Evaluation of an Adapted Greenhouse Cooling System with Pre-Chamber and Inflatable Air Ducts for Semi-Arid Regions in Warm Conditions

Abstract

1. Introduction

2. Materials and Methods

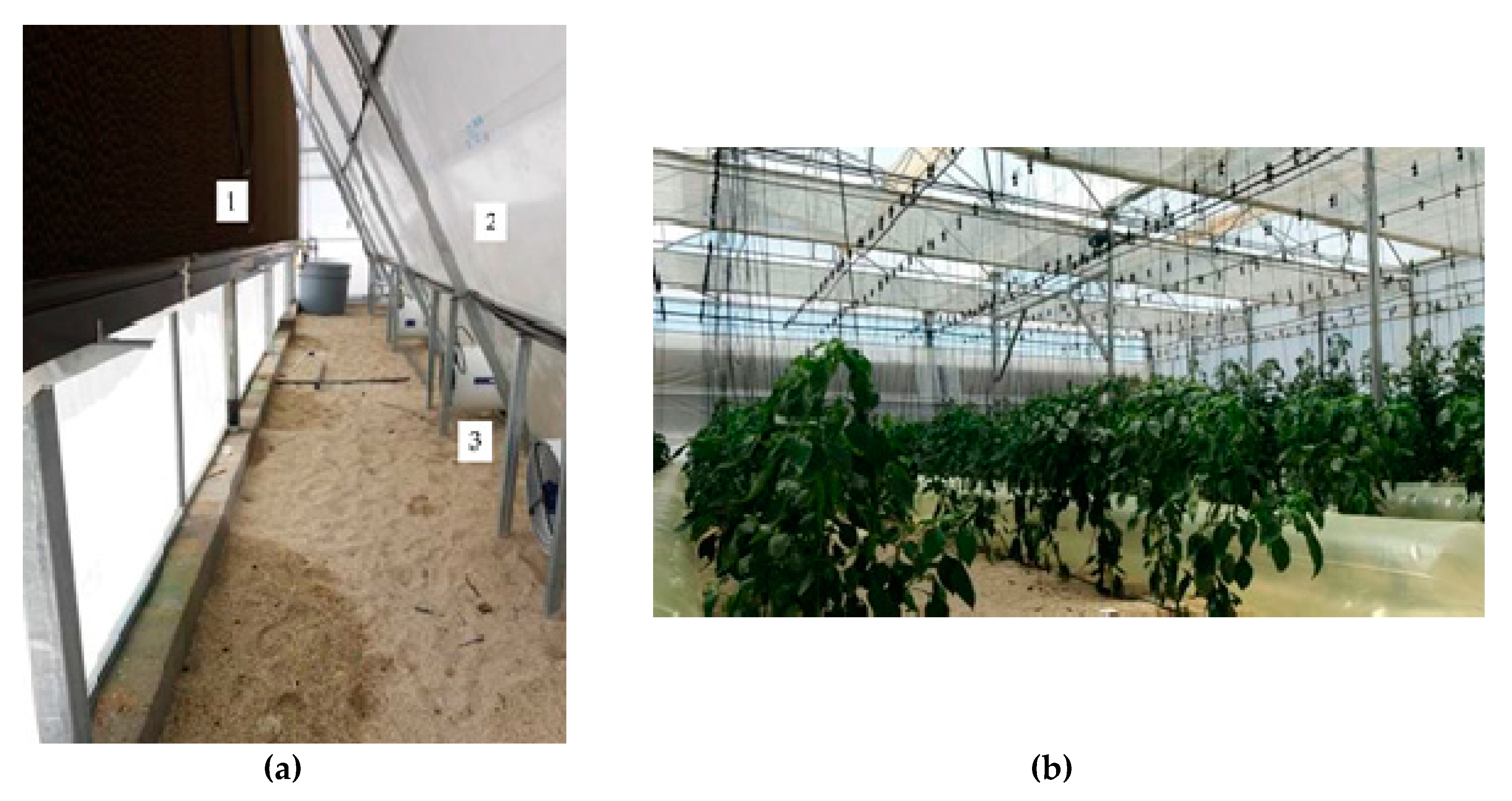

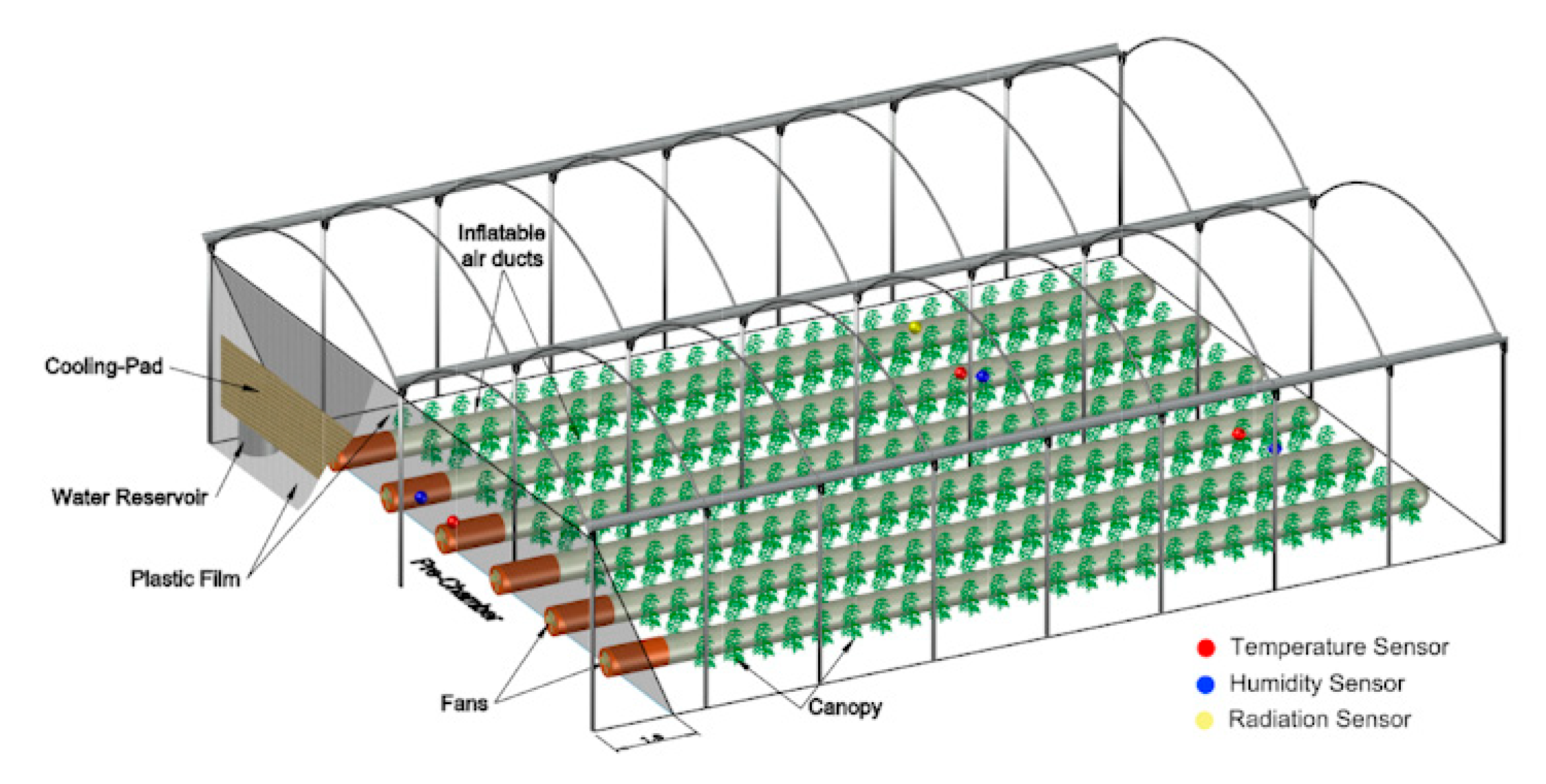

2.1. Greenhouse, Crop, Sensors and Actuators

2.2. Greenhouse Cooling System with Evaporative Chamber and Inflatable Air Ducts

2.3. Sensors and Data Collection System

2.4. Analysis of the Fan-Pad System Operation

2.5. Testing Schedule

- Test 1 (Fan-pad system, P). In the initial state, the ventilation is closed, the shading screens are drawn back and the temperature is constant. The fan-pad system is then activated until the temperature and humidity remain constant.

- Test 2 (Increased ventilation, V > 0). In the initial state, the ventilation is closed, the shading screens are drawn back and the temperature is constant. The greenhouse is then ventilated in 20% steps for 20-min periods until the temperature and humidity remain constant.

- Test 3 (Reduced ventilation, V < 0). In the initial state, the ventilation is completely open, the shading screens are drawn back and the temperature is constant. The ventilation is then closed in 20% steps for 20-min periods until the temperature and humidity remain constant.

- Test 4 (Shading screens, S). In the initial state, the ventilation is closed, the shading screens are drawn back and the temperature is constant. Then, the shading screens are opened out for 2 h.

- Test 5 (Ventilation and shading screens, V + S). In the initial state, the ventilation is completely open, the shading screens are drawn back and the temperature is constant. Then, the shading screens are opened out for 2 h.

- Test 6 (Fan-pad system and ventilation, P + V). In the initial state, the ventilation is completely open, the shading screens drawn back and the temperature is constant. The fan-pad system is then activated until the temperature and humidity remain constant.

- Test 7 (Fan-pad and shading system, P + S). In the initial state, the ventilation is closed, the shading screens are opened and the temperature is constant. The fan-pad system is then activated until the temperature and humidity remain constant.

- Test 8 (Fan-pad system, ventilation and shading, P + V + S). In the initial state, the ventilation is completely open, the shading screens are opened and the temperature is constant. The fan-pad system is then activated until the temperature and humidity remain constant.

- Tests 9–16. Repeat of tests 1 to 8.

3. Results

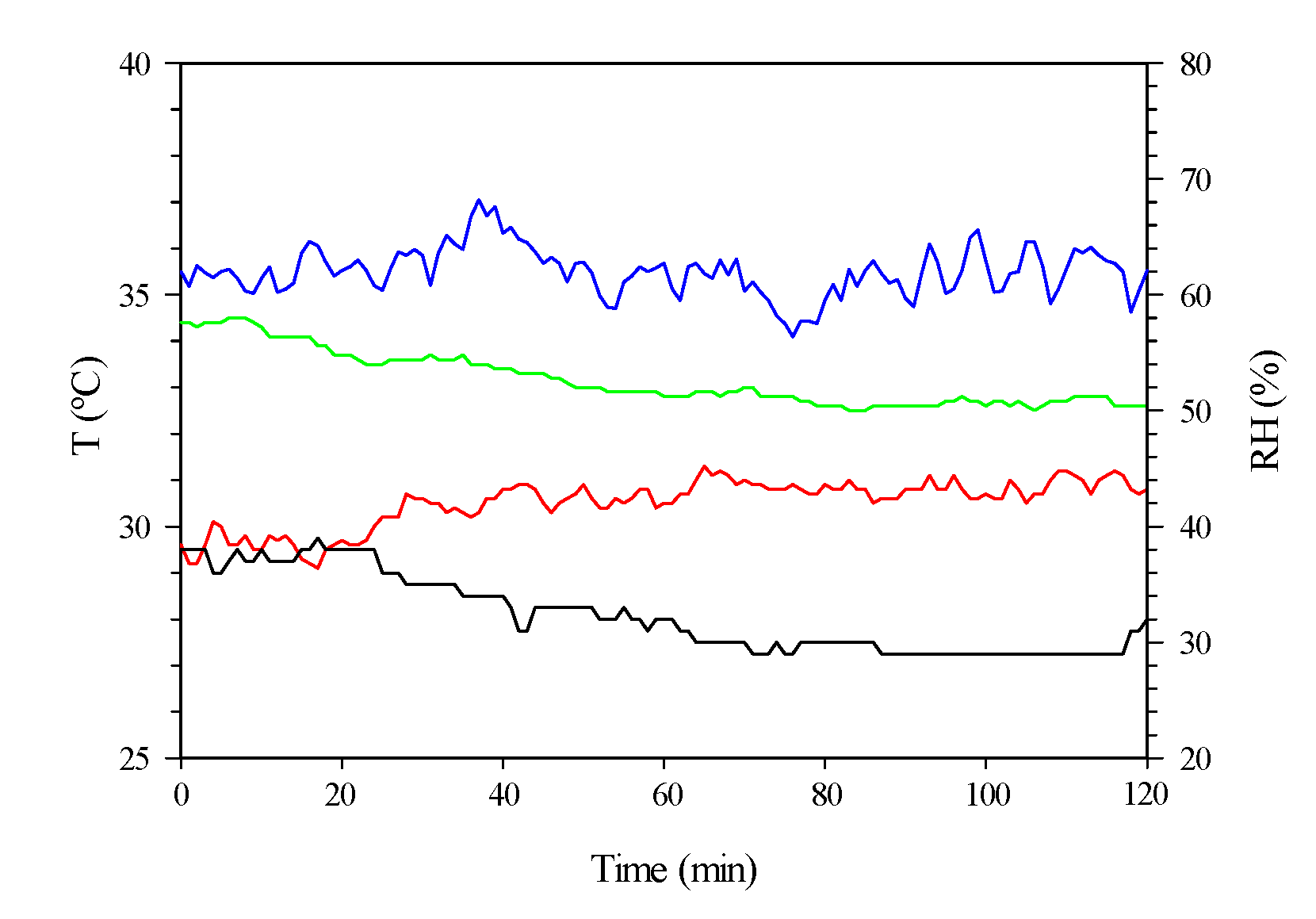

3.1. Characterization of the Fan-Pad System Operation

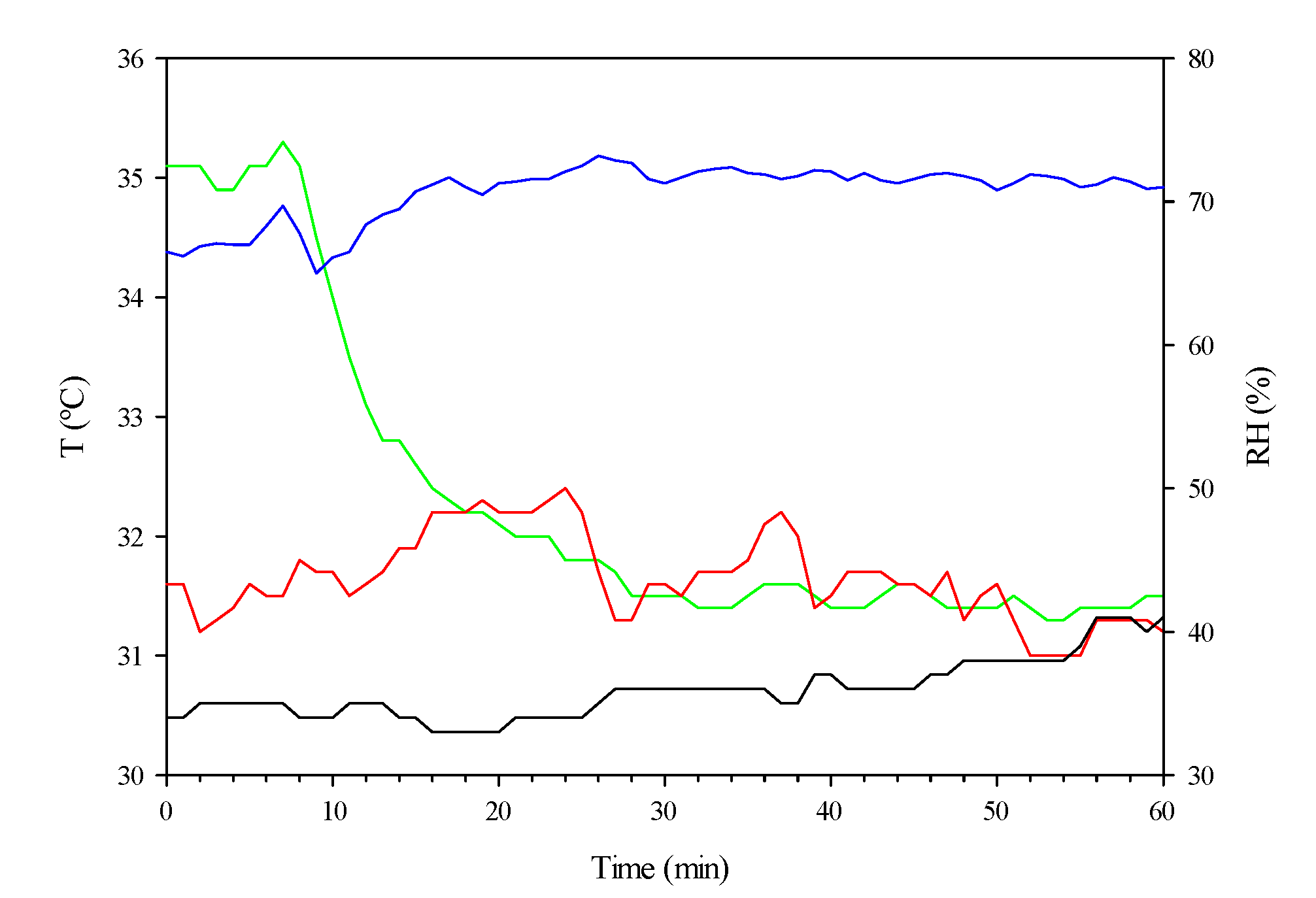

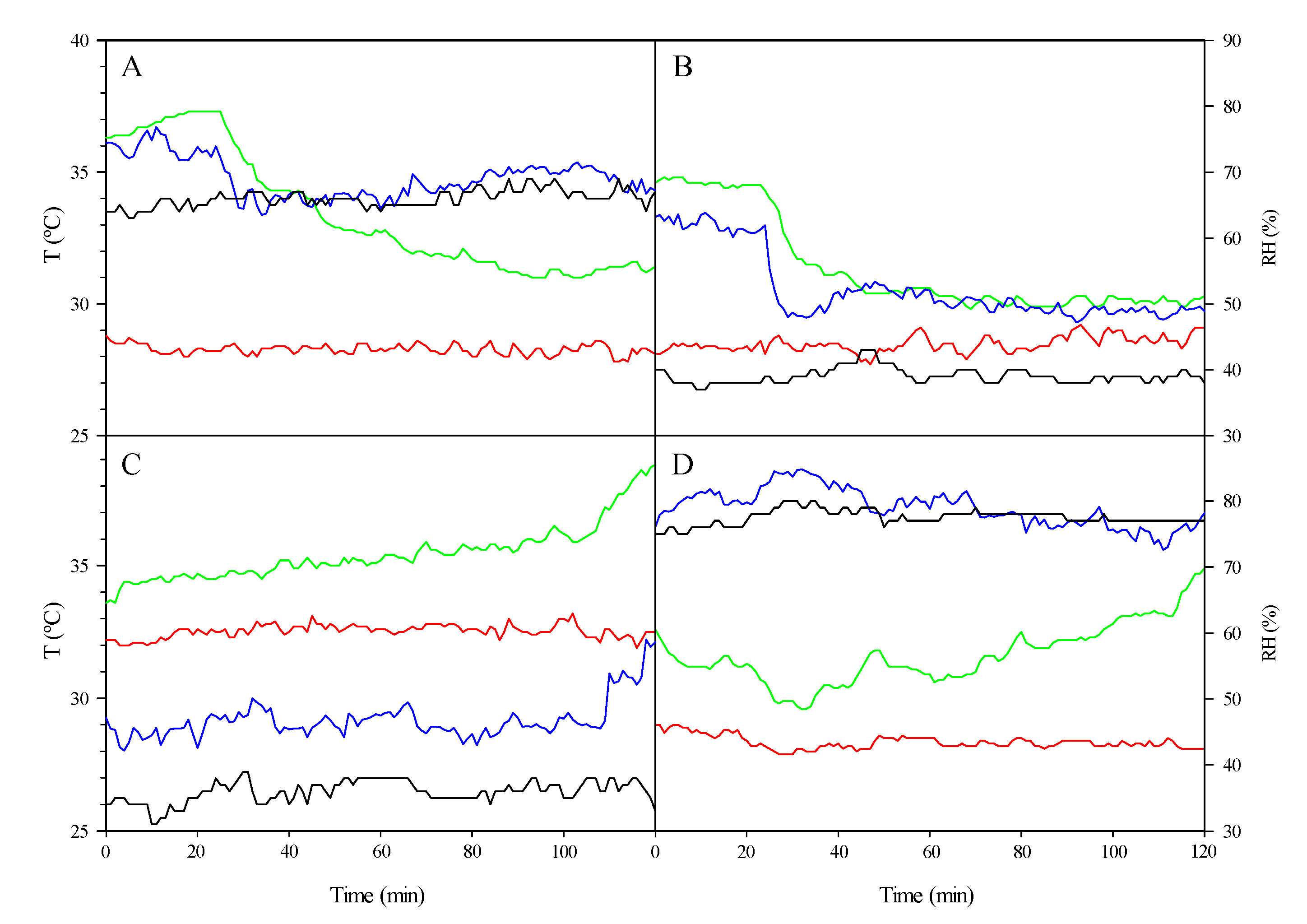

3.1.1. Effect of the Fan-Pad System on the Temporal Climate Evolution in the Greenhouse

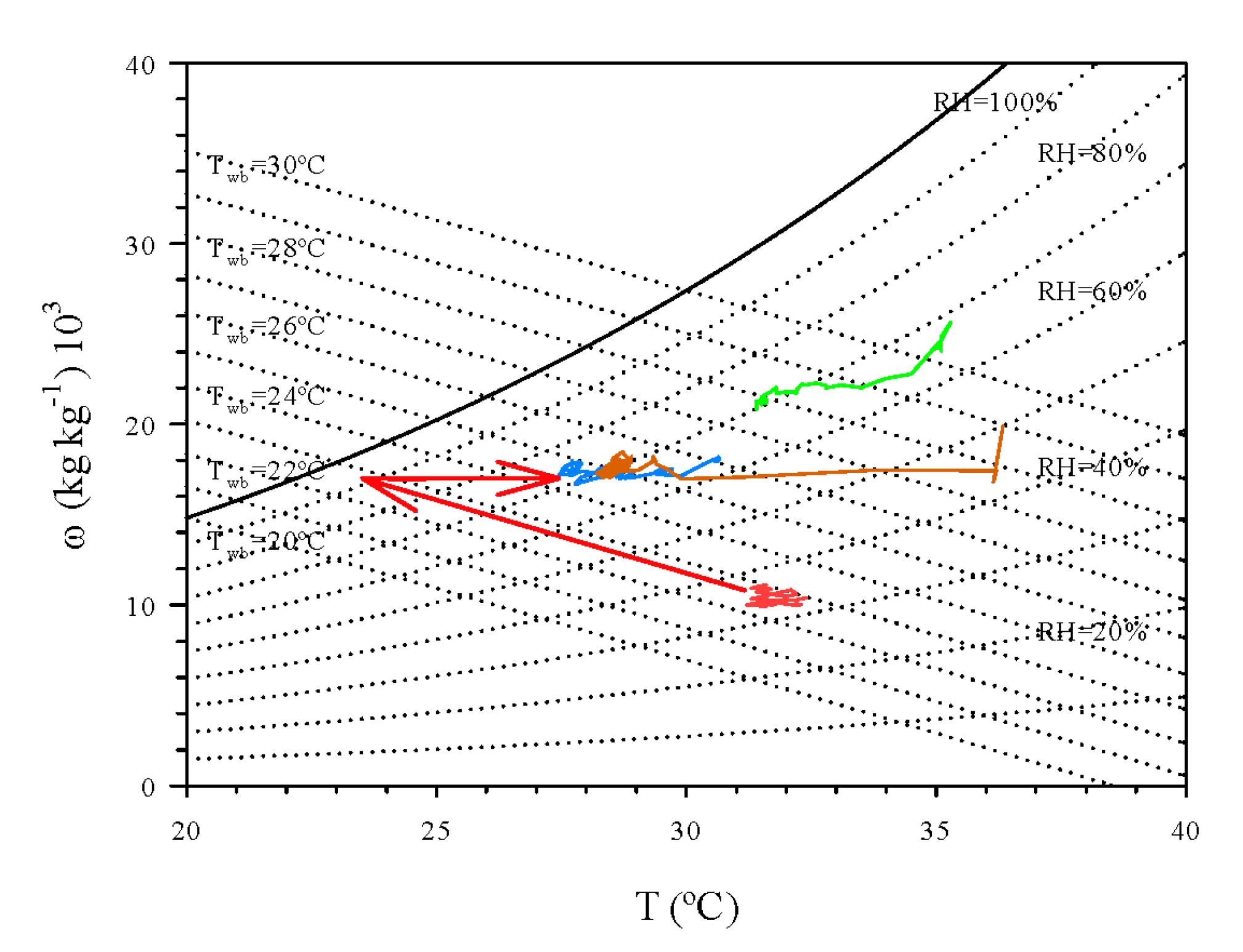

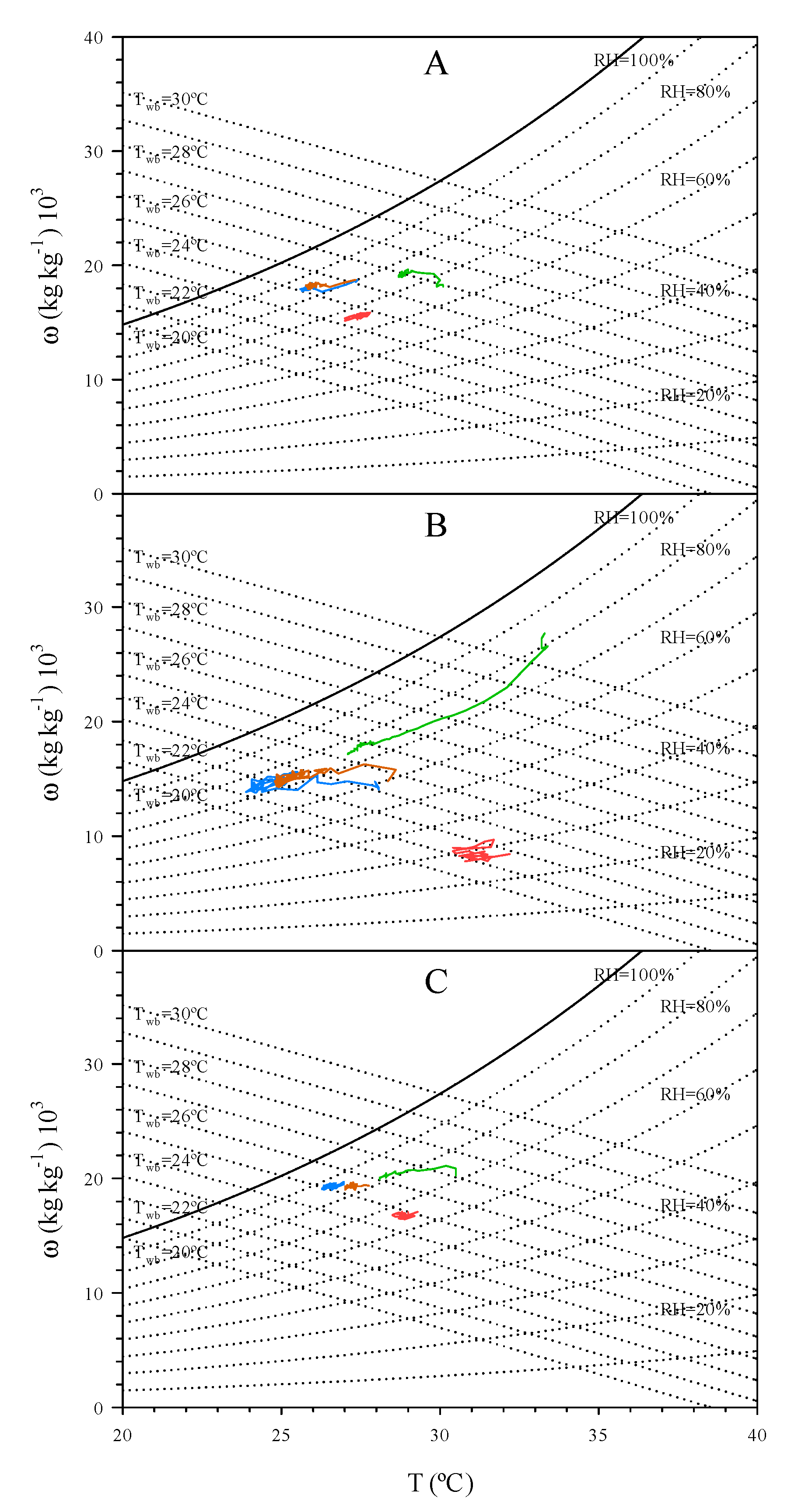

3.1.2. Psychrometric Assessment of the Fan-Pad System with Distribution Air Ducts

3.1.3. Fan-Pad System Operating Parameters

3.1.4. Evaporative Cooling Analysis

3.2. Evaporative Pad Behaviour in Combination with the other Actuators

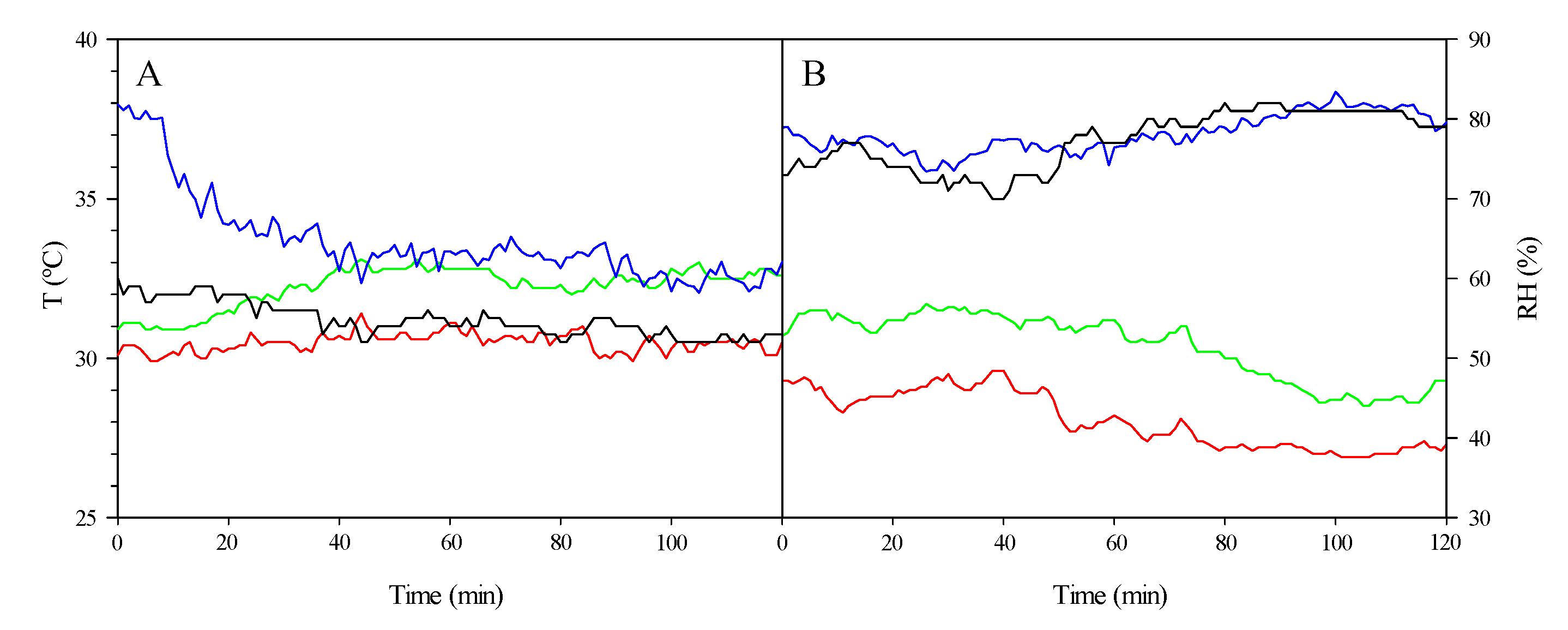

3.2.1. Effect of Natural Ventilation and Shading Screens on the Greenhouse Climate

Natural Ventilation

Shading Screens

Natural Ventilation and Shading Screens

3.2.2. Effect of Combining the Fan-Pad System with Natural Ventilation

3.2.3. Effect of Combining the Fan-Pad System with the Shading Screens

3.2.4. Effect of Combining the Fan-Pad System with Natural Ventilation and Shading Screens

4. Discussion

4.1. Fan-Pad System and Air Duct Distribution

4.2. Combining the Fan-Pad System and Air Duct Distribution with Other Actuators

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| c | Specific heat (J kg−1 °C−1) |

| D | Wind direction (°) |

| EFI | Efficiency of air saturation when circulating through the fan-pad system (%) |

| h | Enthalpy per unit of dry or specific air mass (J kg−1) |

| m | mass (kg) |

| mw/ma | evaporated water mass per unit of treated air mass or specific mass of evaporated water (kg kg−1). |

| pw | evaporated water mass per unit of treated air mass, time, pad area and temperature difference between the outside and the pre-chamber |

| q | Energy transferred in the form of heat per unit of dry air mass (J kg−1) |

| RH | Relative humidity (%) |

| SR | Solar radiation intensity (W m−2) |

| EP | Water evaporation performance in the fan-pad system (%) |

| T | Dry bulb air temperature (°C) |

| v | Wind speed (m s−1) |

| ω | Specific air humidity (kg kg−1) |

| Subscripts | |

| a | dry air |

| c | pre-chamber |

| g | greenhouse |

| d | duct |

| l | latent |

| o | exterior |

| p | pad |

| s | sensible |

| v | vapour |

| w | water |

| wb | wet bulb |

References

- Dehbi, A.; Youssef, B.; Chappey, C.; Mourad, A.-H.; Picuno, P.; Statuto, D. Multilayers Polyethylene Film for Crop Protection in Harsh Climatic Conditions. Adv. Mater. Sci. Eng. 2017, 2017, 4205862. [Google Scholar] [CrossRef]

- Gulrez, S.K.; Abdel-Ghany, A.M.; Al-Helal, I.M.; Al-Zaharani, S.M.; Alsadon, A.A. Evaluation of PE films having NIR-reflective additives for greenhouse applications in arid regions. Adv. Mater. Sci. Eng. 2013, 2013, 575081. [Google Scholar] [CrossRef]

- Callejón-Ferre, A.J.; Manzano-Agugliaro, F.; Díaz-Pérez, M.; Carreño-Ortega, A.; Pérez-Alonso, J. Effect of shading with aluminised screens on fruit production and quality in tomato (Solanum lycopersicum L.) under greenhouse conditions. Span. J. Agric. Res. 2009, 1, 41–49. [Google Scholar] [CrossRef]

- Al-Helal, I.; Al-Abbadi, N.; Al-Ibrahim, A. A study of fan-pad performance for a photovoltaic powered greenhouse in Saudi Arabian summer. Int. Agric. Eng. J. 2004, 1, 14. [Google Scholar]

- Kittas, C.; Boulard, T.; Bartzanas, T.; Katsoulas, N.; Mermier, M. Influence of an insect screen on greenhouse ventilation. Trans. ASAE 2002, 45, 1083–1090. [Google Scholar] [CrossRef]

- Muñoz, P.; Montero, J.I.; Antón, A.; Giuffrida, F. Effect of insect-proof screens and roof openings on greenhouse ventilation. J. Agric. Eng. Res. 1999, 73, 171–178. [Google Scholar] [CrossRef]

- Baille, A.; Kittas, C.; Katsoulas, N. Influence of whitening on greenhouse micro-climate and crop energy partitioning. Agric. Forest Meteorol. 2001, 107, 293–306. [Google Scholar] [CrossRef]

- Fernandez-Rodríguez, E.J.; Fernández, J.; Kenig, A. Radiative field uniformity under shading screens under greenhouse vs. whitewash in Spain. Acta Hortic. 2000, 534, 125–130. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. Amst. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Montero, J.; Muñoz, P.; Sánchez-Guerrero, M.; Medrano, E.; Piscia, D.; Lorenzo, P. Shading screens for the improvement of the night time climate of unheated greenhouses. Span. J. Agric. Res. 2013, 11, 32–46. [Google Scholar] [CrossRef]

- González-Real, M.M.; Baille, A. Plant response to greenhouse cooling. Acta Hortic. 2006, 719, 427–438. [Google Scholar] [CrossRef]

- Castilla, N. Intervención contra altas temperaturas: Refrigeración. In Invernaderos de Plástico. Tecnología y Manejo, 2nd ed.; Mundi-Prensa: Madrid, Spain, 2007; pp. 207–233. [Google Scholar]

- Misra, D.; Ghosh, S. Evaporative cooling technologies for greenhouses: A comprehensive review. Agric. Eng. Int. CIGR J. 2018, 20, 1–15. [Google Scholar]

- López, A.; Valera, D.L.; Molina-Aiz, F.D.; Peña, A. Sonic anemometry to evaluate airflow characteristics and temperature distribution in empty Mediterranean greenhouses equipped with pad-fan and fog systems. Biosyst. Eng. 2012, 113, 334–350. [Google Scholar] [CrossRef]

- Jimenez, J.I.; Casas-Vazquez, J. An experimental study of micrometeorological modification in a glasshouse during summer. Agric. Meteorol. 1978, 19, 337–348. [Google Scholar] [CrossRef]

- Rabbi, B.; Chen, Z.-H.; Sethuvenkatraman, S. Protected Cropping in Warm Climates: A Review of Humidity Control and Cooling Methods. Energies 2019, 12, 2737. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, R.Z.; Liu, W.; Zhou, P. Experimental performance of evaporative cooling pad systems in greenhouses in humid subtropical climates. Appl. Energy 2015, 138, 291–301. [Google Scholar] [CrossRef]

- Franco, A.; Valera, D.L.; Madueño, A.; Peña, A. Influence of water and air flow on the performance of cellulose evaporative cooling pads used in Mediterranean greenhouses. Trans. ASABE 2015, 53, 565–576. [Google Scholar] [CrossRef]

- Franco, A.; Valera, D.L.; Peña, A. Energy Efficiency in greenhouse evaporative cooling techniques: Cooling boxes versus Cellulose Pads. Energies 2014, 7, 1427–1447. [Google Scholar] [CrossRef]

- Sun, W.; Zhou, B.; Xu, F.; Shang, C.; Lu, C.; Guo, W. Performance of positive pressure fan-pad cooling system and cooling load model for Chinese solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2019, 35, 214–224. [Google Scholar]

- Ghosal, M.K.; Tiwari, G.N.; Sirivastava, N.S.L. Modeling and experimental validation of a greenhouse with evaporative cooling by moving water film over external shade cloth. Energ. Build. 2003, 35, 843–850. [Google Scholar] [CrossRef]

- Bailey, B.J.; Raoueche, A. Design and performance aspects of a water producing greenhouse cooled by seawater. Acta Hortic. 1998, 458, 311–316. [Google Scholar] [CrossRef]

- Abbouda, S.K.; Almuhanna, E.A. Improvement of evaporative cooling system efficiency in greenhouses. Int. J. Latest Trends Agric. Food Sci. 2012, 2, 83–89. [Google Scholar]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- TECNOVA Foundation Experimental Farm. Available online: http://www.fundaciontecnova.com/ (accessed on 21 April 2020).

- Jamal, K.A. Greenhouse cooling in hot countries. Energy 1994, 19, 1187–1192. [Google Scholar] [CrossRef]

- Fernández, M.D.; López, J.C.; Baeza, E.; Céspedes, A.; Meca, D.E.; Bailey, B. Generation and evaluation of typical meteorological year datasets for greenhouse and external conditions on the Mediterranean coast. Int. J. Biometeorol. 2015, 59, 1067–1081. [Google Scholar] [CrossRef]

- Ganguly, A.; Ghosh, S. Modeling and analysis of a fan-pad ventilated floricultural greenhouse. Energy Build. 2007, 39, 1092–1097. [Google Scholar] [CrossRef]

- Chen, X.; Su, Y.; Aydin, D.; Ding, Y.; Zhang, S.; Reay, D.; Riffat, S. A novel evaporative cooling system with a polymer hollow fibre spindle. X. App. Therm. Eng. 2018, 132, 665–675. [Google Scholar] [CrossRef]

- Sabeh, N.C.; Giacomelli, G.A.; Kubota, C. Water use for pad and fan evaporative cooling of a greenhouse in a semiarid climate. Acta Hortic. 2006, 719, 409–416. [Google Scholar] [CrossRef]

- Fuchs, M.; Dayan, E.; Presnov, E. Evaporative cooling of a ventilated greenhouse rose crop. Agric. Forest Meteorol. 2006, 138, 203–215. [Google Scholar] [CrossRef]

- Wu, J.M.; Huang, X.; Zhang, H. Theoretical analysis on heat and mass transfer in a direct evaporative cooler. App. Therm. Eng. 2009, 29, 980–984. [Google Scholar] [CrossRef]

- Farmahini-Farahani, M.; Heidarinejad, G. Increasing effectiveness of evaporative cooling by pre-cooling using nocturnally stored water. App. Therm. Eng. 2012, 38, 117–123. [Google Scholar] [CrossRef]

- Baeza, E.J.; Pérez-Parra, J.J.; Montero, J.I.; Bailey, B.J.; López, J.C.; Gázquez, J.C. Analysis of the role of sidewall vents on buoyancy-driven natural ventilation in parral-type greenhouses with and without insect screens using computational fluid dynamics. Biosyst. Eng. 2009, 104, 86–96. [Google Scholar] [CrossRef]

- Mashonjowa, E.; Ronsse, F.; Milford, J.R.; Pieters, J.G. Modelling the thermal performance of a naturally ventilated greenhouse in Zimbabwe using a dynamic greenhouse climate model. Sol. Energy 2013, 91, 381–393. [Google Scholar] [CrossRef]

- Thipe, E.L.; Workneh, T.; Odindo, A.; Laing, M. Greenhouse technology for agriculture under arid conditions. Sustain. Agric. Rev. 2017, 22, 37–55. [Google Scholar]

- Willits, D.H. The effect of cloth characteristics on the cooling performance of external shade cloths for greenhouses. J. Agric. Eng. Res. 2001, 79, 331–340. [Google Scholar] [CrossRef]

- Kittas, C.; Bartzanas, T.; Jaffrin, A. Greenhouse evaporative cooling: Measurement and data analysis. Trans. ASAE 2001, 44, 683–689. [Google Scholar] [CrossRef]

- Kittas, C.; Bartzanas, T.; Jaffrin, A. Temperature gradients in a partially shaded large greenhouse equipped with evaporative cooling pads. Biosyst. Eng. 2003, 85, 87–94. [Google Scholar] [CrossRef]

| Test | Date | On/Off (hh:mm) | P | V | S | T (°C) | HR (%) | SR (W m−2) | v (m s−1) | D (Angle, °) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 (P) | 21/08 | 13:00/14:00 | 1 | 0 | 0 | 31.7 | 35 | 848 | 4.5 | 88 |

| 2 (V > 0) | 09/08 | 13:00/15:00 | 0 | 1 | 0 | 28.3 | 66 | 904 | 4.4 | 190 |

| 3 (V < 0) | 04/08 | 13:00/15:00 | 0 | 1 | 0 | 32.5 | 36 | 893 | 3.5 | 185 |

| 4 (S) | 12/08 | 13:00/14:00 | 0 | 0 | 1 | 31.0 | 31 | 906 | 6.1 | 99 |

| 5 (V + S) | 03/08 | 13:00/15:00 | 0 | 1 | 1 | 30.5 | 54 | 890 | 3.7 | 190 |

| 6 (P + V) | 23/08 | 13:00/14:00 | 1 | 1 | 0 | 27.4 | 67 | 868 | 3.5 | 198 |

| 7 (P + S) | 22/08 | 13:00/14:00 | 1 | 0 | 1 | 30.4 | 35 | 863 | 4.8 | 177 |

| 8 (P + V + S) | 18/08 | 13:00/14:00 | 1 | 1 | 1 | 28.9 | 66 | 857 | 3.5 | 157 |

| 9 (V > 0) | 11/08 | 13:00/15:00 | 0 | 1 | 0 | 28.5 | 39 | 903 | 5.8 | 119 |

| 10 (V < 0) | 07/08 | 13:00/15:00 | 0 | 1 | 0 | 28.4 | 77 | 568 | 3.8 | 185 |

| 11 (S) | 13/08 | 13:00/14:00 | 0 | 0 | 1 | 30.2 | 35 | 852 | 5.2 | 94 |

| 12 (V + S) | 08/08 | 13:00/15:00 | 0 | 1 | 1 | 28.1 | 77 | 673 | 4.6 | 161 |

| 13 (P + V) | 25/08 | 13:00/14:00 | 1 | 1 | 0 | 28.2 | 66 | 843 | 3.8 | 193 |

| 14 (P + V + S) | 24/08 | 13:00/14:00 | 1 | 1 | 1 | 26.5 | 63 | 869 | 4.5 | 195 |

| Operating Parameters | Average Values ± Standard Deviation |

|---|---|

| To–Tc (°C) | 3.5 ± 0.1 |

| To–Tg (°C) | −0.3 ± 0.2 |

| EFI (%) | 32.1 ± 1.0 |

| EP (%) | 34.7 ± 0.3 |

| qs (kJ kg−1) | 1.9 ± 0.2 |

| ql (kJ kg−1) | 17.0 ± 0.1 |

| mw/ma (kg kg−1) | 0.007 ± 0.000 |

| pw (kg kg−1 h−1 m−2 °C−1) | 0.006 ± 0.000 |

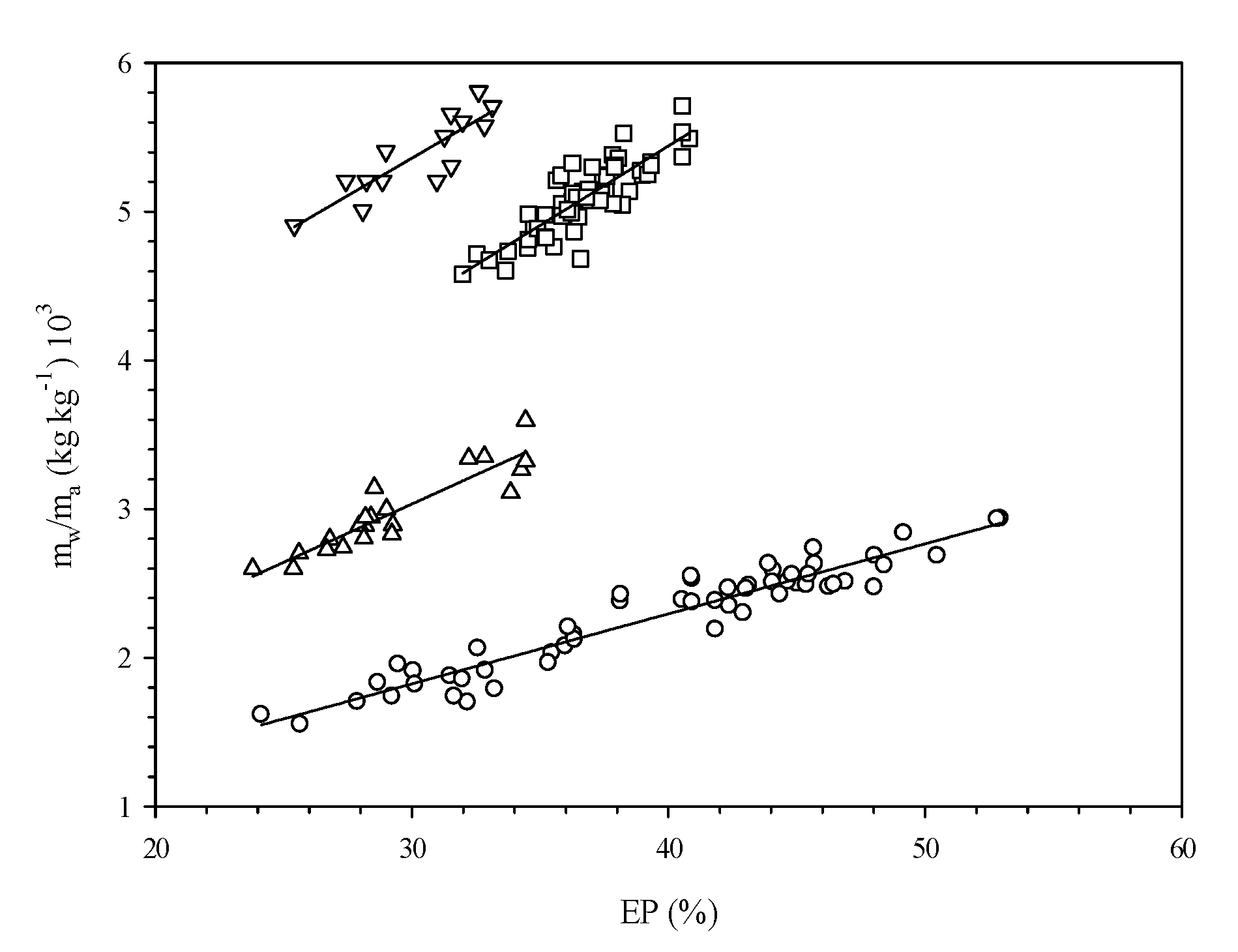

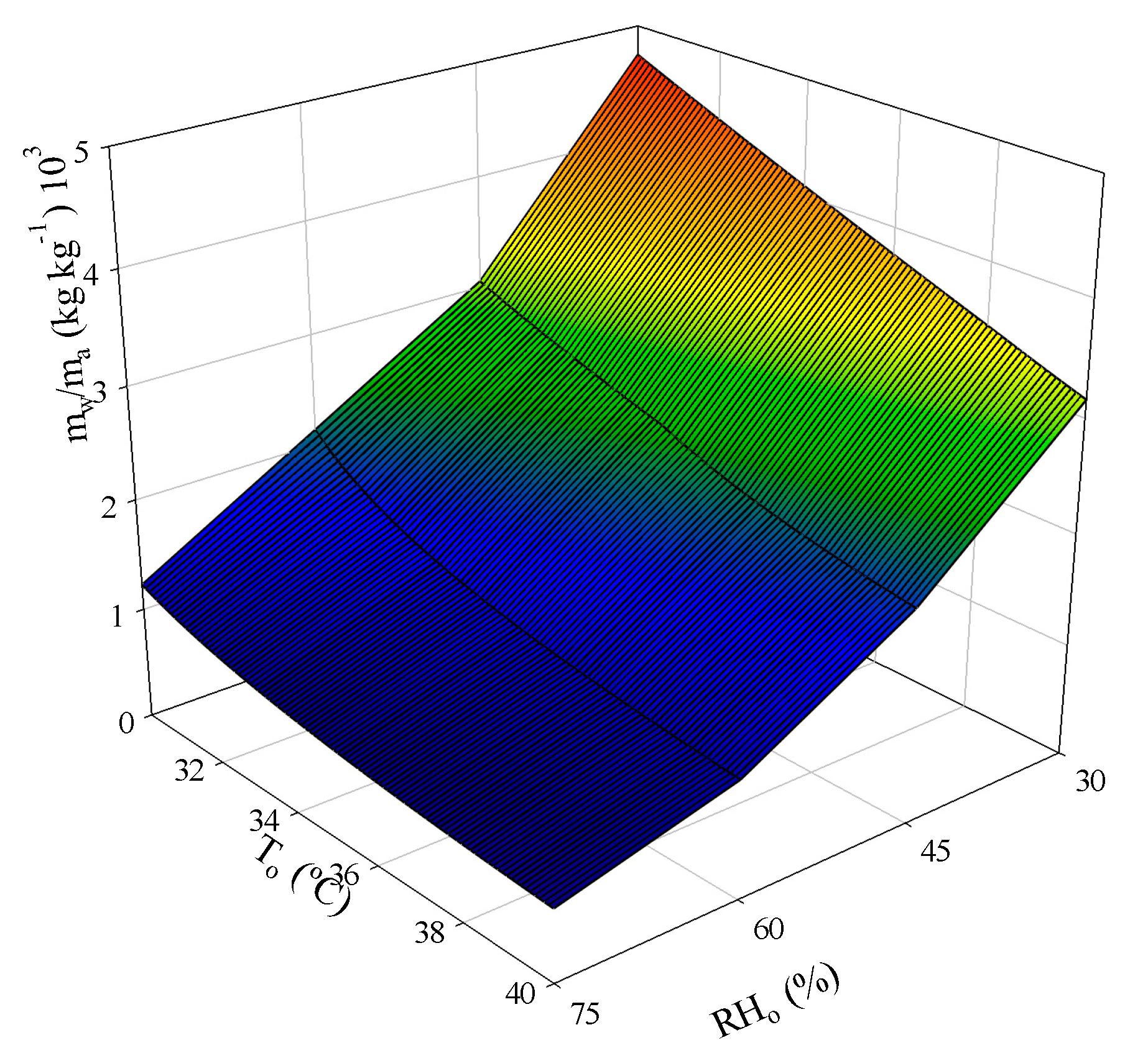

| 103 mw/ma = A·EP + B | |||

|---|---|---|---|

| RHo, % | A | B | R2 |

| 75 | 0.047 | 0.407 | 0.89 *** |

| 60 | 0.078 | 0.648 | 0.73 *** |

| 45 | 0.091 | 1.315 | 0.71 *** |

| 30 | 0.103 | 2.336 | 0.79 *** |

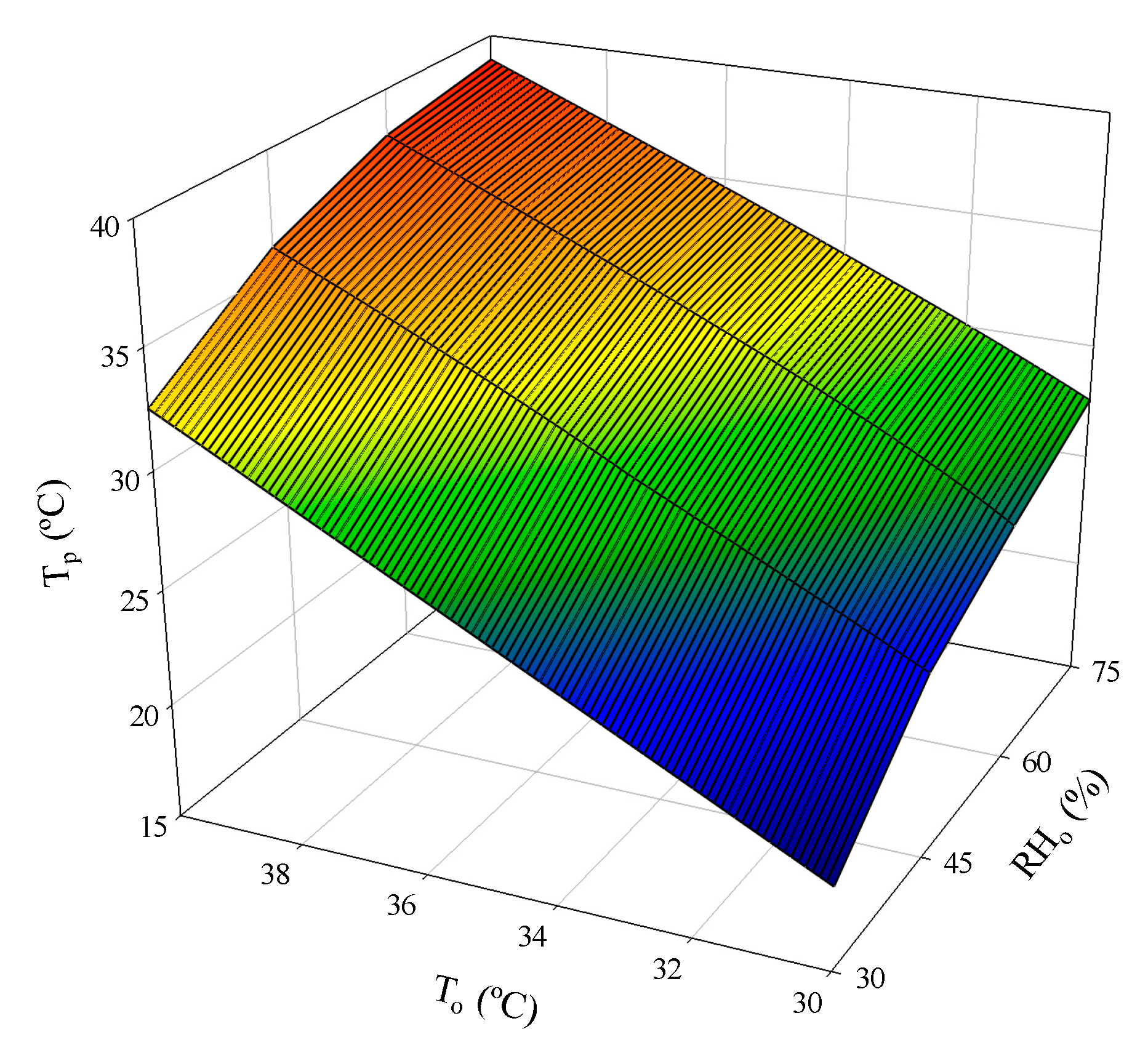

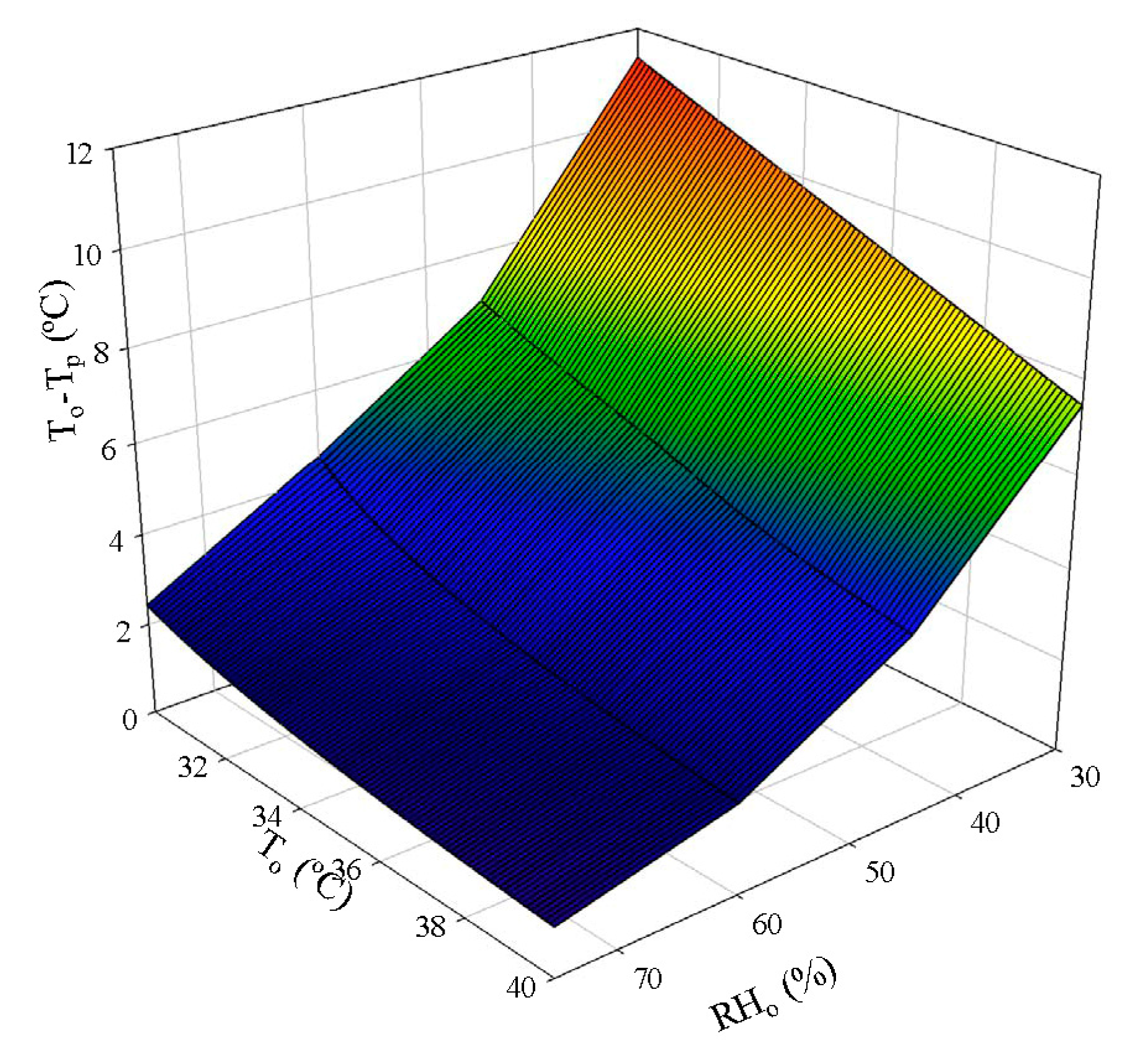

| Tp (°C) = A·To (°C) + B | |||

|---|---|---|---|

| RHo, % | A | B | R2 |

| 75 | 1.13 | −5.58 | 0.99 *** |

| 60 | 1.23 | −10.83 | 0.99 *** |

| 45 | 1.30 | −15.91 | 0.99 *** |

| 30 | 2.39 | −23.11 | 0.99 *** |

| Operating Parameters | P + V | P + S | P + V + S |

|---|---|---|---|

| To–Tc (°C) | −1.4 ± 0.0 | 6.2 ± 0.1 | 1.7 ± 0.0 |

| To–Tg (°C) | −1.6 ± 0.1 | 3.1 ± 0.1 | 0.5 ± 0.0 |

| EFI (%) | 29.2 ± 0.8 | 52.3 ± 0.8 | 34.4 ± 0.5 |

| EP (%) | 34.5 ± 0.4 | 29.9 ± 0.4 | 28.7 ± 0.3 |

| qs (kJ kg−1) | 0.3 ± 0.1 | −3.0 ± 0.2 | −0.4 ± 0.1 |

| ql (kJ kg−1) | 6.6 ± 0.1 | 14.9 ± 0.2 | 6.3 ± 0.1 |

| mw/ma (kg kg−1) | 0.003 ± 0.000 | 0.006 ± 0.000 | 0.003 ± 0.000 |

| pw (kg kg−1 h−1 m−2 °C−1) | 0.006 ± 0.000 | 0.003 ± 0.000 | 0.004 ± 0.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cámara-Zapata, J.M.; Sánchez-Molina, J.A.; Wang, H.; Carreño-Ortega, A.; Rodríguez, F. Evaluation of an Adapted Greenhouse Cooling System with Pre-Chamber and Inflatable Air Ducts for Semi-Arid Regions in Warm Conditions. Agronomy 2020, 10, 752. https://doi.org/10.3390/agronomy10050752

Cámara-Zapata JM, Sánchez-Molina JA, Wang H, Carreño-Ortega A, Rodríguez F. Evaluation of an Adapted Greenhouse Cooling System with Pre-Chamber and Inflatable Air Ducts for Semi-Arid Regions in Warm Conditions. Agronomy. 2020; 10(5):752. https://doi.org/10.3390/agronomy10050752

Chicago/Turabian StyleCámara-Zapata, José M., Jorge Antonio Sánchez-Molina, Hui Wang, Angel Carreño-Ortega, and Francisco Rodríguez. 2020. "Evaluation of an Adapted Greenhouse Cooling System with Pre-Chamber and Inflatable Air Ducts for Semi-Arid Regions in Warm Conditions" Agronomy 10, no. 5: 752. https://doi.org/10.3390/agronomy10050752

APA StyleCámara-Zapata, J. M., Sánchez-Molina, J. A., Wang, H., Carreño-Ortega, A., & Rodríguez, F. (2020). Evaluation of an Adapted Greenhouse Cooling System with Pre-Chamber and Inflatable Air Ducts for Semi-Arid Regions in Warm Conditions. Agronomy, 10(5), 752. https://doi.org/10.3390/agronomy10050752