Integrating Biochar and Inorganic Fertilizer Improves Productivity and Profitability of Irrigated Rice in Ghana, West Africa

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Biochar Production and Characterization

2.3. Experimental Design and Treatments

2.4. Plant and Soil Sampling and Analysis

2.5. Nitrogen Use Efficiency

2.6. Economic Analysis

2.7. Statistical Analysis

3. Results

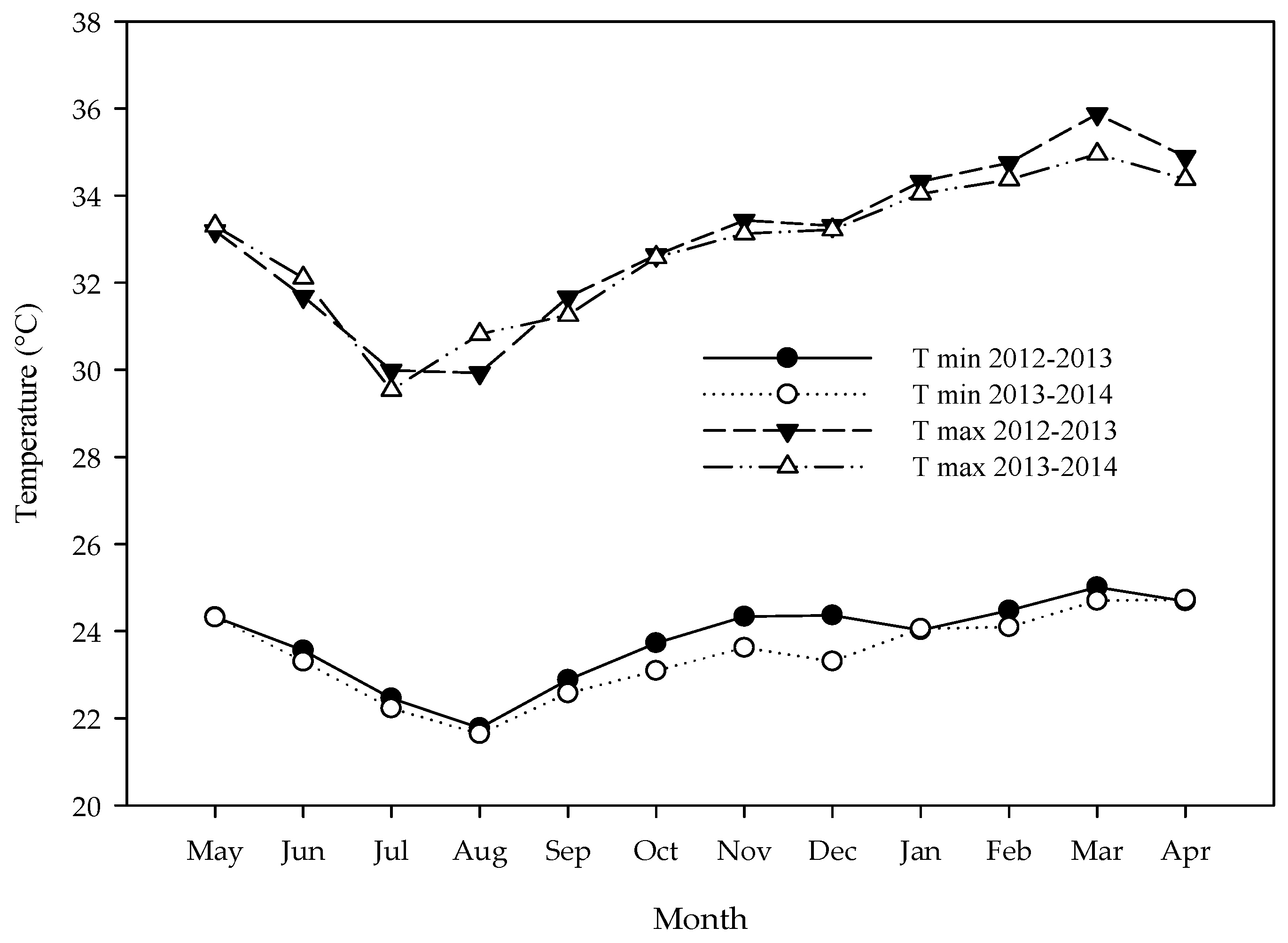

3.1. Temperatures during Cropping Cycles

3.2. Biochar and Soil Properties

3.2.1. Biochar Properties

3.2.2. Soil Properties

3.3. Crop Growth

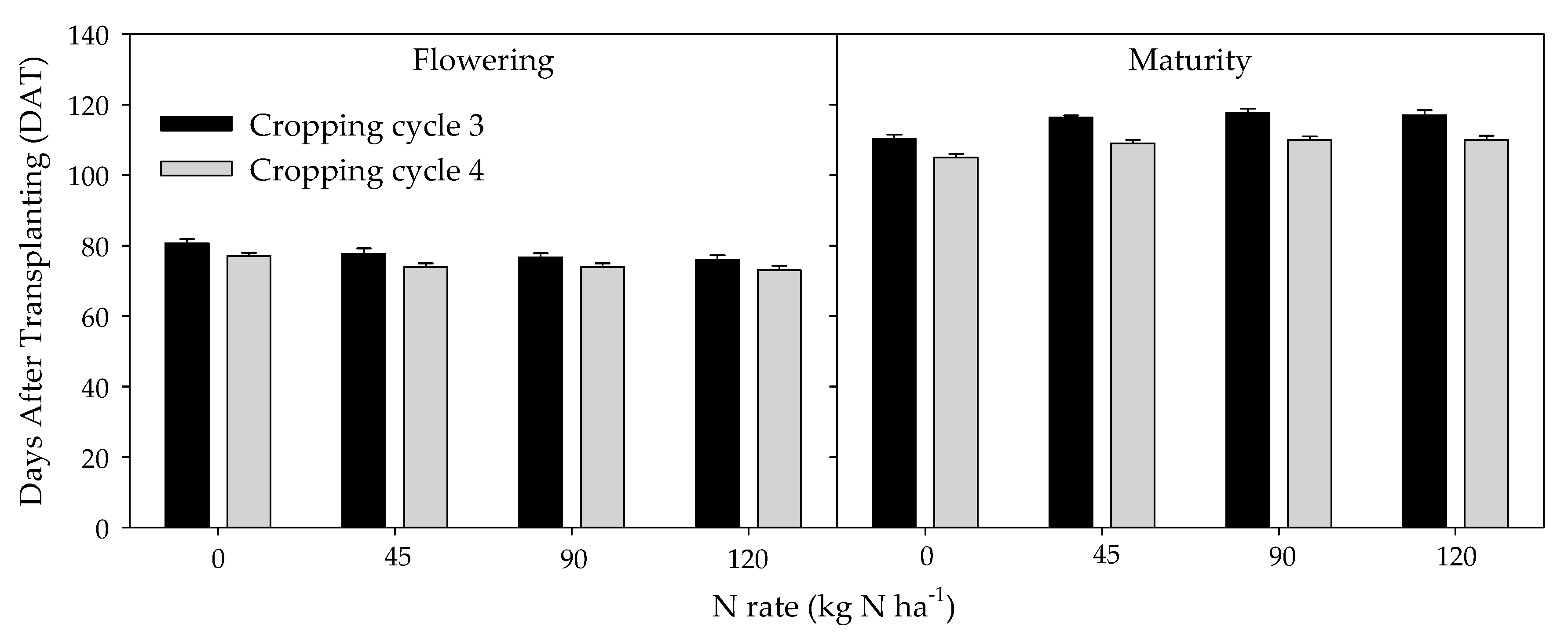

3.3.1. Crop Development

3.3.2. Root Volume

3.4. Straw and Grain Yield

3.5. Proportion of Grain Filled

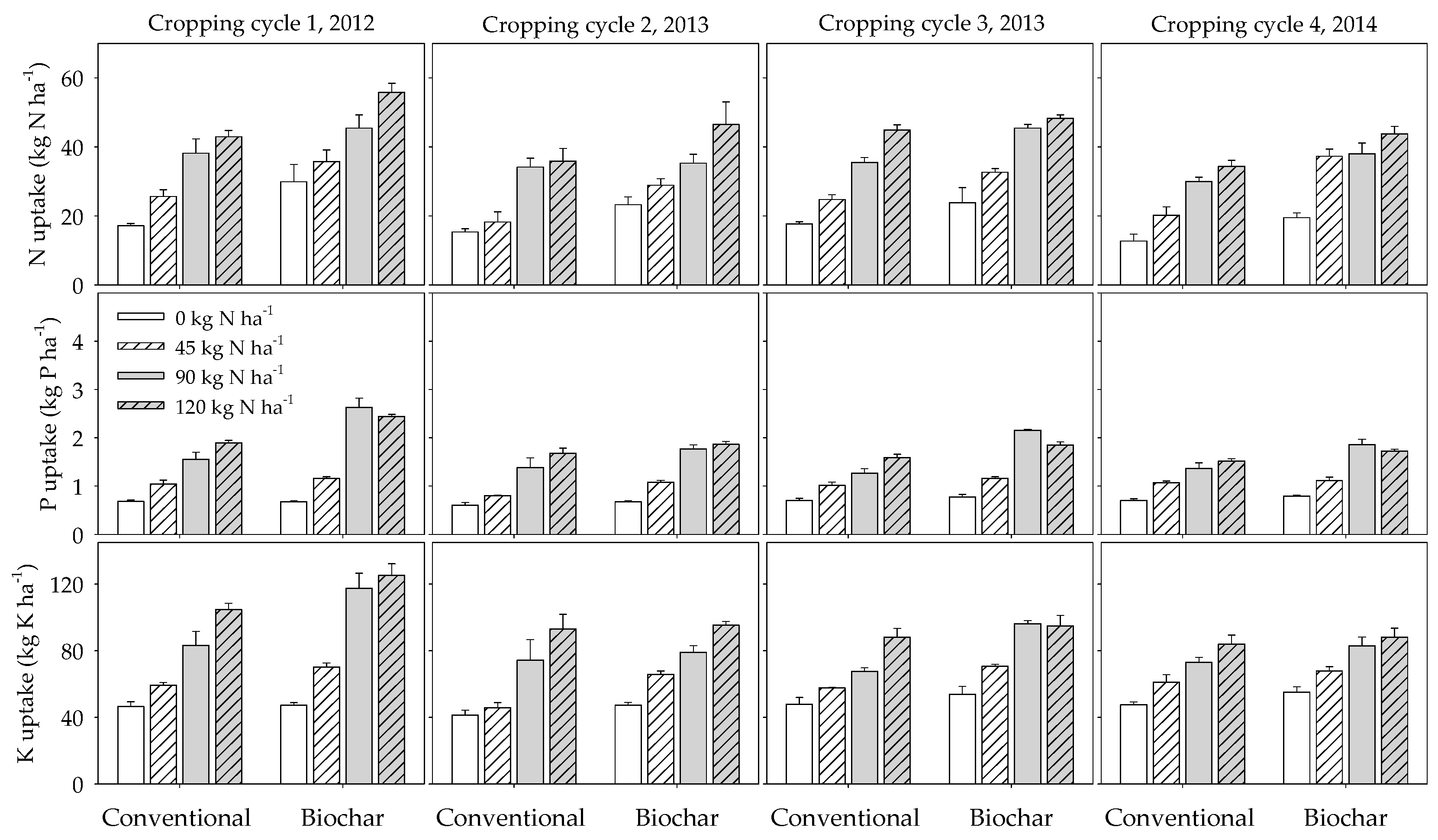

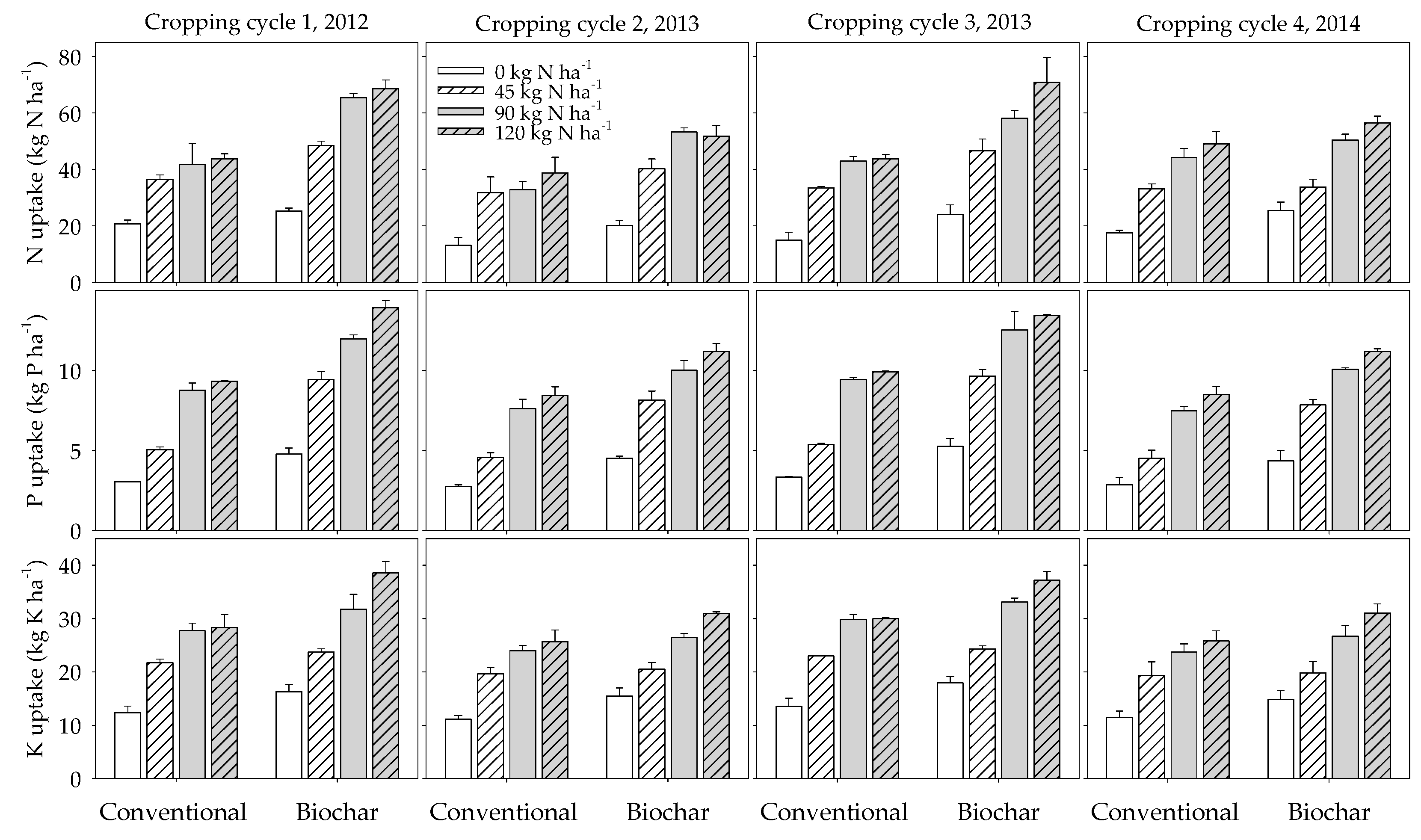

3.6. Nutrient Uptake in Straw and Grain

3.7. Agronomic Efficiency of Nitrogen and Apparent Recovery Efficiency of Nitrogen Applied

3.8. Soil-Biochar Interactions

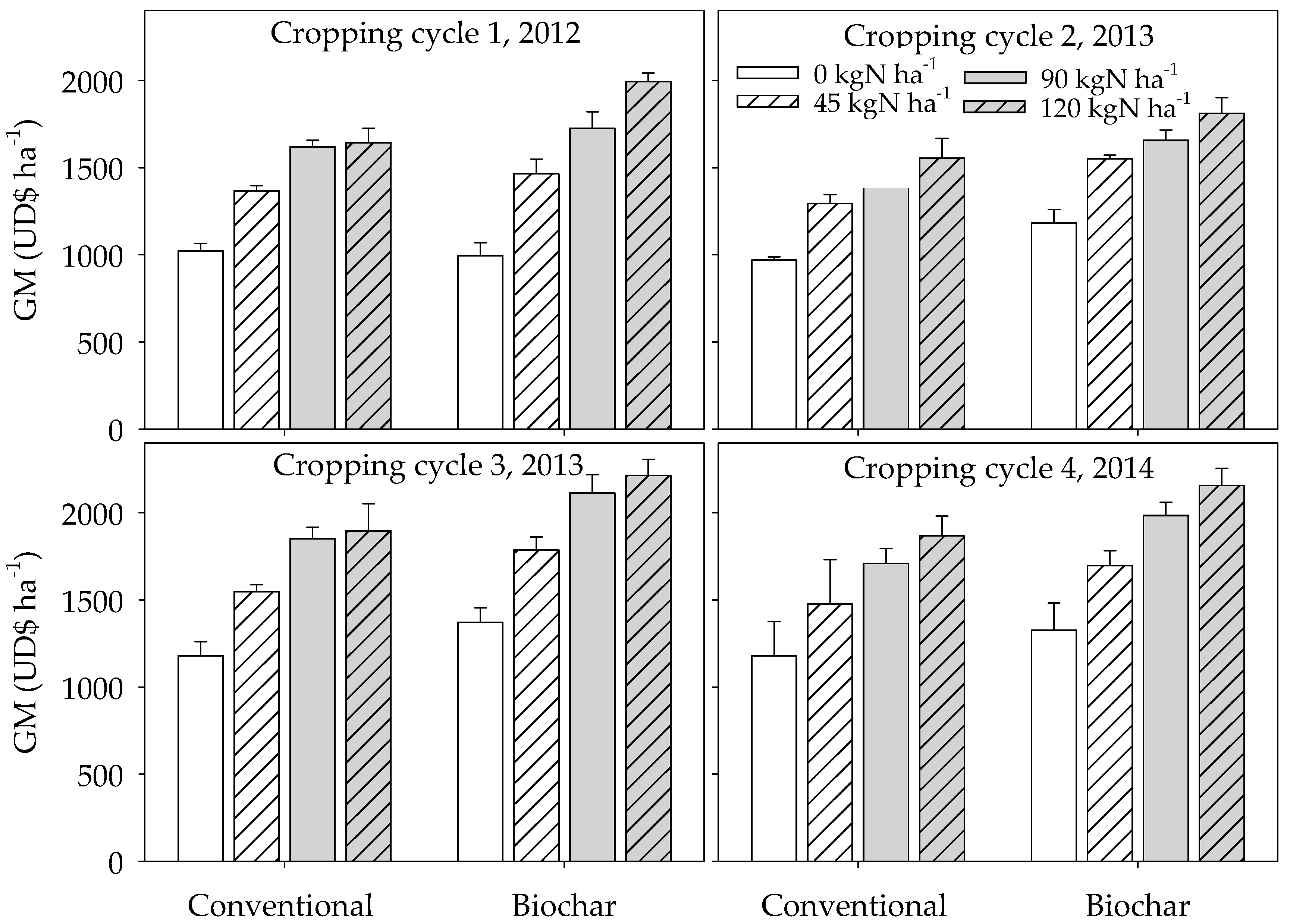

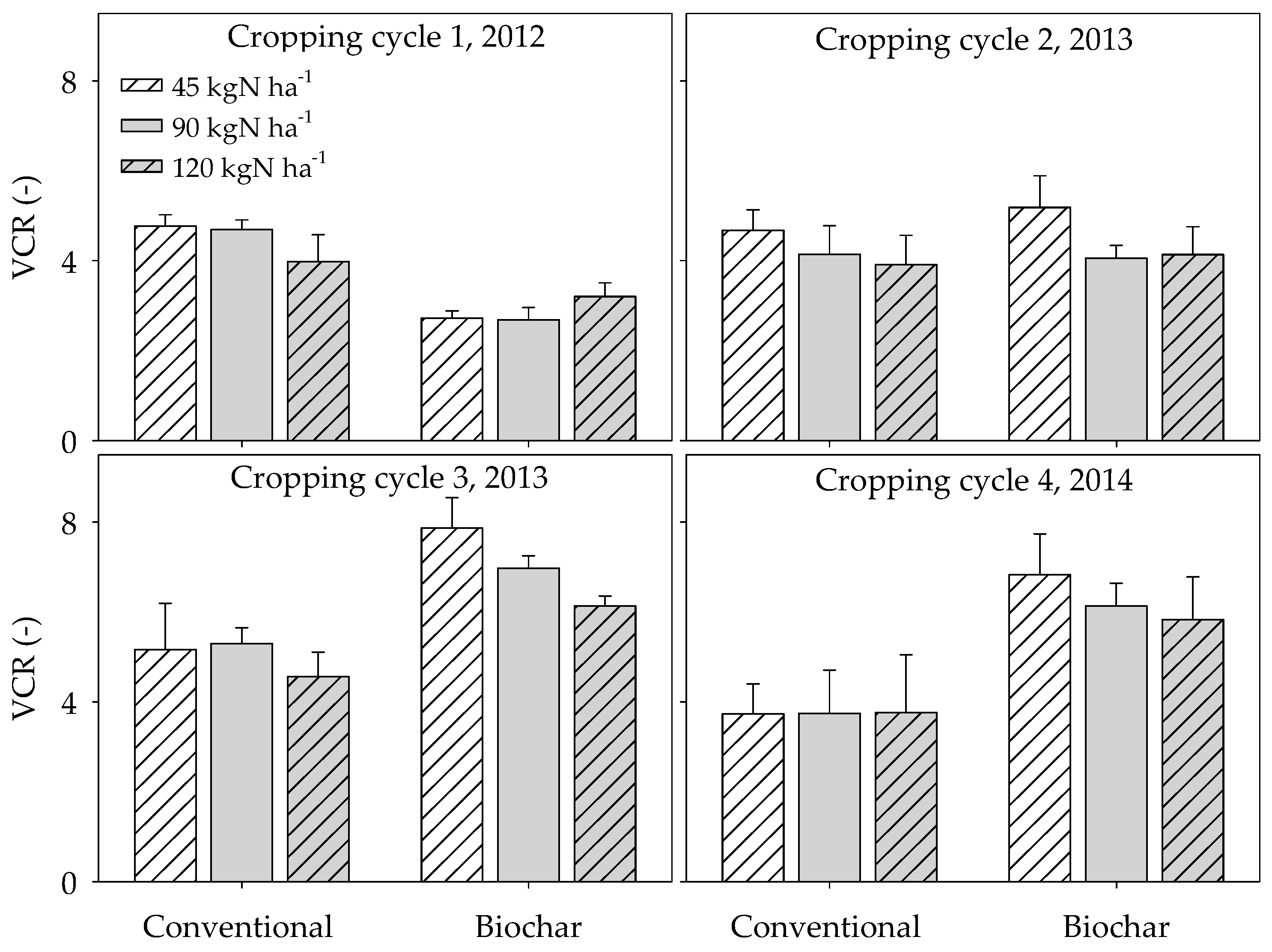

3.9. Economic Performance Indicators

4. Discussion

4.1. Soil-Biochar Interactions

4.2. Biochar Crop Development and Root Volume

4.3. Straw and Grain Yield

4.4. Nutrient Uptake and Use Efficiency

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mwangi, W.M. Low use of fertilizers and low productivity in sub-Saharan Africa. Nutr. Cycl. Agroecosyst. 1996, 47, 135–147. [Google Scholar] [CrossRef]

- Bumb, B.L.; Johnson, M.E.; Fuentes, P.A. Policy Options for Improving Regional Fertilizer Markets in West Africa; IFPRI Discussion Paper 01084; IFPRI: Washington, DC, USA, 2011; p. 73. [Google Scholar]

- Sanchez, P.A.; Denning, G.L.; Nziguheba, G. The African green revolution moves forward. Food Secur. 2009, 1, 37–44. [Google Scholar] [CrossRef]

- Vanlauwe, B.; Kihara, J.; Chivenge, P.; Pypers, P.; Coe, R.; Six, J. Agronomic use efficiency of N fertilizer in maize-based systems in sub-Saharan Africa within the context of integrated soil fertility management. Plant Soil 2011, 339, 35–50. [Google Scholar] [CrossRef]

- Castelli, F.; Ceotto, E.; Borrelli, L.; Cabassi, G.; Moschella, A.; Fornara, D. No-till permanent meadow promotes soil carbon sequestration and nitrogen use efficiency at the expense of productivity. Agron. Sustain. Dev. 2017, 37, 55. [Google Scholar] [CrossRef]

- Kihara, J.; Huising, J.; Nziguheba, G.; Waswa, B.S.; Njoroge, S.; Kabambe, V.; Iwuafor, E.; Kibunja, C.; Esilaba, A.O.; Coulibaly, A. Maize response to macronutrients and potential for profitability in sub-Saharan Africa. Nutr. Cycl. Agroecosyst. 2016, 105, 171–181. [Google Scholar] [CrossRef]

- MacCarthy, D.S.; Sommer, R.; Vlek, P.L. Modeling the impacts of contrasting nutrient and residue management practices on grain yield of sorghum (Sorghum bicolor (L.) Moench) in a semi-arid region of Ghana using APSIM. Field Crop. Res. 2009, 113, 105–115. [Google Scholar] [CrossRef]

- Iwasaki, S.; Endo, Y.; Hatano, R. The effect of organic matter application on carbon sequestration and soil fertility in upland fields of different types of Andosols. Soil Sci. Plant Nutr. 2017, 63, 200–220. [Google Scholar] [CrossRef]

- Oades, J. Soil organic matter and structural stability: Mechanisms and implications for management. Plant Soil 1984, 76, 319–337. [Google Scholar] [CrossRef]

- Kleemann, L.; Abdulai, A. Organic Certification, Agro-Ecological Practices and Return on Investment: Farm Level Evidence from Ghana; Kiel Working Paper: Kiel, Germany, 2012; pp. 4–21. [Google Scholar]

- Bossio, D.A.; Horwath, W.R.; Mutters, R.G.; van Kessel, C. Methane pool and flux dynamics in a rice field following straw incorporation. Soil Biol. Biochem. 1999, 31, 1313–1322. [Google Scholar] [CrossRef]

- Devêvre, O.C.; Horwáth, W.R. Decomposition of rice straw and microbial carbon use efficiency under different soil temperatures and moistures. Soil Biol. Biochem. 2000, 32, 1773–1785. [Google Scholar] [CrossRef]

- Kanouo, B.M.D.; Allaire, S.E.; Munson, A.D. Quantifying the influence of eucalyptus bark and corncob biochars on the physico-chemical properties of a tropical oxisol under two soil tillage modes. Int. J. Recycl. Org. Waste Agric. 2019, 8, 211–224. [Google Scholar] [CrossRef]

- Haefele, S.; Konboon, Y.; Wongboon, W.; Amarante, S.; Maarifat, A.; Pfeiffer, E.; Knoblauch, C. Effects and fate of biochar from rice residues in rice-based systems. Field Crop. Res. 2011, 121, 430–440. [Google Scholar] [CrossRef]

- Coomes, O.T.; Miltner, B.C. Indigenous charcoal and biochar production: Potential for soil improvement under shifting cultivation systems. Land Degrad. Dev. 2017, 28, 811–821. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. Biochar production potential in Ghana—A review. Renew. Sustain. Energy Rev. 2011, 15, 3539–3551. [Google Scholar] [CrossRef]

- Shackley, S.; Carter, S.; Knowles, T.; Middelink, E.; Haefele, S.; Sohi, S.; Cross, A.; Haszeldine, S. Sustainable gasification–biochar systems? A case-study of rice-husk gasification in Cambodia, Part I: Context, chemical properties, environmental and health and safety issues. Energy Policy 2012, 42, 49–58. [Google Scholar] [CrossRef]

- Shackley, S.; Sohi, S. Benefits and Issues Associated with the Application of Biochar to Soil; A report commissioned by the UK Department for Environment, Food and Rural Affairs and Department of Energy and Climate Change; DECC: London, UK, 2010; 132p. [Google Scholar]

- Arif, M.; Ilyas, M.; Riaz, M.; Ali, K.; Shah, K.; Haq, I.U.; Fahad, S. Biochar improves phosphorus use efficiency of organic-inorganic fertilizers, maize-wheat productivity and soil quality in a low fertility alkaline soil. Field Crop. Res. 2017, 214, 25–37. [Google Scholar] [CrossRef]

- Oladele, S.; Adeyemo, A.; Awodun, M.; Ajayi, A.; Fasina, A. Effects of biochar and nitrogen fertilizer on soil physicochemical properties, nitrogen use efficiency and upland rice (Oryza sativa) yield grown on an Alfisol in Southwestern Nigeria. Int. J. Recycl. Org. Waste Agric. 2019, 336, 1–11. [Google Scholar] [CrossRef]

- Faloye, O.; Alatise, M.; Ajayi, A.; Ewulo, B. Synergistic effects of biochar and inorganic fertiliser on maize (zea mays) yield in an alfisol under drip irrigation. Soil Tillage Res. 2017, 174, 214–220. [Google Scholar] [CrossRef]

- Yeboah, E.; Asamoah, G.; Kofi, B.; Abunyewa, A.A. Effect of biochar type and rate of application on maize yield indices and water use efficiency on an Ultisol in Ghana. Energy Procedia 2016, 93, 14–18. [Google Scholar] [CrossRef]

- Manso, E.F.; Nartey, E.; Adjadeh, T.; Darko, D.; Lawson, I.; Amoatey, C. Use of Corn Cob and Rice Husk Biochar as Liming Materials in Acid Soils. West Afr. J. Appl. Ecol. 2019, 27, 32–50. [Google Scholar]

- Lehmann, J.; da Silva, J.P.; Steiner, C.; Nehls, T.; Zech, W.; Glaser, B. Nutrient availability and leaching in an archaeological Anthrosol and a Ferralsol of the Central Amazon basin: Fertilizer, manure and charcoal amendments. Plant Soil 2003, 249, 343–357. [Google Scholar] [CrossRef]

- Liang, B.; Lehmann, J.; Solomon, D.; Kinyangi, J.; Grossman, J.; O’neill, B.; Skjemstad, J.; Thies, J.; Luizao, F.; Petersen, J. Black carbon increases cation exchange capacity in soils. Soil Sci. Soc. Am. J. 2006, 70, 1719–1730. [Google Scholar] [CrossRef]

- Fidel, R.B.; Laird, D.A.; Parkin, T.B. Effect of biochar on soil greenhouse gas emissions at the laboratory and field scales. Soil Syst. 2019, 3, 8. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, L.; Cheng, H.; Yue, S.; Li, S. Effects of biochar application on CO2 emissions from a cultivated soil under semiarid climate conditions in Northwest China. Sustainability 2017, 9, 1482. [Google Scholar] [CrossRef]

- Si, L.; Xie, Y.; Ma, Q.; Wu, L. The short-term effects of rice straw biochar, nitrogen and phosphorus fertilizer on rice yield and soil properties in a cold waterlogged paddy field. Sustainability 2018, 10, 537. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, H.; Yang, S.; Wang, Y. Impacts of biochar addition on rice yield and soil properties in a cold waterlogged paddy for two crop seasons. Field Crop. Res. 2016, 191, 161–167. [Google Scholar] [CrossRef]

- Sarfraz, R.; Shakoor, A.; Abdullah, M.; Arooj, A.; Hussain, A.; Xing, S. Impact of integrated application of biochar and nitrogen fertilizers on maize growth and nitrogen recovery in alkaline calcareous soil. Soil Sci. Plant Nutr. 2017, 63, 488–498. [Google Scholar] [CrossRef]

- Nwajiaku, I.M.; Olanrewaju, J.S.; Sato, K.; Tokunari, T.; Kitano, S.; Masunaga, T. Change in nutrient composition of biochar from rice husk and sugarcane bagasse at varying pyrolytic temperatures. Int. J. Recycl. Org. Waste Agric. 2018, 7, 269–276. [Google Scholar] [CrossRef]

- Amatekpor, J.K.; Dowuona, G.N.N. Site Characterization. IBSRAM Vertisol Project; Department of Soil Science, University of Ghana: Legon, Ghana, 1995; p. 42. [Google Scholar]

- Steiner, C.; Bellwood-Howard, I.; Häring, V.; Tonkudor, K.; Addai, F.; Atiah, K.; Abubakari, A.H.; Kranjac-Berisavljevic, G.; Marschner, B.; Buerkert, A. Participatory trials of on-farm biochar production and use in Tamale, Ghana. Agron. Sustain. Dev. 2018, 38, 12. [Google Scholar] [CrossRef]

- Walkley, A.; Black, A. Organic matter was determined by wet digestion: An examination of the Degtjareff method for determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Watanabe, F.; Olsen, S. Test of an ascorbic acid method for determining phosphorus in water and NaHCO3 extracts from soil 1. Soil Sci. Soc. Am. J. 1965, 29, 677–678. [Google Scholar] [CrossRef]

- Bremmer, J.M. Total Nitrogen. In Methods of Soil Analysis. Part 2 Chemical and Microbiological Properties; Agronomy Monograph 9; Black, C.A., Ed.; America Society of Agronomy-Soil Science Society of America: Madision, WI, USA, 1965; pp. 1149–1178. [Google Scholar]

- Murphy, J.; Riley, J.P. A modified single solution method for the determination of phosphate in natural waters. Anal. Chim. Acta 1962, 27, 31–36. [Google Scholar] [CrossRef]

- Day, P.R. Fractionation and particle-size analysis. In Methods of Soil Analysis; Agronomy No. 9 Part 1; Black, C.A., Ed.; America Society of Agronomy-Soil Science Society of America: Madison, WI, USA, 1965; Volume 9, pp. 545–567. [Google Scholar]

- Ministry of Food and Agriculture, (MoFA). Statistics Research and Information Directorate, (SRID); Commodity Prices Unit.: Accra, Ghana, 2014. [Google Scholar]

- Bank of Ghana (BoG). Historical Interbank FX Rates. Available online: https://www.bog.gov.gh/treasury-and-the-markets/historical-interbank-fx-rates/ (accessed on 10 April 2020).

- Masulili, A.; Utomo, W.H.; Syechfani, M. Rice husk biochar for rice based cropping system in acid soil 1. The characteristics of rice husk biochar and its influence on the properties of acid sulfate soils and rice growth in West Kalimantan, Indonesia. J. Agric. Sci. 2010, 2, 39. [Google Scholar] [CrossRef]

- Wiesmeier, M.; Urbanski, L.; Hobley, E.; Lang, B.; von Lützow, M.; Marin-Spiotta, E.; van Wesemael, B.; Rabot, E.; Ließ, M.; Garcia-Franco, N. Soil organic carbon storage as a key function of soils-A review of drivers and indicators at various scales. Geoderma 2019, 333, 149–162. [Google Scholar] [CrossRef]

- Wonprasaid, S.; Khunthasuvon, S.; Sittisuang, P.; Fukai, S. Performance of contrasting rice cultivars selected for rainfed lowland conditions in relation to soil fertility and water availability. Field Crop. Res. 1996, 47, 267–275. [Google Scholar] [CrossRef]

- Ahmed, N.; Tetlow, I.J.; Nawaz, S.; Iqbal, A.; Mubin, M.; Nawaz ul Rehman, M.S.; Butt, A.; Lightfoot, D.A.; Maekawa, M. Effect of high temperature on grain filling period, yield, amylose content and activity of starch biosynthesis enzymes in endosperm of basmati rice. J. Sci. Food Agric. 2015, 95, 2237–2243. [Google Scholar] [CrossRef]

- Fahad, S.; Bajwa, A.A.; Nazir, U.; Anjum, S.A.; Farooq, A.; Zohaib, A.; Sadia, S.; Nasim, W.; Adkins, S.; Saud, S. Crop production under drought and heat stress: Plant responses and management options. Front. Plant Sci. 2017, 8, 1147. [Google Scholar] [CrossRef]

- MacCarthy, D.; Vlek, P.L. Impact of climate change on sorghum production under different nutrient and crop residue management in semi-arid region of Ghana: A modeling perspective. Afr. Crop Sci. J. 2012, 20, 243–259. [Google Scholar]

- Olmo, M.; Alburquerque, J.A.; Barrón, V.; Del Campillo, M.C.; Gallardo, A.; Fuentes, M.; Villar, R. Wheat growth and yield responses to biochar addition under Mediterranean climate conditions. Biol. Fertil. Soils 2014, 50, 1177–1187. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar impacts on soil physical properties and greenhouse gas emissions. Agronomy 2013, 3, 313–339. [Google Scholar] [CrossRef]

- Koyama, S.; Hayashi, H. Rice yield and soil carbon dynamics over three years of applying rice husk charcoal to an Andosol paddy field. Plant Prod. Sci. 2017, 20, 176–182. [Google Scholar] [CrossRef]

- Zhang, A.; Bian, R.; Pan, G.; Cui, L.; Hussain, Q.; Li, L.; Zheng, J.; Zheng, J.; Zhang, X.; Han, X. Effects of biochar amendment on soil quality, crop yield and greenhouse gas emission in a Chinese rice paddy: A field study of 2 consecutive rice growing cycles. Field Crop. Res. 2012, 127, 153–160. [Google Scholar] [CrossRef]

- Jagadish, S.V.K.; Craufurd, P.Q.; Wheeler, T.R. High temperature stress and spikelet fertility in rice (Oryza sativa L.). J. Exp. Bot. 2007, 58, 1627–1635. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Aggarwal, P.; Yadav, R. Growth and Yield Response of Rice under Heat Stress during Vegetative, Reproductive, and Ripening Growth Phases; IRRI: Los Baños, Philippines, 2010; pp. 1–4. [Google Scholar]

- Krishnan, P.; Ramakrishnan, B.; Reddy, K.R.; Reddy, V. High-temperature effects on rice growth, yield, and grain quality. Adv. Agron. 2011, 111, 87–206. [Google Scholar]

- Yousaf, M.; Li, X.; Zhang, Z.; Ren, T.; Cong, R.; Ata-Ul-Karim, S.T.; Fahad, S.; Shah, A.N.; Lu, J. Nitrogen fertilizer management for enhancing crop productivity and nitrogen use efficiency in a rice-oilseed rape rotation system in China. Front. Plant Sci. 2016, 7, 1496. [Google Scholar] [CrossRef]

- Tsujimoto, Y.; Inusah, B.; Katsura, K.; Fuseini, A.; Dogbe, W.; Zakaria, A.I.; Fujihara, Y.; Oda, M.; Sakagami, J.-I. The effect of sulfur fertilization on rice yields and nitrogen use efficiency in a floodplain ecosystem of northern Ghana. Field Crop. Res. 2017, 211, 155–164. [Google Scholar] [CrossRef]

- Tsujimoto, Y.; Rakotoson, T.; Tanaka, A.; Saito, K. Challenges and opportunities for improving N use efficiency for rice production in sub-Saharan Africa. Plant Prod. Sci. 2019, 22, 413–427. [Google Scholar] [CrossRef]

- Fixen, P.; Brentrup, F.; Bruulsema, W.T.; Garcia, F.; Norton, R.; Zingore, S. Nutrient/fertilizer use efficiency: Measurement, current situation and trends. In Managing Water Fertilizer for Sustainable Agricultural Intensification; Drechsel, P., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA): Paris, France; International Water Management Institute (IWMI): Colombo, Sri Lanka; International Plant Nutrition Institute (IPNI): Norcross, GA, USA; International Potash Institute (IPI): Horgen, Switzerland, 2015; Volume 270, pp. 1–29. [Google Scholar]

- Montemurro, F.; Diacono, M. Towards a better understanding of agronomic efficiency of nitrogen: Assessment and improvement strategies. Agronomy 2016, 6, 31. [Google Scholar] [CrossRef]

- Chikowo, R.; Corbeels, M.; Mapfumo, P.; Tittonell, P.; Vanlauwe, B.; Giller, K.E. Nitrogen and phosphorus capture and recovery efficiencies, and crop responses to a range of soil fertility management strategies in sub-Saharan Africa. In Innovations as Key to the Green Revolution in Africa; Springer: Berlin/Heidelberg, Germany, 2011; pp. 571–589. [Google Scholar] [CrossRef]

- Agyin-Birikorang, S.; Tindjina, I.; Boubakary, C.; Dogbe, W.; Singh, U. Resilient rice fertilization strategy for submergence-prone savanna agro-ecological zones of Northern Ghana. J. Plant Nutr. 2020, 43, 965–986. [Google Scholar] [CrossRef]

- Tovihoudji, P.G.; Akponikpè, P.I.; Adjogboto, A.; Djenontin, J.A.; Agbossou, E.K.; Bielders, C.L. Combining hill-placed manure and mineral fertilizer enhances maize productivity and profitability in northern Benin. Nutr. Cycl. Agroecosyst. 2018, 110, 375–393. [Google Scholar] [CrossRef]

- Njoroge, R.; Otinga, A.N.; Okalebo, J.R.; Pepela, M.; Merckx, R. Maize (Zea mays L.) response to secondary and micronutrients for profitable N, P and K fertilizer use in poorly responsive soils. Agronomy 2018, 8, 49. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar] [CrossRef]

- Adjei-Nsiah, S.; Leeuwis, C.; Sakyi-Dawson, O.; Giller, K.; Kuyper, T. Exploring diversity among farmers for orienting inter-disciplinary action research on cropping system management in Wenchi, Ghana: The significance of time horizons. Int. J. Agric. Sustain. 2007, 5, 176–194. [Google Scholar] [CrossRef]

| Items | Per Cycle (US$) |

|---|---|

| Labor cost | |

| Biochar preparation (tonne−1) | 17 |

| Herbicide application (ha−1) | 42 |

| Transplanting (ha−1) | 83 |

| Irrigation (ha−1) | 83 |

| Fertilizer application (ha−1) | 21 |

| Biochar application (ha−1) | 21 |

| Scaring birds (ha−1) | 83 |

| Drying & bagging (ha−1) | 42 |

| Input cost | |

| Cost of water for irrigation (ha−1) | 83 |

| Cost of herbicides | |

| 2 L of 2-4-D (ha−1) | 8 |

| 4 litters of Bounty (ha−1) | 42 |

| Fertilizer Cost | |

| NPK 15:15:15 (kg−1) | 0.37 |

| Urea (kg−1) | 0.31 |

| Rice seed (ha−1) | 37 |

| Other cost | |

| Ploughing (ha−1) | 125 |

| Cost of mechanized harvesting (ha−1) | 117 |

| Land rental (ha−1) | 62 |

| Selling price of rice (US$ tonne−1) | 430 |

| Parameter | Rice Husk | Rice Husk Biochar |

|---|---|---|

| Bulk density (g·cm−3) | 0.13 | 0.22 |

| pH (H2O) | 5.90 | 6.60 |

| Total C (g·kg−1) | 340 | 384 |

| Total N (g·kg−1) | 7.1 | 0.80 |

| K (cmolc·kg−1) | 0.38 | 0.53 |

| Na (cmolc·kg−1) | 0.90 | 1.17 |

| Available P (mg·kg−1) | np | 1620 |

| Exchangeable Ca (cmolc·kg−1) | 0.32 | 0.61 |

| Exchangeable Mg (cmolc·kg−1) | 0.22 | 0.36 |

| CEC (cmolc·kg−1) | np | 20.30 |

| Soil Depth | Bulk Density | Particle Size Distribution | pH | OC | TN | ||

|---|---|---|---|---|---|---|---|

| Sand | Silt | Clay | |||||

| (cm) | (g·cm−3) | (g·kg−1) | (H2O) | (g·kg−1) | |||

| 0–15 | 1.37 (0.03) | 298 (27) | 122 (37) | 580 (36) | 6.90 (0.30) | 6.7 (0.7) | 0.6 (0.1) |

| 15–30 | 1.45 (0.04) | 284 (33) | 96 (38) | 621 (54) | 7.10 (0.20) | 5.3 (0.4) | 0.5 (0.1) |

| 30–45 | 1.64 (0.03) | 251 (27) | 129 (31) | 620 (33) | 7.10 (0.20) | 4.5 (0.4) | 0.5 (0.1) |

| Exchangeable bases | |||||||

| TP | Av. P | K | Na | Ca | Mg | CEC | |

| (mg·kg−1) | (cmol·kg−1) | ||||||

| 0–15 | 241.0 (18) | 5.43 (0.56) | 0.51 (0.14) | 0.90 (0.19) | 21.06 (2.92) | 10.13 (1.80) | 37.22 (4.74) |

| 15–30 | 241.0 (14) | 4.25 (0.30) | 0.59 (0.18) | 0.94 (0.24) | 17.70 (2.35) | 12.27 (2.86) | 36.81 (4.43) |

| 30–45 | 207 (11) | 3.48 (0.34) | 0.30 (0.12) | 0.73 (0.14) | 17.20 (3.54) | 10.67 (2.83) | 31.68 (3.74) |

| Variables | Sources of Variation (p Values) | ||||||

|---|---|---|---|---|---|---|---|

| Cropping Cycle (C) | Biochar (B) | Nitrogen (N) | C × B | C × N | B × N | C × B × N | |

| Root volume (cm3) | <0.001 | <0.001 | <0.001 | <0.001 | 0.006 | <0.001 | <0.001 |

| Grain yield (t·ha−1) | <0.001 | <0.001 | <0.001 | 0.029 | <0.001 | 0.004 | 0.401 |

| Straw yield (t·ha−1) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.003 | <0.001 |

| Grain filling (%) | <0.001 | 0.988 | <0.001 | 0.021 | <0.001 | 0.034 | 0.343 |

| Grain N (kg·ha−1) | <0.001 | <0.001 | <0.001 | <0.001 | 0.004 | <0.001 | 0.001 |

| Grain P (kg·ha−1) | <0.001 | <0.001 | <0.001 | 0.001 | <0.001 | <0.001 | 0.484 |

| Grain K (kg·ha−1) | <0.001 | <0.001 | <0.001 | 0.099 | 0.012 | <0.001 | 0.724 |

| Straw N (kg·ha−1) | <0.001 | <0.001 | <0.001 | 0.037 | 0.005 | 0.030 | 0.010 |

| Straw P (kg·ha−1) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Straw K (kg·ha−1) | <0.001 | <0.001 | <0.001 | 0.002 | <0.001 | <0.001 | <0.001 |

| AEN (kg·grain·kg−1·N) | 0.001 | 0.022 | <0.001 | 0.307 | 0.939 | 0.828 | 0.996 |

| ARE (kg·grain·kg−1·N) | 0.002 | <0.001 | <0.001 | 0.181 | 1.000 | 0.933 | 0.977 |

| GM (USD·ha−1) | <0.001 | <0.001 | <0.001 | 0.040 | 0.001 | 0.011 | 0.644 |

| GR (USD·ha−1) | <0.001 | <0.001 | <0.001 | 0.040 | 0.001 | 0.011 | 0.644 |

| VCR | <0.001 | <0.001 | <0.001 | <0.001 | 0.003 | 0.032 | <0.001 |

| Biochar (t·ha−1) | N Rate (kg·ha−1) | Cycle 1 (Vol (cm3)) | Cycle 2 (Vol (cm3)) |

|---|---|---|---|

| 0 | 0 | 23.00e | 20.87d |

| 45 | 31.67d | 37.67c | |

| 90 | 35.33c | 39.33c | |

| 120 | 38.67b | 50.00b | |

| 10 | 0 | 22.67e | 36.00c |

| 45 | 32.30cd | 37.67c | |

| 90 | 41.33b | 51.67b | |

| 120 | 48.00a | 60.33a | |

| pvalue (5%) | |||

| Biochar (B) | <0.001 | <0.001 | |

| N rates (N) | <0.001 | <0.001 | |

| B × N | <0.001 | 0.002 |

| Biochar (t·ha−1) | N Rate (kg·ha−1) | Grain Yield (t·ha−1) | Straw Yield (t·ha−1) | Grain Filling (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | ||

| 0 | 0 | 2.58f | 2.33g | 2.83f | 2.42g | 3.81f | 3.40d | 3.92d | 3.91d | 88.60a | 79.17ab | 86.93ab | 77.43ab |

| 45 | 3.68d | 3.33e | 3.93d | 3.22ef | 4.78e | 3.68d | 4.65c | 4.92c | 87.80ab | 78.23bc | 87.13a | 76.90abc | |

| 90 | 4.49c | 3.89d | 4.83bc | 3.84cd | 6.44c | 5.74b | 5.25b | 5.68ab | 85.10cd | 78.23bc | 84.80d | 75.33cd | |

| 120 | 4.67c | 4.23bc | 5.05b | 4.26bc | 7.42b | 6.60a | 6.24a | 5.94a | 84.20d | 75.67d | 83.68e | 75.67cd | |

| 10 | 0 | 2.99e | 2.84f | 3.29e | 2.72fg | 3.70f | 3.72d | 4.20d | 4.31d | 89.27a | 79.77a | 86.17bc | 78.37a |

| 45 | 4.40c | 3.94cd | 4.51c | 3.67de | 5.43d | 5.07c | 5.46b | 5.24bc | 86.80bc | 78.47ab | 85.63cd | 76.47bcd | |

| 90 | 5.24b | 4.37b | 5.47a | 4.40ab | 7.77b | 5.23bc | 6.37a | 5.48b | 85.87cd | 78.13bc | 85.00d | 76.47bcd | |

| 120 | 6.03a | 4.85a | 5.82a | 4.85a | 8.60a | 6.56a | 6.51a | 6.07a | 84.13d | 76.97c | 82.47f | 74.87d | |

| p value (5%) | |||||||||||||

| Biochar (B) | <0.001 | <0.001 | <0.001 | 0.002 | <0.001 | 0.062 | <0.001 | 0.136 | 0.811 | 0.106 | 0.001 | 0.560 | |

| N rates (N) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| B × N | 0.001 | 0.814 | 0.705 | <0.827 | <0.001 | 0.002 | 0.009 | 0.220 | 0.384 | 0.409 | 0.052 | 0.172 | |

| Biochar (t·ha−1) | N Rate (kg·ha−1) | AEN (kg grain kg−1·N) | ARE (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | ||

| 0 | 45 | 24c | 22b | 25c | 18b | 54ab | 48b | 57bc | 53ab |

| 90 | 21d | 17c | 22cd | 16b | 47bc | 43bc | 51cd | 50b | |

| 120 | 17e | 16c | 19d | 15b | 41c | 38c | 47d | 45b | |

| 10 | 45 | 40a | 36a | 37a | 33a | 64a | 57a | 70a | 58a |

| 90 | 30b | 23b | 29b | 19b | 62a | 50ab | 62ab | 48b | |

| 120 | 29b | 21b | 25c | 20b | 58ab | 46bc | 60bc | 46b | |

| p value (5%) | |||||||||

| Biochar (B) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.004 | <0.001 | 0.405 | |

| N rates (N) | <0.001 | <0.001 | <0.001 | <0.001 | 0.05 | 0.008 | 0.018 | 0.009 | |

| B × N | 0.002 | 0.003 | 0.041 | 0.01 | 0.649 | 0.934 | 0.954 | 0.461 | |

| Biochar (t·ha−1) | N Rate (kg·ha−1) | Avail. P (mg·kg−1) | CEC (cmol·kg−1) | SOC (g·kg−1) | TN (g·kg−1) | TP (mg·kg−1) | pH | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | Initial | Final | Initial | Final | Initial | Final | Initial | Final | Initial | Final | ||

| 0 | 0 | 5.43 | 5.6b | 37 | 37c | 6.7 | 6.7b | 0.6 | 0.51b | 241 | 256c | 6.6 | 6.6a |

| 120 | 6.3b | 38bc | 7.1b | 0.57ab | 278c | 6.6a | |||||||

| 10 | 0 | 7.7a | 41ab | 8.2a | 0.64a | 300b | 6.8a | ||||||

| 120 | 8.1a | 44a | 9.3a | 0.68a | 339a | 6.8a | |||||||

| p value (5%) | |||||||||||||

| Biochar (B) | <0.001 | <0.001 | <0.001 | 0.004 | 0.002 | 0.010 | |||||||

| N rates (N) | 0.163 | 0.049 | <0.001 | 0.086 | <0.001 | 0.551 | |||||||

| B × N | 0.958 | 0.144 | 0.201 | 0.679 | 0.185 | 0.631 | |||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

MacCarthy, D.S.; Darko, E.; Nartey, E.K.; Adiku, S.G.K.; Tettey, A. Integrating Biochar and Inorganic Fertilizer Improves Productivity and Profitability of Irrigated Rice in Ghana, West Africa. Agronomy 2020, 10, 904. https://doi.org/10.3390/agronomy10060904

MacCarthy DS, Darko E, Nartey EK, Adiku SGK, Tettey A. Integrating Biochar and Inorganic Fertilizer Improves Productivity and Profitability of Irrigated Rice in Ghana, West Africa. Agronomy. 2020; 10(6):904. https://doi.org/10.3390/agronomy10060904

Chicago/Turabian StyleMacCarthy, Dilys S., Eric Darko, Eric K. Nartey, Samuel G. K. Adiku, and Abigail Tettey. 2020. "Integrating Biochar and Inorganic Fertilizer Improves Productivity and Profitability of Irrigated Rice in Ghana, West Africa" Agronomy 10, no. 6: 904. https://doi.org/10.3390/agronomy10060904

APA StyleMacCarthy, D. S., Darko, E., Nartey, E. K., Adiku, S. G. K., & Tettey, A. (2020). Integrating Biochar and Inorganic Fertilizer Improves Productivity and Profitability of Irrigated Rice in Ghana, West Africa. Agronomy, 10(6), 904. https://doi.org/10.3390/agronomy10060904