Rice Hulls and Anaerobic Digestion Residues as Substrate Components for Potted Production of Geranium and Rose

Abstract

1. Introduction

2. Materials and Methods

2.1. Treatments and Substrate Preparation

2.2. Physical and Chemical Properties of Substrates

2.3. Agronomic Evaluation of Substrates

2.4. Statistical Analysis

3. Results and Discussion

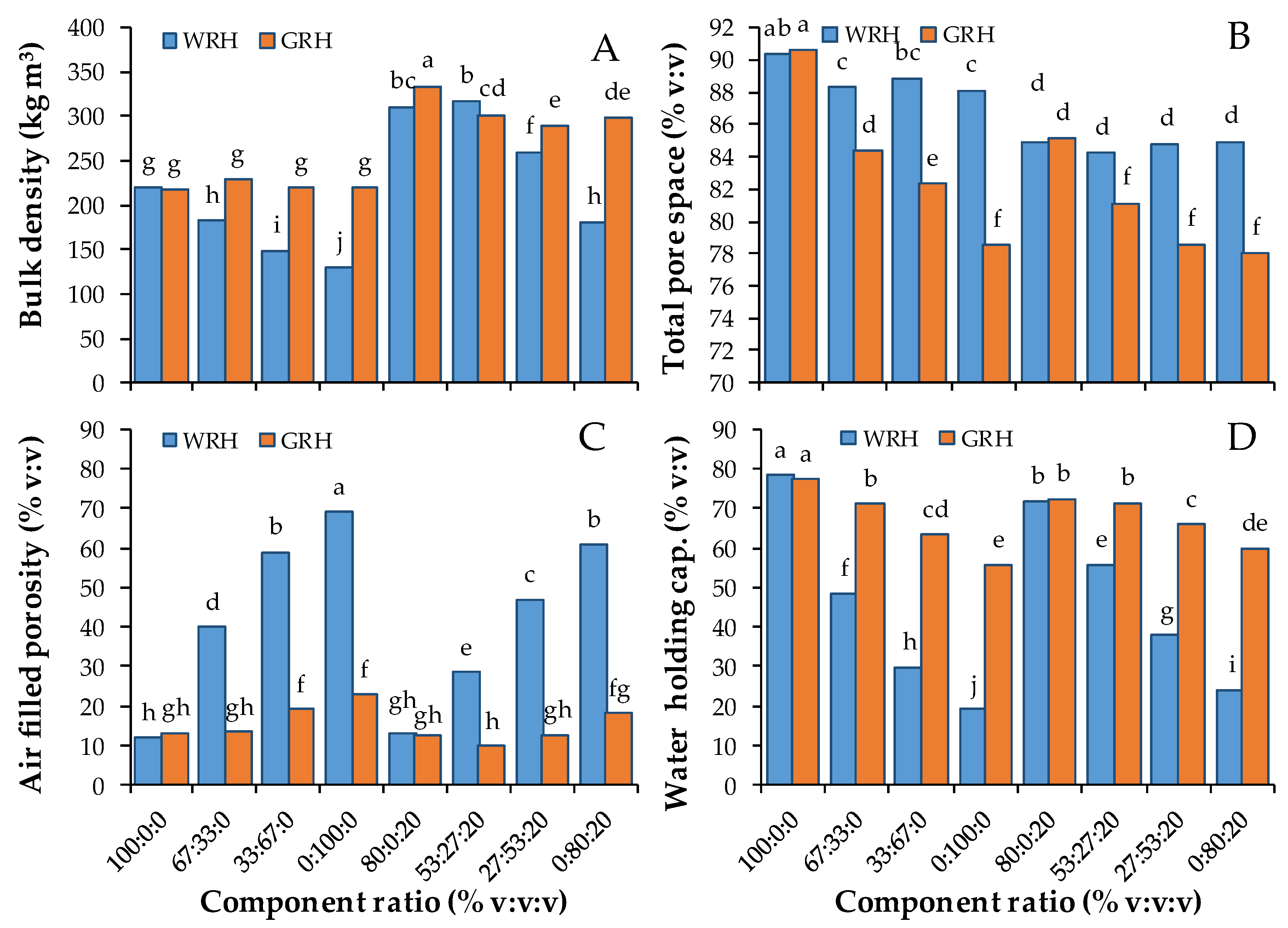

3.1. Physical Properties of Substrates

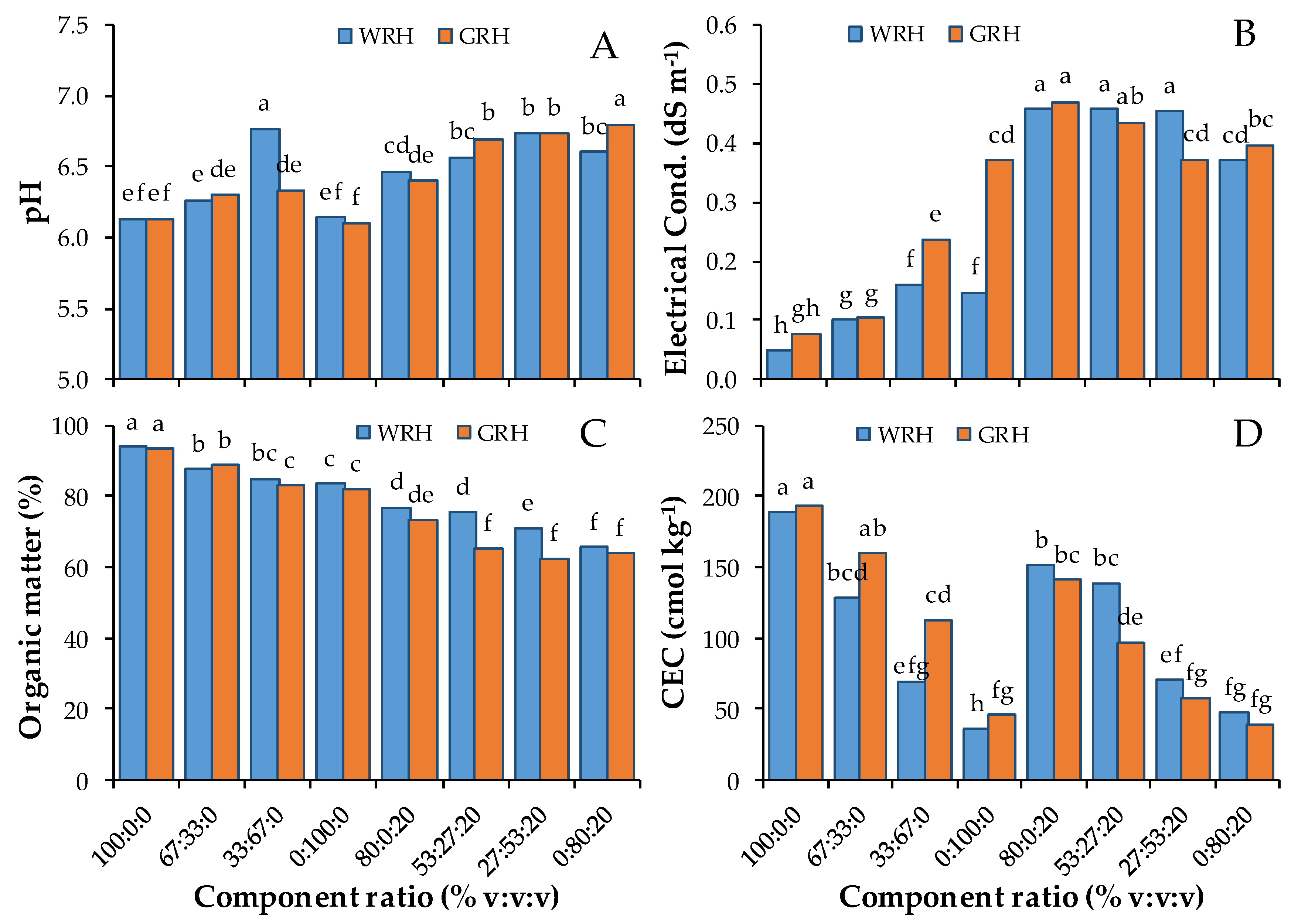

3.2. Chemical Properties of Substrates

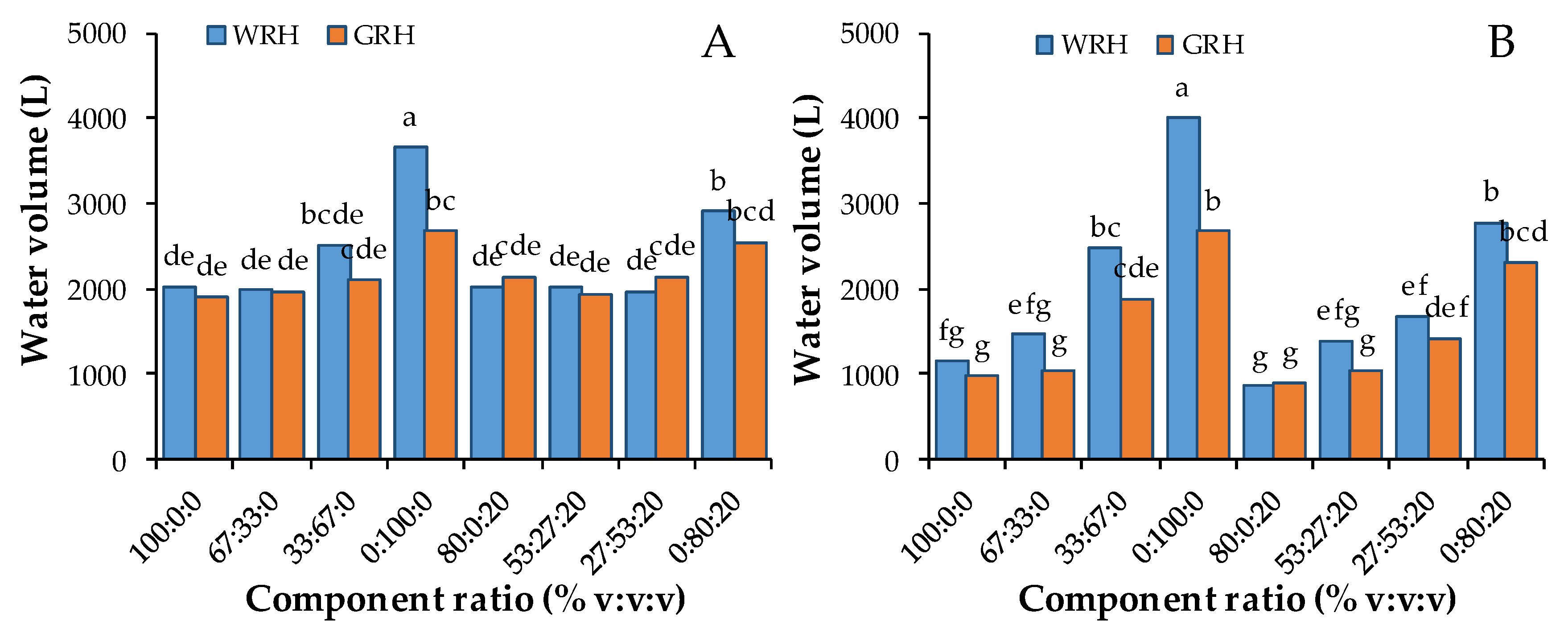

3.3. Agronomic Evaluation of Substrates

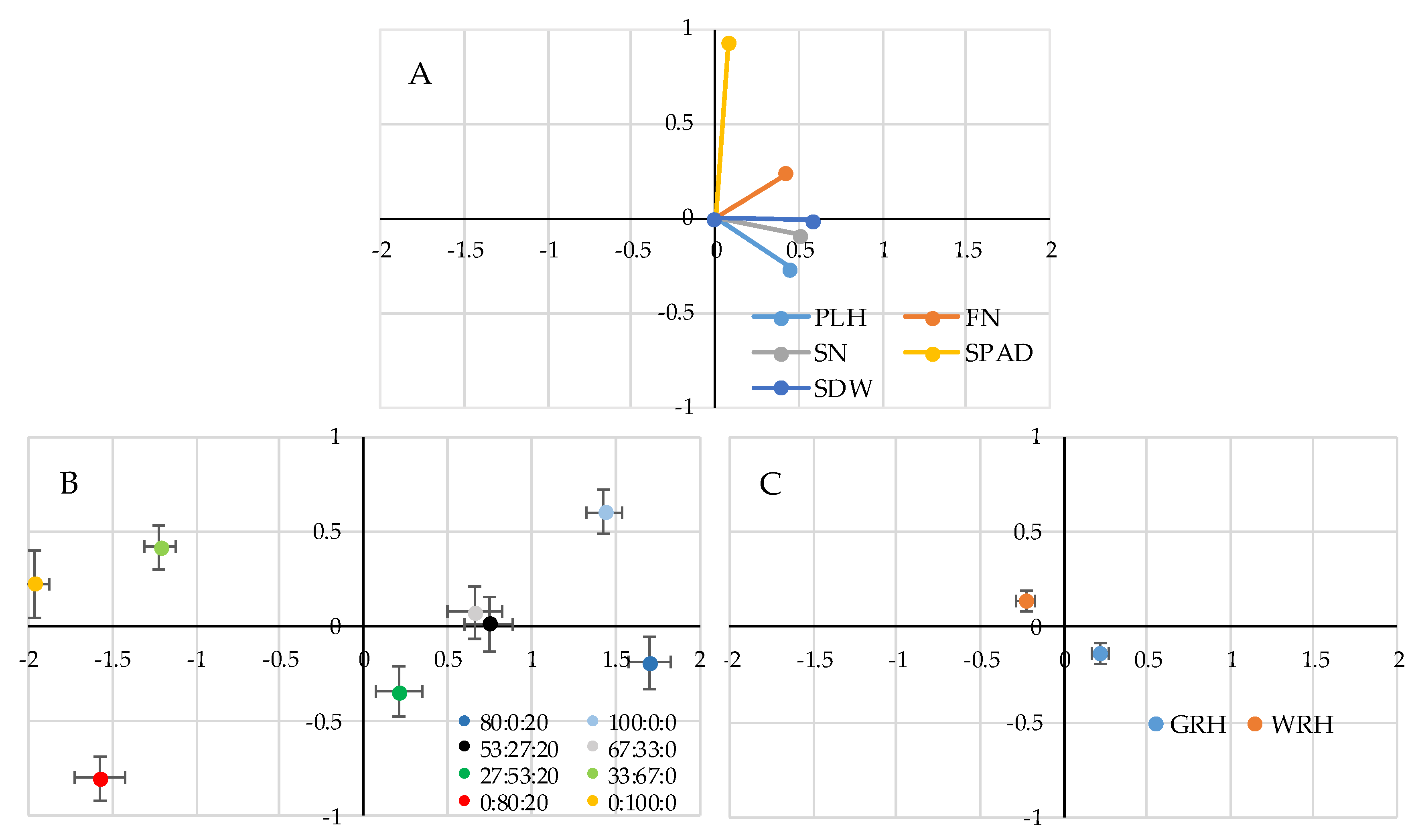

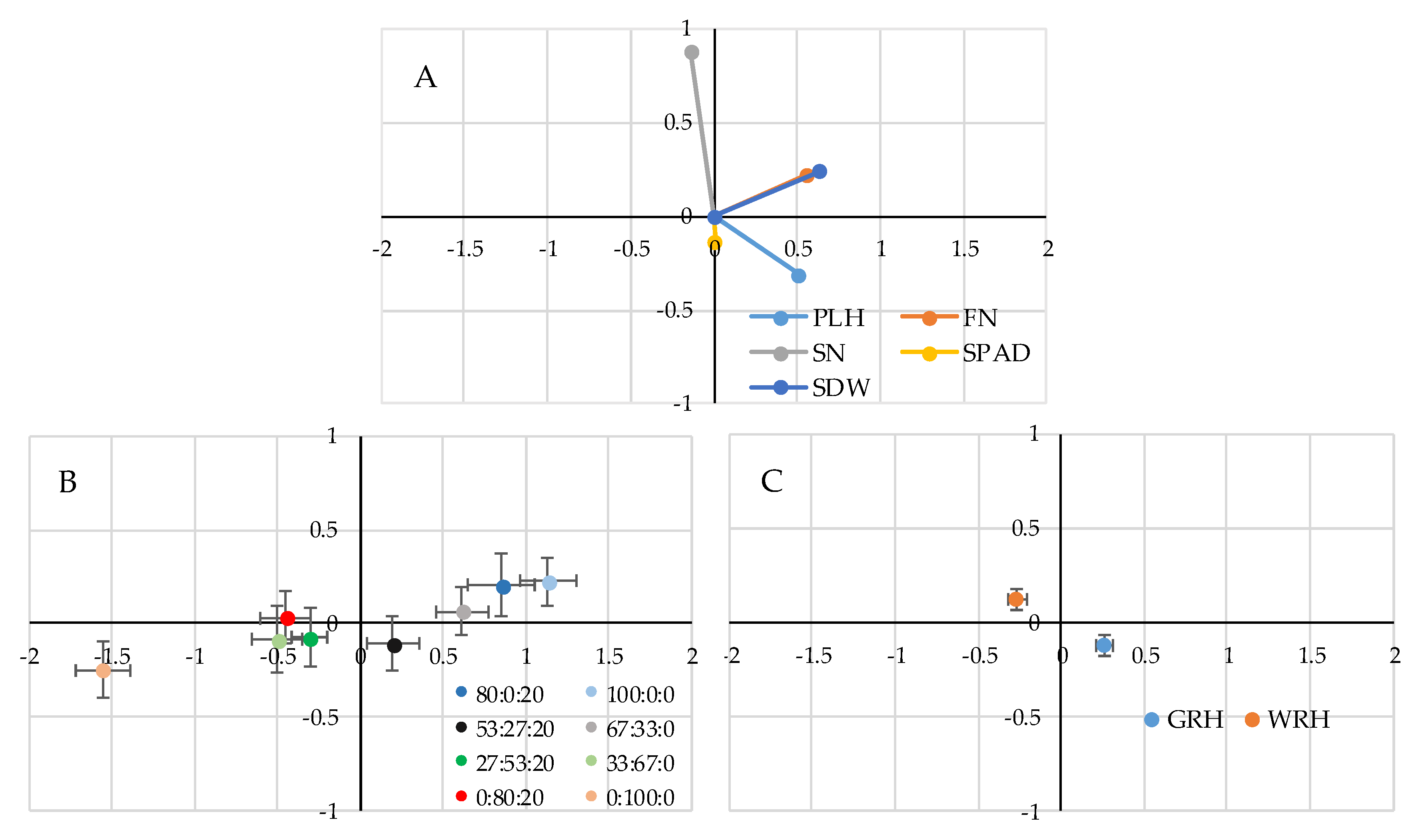

3.4. Multiple Regression and PCA Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Q.; Chen, J.; Caldwell, R.D.; Deng, M. Cowpeat as a Substitute for Peat in Container Substrates for Foliage Plant Propagation. HortTechnology 2009, 19, 340–345. [Google Scholar] [CrossRef]

- Robertson, R.A.; Buckland, P.C.; Lindsay, R.A.; Barber, K.E.; Wohlsein, P.; Trautwein, G.; Deegen, E.; Schaaff-Gerstenschlager, I.; Zimmermann, F.K. Peat, horticulture and environment. Biodivers Conserv. 1993, 2, 541–547. [Google Scholar] [CrossRef]

- Poulin, M.; Pellerin, S.; Cimon-Morin, J.; Lavallée, S.; Courchesne, G.; Tendland, Y. Inefficacy of wetland legislation for conserving Quebec wetlands as revealed by mapping of recent disturbances. Wetl. Ecol. Manag. 2016, 24, 651–665. [Google Scholar] [CrossRef]

- Urák, I.; Hartel, T.; Gallé, R.; Balog, A. Worldwide peatland degradations and the related carbon dioxide emissions: The importance of policy regulations. Environ. Sci. Policy 2017, 69, 57–64. [Google Scholar] [CrossRef]

- Dalias, P.; Prasad, M.; Mumme, J.; Kern, J.; Stylianou, M.; Christou, A. Low-cost post-treatments improve the efficacy of hydrochar as peat replacement in growing media. J. Environ. Chem. Eng. 2018, 6, 6647–6652. [Google Scholar] [CrossRef]

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Gallagher, F. Legislation and Permit Policies Regulating the Use of Horticultural and Energy Peat Resources and Peat-Based Products in the Eu; EPAGMA: Brussels, Belgium, 2008. [Google Scholar]

- Ostos, J.C.; López-Garrido, R.; Murillo, J.M.; López, R. Substitution of peat for municipal solid waste-and sewage sludge-based composts in nursery growing media: Effects on growth and nutrition of the native shrub Pistacia lentiscus L. Bioresour. Technol. 2008, 99, 1793–1800. [Google Scholar] [CrossRef] [PubMed]

- Tsakaldimi, M. Kenaf (Hibiscus cannabinus L.) core and rice hulls as components of container media for growing Pinus halepensis M. seedlings. Bioresour. Technol. 2006, 97, 1631–1639. [Google Scholar] [CrossRef]

- Mohammadbagheri, L.; Naderi, D. Effect of Growth Medium and Calcium Nano-Fertilizer on Quality and Some Characteristics of Gerbera Cut Flower. J. Ornam. Plants 2017, 7, 205–213. [Google Scholar]

- Miserez, A.; Pauwels, E.; Schamp, B.; Reubens, B.; De Nolf, W.; De Nolf, L.; Nelissen, V.; Grunert, O.; Ceusters, J.; Vancampenhout, K. The potential of management residues from heathland and forest as a growing medium constituent and possible peat alternative for containerized ornamentals. Acta Hortic. 2019, 1266, 395–404. [Google Scholar] [CrossRef]

- Uva, W.-F.; Weiler, T.C.; Milligan, R.A. A survey on the planning and adoption of zero runoff subirrigation systems in greenhouse operations. HortScience 1998, 33, 193–196. [Google Scholar]

- Fecondini, M.; Mezzetti, M.; Orsini, F.; Gianquinto, G.; Poppi, S. Zeolites in media mixes for soilless production: First results on tomato. Acta Hortic. 2011, 893, 1007–1012. [Google Scholar] [CrossRef]

- Gavilanes-Terán, I.; Jara-Samaniego, J.; Idrovo-Novillo, J.; Bustamante, M.A.; Pérez-Murcia, M.D.; Pérez-Espinosa, A.; López, M.; Paredes, C. Agroindustrial compost as a peat alternative in the horticultural industry of Ecuador. J. Environ. Manag. 2017, 186, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Fonteno, W.C. Problems & considerations in determining physical properties of horticultural substrates. Acta Hortic. 1992, 342, 197–204. [Google Scholar] [CrossRef]

- Bachman, G.R.; Metzger, J.D. Physical and chemical characteristics of a commercial potting substrate amended with vermicompost produced from two different manure sources. HortTechnology 2007, 17, 336–340. [Google Scholar] [CrossRef]

- Del Amor, F.M.; Gómez-López, M.D. Agronomical response and water use efficiency of sweet pepper plants grown in different greenhouse substrates. HortScience 2009, 44, 810–814. [Google Scholar] [CrossRef]

- Bassan, A.; Sambo, P.; Zanin, G.; Evans, M.R. Rice hull-based substrates amended with anaerobic digested residues for tomato transplant production. Acta Hortic. 2014, 1018, 573–581. [Google Scholar] [CrossRef]

- Bonaguro, J.E.; Coletto, L.; Zanin, G. Environmental and agronomic performance of fresh rice hulls used as growing medium component for Cyclamen persicum L. pot plants. J. Clean. Prod. 2017, 142, 2125–2132. [Google Scholar] [CrossRef]

- Einert, A.E. Performance of rice hulls as a growing media for pot lilies under three forcing systems. HortSience 1972, 60–61. [Google Scholar]

- Kämpf, A.N.; Jung, M. The Use of Carbonized Rice Hulles as an Horticultural Substrate. Acta Hortic. 1991, 294, 271–284. [Google Scholar] [CrossRef]

- García, O.C.; Alcántar, G.; Cabrera, R.I.; Gavi, F.; Volke, V. Evaluación de sustratos para la producción de Epipremnum aureum y Spathiphyllum wallisii cultivadas en maceta. Terra Latinoam. 2001, 19, 249–258. [Google Scholar]

- Sambo, P.; Sannazzaro, F.; Evans, M.R. Physical properties of ground fresh rice hulls and sphagnum peat used for greenhouse root substrates. HortTechnology 2008, 18, 384–388. [Google Scholar] [CrossRef]

- Buck, J.S.; Evans, M.R. Physical properties of ground parboiled fresh rice hulls used as a horticultural root substrate. HortScience 2010, 45, 643–649. [Google Scholar] [CrossRef]

- Bartz, W.C.; Pill, W.G.; Evans, T.A. Yield of greenhouse-grown tomato in substrates containing coir and parboiled rice or burnt rice hulls. J. Hortic. Sci. Biotech. 2017, 92, 231–239. [Google Scholar] [CrossRef]

- Gachukia, M.M.; Evans, M.R. Root substrate pH, electrical conductivity, and macroelement concentration of sphagnum peat-based substrates amended with parboiled fresh rice hulls or perlite. HortTechnology 2008, 18, 644–649. [Google Scholar] [CrossRef]

- Evans, M.R.; Gachukia, M.M. Secondary macro-and microelements in sphagnum peat-based substrates amended with parboiled fresh rice hulls or perlite. HortTechnology 2008, 18, 650–655. [Google Scholar] [CrossRef]

- Zanin, G.; Bassan, A.; Sambo, P.; Evans, M.R. Rice hulls and peat replacement in substrates for vegetable transplant production. Acta Hortic. 2011, 893, 963–970. [Google Scholar] [CrossRef]

- Choi, S.; Xu, L.; Kim, H.-J. Influence of physical properties of peat-based potting mixes substituted with parboiled rice hulls on plant growth under two irrigation regimes. Hortic. Environ. Biotech. 2019, 60, 895–911. [Google Scholar] [CrossRef]

- Gómez, C.; Robbins, J. Pine bark substrates amended with parboiled rice hulls: Physical properties and growth of container-grown Spirea during long-term nursery production. HortScience 2011, 46, 784–790. [Google Scholar] [CrossRef]

- Bassan, A.; Sambo, P.; Zanin, G.; Evans, M.R. Use of fresh rice hulls and anaerobic digestion residues as substrates alternative to peat. Acta Hortic. 2012, 927, 1003–1010. [Google Scholar] [CrossRef]

- Papafotiou, M.; Chronopoulos, J.; Kargas, G.; Voreakou, M.; Leodaritis, N.; Lagogiani, O.; Gazi, S. Cotton gin trash compost and rice hulls as growing medium components for ornamentals. J. Hortic. Sci. Biotech. 2001, 76, 431–435. [Google Scholar] [CrossRef]

- Evans, M.R.; Gachukia, M. Fresh parboiled rice hulls serve as an alternative to perlite in greenhouse crop substrates. HortScience 2004, 39, 232–235. [Google Scholar] [CrossRef]

- Treichel, H.; Fongaro, G.; Scapini, T.; Camargo, A.F.; Stefanski, F.S.; Venturin, B. Circular Economy Based on Residue Valorization. In Utilising Biomass in Biotechnology; Springer: Cham, Switzerland, 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing amendment properties of digestate by studying the organic matter composition and the degree of biological stability during the anaerobic digestion of the organic fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef]

- Cavalli, D.; Cabassi, G.; Borrelli, L.; Geromel, G.; Bechini, L.; Degano, L.; Gallina, P.M. Nitrogen fertilizer replacement value of undigested liquid cattle manure and digestates. Eur. J. Agron. 2016, 73, 34–41. [Google Scholar] [CrossRef]

- Ronga, D.; Caradonia, F.; Parisi, M.; Bezzi, G.; Parisi, B.; Allesina, G.; Pedrazzi, S.; Francia, E. Using Digestate and Biochar as Fertilizers to Improve Processing Tomato Production Sustainability. Agronomy 2020, 10, 138. [Google Scholar] [CrossRef]

- Compton, M.; Zauche, T. Growth of Cypripedium orchids in soilless media containing anaerobic digestion-derived biosolids. HortScience 2006, 41, 980. [Google Scholar] [CrossRef]

- Compton, M.; Zauche, T. Growth of Geranium plants in soilless media containing sphagnum peat and anaerobic digestion-derived biosolids. HortScience 2006, 41, 979. [Google Scholar] [CrossRef]

- Lamont, J.R.; Elliott, G.C. Anaerobically digested dairy fiber in soilless potting media for poinsettias. Int. J. Recycl. Org. Waste Agric. 2016, 5, 173–177. [Google Scholar] [CrossRef]

- Ponchia, G.; Passoni, M.; Bonato, S.; Nicoletto, C.; Sambo, P.; Zanin, G. Evaluation of compost and anaerobic digestion residues as a component of growing media for ornamental shrub production. Acta Hortic. 2017, 1168, 71–78. [Google Scholar] [CrossRef]

- Fonteno, W.C.; Bilderback, T.E. Impact of Hydrogel on Physical Properties of Coarse-structured Horticultural Substrates. J. Am. Soc. Hortic. Sci. 1993, 118, 217–222. [Google Scholar] [CrossRef]

- Lax, A.; Roig, A.; Costa, F. A method for determining the cation-exchange capacity of organic materials. Plant Soil 1986, 94, 349–355. [Google Scholar] [CrossRef]

- Sprent, P.; Smeeton, N.C. Applied Nonparametric Statistical Methods; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Efron, B.; Tibshirani, R. An Introduction to the Bootstrap; Monographs on Statistics and Applied Probability; Chapman & Hall/CRC: London, UK, 1993. [Google Scholar]

- Abad, M.; Noguera, P.; Burés, S. National inventory of organic wastes for use as growing media for ornamental potted plant production: Case study in Spain. Bioresour. Technol. 2001, 77, 197–200. [Google Scholar] [CrossRef]

- Bilderback, T.E.; Warren, S.L.; Owen, J.S.; Albano, J.P. Healthy Substrates Need Physicals Too! Horttechnology 2005, 15, 747–751. [Google Scholar] [CrossRef]

- Bik, A.R. Substrates in floriculture. In Proceedings of the 21th International Horticultural Congress, Hamburg, Germany, 29 August – 4 September 1982; Volume 2, pp. 811–822. [Google Scholar]

- Boertje, G.A. Physical Laboratory Analyses of Potting Composts. Acta Hortic. 1984, 47–50. [Google Scholar] [CrossRef]

- Jenkins, J.R.; Jarrell, W.M. Predicting physical and chemical properties of container mixtures. HortScience. 1989, 24, 292–295. [Google Scholar]

- Handreck, K.; Black, N. Growing Media for Ornamental Plants and Turf, 3rd ed.; New South Wales University Press: Randwick, NSW, Australia, 2005. [Google Scholar]

- De Boodt, M.; Verdonck, O. The Physical properties of the Substrates in Horticulture. Acta Hortic. 1972, 37–44. [Google Scholar] [CrossRef]

- Evans, M.R.; Gachukia, M.M. Physical Properties of Sphagnum Peat-based Root Substrates Amended with Perlite or Parboiled Fresh Rice Hulls. HortTechnology 2007, 17, 312–315. [Google Scholar] [CrossRef]

- Gruda, N.; Sippel, C.; Schnitzler, W.H. Investigation of Physical Properties of Wood Fiber Substrates Uunder Press Pot Conditions. Acta Hortic. 2001, 51–58. [Google Scholar] [CrossRef]

- Benito, M.; Masaguer, A.; Moliner, A.; De Antonio, R. Chemical and physical properties of pruning waste compost and their seasonal variability. Bioresour. Technol. 2006, 97, 2071–2076. [Google Scholar] [CrossRef]

- Carlson, W.H.; Kaczperski, M.P.; Rowley, E.M. Bedding plants. In Introduction to Floriculture; Elsevier: Amsterdam, The Netherlands, 1992; pp. 511–550. [Google Scholar]

- Carlile, W.R.; Cattivello, C.; Zaccheo, P. Organic Growing Media: Constituents and Properties. Vadose Zone J. 2015, 14, 1–3. [Google Scholar] [CrossRef]

- Evans, M.R.; Buck, J.S.; Sambo, P. The pH, Electrical Conductivity, and Primary Macronutrient Concentration of Sphagnum Peat and Ground Parboiled Fresh Rice Hull Substrates Over Time in a Greenhouse Environment. HortTechnology 2011, 21, 103–108. [Google Scholar] [CrossRef]

- Argo, W.R. Root Medium Chemical Properties. Horttechnology 1998, 8, 486–494. [Google Scholar] [CrossRef]

- Allaire, S.E.; Caron, J.; Duchesne, I.; Parent, L.-É.; Rioux, J.-A. Air-filled Porosity, Gas Relative Diffusivity, and Tortuosity: Indices of Prunus ×cistena sp. Growth in Peat Substrates. J. Am. Soc. Hortic. Sci. 1996, 121, 236–242. [Google Scholar] [CrossRef]

- Pozzi, A.; Valagussa, M. Caratterizzazione agronomica dei substrati di coltivazione: Metodologie ed esperienze a confronto. Fertil. Agrorum 2009, 3, 50–55. Available online: https://fertilitasagrorum.ciec-italia.it/Rivista/fertilitas_vol3_num1.pdf (accessed on 8 May 2020).

- Cadell, M.L. Rice hull composting in Australia. BioCycle (USA) 1988, 29, 49. [Google Scholar]

- Lee, J.; Lee, B.; Kim, K.; Kang, S. Influence of pH and NO3/NH4 ratio of nutrient solution and particle size distribution of rice hull on growth of hot pepper seedling in expanded rice hull-based substrates. J. Korean Soc. Hortic. Sci. 2000, 41, 36–40. [Google Scholar]

- Lee, J.; Lee, B.; Lee, Y.; Kim, K. Growth and inorganic element contents of hot pepper seedlings in fresh and decomposed expanded rice hull-based substrates. J. Korean Soc. Hortic. Sci. 2000, 41, 147–151. [Google Scholar]

- Taiz, L.; Zeiger, E. Plant Physiology, 2nd ed.; Sinaure Associates: Sunderland, MA, USA, 1998; p. 792. [Google Scholar]

- Herrera, F.; Castillo, J.E.; Chica, A.F.; Bellido, L.L. Use of municipal solid waste compost (MSWC) as a growing medium in the nursery production of tomato plants. Bioresour. Technol. 2008, 99, 287–296. [Google Scholar] [CrossRef]

- D’Angelo, G.; Castelnuovo, M.; Galli, A.; Valagussa, M. Relations between physical and chemical properties of the substrate and growth of some pot ornamentals. Acta Hortic. 1993, 342, 313–324. [Google Scholar] [CrossRef]

- García-Sánchez, F.; Jifon, J.L.; Carvajal, M.; Syvertsen, J.P. Gas exchange, chlorophyll and nutrient contents in relation to Na+ and Cl− accumulation in ‘Sunburst’ mandarin grafted on different rootstocks. Plant Sci. 2002, 162, 705–712. [Google Scholar] [CrossRef]

- Munns, R.; Tester, M. Mechanisms of salinity tolerance. Annu. Rev. Plant Biol. 2008, 59, 651–681. [Google Scholar] [CrossRef] [PubMed]

- Shah, S.H.; Houborg, R.; McCabe, M.F. Response of chlorophyll, carotenoid and SPAD-502 measurement to salinity and nutrient stress in wheat (Triticum aestivum L.). Agronomy 2017, 7, 61. [Google Scholar] [CrossRef]

- Altieri, R.; Esposito, A.; Baruzzi, G. Use of olive mill waste mix as peat surrogate in substrate for strawberry soilless cultivation. Int. Biodeter. Biodegr. 2010, 64, 670–675. [Google Scholar] [CrossRef]

- Alvarez, J.M.; Pasian, C.; Lal, R.; López, R.; Fernández, M. Vermicompost and biochar substrates can reduce nutrients leachates on containerized ornamental plant production. Hortic. Bras. 2019, 37, 47–53. [Google Scholar] [CrossRef]

- EU Commission Commission Decision of 3 November 2006 Establishing Revised Ecological Criteria and the Related Assessment and Verification Requirements for the Award of the Community Eco-Label to Growing Media (2006/799/EC). Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32006D0799&from=EN (accessed on 8 May 2020).

- Clarke, D. The wise use of peat in horticulture. Acta Hortic. 2008, 779, 161–164. [Google Scholar] [CrossRef]

- Caron, J.; Rochefort, L. Use of peat in growing media: State of the art on industrial and scientific efforts envisioning sustainability. Acta Hortic. 2013, 982, 15–22. [Google Scholar] [CrossRef]

| Component Ratio (% v:v:v) | RH Grinding | Substrate ID | Peat | WRH | GRH | ADR |

|---|---|---|---|---|---|---|

| 100:0:0 | WRH | 100:0:0-W | 100.0 | 0.0 | 0.0 | 0.0 |

| 67:33:0 | WRH | 67:33:0-W | 66.7 | 33.3 | 0.0 | 0.0 |

| 33:67:0 | WRH | 33:67:0-W | 33.3 | 66.7 | 0.0 | 0.0 |

| 0:100:0 | WRH | 0:100:0-W | 0.0 | 100.0 | 0.0 | 0.0 |

| 80:0:20 | WRH | 80:0:20-W | 100 | 0.0 | 0.0 | 0.0 |

| 53:27:20 | WRH | 53:27:20-W | 66.7 | 0.0 | 33.3 | 0.0 |

| 27:53:20 | WRH | 27:53:20-W | 33.3 | 0.0 | 66.7 | 0.0 |

| 0:80:20 | WRH | 0:80:20-W | 0.0 | 0.0 | 100 | 0.0 |

| 100:0:0 | GRH | 100:0:0-G | 80.0 | 0.0 | 0.0 | 20.0 |

| 67:33:0 | GRH | 67:33:0-G | 53.3 | 26.7 | 0.0 | 20.0 |

| 33:67:0 | GRH | 33:67:0-G | 26.7 | 53.3 | 0.0 | 20.0 |

| 0:100:0 | GRH | 0:100:0-G | 0.0 | 80.0 | 0.0 | 20.0 |

| 80:0:20 | GRH | 80:0:20-G | 80.0 | 0.0 | 0.0 | 20.0 |

| 53:27:20 | GRH | 53:27:20-G | 53.3 | 0.0 | 26.7 | 20.0 |

| 27:53:20 | GRH | 27:53:20-G | 26.7 | 0.0 | 53.3 | 20.0 |

| 0:80:20 | GRH | 0:80:20-G | 0.0 | 0.0 | 80.0 | 20.0 |

| Parameter | Methodology | Instrument | Literature |

|---|---|---|---|

| Bulk Density | EN 13040 (1999) | ||

| Total pore space, air filled porosity, water holding capacity | NCSU porometer | NCSU Porometer, Horticultural Substrates Laboratory, North Carolina State University (NCSU), Raleigh, NC, USA | [43] |

| pH | EN 13037 | HI 9813-5, Hanna Instruments, Padova Italy | |

| Electrical conductivity | EN 13038 | HI 9813-5, Hanna Instruments, Padova Italy | |

| Organic matter | EN 13039 | ||

| Cation exchange capacity | BaCl2-TEA | [44] | |

| Total Kjeldahl nitrogen | Total Kjeldahl nitrogen | ||

| NO3-N, NH4-N, P, K, Ca, Mg | EN 13652 | ICS-900, Dionex, Sunnyvale, CA, USA |

| Substrate ID | C:N | NO3-N | NH4-N | P | K | Ca | Mg |

|---|---|---|---|---|---|---|---|

| 100:0:0-W | 119.7 bc | 0.52 e | 0.87 b | 0.01 g | 1.01 i | 6.46 def | 0.87 bc |

| 67:33:0-W | 127.0 b | 0.02 e | 0.79 b | 0.94 f | 16.80 h | 6.78 de | 0.70 bc |

| 33:67:0-W | 106.0 bc | 0.02 e | 1.49 a | 1.75 e | 29.55 gh | 3.91 ef | 0.67 c |

| 0:100:0-W | 164.7 ab | 0.12 e | 1.65 a | 4.13 c | 35.69 fg | 1.44 f | 0.84 bc |

| 80:0:20-W | 26.1 d | 17.92 bc | 0.13 c | 0.90 f | 45.05 ef | 27.42 a | 1.89 ab |

| 53:27:20-W | 26.7 d | 22.83 a | 0.18 c | 2.81 d | 61.60 cd | 26.04 a | 2.22 a |

| 27:53:20-W | 32.7 cd | 19.82 b | 0.20 c | 4.00 c | 75.43 bc | 19.12 ab | 2.77 a |

| 0:80:20-W | 45.1cd | 15.76 c | 1.32 a | 7.63 a | 79.24 b | 11.05 cd | 2.72 a |

| 100:0:0-G | 117.0 bc | 0.42 e | 0.77 b | 0.01 g | 0.95 i | 5.89 def | 0.93 bc |

| 67:33:0-G | 141.9 b | 0.01 e | 0.42 bc | 0.21 g | 15.05 hi | 5.65 ef | 0.52 c |

| 33:67:0-G | 193.2 a | 0.02 e | 0.28 c | 2.83 d | 53.13 de | 2.48 ef | 0.52 c |

| 0:100:0-G | 200.4 a | 0.85 e | 0.54 bc | 5.12 d | 95.08 a | 1.46 f | 1.10 bc |

| 80:0:20-G | 28.7 d | 23.99 a | 0.26 c | 0.93 f | 43.40 efg | 25.24 a | 1.91 ab |

| 53:27:20-G | 42.8 cd | 15.90 c | 0.08 c | 1.13 f | 70.28 bc | 15.19 bc | 1.79 ab |

| 27:53:20-G | 69.0 c | 4.17 d | 0.14 c | 3.06 d | 69.66 bc | 4.00 ef | 0.83 bc |

| 0:80:20-G | 97.6 c | 6.35 d | 0.52 bc | 5.55 b | 101.71 a | 2.57 ef | 1.02 bc |

| Significance 1 | |||||||

| Component ratio | *** | *** | *** | *** | *** | *** | *** |

| RH grinding | *** | *** | ** | *** | *** | *** | *** |

| Interaction | n.s. | *** | ** | *** | *** | *** | *** |

| Normal range 2 | 11–23 | 8–12 | 4.6–6.2 | 4–14 | 10–19 | 6–10 |

| Substrate ID | Height (cm) | SPAD Value | Flower Number | Stem Number | Shoot Dry Weight (g) | Root Dry Weight (g) |

|---|---|---|---|---|---|---|

| 100:0:0-W | 37.3 a | 53.0 a | 5.4 ab | 10.0 ab | 10.73 a | 0.97 abc |

| 67:33:0-W | 36.6 ab | 50.3 abcd | 3.9 cdef | 7.5 def | 8.21 b | 0.95 abc |

| 33:67:0-W | 30.5 de | 53.0 a | 3.1 efg | 5.6 fg | 6.34 cd | 0.86 abcd |

| 0:100:0-W | 27.2 e | 51.7 abc | 3.4 defg | 5.3 fg | 5.10 de | 0.93 abc |

| 80:0:20-W | 40.0 a | 49.1 cde | 5.3 ab | 11.8 a | 10.78 a | 0.58 e |

| 53:27:20-W | 37.2 a | 50.5 abcd | 4.4 abcde | 8.1 cde | 8.82 b | 0.78 cde |

| 27:53:20-W | 35.8 abc | 48.4 def | 4.5 abcd | 7.4 def | 8.39 b | 0.82 bcde |

| 0:80:20-W | 31.3 cde | 46.3 ef | 2.5 g | 4.6 g | 5.05 e | 0.84 bcd |

| 100:0:0-G | 38.4 a | 52.1 ab | 5.1 abc | 10.5 ab | 10.63 a | 0.67 de |

| 67:33:0-G | 38.4 a | 50.3 abcd | 5.6 a | 9.9 abc | 10.33 a | 0.86 abcd |

| 33:67:0-G | 32.3 bcde | 49.6 bcd | 3.1 efg | 6.6 efg | 6.78 c | 1.02 ab |

| 0:100:0-G | 27.2 e | 48.0 def | 2.6 fg | 5.0 g | 5.01 e | 0.96 abc |

| 80:0:20-G | 39.4 a | 50.3 abcd | 5.0 abc | 10.5 ab | 11.34 a | 0.77 cde |

| 53:27:20-G | 39.2 a | 50.8 abcd | 3.8 cdefg | 9.5 bcd | 11.26 a | 0.80 bcde |

| 27:53:20-G | 36.6 ab | 48.6 def | 4.2 bcde | 9.1 bcd | 8.76 b | 0.77 cde |

| 0:80:20-G | 31.9 bcd | 46.1 f | 3.3 defg | 6.5 efg | 6.89 c | 1.10 a |

| Sign 1 | ||||||

| Component ratio | *** | *** | *** | *** | *** | *** |

| RH grinding | ** | ** | n.s. | *** | n.s. | n.s. |

| Interaction | n.s. | *** | *** | *** | *** | *** |

| Substrate ID | Height (cm) | SPAD Value | Flower Number | Stem Number | Shoot Dry Weight (g) |

|---|---|---|---|---|---|

| 100:0:0-W | 29.7 ab | 41.9 abc | 4.3 a | 3.2 | 14.2 a |

| 67:33:0-W | 28.8 abc | 39.7 abc | 3.3 abc | 3.3 | 13.3 abc |

| 33:67:0-W | 21.4 de | 42.4 ab | 2.3 cde | 3.5 | 9.1 ef |

| 0:100:0-W | 16.5 e | 39.1 abc | 1.7 e | 3.5 | 5.4 g |

| 80:0:20-W | 31.0 ab | 37.3 bc | 3.2 abc | 3.5 | 12.7 abcd |

| 53:27:20-W | 26.3 abcd | 40.5 abc | 2.8 bcde | 3.4 | 10.6 de |

| 27:53:20-W | 25.0 abcd | 41.4 abc | 2.7 bcde | 3.4 | 9.3 ef |

| 0:80:20-W | 21.8 cde | 39.0 abc | 2.5 bcd | 3.6 | 8.1 f |

| 100:0:0-G | 26.4 abcd | 43.6 a | 3.6 ab | 3.3 | 13.7 ab |

| 67:33:0-G | 27.9 abcd | 39.2 abc | 3.2 abc | 3.1 | 12.2 abcd |

| 33:67:0-G | 30.3 ab | 37.0 c | 2.4 cde | 3.1 | 10.8 de |

| 0:100:0-G | 24.3 bcd | 39.1 abc | 2.0 de | 3.0 | 9.1 ef |

| 80:0:20-G | 31.8 a | 39.6 abc | 3.4 abc | 3.4 | 13.4 abc |

| 53:27:20-G | 29.5 ab | 39.6 abc | 3.3 abc | 3.0 | 11.9 bcd |

| 27:53:20-G | 24.1 bcd | 42.5 ab | 2.9 bcd | 3.1 | 11.3 cde |

| 0:80:20-G | 29.4 ab | 39.0 abc | 2.8 bcde | 3.2 | 11.2 cde |

| Sign 1 | |||||

| Component ratio | *** | *** | *** | n.s. | *** |

| RH grinding | *** | n.s. | n.s. | ** | *** |

| Interaction | *** | * | n.s. | n.s. | *** |

| Geranium | Rose | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PLH^ | SN | FN | SPAD | SDW | PLH | SN | FN | SPAD | SDW | |

| Constant (*106) | 0 | -0.234 | 0 | 0 | 0 | 0.149 | -0.02 | 0.124 | 0 | 0.272 |

| BD | 0.042 | 0.067 | 0.663 | -0.191 | 0.068 | 0.132 | 0.063 | 0.251 | 0.323 | 0.408 |

| TPS | −0.274 | - | −0.165 | 0.385 | - | - | - | - | 0.345 | 0.051 |

| AIF | −0.118 | - | 0.139 | - | −0.318 | −0.209 | 0.593 | 0.316 | - | - |

| WHC | - | 0.575 | - | - | 0.113 | - | 0.501 | 0.513 | −0.229 | 0.209 |

| pH | 0.024 | 0.060 | −0.068 | 0.067 | 0.108 | −0.052 | 0.018 | - | 0.069 | −0.070 |

| EC | −0.147 | −0.344 | −0.620 | 0.506 | −0.366 | −0.635 | - | −0.431 | 1.024 | −0.217 |

| CEC | 0.118 | −0.240 | −0.149 | - | −0.139 | 0.113 | - | −0.083 | 0.104 | 0.097 |

| OM | 0.126 | −0.221 | 0.091 | 0.079 | 0.188 | −0.090 | −0.105 | 0.353 | 0.424 | 0.223 |

| C:N | −0.174 | −0.105 | −0.066 | 0.064 | −0.092 | 0.088 | −0.024 | −0.115 | −0.186 | −0.122 |

| NO3-N | 0.158 | - | 0.080 | −0.123 | 0.636 | 0.606 | −0.104 | 0.464 | −0.821 | 0.084 |

| NH4-N | −0.013 | −0.058 | −0.084 | −0.040 | −0.045 | 0.073 | 0.033 | 0.044 | - | 0.124 |

| P | −0.241 | −0.040 | - | −0.440 | −0.475 | −0.243 | 0.159 | −0.083 | - | −0.183 |

| K | -0.152 | −0.315 | −0.382 | - | −0.058 | 0.548 | −0.115 | 0.128 | −0.327 | 0.188 |

| Ca | 0.086 | 0.121 | 0.115 | −0.069 | −0.122 | −0.141 | 0.083 | −0.065 | - | - |

| Mg | 0.140 | 0.099 | 0.159 | −0.054 | 0.121 | −0.111 | −0.029 | 0.041 | 0.144 | −0.034 |

| R2 | 0.365 | 0.454 | 0.300 | 0.217 | 0.712 | 0.189 | 0.032 | 0.204 | 0.075 | 0.447 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bassan, A.; Bona, S.; Nicoletto, C.; Sambo, P.; Zanin, G. Rice Hulls and Anaerobic Digestion Residues as Substrate Components for Potted Production of Geranium and Rose. Agronomy 2020, 10, 950. https://doi.org/10.3390/agronomy10070950

Bassan A, Bona S, Nicoletto C, Sambo P, Zanin G. Rice Hulls and Anaerobic Digestion Residues as Substrate Components for Potted Production of Geranium and Rose. Agronomy. 2020; 10(7):950. https://doi.org/10.3390/agronomy10070950

Chicago/Turabian StyleBassan, Antonio, Stefano Bona, Carlo Nicoletto, Paolo Sambo, and Giampaolo Zanin. 2020. "Rice Hulls and Anaerobic Digestion Residues as Substrate Components for Potted Production of Geranium and Rose" Agronomy 10, no. 7: 950. https://doi.org/10.3390/agronomy10070950

APA StyleBassan, A., Bona, S., Nicoletto, C., Sambo, P., & Zanin, G. (2020). Rice Hulls and Anaerobic Digestion Residues as Substrate Components for Potted Production of Geranium and Rose. Agronomy, 10(7), 950. https://doi.org/10.3390/agronomy10070950