Maize Grain Composition with Additions of NPK Briquette and Organically Enhanced N Fertilizer

Abstract

1. Introduction

2. Materials and Methods

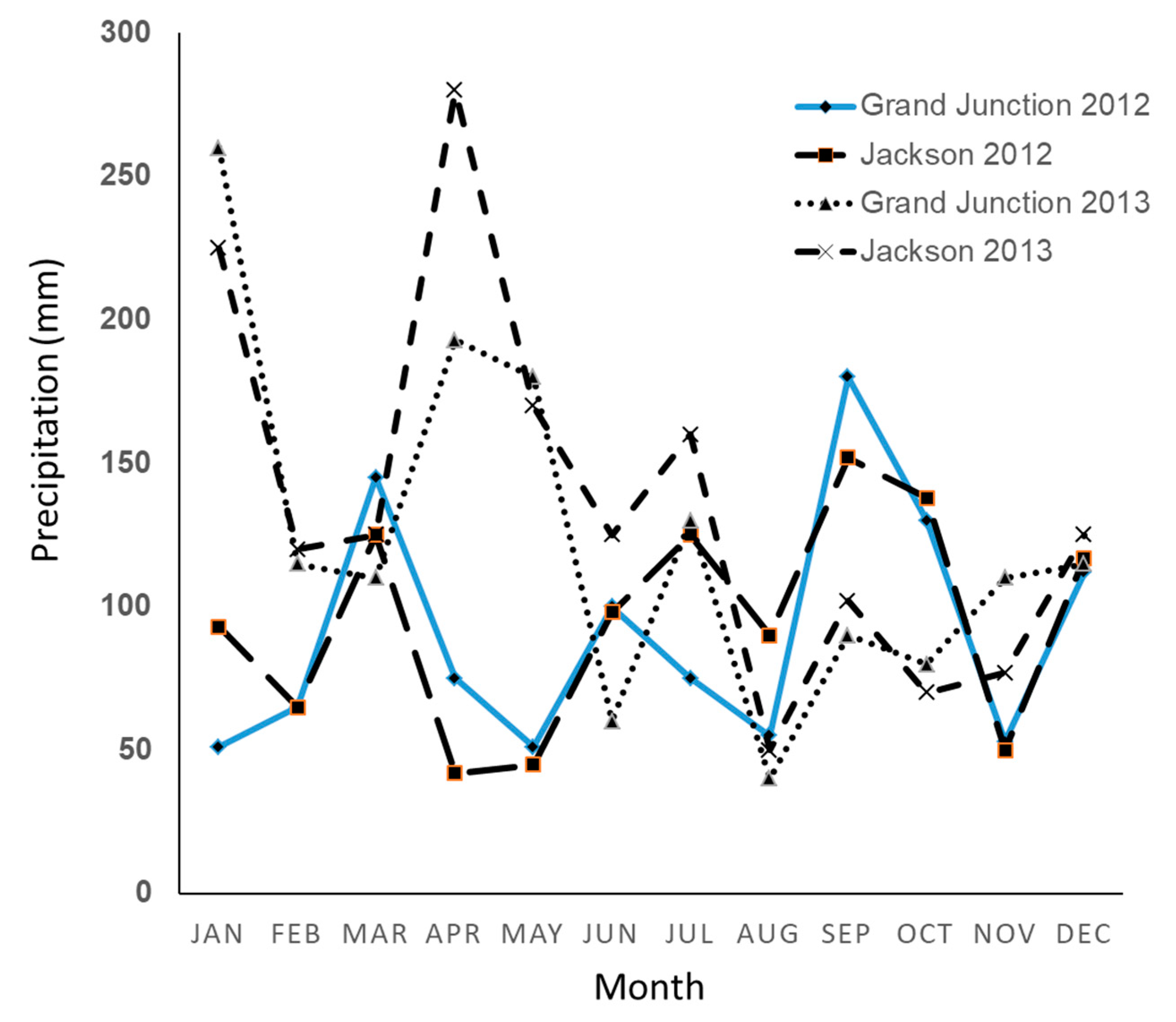

2.1. Experimental Site and Soil

2.2. Experimental Design and Sample Analysis

2.3. Statistical Analyses

3. Results and Discussions

3.1. Effects of N Fertilizer Source on Protein, Oil, Fiber, Ash, and Starch Concentrations

3.1.1. Protein

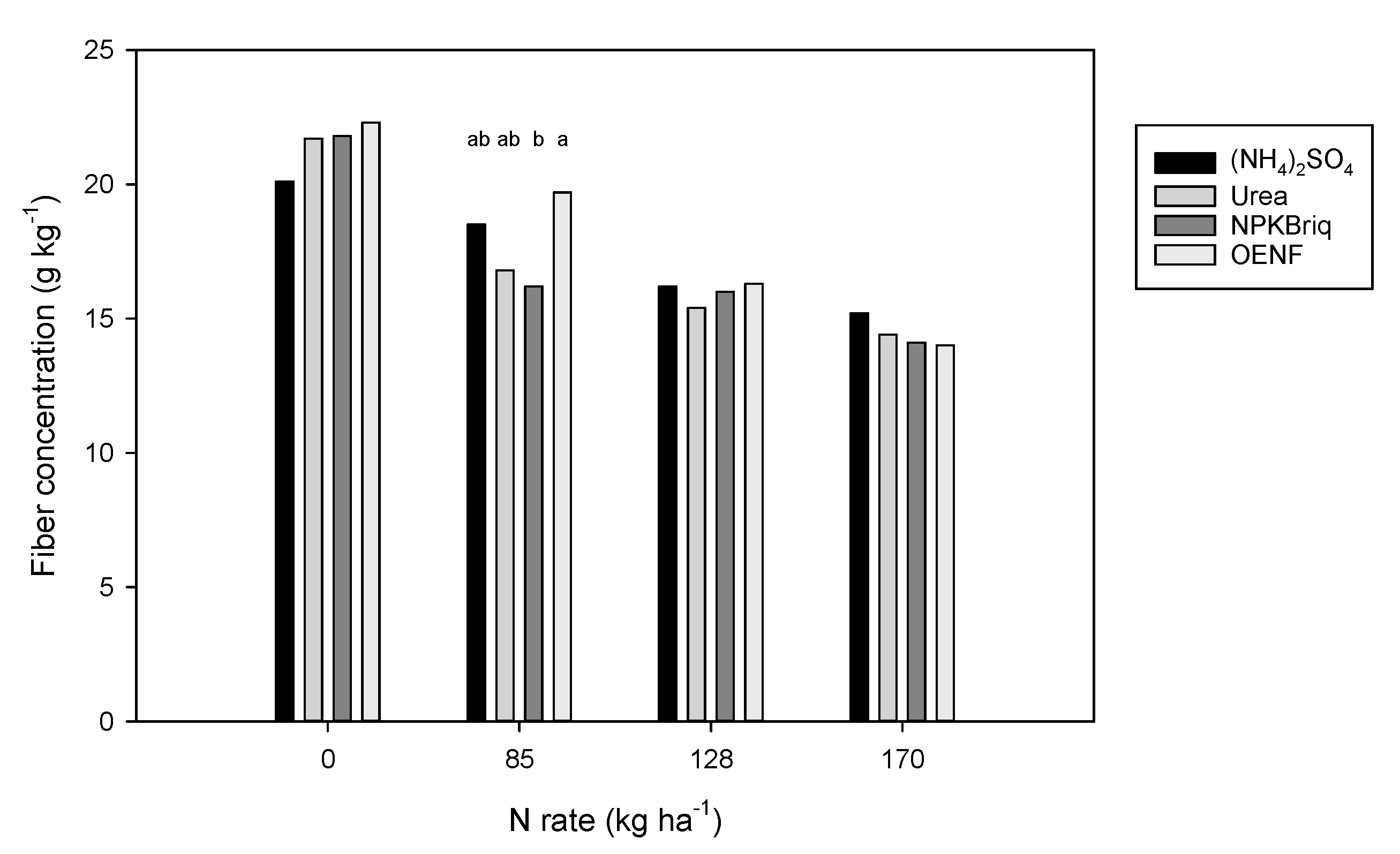

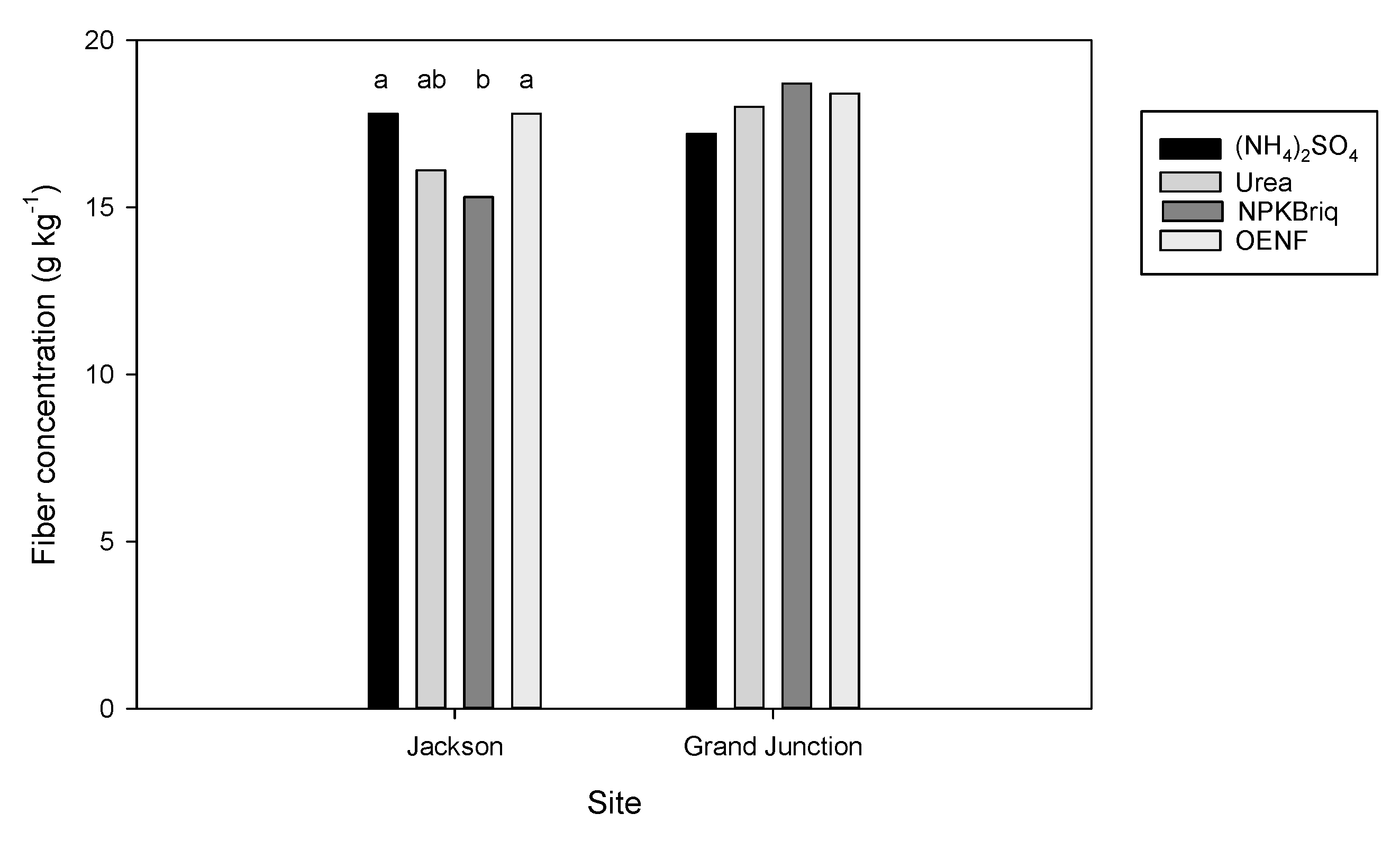

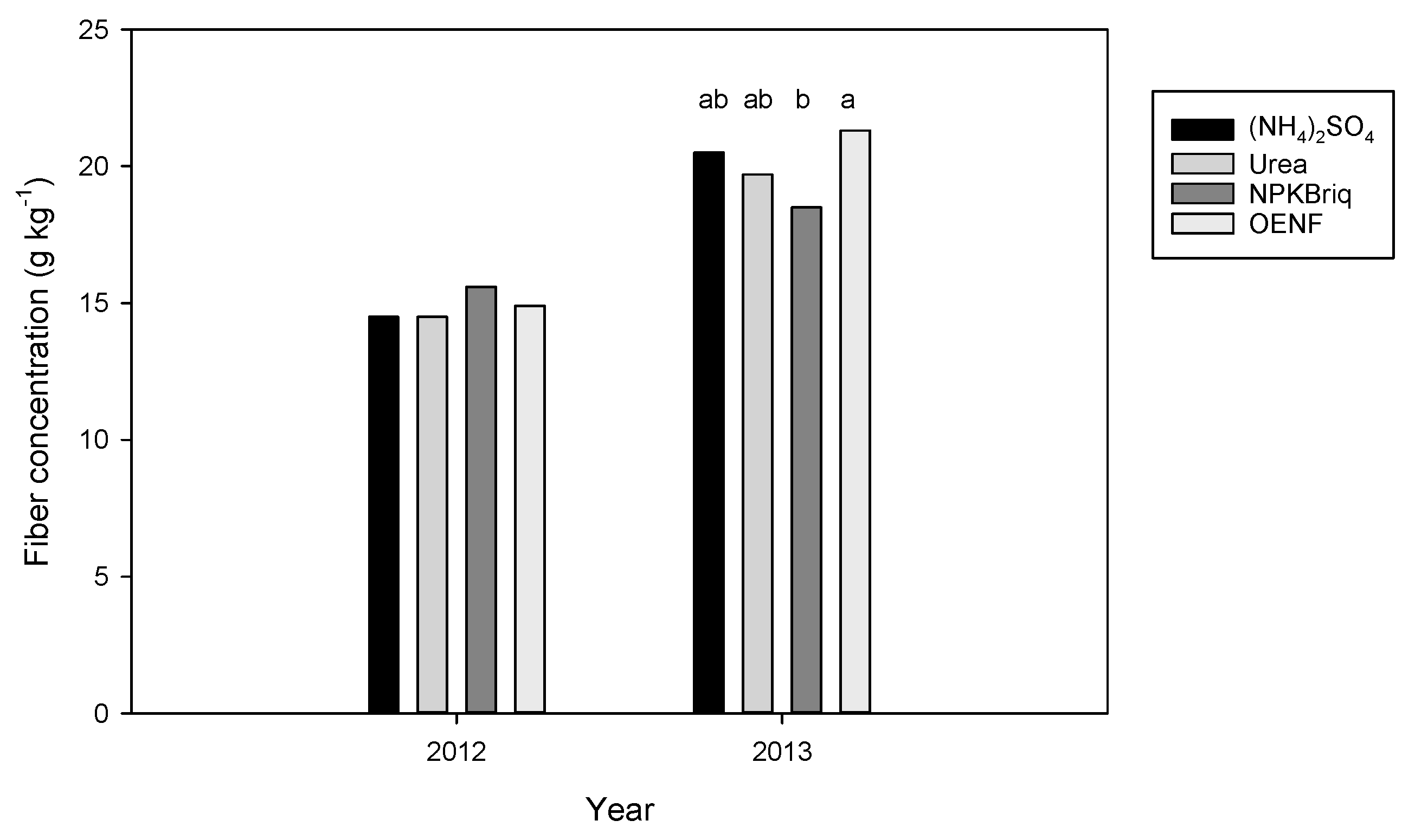

3.1.2. Fiber

3.2. Effects of N Fertilizer Source on Protein, Oil, Fiber, Ash, and Starch Yields

3.2.1. Protein

3.2.2. Oil

3.2.3. Fiber

3.2.4. Ash

3.2.5. Starch

3.3. Correlations Among Protein, Oil, Fiber, Ash, and Starch Concentrations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tadesse, A.; Kim, H.K. Yield related traits and yield of quality protein maize (Zea mays L.) affected by nitrogen levels to achieve maximum yield in the central Rift Valley of Ethiopia. J. Biol. Agric. Healthc. 2015, 5, 2224–3208. [Google Scholar]

- Zhong, W.; Zhang, Z.; Luo, Y.; Sun, S.; Qiao, W.; Xiao, M. Effect of biological pretreatments in enhancing corn straw biogas production. Bioresour. Technol. 2011, 102, 11177–11182. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT (Food and Agriculture Organization of the United Nations). Statistics Division. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 13 May 2014).

- Abbasi, M.K.; Tahir, M.M.; Rahim, N. Effect of N fertilizer source and timing on yield and N use efficiency of rainfed maize (Zea mays L.) in Kashmir–Pakistan. Geoderma 2013, 195, 87–93. [Google Scholar] [CrossRef]

- Szulc, P.; Bocianowski, J.; Kruczek, A.; Szymanska, G.; Roszkiewicz, R. Response of two cultivar types of maize (Zea mays L.) expressed in protein content and its yield to varied soil resources of N and Mg and a form of nitrogen fertilizer. Pol. J. Environ. Stud. 2013, 22, 1845–1853. [Google Scholar]

- Bautista, E.U.; Koike, M.; Suministrado, D.C. Mechanical deep placement of nitrogen in wetland rice. J. Agric. Eng. Res. 2001, 78, 333–346. [Google Scholar] [CrossRef]

- IFDC (International Fertilizer Development Center) Fertilizer Deep Placement. Mitigating Poverty and Environmental Degradation through Nutrient Management in South Asia; IFDC: Muscle Shoals, AL, USA, March 2007. [Google Scholar]

- IFDC (International Fertilizer Development Center) Fertilizer Deep Placement. IFDC Solutions; IFDC: Muscle Shoals, AL, USA; Available online: http://issuu.com/ifdcinfo/docs/fdp_8pg_final_web?e=1773260/1756718 (accessed on 22 May 2015).

- IFDC (International Fertilizer Development Center). IFDC Quarterly Magazine; IFDC: Muscle Shoals, AL, USA; Available online: http://ifdc.org/ifdc-magazine (accessed on 15 March 2015).

- Kapoor, V.; Singh, U.; Patil, S.K.; Magre, H.; Shrivastava, L.K.; Mishra, V.N.; Das, R.O.; Samadhiya, V.K.; Sanabria, J.; Diamond, R. Rice growth, grain yield and floodwater nutrient dynamics as affected by nutrient placement method and rate. Agron. J. 2008, 100, 526–536. [Google Scholar] [CrossRef]

- Islam, M.S.; Rahman, F.; Hossain, A. Effects of NPK Briquette on Rice (Oryza sativa) in Tidal Flooded Ecosystem. Agriculturalists 2011, 9, 37–43. [Google Scholar] [CrossRef]

- Bandaogo, A.; Fofana, B.; Youl, S.; Safo, E.; Abaidoo, R.C.; Andrews, O. Effect of fertilizer deep placement with urea supergranule on nitrogen use efficiency of irrigated rice in Sourou Valley (Burkina Faso). Nutr. Cycl. Agroecosyst. 2014, 102, 79–89. [Google Scholar] [CrossRef]

- Miah, A.M.; Gaihre, Y.K.; Hunter, G.; Singh, U.; Hossain, S.A. Fertilizer Deep Placement Increases Rice Production: Evidence from Farmers’ Fields in Southern Bangladesh. Agron. J. 2016, 108, 805–812. [Google Scholar] [CrossRef]

- Agyin-Birikorang, S.; Winings, J.H.; Yin, X.H.; Singh, U.; Sanabria, J. Field evaluation of agronomic effectiveness of balanced-nutrient fertilizer briquettes for upland crop production. Nutr. Cycl. Agroecosyst. 2018, 110, 395–406. [Google Scholar] [CrossRef]

- Savant, N.K.; Stangel, P.J. Deep placement of urea supergranules in transplanted rice: Principles and practices. FeNutrti. Cycl. Agroecosyst. 1990, 25, 1–83. [Google Scholar] [CrossRef]

- Huda, A.; Gaihre, Y.K.; Islam, M.R.; Singh, U.; Islam, R.; Sanabria, J.; Satter, M.A.; Afroz, H.; Halder, A.; Jahiruddin, M. Floodwater ammonium, nitrogen use efficiency and rice yields with fertilizer deep placement and alternate wetting and drying under triple rice cropping systems. Nutr. Cycl. Agroecosyst. 2016, 104, 53–66. [Google Scholar] [CrossRef]

- Gaihre, Y.K.; Singh, U.; Jahan, I.; Hunter, G. Improved nitrogen use efficiency in lowland rice fields for food security. Fertil. Focus 2017, 4, 48–51. [Google Scholar]

- Gaihre, Y.K.; Singh, U.; Islam, S.M.; Huda, A.; Satter, M.A.; Sanabria, J.; Islam, R.; Shah, A. Impacts of urea deep placement on nitrous oxide and nitric oxide emissions from rice fields in Bangladesh. Geoderma 2015, 6, 370–379. [Google Scholar] [CrossRef]

- NSF International. NSF Protocol P353: Sewage Sludge Sterilization in Organically Enhanced Granular Fertilizer Production; NSF International: Ann Arbor, MI, USA; Available online: www.nsf.org/business/engineering_and_research/protocols.asp?program=EngineeringSer (accessed on 30 August 2015).

- Singh, U.; Sanabria, J.; Austin, E.R.; Agyin-Birikorang, S. Nitrogen transformation, ammonia volatilization loss, and nitrate leaching in organically enhanced nitrogen fertilizers relative to urea. Soil Sci. Soc. Am. J. 2012, 76, 1842–1854. [Google Scholar] [CrossRef]

- Winings, J.H.; Yin, X.; Agyin-Birikorang, S.; Singh, U.; Sanabria, J.; Savoy, H.J.; Allen, F.L.; Saxton, A.M. Agronomic effectiveness of an organically enhanced nitrogen fertilizer. Nutr. Cycl. Agroecosyst. 2017, 108, 149–161. [Google Scholar] [CrossRef]

- Mehlich, A. Mehlich 3 soil test extractant: A modification of Mehlich 2 extractant. Commun. Soil Sci. Plant Anal. 1984, 15, 1409–1416. [Google Scholar] [CrossRef]

- Winings, J.H. Effects of Organically Enhanced Biofertilizer and Fertilizer Briquettes on Mineral Nutrition, Quality, and Yield of Corn and Soil Health. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2014. [Google Scholar]

- Reddy, K.; Bellaloui, N.; Zablotowicz, R. Glyphosate Effect on Shikimate, Nitrate Reductase Activity, Yield, and Seed Composition in Corn. J. Agric. Food Chem. 2010, 58, 3646–3650. [Google Scholar] [CrossRef]

- Zaidi, P.H.; Vasal, S.K.; Maniselvan, P.; Jha, G.C. Stability in performance of quality protein maize under abiotic stress. Maydica 2008, 53, 249−260. [Google Scholar]

- Zhang, F.; Mackenzie, A.F.; Smith, D.L. Corn yield and shifts among corn quality constituents following applications of different nitrogen fertilizer sources at several times during corn development. J. Plant Nutr. 1993, 16, 1317–1337. [Google Scholar] [CrossRef]

- Safdarian, M.; Razmjoo, J.; Dehnavi, M.M. Effect of nitrogen sources and rates on yield and quality of silage corn. J. Plant Nutr. 2014, 37, 611–617. [Google Scholar] [CrossRef]

- Siam, H.S.; Mona, G.; Kader, A.E.; El-Alia, H.I. Yield and yield components of maize as affected by different sources and application rates of nitrogen fertilizer. Res. J. Agric. Biol. Sci. 2008, 4, 399–412. [Google Scholar]

- Souza, J.A.; Buzetti, S.; Filho, M.C.M.T.; Moreira, A. Sources, Rates and Time of Nitrogen Application on Maize Crops under No-Tillage System. Commun. Soil Sci. Plant Anal. 2016, 47, 2200–2207. [Google Scholar] [CrossRef]

- Chaudhary, D.P.; Kumar, A.; Kumar, R.; Singode, A.; Mukri, G.; Sah, R.P.; Tiwana, U.S.; Kumar, B. Evaluation of normal and specialty corn for fodder yield and quality traits. Range Manag. Agrofor. 2016, 37, 79–83. [Google Scholar]

| Effect | DF | Protein | Oil | Fiber | Ash | Starch | Protein | Oil | Fiber | Ash | Starch |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ------------------ g kg−1 ------------------ | ------------------ kg ha−1 ------------------ | ||||||||||

| St | 1 | *** | * | ** | ns | ns | * | ns | ns | ns | ns |

| Yr | 1 | *** | ns | *** | ns | *** | *** | *** | *** | *** | *** |

| St × Yr | 1 | *** | ns | *** | *** | ns | ns | ns | ** | ns | ns |

| F | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| St × F | 3 | ns | ns | ** | ns | ns | ns | ns | * | ns | ns |

| Yr × F | 3 | ** | ns | ** | ns | ns | ** | * | ns | * | * |

| St × Yr × F | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| N | 3 | *** | ns | *** | *** | * | *** | *** | *** | *** | *** |

| St × N | 3 | * | ns | *** | *** | *** | *** | ** | * | *** | *** |

| Yr × N | 3 | *** | ns | ns | ** | *** | *** | *** | *** | *** | *** |

| St × Yr × N | 3 | ns | ns | *** | ns | *** | *** | *** | ** | *** | *** |

| F × N | 9 | ns | ns | * | ns | ns | * | ** | * | * | ** |

| St × F × N | 9 | * | ns | * | ns | ns | ns | ns | *** | ns | ns |

| Yr × F × N | 9 | *** | ns | * | ns | ns | ** | ** | ** | ** | *** |

| St × Yr × F × N | 9 | ns | ns | ns | ns | ns | ns | ns | * | ns | ns |

| Year | N Rate | (NH4)2SO4 | Urea | NPKBriq | OENF |

|---|---|---|---|---|---|

| --------------------------g kg−1-------------------------- | |||||

| 2012 | 0 | 17.4a | 19.4a | 18.8a | 19.8a |

| 85 | 15.3a | 14.8a | 14.4a | 15.1a | |

| 128 | 13.0a | 12.6a | 15.1a | 13.0a | |

| 170 | 12.3a | 11.1a | 14.0a | 11.6a | |

| 2013 | 0 | 22.9a | 24.0a | 24.8a | 24.8a |

| 85 | 21.8ab | 18.8b | 18.0b | 24.3a | |

| 128 | 19.4a | 18.1a | 16.9a | 19.6a | |

| 170 | 18.1a | 17.8a | 14.3a | 16.4a | |

| Year | N Rate | Fertilizer | Protein | Oil | Ash | Starch |

|---|---|---|---|---|---|---|

| kg ha−1 | kg ha−1 | kg ha−1 | kg ha−1 | |||

| 2012 | 0 | (NH4)2SO4 | 161.3a | 79.7a | 26.6a | 1371.8a |

| Urea | 150.8a | 75.1a | 25.4a | 1305.4a | ||

| NPKBriq | 135.5a | 60.8a | 21.1a | 1077.5a | ||

| OENF | 136.4a | 66.5a | 23.4a | 1200.2a | ||

| 85 | (NH4)2SO4 | 299.2a | 130.7a | 43.1a | 2229.2a | |

| Urea | 359.6a | 158.9a | 53.9a | 2760.6a | ||

| NPKBriq | 339.7a | 157.7a | 50.9a | 2651.7a | ||

| OENF | 373.3a | 163.2a | 55.8a | 2958.8a | ||

| 128 | (NH4)2SO4 | 322.2a | 141.1a | 45.4a | 2363.3a | |

| Urea | 443.8a | 184.9a | 61.7a | 3257.7a | ||

| NPKBriq | 364.1a | 162.3a | 54.5a | 2878.2a | ||

| OENF | 395.3a | 164.6a | 54.3a | 2932.9a | ||

| 170 | (NH4)2SO4 | 397.4a | 145.5a | 49.2a | 2669.2a | |

| Urea | 492.4a | 198.5a | 65.5a | 3508.2a | ||

| NPKBriq | 449.1a | 172.8a | 60.1a | 3280.2a | ||

| OENF | 428.0a | 161.3a | 55.2a | 2953.7a | ||

| 2013 | 0 | (NH4)2SO4 | 149.4a | 80.4a | 26.4a | 1432.1a |

| Urea | 170.4a | 74.8a | 27.2a | 1483.3a | ||

| NPKBriq | 138.3a | 74.4a | 24.8a | 1283.5a | ||

| OENF | 135.3a | 70.4a | 23.6a | 1259.7a | ||

| 85 | (NH4)2SO4 | 405.6b | 215.6b | 75.5b | 3982.0b | |

| Urea | 433.7ab | 245.7ab | 80.9ab | 4124.5b | ||

| NPKBriq | 584.8a | 315.7a | 101.1a | 5340.1a | ||

| OENF | 428.2b | 230.4b | 78.8ab | 4176.9ab | ||

| 128 | (NH4)2SO4 | 595.7a | 288.3a | 100.9a | 5426.3a | |

| Urea | 572.8a | 306.9a | 102.4a | 5236.2a | ||

| NPKBriq | 697.7a | 336.8a | 116.3a | 6076.1a | ||

| OENF | 587.5a | 292.3a | 102.7a | 5628.7a | ||

| 170 | (NH4)2SO4 | 775.4ab | 364.5ab | 129.7a | 6782.6a | |

| Urea | 667.2b | 296.9b | 107.6a | 5663.1a | ||

| NPKBriq | 838.9a | 386.6a | 132.1a | 6814.0a | ||

| OENF | 771.5ab | 371.9ab | 128.2a | 6801.5a |

| Site | Year | N Rate | (NH4)2SO4 | Urea | NPKBriq | OENF |

|---|---|---|---|---|---|---|

| ---------------------kg ha−1--------------------- | ||||||

| Jackson | 2012 | 0 | 22.3a | 20.6a | 18.0a | 22.0a |

| 85 | 62.9a | 50.5a | 43.2a | 61.4a | ||

| 128 | 44.4a | 66.4a | 53.9a | 49.5a | ||

| 170 | 50.6a | 49.8a | 51.2a | 54.6a | ||

| 2013 | 0 | 63.9a | 60.2a | 53.2a | 59.2a | |

| 85 | 142.4a | 116.2a | 161.4a | 139.4a | ||

| 128 | 192.9a | 154.2a | 160.0a | 181.2a | ||

| 170 | 218.7a | 157.9ab | 142.1b | 211.1a | ||

| Grand Junction | 2012 | 0 | 56.4a | 65.5a | 46.5a | 53.7a |

| 85 | 47.7a | 79.3a | 75.1a | 78.4a | ||

| 128 | 50.3a | 63.9a | 89.0a | 71.2a | ||

| 170 | 55.3a | 75.6a | 94.7a | 55.6a | ||

| 2013 | 0 | 31.3a | 43.8a | 41.1a | 33.5a | |

| 85 | 125.8a | 125.0a | 142.2a | 178.1a | ||

| 128 | 128.7a | 138.0a | 158.4a | 160.0a | ||

| 170 | 161.6a | 147.8a | 160.5a | 136.2a | ||

| Quality | Oil | Fiber | Ash | Starch |

|---|---|---|---|---|

| Protein | −0.02 ns | −0.67 *** | −0.18 ** | −0.30 *** |

| Oil | −0.10 ns | 0.31 *** | −0.55 *** | |

| Fiber | 0.10 ns | −0.13 * | ||

| Ash | −0.16 * |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, S.; Yin, X.; Bellaloui, N.; Winings, J.H.; Agyin-Birikorang, S.; Singh, U.; Sanabria, J.; Mengistu, A. Maize Grain Composition with Additions of NPK Briquette and Organically Enhanced N Fertilizer. Agronomy 2020, 10, 852. https://doi.org/10.3390/agronomy10060852

Wang X, Liu S, Yin X, Bellaloui N, Winings JH, Agyin-Birikorang S, Singh U, Sanabria J, Mengistu A. Maize Grain Composition with Additions of NPK Briquette and Organically Enhanced N Fertilizer. Agronomy. 2020; 10(6):852. https://doi.org/10.3390/agronomy10060852

Chicago/Turabian StyleWang, Xiaohui, Shuangli Liu, Xinhua Yin, Nacer Bellaloui, John H. Winings, Sampson Agyin-Birikorang, Upendra Singh, Joaquin Sanabria, and Alemu Mengistu. 2020. "Maize Grain Composition with Additions of NPK Briquette and Organically Enhanced N Fertilizer" Agronomy 10, no. 6: 852. https://doi.org/10.3390/agronomy10060852

APA StyleWang, X., Liu, S., Yin, X., Bellaloui, N., Winings, J. H., Agyin-Birikorang, S., Singh, U., Sanabria, J., & Mengistu, A. (2020). Maize Grain Composition with Additions of NPK Briquette and Organically Enhanced N Fertilizer. Agronomy, 10(6), 852. https://doi.org/10.3390/agronomy10060852