1. Introduction

The optimism regarding the potential of biofuels as an alternative to fossil fuels was high at the beginning of the 21st century [

1]. Benefits, such as greenhouse gases (GHG) emission reduction, heat, electricity de-carbonization, and the development of rural areas, were expected for biofuel use [

2]. However, there is speculation regarding the contribution of biofuels to the increase of food prices and the use of freshwater [

3,

4]. This raised important issues regarding the use of arable lands for growing crops dedicated to biofuel production [

5,

6,

7] and it created a conflict between both alternatives [

8].

In this context, marginal lands have been revealed as an important source of land for growing energy crops [

7]. Marginal lands are areas where it is difficult to grow food crops profitably given the conditions that exist at the site, the agricultural policies and available growing methods, as well as the global or national economic situations [

9,

10]. According to the European Environmental Agency (EEA), marginal land is “a low-quality land whose production barely covers its cultivation costs”. The United States Department of Agriculture (USDA) defines marginal lands as “in farming, poor quality land that is likely to yield a poor term return”. Those lands are therefore characterized by low food and feed productivity associated with socio-economic and biophysical constraints [

11,

12].

The uses of perennial grasses have been widely reported as the best alternative for producing biomass in marginal lands in agronomic, economic, and environmental terms. Perennial grasses compared to traditional annual crops reduce soil nutrient depletion and soil erosion, require a low input for their production and provide a better profit margin, increase soil quality and carbon sequestration, enhance the agricultural ecosystems’ biodiversity by avoiding the mono-cropping and providing protection and feed to wild fauna (mammals, birds and insects), and increase soil water retention [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29]. The perennial grasses most used for producing biomass in Europe and the US are miscanthus (

Miscanthus giganteus Greef et Deuter), giant reed (

Arundo donax L.), switchgrass (

Panicun virgatum L.), and reed canary grass (

Phalaris arundinacea L.), but implanting them under marginal conditions is not recommended due to their soil and water requirements [

30]. In turn, perennial cool-season grasses can be alternative bioenergy crops for sustainable biomass production on marginal lands generally not suited to grain crop production [

31,

32]. In particular, tall wheatgrass, crested wheatgrass (

Agropyron cristatum (L.) Gaertn.), and Siberian wheatgrass (

Agropyron sibiricum (Willd.) P. Beauv.) possess characteristics that can be useful in marginal lands. These species share similar traits regarding their salinity and drought tolerance, winter frost hardiness, and resistance to pests and illnesses [

33,

34,

35], in addition to the rest of the advantages described above for being perennial grasses. All of them are cool-season grasses that have been traditionally used as pastures for grazing or for obtaining hay [

36].

Many studies around the world provide information on yields and the quality of these grasses in terms of forage production for animals [

36,

37], while others show the production and quality of the biomass of different varieties on fertile arable land or grasslands [

38,

39,

40,

41]. However, very scarce information is available on the use of these

Agropyron species as combustion feedstock on arable lands under marginal conditions. The composition and the combustion behavior of grass biomass are strongly influenced by crop management and developmental stage but also depend on the species considered and on site factors, such as soil characteristics and weather conditions [

30,

42,

43]. The literature shows how the composition of cool-season grasses differs greatly within and among different locations [

30,

44,

45], and they can thus have considerably different amounts of certain “anti-quality” minerals like Cl, K, Si, N, or S that cause emissions, slagging, and/or corrosion at the operating temperatures of combustion plants [

30,

42,

43,

45,

46]. For all these reasons, it is important to clarify from a productive and a quality perspective whether or not cool-season grasses can be a long-term sustainable resource for energy feedstock under marginal conditions.

In the above context, the main aim of this study was to evaluate three species of Agropyron spp. from an agronomic and energy perspective, comparing their biomass yield, composition, and quality in a low productive agricultural area under rainfed conditions. One cultivar (cv.) of crested wheatgrass (Hycrest), one cultivar of Siberian wheatgrass (Vavilov II), and three cultivars of tall wheatgrass (Alkar, Jose, and Riparianslopes) were tested for eight years in a marginal location, while another three tall wheatgrass cultivars (Alkar, Bamar, and Szarvasi-1) were tested for five years in a second marginal location. These results are of key importance for determining the commercial future of these crops as a feedstock for energy production when growing under marginal conditions.

2. Materials and Methods

2.1. Experimental Sites

The study was carried out in two different locations of Spain’s North-Central Plateau, one of the most extended areas of rainfed agriculture in southern Europe. The experimental fields were located in Cubo de la Solana (CS) [41° 36′ N and 2° 28′ W], 1010 m above sea level, and in Alconaba (AL) [41° 42′ N and 2° 22′ W], 1000 m above sea level.

Experimental fields were located in areas with severe biophysical limitations [

47]. In both places, soils were poor and sandy (81% of sand in the CS fields and 88% of sand in the AL fields), with a content of coarse elements (>2 mm) higher than 15% in soil volume. Soils were characterized by low levels of organic matter (≤1%), and low water and nutrient retentions, indicating potential high losses by leaching. Soils were pH neutral and did not exhibit salinity problems. Soil nitrogen content was 0.06% in the CS plots and 0.03% in AL; the content in phosphorus (P

2O

5) was 10.2 and 10.0 mg·kg

−1 in CS and AL, respectively; and the content of the soil in potassium (K

2O) was 152.5 mg·kg

−1 in the CS fields and 150 mg·kg

−1 in the AL plots. Soil samples were taken from the upper layer (0–30 cm) as indicated in ISO 10381-1, and analyzed according to ISO standards for texture (ISO 11277), pH (ISO 10390), electrical conductivity (ISO 11265), organic matter (ISO 10694), phosphorus (ISO 11263), potassium (ISO 11260), and ammonium and nitrates (ISO/TS 14256-1 EX).

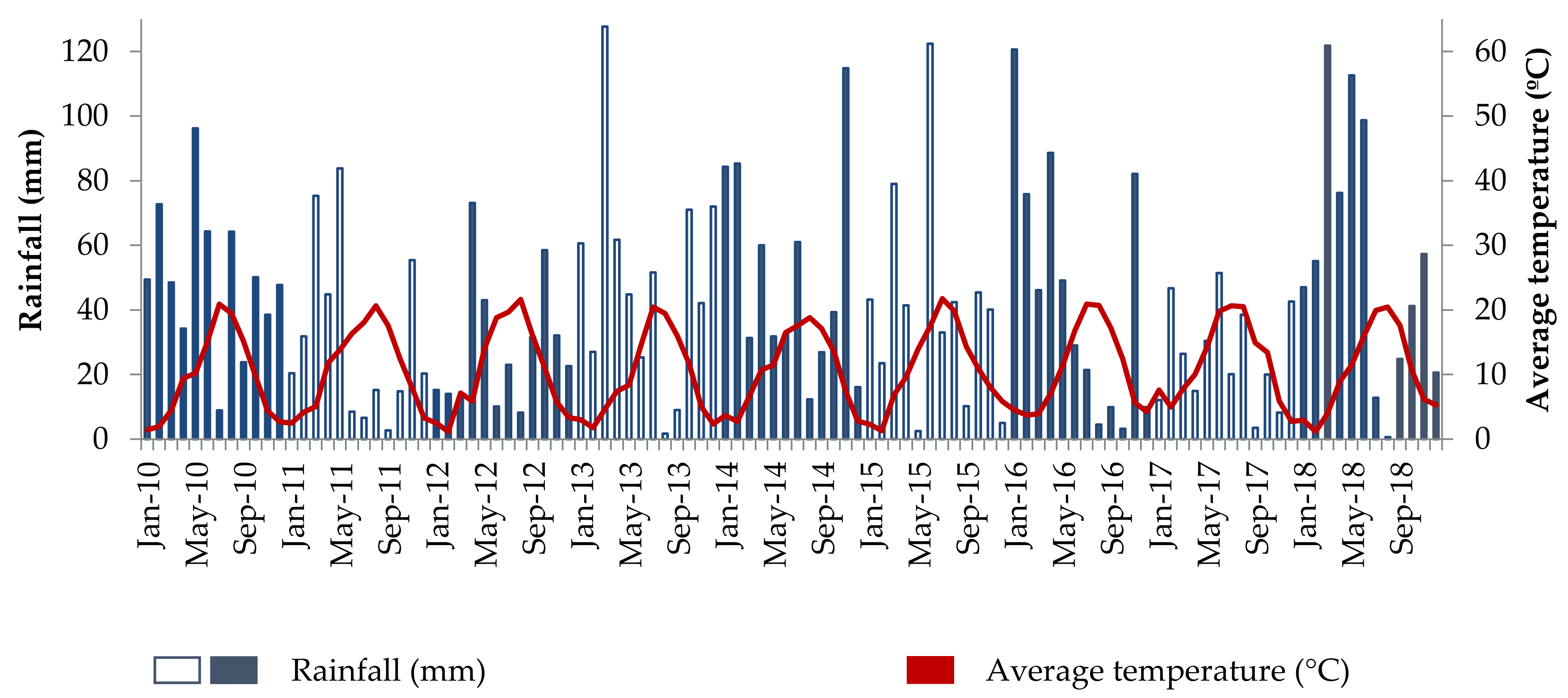

Climate conditions were continental Mediterranean with cold winters, warm summers, and low rainfall levels. Climate data were taken from the nearest national grid of meteorological stations. The average annual rainfall during the study period was 502.7 mm in the CS fields, with 2018 being the wettest year (669 mm) and 2017 the driest (315 mm). Harvesting was hardly possible in 2017 due to the extremely low biomass production obtained as a consequence of the low annual precipitation registered at this location, particularly between March and June (123 mm). The annual average temperature was 10.6 °C, with minimum and maximum absolute temperatures of −11.9 °C in January 2011 and 37 °C in August 2012, respectively. The free frost period was from late May to early October, and drought conditions usually appeared during the summer.

Figure 1 shows the monthly rainfall and average temperatures during the study period in the CS experimental trials.

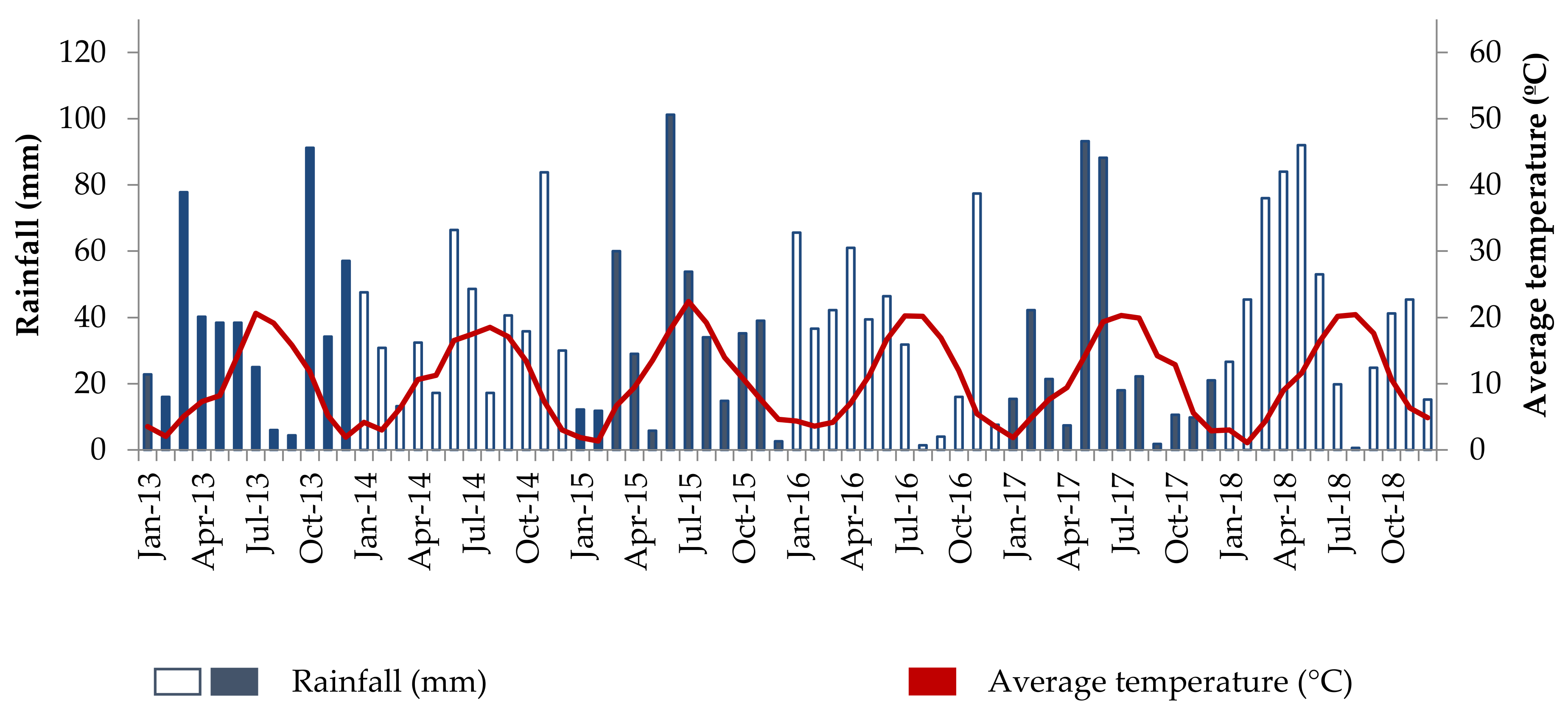

The AL fields registered 437 mm of annual average rainfall, with 2018 being the wettest year (524 mm) and 2017 the driest with 351 mm. The annual average temperature was 10.5 °C, and the minimum and maximum absolute temperatures were −10.5 °C in January 2017 and 36.01 °C in July 2015, respectively. AL exhibited the same frost and drought periods as CS.

Figure 2 depicts the monthly rainfall and average temperatures.

2.2. Experimental Design and Crop Management

CS field trials were studied for 8 years (October 2010–August 2018). The experiment in the CS fields was designed by sowing three repetitions in a randomized complete block design in 300-m2 plots (3 m wide × 100 m long) for each experimental unit. As it was commented previously, the varieties sown were tall wheatgrass (cv. Alkar (TWA), cv. Jose (TWJ), cv. Riparianslopes (TWR)), crested wheatgrass (cv. Hycrest) (CWH), and Siberian wheatgrass (cv. Vavilov) (SWV).

In the AL fields, 3 cultivars of tall wheatgrass were sown with 4 repetitions for 5 years (October 2013–August 2018) in plots with a similar surface area, shape, and design as the CS fields. The cultivars sown in the AL experiment were tall wheatgrass (cv. Alkar (TWA), cv. Bamar (TWB), and cv. Szarvasi-1 (TWS)).

The previous crop in both trials was fallow land. It was plowed seven months earlier, cultivated in summer, and sown in October (2010 in the CS fields and 2013 in Al plots). The seeding dose was 20 kg·ha−1 for tall wheatgrass cultivars and 15 kg·ha−1 for crested wheatgrass and Siberian wheatgrass, with a seeding drill in rows 13 cm apart. A complex fertilizer NPK 8-24-8 (300 kg·ha−1) was applied for base fertilization in the establishment year. Base fertilization was applied two days before sowing and buried with a cultivator. In addition, plots were rolled in mid-March in the establishment year, prior to the application of the top fertilization. Experimental plots were sprayed in late April for controlling broadleaves weeds with 1 L·ha−1 of 2.4-D acid 34.5% + 2-methyl-4-chlorophenoxyacetic acid 34.5%. Nitrogen fertilizer was applied as top dressing between mid- and late-March every year using nitrogen (27% purity) at 300 kg·ha−1·y−1. Crops were harvested with a mower conditioner from mid-July to early August depending on the year, always when crops were in the doughy grain stage and leaving 10 cm of stubble to encourage further regrowth. After 5 to 6 days of field drying, biomass was baled in prismatic bales (<10% moisture).

The main limiting factor for plant growth under rainfed conditions is water availability. Biomass production of crops depends on their efficiency in water use. Hence, crops with better efficiency also achieve a better economic margin. The cited efficiency is often expressed as water-use efficiency (WUE) or rain-use efficiency (RUE), and it is measured in terms of crop production per unit of water input. Specifically, RUE = yield (g DM·ha

−1)/rainfall occurred (l) [

48]. Although WUE and RUE have been primarily evaluated in traditional agronomic crops, they can also impact the potential of crops for cellulosic biofuels [

49]. The RUE was calculated to assess the differences among cultivars and species. The calculation period occurred in the months with the highest vegetative activity (March to June), which is when rainfall is considered to be of key importance for biomass production in cool-season grasses under rainfed conditions, as other authors reported [

48,

50].

2.3. Experimental Characteristics and Analytical Methods

Sample preparation was performed according to ISO 14780:2017 [

51] and test analyses were carried out following the corresponding international standards for solid biofuels (

Table 1).

Bales were weighed with a laboratory scale in the fields. Moisture content was measured by oven-drying subsamples in an oven at 40 °C until constant weight. Dry matter yields were calculated by taking into account the plot area, as well as the weight and moisture content of the bales.

Before baling, a combined sample per replicate plot, cultivar, and year was analyzed to determine the main properties and the chemical composition of the biomass. Every combined sample was formed by manually collecting 3 subsamples from different random locations in the replicate plot and leaving the same stubble as the mower did. Biomass from CS fields was analyzed for 7 years from 2012 until 2018. The biomass from the establishment year was not analyzed. Biomass from the AL plots was analyzed annually between 2014 and 2018.

Major elements were analyzed by digesting the ashes of the biomass obtained at 550 °C (ISO 18122:2015), followed by ICP-OES determination according to ISO 16967:2015. Results were expressed in biomass dry basis (db). Titanium contents were very low and frequently below the method quantification limit (<0.0002%), and thus the results obtained for this element are not shown or treated statistically. Calorific values were analyzed by calorimetry (ISO 16994:2016) and expressed as the gross calorific value at constant volume (GCVv,o) and net calorific value at constant pressure (NCVp,o), both in db.

A number of fuel predictive indices and ratios between chemical elements were calculated to predict the combustion behavior of the biomass cultivated. These indices were selected from the literature because they were previously used as a measure of the quality of other herbaceous biofuels for combustion.

In this sense, the ratio between the earth alkaline oxides and alkaline oxides (AE/A), the ratio between the content of K and the sum of Ca and Mg [K/(Ca + Mg)], as well as the molar ratio between the sum of Si, P, and K and the sum of Ca and Mg [(Si + P + K)/(Ca + Mg)] were used as indicators of problems related to ash sintering and fusion.

AE/A is calculated by dividing the concentrations of CaO and MgO and the concentrations of K2O and Na2O in the ash fuel [

52]. Solid biofuels with AE/A ratios over 2 have been associated with a lower risk of ash sintering in a 1 MWth bubbling fluidized bed combustion pilot plant [

52].

The K/(Ca + Mg) ratio was used as an indicator of slagging for the thermo-chemical processing of grasses [

53]. It was estimated that grasses with ratios below 0.5 did not pose issues regarding ash sintering or ash fusion, e.g., in operational gasifiers [

53].

A linear correlation between the ash sintering temperature (SST) and the molar ratio (Si + P + K)/(Ca + Mg) was also empirically demonstrated for P and K-rich fuel ash systems [

54,

55]. Zeng et al. did find a good correlation between SST and pellets produced from blends of miscanthus, a warm-season grass, with wood and wheat straw [

55]. Fuels with lower (Si + P + K)/(Ca + Mg) molar ratios tend to exhibit higher ash sintering temperatures [

54]. Fuels with indices below 1 and 3 are expected to exhibit SSTs equal to or higher than 1200 and 1000 °C, respectively [

54].

The sum of K + Na + Zn + Pb can be used as an indicator of PM1 emissions [

54]. Low PM1 emissions are expected for indices below 1000 mg kg

−1. In turn, fuels with indices over 10,000 mg kg

−1 tend to cause high PM1 emissions [

54]. As trace elements were not determined in this study, a Pb content of 1 mg kg

−1 was used to calculate this index, based on previous experimental trials where the biomass of tall wheatgrass was analyzed in these regions.

The molar Si/K ratio was used to predict aerosol formation during the combustion of grasses, among other fuels [

54,

56]. A high molar Si/K ratio can lead to a preferred formation of potassium silicates in the bottom ash, resulting in a lower K release and aerosol formation, but gaseous SOx and HCl emissions may increase [

54].

The molar ratio (K + Na)/[x(2S + Cl)] was used to predict SOx and HCl emission levels [

54,

55]. In this study, an x factor of 4.9 was used to calculate this index, as this is the value that was experimentally determined by Sommersacher et al. for

Arundo donax, also a cold-season grass perennial. For fuels with high molar ratios, S and Cl will be preferably embedded in the ashes, forming alkaline sulfates and chlorides, potentially resulting in low SOx and HCl emission levels [

54,

55].

The 2S/Cl molar ratio has been used as an indicator for high-temperature corrosion risks [

54]. Fuels with ratios below 2 are expected to pose a severe risk. Minor risks are expected when ratios are >4. In turn, for 2S/Cl ratios <2, severe corrosion risks need to be taken into account, as a result of a high Cl surplus in aerosols [

54].

2.4. Statistical Analysis

Statistical analyses were performed using the Statgraphics Centurion XVII (Statpoint Technologies INC, 2017, The Plains, VA, USA) software. The effects of the different species (S), cultivars (C), and years (Y) on biomass production and composition as well as on empirical fuel indices were evaluated by means of the variance analysis (ANOVA). Multifactorial two-way ANOVAs (Type III sums of squares) with a maximum order interaction of 2 were used. All F-ratios were based on the residual mean square error. The normality of the data and the homoscedasticity of variances were verified using the standardized skewness/kurtosis and Levene’s test, respectively. No data transformations were considered necessary. In AL fields, C, Y, and the interaction between both factors (C × Y) were considered to be fixed effects. In CS fields, two types of analysis were performed as different species and cultivars were tested. On the one hand, an analysis of variance with S, Y, and S × Y as fixed effects, with the factor species at three levels (tall wheatgrasses—TW, crested wheatgrass—CW, and Siberian wheatgrass—SW). On the other hand, an analysis of variance with species/cultivars (S/C), Y, and their interaction (X/C × Y) as fixed effects, and considering five levels for factor S/C (TWR, TWA, TWJ, CWH, and SWV) was conducted. Block (replicate plots) was considered a random effect at both sites. Mean differences across species, cultivars, and years were assessed using multiple range tests according to the Fisher’s least significant difference (LSD) test. Significant effects were revealed at p-values ≤0.05 (95% of confidence level). Interactions among factors (species and years or cultivars and years) were depicted by using the means and Fisher´s LSD interaction plots. Means, standard deviations (SD), 75% percentiles (P75), as well as minimum and maximum individual values obtained for each property were also included in their corresponding tables.

4. Discussion

As normally occurs in all perennial grasses [

57], the lowest yields were obtained during the first annual harvest, no matter the species, cultivar, or location considered, with the exception of 2017. The highest yield among all the species and cultivars tested at this site (TWA, TWJ, TWR, CWH, and SWV) was achieved by TWA (4.8 Mg DM·ha

−1) and TWJ (4.7 Mg DM·ha

−1). In turn, TWA was the cultivar that provided the lowest yield in the AL plots (3.0 Mg DM·ha

−1), where another two tall wheatgrass cultivars were also tested (TWB and TWS).

Only a few studies deal with perennial grasses in marginal land, particularly when it comes to

Agropyron spp. species dedicated to bioenergy production. In turn, biomass yields are commonly reported in grasslands and fertile land. In this study, tall wheatgrass cultivars performed better in terms of biomass production than they did in another study that was carried out under marginal conditions in the USA, where yields of 3.1 Mg DM·ha

−1 were reported [

58]. However, studies under irrigation or located in areas without biophysical constraints provided better yields for tall wheatgrass cultivars, with biomass productions over 10 Mg DM·ha

−1 in North America [

37,

59] and of 17.2 Mg DM·ha

−1 in Germany for biogas production [

23].

As it was commented before, TWA averaged 4.8 and 3.0 Mg DM·ha

−1 in the CS and AL fields, respectively, lower than the yields of 8.2 Mg DM·ha

−1 reported in a 3-year study in fertile land in the USA [

39].

TWJ yielded 12.6 Mg DM·ha

−1 in the current study. Lower yields (8 Mg DM·ha

−1·y

−1) were reported in irrigated areas of the Mediterranean area suffering from salinity problems [

60]. This cultivar achieved yields of 5.9–8.3 Mg DM·ha

−1 (average production during a 2-year period) under irrigation in marginal lands for forage production [

61].

TWS yielded up to 25 Mg DM·ha

−1 in fertile land, obtaining annual biomass productions of 5 Mg DM·ha

−1 in areas with biophysical constraints [

62], close to those obtained in the AL station (4.3 Mg DM·ha

−1).

In a 3-year study carried out in Poland [

63], TWB provided yields in the range 6.6-10.4 Mg DM·ha

−1. These results were also obtained in low-quality land although in an area characterized by higher precipitation than the one in this study.

Biomass production obtained in this study for CWH (2.8 Mg DM·ha

−1) was similar to that reported in North America (2.9 to 3.6 Mg DM·ha

−1), where this cultivar was monitored during two years under rainfed conditions for forage production [

64]. Higher biomass productions (5.55–8.05 Mg DM·ha

−1) were reported in irrigated lands in the U.S. [

65].

No matter the species or the cultivar, biomass production increased with annual rainfall. However, the extent to which precipitation affected yields depended on the species considered [

28]. Generally, the RUE of warm-season grasses, such as switchgrass, is higher than cool-season grasses due to their different metabolism [

49]. It is also worth mentioning that biomass production was found to increase in connection with spring rainfall, as this is the season when perennial grasses go through their highest active vegetative period. Other authors also noted a similar correlation [

49,

66,

67]. According to our results, the

Agropyron spp. considered in this study achieved higher biomass yields when the precipitation registered between March and June was over 240 mm. Poor biomass yields were obtained when precipitation during the aforementioned period was around 150 mm. Rainfall levels below 120 mm resulted in a great difficulty in harvesting the crop, as other authors also pointed out [

13].

The

Agropyron spp. cultivated in both marginal locations exhibited the typical chemical composition of perennial grasses harvested in summer, which are characterized by high contents of ash, silicon, and alkali elements [

30,

42,

43,

46,

68].

The perennial grasses cultivated in both locations (CS and AL) averaged 40 g·kg

−1 db ash and ranged from 27–63 g·kg

−1 db, and 75% of all the analyzed samples was ≤ 46 g·kg

−1 db no matter the site. This was well within the typical ash mean values and ranges specified in ISO 17225-1:2014 [

68] for virgin grass in general (hay, 10–100 g·kg

−1 db) and other cool-season grasses, such as reed canary grass (summer harvest: 25–100 g·kg

−1 db). However, the ash content of the grasses cultivated in this study is more comparable to that of miscanthus, a C4 grass that is usually characterized by lower ash contents than C3 grasses, showing in the literature mean ash contents of 40 g·kg

−1 db [

30,

46,

68] and a typical variation from 10-60 g·kg

−1 db [

68]. Martyniak et al. [

41] studied TWS and four wild populations of tall wheatgrass in Poland, reporting elevated ash contents for these grasses (78 g·kg

−1 db for TWS and 100–170 g·kg

−1 db for the wild populations). Nazli et al. reported ash contents between 51 and 96 g·kg

−1 db for other C3 grasses (giant reed and bulbous canary grass) and in the range of 31–60 g·kg

−1 db for C4 grasses (miscanthus and switchgrass) in marginal land in Turkey [

31]. It has been reported that air temperature, water availability, and rain distribution play an important role in affecting the biomass ash content [

42]. A decrease in ash content has been observed in giant reed grown without irrigation [

30] and in central Italy in years with low precipitation and after long periods of summer drought [

42]. Besides meteorological conditions, sandy soils like the ones in the study have a low water-holding capacity, increasing the likelihood of water stress [

69]. Therefore, the relatively low ash contents found in our study could be due to the sandy soils and the semi-arid climate of the marginal regions considered. Nevertheless, it should be pointed out that ash contents higher than those shown in our study, where grasses were collected manually, should be expected when biomass is harvested mechanically, which could result in the inclusion of mineral impurities from soil.

Net calorific values in db ranged from 16.7–18.5 MJ·kg

−1, and averaged 17.7 MJ·kg

−1 for the biomass cultivated in CS and 17.3 MJ·kg

−1 in AL. They are within the typical ranges listed in ISO 17225-1 [

58] for perennial grasses (16–19 MJ·kg

−1). This international standard [

68] also lists the mean typical net calorific values for virgin grass (17.1 MJ·kg

−1), reed canary grass (16.6 MJ·kg

−1), and miscanthus (17.7 MJ·kg

−1). Again, the tall wheatgrass cultivars considered in our study showed mean calorific values closer to miscanthus, a warm-season grass, than to other cool-season grasses. As calorific values are known to be negatively correlated to ash content [

43,

70], the higher heating values found in our study are in line with the relatively lower ash contents that characterized this biomass. Our net calorific values are very close to those found for giant reed harvested in the fall (17.4 MJ·kg

−1) and bulbous canary grass (17.2 MJ·kg

−1), the latter in marginal land in a semi-arid Mediterranean environment in Turkey [

31]. Lower net calorific values were found for wild populations of tall wheatgrass in Poland (15.8–17.0 MJ·kg

−1), in connection with the elevated ash contents obtained for the biomass (78–170 g·kg

−1) [

41].

The chemical composition of the perennial grasses cultivated in our study are well within the ranges documented in the literature for cool perennial grasses [

30,

41,

42,

43,

44,

45,

46,

56,

60,

68].

Agropyron spp. averaged 12 g·kg

−1 db and 8.3 g·kg

−1 db N in CS and AL, respectively, 1.6 g·kg

−1 db Cl in CS, 2.8 g·kg

−1 db Cl in AL, and 0.10% S at both sites. ISO 17225-1 specifies typical values of 1.3% N, 0.1–0.2% S, and 0.5–0.7% for virgin grasses and reed canary grass harvested in summer, and 0.7% of N, and 0.2% of S and Cl for miscanthus [

68]. Sulfur contents between 0.9 and 1.0 g·kg

−1 db and chlorine contents from 0.13–0.25% were reported for TWS and wild populations of tall wheatgrass in Poland [

41]. Tall wheatgrass ranged from 6–11 g·kg

−1 db N, depending on the N fertilization rate in the Mediterranean climate in California [

60]. In marginal land, giant reed and bulbous canary grasses harvested in the fall, two different C3 species, ranged from 5.4–16 g·kg

−1 db N and 1.1–3.0 g·kg

−1 db S across different N fertilization rates and years [

56]. Perennial pastures dominated by cool-season grass species in the U.S. ranged from 6–18 g·kg

−1 db N, 1.0–2.5% S, and 1.0–5.0 g·kg

−1 db Cl [

44]. Similar concentrations were also reported for native temperate grasses in the maturity stage in the Western U.S. [

45], obtaining 0.3–1.8 g·kg

−1 db of S and 0.5–4.0 g·kg

−1 db of Cl.

When a fuel N concentration exceeds 6 g·kg

−1 db, the NOx emission limits during combustion could be exceeded [

46]. Corrosion and HCl emission problems are to be expected as well at Cl concentrations above 1 g·kg

−1 db and S concentrations over 1 g·kg

−1 db, while emissions of dioxins and furans could be of relevance when the concentration of Cl exceeds 0.3% [

46]. Significant SOx emissions should also be considered when the concentration of S in the fuel is >20 g·kg

−1 db [

46]. When using this type of biomass for combustion purposes, severe high corrosion risks should be taken into account. The biomass grown in this study always exhibited 2S/Cl molar ratios below 2, the guideline specified in [

54] to avoid this issue.

Other important elements from a quality point of view, such as K, Si, Ca, Mg, P, and Na were also well within the typical values gathered in the literature for other cool perennial grasses cultivated under different conditions [

30,

43,

46,

68]. Besides the developmental stage, the content of major elements in grasses is strongly influenced by site factors and environmental conditions, such as soil type and weather conditions, and therefore differences in the mineral concentrations of these grasses are expected between different locations [

30,

42,

45]. Depending on the location, our grasses averaged 2.3–2.4 g·kg

−1 db of Ca, 9.7–11 g·kg

−1 db of K, 0.09–0.36 g·kg

−1 db of Na, 4.8–5.4 g·kg

−1 db of Si, 1.0–1.4 g·kg

−1 db of P, and 0.59–0.64 g·kg

−1 db Mg. For grasses harvested in summer or in the fall, other authors reported values ranging from 0.6–8.1 g·kg

−1 db K, 5.6–37 g·kg

−1 db Si, and 0.8–3.2 g·kg

−1 db Ca for reed canary grass [

30], or 2.2–23 g·kg

−1 db Si, 0.9–3.0 g·kg

−1 db P, and 9.6–22 g·kg

−1 db K for native temperate grasses in the western US [

45]. Similar mineral concentrations were obtained in marginal land for giant reed and bulbous canary grass (

Phalaris aquatica L.), with 7.0–21 g·kg

−1 db K, 4.4–16 g·kg

−1 db P, 1.6–3.7 g·kg

−1 db Ca, 12–21 g·kg

−1 db Si, and 0.9–1.4 g·kg

−1 db Mg [

56].

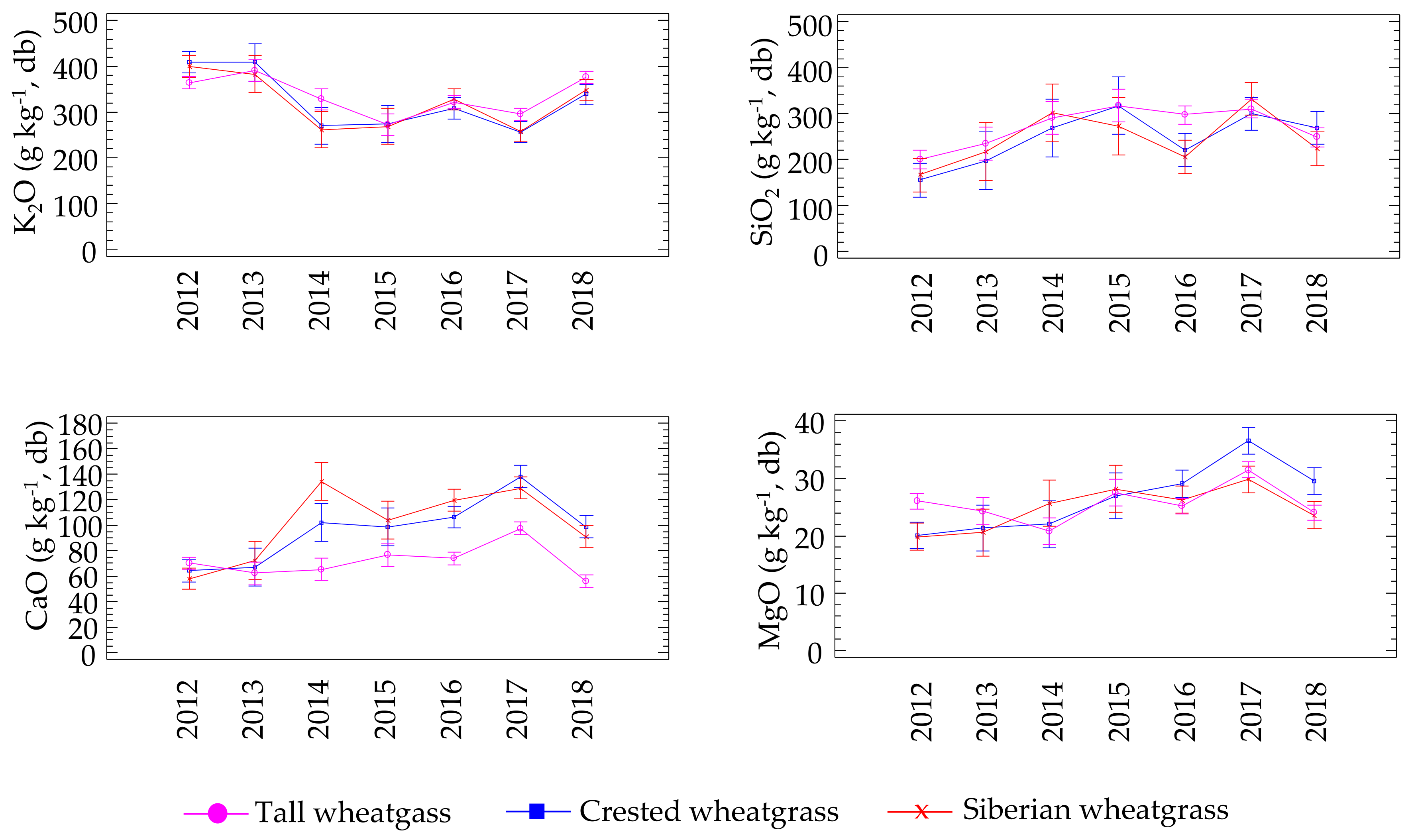

When grown in the same location (CS), the main differences were found across species rather than among cultivars. In this sense, the chemical composition of tall wheatgrass cultivars differed from crested and Siberian wheatgrass, finding higher ash, K, Na, and Si contents for the former, which resulted in lower AE/A ratios and higher K/(Ca + Mg), (Si + P + K)/(Ca + Mg), and K + Na + Pb + Zn indices. Therefore, fuel indices predict a slightly better combustion behavior of crested and Siberian wheatgrass with regard to ash sintering and aerosol emissions.

When different tall wheatgrass cultivars were grown in the same environment (TWA, TWJ, and TWR in CS and TWA, TWB, and TWS in AL), most of their properties varied in a relatively narrow range. Genotypic differences in the accumulation of minerals and the fuel quality of other grass species have been previously reported [

30,

45,

71], and they can only be quantified when the grasses are grown at the same location.

However, it should be highlighted that the slight differences found among all the species and cultivars tested are not expected to be of any practical relevance if theses grasses are utilized in combustion processes. No matter the species or year considered, AE/A ratios were always maintained low (<0.8), and K/(Ca + Mg) ratios were >2, far from the guidelines to avoid sintering problems (AE/A >2 [

52], and K/(Ca + Mg)<0.5 [

53]). In addition, (Si + P + K)/(Ca + Mg) molar ratios were always from 3–10. Therefore, low sintering temperatures are expected for the cultivated grasses [

52,

53,

54,

55]. K + Na + Pb + Zn were always between 8000 and 16,000 mg kg

−1 (

Figure 5), suggesting medium aerosol emissions (PM

1) for crested and Siberian wheatgrass to high aerosol emissions in the case of TW cultivars [

54]. Si/K molar ratios were low (<1.2,

Figure 5), also suggesting a high K release and aerosol formation.

Our results suggest an improvement in the biomass quality of the grasses with crop age. In this sense, the ash content, as well as the concentrations of K, S, Na, and Cl, tended to decrease over the years, while the content of CaO, MgO, and SiO

2 in the ashes tended to increase. As a result of the changes noted in the chemical composition, the biomass collected during the first years exhibited lower AE/A and Si/K ratios, and higher (Si + P + K)/(Ca + Mg) and K + Na + Pb + Zn indices. Therefore, the results obtained suggest a better ash fusibility behavior for the biomass harvested during the later years of the study, as well as lower gaseous and aerosol emissions. The positive effect of crop age on the chemical characteristics of other grasses was previously documented [

31,

42,

45,

56,

71]. Similar to our results, ash content reductions and higher SiO

2/K

2O and CaO/K

2O ratios were found in 10-year-old giant reed crops in central Italy [

42]. The mineral concentration decline with plant maturation has been previously related to the different morphological characteristics of the stand crops during ageing, which produces a greater amount of thinner stems per unit area with fewer leaves [

42,

72]. However, as suggested by Di Nasso [

42], it is very difficult to separate the effect of crop age from the effect of different annual meteorological conditions, particularly the rainfall distribution during the growing seasons.

Based on the chemical composition and the assessment of the calculated fuel combustion indices, the grasses cultivated in these marginal regions are expected to show the typical combustion behavior of cold perennial grasses harvested in summer. When assessing the fuel indices, results suggest that the differences found among wheatgrass species and cultivars for some of their combustion properties and chemical characteristics are not likely to affect their combustion behavior from a practical point of view. If these grasses are going to be used for producing bioenergy in a thermochemical conversion process, technological measures in power plants should be implemented to avoid sintering, corrosion, and emission-related problems [

30,

45,

46]. Another possibility worth considering would be to try reducing the content of troublesome elements directly in the fuel. Practices, such as leaching during field drying or a harvest delay, have been proven effective for grasses [

30,

31,

43,

56,

68,

71], due to the reduction in ash content and water-soluble elements in the fuel, as well as an increase in ash deformation temperatures. The impact of leaching and/or a delayed harvest on the chemical composition and fuel quality parameters of theses grasses should be explored in marginal land and semi-arid environments with scarce precipitation and variable rain distribution. In addition, an economic assessment would also be useful to determine whether these alternatives would be viable in low-productive soils, as the improvement in the quality properties of the fuel is usually accompanied by significant dry matter losses and the risk of displacing the baling to periods with unfavorable weather conditions [

43,

71]. The biomass cultivated in this study could also be used to produce herbaceous pellets, class B [

73]. The limitations established in ISO 17225-6 for herbaceous pellets, class A, would not be met, as the Cl content of the cultivated perennial grasses surpassed the limitation of 1.0 g·kg

−1 db at both locations, but especially in AL, where higher levels of Na and Cl were found.