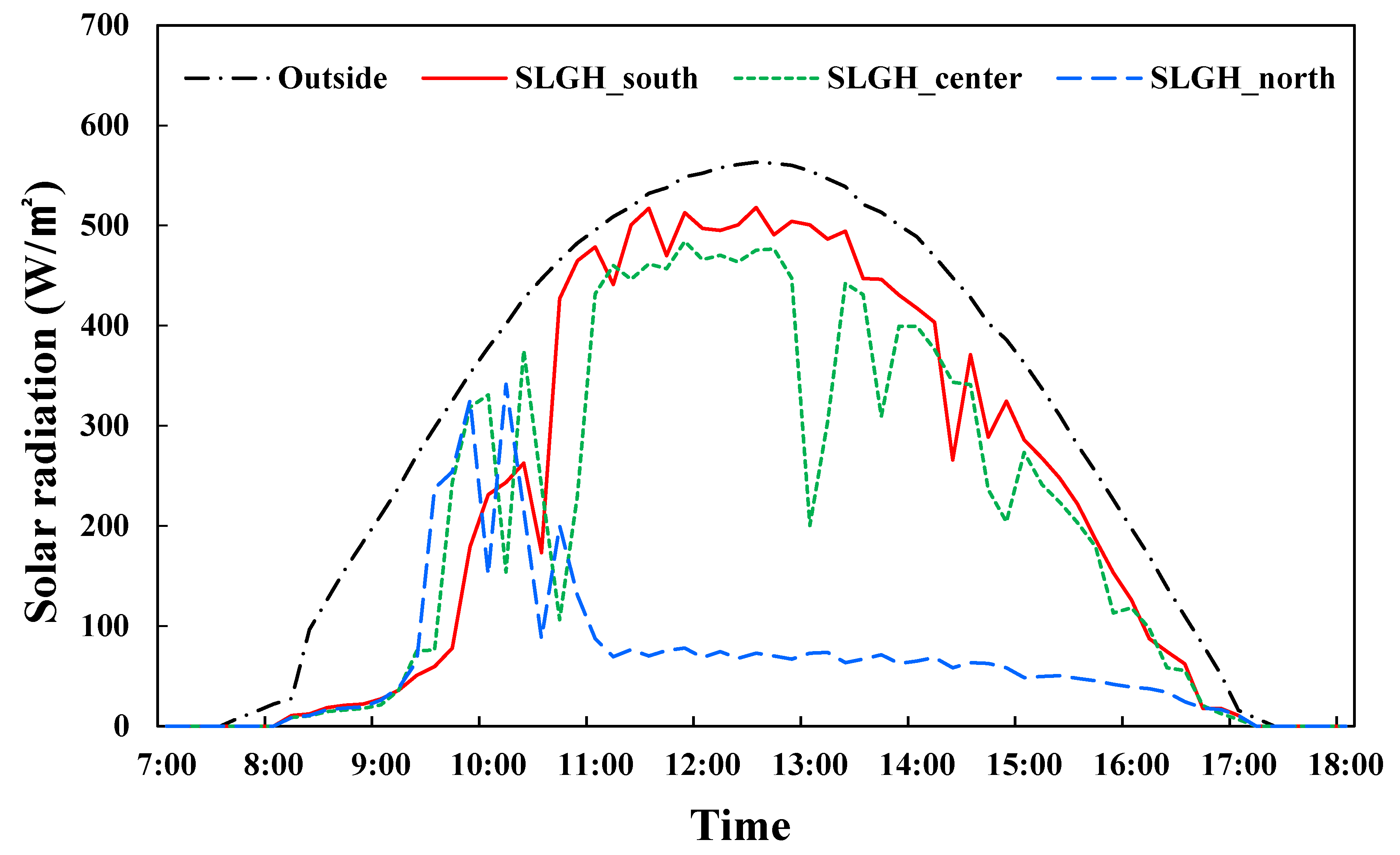

| Solar Radiation (SR), W/m2 | ** 151.94 | 101.76 | 8.71 | 549.83 | 541.12 |

| DLGH | |||||

| Temperature, °C | 15.92 | 2.46 | 9.21 | 21.70 | 12.50 |

| RH, % | 66.13 | 10.28 | 46.56 | 93.47 | 46.92 |

| VPD, kPa | 0.83 | 0.28 | 0.22 | 1.58 | 1.35 |

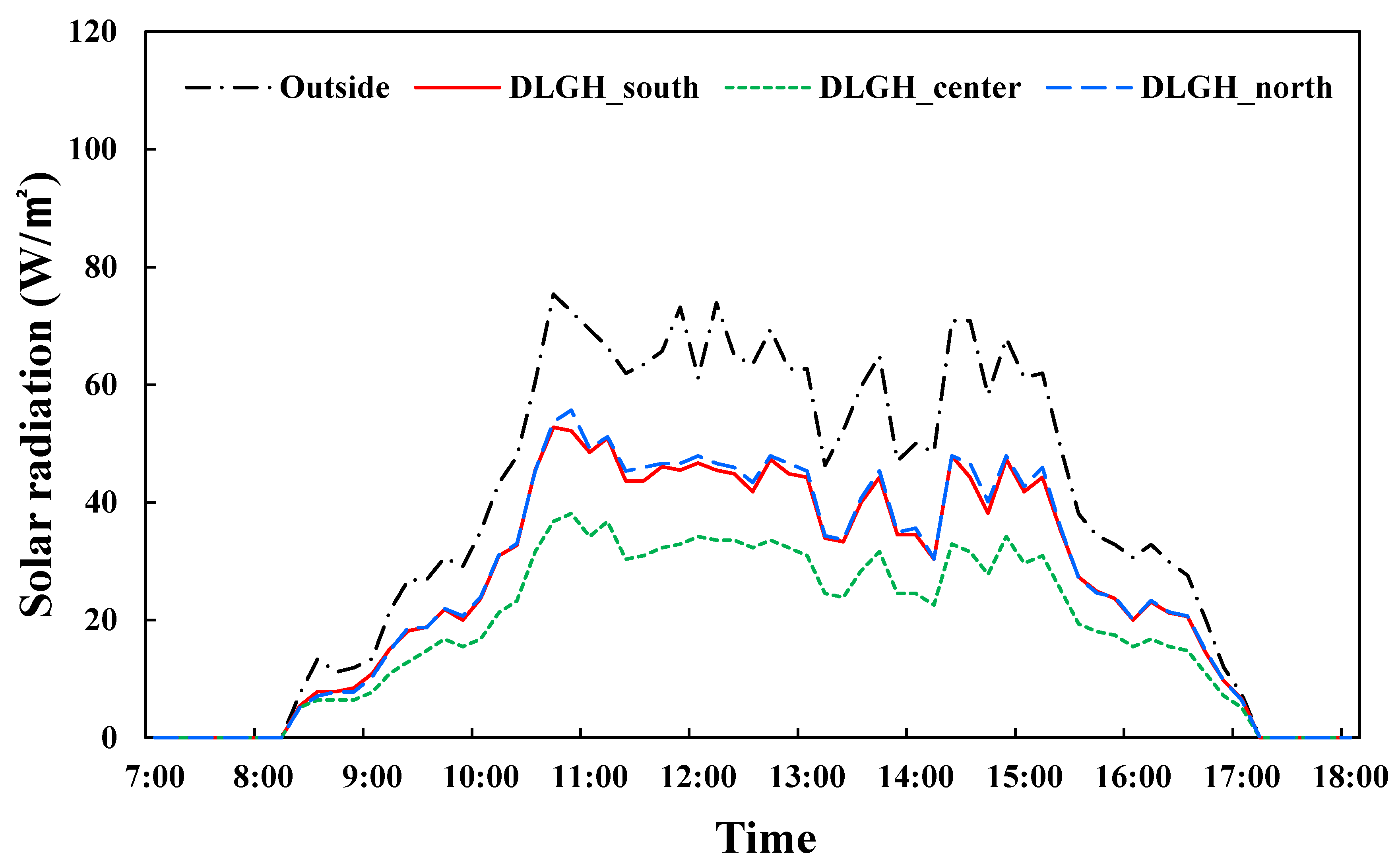

| SR, W/m2 | ** 160.92 | 111.47 | 3.24 | 631.57 | 628.33 |

| Parameters | Mean | Standard Deviation | Minimum | Maximum | Range |

|---|---|---|---|---|---|

| SLGH | |||||

| Temperature, °C | 10.21 | 2.33 | 8.08 | 19.56 | 11.48 |

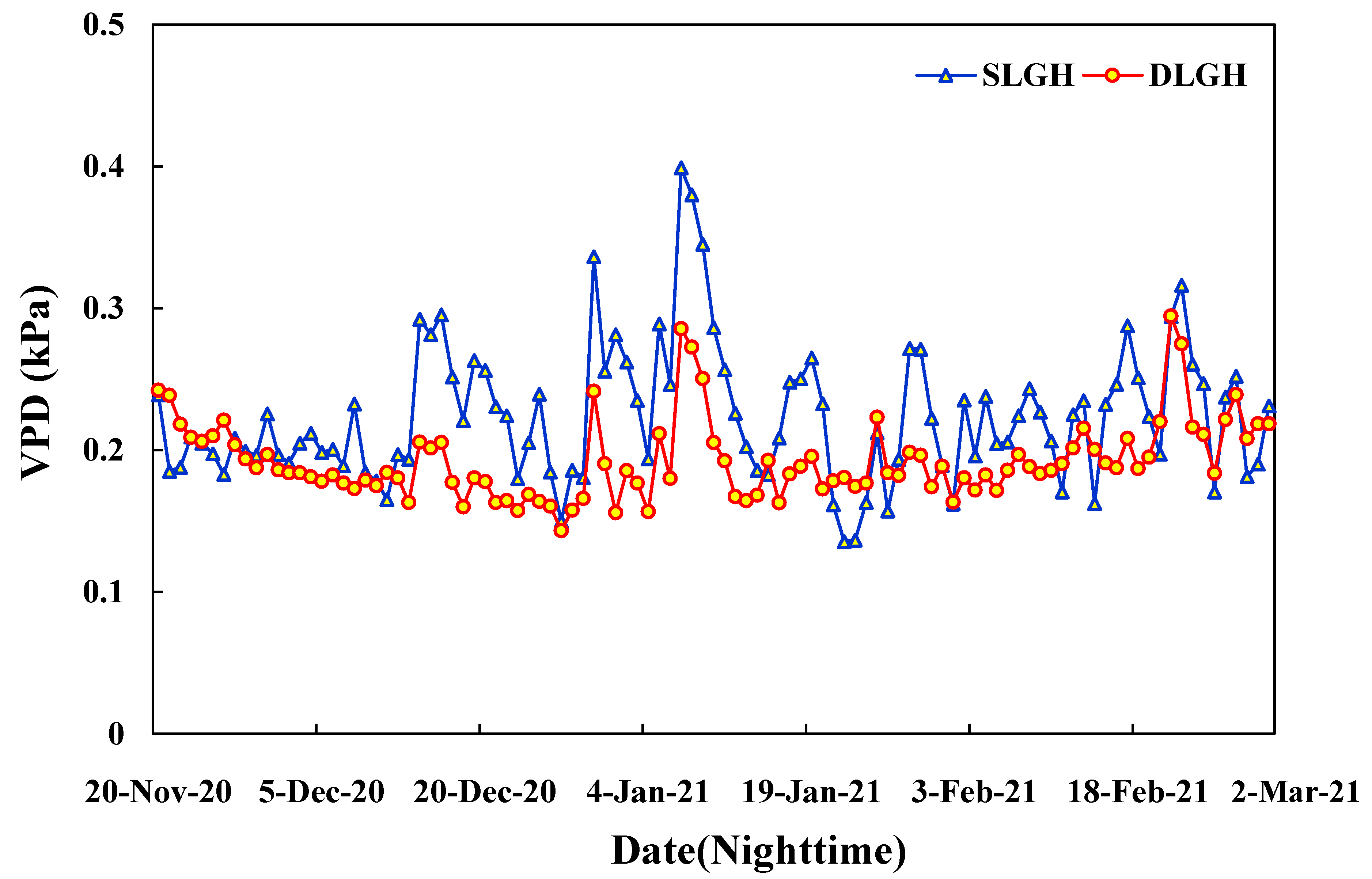

| RH, % | ** 87.48 | 3.96 | 73.80 | 94.59 | 20.78 |

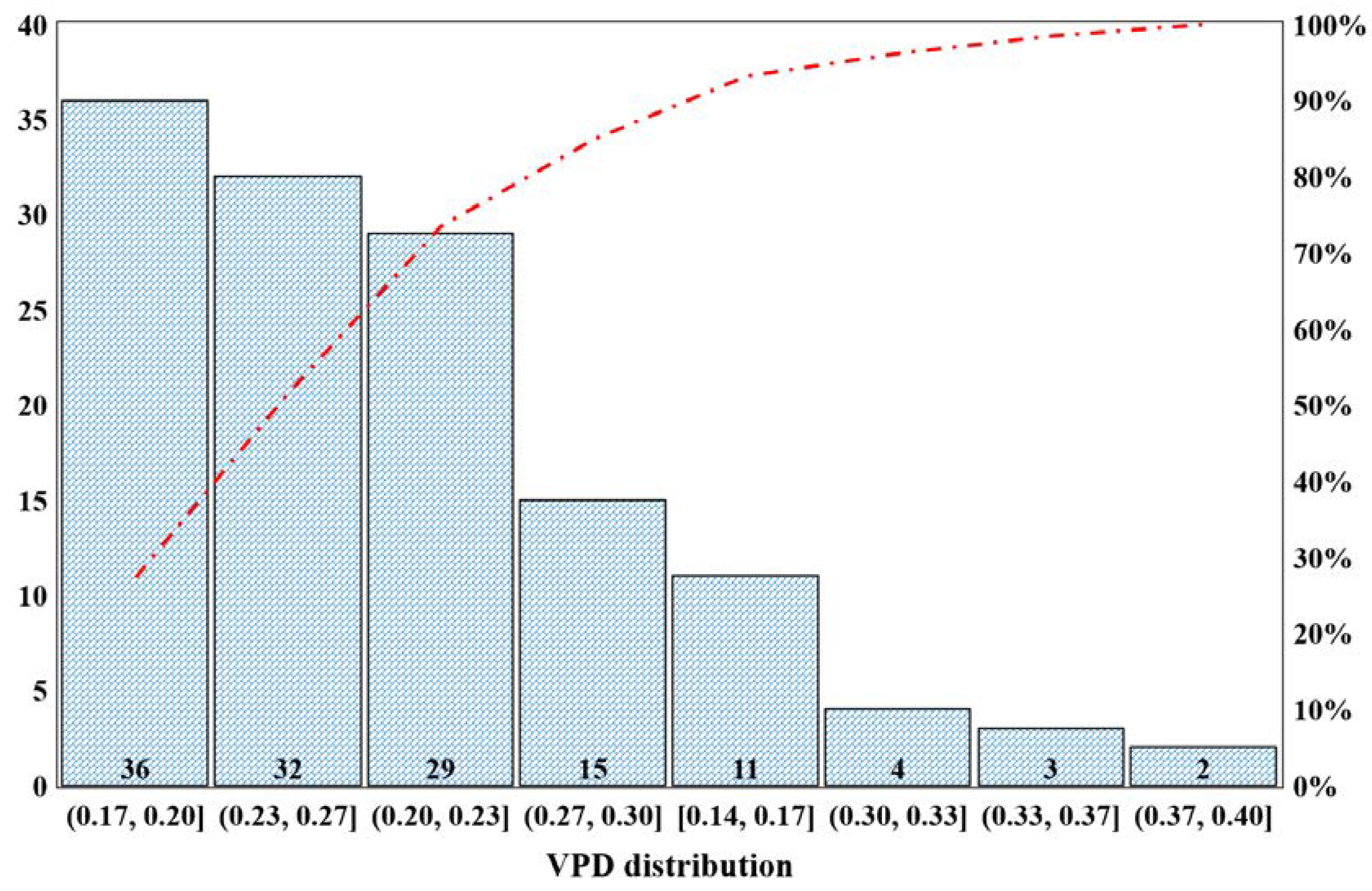

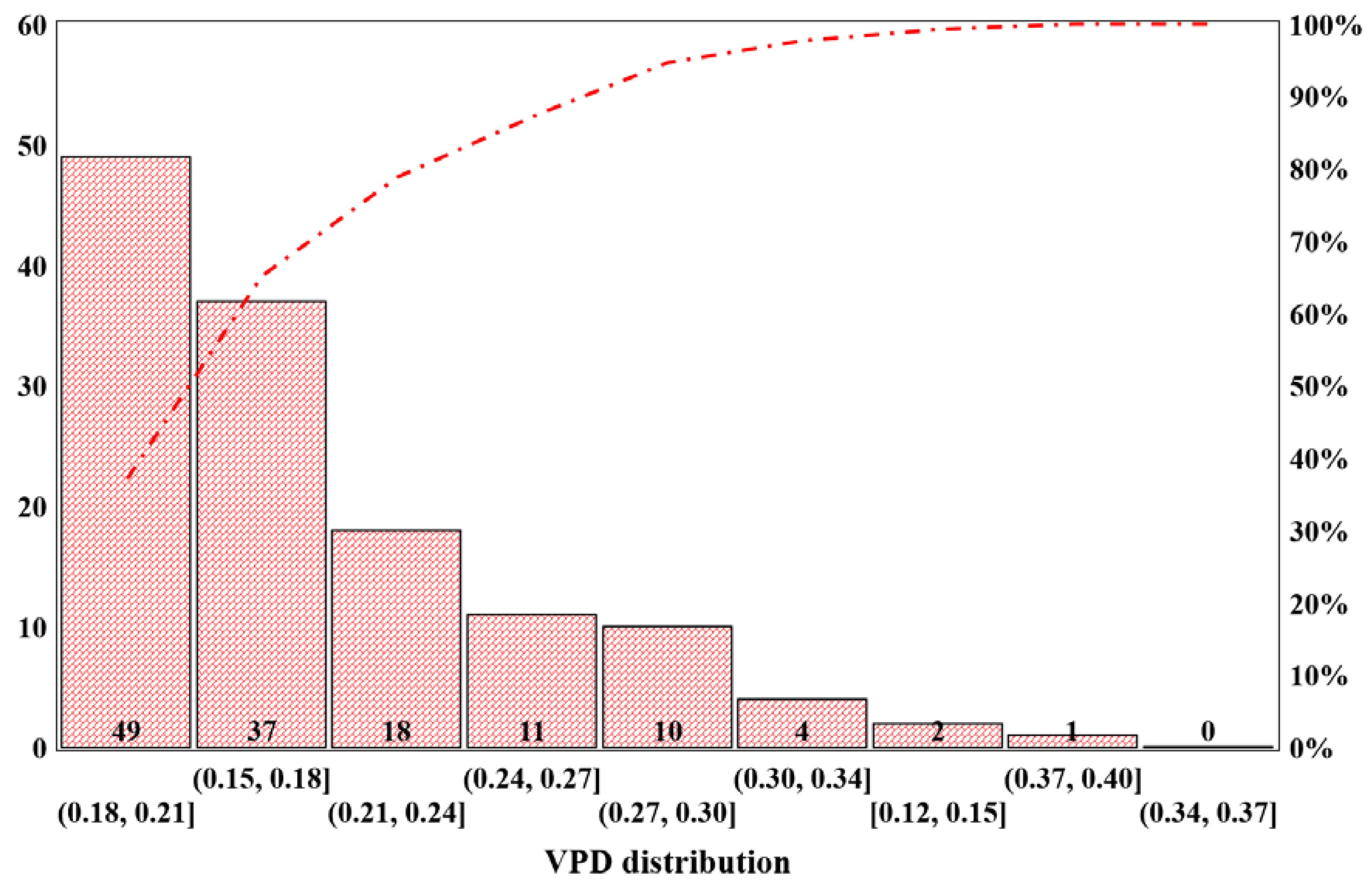

| VPD, kPa | ** 0.23 | 0.05 | 0.14 | 0.40 | 0.26 |

| DLGH | |||||

| Temperature, °C | 10.24 | 2.48 | 5.82 | 19.33 | 13.48 |

| RH, % | ** 93.81 | 2.16 | 85.52 | 97.98 | 12.45 |

| VPD, kPa | ** 0.21 | 0.04 | 0.12 | 0.37 | 0.25 |

| Groups | Sum | Mean | Variance | SD |

|---|---|---|---|---|

| SLGH | 198.2 | 39.6 | 962.5 | 31.0 |

| DLGH | 169.8 | 33.9 | 308.0 | 17.6 |

| Single Layer Greenhouse | Double Layer Greenhouse | ||||

|---|---|---|---|---|---|

| Unit Price (USD) | Quantity | Cost (USD) | Quantity | Cost (USD) | |

| Strawberry yield | 8.81 ** | 198 kg | 1744 | 170 kg | 1498 |

| Fuel consumption | 1.07 *** | 486.9 L | −520.98 | 307.7 L | −329.24 |

| Glazing material cost | * | * | * | PE film 0.15 mm × 8 m × 18 m | −85 |

| Income (USD) | 1223.02 | 1083.76 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akpenpuun, T.D.; Na, W.-H.; Ogunlowo, Q.O.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.-T.; Lee, H.-W. Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter. Agronomy 2021, 11, 2498. https://doi.org/10.3390/agronomy11122498

Akpenpuun TD, Na W-H, Ogunlowo QO, Rabiu A, Adesanya MA, Addae KS, Kim H-T, Lee H-W. Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter. Agronomy. 2021; 11(12):2498. https://doi.org/10.3390/agronomy11122498

Chicago/Turabian StyleAkpenpuun, Timothy Denen, Wook-Ho Na, Qazeem Opeyemi Ogunlowo, Anis Rabiu, Misbaudeen Aderemi Adesanya, Kwame Sasu Addae, Hyeon-Tae Kim, and Hyun-Woo Lee. 2021. "Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter" Agronomy 11, no. 12: 2498. https://doi.org/10.3390/agronomy11122498

APA StyleAkpenpuun, T. D., Na, W.-H., Ogunlowo, Q. O., Rabiu, A., Adesanya, M. A., Addae, K. S., Kim, H.-T., & Lee, H.-W. (2021). Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter. Agronomy, 11(12), 2498. https://doi.org/10.3390/agronomy11122498