Design, Control, and Performance Aspects of Semi-Closed Greenhouses

Abstract

1. Introduction

2. Principles, Design, and Control of a Semi-Closed Greenhouse

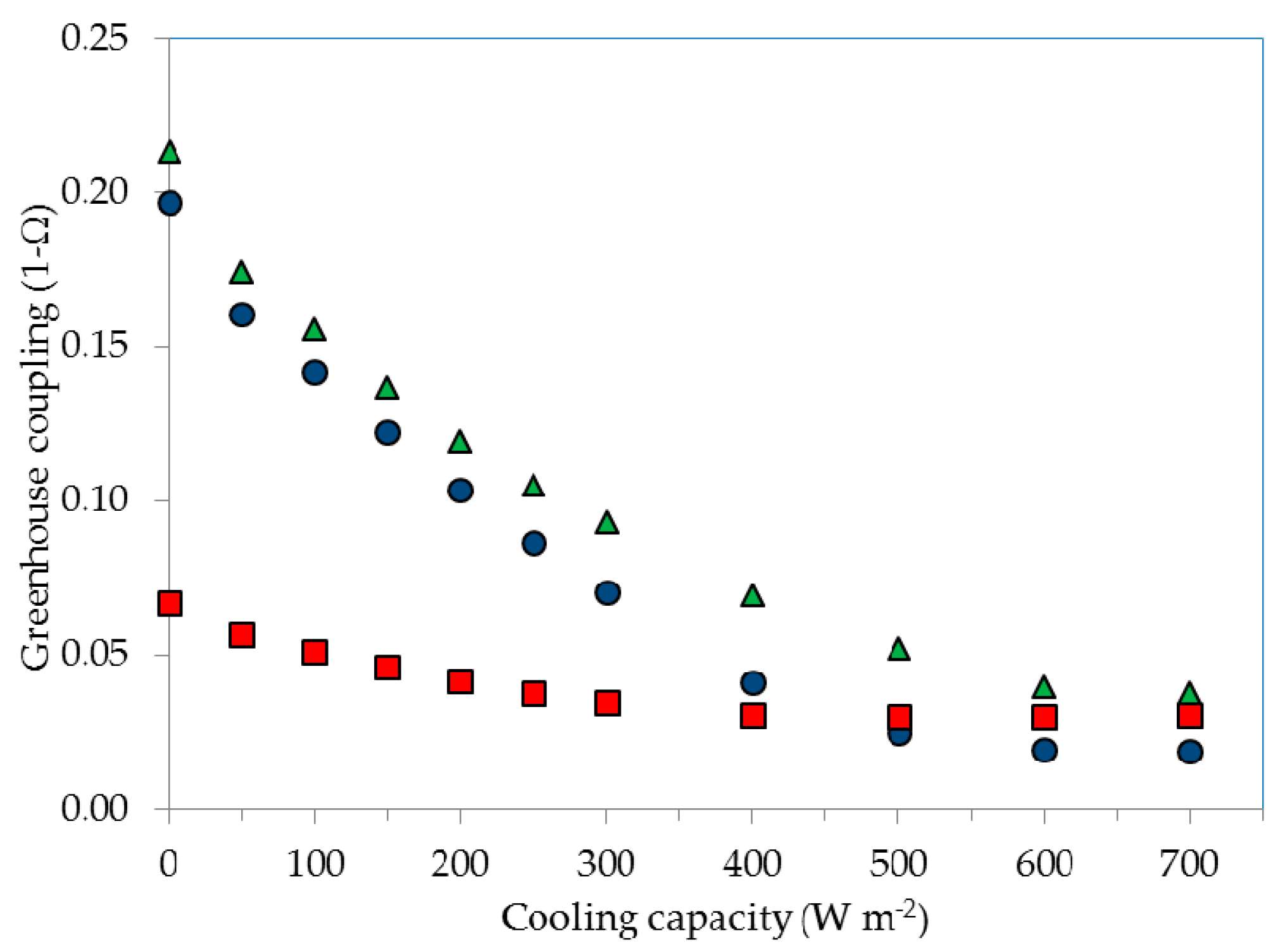

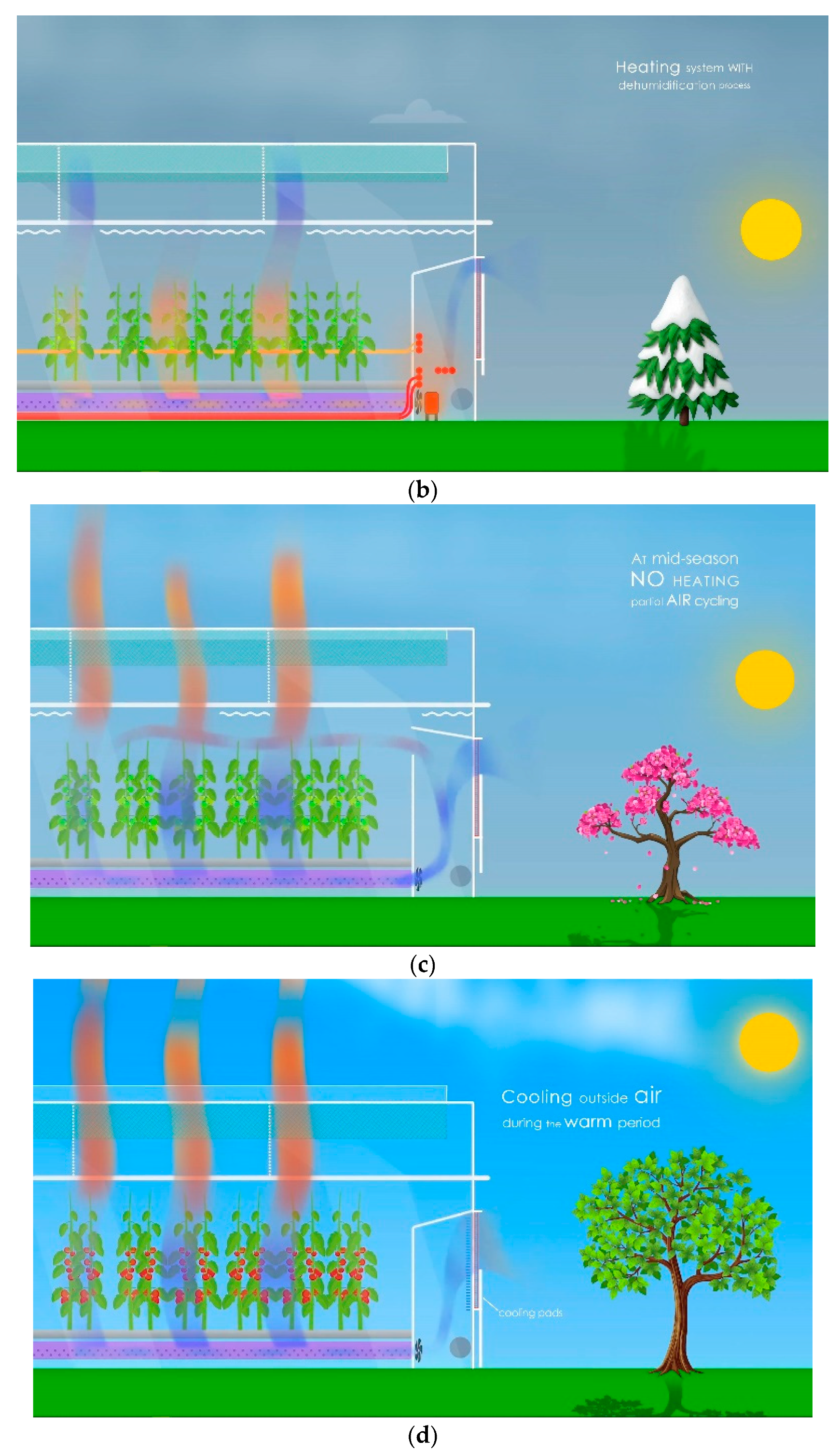

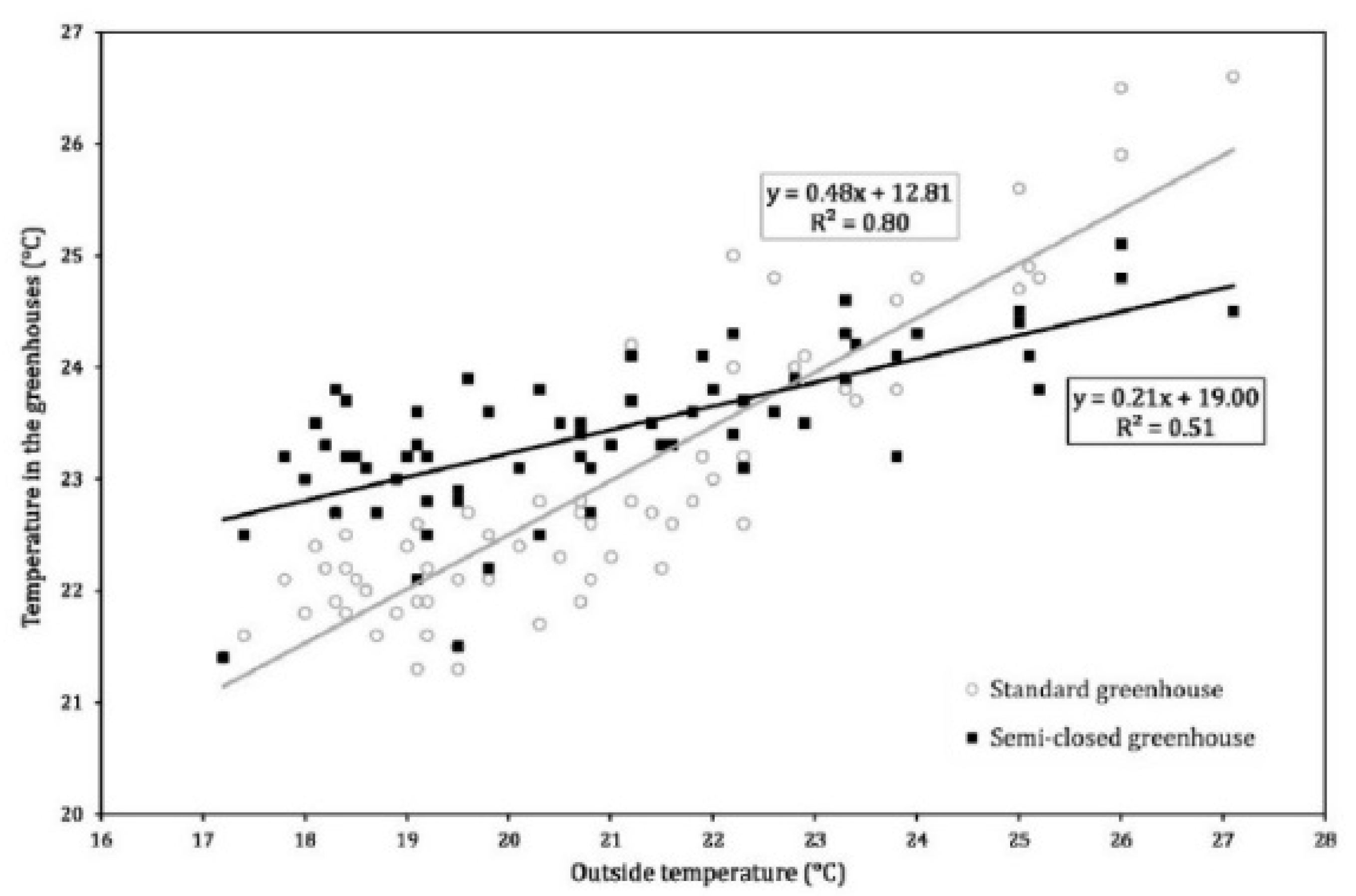

2.1. Degree of Coupling of Semi-Closed Greenhouses to Outside Climate

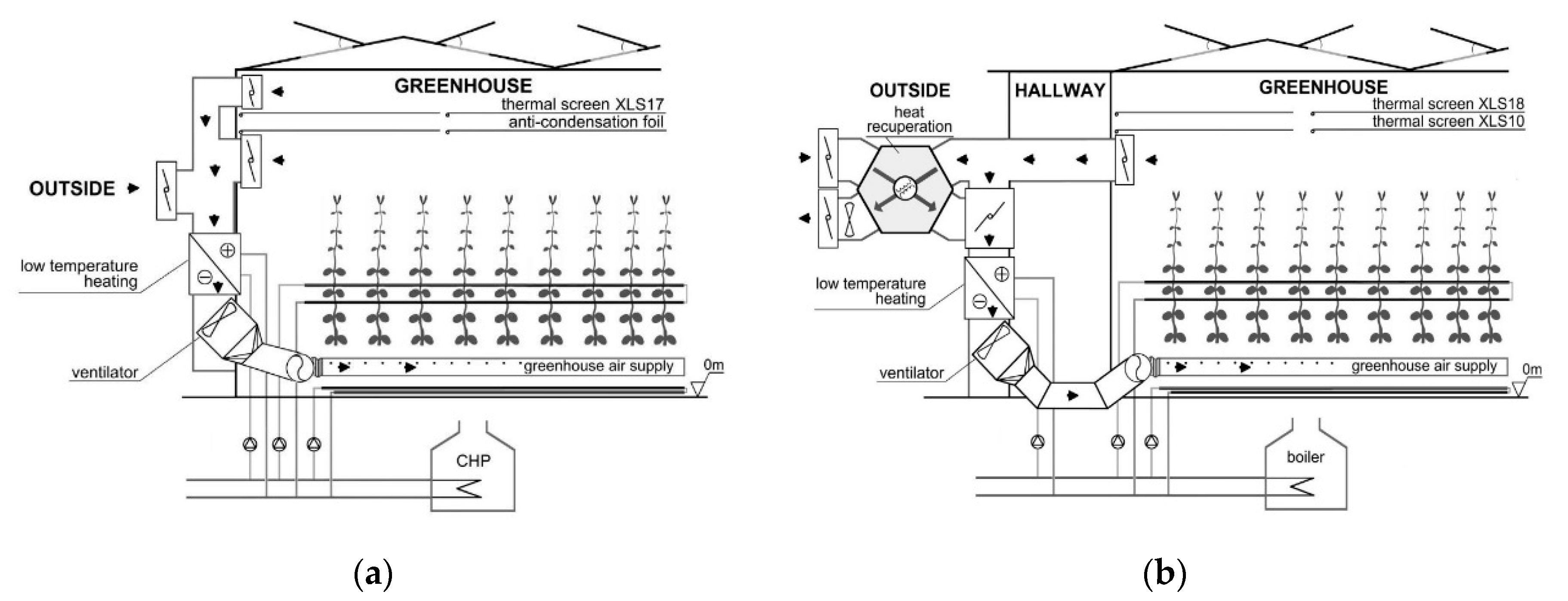

2.2. Main Design and Control Variations of Semi-Closed Greenhouse

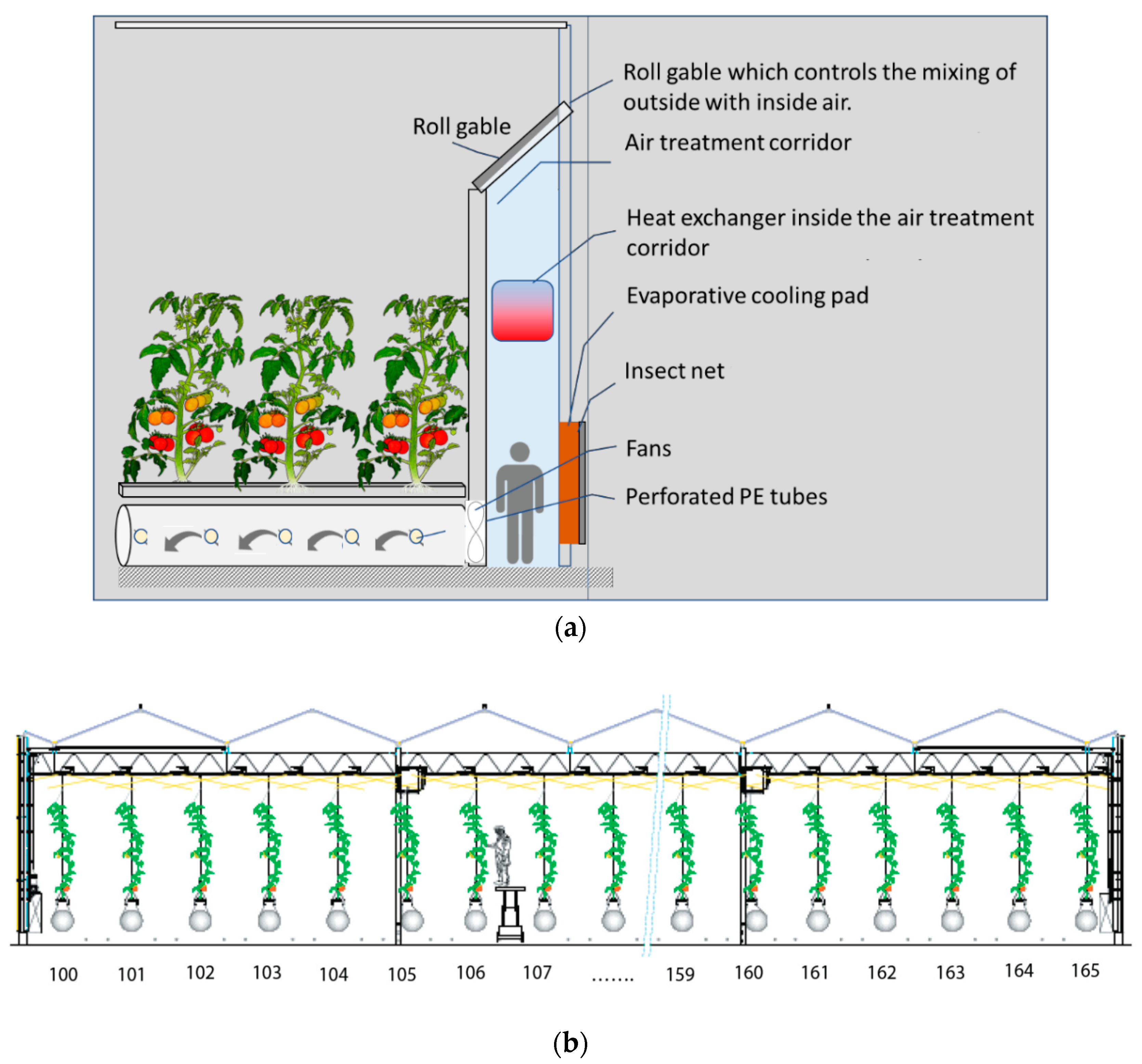

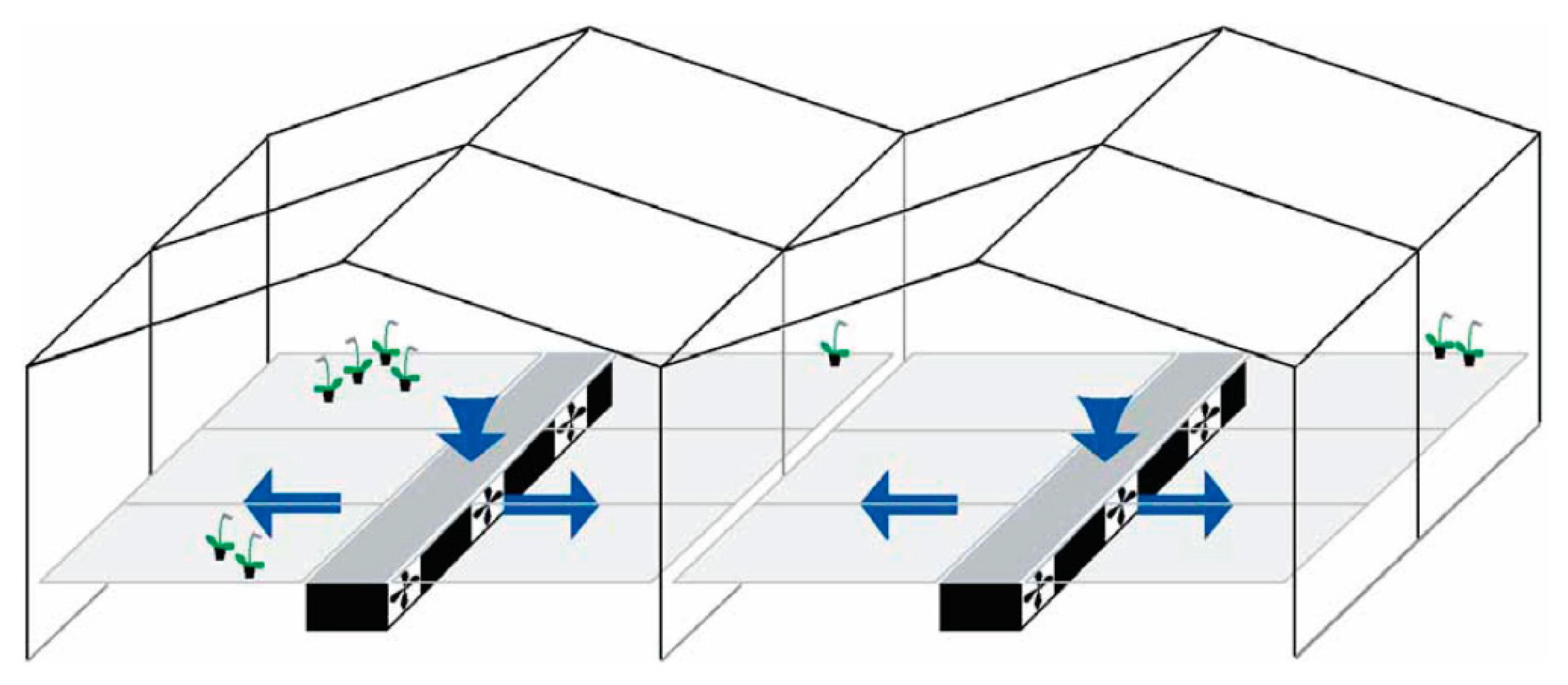

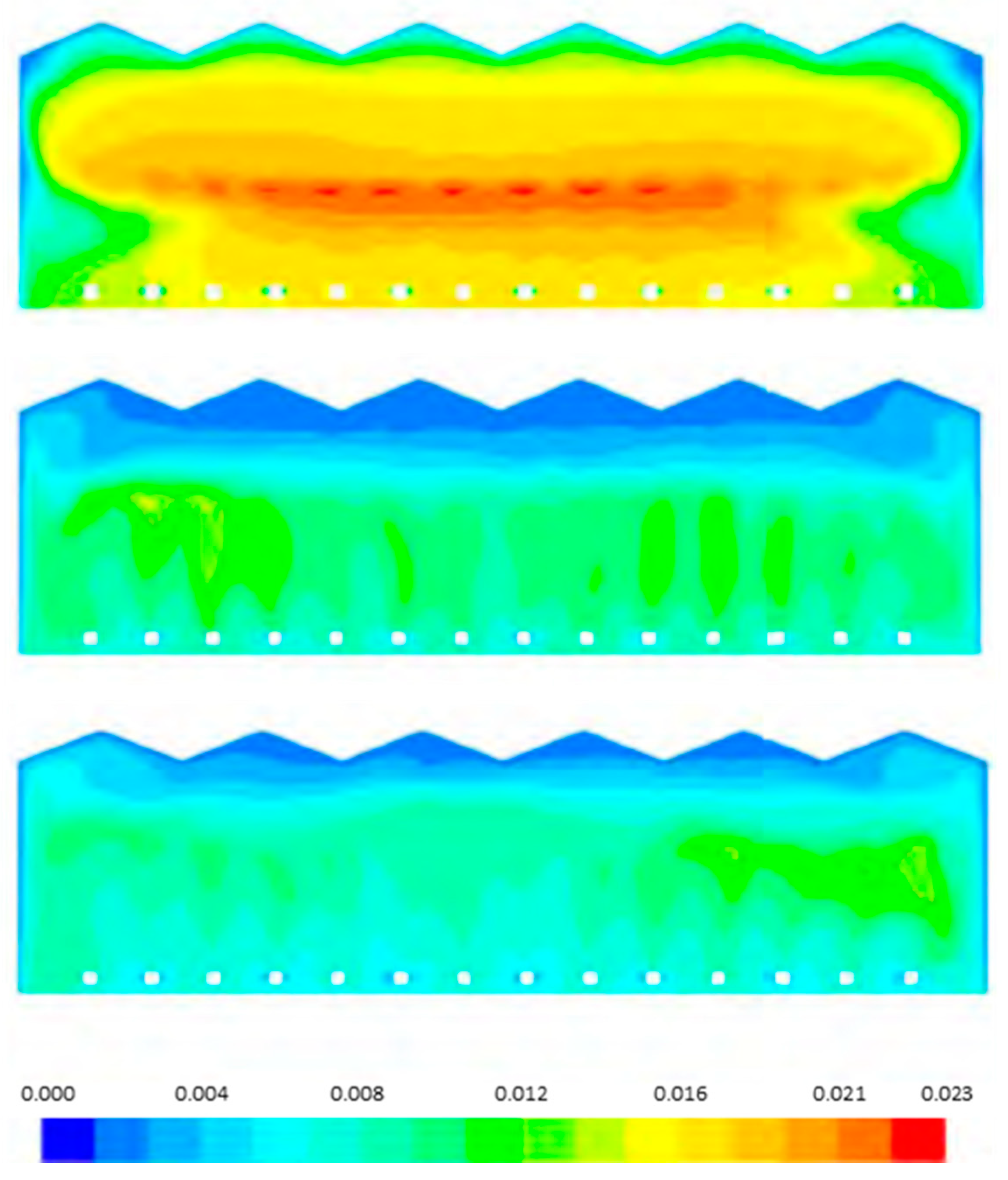

2.2.1. Air Treatment Corridor and Air Distribution System

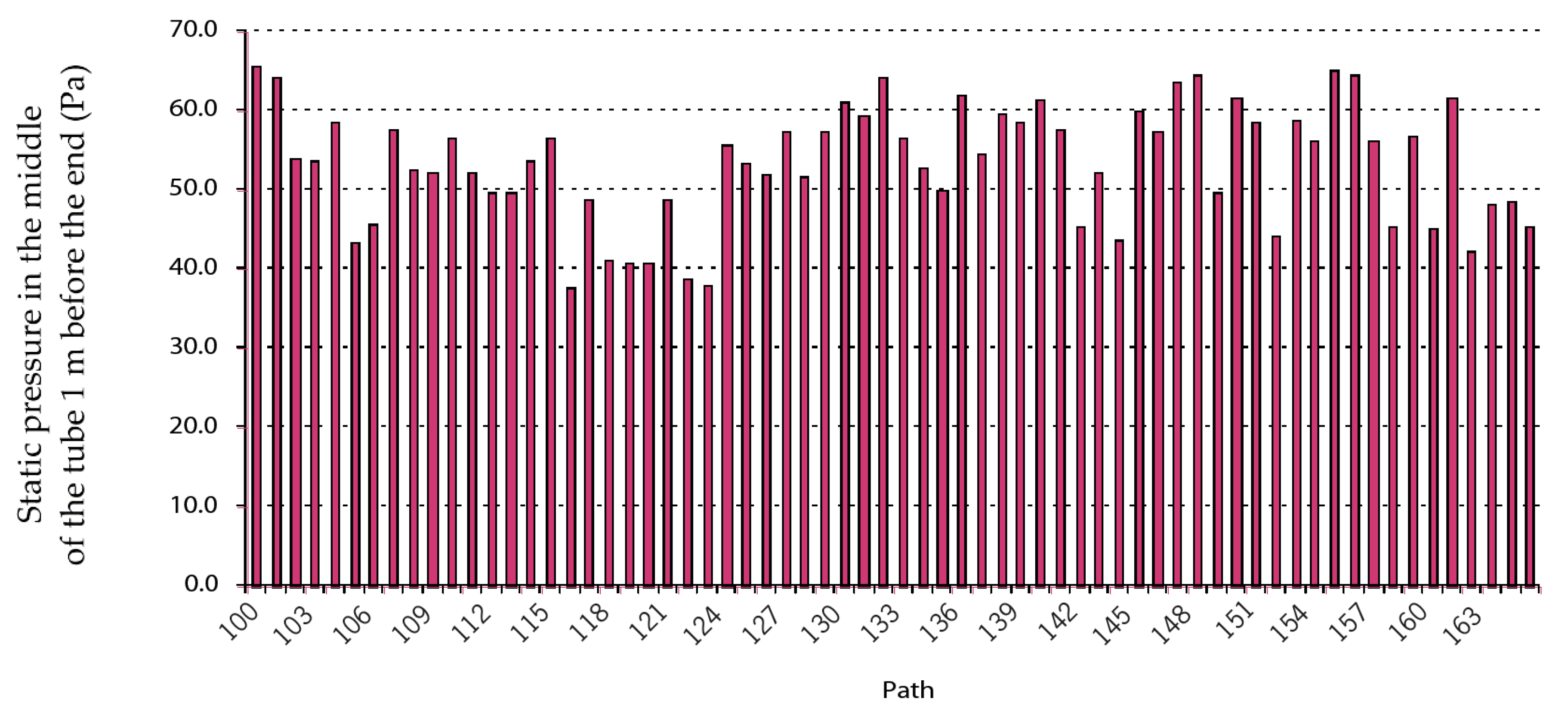

- the friction of the air with the tube wall, which causes a decrease of pressure to the direction of flow and is characterized by the friction factor;

- the reduction of the air momentum in the tube as the air is discharged at the openings, which results in an increase of pressure in the tube across each opening. This has been named the ‘diffusion’, ‘inertia’, and ‘static regain’ effect, and is characterized by the static regain coefficient, which is the change in static pressure expressed as a decimal part of the velocity pressure change.

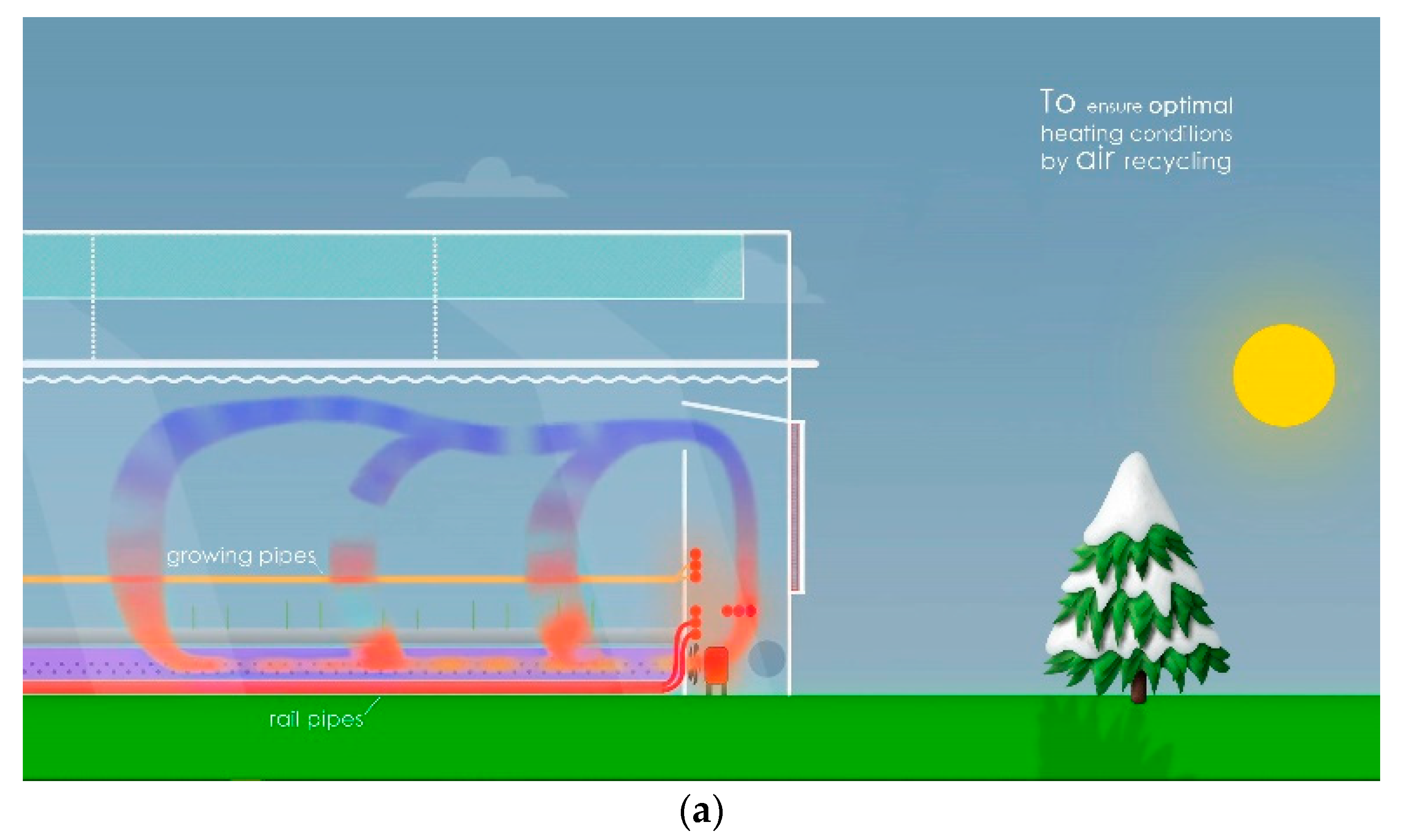

2.2.2. Decentralized Air Treatment Units

2.3. Measurements and Control of a Semi-Closed Greenhouse

3. Performance Evaluation of Semi-Closed Greenhouses

3.1. Climatic Conditions

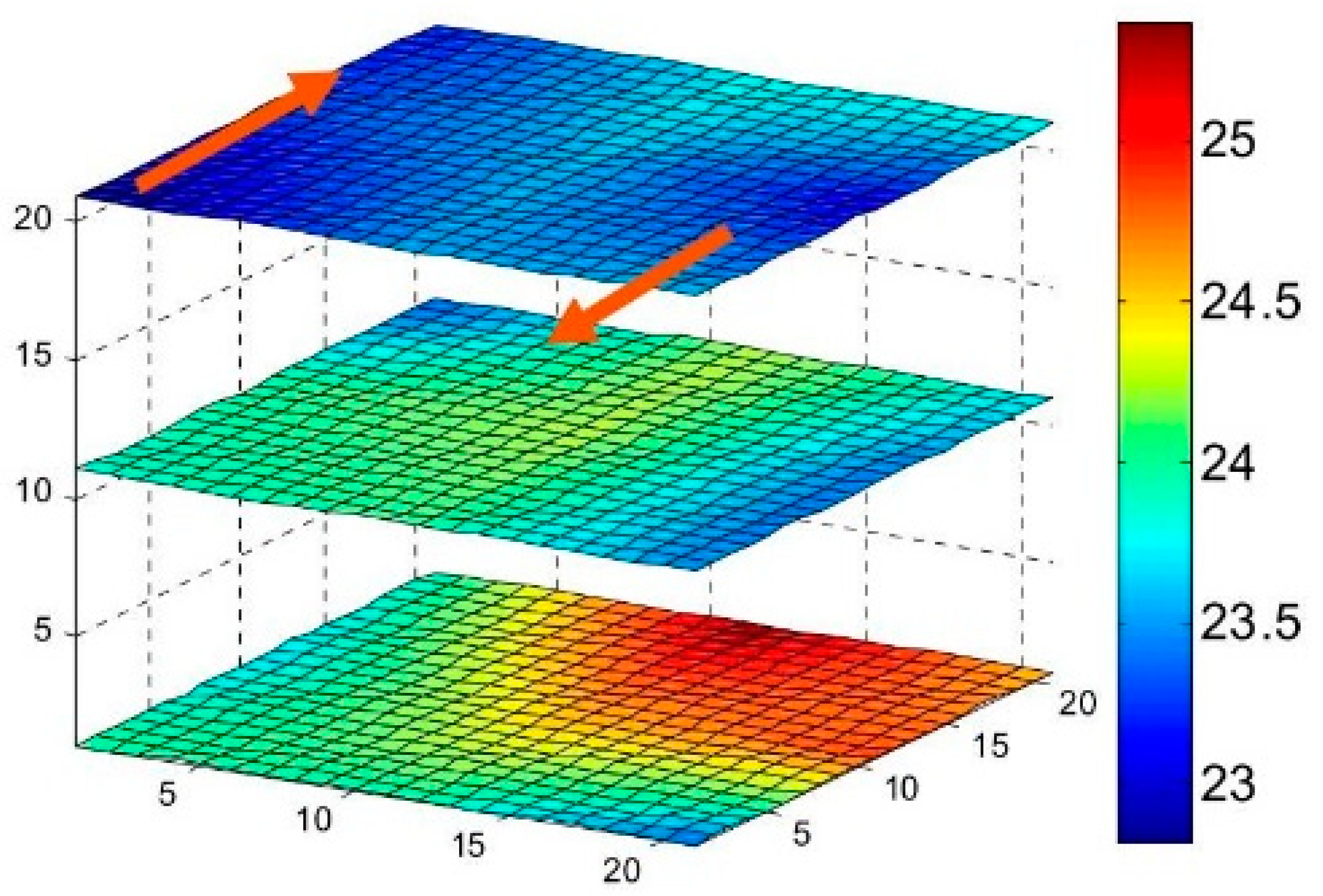

3.1.1. Air Temperature, Humidity, and Velocity

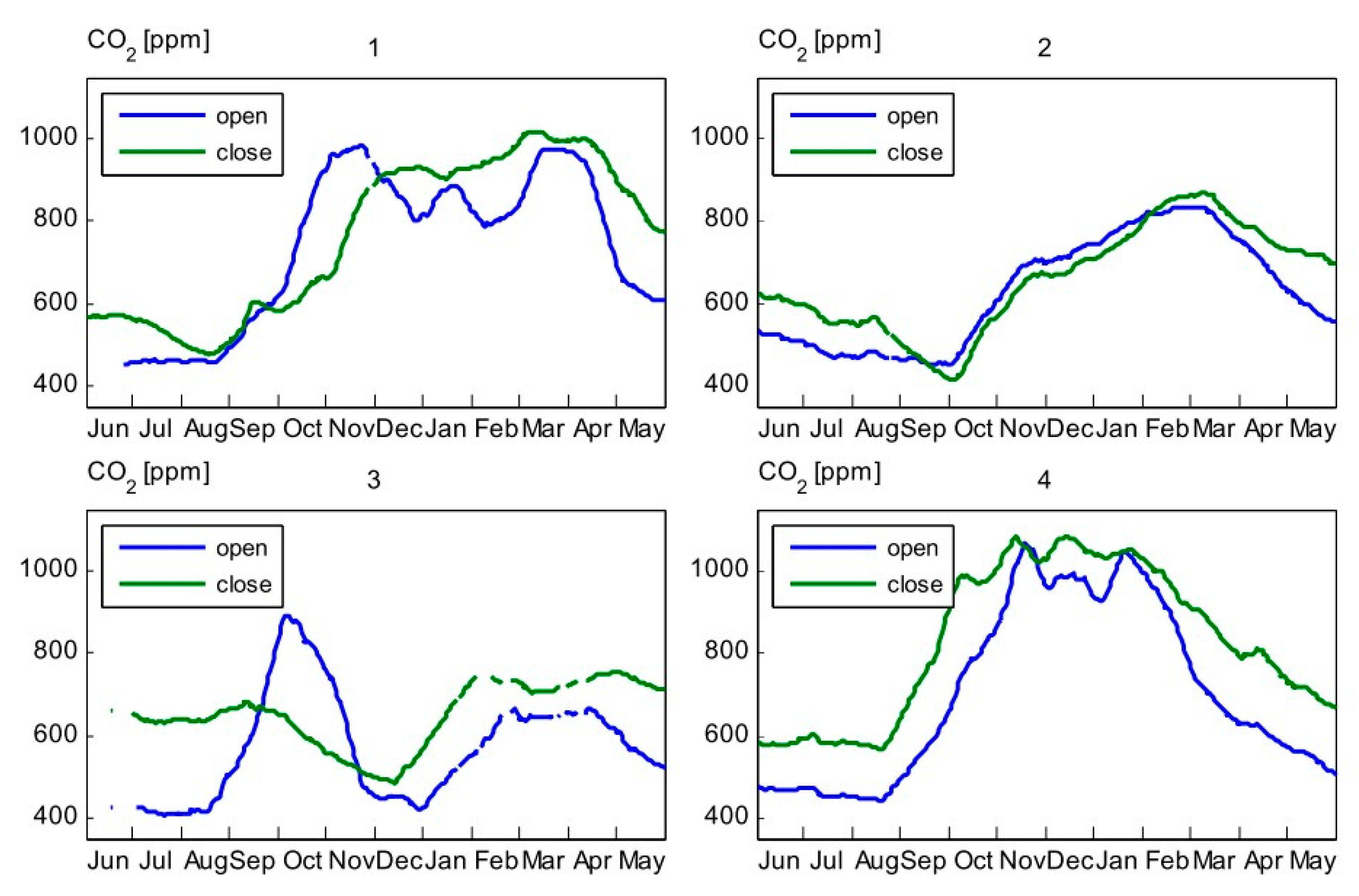

3.1.2. CO2 Concentration

3.2. Energy Consumption and Saving

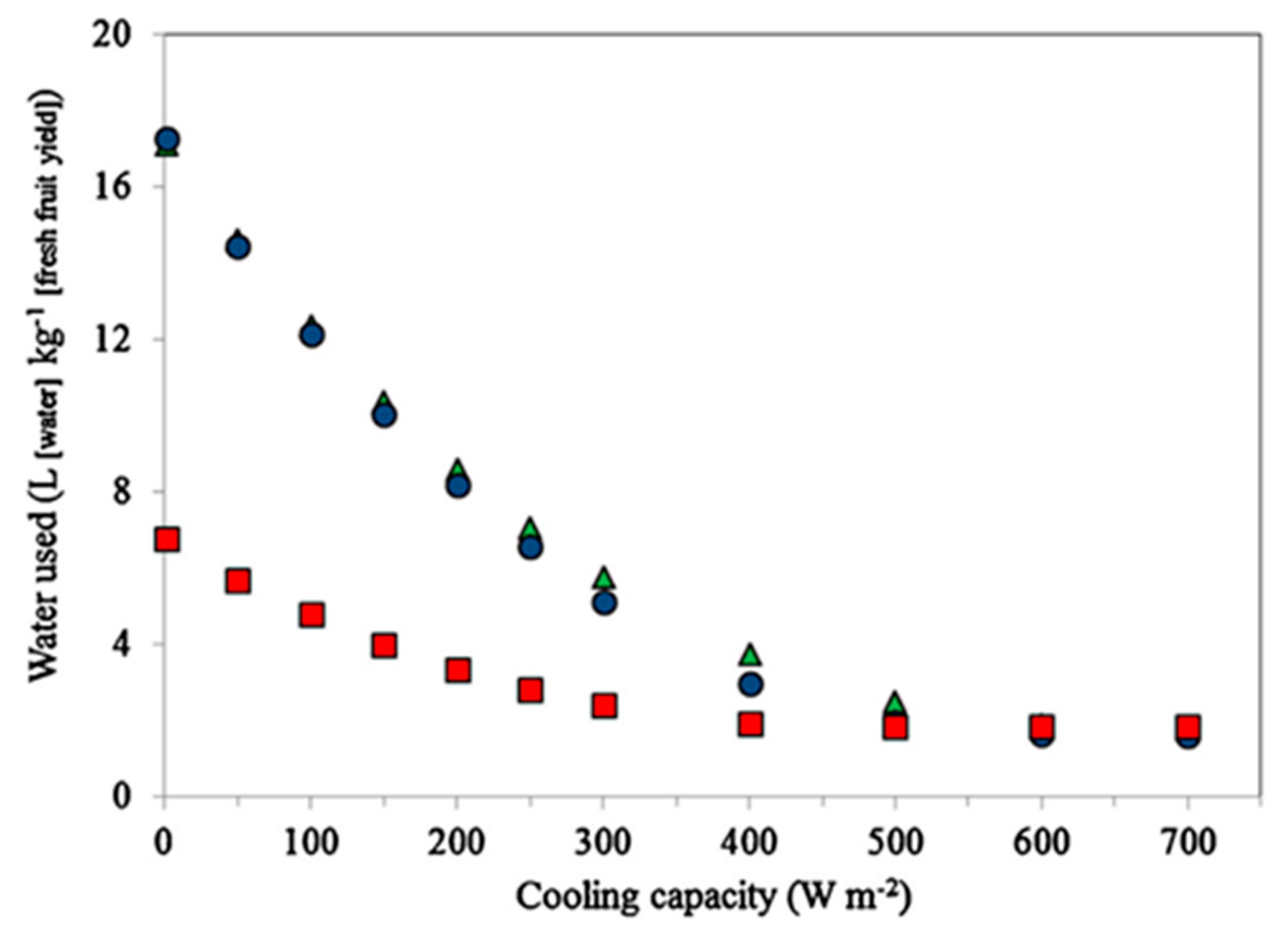

3.3. Irrigation and Water Saving

3.4. Pest Control

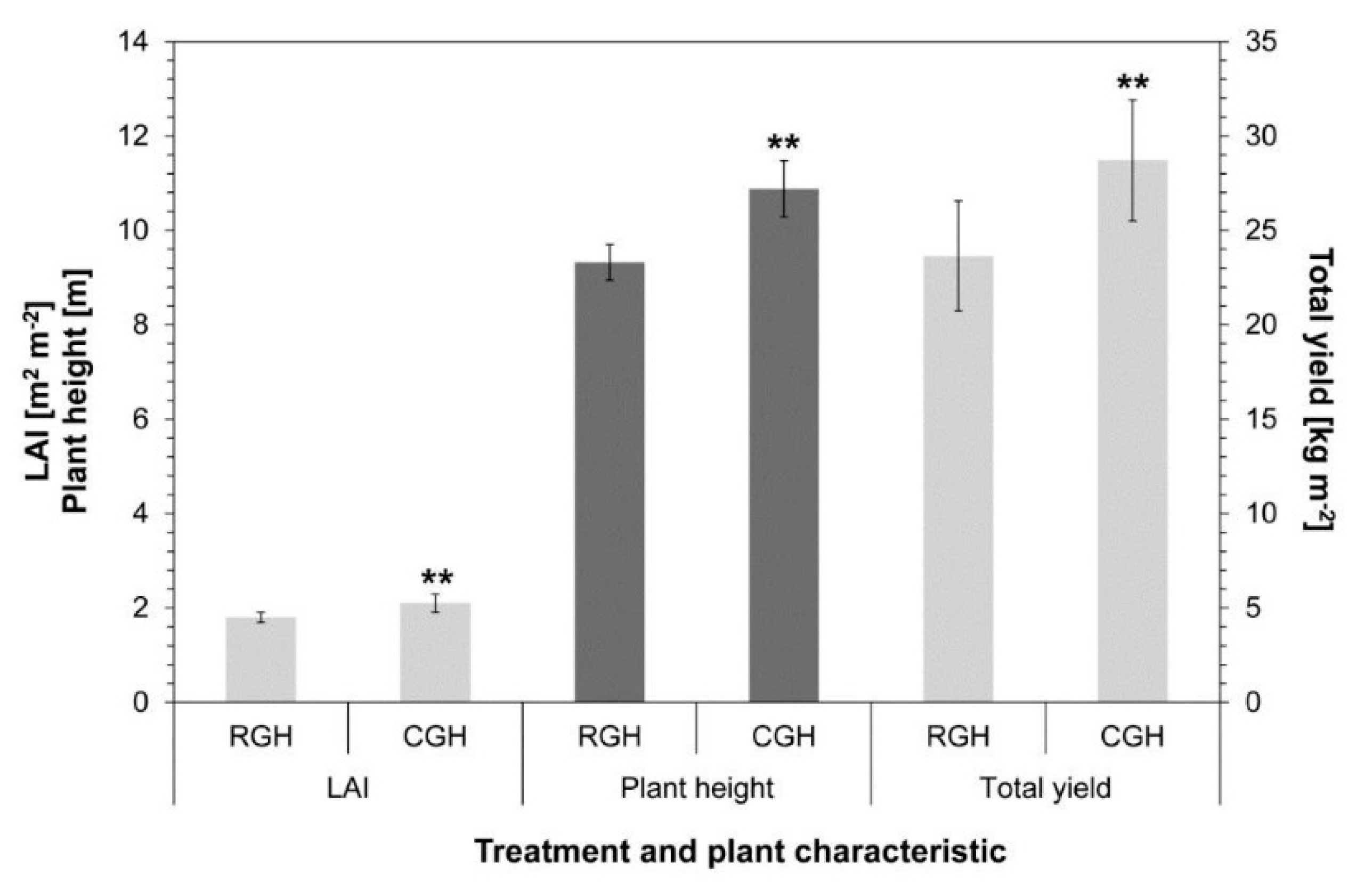

3.5. Crop Growth and Yield

4. General Discussion and Conclusions

- Improve the design and operation of the air treatment corridor (e.g., reduce the pressure loss, optimize the air flow via the pad and heat exchangers, use fans with high efficiency at wide range of ventilation rates, etc.).

- Improve the design and operation of the air distribution system (e.g., by using better perforated tubes, by using sensors to identify the spatial climate distribution and its correlation to the operation of the fans, etc.).

- Integrate different technologies and systems mainly in air treatment corridor in order to change the properties of the air distributed in the greenhouse such as use of desiccant materials for dehumidification or misting for humidification, capture, and reuse water from transpiration or water condensed at the cold surface of heat exchangers, integrate systems based on use of sustainable energy or on district heating and cooling systems, etc.

- Develop greenhouse concepts for different areas in the world in order to address challenges related to extreme climatic conditions such as those occurring in tropical areas, in deserts, or water scarcity areas, etc.

- Develop the semi-closed concept for agroparks or greenhouse clusters by decoupling the air treatment corridor from the air distribution system and developing systems where one air treatment area serves more than one air distribution system with different requirements and priorities.

Author Contributions

Funding

Conflicts of Interest

References

- UNFFC. Kyoto Protocol to the United Nations Framework; UNFFC: Rio de Janeiro, Brazil, 1998; Volume 7. [Google Scholar]

- Ministerie van Landbouw Natuur en Voedselkwaliteit Meerjarenafspraak Energietransitie Glastuinbouw 2014–2020. 2014. Available online: https://www.rijksoverheid.nl/documenten/convenanten/2018/11/09/wijziging-meerjarenafspraak-energietransitie-glastuinbouw-2014-2020 (accessed on 7 November 2020).

- Van Der Velden, N.; Smit, P. Energiemonitor van de Nederlandse Glastuinbouw 2017; Wageningen University & Research: Wageningen, The Netherlands, 2018. [Google Scholar]

- Bot, G. Greenhouse growing: Outlook 2000. Acta Hortic. 1992, 304, 43–47. [Google Scholar] [CrossRef]

- Bot, G.; Van De Braak, N.; Challa, H.; Hemming, S.; Rieswijk, T.; Straten, G.V.; Verlodt, I. The solar greenhouse: State of the art in energy saving and sustainable energy supply. Acta Hortic. 2005, 691, 501–508. [Google Scholar] [CrossRef]

- Buchholz, M.; Jochum, P.; Zaragoza, G. Concept for water, heat and food supply from a closed greenhouse -the watergy project. Acta Hortic. 2005, 691, 509–516. [Google Scholar] [CrossRef]

- Bakker, J.C.; De Zwart, H.F.; Campen, J.B. Greenhouse cooling and heat recovery using fine wire heat exchangers in a closed pot plant greenhouse: Design of an energy producing greenhouse. Acta Hortic. 2006, 719, 263–270. [Google Scholar] [CrossRef]

- De Zwart, H.F. The sunergy greenhouse—One year of measurements in a next generation greenhouse. Acta Hortic. 2011, 893, 351–358. [Google Scholar] [CrossRef]

- Tantau, H.J.; Schmidt, U.; Meyer, J.; Bessler, B. Low energy greenhouse—A system approach. Acta Hortic. 2011, 893, 75–84. [Google Scholar] [CrossRef]

- De Zwart, H.F. Lessons learned from experiments with semi-closed greenhouses. Acta Hortic. 2012, 952, 583–588. [Google Scholar] [CrossRef]

- Gieling, T.H.; Dieleman, J.A.; Janssen, H.J.J.; Campen, J.B.; Raaphorst, M.G.M.; Kromwijka, J.A.M.; Kempkes, F.L.K.; Garcia, N. Monitoring of climate variables in semi-closed greenhouses. Acta Hortic. 2015, 893, 1073–1080. [Google Scholar] [CrossRef]

- Heuvelink, E.; Bakker, M. Climate and Yield in a Closed Greenhouse. Acta Hortic. 2008, 1083–1092. [Google Scholar] [CrossRef]

- Qian, T.; Dieleman, J.A.; Elings, A.; De Gelder, A.; Marcelis, L.F.M.; Van KootenA, O. Comparison of climate and production in closed, semi-closed and open greenhouses. Acta Hortic. 2011, 893, 807–814. [Google Scholar] [CrossRef]

- Jarvis, P.G.; Mcnaughton, K.G. Stomatal control of transpiration: Scaling up from leaf to region. Adv. Ecol. Res. 1986, 15, 1–49. [Google Scholar]

- Katsoulas, N.; Sapounas, A.; De Zwart, F.; Dieleman, J.A.; Stanghellini, C. Reducing ventilation requirements in semi-closed greenhouses increases water use efficiency. Agric. Water Manag. 2015, 156, 90–99. [Google Scholar] [CrossRef]

- Gieling, T.H.; Bruins, M.A.; Campen, J.B.; Lanssen, H.J.J.; Kempkes, F.L.K.; Raaohorst, M.G.M.; Sapounas, A. Moniroting technishe system in semi-gesloten kassen. In Wageningen UR Glastuinbouw; Rapport GTB-1008, PT nummer 13107; Wageningen University & Research: Wageningen, The Netherlands, 2015; p. 108. [Google Scholar]

- Van der Hoeven Horticultural Projects B.V. Available online: https://www.vanderhoeven.nl/products/modulair.html (accessed on 2 October 2020.).

- KUBO Ultra Clima. Available online: https://www.kubogroup.nl/en/productlabels/ultra-clima (accessed on 2 October 2020.).

- He, S.; Gurgenci, H.; Alkhedhair, A.M. Experimental study of heat transfer coefficient and pressure drop of cellulose corrugated media. In Proceedings of the 19th Australasian Fluid Mechanics Conference, Melbourne, Australia, 8–11 December 2014; pp. 3–6. [Google Scholar]

- MacKinnon, R.I. Air Distribution from Ventilation Ducts. Ph.D. Thesis, Department of Agricultural Engineering, Macdonald College of McGill University, Quebec, QC, Canada, 1990. [Google Scholar]

- Coomans, M.; Allaerts, K.; Wittemans, L.; Pinxteren, D. Monitoring and energetic performance of two similar semi-closed greenhouse ventilation systems. Energy Convers. Manag. 2013, 76, 128–136. [Google Scholar] [CrossRef]

- Dannehl, D.; Josuttis, M.; Ulrichs, C.; Schmidt, U. The potential of a confined closed greenhouse in terms of sustainable production, crop growth, yield and valuable plant compounds of tomatoes. J. Appl. Bot. Food Qual. 2014, 87, 210–219. [Google Scholar]

- Campen, J.B.; Kempkes, F.L.K. Climatic evaluation of semi-closed greenhouses. Acta Hortic. 2011, 893, 495–502. [Google Scholar] [CrossRef]

- De Gelder, A.; Dieleman, J.A.; Bot, G.P.A.; Marcelis, L.F.M. An overview of climate and crop yield in closed greenhouses. J. Hortic. Sci. Biotechnol. 2012, 87, 193–202. [Google Scholar] [CrossRef]

- Bournet, P.E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Sase, S. Air movement and climate uniformity in ventilated greenhouses. Acta Hortic. 2006, 719, 313–324. [Google Scholar] [CrossRef]

- Quillec, S.L.; Albert, B.; Lesourd, D.; Loda, D.; Barette, R.; Brajeul, E. Benefits of a semi-closed greenhouse for tomato production in the West of France. Acta Hortic. 2017, 1170, 883–888. [Google Scholar] [CrossRef]

- Kittas, C.; Katsoulas, N.; Bartzanas, T.; Mermier, M.; Boulard, T. The impact of insect screens and ventilation openings on the greenhouse microclimate. Trans. ASABE 2009, 51, 2151–2165. [Google Scholar] [CrossRef]

- Campen, J.B.; Kempkes, F.L.K.; Sapounas, A. Klimaat “Kas zonder gas”. In Wageningen UR Greenhouse Horticulture; Report 1001; Wageningen University & Research: Wageningen, The Netherlands, 2008; p. 27. [Google Scholar]

- Salazar-Moreno, R.; López-Cruz, I.L.; Miranda, L.; Schmidt, U.; Fitz-Rodríguez, E.; Rojano-Aguilar, A. Development and validation of a dynamic climate model in a semiclosed greenhouse. Acta Hortic. 2017, 1182, 111–118. [Google Scholar] [CrossRef]

- Roy, J.C.; Fatnassi, H.; Boulard, T.; Pouillard, J.B.; Grisey, A. CFD determination of the climate distribution in a semi closed greenhouse with air cooling. Acta Hortic. 2017, 1170, 103–110. [Google Scholar] [CrossRef]

- Vadiee, A. Energy Analysis of the Closed Greenhouse Concept. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2011; p. 89. [Google Scholar]

- Salazar, R.; Miranda, L.; Schmidt, U.; Rojano, A.; Lopez, I. Simulation of energy harvesting in a semiclosed greenhouse. Acta Hortic. 2014, 1037, 461–468. [Google Scholar] [CrossRef]

- De Gelder, A.; Janse, J.; Lagas, P. Teelt komkommer in een geconditioneerde kas. In Wageningen UR Greenhouse Horticulture; Report 529; Wageningen University & Research: Wageningen, The Netherlands, 2008; p. 33. [Google Scholar]

- Marcelis, L.F.M.; Heuvelink, E.; Goudriaan, J. Modelling biomass productionand yield of horticultural crops: A review. Sci. Hortic. 1998, 74, 83–111. [Google Scholar] [CrossRef]

- Qian, T. Crop Growth and Development in Closed and Semi-Closed Greenhouses. Ph.D. Thesis, Wageningen University & Research, Wageningen, The Netherlands, 2017; p. 112. [Google Scholar]

- Van’t Ooster, A.; Van Ieperen, W.; Kalaitzoglou, P. Model study on applicability of a semi closed greenhouse concept in Almeria: Effects on greenhouse climate, crop yield and resource use efficiency. Acta Hortic. 2012, 927, 51–58. [Google Scholar] [CrossRef]

- Dannehl, D.; Suhl, J.; Huyskens-Keil, S.; Ulrichs, C.; Schmidt, U. Effects of a special solar collector greenhouse on water balance, fruit quantity and fruit quality of tomatoes. Agric. Water Manag. 2014, 134, 14–23. [Google Scholar] [CrossRef]

- Stanghellini, C. Horticultural production in greenhouses: Efficient use ofwater. Acta Hortic. 2014, 1034, 25–32. [Google Scholar] [CrossRef]

- Shipp, L.; Johansen, N.; Vänninen, I.; Jacobson, R. Greenhouse climate: An important consideration when developing pest management programs for greenhouse crop. Acta Hortic. 2011, 893, 133–144. [Google Scholar] [CrossRef]

- De Zwart, H.F. Overall energy analysis of (semi) closed greenhouses. Acta Hortic. 2008, 801, 811–818. [Google Scholar] [CrossRef]

- Sugiyama, K.; Ohishi, N.; Saito, T. Preliminary evaluation of greenhouses employing positive-pressure forced ventilation to prevent invasion by insect pests. Appl. Entomol. Zool. 2014, 49, 553–559. [Google Scholar] [CrossRef]

- Eden, M.A.; Hill, R.A.; Stewart, A. Biological control of Botrytis stem infection of greenhouse tomatoes. Plant Pathol. 1996, 45, 276–284. [Google Scholar] [CrossRef]

- De Gelder, A.; Nederhoff, E.M.; Janse, J.; Dekok, L.; Nieboer, S.; Keijzer, M.; Raaphorst, M.G.M.; Devisser, P.H.B. Totaalconcept komkommerteelt 2008–2010: Teeltproef2009 aan Innokom + teeltsysteem met belichting en gecondition-eerd telen. In Wageningen UR GreenhouseHorticulture; Report 264; Wageningen University & Research: Wageningen, The Netherlands, 2009; p. 56. [Google Scholar]

- Elings, A.; Marcelis, L.F.M.; Dieleman, A.; Qian, T. Crop physiology in (semi-) closed greenhouses. Final report of the TransForum scientific project “SynErgy”: Monitoring and control system for conditioning of plants and greenhouse. In Wageningen UR GreenhouseHorticulture; Rapport GTB-1051; Wageningen University & Research: Wageningen, The Netherlands, 2010; p. 20. [Google Scholar]

- Salazar, R.; López, I.; Rojano, A.; Schmidt, U.; Dannehl, D. Tomato yield prediction in a semi-closed greenhouse. Acta Hortic. 2015, 1107, 263–269. [Google Scholar] [CrossRef]

| Greenhouse | Summer 2015 | Autumn 2014 | ||

|---|---|---|---|---|

| Gas | Electricity | Gas | Electricity | |

| kWh m−2 | ||||

| Conventional | 253 | 3.5 | 322 | 5.2 |

| Semi-closed | 217 | 11.3 | 307 | 31.9 |

| Process | Conventional | Closed | Semi-Closed |

|---|---|---|---|

| Heating (MJ m−2 y−1) | 1182 | 557 | 620 |

| Cooling (MJ m−2 y−1) | 0 | 530 | 134 |

| Treatment | Early Production | Final Production | Supplied CO2 |

|---|---|---|---|

| Conventional | 24 | 55 | 55 |

| Semi-closed (cooling 150 W m−2) | 26 | 59 | 46 |

| Semi-closed (cooling 350 W m−2) | 27 | 61 | 30 |

| Semi-closed (cooling 700 W m−2) | 28 | 57 | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapounas, A.; Katsoulas, N.; Slager, B.; Bezemer, R.; Lelieveld, C. Design, Control, and Performance Aspects of Semi-Closed Greenhouses. Agronomy 2020, 10, 1739. https://doi.org/10.3390/agronomy10111739

Sapounas A, Katsoulas N, Slager B, Bezemer R, Lelieveld C. Design, Control, and Performance Aspects of Semi-Closed Greenhouses. Agronomy. 2020; 10(11):1739. https://doi.org/10.3390/agronomy10111739

Chicago/Turabian StyleSapounas, Athanasios, Nikolaos Katsoulas, Bart Slager, Robert Bezemer, and Charlotte Lelieveld. 2020. "Design, Control, and Performance Aspects of Semi-Closed Greenhouses" Agronomy 10, no. 11: 1739. https://doi.org/10.3390/agronomy10111739

APA StyleSapounas, A., Katsoulas, N., Slager, B., Bezemer, R., & Lelieveld, C. (2020). Design, Control, and Performance Aspects of Semi-Closed Greenhouses. Agronomy, 10(11), 1739. https://doi.org/10.3390/agronomy10111739