Adaptation of a Traditional Irrigation System of Micro-Plots to Smart Agri Development: A Case Study in Murcia (Spain)

Abstract

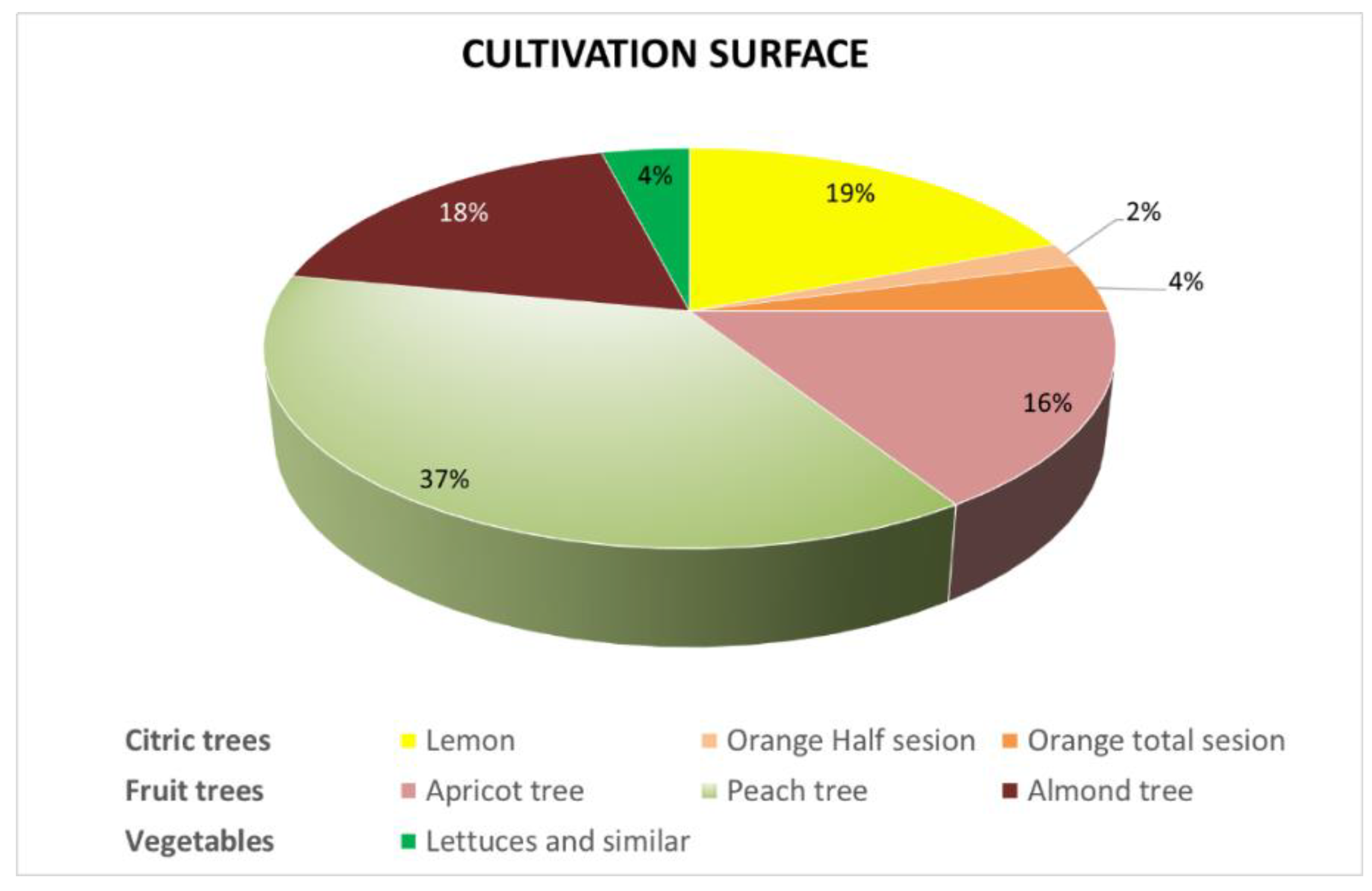

1. Introduction

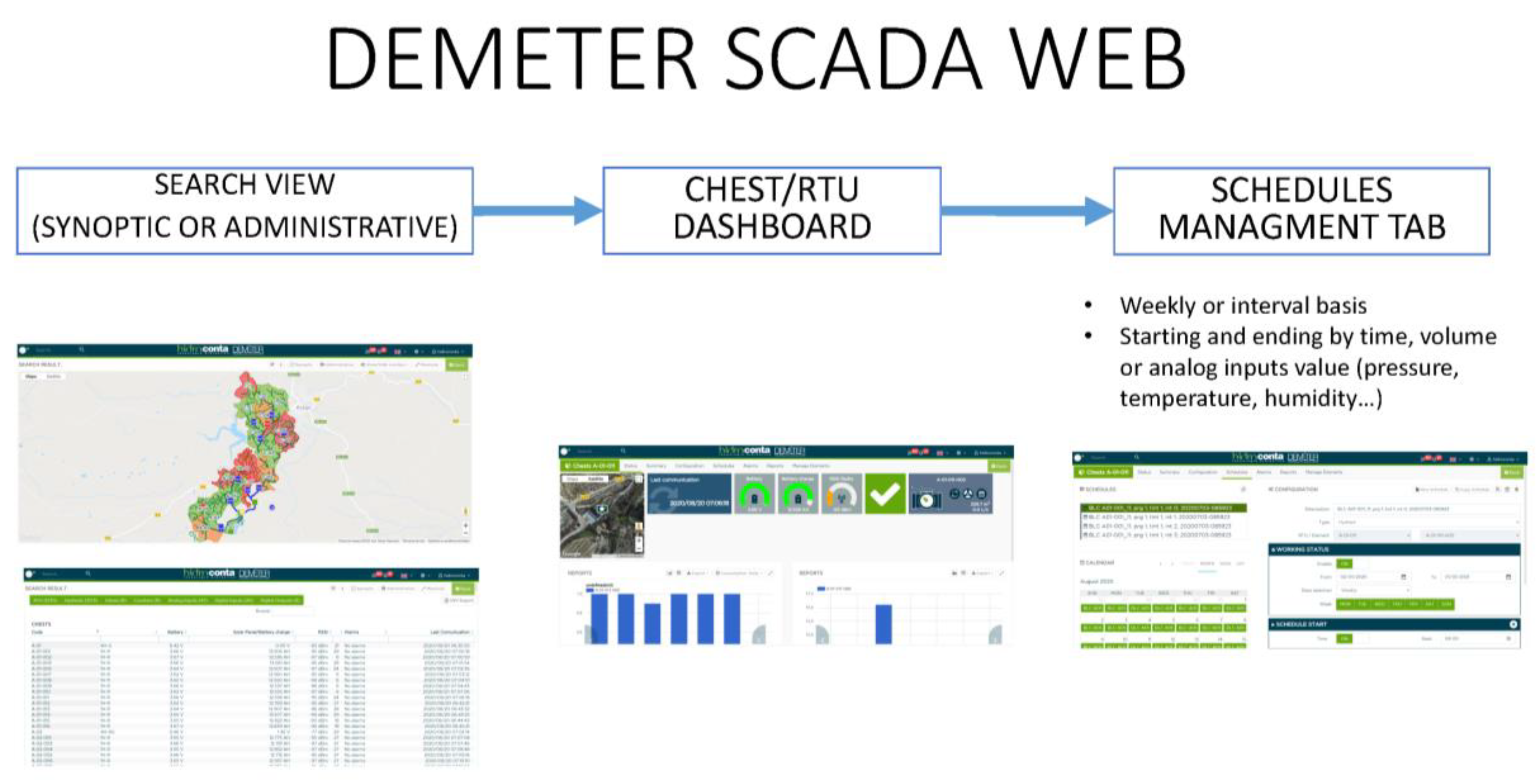

2. Materials and Methods

- 1.

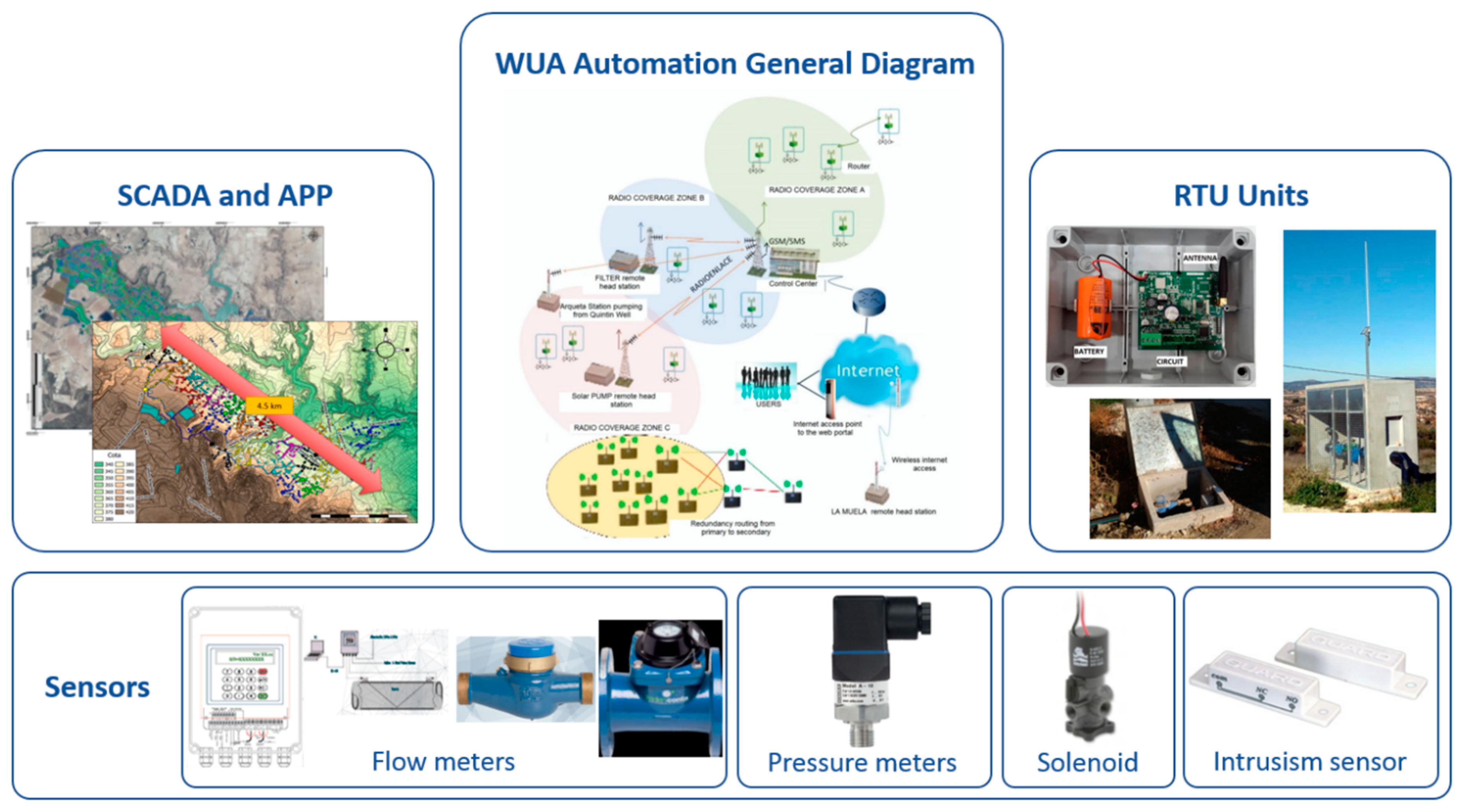

- System consultation: serves the managers to be able to control the operation of the system in real time (not open hydrants flow consumed, pressure at control points, etc.).

- 2.

- Acquisition of historical data: allows administrators and users to know and consult the data already recorded (consumption, pressure, valve opening/closing states, etc.).

- 3.

- Reading or on-demand action: provides the last recorded data and allows interactions with connected elements.

2.1. Analysis of Smart Agri System

2.1.1. Average Parcel Size

- Census of the WUA of spread registers;

- Official mapping of the cadstre;

- Irrigation area recognized by the Segura River Basin.

2.1.2. Distribution of Hydrants

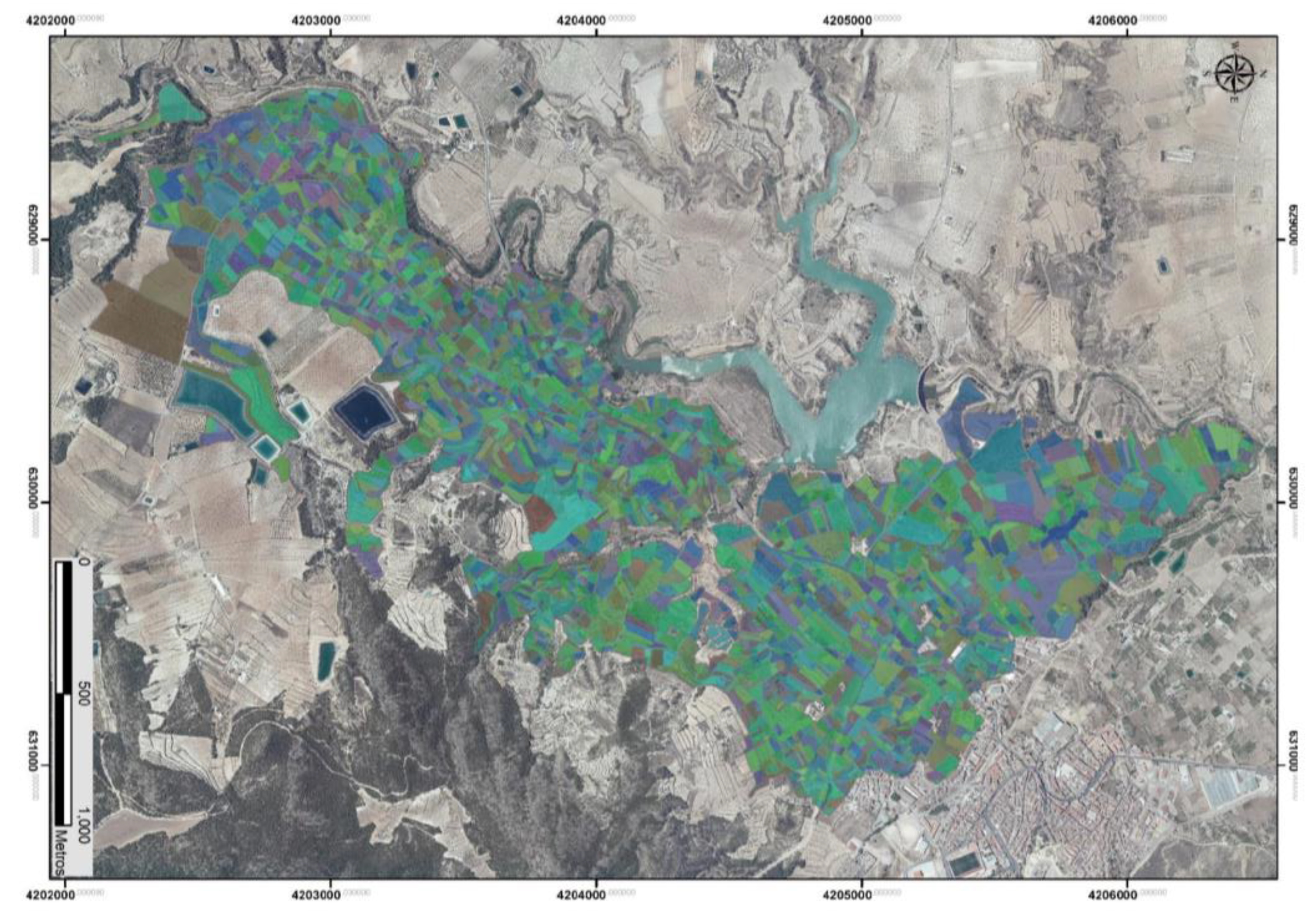

2.1.3. Occupied Geophysical Space

3. Results and Discussion

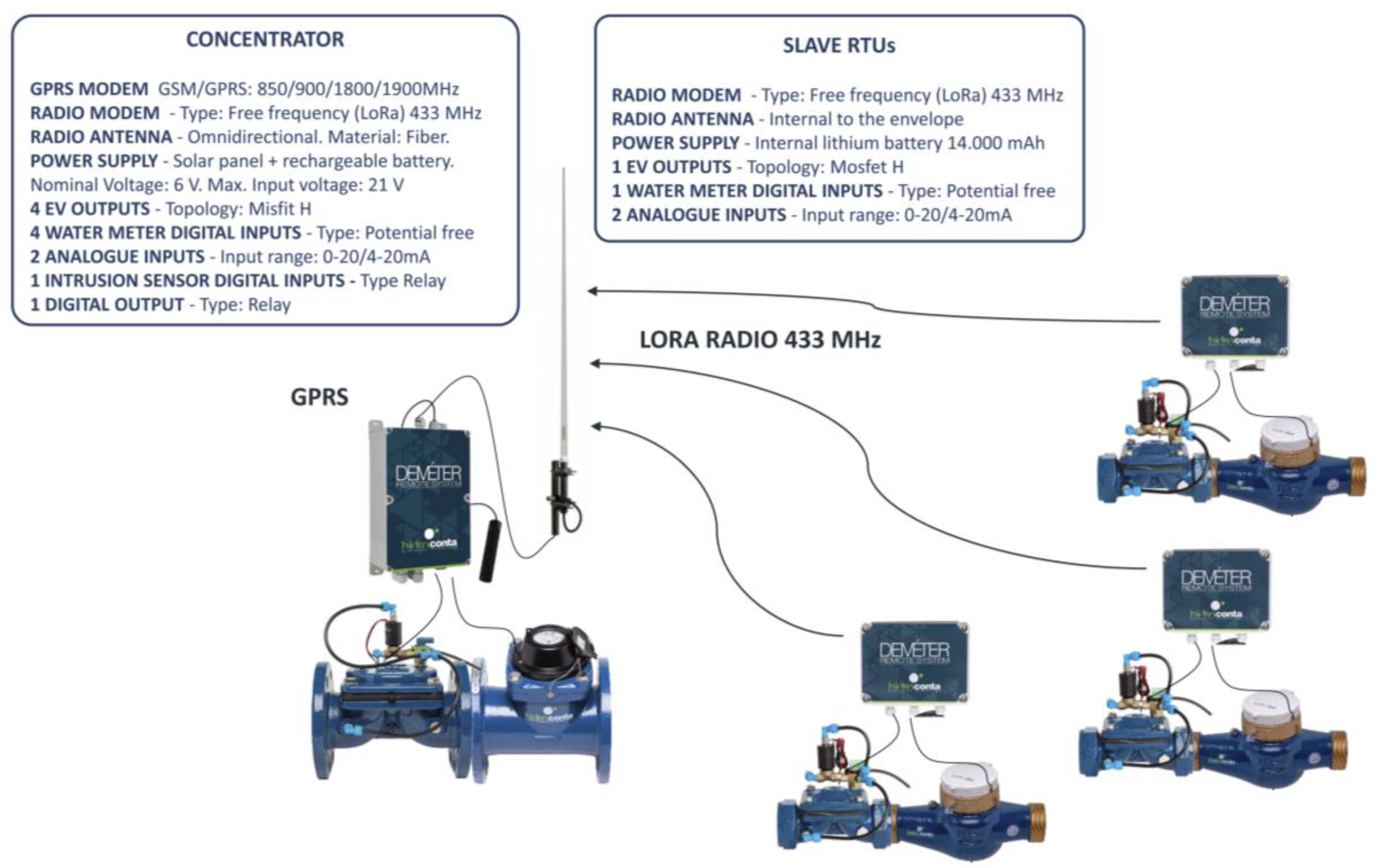

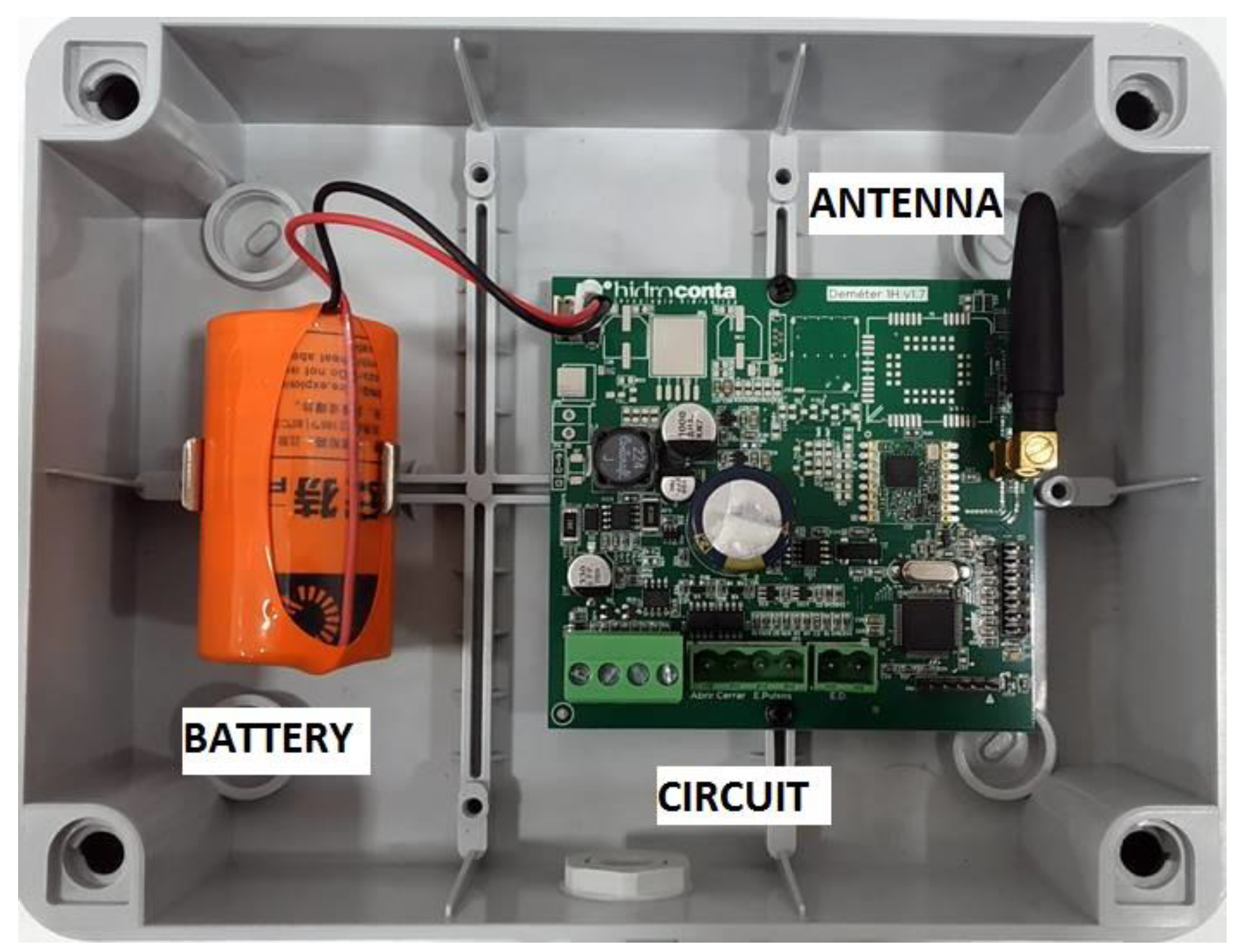

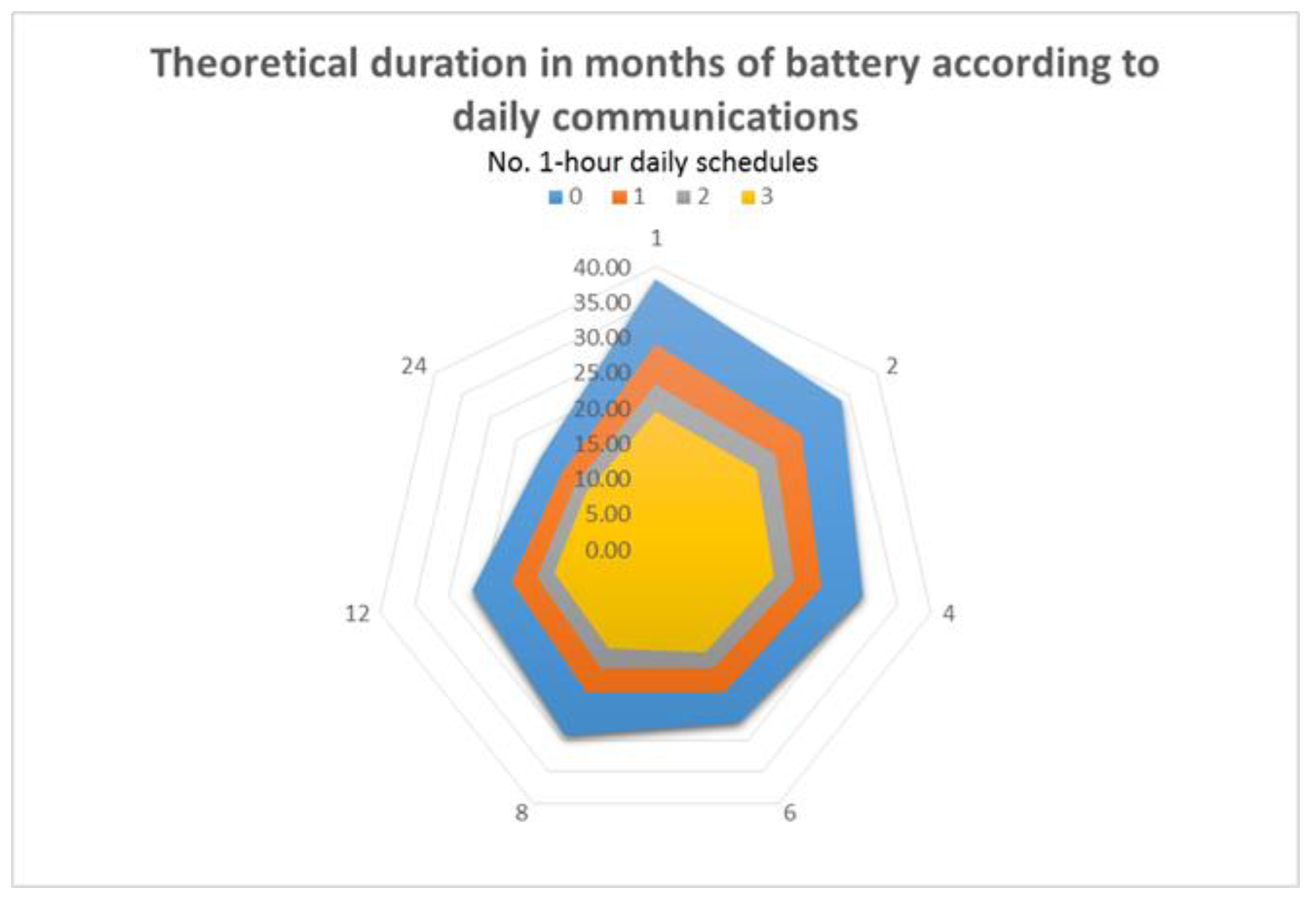

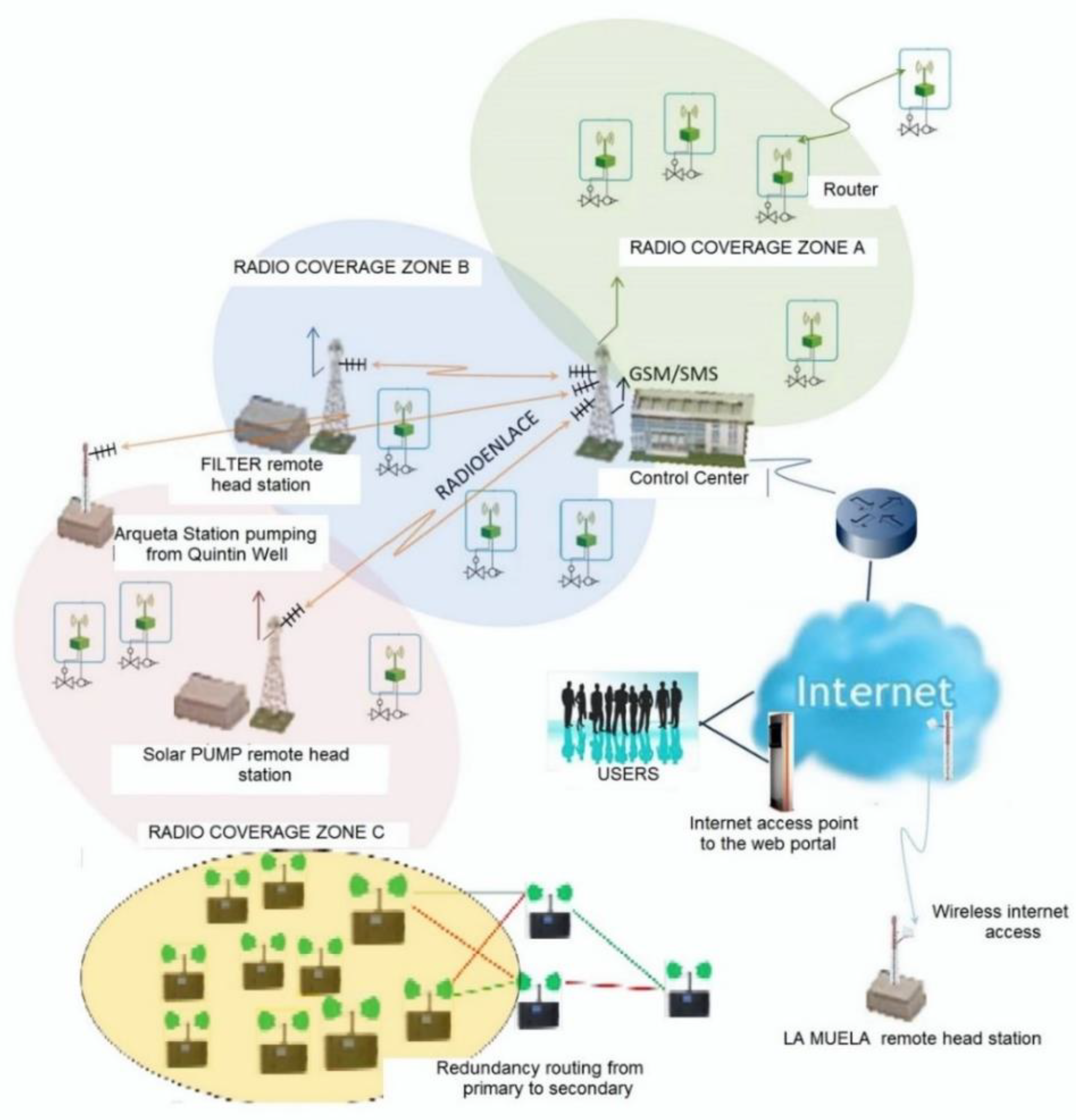

3.1. Integration of Communications in Latest Generation Free-Band

3.2. GPRS-Radio Mixed Hubs

3.3. Ease of Deployment and Maintenance

3.4. Flow Detection and Alert Generation

3.5. Elimination of Its Own Large Infrastructure

4. Conclusions

- The telemetry solution is open and allows connection to various sensors with standardized outputs on the market.

- It is possible to monitor the state of other devices, relay outputs, and analog or digital outputs.

- The included I/O device is a data server that responds to requests from a data cloud platform or other devices such as mobile phones and tablets, among others.

- The monitoring devices are connected to the Internet. Machine-to-machine (M2M) protocols determine whether they operate independently or as part of the SCADA system. This allows communication with other devices or machines.

- Communication between devices and people is a strong point. It is possible to connect with a single click from anywhere. Additionally, it is possible to configure alerts.

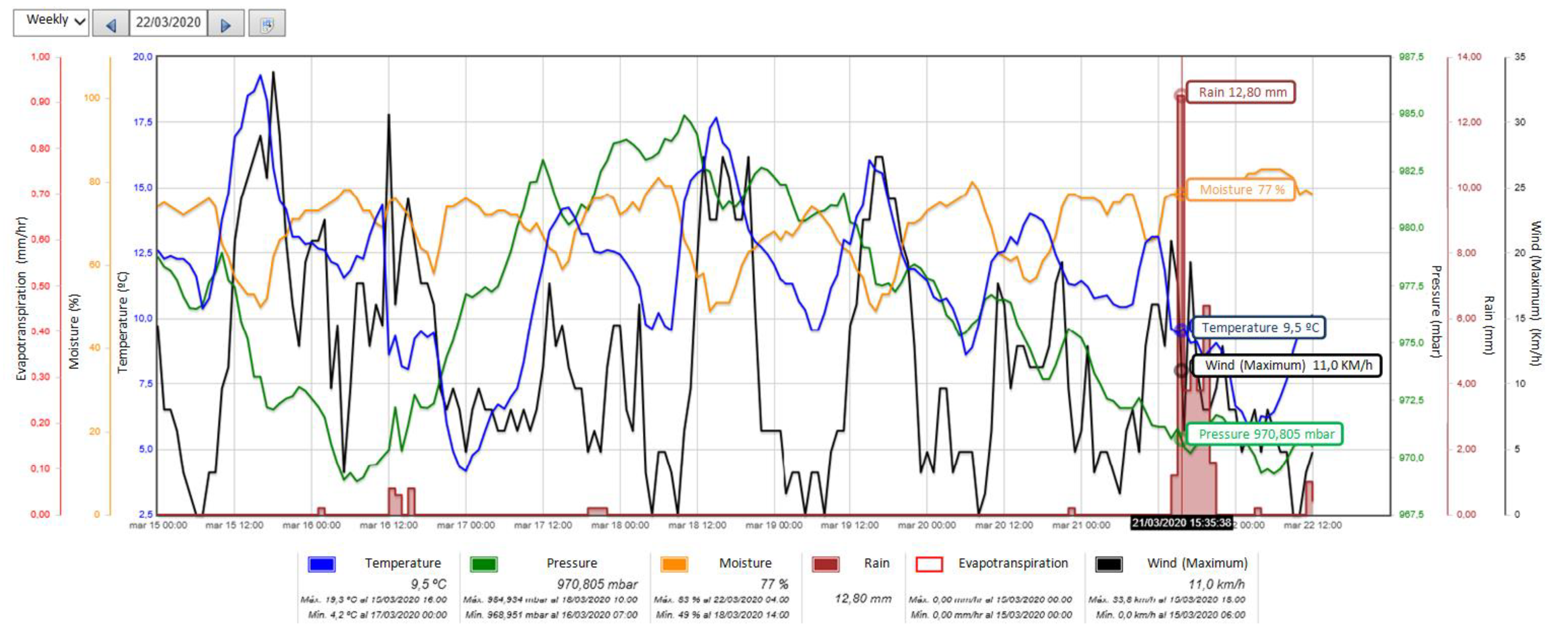

- The stored data (historical and real time) are exposed on dashboards accessible by the web on any browser and are very intuitive to interpret.

- The precision agriculture telemetry platform enables graphics to be customized to the needs of the user.

- The charts are helpful to interpret what is happening and allow the user to establish better criteria for managing the farm as a whole.

- The data make agriculture smarter by improving management from the agronomic, environmental, and economic points of view.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| API | Application programming interface |

| BBDD | Databases |

| FSK | Frequency shift keying |

| GPRS | General Packet Radio Service |

| GSM | Global System for Mobile Communications |

| ICT | Information and communication technology |

| LoRad | Low radiation of electric and magnetic alternating fields |

| NBIoT | Narrowband IoT |

| RTU | Remote terminal unit |

| SASW | Smart Agri SCADA web |

| SCADA | Supervisory Control and Data Acquisition |

| SDGs | Sustainable Development Goals |

| SMS | Short message service |

| TST | Tajo-Segura transfer |

| WUA | Water user’s association |

| WWTP | Wastewater treatment plant |

References

- Ewaid, S.H.; Abed, S.A.; Al-Ansari, N. Assessment of Main Cereal Crop Trade Impacts on Water and Land Security in Iraq. Agronomy 2020, 10, 98. [Google Scholar] [CrossRef]

- Fonte, A.; Garcerá, C.; Tena, A.; Chueca, P. CitrusVol Validation for the Adjustment of Spray Volume in Treatments against Tetranychus urticae in Clementines. Agronomy 2020, 10, 32. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K. Water footprints of nations: Water use by people as a function of their consumption pattern. In Integrated Assessment of Water Resources and Global Change; Craswell, E., Bonnell, M., Bossio, D., Demuth, S., Van De Giesen, N., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 35–48. [Google Scholar] [CrossRef]

- Bouguera, T.; Diouris, J.-F.; Chaillout, J.-J.; Jaouadi, R.; Andrieux, G. Energy Consumption Model for Sensor Nodes Based on LoRa and LoRaWAN. Sensors 2018, 18, 2104. [Google Scholar] [CrossRef] [PubMed]

- Flak, J. Technologies for Sustainable Biomass Supply—Overview of Market Offering. Agronomy 2020, 10, 798. [Google Scholar] [CrossRef]

- Koubaa, A.; Aldawood, A.; Saeed, B.; Hadid, A.; Ahmed, M.; Saad, A.; Alkhouja, H.; Ammar, A.; Alkanhal, M. Smart Palm: An IoT Framework for Red Palm Weevil Early Detection. Agronomy 2020, 10, 987. [Google Scholar] [CrossRef]

- Martinez, B.; Adelantado, F.; Bartoli, A.; Vilajosana, X. Exploring the Performance Boundaries of NB-IoT. IEEE Internet Things J. 2019, 6, 5702–5712. [Google Scholar] [CrossRef]

- Mota, C.; Alcaraz López, C.; Iglesias, M.; Martínez Ballesta, M.C.; Carvajal Alcaraz, M. Absorción de co2 por los cultivos más representativos de la Región de Murcia. Hortic. Glob. 2011, 294, 58–63. [Google Scholar]

- Augustin, A.; Yi, J.; Clausen, T.; Townsley, W.M. A Study of LoRa: Long Range & Low Power Networks for the Internet of Things. Sensors 2016, 16, 1466. [Google Scholar] [CrossRef]

- Cuero, C. La Pandemia del COVID-19 (The COVID-19 Pandemic). Rev. Méd. Panamá 2020, 40, 1–2. [Google Scholar] [CrossRef][Green Version]

- The United Nations. Sustainable Development Goals: Goal 15.3. Available online: https://www.un.org/sustainabledevelopment/es/biodiversity/ (accessed on 22 January 2020).

- Jara-Rojas, R.; Canales, R.; Gil, J.M.; Engler, A.; Bravo-Ureta, B.; Bopp, C. Technology Adoption and Extension Strategies in Mediterranean Agriculture: The Case of Family Farms in Chile. Agronomy 2020, 10, 692. [Google Scholar] [CrossRef]

- Velasco, L.; Ruiz, L.; Galipienso, L.; Rubio, L.; Janssen, D. A Historical Account of Viruses in Intensive Horticultural Crops in the Spanish Mediterranean Arc: New Challenges for a Sustainable Agriculture. Agronomy 2020, 10, 860. [Google Scholar] [CrossRef]

- The United Nations. Sustainable Development Goals: Goal 12.4. Available online: https://www.un.org/sustainabledevelopment/es/biodiversity/ (accessed on 22 January 2020).

- Sánchez-Sastre, L.F.; Alte da Veiga, N.; Ruiz-Potosme, N.M.; Hernández-Navarro, S.; Marcos-Robles, J.L.; Martín-Gil, J.; Martín-Ramos, P. Sugar Beet Agronomic Performance Evolution in NW Spain in Future Scenarios of Climate Change. Agronomy 2020, 10, 91. [Google Scholar] [CrossRef]

- Abrisqueta, I.; Vera, J.; Tapia, L.M.; Abrisqueta, J.M.; Ruiz-Sánchez, M.C. Soil water content criteria for peach trees water stress detection during the postharvest period. Agric. Water Manag. 2012, 104, 62–67. [Google Scholar] [CrossRef]

- Fernández-Pacheco, D.; Molina-Martinez, J.M.; Jimenez, M.; Pagán, F.J.; Ruiz-Canales, A. SCADA Platform for Regulated Deficit Irrigation Management of Almond Trees. J. Irrig. Drain. Eng. 2014, 140, 04014008. [Google Scholar] [CrossRef]

- Heider, K.; Rodriguez Lopez, J.M.; Garcia Aviles, J.M.; Balbo, A.L. Land fragmentation index for drip-irrigated field systems in the Mediterranean: A case study from Ricote (Murcia, SE Spain). Agric. Syst. 2018, 166, 48–56. [Google Scholar] [CrossRef]

- Lopez Riquelme, J.A.; Soto, F.; Suardiaz, J.; Sanchez, P.; Iborra, A.; Vera, J.A. Wireless Sensor Networks for precision horticulture in Southern Spain. Comput. Electron. Agric. 2009, 68, 25–35. [Google Scholar] [CrossRef]

- Aliste, M.; Garrido, I.; Flores, P.; Hellín, P.; Vela, N.; Navarro, S.; Fenoll, J. Reclamation of agro-wastewater polluted with thirteen pesticides by solar photocatalysis to reuse in irrigation of greenhouse lettuce grown. J. Environ. Manag. 2020, 266, 110565. [Google Scholar] [CrossRef]

- Garrido, I.; Flores, P.; Hellín, P.; Vela, N.; Navarro, S.; Fenoll, J. Solar reclamation of agro-wastewater polluted with eight pesticides by heterogeneous photocatalysis using a modular facility. A case study. Chemosphere 2020, 249, 126156. [Google Scholar] [CrossRef]

- Ricart, S.; Villar-Navascués, R.; Gil-Guirado, S.; Rico-Amorós, A.M.; Arahuetes, A. How to Close the Gap of Desalinated Seawater for Agricultural Irrigation? Confronting Attitudes between Managers and Farmers in Alicante and Murcia (Spain). Water 2020, 12, 1132. [Google Scholar] [CrossRef]

- Guillén-Navarro, M.A.; Pereñíguez-Garcia, F.; Martinez-España, R. Iot-Based system to forecast crop frost. In Proceedings of the 13th International Conference on Intelligent Environments, Seoul, Korea, 21–25 August 2017; pp. 28–35. [Google Scholar]

- Azuara, J.; Lebreton, V.; Dezileau, L.; Ruzafa, A.P.; Combourieu-Nebout, N. Middle and Late Holocene vegetation history of the region of Murcia from a new high-resolution pollen sequence from the Mar Menor lagoon. J. Archaeol. Sci. Rep. 2020, 31, 102353. [Google Scholar] [CrossRef]

- Cano, A.J.G. Segura River meanders in the section of Rincon de Beniscornia (Huerta de Murcia). Opportunities in the context of climate change. Ecosistemas 2016, 25, 98–104. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Gallego-Elvira, B.; Martínez-Alvarez, V.; Maestre-Valero, J.F. Life cycle assessment of fruit and vegetable production in the Region of Murcia (south-east Spain) and evaluation of impact mitigation practices. J. Clean. Prod. 2020, 265, 121656. [Google Scholar] [CrossRef]

- Gómez Espín, J.M.; Gil Meseguer, E.; García Marín, R. El Antes y Después de la Modernización de Regadíos. La Experiencia de Mula; Universidad de Murcia, Consejería de Agricultura y Agua de la Comunidad Autónoma de la Región de Murcia: Murcia, Spain, 2006; Volume 2. [Google Scholar]

- Damas, M.; Prados, A.M.; Gómez, F.; Olivares, G. HidroBus® system: Fieldbus for integrated management of extensive areas of irrigated land. Microprocess. Microsyst. 2001, 25, 177–184. [Google Scholar] [CrossRef]

- Shue, S.; Johnson, L.E.; Conrad, J.M. Utilization of XBee ZigBee modules and MATLAB for RSSI localization applications. In Proceedings of the SoutheastCon 2017, Charlotte, NC, USA, 30 March–2 April 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Baudet, S.; Frene, P. General packet radio service. Alcatel Telecommun. Rev. 1999, 2, 125–130. [Google Scholar]

- Baseca, C.C.; Sendra, S.; Lloret, J.; Tomás, J. A Smart Decision System for Digital Farming. Agronomy 2019, 9, 216. [Google Scholar] [CrossRef]

- Cao, Q.; Miao, Y.; Shen, J.; Yuan, F.; Cheng, S.; Cui, Z. Evaluating Two Crop Circle Active Canopy Sensors for In-Season Diagnosis of Winter Wheat Nitrogen Status. Agronomy 2018, 8, 201. [Google Scholar] [CrossRef]

- Fogarassy, C.; Nagy-Pércsi, K.; Ajibade, S.; Gyuricza, C.; Ymeri, P. Relations between Circular Economic “Principles” and Organic Food Purchasing Behavior in Hungary. Agronomy 2020, 10, 616. [Google Scholar] [CrossRef]

- Ushakova, M.V.; Ushakov, Y.A.; Polezhaev, P.N.; Tarasov, V.N. Model of the distributed self-organizing network of IoT sensors. In Proceedings of the 2018 International Scientific and Technical Conference Modern Computer Network Technologies (MoNeTeC), Moscow, Russia, 25–26 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Fernández-Ahumada, L.M.; Ramírez-Faz, J.; Torres-Romero, M.; López-Luque, R. Proposal for the Design of Monitoring and Operating Irrigation Networks Based on IoT, Cloud Computing and Free Hardware Technologies. Sensors 2019, 19, 2318. [Google Scholar] [CrossRef]

- Rodríguez-Robles, J.; Martin, Á.; Martin, S.; Ruipérez-Valiente, J.A.; Castro, M. Autonomous Sensor Network for Rural Agriculture Environments, Low Cost, and Energy Self-Charge. Sustainability 2020, 12, 5913. [Google Scholar] [CrossRef]

- Pérez Hernández, F.; Martínez Vicente, D.; Carmona Cabrera, A.J.; Barba Martínez, E.; Portillo Muñoz, J.M.; Mora Rufete, I.; Corbalán Pellicer, J.; Campillo Moreno, F. Estadística Agraria de Murcia 2016–2017; Dirección General de Innovación, Producciones y Mercados Agroalimentarios: Murcia, Spain, 2017; Volume 25. [Google Scholar]

- Melián Navarro, A.; Costa Botella, D.A. Los Retos del Uso del Agua Depurada y Desalada en el Sureste Español: Aplicación a la Agricultura; Aranzadi: San Sebastián, Spain, 2016; pp. 451–461. [Google Scholar]

- Giannakis, E.; Bruggeman, A.; Djuma, H.; Kozyra, J.; Hammer, J. Water pricing and irrigation across Europe: Opportunities and constraints for adopting irrigation scheduling decision support systems. Water Sci. Technol. Water Supply 2016, 16, 245–252. [Google Scholar] [CrossRef]

- Barnes, A.P.; Soto, I.; Eory, V.; Beck, B.; Balafoutis, A.; Sánchez, B.; Vangeyte, J.; Fountas, S.; Van Der Wal, T.; Gómez-Barbero, M. Exploring the adoption of precision agricultural technologies: A cross regional study of EU farmers. Land Use Policy 2019, 80, 163–174. [Google Scholar] [CrossRef]

- Barnes, A.P.; Soto, I.; Eory, V.; Beck, B.; Balafoutis, A.T.; Sánchez, B.; Vangeyte, J.; Fountas, S.; van der Wal, T.; Gómez-Barbero, M. Influencing factors and incentives on the intention to adopt precision agricultural technologies within arable farming systems. Environ. Sci. Policy 2018, 93, 66–74. [Google Scholar] [CrossRef]

- Watcharaanantapong, P.; Roberts, R.K.; Lambert, D.M.; Larson, J.A.; Velandia, M.; English, B.C.; Rejesus, R.M.; Wang, C. Timing of precision agriculture technology adoption in US cotton production. Precis. Agric. 2014, 15, 427–446. [Google Scholar] [CrossRef]

- Galioto, F.; Raggi, M.; Viaggi, D. Assessing the Potential Economic Viability of Precision Irrigation: A Theoretical Analysis and Pilot Empirical Evaluation. Water 2017, 9, 990. [Google Scholar] [CrossRef]

- García García, J. Estructura de Costes de las Orientaciones Productivas Agrícolas de la Región de Murcia: Frutales de Hueso y Cítricos; Consejería de Agua, Ganadería y Pesca de la Comunidad Autónoma de la Región de Murcia: Murcia, Spain, 2018; Volume 38. [Google Scholar]

- Sajed, A.N.; Amgain, K. Corona Virus Disease (COVID-19) Outbreak and the Strategy for Prevention. Eur. J. Med Sci. 2020, 2, 1–4. [Google Scholar] [CrossRef]

| Number of Daily Communications | Always Connected (1 Hourly Communication) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 4 | 6 | 8 | 12 | 24 | |||

| Analog input reading interval 4–20 mA (min) | 60 | 7.85 | 7.64 | 7.44 | 7.25 | 7.44 | 7.25 | 6.73 | 0.11 |

| 30 | 4.37 | 4.31 | 4.24 | 4.18 | 4.24 | 4.18 | 4.00 | 0.11 | |

| 15 | 2.32 | 2.30 | 2.28 | 2.26 | 2.28 | 2.26 | 2.21 | 0.10 | |

| 10 | 1.58 | 1.57 | 1.56 | 1.55 | 1.56 | 1.55 | 1.53 | 0.10 | |

| 5 | 1.21 | 1.21 | 1.20 | 1.20 | 1.20 | 1.20 | 1.18 | 0.10 | |

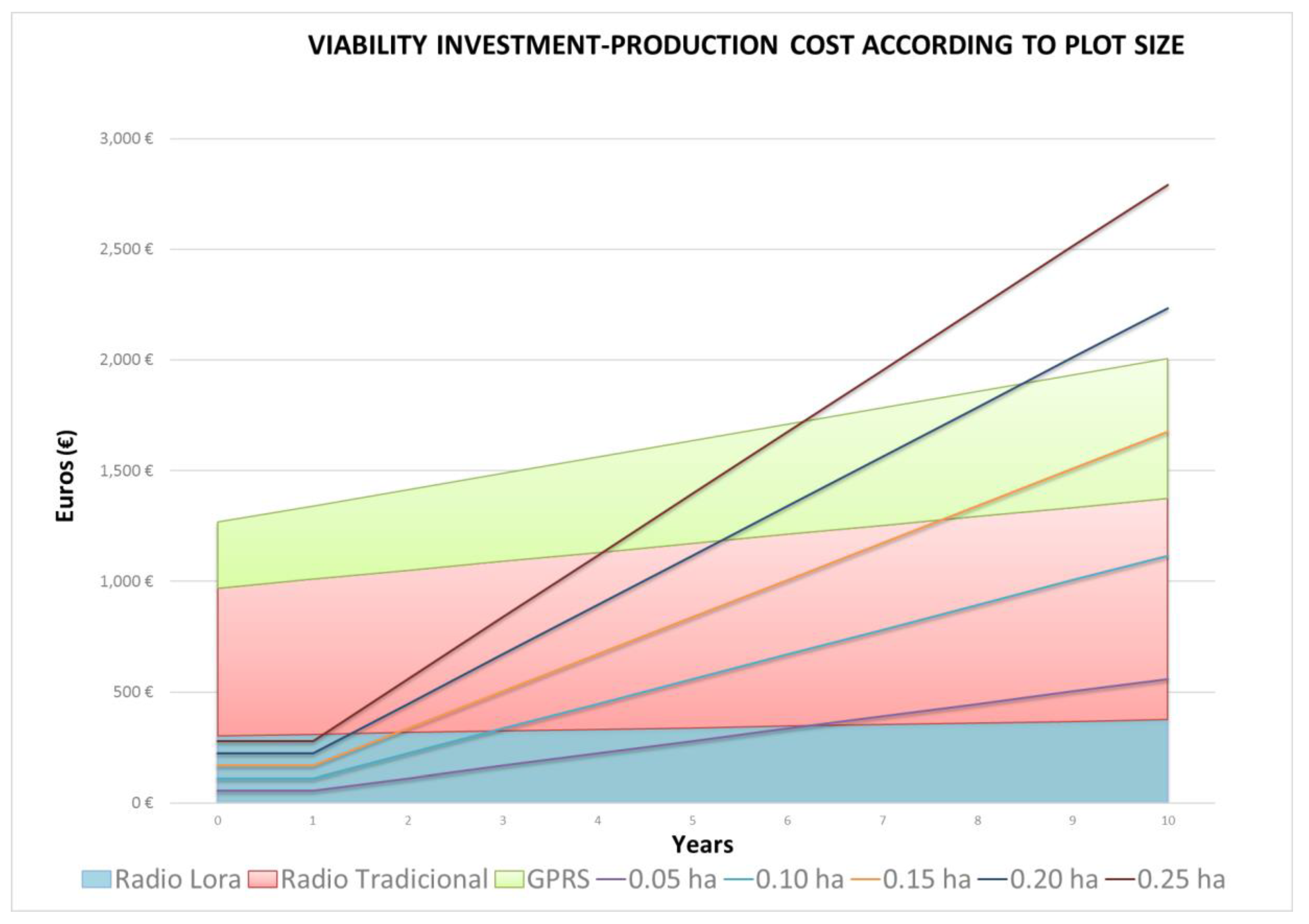

| Systems | Description | Amount |

|---|---|---|

| Radio long-range (LoRa) | Battery replacement (autonomous, 10 years) | 145.3 |

| Equipment replenishment and maintenance (2%) ** | 30 | |

| GPRS communications | 21 | |

| Traditional radio | Battery replacement (autonomous, 10 years) | 147.3 |

| Equipment replenishment and maintenance (5%) ** | 74 | |

| GPRS | Battery replacement (autonomous, 10 years) | 147.3 |

| Equipment replenishment and maintenance (5%) ** | 30 | |

| GPRS communications | 1473 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chazarra-Zapata, J.; Parras-Burgos, D.; Arteaga, C.; Ruiz-Canales, A.; Molina-Martínez, J.M. Adaptation of a Traditional Irrigation System of Micro-Plots to Smart Agri Development: A Case Study in Murcia (Spain). Agronomy 2020, 10, 1365. https://doi.org/10.3390/agronomy10091365

Chazarra-Zapata J, Parras-Burgos D, Arteaga C, Ruiz-Canales A, Molina-Martínez JM. Adaptation of a Traditional Irrigation System of Micro-Plots to Smart Agri Development: A Case Study in Murcia (Spain). Agronomy. 2020; 10(9):1365. https://doi.org/10.3390/agronomy10091365

Chicago/Turabian StyleChazarra-Zapata, Jesús, Dolores Parras-Burgos, Carlos Arteaga, Antonio Ruiz-Canales, and José Miguel Molina-Martínez. 2020. "Adaptation of a Traditional Irrigation System of Micro-Plots to Smart Agri Development: A Case Study in Murcia (Spain)" Agronomy 10, no. 9: 1365. https://doi.org/10.3390/agronomy10091365

APA StyleChazarra-Zapata, J., Parras-Burgos, D., Arteaga, C., Ruiz-Canales, A., & Molina-Martínez, J. M. (2020). Adaptation of a Traditional Irrigation System of Micro-Plots to Smart Agri Development: A Case Study in Murcia (Spain). Agronomy, 10(9), 1365. https://doi.org/10.3390/agronomy10091365