Evaluating Irrigation and Farming Systems with Solar MajiPump in Ethiopia

Abstract

1. Introduction

2. Materials and Methods

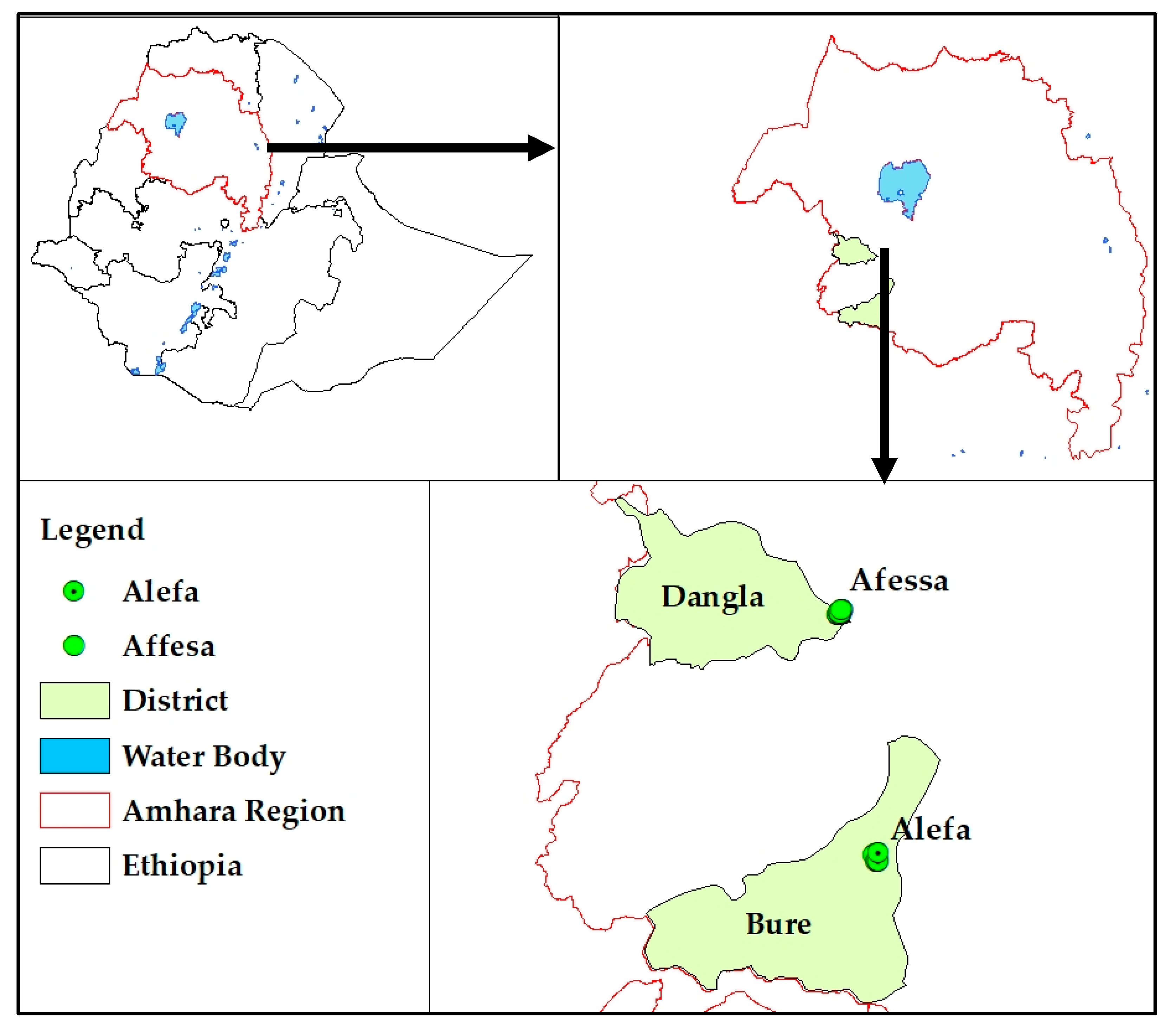

2.1. Study Area

2.2. Experimental Design

2.3. Soil Physico-Chemical Properties

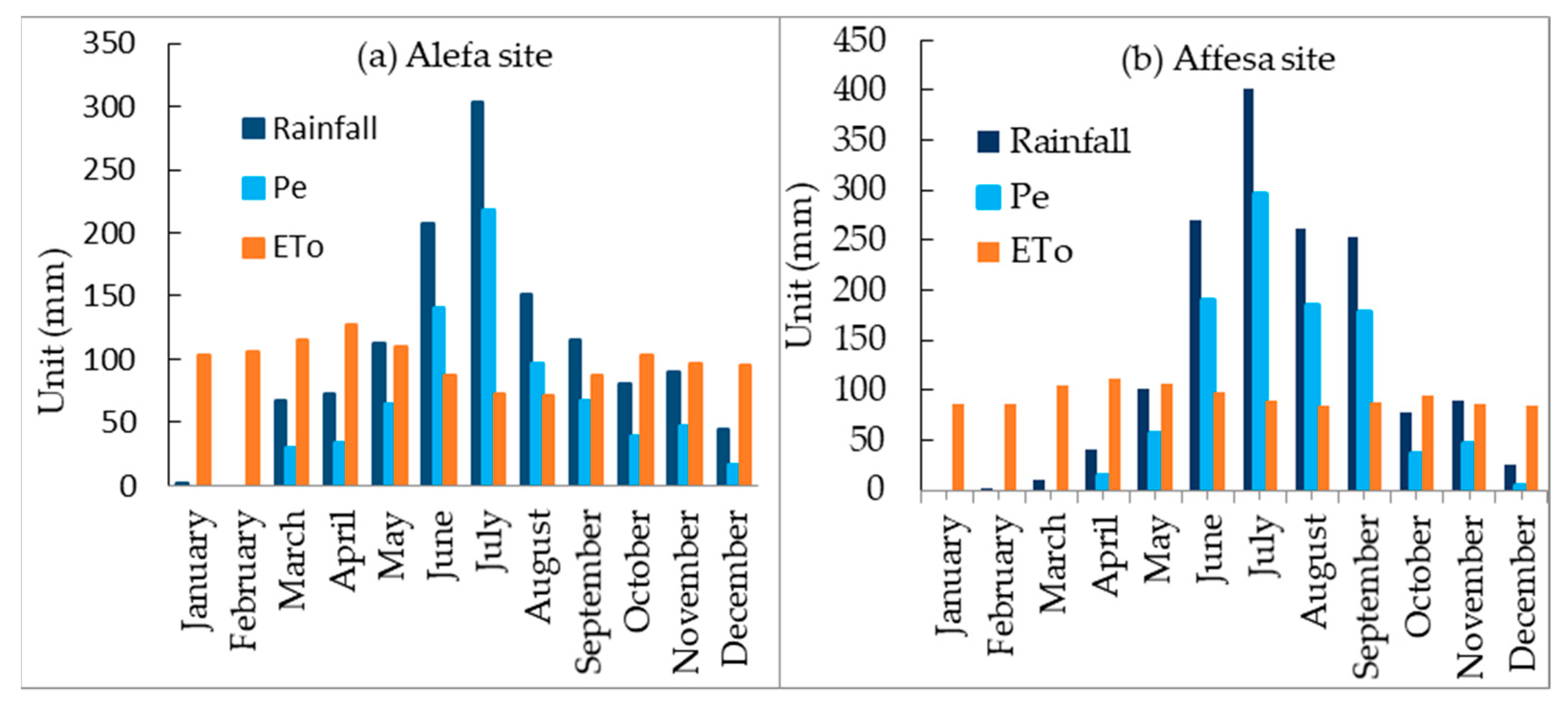

2.4. Climate Data

2.5. Agronomic Data

2.6. Solar MajiPump and Its Applicability

2.7. Water and Crop Productivity Data Analysis

3. Results

3.1. Soil Properties Across Experimental Plots

3.2. MajiPumps Capacity and Groundwater Depth in the Study Area

3.3. Effects of Farming and IrrigationSystems on Crop Growth Characteristics

3.4. Direct Effects of Farming and Irrigation Systems on Water Use and Crop Yield

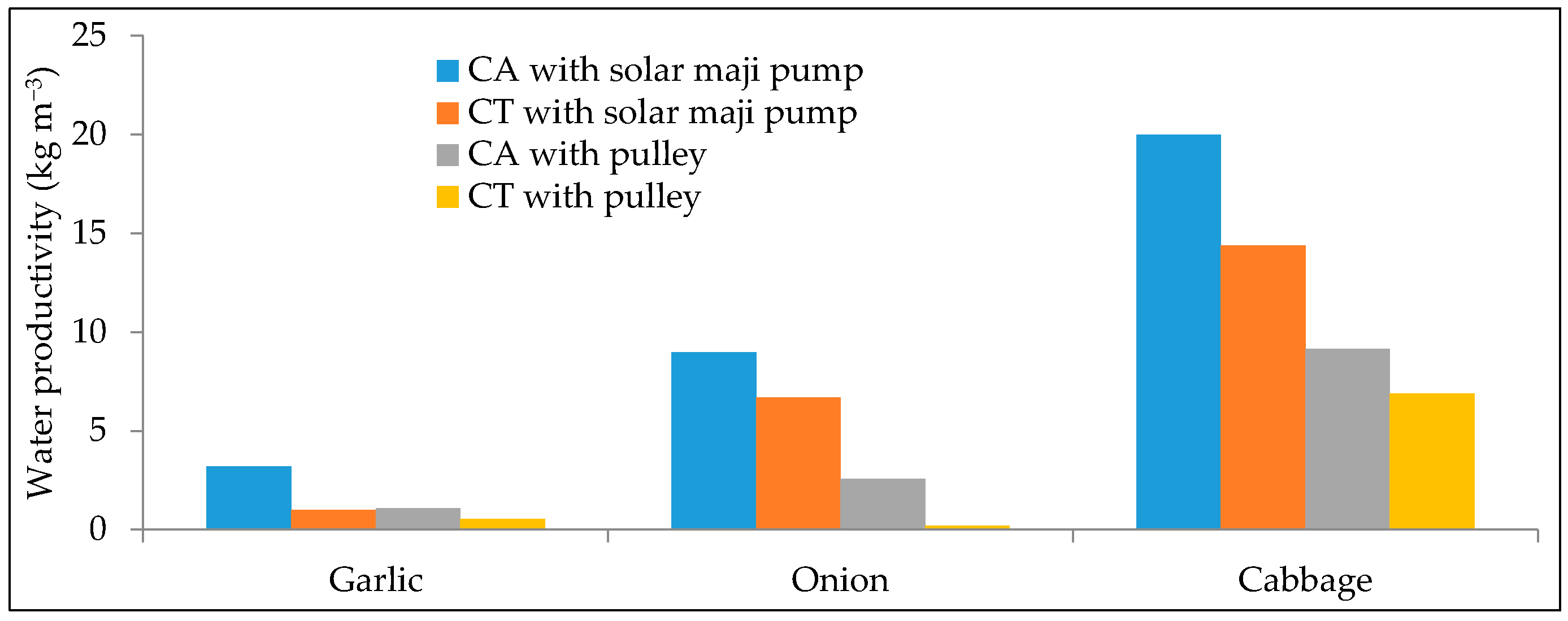

3.5. Effects of CA and Irrigation System on Water Productivity

4. Discussion

4.1. Evaluation of Solar MajiPumps

4.2. Effects of CA on Water Productivity, and Crop Yields

4.3. Effects of Drip Irrigation on Water Productivity and Crop Yield

4.4. Comparison of MajiPump with Previous Pulley Studies on Water Productivity

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diao, X.; Nin Pratt, A. Growth options and poverty reduction in Ethiopia—An economy-wide model analysis. Food Policy 2007, 32, 205–228. [Google Scholar] [CrossRef]

- Weldearegawi, B.; Ashebir, Y.; Gebeye, E.; Gebregziabiher, T.; Yohannes, M.; Mussa, S.; Berhe, H.; Abebe, Z. Emerging chronic non-communicable diseases in rural communities of Northern Ethiopia: Evidence using population-based verbal au-topsy method in Kilite Awlaelo surveillance site. Health Policy Plan. 2013, 28, 891–898. [Google Scholar] [CrossRef] [PubMed]

- Belachew, T.; Hadley, C.; Lindstrom, D.; Mariam, A.G.; Lachat, C.; Kolsteren, P. Food insecurity, school absenteeism and educational attainment of adolescents in Jimma Zone Southwest Ethiopia: A longitudinal study. Nutr. J. 2011, 10, 29. [Google Scholar] [CrossRef] [PubMed]

- Awulachew, S.B.; Yilma, A.D.; Loulseged, M.; Loiskandl, W.; Ayana, M.; Alamirew, T. Water Resources and Irrigation Development in Ethiopia; IWMI: Colombo, Siri Lanka, 2007; Volume 123. [Google Scholar]

- Tesfaye, A.; Bogale, A.; Namara, R.E.; Bacha, D. The impact of small-scale irrigation on household food security: The case of Filtino and Godino irrigation schemes in Ethiopia. Irrig. Drain. Syst. 2008, 22, 145–158. [Google Scholar] [CrossRef]

- Haile, G.G.; Kasa, A.K. Irrigation in Ethiopia: A review. Acad. J. Agric. Res. 2015, 3, 264–269. [Google Scholar]

- Aseyehegu, K.; Yirga, C.; Rajan, S. Effect of Small-Scale Irrigation on the Income of Rural Farm Households: The Case of Laelay Maichew District, Central Tigray, Ethiopia. J. Stored Prod. Postharvest Res. 2011, 2, 208–215. [Google Scholar] [CrossRef]

- Mengistie, D.; Asmamaw, D.K. Assessment of the Impact of Small-Scale Irrigation on Household Livelihood Improvement at Gubalafto District, North Wollo, Ethiopia. Agriculture 2016, 6, 27. [Google Scholar] [CrossRef]

- Kuma, A.N.Y.; Alemu, A.A.T.; Nigussie, A.; Adisu, A.; Desalegn, K. Onion Production for Income Generation in Small Scale Irrigation Users Agropastoral Households of Ethiopia. J. Hortic. 2015, 2, 1–5. [Google Scholar] [CrossRef]

- Gebrehiwot, N.T.; Mesfin, K.A.; Nyssen, J. Small-scale irrigation: The driver for promoting agricultural production and food security (the case of Tigray Regional State, Northern Ethiopia). Irrig. Drain. Syst. Eng. 2015, 4, 1000141. [Google Scholar] [CrossRef]

- Assefa, T.; Jha, M.; Reyes, M.; Tilahun, S.; Worqlul, A.W. Experimental evaluation of conservation agriculture with drip irri-gation for water productivity in Sub-Saharan Africa. Water 2019, 11, 530. [Google Scholar] [CrossRef]

- Berg, M.V.D.; Ruben, R. Small-Scale irrigation and income distribution in Ethiopia. J. Dev. Stud. 2006, 42, 868–880. [Google Scholar] [CrossRef]

- Xie, H.; You, L.; Dile, Y.T.; Worqlul, A.W.; Bizimana, J.-C.; Srinivasan, R.; Richardson, J.W.; Gerik, T.; Clark, N. Mapping development potential of dry-season small-scale irrigation in Sub-Saharan African countries under joint biophysical and economic constraints—An agent-based modeling approach with an application to Ethiopia. Agric. Syst. 2021, 186, 102987. [Google Scholar] [CrossRef]

- You, L.; Ringler, C.; Wood-Sichra, U.; Robertson, R.; Wood, S.; Zhu, T.; Nelson, G.; Guo, Z.; Sun, Y. What is the irrigation potential for Africa? A combined biophysical and socioeconomic approach. Food Policy 2011, 36, 770–782. [Google Scholar] [CrossRef]

- Worqlul, A.W.; Jeong, J.; Dile, Y.T.; Osorio, J.; Schmitter, P.; Gerik, T.; Srinivasan, R.; Clark, N. Assessing potential land suita-ble for surface irrigation using groundwater in Ethiopia. Appl. Geogr. 2017, 85, 1–13. [Google Scholar] [CrossRef]

- Assefa, T.; Jha, M.K.; Worqlul, A.W.; Reyes, M.R.; Tilahun, S.A. Scaling-Up Conservation Agriculture Production System with Drip Irrigation by Integrating MCE Technique and the APEX Model. Water 2019, 11, 2007. [Google Scholar] [CrossRef]

- Awulachew, S.B. Irrigation potential in Ethiopia: Constraints and opportunities for enhancing the system. Gates Open Re-search 2019, 3. [Google Scholar] [CrossRef]

- Worqlul, A.W.; Collick, A.S.; Rossiter, D.G.; Langan, S.; Steenhuis, T.S. Assessment of surface water irrigation potential in the Ethiopian highlands: The Lake Tana Basin. Catena 2015, 129, 76–85. [Google Scholar] [CrossRef]

- Bacha, D.; Namara, R.E.; Bogale, A.; Tesfaye, A. Impact of small-scale irrigation on household poverty: Empirical evidence from the Ambo district in Ethiopia. Irrig. Drain. 2011, 60, 1–10. [Google Scholar] [CrossRef]

- Derib, S.D.; Descheemaeker, K.; Haileslassie, A.; Amede, T. Irrigation water productivity as affected by water management in a small-scale irrigation scheme in the blue nile basin, ethiopia. Exp. Agric. 2011, 47, 39–55. [Google Scholar] [CrossRef]

- Theis, S.; Lefore, N.; Meinzen-Dick, R.; Bryan, E. What happens after technology adoption? Gendered aspects of small-scale irrigation technologies in Ethiopia, Ghana, and Tanzania. Agric. Hum. Values 2018, 35, 671–684. [Google Scholar] [CrossRef]

- Yimam, A.Y.; Assefa, T.T.; Adane, N.F.; Tilahun, S.A.; Jha, M.K.; Reyes, M.R. Experimental Evaluation for the Impacts of Conservation Agriculture with Drip Irrigation on Crop Coefficient and Soil Properties in the Sub-Humid Ethiopian Highlands. Water 2020, 12, 947. [Google Scholar] [CrossRef]

- Evans, A.E.; Giordano, M.; Clayton, T. Investing in Agricultural Water Management to Benefit Smallholder Farmers in Ethio-pia; AgWater Solutions Project Country Synthesis Report; IWMI: Colombo, Siri Lanka, 2012; Volume 152. [Google Scholar]

- Namara, R.E.; Hope, L.; Sarpong, E.O.; De Fraiture, C.; Owusu, D. Adoption patterns and constraints pertaining to small-scale water lifting technologies in Ghana. Agric. Water Manag. 2014, 131, 194–203. [Google Scholar] [CrossRef]

- Belay, S.A.; Schmitter, P.; Worqlul, A.W.; Steenhuis, T.S.; Reyes, M.R.; Tilahun, S.A. Conservation Agriculture Saves Irrigation Water in the Dry Monsoon Phase in the Ethiopian Highlands. Water 2019, 11, 2103. [Google Scholar] [CrossRef]

- Belay, S.A.; Assefa, T.T.; Prasad, P.V.V.; Schmitter, P.; Worqlul, A.W.; Steenhuis, T.S.; Reyes, M.R.; Tilahun, S.A. The Response of Water and Nutrient Dynamics and of Crop Yield to Conservation Agriculture in the Ethiopian Highlands. Sustainability 2020, 12, 5989. [Google Scholar] [CrossRef]

- Assefa, T.T. Experimental and Modeling Evaluation of Conservation Agriculture with Drip Irrigation for Small-scale Agri-culture in Sub-Saharan Africa. Ph.D. Thesis, North Carolina Agricultural and Technical State University, Greensboro, North Carolina, NC, USA, 2018. [Google Scholar]

- Assefa, T.T.; Jha, M.K.; Reyes, M.R.; Worqlul, A.W. Modeling the Impacts of Conservation Agriculture with a Drip Irrigation System on the Hydrology and Water Management in Sub-Saharan Africa. Sustainability 2018, 10, 4763. [Google Scholar] [CrossRef]

- Assefa, T.; Jha, M.; Reyes, M.; Worqlul, A.; Doro, L.; Tilahun, S. Conservation agriculture with drip irrigation: Effects on soil quality and crop yield in sub-Saharan Africa. J. Soil Water Conserv. 2020, 75, 209–217. [Google Scholar] [CrossRef]

- Heumesser, C.; Fuss, S.; Szolgayová, J.; Strauss, F.; Schmid, E. Investment in irrigation systems under precipitation uncer-tainty. Water Resour. Manag. 2012, 26, 3113–3137. [Google Scholar] [CrossRef]

- Burney, J.; Woltering, L.; Burke, M.; Naylor, R.; Pasternak, D. Solar-powered drip irrigation enhances food security in the Sudano–Sahel. Proc. Natl. Acad. Sci. USA 2010, 107, 1848–1853. [Google Scholar] [CrossRef]

- Gowing, J.; Walker, D.; Parkin, G.; Forsythe, N.; Haile, A.T.; Ayenew, D.A.; Alamirew, D. Can shallow groundwater sustain small-scale irrigated agriculture in sub-Saharan Africa? Evidence from N-W Ethiopia. Groundw. Sustain. Dev. 2020, 10, 100290. [Google Scholar] [CrossRef]

- Siebert, S.; Burke, J.; Faures, J.-M.; Frenken, K.; Hoogeveen, J.; Döll, P.; Portmann, F.T. Groundwater use for irrigation–A global inventory. Hydrol. Earth Syst. Sci. 2010, 14, 1863–1880. [Google Scholar] [CrossRef]

- Nigussie, L.; Lefore, N.; Schmitter, P.; Nicol, A. Gender and Water Technologies: Water Lifting for Irrigation and Multiple Purposes in Ethiopia; International Livestock Research Institute (ILRI); East Africa and Nile Basin Office: Addis Ababa, Ethiopia, 2017. [Google Scholar]

- Gray, C.; Mueller, V. Drought and Population Mobility in Rural Ethiopia. World Dev. 2012, 40, 134–145. [Google Scholar] [CrossRef] [PubMed]

- Biswas, S.; Iqbal, M.T. Dynamic Modelling of a Solar Water Pumping System with Energy Storage. J. Sol. Energy 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Kelley, L.C.; Gilbertson, E.; Sheikh, A.; Eppinger, S.D.; Dubowsky, S. On the feasibility of solar-powered irrigation. Renew. Sustain. Energy Rev. 2010, 14, 2669–2682. [Google Scholar] [CrossRef]

- Gupta, E. The impact of solar water pumps on energy-water-food nexus: Evidence from Rajasthan, India. Energy Policy 2019, 129, 598–609. [Google Scholar] [CrossRef]

- Chandel, S.; Naik, M.N.; Chandel, R. Review of solar photovoltaic water pumping system technology for irrigation and community drinking water supplies. Renew. Sustain. Energy Rev. 2015, 49, 1084–1099. [Google Scholar] [CrossRef]

- Foley, G. Photovoltaic Applications in Rural Areas of the Developing World; World Bank: Washington, DC, USA, 1995; Volume 304. [Google Scholar]

- Beriso, B.S. Prevalence of protein-energy malnutrition in children under five years of age admitted to pediatric wards at Asella Referral and Teaching Hospital, Arsi Zone, Oromiya, Ethiopia. East Afr. J. Sci. 2019, 13, 81–88. [Google Scholar]

- Belay, M.; Bewket, W. Traditional Irrigation and Water Management Practices in Highland Ethiopia: Case Study IN Dangila Woreda. Irrig. Drain. 2013, 62, 435–448. [Google Scholar] [CrossRef]

- Lemma, T.; Sehai, E.; Hoekstra, D. Status and Capacity of Farmer Training Centers (FTCs) in the Improving Productivity and Market Success (IPMS) Pilot Learning Woredas (PLWs); International Livestock Research Institute (ILRI): Addis Ababa, Ethiopia, 2011. [Google Scholar]

- Walker, D.; Parkin, G.; Schmitter, P.; Gowing, J.; Tilahun, S.A.; Haile, A.T.; Yimam, A.Y. Insights from a multi-method re-charge estimation comparison study. Groundwater 2019, 57, 245–258. [Google Scholar] [CrossRef] [PubMed]

- Abay, A. Market Chain Analysis of Red Pepper: The Case of Bure Woreda, West Gojjam Zone, Amhara National Regional State, Ethiopia; Haramaya University: Harar Haramaya, Ethiopia, 2010. [Google Scholar]

- Eng, J. Sample Size Estimation: How Many Individuals Should Be Studied? Radiology 2003, 227, 309–313. [Google Scholar] [CrossRef] [PubMed]

- De Winter, J.C. Using the Student’s t-test with extremely small sample sizes. Pract. Assess. Res. Eval. 2013, 18, 10. [Google Scholar]

- Assefa, T.; Jha, M.; Reyes, M.; Srinivasan, R.; Worqlul, A.W. Assessment of suitable areas for home gardens for irrigation po-tential, water availability, and water-lifting technologies. Water 2018, 10, 495. [Google Scholar] [CrossRef]

- Iwama, K. Physiology of the Potato: New Insights into Root System and Repercussions for Crop Management. Potato Res. 2008, 51, 333–353. [Google Scholar] [CrossRef]

- Gao, Y.; Duan, A.; Qiu, X.; Liu, Z.; Sun, J.; Zhang, J.; Wang, H. Distribution of roots and root length density in a maize/soybean strip intercropping system. Agric. Water Manag. 2010, 98, 199–212. [Google Scholar] [CrossRef]

- Westerveld, S.M.; McKeown, A.W.; McDonald, M.R. Distribution of nitrogen uptake, fibrous roots and nitrogen in the soil profile for fresh-market and processing carrot cultivars. Can. J. Plant Sci. 2006, 86, 1227–1237. [Google Scholar] [CrossRef]

- Hsu, S.-L.; Hung, J.; Wallace, A. Soil pH Variation Within a Soil. I. pH Variation in Soil Pores Observed in a Column-Leaching Method. Commun. Soil Sci. Plant Anal. 2004, 35, 319–329. [Google Scholar] [CrossRef]

- Tesema, M.; Schmitter, P.; Nakawuka, P.; Tilahun, S.A.; Steenhuis, T.; Langan, S. Evaluating Irrigation Technologies to Im-prove Crop and Water Productivity of Onion in Dangishta Watershed During the Dry Monsoon Phase. In Proceedings of the Fourth International Conference on the Advancement of Science and Technology in Civil and Water Resources Engineering, Bahir Dar, Ethiopia, 13–29 November 2019. [Google Scholar]

- Zotarelli, L.; Dukes, M.D.; Romero, C.C.; Migliaccio, K.W.; Morgan, K.T. Step by Step Calculation of the Penman-Monteith Evapotranspiration (FAO-56 Method); Institute of Food and Agricultural Sciences, University of Florida: Gainesville, FL, USA, 2010. [Google Scholar]

- Burney, J.; Naylor, R.L.; Postel, S.L. The case for distributed irrigation as a development priority in sub-Saharan Africa. Proc. Natl. Acad. Sci. USA 2013, 110, 12513–12517. [Google Scholar] [CrossRef]

- Water Requirements for Irrigation and the Environment; Springer Science and Business Media LLC: Berlin, Germany, 2009.

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop evapotranspiration-Guidelines for computing crop water requirements-FAO Irrigation and drainage paper 56. FAO Rome 1998, 300, D05109. [Google Scholar]

- Ali, M.; Talukder, M. Increasing water productivity in crop production—A synthesis. Agric. Water Manag. 2008, 95, 1201–1213. [Google Scholar] [CrossRef]

- Gallardo, A. Spatial Variability of Soil Properties in a Floodplain Forest in Northwest Spain. Ecosystems 2003, 6, 564–576. [Google Scholar] [CrossRef]

- Aredehey, G.; Libsekal, H.; Brhane, M.; Welde, K.; Giday, A.; Moral, M.T. Top-soil salinity mapping using geostatistical approach in the agricultural landscape of Timuga irrigation scheme, South Tigray, Ethiopia. Cogent Food Agric. 2018, 4, 1514959. [Google Scholar] [CrossRef]

- Kigalu, J.M.; Kimambo, E.I.; Msite, I.; Gembe, M. Drip irrigation of tea (Camellia sinensis L.): 1. Yield and crop water produc-tivity responses to irrigation. Agric. Water Manag. 2008, 95, 1253–1260. [Google Scholar] [CrossRef]

- Dawit, M.; Dinka, M.O.; Leta, O.T. Implications of Adopting Drip Irrigation System on Crop Yield and Gender-Sensitive Issues: The Case of Haramaya District, Ethiopia. J. Open Innov. Technol. Mark. Complex. 2020, 6, 96. [Google Scholar] [CrossRef]

- Fandika, I.R.; Kadyampakeni, D.M.; Zingore, S. Performance of bucket drip irrigation powered by treadle pump on tomato and maize/bean production in Malawi. Irrig. Sci. 2011, 30, 57–68. [Google Scholar] [CrossRef]

- Elhindi, K.M.; El-Hendawy, S.; Abdel-Salam, E.; Elgorban, A.; Ahmed, M. Impacts of fertigation via surface and subsurface drip irrigation on growth rate, yield and flower quality of Zinnia elegans. Bragantia 2015, 75, 96–107. [Google Scholar] [CrossRef]

- Mirjat, M.; Jiskani, M.; Siyal, A.; Mirjat, M. Mango production and fruit quality under properly managed drip irrigation sys-tem. Pak. J. Agric. Agric. Eng. Vet. Sci. 2011, 27, 1–12. [Google Scholar]

| Site | Vegetable | Management Activity | Date |

|---|---|---|---|

| Alefa | Irrigated Garlic (1st cycle) | Plot preparation | 5 January 2019 |

| Mulch application 2 | 14 January 2019 | ||

| Planting | 16 January 2019 | ||

| Harvest | 11 May 2019 | ||

| Irrigated Cabbage (2nd cycle) | Tillage 1 | 6 October 2019 | |

| Mulch application 2 | 19 October 2019 | ||

| Transplanting | 20 October 2019 | ||

| Harvest | 25 February 2020 | ||

| Irrigated Potato (3rd cycle) | Tillage 1 | 28 February 2020 | |

| Mulch application 2 | 3 March 2020 | ||

| Planting | 5 March 2020 | ||

| Harvest | 30 June 2020 | ||

| Affesa | Irrigated Potato (1st cycle) | Plot preparation | 5 February 2019 |

| Mulch application 2 | 10 February 2019 | ||

| Planting | 11 February 2019 | ||

| UREA3 application | 13 March 2019 | ||

| Harvest | 20 May 2019 | ||

| Irrigated Onion (2nd cycle) | Tillage 1 | 10 December 2019 | |

| Mulch application 2 | 14 December 2019 | ||

| Planting | 15 December 2019 | ||

| URAE3 application | 26 January 2020 | ||

| Harvest | 25 March 2020 | ||

| Rainfed Maize | Plot preparation | 27 March 2019 | |

| Mulch application 2 | 15 May 2019 | ||

| Planting | 23 May 2019 | ||

| DAP 3 application | 23 May 2019 | ||

| UREA 3 application | 14 June 2019 | ||

| Diazinon 60% 4 application | 7 July 2019 | ||

| Forage inter-cropping | 21 September 2019 | ||

| Maize harvest | 18 October 2019 | ||

| Forage harvest | 21 November 2019 |

| Site | Soil Properties | No. | Soil Depth | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0–30 cm | 30–60 cm | 60–90 cm | ||||||||

| Mean | Max. | Min. | CV | Mean | CV | Mean | CV | |||

| Alefa | pH | H2O | 5.7 | 6.4 | 5.1 | 9.7 | 5.7 | 3.9 | 5.2 | 2.3 |

| Texture | % sand | 43.8 | 61 | 27 | 28.3 | 19.0 | 33.3 | 23.8 | 45.5 | |

| % silt | 28.6 | 31 | 27 | 5.9 | 23.8 | 14.1 | 22.6 | 40.3 | ||

| % clay | 27.6 | 44 | 12 | 43.6 | 57.2 | 16.3 | 53.6 | 36.5 | ||

| OC | % | 3.1 | 4.5 | 2.1 | 29.2 | 1.7 | 22.6 | 1.5 | 37.2 | |

| OM | % | 5.4 | 5.4 | 7.7 | 29.1 | 2.9 | 22.7 | 2.6 | 37.2 | |

| TN | % | 0.3 | 0.4 | 0.2 | 30.2 | 0.1 | 21.4 | 0.1 | 39.5 | |

| Av. P | ppm | 36.9 | 71.8 | 11.1 | 71.7 | 11.1 | 31.5 | 4.6 | 112 | |

| Av. K | ppm | 127.0 | 163 | 100 | 18.4 | 96.3 | 28.0 | 83.0 | 43.7 | |

| FC | % | 30.2 | 31 | 29 | 3.7 | 29.7 | 4.4 | 35.9 | 6.8 | |

| PWP | % | 16.5 | 21.5 | 11.1 | 25.7 | 13.7 | 7.0 | 21.4 | 4.8 | |

| Affesa | pH | H2O | 4.6 | 5 | 4.2 | 7.8 | 4.55 | 4.9 | 4.6 | 3 |

| Texture | % sand | 19 | 22 | 14 | 18.2 | 19.5 | 30.6 | 13.0 | 19.9 | |

| % silt | 35.5 | 50 | 26 | 31.0 | 18.5 | 29.8 | 20.0 | 21.6 | ||

| % clay | 45.5 | 55 | 36 | 19.5 | 62.0 | 7.4 | 67.0 | 9.9 | ||

| OC | % | 2.5 | 2.7 | 2.3 | 7.8 | 1.8 | 35.7 | 2.1 | 24.8 | |

| OM | % | 4.3 | 4.6 | 3.9 | 7.8 | 3.1 | 35.9 | 3.6 | 25.0 | |

| TN | % | 0.2 | 0.2 | 0.18 | 20.7 | 0.1 | 31.1 | 0.2 | 21.6 | |

| Av. P | ppm | 8.6 | 13 | 3.6 | 44.1 | 3.7 | 11.5 | 4.7 | 25.5 | |

| Av. K | ppm | 41.6 | 56 | 28.5 | 27.3 | 38.4 | 30.2 | 33.8 | 30.5 | |

| FC | % | 27.6 | 30 | 27 | 1.5 | 27.6 | 1.0 | 26.8 | 3.4 | |

| PWP | % | 17.2 | 18 | 16 | 3.7 | 16.9 | 2.1 | 17.0 | 4.3 | |

| Management | Statistics | Plant Height (cm) | |||

|---|---|---|---|---|---|

| Garlic | Cabbage | Potato | Maize | ||

| Sample size | N | 120 | 90 | 90 | 90 |

| CA | Mean | 44.8 | 30.6 | 44 | 293.4 |

| Max. | 55 | 56 | 52 | 327 | |

| Min. | 13 | 12 | 12 | 118 | |

| CT | Mean | 38.4 | 29.3 | 41.3 | 292.3 |

| Max. | 50 | 37 | 47 | 325 | |

| Min. | 8 | 13 | 9 | 116 | |

| CA|CT | SEM± | 1.95|2.2 | 0.7|0.7 | 3|2.3 | 16.9|17.3 |

| p-value | 0.0005 *** | 0.3 | 0.02 ** | 0.19 | |

| Potato | Onion | ||||

| Sample size | N | 105 | 105 | ||

| Drip | Mean | 34.1 | 49 | ||

| Max. | 46.4 | 67 | |||

| Min. | 17.5 | 5 | |||

| Overhead | Mean | 31.7 | 48 | ||

| Max. | 43.9 | 65 | |||

| Min. | 15.9 | 4 | |||

| Drip|Overhead | SEM± | 4.8|4.9 | 0.63|0.93 | ||

| p-value | 0.00003 *** | 0.09 | |||

| Management | Statistics | Diameter (cm) | |

|---|---|---|---|

| Garlic Bulb | Cabbage Head | ||

| Sample size | N | 120 | 90 |

| CA | Mean | 3.5 | 9.3 |

| Max. | 5 | 11.6 | |

| Min. | 1.9 | 7.2 | |

| CT | Mean | 2.6 | 7.4 |

| Max. | 4 | 9.5 | |

| Min. | 1.5 | 5.6 | |

| CA|CT | SEM± | 0.18|0.17 | 0.6|0.5 |

| p-value | 0.001 *** | 0.0004 *** | |

| Potato tuber | Onion bulb | ||

| Sample size | N | 105 | 105 |

| Drip | Mean | 3.8 | 4.0 |

| Max. | 5.2 | 6 | |

| Min. | 1.95 | 2 | |

| Overhead | Mean | 3.1 | 3.8 |

| Max. | 5.34 | 6 | |

| Min. | 1.9 | 2 | |

| Drip|Overhead | SEM± | 0.18|0.09 | 0.13|0.26 |

| p-value | 0.002 ** | 0.2 | |

| Management | Statistics | Water Use (mm) | ||

|---|---|---|---|---|

| Garlic | Cabbage | Potato | ||

| N | 8 | 6 | 6 | |

| CA | Mean | 316 | 380 | 294 |

| Max. | 425 | 497 | 304 | |

| Min. | 267 | 294 | 281 | |

| CT | Mean | 386 | 414 | 323 |

| Max. | 435 | 301 | 331 | |

| Min. | 308 | 549 | 313 | |

| CA|CT | SEM± | 18.7|16.3 | 33.4|38.7 | 4.5|3.6 |

| p-value | 0.0007 *** | 0. 0002 *** | 0.0003 *** | |

| Potato | Onion | |||

| N | 7 | 7 | ||

| Drip | Mean | 341 | 247 | |

| Max. | 374 | 265 | ||

| Min. | 295 | 204 | ||

| Overhead | Mean | 350 | 246 | |

| Max. | 398 | 270 | ||

| Min. | 304 | 207 | ||

| Drip|Overhead | SEM± | 10.3|11.7 | 5.9|6.0 | |

| p-value | 0.21 | 0.5 | ||

| Management | Statistics | Crop Yield (t ha−1) | |||

|---|---|---|---|---|---|

| Garlic Bulb | Cabbage Fresh | Potato Tuber | Maize Grain | ||

| Sample size | N | 8 | 6 | 6 | 6 |

| CA | Mean | 10 | 78 | 38.6 | 8.3 |

| Max. | 17 | 95 | 50 | 10 | |

| Min. | 3.55 | 62.5 | 30 | 6.3 | |

| CT | Mean | 3.7 | 55 | 27 | 7.2 |

| Max. | 6.5 | 72.5 | 35 | 9.5 | |

| Min. | 1 | 45 | 20 | 5 | |

| CA|CT | SEM± | 1.5|0.77 | 4.5|4.3 | 2.8|2.3 | 0.54|0.63 |

| p-value | 0.0003 *** | 0. 007 *** | 0.00008 *** | 0.001 *** | |

| Potato Tuber | Onion Bulb | ||||

| Sample size | N | 7 | 7 | ||

| Drip | Mean | 38.6 | 9.1 | ||

| Max. | 43.9 | 11.2 | |||

| Min. | 21.9 | 6 | |||

| Overhead | Mean | 27 | 6.7 | ||

| Max. | 35.3 | 9 | |||

| Min. | 18 | 3.6 | |||

| Drip|Overhead | SEM± | 3.5|2.1 | 0.58|0.61 | ||

| p-value | 0.016 * | 0.0001 *** | |||

| Management | Statistics | Water Productivity (kg m−3) | |||

|---|---|---|---|---|---|

| Garlic Bulb | Cabbage Fresh | Potato Tuber | Maize Grain | ||

| Sample size | N | 8 | 6 | 6 | 6 |

| CA | Mean | 3.2 | 20.4 | 13.3 | 1.2 |

| Max. | 4.6 | 24.9 | 16.4 | 1.5 | |

| Min. | 1.3 | 16 | 10 | 0.9 | |

| CT | Mean | 1 | 14.3 | 8.7 | 1.1 |

| Max. | 1.7 | 20.8 | 10.6 | 1.5 | |

| Min. | 0.3 | 9.8 | 6 | 0.7 | |

| CA|CT | SEM± | 0.42|0.18 | 1.6|1.8 | 3.3|1.8 | 0.08|0.09 |

| p-value | 0.0001 *** | 0. 003 ** | 0.002 ** | 0.001 *** | |

| Potato Tuber | Onion Bulb | ||||

| Sample size | N | 7 | 7 | ||

| Drip | Mean | 9.8 | 3.6 | ||

| Max. | 13.9 | 4.7 | |||

| Min. | 5.8 | 2.5 | |||

| Overhead | Mean | 7.1 | 2.7 | ||

| Max. | 9.5 | 3.9 | |||

| Min. | 3.8 | 1.6 | |||

| Drip|Overhead | SEM± | 3.5|2.1 | 0.58|0.61 | ||

| p-value | 0.016 * | 0.0001 *** | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assefa, T.T.; Adametie, T.F.; Yimam, A.Y.; Belay, S.A.; Degu, Y.M.; Hailemeskel, S.T.; Tilahun, S.A.; Reyes, M.R.; Prasad, P.V.V. Evaluating Irrigation and Farming Systems with Solar MajiPump in Ethiopia. Agronomy 2021, 11, 17. https://doi.org/10.3390/agronomy11010017

Assefa TT, Adametie TF, Yimam AY, Belay SA, Degu YM, Hailemeskel ST, Tilahun SA, Reyes MR, Prasad PVV. Evaluating Irrigation and Farming Systems with Solar MajiPump in Ethiopia. Agronomy. 2021; 11(1):17. https://doi.org/10.3390/agronomy11010017

Chicago/Turabian StyleAssefa, Tewodros T., Temesgen F. Adametie, Abdu Y. Yimam, Sisay A. Belay, Yonas M. Degu, Solomon T. Hailemeskel, Seifu A. Tilahun, Manuel R. Reyes, and P. V. Vara Prasad. 2021. "Evaluating Irrigation and Farming Systems with Solar MajiPump in Ethiopia" Agronomy 11, no. 1: 17. https://doi.org/10.3390/agronomy11010017

APA StyleAssefa, T. T., Adametie, T. F., Yimam, A. Y., Belay, S. A., Degu, Y. M., Hailemeskel, S. T., Tilahun, S. A., Reyes, M. R., & Prasad, P. V. V. (2021). Evaluating Irrigation and Farming Systems with Solar MajiPump in Ethiopia. Agronomy, 11(1), 17. https://doi.org/10.3390/agronomy11010017