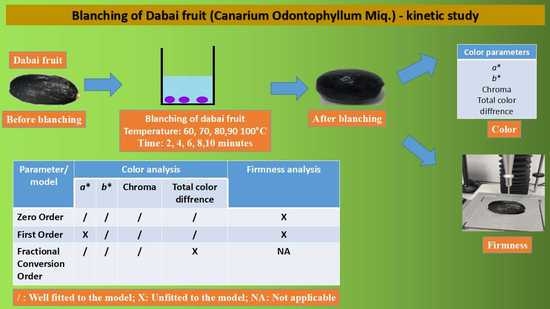

Modelling the Kinetics of Color and Texture Changes of Dabai (Canarium odontophyllum Miq.) during Blanching

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials and Their Preparation

2.2. Blanching

2.3. Color Analysis

2.4. Texture Analysis

2.5. Mathematical Models and Kinetics Analysis for Color and Texture of Blenched Dabai Fruits

2.6. Statistical Analysis

3. Results and Discussion

3.1. Mathematical Model and Kinetic Analysis for Color of Blenched Dabai Fruit

3.2. Mathematical Model and Kinetic Analysis for Texture of Blenched Dabai Fruit

3.3. Activation Energy Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rukayah, A. Buah-buahan eksotik dari Sabah dan Sarawak di Mardi, Serdang. Agromedia 2009, 22, 28–34. [Google Scholar]

- Chua, H.P.; Nicholas, D. Dabai—Speciality fruit of Sarawak. Agromedia 2009, 30, 28–30. [Google Scholar]

- Chua, H.P.; Nicholas, D.; Adros Yahya, M.N. Physical properties and nutritional values of Dabai fruit (Canarium odontophyllum) of different genotypes. J. Trop. Agric. Food Sci. 2015, 43, 1–10. [Google Scholar]

- Ding, P. Dabai (Canarium odontophyllum Miq.). In Postharvest Biology and Technology of Tropical and Subtropical Fruits; Woodhead Publishing Limited: Milton Keynes, UK, 2011; Volume 3. [Google Scholar] [CrossRef]

- Basri, D.F.; Fudholi, A.; Ruslan, M.H. Drying characteristics of the Borneo Canarium Odontophyllum (Dabai) fruit. Am. J. Agric. Bio. Sci. 2012, 7, 347–356. [Google Scholar] [CrossRef] [Green Version]

- Khoo, H.E.; Azlan, A.; Tang, S.T.; Lim, S.M. Antocyanidins and anthocyanins:colored pigments as food, pharmaceutical ingredients, and the potential helath benefits. Food Nutr. Res. 2017, 61, 1812. [Google Scholar] [CrossRef] [Green Version]

- Deylami, M.Z.; Rahman, R.A.; Tan, C.P.; Bakar, J.; Olusegun, L. Effect of blanching on enzyme activity, color changes, anthocyanin stability and extractability of mangosteen pericarp: A kinetic study. J. Food Eng. 2016, 178, 12–19. [Google Scholar] [CrossRef]

- Shakirin, F.H.; Prasad, K.N.; Ismail, A.; Yuon, L.C.; Azlan, A. Antioxidant capacity of underutilized Malaysian Canarium odontophyllum (Dabai) Miq. fruit. J. Food Compos. Anal. 2010, 23, 777–781. [Google Scholar] [CrossRef]

- Xiao, H.W.; Pan, Z.; Deng, L.Z.; El-Mashad, H.M.; Yang, X.H.; Mujumdar, A.S.; Gao, Z.J.; Zhang, Q. Recent developments and trends in thermal blanching—A comprehensive review. Inf. Process. Agric. 2017, 4, 101–127. [Google Scholar] [CrossRef]

- Abu-Ghannam, N.; Crowley, H. The effect of low temperature blanching on the texture of whole processed new potatoes. J. Food Eng. 2006, 74, 335–344. [Google Scholar] [CrossRef] [Green Version]

- Ding, P.; Tee, Y.K. Physicochemical characteristics of Dabai (Canarium odontophyllum Miq.) fruit. Fruits 2011, 66, 47–52. [Google Scholar] [CrossRef]

- Ruiz-Ojeda, L.M.; Peñas, F.J. Comparison study of conventional hot-water and microwave blanching on quality of green beans. Innov. Food Sci. Emerg. Tech. 2013, 20, 191–197. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Gupta, S.; Abu-Ghannam, N. Kinetic evaluation of colour, texture, polyphenols and antioxidant capacity of Irish York cabbage after blanching treatment. Food Chem. 2012, 131, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Azman, P.N.M.A.; Shamsudin, R.; Che Man, H.; Ya’acob, M.A. Kinetics of Quality Changes in Soaking Water during Retting Process of Pepper Berries (Piper nigrum L.). Processes 2020, 8, 1255. [Google Scholar] [CrossRef]

- Gonçalves, E.M.; Pinheiro, J.; Abreu, M.; Brandão, T.R.S.; Silva, C.L.M. Modelling the kinetics of peroxidase inactivation, colour and texture changes of pumpkin (Cucurbita maxima L.) during blanching. J. Food Eng. 2007, 81, 693–701. [Google Scholar] [CrossRef]

- Gonçalves, E.M.; Pinheiro, J.; Abreu, M.; Brandão, T.R.S.; Silva, C.L.M. Carrot (Daucus carota L.) peroxidase inactivation, phenolic content and physical changes kinetics due to blanching. J. Food Eng. 2010, 97, 574–581. [Google Scholar] [CrossRef]

- Cruz, R.M.S.; Vieira, M.C.; Silva, C.L.M. Modelling kinetics of watercress (Nasturtium officinale) colour changes due to heat and thermosonication treatments. Innov. Food Sci. Emerg. Technol. 2007, 8, 244–252. [Google Scholar] [CrossRef]

- Dini, A.; Falahati-Pour, S.K.; Behmaram, K.; Sedaghat, N. The kinetics of colour degradation, chlorophylls and xanthophylls loss in pistachio nuts during roasting process. Food Qual. Saf. 2019, 3, 251–263. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, P.; Sharma, A.; Patil, R.T. Color kinetics of aonla shreds with amalgamated blanching during drying. Int. J. Food Prop. 2011, 14, 1232–1240. [Google Scholar] [CrossRef]

- Manjunatha, S.S.; Mathews, A.T.; Patki, P.E. Modelling the kinetics of mass transfer and change in colour during deep fat frying of green peas (Pisum sativum L.) at different frying temperatures. Heat Mass Transf. 2019, 55, 3087–3102. [Google Scholar] [CrossRef]

- Demirhan, E.; Özbek, B. Color Change Kinetics of Tea Leaves during Microwave Drying. Int. J. Food Eng. 2015, 11, 255–263. [Google Scholar] [CrossRef]

- Onwude, D.; Nawi, N.M.; Hashim, N.; Abdan, K. Color Change Kinetics and Total Carotenoid Content of Pumpkin as Affected by Drying Temperature. Ital. Food Sci. 2016, 28, 744–748. [Google Scholar] [CrossRef]

- Sodiqovna, O.M.; Qizi, I.G.O. The Rate of A Chemical Reaction Factors Affecting It. EPRA Int. J. Res. Dev. 2020, 5, 261–263. [Google Scholar]

- Inheiro, J.O.P.; Legria, C.A.A.; Breu, M.A.A. Degradation Kinetics of Peroxidase Enzyme Phenolic Content and Physical and Sensorial Characteristics in Broccoli (Brassica oleracea L. ssp. Italica) during Blanching. J. Agric. Food Chem. 2009, 57, 5370–5375. [Google Scholar] [CrossRef]

- Eyarkai Nambi, V.; Gupta, R.K.; Kumar, S.; Sharma, P.C. Degradation kinetics of bioactive components, antioxidant activity, colour and textural properties of selected vegetables during blanching. J. Food Sci. Tech. 2016, 53, 3073–3082. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Temperature (℃) | k | R2 | |

|---|---|---|---|---|

| a* | Zero-order | 60 | 0.532 | 0.989 |

| 70 | 1.189 | 0.853 | ||

| 80 | 5.604 | 0.986 | ||

| 90 | 7.874 | 0.979 | ||

| 100 | 7.983 | 0.980 | ||

| Fractional conversion-order | 60 | 0.003 | 0.915 | |

| 70 | 0.001 | 0.931 | ||

| 80 | 0.005 | 0.876 | ||

| 90 | 0.005 | 0.923 | ||

| 100 | 0.005 | 0.908 | ||

| b* | Zero-order | 60 | −0.025 | 0.978 |

| 70 | −0.037 | 0.972 | ||

| 80 | −0.071 | 0.912 | ||

| 90 | −0.085 | 0.934 | ||

| 100 | −0.108 | 0.965 | ||

| First-order | 60 | −0.0004 | 0.984 | |

| 70 | −0.0005 | 0.965 | ||

| 80 | −0.001 | 0.902 | ||

| 90 | −0.0011 | 0.916 | ||

| 100 | −0.0013 | 0.948 | ||

| Fractional conversion-order | 60 | 0.003 | 0.915 | |

| 70 | 0.001 | 0.931 | ||

| 80 | 0.005 | 0.876 | ||

| 90 | 0.005 | 0.923 | ||

| 100 | 0.005 | 0.908 | ||

| C | Zero-order | 60 | −0.037 | 0.977 |

| 70 | −0.071 | 0.961 | ||

| 80 | −0.242 | 0.989 | ||

| 90 | −0.349 | 0.981 | ||

| 100 | −0.366 | 0.986 | ||

| First-order | 60 | −0.0007 | 0.979 | |

| 70 | −0.0009 | 0.935 | ||

| 80 | −0.0023 | 0.971 | ||

| 90 | −0.0028 | 0.958 | ||

| 100 | −0.0029 | 0.964 | ||

| Fractional-conversion order | 60 | 0.004 | 0.946 | |

| 70 | 0.002 | 0.956 | ||

| 80 | 0.005 | 0.899 | ||

| 90 | 0.004 | 0.920 | ||

| 100 | 0.005 | 0.923 | ||

| TCD | Zero-order | 60 | −0.485 | 0.961 |

| 70 | −0.309 | 0.750 | ||

| 80 | −0.356 | 0.931 | ||

| 90 | −0.315 | 0.889 | ||

| 100 | −0.292 | 0.906 | ||

| First-order | 60 | −0.0034 | 0.982 | |

| 70 | −0.0026 | 0.866 | ||

| 80 | −0.0029 | 0.907 | ||

| 90 | −0.0028 | 0.855 | ||

| 100 | −0.0026 | 0.879 | ||

| Fractional conversion-order | 60 | 0.004 | 0.816 | |

| 70 | 0.001 | 0.900 | ||

| 80 | 0.008 | 0.874 | ||

| 90 | 0.007 | 0.908 | ||

| 100 | 0.007 | 0.913 |

| Parameter | Kinetic Model | Temperature (℃) | k | R2 |

|---|---|---|---|---|

| Firmness | Zero-order | 60 | 0.0006 | 0.712 |

| 70 | 0.001 | 0.757 | ||

| 80 | 0.0011 | 0.788 | ||

| 90 | 0.0011 | 0.784 | ||

| 100 | 0.094 | 0.810 | ||

| First-order | 60 | 0.0007 | 0.692 | |

| 70 | 0.0014 | 0.732 | ||

| 80 | 0.0016 | 0.774 | ||

| 90 | 0.0016 | 0.767 | ||

| 100 | 0.0027 | 0.794 |

| Kinetic Models | Parameter | Ea (kJ/mol) | R2 |

|---|---|---|---|

| Zero | a* | 1.105 | 0.889 |

| b* | 39.117 | 0.963 | |

| C | 62.273 | 0.904 | |

| TCD | 13.419 | 0.986 | |

| First | b* | 32.761 | 0.923 |

| C | 3.479 | 0.993 | |

| TCD | 6.792 | 0.989 | |

| Fractional Conversion | a* | 27.343 | 0.710 |

| b* | 18.076 | 0.837 | |

| C | 10.744 | 0.892 | |

| TCD | 6.688 | 0.742 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamsudin, R.; Ariffin, S.H.; Zainol @ Abdullah, W.N.Z.; Azmi, N.S.; Abdul Halim, A.A. Modelling the Kinetics of Color and Texture Changes of Dabai (Canarium odontophyllum Miq.) during Blanching. Agronomy 2021, 11, 2185. https://doi.org/10.3390/agronomy11112185

Shamsudin R, Ariffin SH, Zainol @ Abdullah WNZ, Azmi NS, Abdul Halim AA. Modelling the Kinetics of Color and Texture Changes of Dabai (Canarium odontophyllum Miq.) during Blanching. Agronomy. 2021; 11(11):2185. https://doi.org/10.3390/agronomy11112185

Chicago/Turabian StyleShamsudin, Rosnah, Siti Hajar Ariffin, Wan Nor Zanariah Zainol @ Abdullah, Nazatul Shima Azmi, and Arinah Adila Abdul Halim. 2021. "Modelling the Kinetics of Color and Texture Changes of Dabai (Canarium odontophyllum Miq.) during Blanching" Agronomy 11, no. 11: 2185. https://doi.org/10.3390/agronomy11112185

APA StyleShamsudin, R., Ariffin, S. H., Zainol @ Abdullah, W. N. Z., Azmi, N. S., & Abdul Halim, A. A. (2021). Modelling the Kinetics of Color and Texture Changes of Dabai (Canarium odontophyllum Miq.) during Blanching. Agronomy, 11(11), 2185. https://doi.org/10.3390/agronomy11112185