Carbon Footprint and Life-Cycle Costs of Maize Production in Conventional and Non-Inversion Tillage Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection

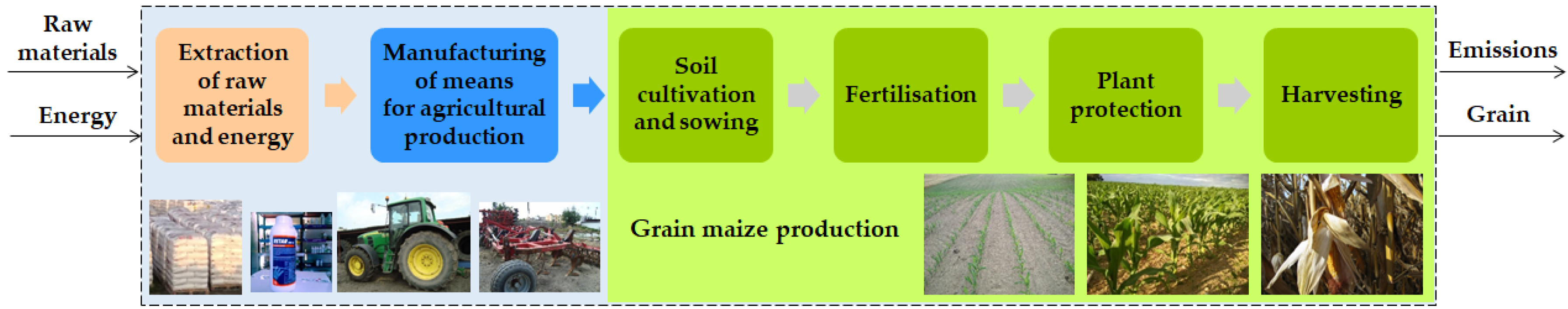

2.2. Carbon Footprint (CF) Assessment

2.3. Life-Cycle Costing

3. Results and Discussion

3.1. Inventory Analysis

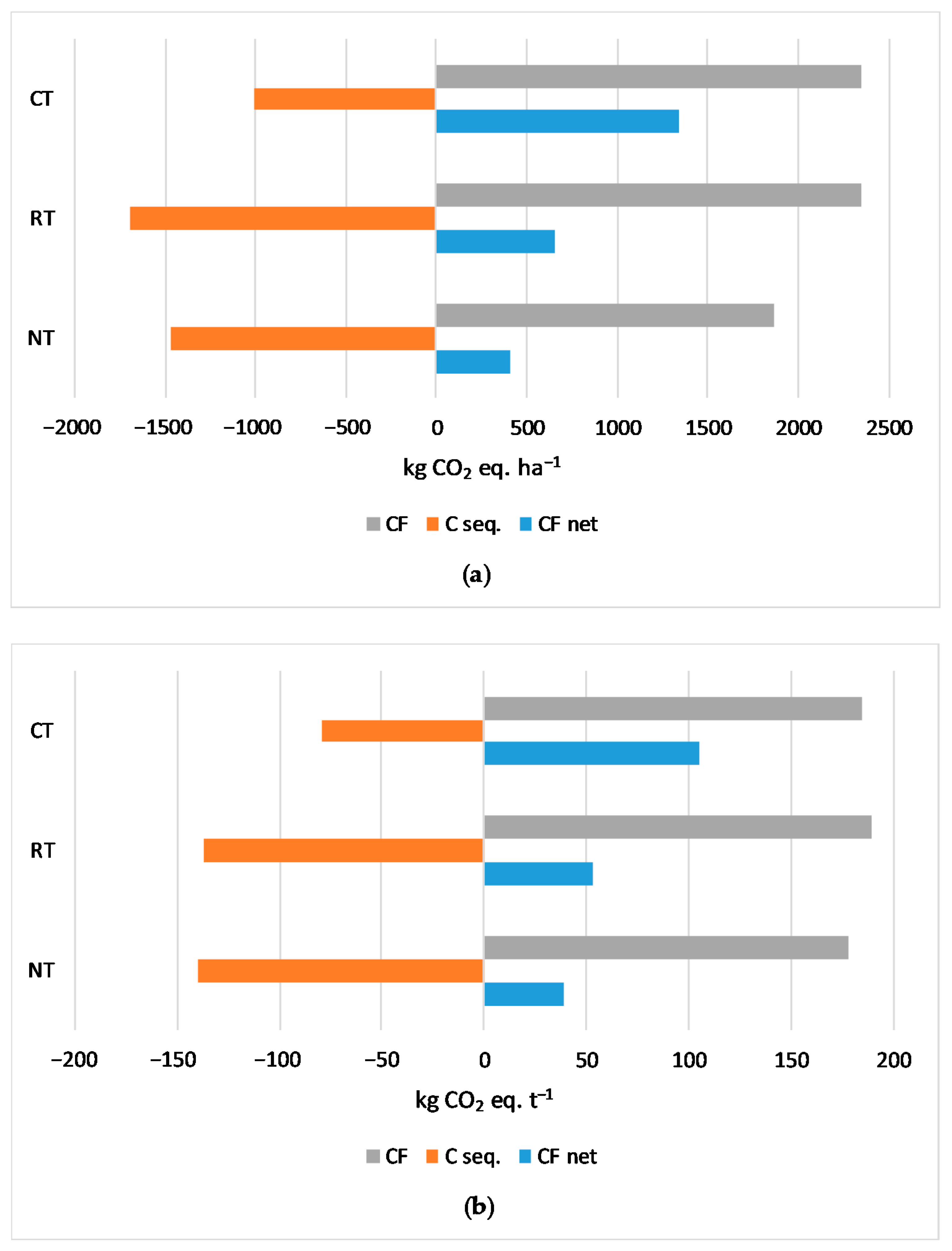

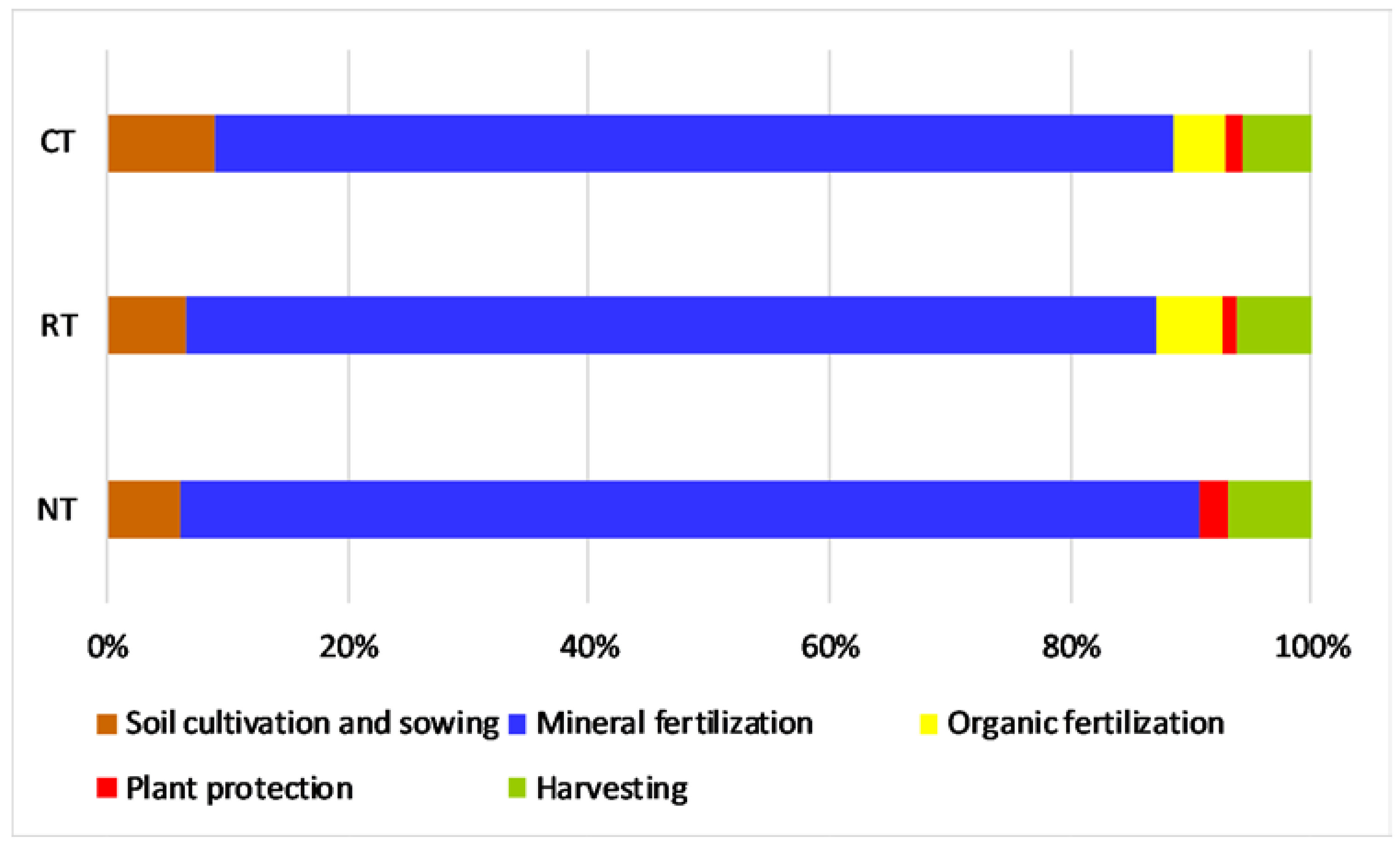

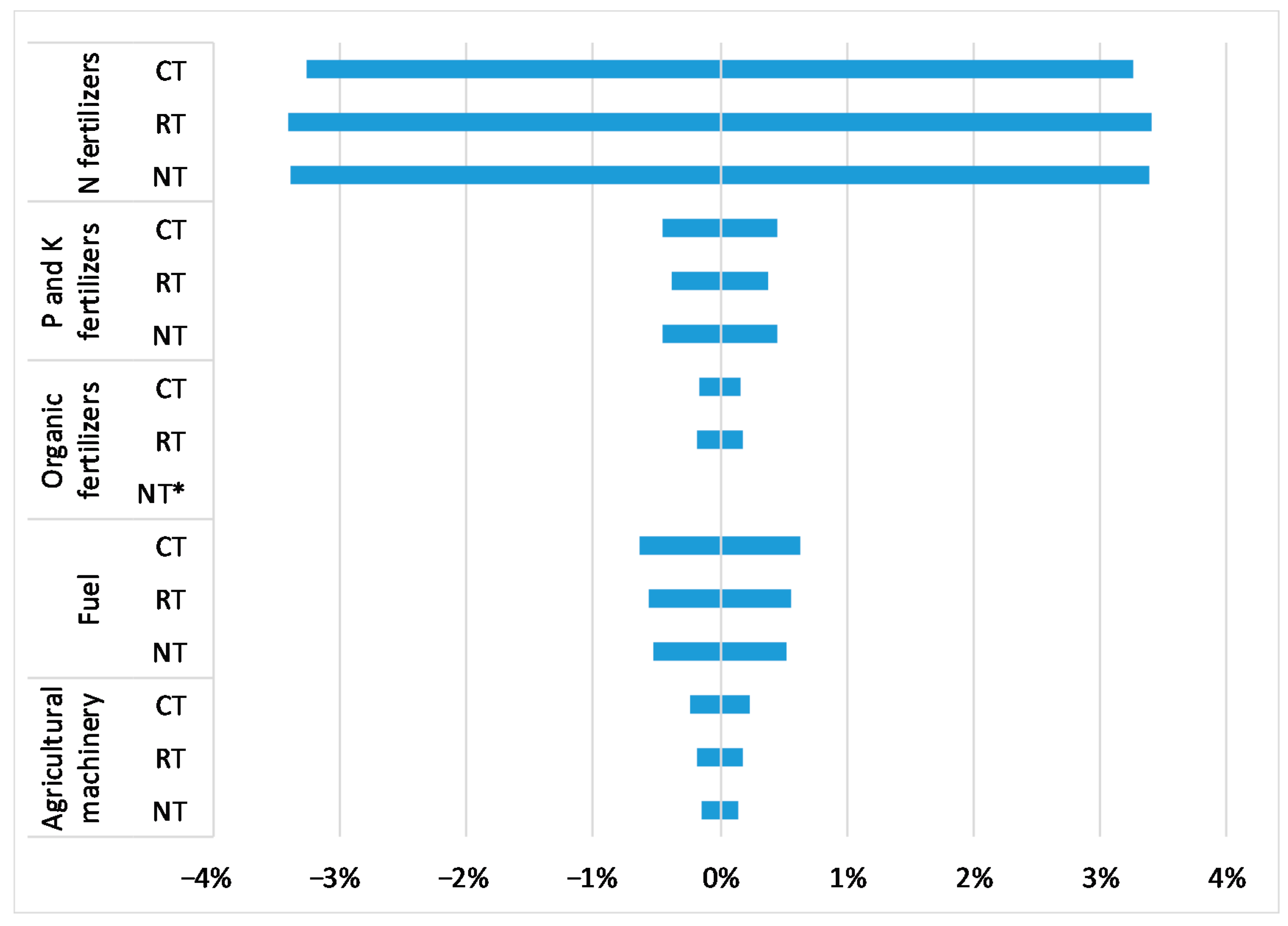

3.2. Carbon Footprint

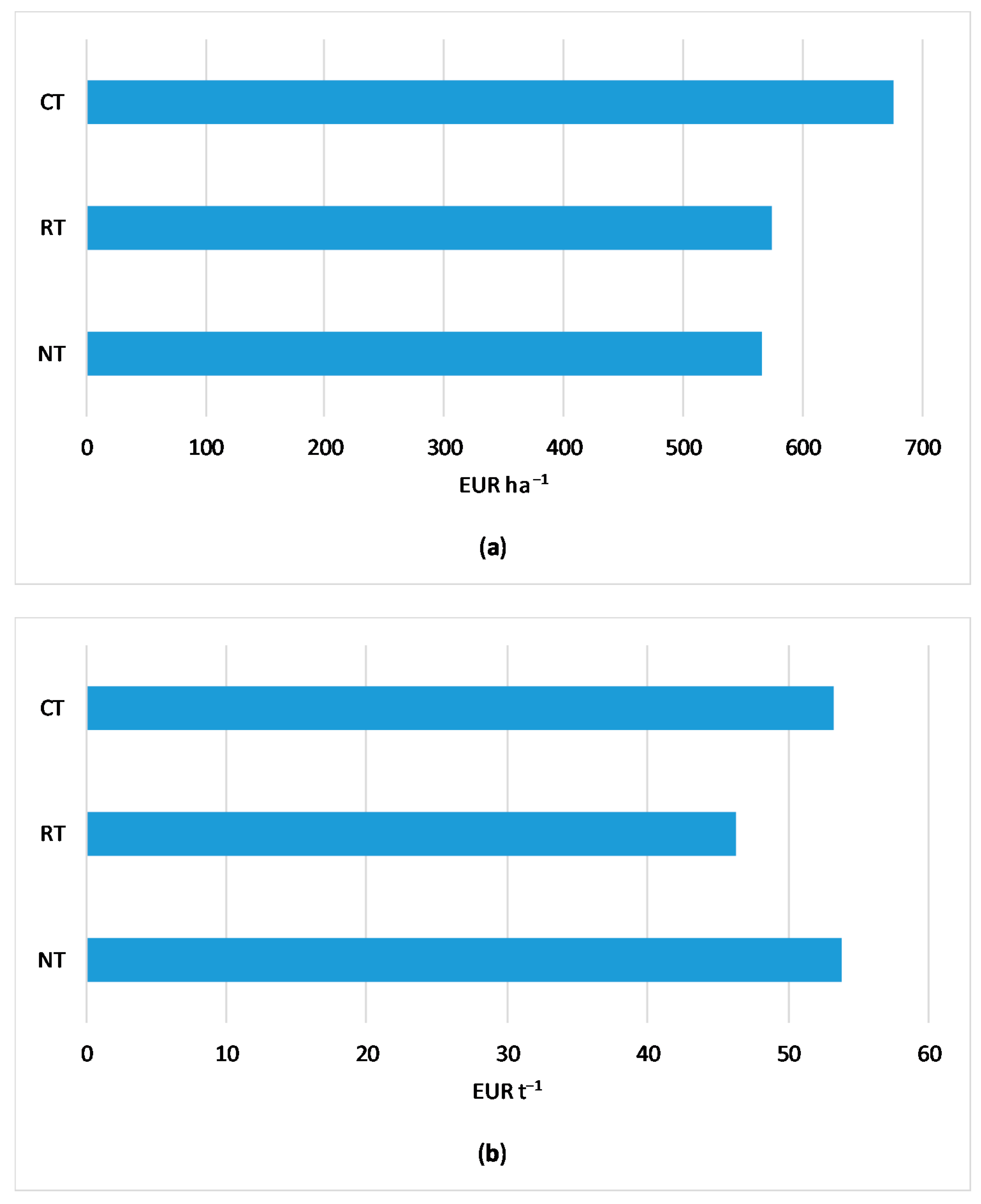

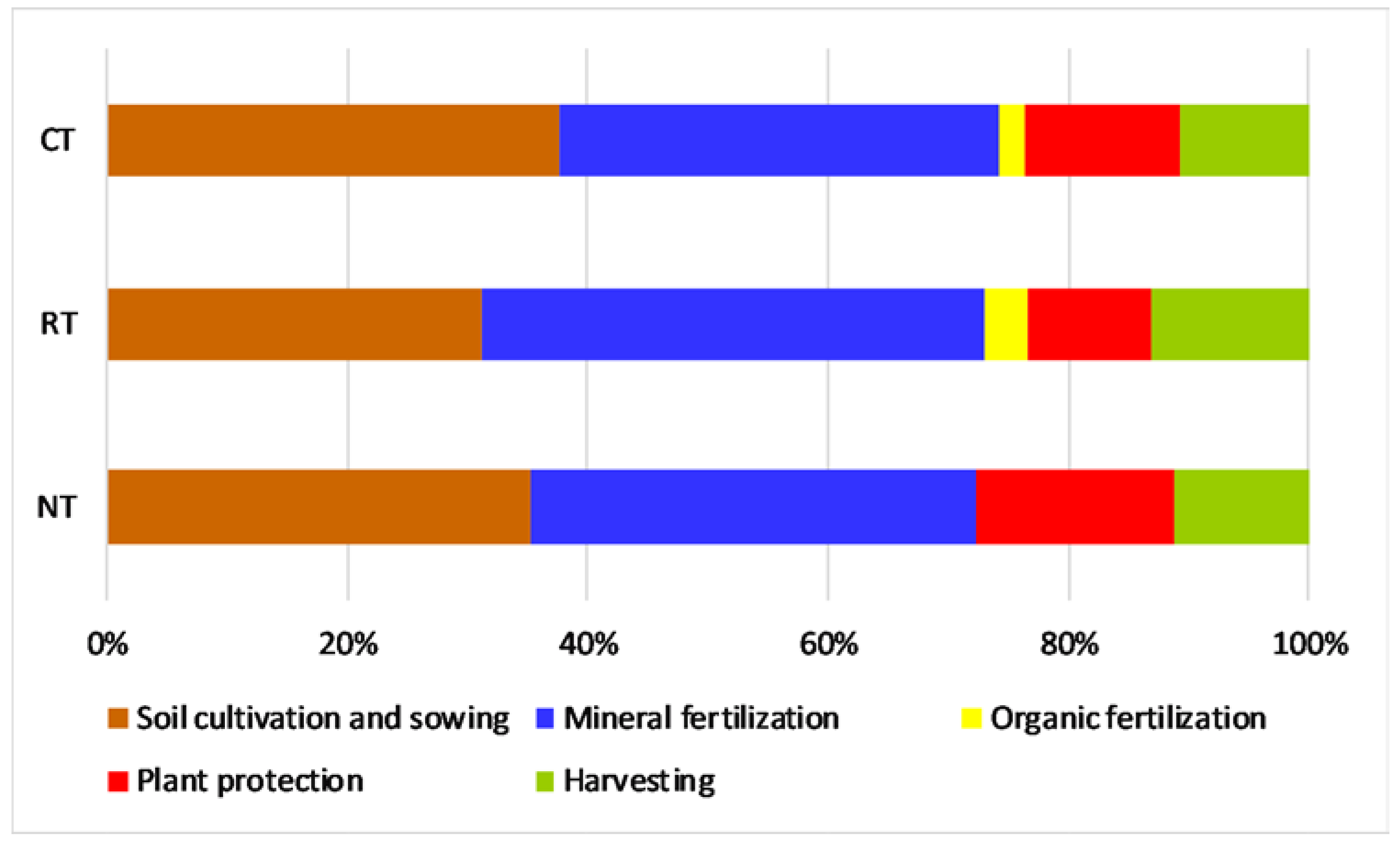

3.3. Costs of Maize Production

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aneja, V.P.; Schlesinger, W.H.; Erisman, J.W. Effects of agriculture upon the air quality and climate: Research, policy, and regulations. Environ. Sci. Technol. 2009, 43, 4234–4240. [Google Scholar] [CrossRef]

- Średnicka-Tober, D.; Obiedzińska, A.; Kazimierczak, R.; Rembiałkowska, E. Environmental impact of organic vs. conventional agriculture-a review. J. Res. Appl. Agric. Eng. 2016, 61, 204–211. [Google Scholar]

- Pawlak, J. Emisja gazów cieplarnianych w wyniku działalności rolniczej krajów Unii Europejskiej. Woda-Środowisko-Obszary Wiejskie 2018, 18, 39–48. [Google Scholar]

- Pawlak, J. Poziom i struktura emisji gazów cieplarnianych w rolnictwie. Probl. Inż. Rol. 2017, 98, 55–63. [Google Scholar]

- Kundzewicz, Z.W.; Kozyra, J. Ograniczanie wpływu zagrożeń klimatycznych w odniesieniu do rolnictwa i obszarów wiejskich. Pol. J. Agron. 2011, 7, 68–81. [Google Scholar]

- European Council Conclusions 2014. 2030 Climate and Energy Policy Framework. Conclusions. EUCO 169/14. 23–24 October 2014. Available online: https://www.consilium.europa.eu/uedocs/cms_data/docs/pressdata/en/ec/145397.pdf (accessed on 21 July 2020).

- Regulation (EU) 2018/842 of the European Parliament and of the Council of 30 May 2018 on Binding Annual Greenhouse Gas Emission Reductions by Member States from 2021 to 2030 Contributing to Climate Action to Meet Commitments under the Paris Agreement and Amending Regulation (EU) No 525/2013 (OJ L 156, 19.6.2018). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32018R0842 (accessed on 21 July 2020).

- Food and Agriculture Organization of the United Nations (FAO). World Food and Agriculture. Statistical Pocketbook 2019; FAO: Rome, Italy, 2019; ISBN 978-92-5-131849-2. [Google Scholar]

- Statistics Poland. Statistical Yearbook of Agriculture 2019; Statistics Poland: Warsaw, Poland, 2020.

- Ranum, P.; Pena-Rosas, J.P.; Garcia-Casal, M.N. Global maize production, utilization, and consumption. Ann. N. Y. Acad. Sci. 2014, 1312, 105–112. [Google Scholar] [CrossRef]

- Księżak, J.; Bojarszczuk, J.; Staniak, M. Produkcyjność kukurydzy i sorga w zależności od poziomu nawożenia azotem. Pol. J. Agron. 2012, 8, 20–28. [Google Scholar]

- Morris, N.; Miller, P.; Orson, J.H.; Froud-Williams, R. The adoption of non-inversion tillage systems in the United Kingdom and the agronomic impact on soil, crops and the environment—A review. Soil Till. Res. 2010, 108, 1–15. [Google Scholar] [CrossRef]

- Soane, B.; Ball, B.; Arvidsson, J.; Basch, G.; Moreno, F.; Roger-Estrade, J. No-till in northern, western and south western Europe: A review of problems and opportunities for crop production and the environment. Soil Till. Res. 2012, 118, 66–87. [Google Scholar] [CrossRef]

- Holland, J.M. The environmental consequences of adopting conservation tillage in Europe: Reviewing the evidence. Agric. Ecosyst. Environ. 2004, 103, 1–25. [Google Scholar] [CrossRef]

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate change and food systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef]

- Romeiko, X.X. A comparative life cycle assessment of crop systems irrigated with the groundwater and reclaimed water in Northern China. Sustainability 2019, 11, 2743. [Google Scholar] [CrossRef]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Løkke, S. Carbon footprint—A catalyst for LCA? J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef] [PubMed]

- Nette, A.; Wolf, P.; Schlüter, O.; Meyer-Aurich, A. A comparison of carbon footprint and production cost of different pasta products based on whole egg and pea flour. Foods 2016, 5, 17. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, Y.; He, Q.; Yang, Y. Calculation and evaluation of carbon footprint in mulberry production: A case of haining in China. Int. J. Environ. Res. Public Health 2020, 17, 1339. [Google Scholar] [CrossRef] [PubMed]

- Platis, D.P.; Anagnostopoulos, C.D.; Tsaboula, A.D.; Menexes, G.C.; Kalburtji, K.L.; Mamolos, A.P. Energy analysis, and carbon and water footprint for environmentally friendly farming practices in agroecosystems and agroforestry. Sustainability 2019, 11, 1664. [Google Scholar] [CrossRef]

- Busari, M.A.; Kukal, S.S.; Kaur, A.; Bhatt, R.; Dulazi, A.A. Conservation tillage impacts on soil, crop and the environment. Int. Soil Water Conserv. Res. 2015, 3, 119–129. [Google Scholar] [CrossRef]

- Debska, B.; Jaskulska, I.; Jaskulski, D. Method of tillage with the factor determining the quality of organic matter. Agronomy 2020, 10, 1250. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A Policy Framework for Climate and Energy in the Period from 2020 to 2030, COM/2014/015 Final; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal, COM/2019/640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Eurostat. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&init=1&language=en&pcode=tag00093&plugin=1 (accessed on 28 October 2020).

- Statistics Poland. Production of Agricultural and Horticultural Crops in 2019; Statistics Poland: Warsaw, Poland, 2019.

- Baum, R.; Bieńkowski, J. Eco-efficiency in measuring the sustainable production of agricultural crops. Sustainability 2020, 12, 1418. [Google Scholar] [CrossRef]

- BSI 2011. PAS 2050: Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; British Standards Institute: London, UK, 2011; ISBN 978-0-580-71382-8. [Google Scholar]

- Cucurachi, S.; Scherer, L.; Guinée, J.; Tukker, A. Life cycle assessment of food systems. One Earth 2019, 1, 292–297. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14040:2006. Environmental Management–Life Cycle Assessment–Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Ecoinvent Center Ecoinvent Database Website. Available online: http://www.ecoinvent.ch/ (accessed on 20 September 2019).

- Intergovernmental Panel on Climate Change (IPCC). 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Volume 4. Agriculture, Forestry and Other Land Use. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html (accessed on 20 September 2019).

- European Environment Agency (EEA). EMEP/EEA Air Pollutant Emission Inventory Guidebook 2013; Publications Office of the European Union: Luxembourg, 2013; ISBN 978-92-9213-403-7. [Google Scholar]

- European Environment Agency (EEA). EMEP/EEA Air Pollutant Emission Inventory Guidebook 2016; Publications Office of the European Union: Luxembourg, 2016; ISBN 978-92-9213-806-6. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; ISBN 978-0-306-48055-3. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2013. In The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; ISBN 978-1-107-85799-1. [Google Scholar]

- Petersen, B.; Knudsen, M.; Hermansen, J.; Halberg, N. An approach to include soil carbon changes in life cycle assessments. J. Clean. Prod. 2013, 52, 217–224. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment. Part 1: Framework, goal and scope definition, inventory analysis and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Muzalewski, A. Koszty Eksploatacji Maszyn; ITP: Falenty-Warsaw, Poland, 2010; ISBN 978-83-62416-05-9. [Google Scholar]

- Camargo, G.G.T.; Ryan, M.R.; Richard, T.L. Energy use and greenhouse gas emissions from crop production using the farm energy analysis tool. BioScience 2013, 63, 263–273. [Google Scholar] [CrossRef]

- Jayasundara, S.; Wagner-Riddle, C.; Dias, G.; Kariyapperuma, K.A. Energy and greenhouse gas intensity of corn (Zea mays L.) production in Ontario: A regional assessment. Can. J. Soil Sci. 2014, 94, 77–95. [Google Scholar] [CrossRef]

- Ma, B.L.; Liang, B.C.; Biswas, D.K.; Morrison, M.J.; McLaughlin, N.B. The carbon footprint of maize production as affected by nitrogen fertilizer and maize-legume rotations. Nutr. Cycl. Agroecosyst. 2012, 94, 15–31. [Google Scholar] [CrossRef]

- Jarosz, Z.; Księżak, J.; Faber, A. Ocena wielkości emisji gazów cieplarnianych systemów uprawy stosowanych w kukurydzy wykorzystywanej do produkcji bioetanolu. Rocz. Nauk. SERiA 2017, 19, 60–65. [Google Scholar] [CrossRef]

- Khorramdel, S.; Koocheki, A.; Nassiri-Mahallati, M.; Khorassani, R.; Ghorbani, R. Evaluation of carbon sequestration potential in corn fields with different management systems. Soil Till. Res. 2013, 133, 25–31. [Google Scholar] [CrossRef]

- Liu, C.; Cutforth, H.; Chai, Q.; Gan, Y. Farming tactics to reduce the carbon footprint of crop cultivation in semiarid areas. A review. Agron. Sustain. Dev. 2016, 36, 69. [Google Scholar] [CrossRef]

- Parajuli, R.; Kristensen, I.S.; Knudsen, M.T.; Mogensen, L.; Corona, A.; Birkved, M.; Peña, N.; Graversgaard, M.; Dalgaard, T. Environmental life cycle assessments of producing maize, grass-clover, ryegrass and winter wheat straw for biorefinery. J. Clean. Prod. 2017, 142, 3859–3871. [Google Scholar] [CrossRef]

- Bacenetti, J.; Fusi, A.; Guidetti, R.; Fiala, M. Life Cycle Assessment of maize cultivation for biogas production. J. Agric. Eng. 2013, 44. [Google Scholar] [CrossRef]

- McGill, B.M.; Hamilton, S.K.; Millar, N.; Robertson, G.P. The greenhouse gas cost of agricultural intensification with groundwater irrigation in a Midwest U.S. row cropping system. Glob. Chang. Biol. 2018, 24, 5948–5960. [Google Scholar] [CrossRef] [PubMed]

| Specification | CT | RT | NT |

|---|---|---|---|

| Number of farms | 5 | 5 | 5 |

| UAA (ha) | 59.4 (18.4–100.8) | 69.5 (29.9–112.7) | 72.6 (28.8–144.9) |

| Share of arable lands (%) | 94.0 (89.4–99.3) | 93.3 (85.0–100.0) | 98.2 (95.2–100.0) |

| Share of permanent grasslands (%) | 6.0 (0.5–10.6) | 6.7 (0.0–15.0) | 1.8 (0.0–4.8) |

| Livestock density (LSU/ha UAA) | 0.5 (0.0–1.7) | 0.4 (0.0–1.4) | 0.4 (0.0–2.1) |

| Cropping pattern (%) | |||

| Cereals | 75.1 (28.6–100.0) | 69.2 (59.6–93.8) | 79.1 (54.7–100.0) |

| Root crops | 4.2 (0.0–13.0) | 17.7 (6.3–38.4) | 5.2 (0.0–20.0) |

| Oilseed plants | 2.8 (0.0–23.9) | 4.3 (0.0–16.2) | 11.6 (0.0–28.1) |

| Other plants | 17.9 (0.0–58.4) | 8.8 (0.0–30.0) | 4.1 (0.0–20.7) |

| Type of Input | Consumption | Cost (EUR) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| per 1 ha | per 1 t | per 1 ha | per 1 t | |||||||||

| CT | RT | NT | CT | RT | NT | CT | RT | NT | CT | RT | NT | |

| Seeds (kg) | 21.1 | 17.9 | 27.2 | 1.66 | 1.44 | 2.59 | 100.5 | 85.2 | 129.4 | 7.91 | 6.87 | 12.3 |

| N fertilizers (kg N) | 129.2 | 143.8 | 113.7 | 10.2 | 11.6 | 10.8 | 91.0 | 102.6 | 79.3 | 7.17 | 8.27 | 7.55 |

| P fertilizers (kg P2O5) | 75.3 | 62.0 | 47.8 | 5.93 | 5.00 | 4.55 | 62.0 | 49.0 | 40.1 | 4.88 | 3.95 | 3.82 |

| K fertilizers (kg K2O) | 97.7 | 99.3 | 106.5 | 7.69 | 8.00 | 10.1 | 59.8 | 61.5 | 62.3 | 4.71 | 4.96 | 5.93 |

| Organic fertilizers (kg N) | 49.3 | 37.4 | 0.0 | 3.88 | 3.02 | 0.00 | 0.0 | 0.0 | 0.0 | 0.00 | 0.00 | 0.00 |

| Organic fertilizers (kg P2O5) | 40.8 | 27.9 | 0.0 | 3.21 | 2.25 | 0.00 | 0.0 | 0.0 | 0.0 | 0.00 | 0.00 | 0.00 |

| Organic fertilizers (kg K2O) | 97.2 | 65.1 | 0.0 | 7.65 | 5.25 | 0.00 | 0.0 | 0.0 | 0.0 | 0.00 | 0.00 | 0.00 |

| Herbicides (kg a.s.) | 0.2 | 0.7 | 1.4 | 0.02 | 0.06 | 0.13 | 51.2 | 37.6 | 56.2 | 4.03 | 3.03 | 5.35 |

| Fungicides (kg a.s.) | 0.0 | 0.0 | 0.05 | 0.00 | 0.00 | 0.005 | 0.0 | 0.0 | 10.1 | 0.00 | 0.00 | 0.96 |

| Insecticides (kg a.s.) | 0.01 | 0.01 | 0.01 | 0.001 | 0.001 | 0.001 | 2.3 | 2.2 | 4.0 | 0.18 | 0.18 | 0.38 |

| Agricultural machinery (kg) | 14.8 | 12.5 | 6.4 | 1.17 | 1.01 | 0.61 | 111.5 | 65.1 | 60.3 | 8.78 | 5.25 | 5.74 |

| Spare parts (kg) | 4.6 | 3.9 | 2.0 | 0.36 | 0.32 | 0.19 | 48.3 | 32.8 | 31.5 | 3.80 | 2.65 | 3.00 |

| Diesel oil (kg) | 87.4 | 77.1 | 51.8 | 6.88 | 6.22 | 4.93 | 92.5 | 81.6 | 61.1 | 7.28 | 6.58 | 5.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Holka, M.; Bieńkowski, J. Carbon Footprint and Life-Cycle Costs of Maize Production in Conventional and Non-Inversion Tillage Systems. Agronomy 2020, 10, 1877. https://doi.org/10.3390/agronomy10121877

Holka M, Bieńkowski J. Carbon Footprint and Life-Cycle Costs of Maize Production in Conventional and Non-Inversion Tillage Systems. Agronomy. 2020; 10(12):1877. https://doi.org/10.3390/agronomy10121877

Chicago/Turabian StyleHolka, Małgorzata, and Jerzy Bieńkowski. 2020. "Carbon Footprint and Life-Cycle Costs of Maize Production in Conventional and Non-Inversion Tillage Systems" Agronomy 10, no. 12: 1877. https://doi.org/10.3390/agronomy10121877

APA StyleHolka, M., & Bieńkowski, J. (2020). Carbon Footprint and Life-Cycle Costs of Maize Production in Conventional and Non-Inversion Tillage Systems. Agronomy, 10(12), 1877. https://doi.org/10.3390/agronomy10121877