Screening of Organic Substrates for Solid-State Fermentation, Viability and Bioefficacy of Trichoderma harzianum AS12-2, a Biocontrol Strain Against Rice Sheath Blight Disease

Abstract

1. Introduction

2. Materials and Methods

2.1. Biocontrol Strain

2.2. Organic Substrates

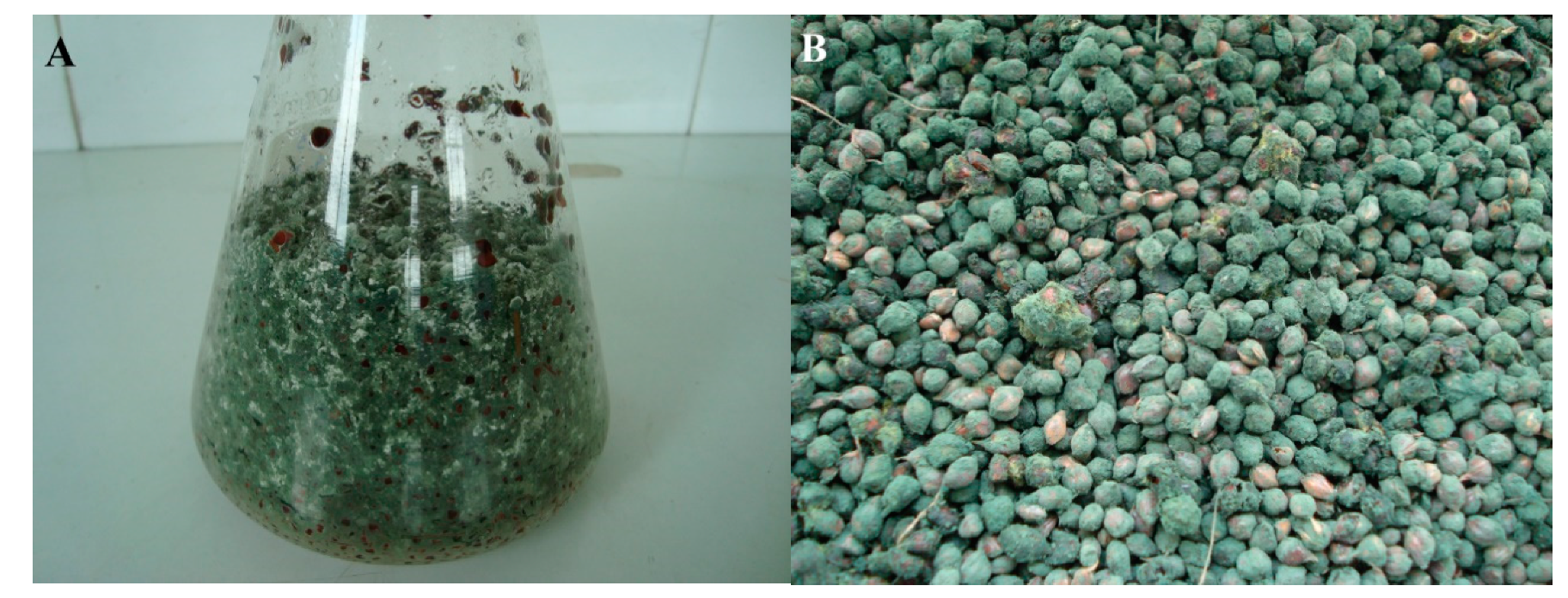

2.3. Solid-State Fermentation

2.4. Sporulation

2.5. Viability and Shelf Life

2.6. Biocontrol Efficacy

2.7. Statistical Analysis

3. Results

3.1. Colonization and Sporulation

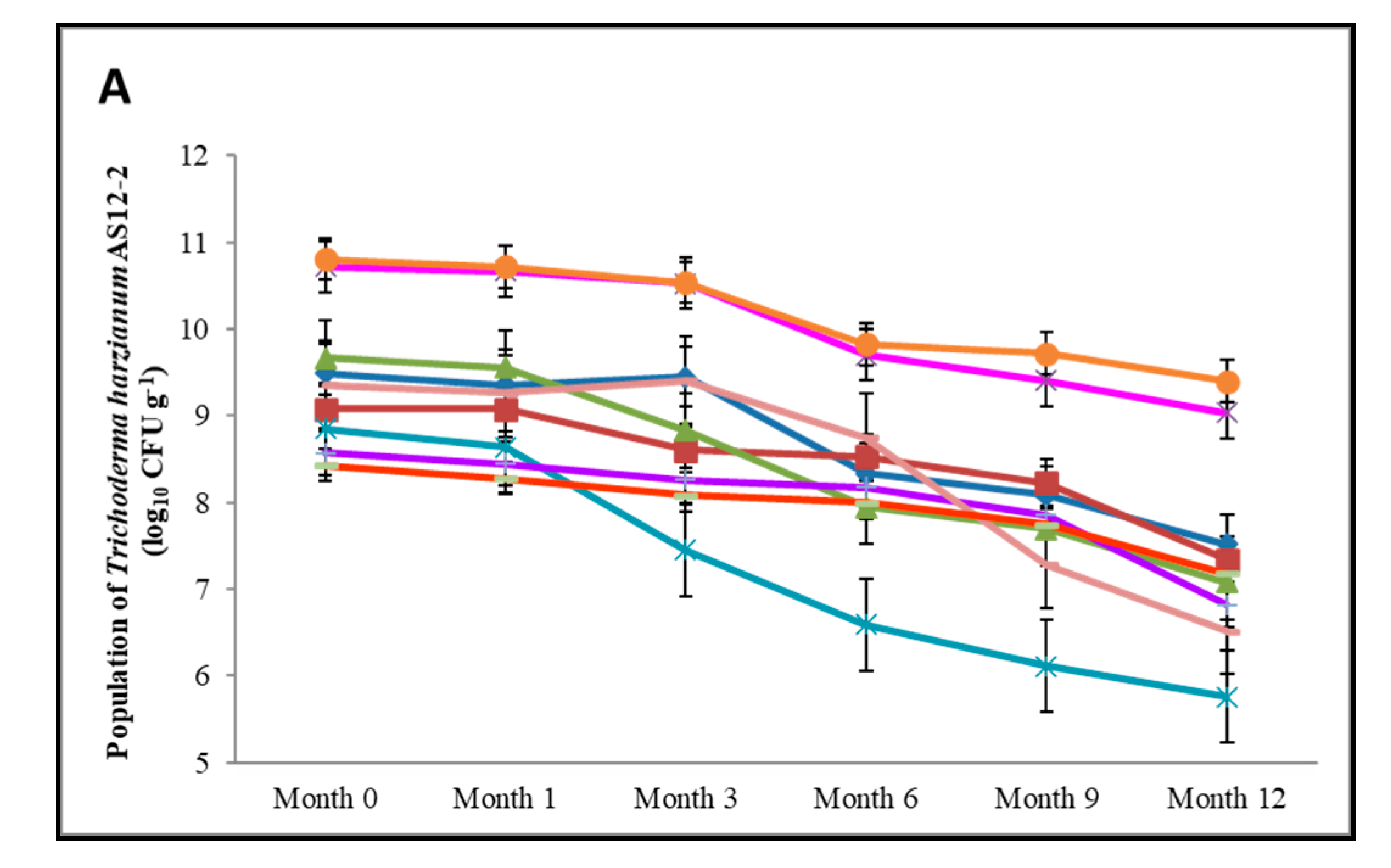

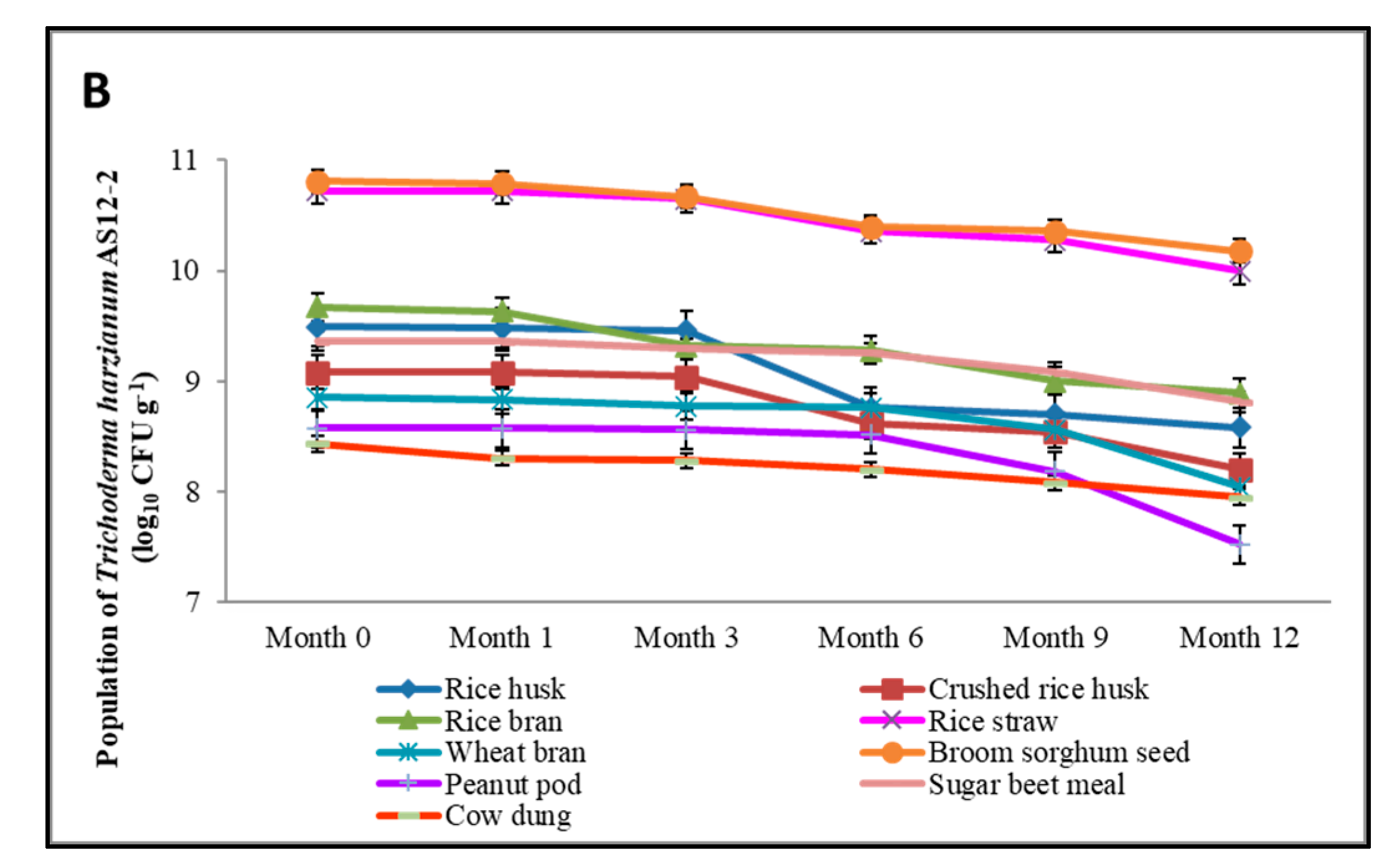

3.2. Viability and Shelf Life

3.3. Bioefficacy

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Glaeser, B. The Green Revolution Revisited: Critique and Alternative; Routledge Taylor & Francis Group: London, UK, 2010. [Google Scholar] [CrossRef]

- Heckel, D.G. Insecticide resistance after silent spring. Science 2012, 337, 1612–1614. [Google Scholar] [CrossRef] [PubMed]

- Glare, T.R.; Caradus, J.; Gelernter, W.; Jackson, T.; Keyhani, N.; Köhl, J.; Marrone, P.; Morin, L.; Stewart, A. Have biopesticides come of age? Trends Biotechnol. 2012, 30, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Chandler, D.; Bailey, A.S.; Tatchell, G.M.; Davidson, G.; Greaves, J.; Grant, W.P. The development, regulation and use of biopesticides for integrated pest management. Philos. Trans. R. Soc. B Biol. Sci. 2011, 366, 1987–1998. [Google Scholar] [CrossRef] [PubMed]

- Hyakumachi, M. Research on biological control of plant diseases: Present state and perspectives. J. Gen. Plant Pathol. 2013, 79, 435–440. [Google Scholar] [CrossRef]

- Moran-Diez, M.E.; Glare, T.R. What are Microbial-based Biopesticides? In Microbial-Based Biopesticides-Methods and Protocols; Glare, T.R., Moran-Diez, M.E., Eds.; Humana Press: New York, NY, USA, 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Mwamburi, L.A. Isolation and Assessment of Stability of Six Formulations of Entomopathogenic Beauveria bassiana. In Microbial-Based Biopesticides-Methods and Protocols; Glare, T.R., Moran-Diez, M.E., Eds.; Humana Press: New York, NY, USA, 2016; pp. 85–91. [Google Scholar] [CrossRef]

- Abbey, L.; Abbey, J.; Leke-Aladekoba, A.; Iheshiulo, E.M.; Ijenyo, M. Biopesticides and Biofertilizers: Types, Production, Benefits, and Utilization. In Byproducts from Agriculture and Fisheries: Adding Value for Food, Feed, Pharma, and Fuels; Simpson, B.K., Aryee, A.N.A., Toldrá, F., Eds.; John Wiley & Sons Ltd.: New York, NY, USA, 2020; pp. 479–500. [Google Scholar] [CrossRef]

- Azadi, N.; Shirzad, A.; Mohammadi, H. A study of some biocontrol mechanisms of Beauveria bassiana against Rhizoctonia disease on tomato. Acta Biol. Szeged. 2016, 60, 119–127. [Google Scholar]

- Cumagun, C.J.R. Advances in Formulation of Trichoderma for Biocontrol. In Biotechnology and Biology of Trichoderma; Gupta, V.K., Schmoll, M., Herrera-Estrella, A., Upadhyay, R.S., Druzhinina, I., Tuohy, M., Eds.; Elsevier: Oxford, UK, 2014; pp. 527–531. [Google Scholar] [CrossRef]

- Whipps, J.M. Developments in the biological control for soilborne plant pathogens. Adv. Bot. Res. 1997, 26, 1–134. [Google Scholar] [CrossRef]

- Adekunle, A.T.; Cardwell, K.F.; Florini, D.A.; Ikotun, T. Seed treatment with Trichoderma species for control of damping-off of cowpea caused by Macrophomina phaseolina. Biocontrol. Sci. Technol. 2001, 11, 449–457. [Google Scholar] [CrossRef]

- Agosin, E.; Aguilera, J.M. Industrial production of active propagules of Trichoderma for agricultural use. In Trichoderma and Gliocladium. Enzymes Biological Control and Commercial Applications; Harman, G.E., Kubicek, C.P., Eds.; Taylor & Francis Ltd.: London, UK, 1998; Volume 2, pp. 205–227. [Google Scholar]

- De La Cruz-Quiroz, R.; Roussos, S.; Hernandez, D.; Rodríguez, R.; Castillo, F.; Aguilar-González, C.N. Challenges and opportunities of the bio-pesticides production by solid-state fermentation: Filamentous fungi as a model. Crit. Rev. Biotechnol. 2014, 35, 1–8. [Google Scholar] [CrossRef]

- Lewis, J.A.; Papavizas, G. Biocontrol of plant diseases: The approach for tomorrow. Crop. Prot. 1991, 10, 95–105. [Google Scholar] [CrossRef]

- Adivitiya, B.; Pal Khasa, Y. Microbes as Biocontrol Agents. In Probiotics and Plant Health; Kumar, V., Kumar, M., Sharma, S., Prasad, R., Eds.; Springer Nature Pte Ltd.: Singapore, 2017; pp. 507–552. [Google Scholar] [CrossRef]

- Jin, X.; Hayes, C.; Harman, G.E. Principles in the development of biological control systems employing Trichoderma species against plant pathogenic fungi. In Frontiers in Industrial Mycology; Leatham, G.F., Ed.; Chapman & Hall: New York, NY, USA, 1992; pp. 174–195. [Google Scholar] [CrossRef]

- Rini, C.R.; Sulochana, K.K. Substrate evaluation for multiplication of Trichoderma spp. J. Trop. Agric. 2007, 45, 58–60. [Google Scholar]

- Bowers, R.C. Commercialization of microbial biological control agents. In Biological Control of Weeds with Plant Pathogens; Charidattan, R., Walker, H.L., Eds.; John Wiley & Sons: New York, NY, USA, 1992; pp. 157–173. [Google Scholar]

- Rayhane, H.; Josiane, M.; Gregoria, M.; Yiannis, K.; Nathalie, D.; Ahmed, M.; Sevastianos, R. From flasks to single used bioreactor: Scale-up of solid state fermentation process for metabolites and conidia production by Trichoderma asperellum. J. Environ. Manag. 2019, 252, 109496. [Google Scholar] [CrossRef] [PubMed]

- Manpreet, S.; Sawraj, S.; Sachin, D.; Pankaj, S.; Banerjee, U.C. Influence of process parameters on the production of metabolites in solid-state fermentation. Malays. J. Microbiol. 2005, 1, 1–9. [Google Scholar] [CrossRef]

- Steudler, S.; Werner, A.; Walther, T. It Is the Mix that Matters: Substrate-Specific Enzyme Production from Filamentous Fungi and Bacteria Through Solid-State Fermentation. In Solid State Fermentation, Research and Industrial Applications; Werner, A., Steudler, S., Cheng, J.J., Eds.; Springer Nature: Cham, Switzerland, 2019; pp. 51–81. [Google Scholar] [CrossRef]

- Flodman, H.R.; Noureddini, H. Effects of intermittent mechanical mixing on solid-state fermentation of wet corn distillers grain with Trichoderma reesei. Biochem. Eng. J. 2013, 81, 24–28. [Google Scholar] [CrossRef]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Sala, A.; Artola, A.; Sánchez, A.; Barrena, R. Rice husk as a source for fungal biopesticide production by solid-state fermentation using B. bassiana and T. harzianum. Bioresour. Technol. 2019, 296, 122322. [Google Scholar] [CrossRef] [PubMed]

- Raimbault, M. General and microbiological aspects of solid substrate fermentation. Electron. J. Biotechnol. 1998, 1, 174–188. [Google Scholar] [CrossRef]

- Pandey, A. Aspects of fermenter design for solid-state fermentations. Process. Biochem. 1991, 26, 355–361. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.R.; Mitchell, D.A. New developments in solid state fermentation: I-bioprocesses and products. Process. Biochem. 2000, 35, 1153–1169. [Google Scholar] [CrossRef]

- Lenz, J.; Hölker, U.; Hofer, M. Biotechnological advantages of laboratory-scale solid-state fermentation with fungi. Appl. Microbiol. Biotechnol. 2004, 64, 175–186. [Google Scholar] [CrossRef]

- Bailey, K.; Boyetchko, S.; Längle, T. Social and economic drivers shaping the future of biological control: A Canadian perspective on the factors affecting the development and use of microbial biopesticides. Biol. Control 2010, 52, 221–229. [Google Scholar] [CrossRef]

- Thomas, L.; Larroche, C.; Pandey, A. Current developments in solid-state fermentation. Biochem. Eng. J. 2013, 81, 146–161. [Google Scholar] [CrossRef]

- Kim, J.H.; Hosobuchi, M.; Kishimoto, M.; Seki, T.; Yoshida, T.; Taguchi, H.; Ryu, D.D.Y. Cellulase production by a solid state culture system. Biotechnol. Bioeng. 1985, 27, 1445–1450. [Google Scholar] [CrossRef] [PubMed]

- Shah, P.; Pell, J.K. Entomopathogenic fungi as biological control agents. Appl. Microbiol. Biotechnol. 2012, 61, 413–423. [Google Scholar] [CrossRef]

- Bartlett, M.C.; Jaronski, S.T. Mass production of entomogenous fungi for biological control of insects. In Fungi in Biological Control Systems; Gurge, M.N., Ed.; Manchester University Press: Manchester, UK, 1988; pp. 61–85. [Google Scholar]

- Larena, I.; Melgarejo, P.; De Cal, A. Production, survival, and evaluation of solid-substrate inocula of Penicillium oxalicum, a biocontrol agent against Fusarium wilt of tomato. Phytopathology 2002, 92, 863–869. [Google Scholar] [CrossRef] [PubMed]

- Faria, M.; Wraight, S.P. Mycoinsecticides and Mycoacaricides: A comprehensive list with worldwide coverage and international classification of formulation types. Biol. Control 2007, 43, 237–256. [Google Scholar] [CrossRef]

- Sargin, S.; Gezgin, Y.; Eltem, R.; Vardar, F. Micropropagule production from Trichoderma harzianum EGE-K38 using solid-state fermentation and a comparative study for drying methods. Turkish J. Biol. 2013, 37, 139–146. [Google Scholar] [CrossRef]

- Lewis, J.A. Formulation and delivery systems of biocontrol agents with emphasis on fungi. In The Rhizosphere and Plant Growth. Beltsville Symposia in Agricultural Research; Keister, D.L., Cregan, P.B., Eds.; Springer: Dordrecht, The Netherlands, 1991; pp. 279–287. [Google Scholar] [CrossRef]

- Carrizales, V.; Jaffe, W. Solid state fermentation: An appropriate biotechnology for developing countries. Interciencia 1986, 11, 9–15. [Google Scholar]

- Carboué, Q.; Claeys-Bruno, M.; Bombarda, I.; Sergent, M.; Jolain, J.; Roussos, S. Experimental design and solid state fermentation: A holistic approach to improve cultural medium for the production of fungal secondary metabolites. Chemom. Intell. Lab. Syst. 2018, 176, 101–107. [Google Scholar] [CrossRef]

- Rhodes, D.J. Economics of baculovirus? Insect cell production systems. Cytotechnology 1996, 20, 291–297. [Google Scholar] [CrossRef]

- Cavalcante, R.S.; Lima, H.L.S.; Pinto, G.A.S.; Gava, C.; Rodrigues, S. Effect of moisture on Trichoderma conidia production on corn and wheat bran by solid state fermentation. Food Bioprocess Technol. 2007, 1, 100–104. [Google Scholar] [CrossRef]

- Burges, H.D. Formulation of Microbial Biopesticides; Kluwer Academic Publisher: Dordrecht, The Netherlands, 1998. [Google Scholar]

- De La Cruz-Quiroz, R.; Roussos, S.; Hernandez-Castillo, D.; Rodriguez-Herrera, R.; López-López, L.I.; Castillo, F.; Aguilar-González, C.N. Solid-State Fermentation in a Bag Bioreactor: Effect of Corn Cob Mixed with Phytopathogen Biomass on Spore and Cellulase Production by Trichoderma asperellum. In Fermentation Processes; IntechOpen: London, UK, 2017; pp. 43–56. [Google Scholar]

- Kredics, L.; Hatvani, L.; Naeimi, S.; Körmöczi, P.; Manczinger, L.; Vágvölgyi, C.; Druzhinina, I. Biodiversity of the Genus Hypocrea/Trichoderma in Different Habitats. In Biotechnology and Biology of Trichoderma; Gupta, V.K., Schmoll, M., Herrera-Estrella, A., Upadhyay, R.S., Druzhinina, I., Tuohy, M., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2014; pp. 3–24. [Google Scholar]

- Harman, G.E.; Howell, C.R.; Viterbo, A.; Chet, I.; Lorito, M. Trichoderma species—Opportunistic, avirulent plant symbionts. Nat. Rev. Genet. 2004, 2, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Savazzini, F.; Longa, C.M.O.; Pertot, I. Impact of the biocontrol agent Trichoderma atroviride SC1 on soil microbial communities of a vineyard in northern Italy. Soil Biol. Biochem. 2009, 41, 1457–1465. [Google Scholar] [CrossRef]

- Howell, C.R. Mechanisms employed by Trichoderma species in the biological control of plant diseases: The history and evolution of current concepts. Plant Dis. 2003, 87, 4–10. [Google Scholar] [CrossRef]

- Segarra, G.; Casanova, E.; Bellido, D.; Odena, M.A.; Oliveira, E.; Trillas, I. Proteome, salicylic acid, and jasmonic acid changes in cucumber plants inoculated with Trichoderma asperellum strain T34. Proteome 2007, 7, 3943–3952. [Google Scholar] [CrossRef] [PubMed]

- Shoresh, M.; Harman, G.E.; Mastouri, F. Induced systemic resistance and plant responses to fungal biocontrol agents. Annu. Rev. Phytopathol. 2010, 48, 21–43. [Google Scholar] [CrossRef] [PubMed]

- Bae, H.; Sicher, R.C.; Kim, M.S.; Kim, S.-H.; Strem, M.D.; Melnick, R.L.; Bailey, B.A. The beneficial endophyte Trichoderma hamatum isolate DIS 219b promotes growth and delays the onset of the drought response in Theobroma cacao. J. Exp. Bot. 2009, 60, 3279–3295. [Google Scholar] [CrossRef]

- Lorito, M.; Woo, S.L.; Harman, G.E.; Monte, E. Translational research on Trichoderma: From ’Omics to the field. Annu. Rev. Phytopathol. 2010, 48, 395–417. [Google Scholar] [CrossRef]

- Harman, G.E. Trichoderma—Not just for biocontrol anymore. Phytoparasitica 2011, 39, 103–108. [Google Scholar] [CrossRef]

- Hanhong, B. Trichoderma species as abiotic and biotic stress quenchers in plants. Res. J. Biotechnol. 2011, 6, 73–79. [Google Scholar]

- Woo, S.L.; Ruocco, M.; Vinale, F.; Nigro, M.; Marra, R.; Lombardi, N.; Pascale, A.; Lanzuise, S.; Manganiello, G.; Lorito, M. Trichoderma-based products and their widespread use in agriculture. Open Mycol. J. 2014, 8, 71–126. [Google Scholar] [CrossRef]

- Verma, M.; Brar, S.K.; Tyagi, R.D.; Surampalli, R.; Valero, J. Antagonistic fungi, Trichoderma spp.: Panoply of biological control. Biochem. Eng. J. 2007, 37, 1–20. [Google Scholar] [CrossRef]

- Mendoza-Mendoza, A.; Clouston, A.; Li, J.-H.; Nieto-Jacobo, M.F.; Cummings, N.; Steyaert, J.; Hill, R. Isolation and Mass Production of Trichoderma. In Microbial-Based Biopesticides, Methods in Molecular Biology; Glare, T.R., Moran-Diez, M.E., Eds.; Humana Press: New York, NY, USA, 2016; Volume 1477, pp. 13–20. [Google Scholar] [CrossRef]

- Papavizas, G.C.; Lewis, J.A. Introduction and Augmentation of Microbial Antagonists for the Control of Soilborne Plant Pathogens. In Biological Control in Crop Production; Papavizas, G.C., Ed.; Allanheld, Osmun Publishers: Totowa, NJ, USA, 1981; pp. 305–322. [Google Scholar]

- Papavizas, G.C. Trichoderma and Gliocladium: Biology, Ecology, and Potential for Biocontrol. Annu. Rev. Phytopathol. 1985, 23, 23–54. [Google Scholar] [CrossRef]

- Harman, G.; Jin, X.; Stasz, T.; Peruzzotti, G.; Leopold, A.; Taylor, A. Production of conidial biomass of Trichoderma harzianum for biological control. Biol. Control 1991, 1, 23–28. [Google Scholar] [CrossRef]

- Jin, X.; Harman, G.; Taylor, A. Conidial biomass and desiccation tolerance of Trichoderma harzianum produced at different medium water potentials. Biol. Control 1991, 1, 237–243. [Google Scholar] [CrossRef]

- Keswani, C.; Bisen, K.; Singh, V.; Sarma, B.K.; Singh, H.B. Formulation Technology of Biocontrol Agents: Present Status and Future Prospects. In Bioformulations: For Sustainable Agriculture; Springer: New Delhi, India, 2016; pp. 35–52. ISBN 978-81-322-2779-3. [Google Scholar]

- Ridder, E.R.; Nokes, S.E.; Knutson, B.L. Optimization of solid-state fermentation parameters for the production of xylanase by Trichoderma longibrachiatum on wheat bran. Trans. ASAE 1998, 41, 1453–1459. [Google Scholar] [CrossRef]

- Kakvan, N.; Heydari, A.; Zamanizadeh, H.R.; Rezaee, S.; Naraghi, L. Development of new bioformulations using Trichoderma and Talaromyces fungal antagonists for biological control of sugar beet damping-off disease. Crop. Prot. 2013, 53, 80–84. [Google Scholar] [CrossRef]

- Motta, F.L.; Santana, M.H.A. Solid-state fermentation for humic acids production by a Trichoderma reesei strain using an oil palm empty fruit bunch as the substrate. Appl. Biochem. Biotechnol. 2013, 172, 2205–2217. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Q. Optimization of solid-state fermentation conditions for Trichoderma harzianum using an orthogonal test. Genet. Mol. Res. 2015, 14, 1771–1781. [Google Scholar] [CrossRef]

- De La Cruz-Quiroz, R.; Robledo-Padilla, F.; Aguilar-González, C.N.; Roussos, S. Forced aeration influence on the production of spores by Trichoderma strains. Waste Biomass—Valorization 2017, 8, 2263–2270. [Google Scholar] [CrossRef]

- Al-Taweil, H.I.; Bin Osman, M.; Hami, A.A.; Yusoff, W.M.W.; Aidil, A.H.; Yussof, W.M. Optimizing of Trichoderma viride cultivation in submerged state fermentation. Am. J. Appl. Sci. 2009, 6, 1284–1288. [Google Scholar] [CrossRef]

- Munoz, G.; Agosin, E.; Cotoras, M.; San Martin, R.; Volpe, D. Comparison of aerial and submerged spore properties of Trichoderma harzianum. Curr. Genet. 1995, 32, 225–230. [Google Scholar] [CrossRef][Green Version]

- Jackson, A.; Whipps, J.; Lynch, J. Production, delivery systems, and survival in soil of four fungi with disease biocontrol potential. Enzyme Microb. Technol. 1991, 13, 636–642. [Google Scholar] [CrossRef]

- Naeimi, S.; Okhovvat, S.M.; Javan-Nikkhah, M.; Vágvölgyi, C.; Khosravi, V.; Kredics, L. Biological control of Rhizoctonia solani AG1-1A, the causal agent of rice sheath blight with Trichoderma strains. Phytopathol. Med. 2010, 49, 287–300. [Google Scholar] [CrossRef]

- Naeimi, S.; Khosravi, V.; Nouri, M.-Z.; Hoda, H.; Vágvölgyi, C.; Kredics, L. Biological control of rice sheath blight disease with formulation of indigenous Trichoderma strains under paddy field conditions. Acta Biol. Szeged. 2019, 63, 37–43. [Google Scholar] [CrossRef]

- Naeimi, S.; Khodaparast, S.A.; Javan-Nikkhah, M.; Vágvölgyi, C.; Kredics, L. Phylogenetic relationship of Trichoderma species isolated from paddy fields of Mazandaran province based on sequence analysis of tef1α gene. Iran. J. Plant Pathol. 2014, 50, 139–149. [Google Scholar]

- IRRI. IRRI: Standard Evaluation System for Rice, 4th ed.; International Rice Research Institute: Manila, Philippines, 1996. [Google Scholar]

- Olson, S. An Analysis of the Biopesticide Market Now and Where it is Going. Outlooks Pest Manag. 2015, 26, 203–206. [Google Scholar] [CrossRef]

- Hynes, R.K.; Boyetchko, S.M. Research initiatives in the art and science of biopesticide formulations. Soil Boil. Biochem. 2006, 38, 845–849. [Google Scholar] [CrossRef]

- Steyaert, J.M.; Weld, R.J.; Mendoza-Mendoza, A.; Stewart, A. Reproduction without sex: Conidiation in the filamentous fungus Trichoderma. Microbiol. 2010, 156, 2887–2900. [Google Scholar] [CrossRef]

- Thangavelu, R.; Palaniswami, A.; Velazhahan, R. Mass production of Trichoderma harzianum for managing fusarium wilt of banana. Agric. Ecosyst. Environ. 2004, 103, 259–263. [Google Scholar] [CrossRef]

- Singh, A.; Srivastava, S.; Singh, H.B. Effect of substrates on growth and shelf life of Trichoderma harzianum and its use in biocontrol of diseases. Bioresour. Technol. 2007, 98, 470–473. [Google Scholar] [CrossRef]

- Li, G.; Fu, Y.; Dang, W.; Hu, R.; Xue, H. The effects of aqueous ammonia-pretreated rice straw as solid substrate on laccase production by solid-state fermentation. Bioprocess Biosyst. Eng. 2019, 42, 567–574. [Google Scholar] [CrossRef] [PubMed]

- Lumsden, R.; Lewis, J. Selection production, formulation and commercial use of plant disease biocontrol fungi. Problems and Progress. In Biotechnology of Fungi for Improving Plant Growth; Whipps, J., Lumsden, R., Eds.; Cambridge University Press: Cambridge, UK, 1988; pp. 171–189. [Google Scholar]

- Rama, S.; Singh, H.; Singh, P.; Kaur, J. A comparison of different substrates for the mass production of Trichoderma. Ann. Plant Prot. Sci. 2001, 9, 248–253. [Google Scholar]

- Tewari, L.; Bhanu, C. Evaluation of agro-industrial wastes for conidia based incoulum production of biocontrol agent: Trichoderma harzianum. J. Sci. Ind. Res. 2004, 6, 807–812. [Google Scholar]

- Gupta, M.; Mahajan, S.; Sharma, D.; Gupta, S.; Mallick, S.A. Agrowastes as substrates for hydrolytic enzymes and biomass production of native isolates of Trichoderma spp. Indian Phytopathol. 2016, 69, 558–564. [Google Scholar]

- Kaushal, S.; Chandel, S. Enhancing the shelf life of Trichoderma species by adding antioxidants producing crops to various substrates. J. Crop. Prot. 2017, 6, 307–314. [Google Scholar]

- El-Tayeb, T.; Abdelhafez, A.; Ali, S.; Ramadan, E. Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Braz. J. Microbiol. 2012, 43, 1523–1535. [Google Scholar] [CrossRef]

- Sahayaraj, K.; Namasivayam, S.K.R. Mass production of entomopathogenic fungi using agricultural products and by products. Afr. J. Biotechnol. 2008, 7, 1907–1910. [Google Scholar] [CrossRef]

- Mascarin, G.M.; Alves, S.B.; Lopes, R.B. Culture media selection for mass production of Isaria fumosorosea and Isaria farinosa. Braz. Arch. Boil. Technol. 2010, 53, 753–761. [Google Scholar] [CrossRef]

- Steinmetz, J.; Schönbeck, F. Conifer bark as growth medium and carrier for Trichoderma harzianum and Gliocladium roseum to control Pythium ultimum on pea. Zeitsch. Pflanzenkrankh. Pflanzenschutz 1994, 101, 200–211. [Google Scholar]

- McQuilken, M.P.; Whipps, J.M. Production, survival and evaluation of solid-substrate inocula of Coniothyrium minitans against Sclerotinia sclerotiorum. Eur. J. Plant Pathol. 1995, 101, 101–110. [Google Scholar] [CrossRef]

| Substrate | Colonization a | Initial Population b (CFU g−1 Substrate) | Final Population c (CFU g−1 Substrate) | Final Population d (CFU g−1 Substrate) |

|---|---|---|---|---|

| Rice husk | + + + | 3.1 × 109 ± 7.0 × 107 bc | 3.3 × 107 ± 7.8 × 106 b | 3.8 × 108 ± 2.2 × 107 b |

| Crushed rice husk | + + + | 1.2 × 109 ± 7.2 × 107 cd | 2.2 × 107 ± 4.3 × 106 bc | 1.6 × 108 ± 2.8 × 107 c |

| Rice straw | + + + | 5.3 × 1010 ± 4.7 × 109 a | 1.1 × 109 ± 1.5 × 108 a | 1.0 × 1010 ± 7.2 × 108 a |

| Rice bran | + + | 4.7 × 109 ± 5.8 × 108 b | 1.2 × 107 ± 1.4 × 106 cd | 7.8 × 108 ± 5.9 × 107 b |

| Wheat bran | + + | 7.0 × 108 ± 1.5 × 108 de | 5.8 × 105 ± 8.9 × 104 f | 1.1 × 108 ± 1.8 × 107 c |

| Broom sorghum grain | + + + | 6.4 × 1010 ± 5.2 × 109 a | 2.5 × 109 ± 4.4 × 108 a | 1.5 × 1010 ± 2.3 × 109 a |

| Waste barley grain | + + | 4.3 × 107 ± 1.2 × 107 f | n/a | n/a |

| Peanut pod | + + | 3.7 × 108 ± 9.6 × 107 e | 6.6 × 106 ± 7.1 × 105 de | 3.3 × 107 ± 9.5 × 106 d |

| Sugar beet pulp | + + + | 2.3 × 109 ± 6.9 × 108 bc | 3.3 × 106 ± 7.8 × 105 e | 6.5 × 108 ± 7.1 × 107 b |

| Soybean meal | + | 1.4 × 103 ± 2.3 × 102 h | n/a | n/a |

| Cow dung | + + + | 2.7 × 108 ± 2.5 × 107 e | 1.5 × 107 ± 2.3 × 106 bcd | 9.0 × 107 ± 4.7 × 106 c |

| Water fern | + + + | 2.0 × 106 ± 3.8 × 105 g | n/a | n/a |

| Sawdust | + | 3.2 × 106 ± 3.3 × 105 g | n/a | n/a |

| Treatment | Disease Severity (%) a |

|---|---|

| Crushed rice husk | 31.84 ± 3.14 b |

| Rice straw | 30.24 ± 2.81 b |

| Broom sorghum grain | 30.29 ± 2.18 b |

| Sugar beet pulp | 34.94 ± 3.72 b |

| Cow dung | 34.06 ± 1.92 b |

| Propiconazole | 16.90 ± 1.53 c |

| Infected control | 68.10 ± 4.68 a |

| Non-infected control | 0.00 ± 0.00 d |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naeimi, S.; Khosravi, V.; Varga, A.; Vágvölgyi, C.; Kredics, L. Screening of Organic Substrates for Solid-State Fermentation, Viability and Bioefficacy of Trichoderma harzianum AS12-2, a Biocontrol Strain Against Rice Sheath Blight Disease. Agronomy 2020, 10, 1258. https://doi.org/10.3390/agronomy10091258

Naeimi S, Khosravi V, Varga A, Vágvölgyi C, Kredics L. Screening of Organic Substrates for Solid-State Fermentation, Viability and Bioefficacy of Trichoderma harzianum AS12-2, a Biocontrol Strain Against Rice Sheath Blight Disease. Agronomy. 2020; 10(9):1258. https://doi.org/10.3390/agronomy10091258

Chicago/Turabian StyleNaeimi, Shahram, Vahid Khosravi, András Varga, Csaba Vágvölgyi, and László Kredics. 2020. "Screening of Organic Substrates for Solid-State Fermentation, Viability and Bioefficacy of Trichoderma harzianum AS12-2, a Biocontrol Strain Against Rice Sheath Blight Disease" Agronomy 10, no. 9: 1258. https://doi.org/10.3390/agronomy10091258

APA StyleNaeimi, S., Khosravi, V., Varga, A., Vágvölgyi, C., & Kredics, L. (2020). Screening of Organic Substrates for Solid-State Fermentation, Viability and Bioefficacy of Trichoderma harzianum AS12-2, a Biocontrol Strain Against Rice Sheath Blight Disease. Agronomy, 10(9), 1258. https://doi.org/10.3390/agronomy10091258