Pattern Switching in Soft Cellular Structures and Hydrogel-Elastomer Composite Materials under Compression

Abstract

:1. Introduction

2. Pattern Switching in Soft Cellular Solids

2.1. Materials for Soft Cellular Solids

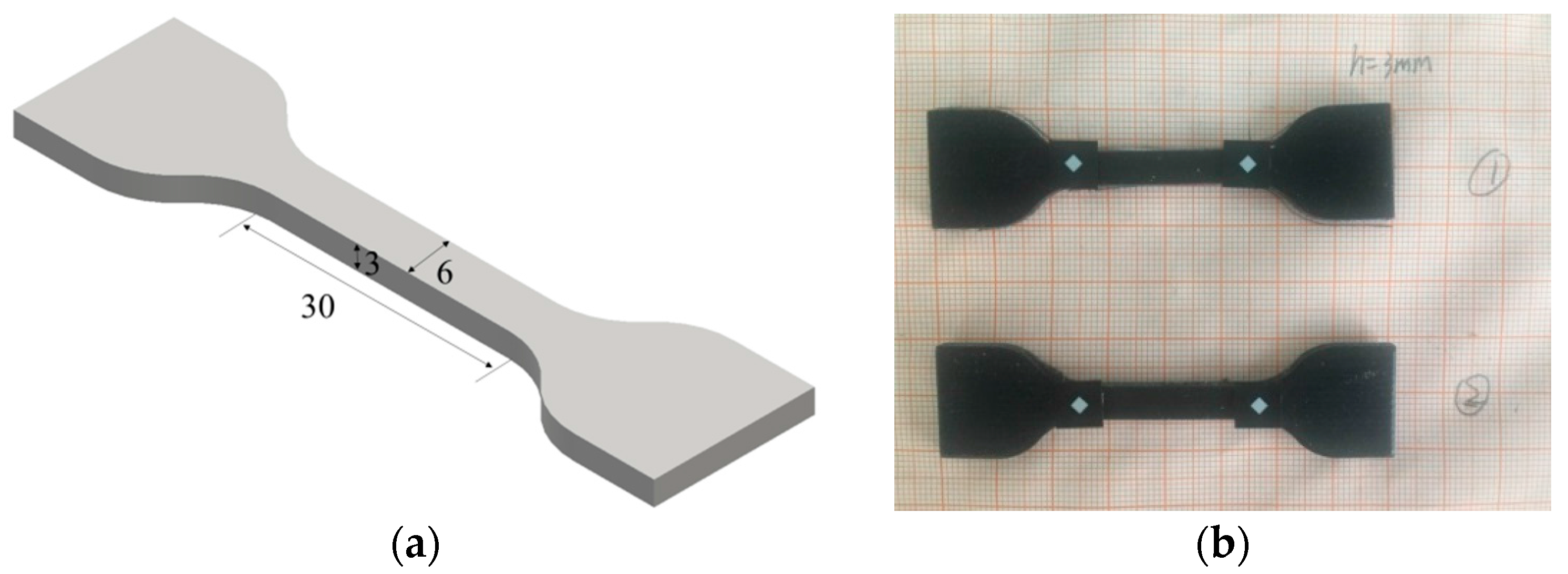

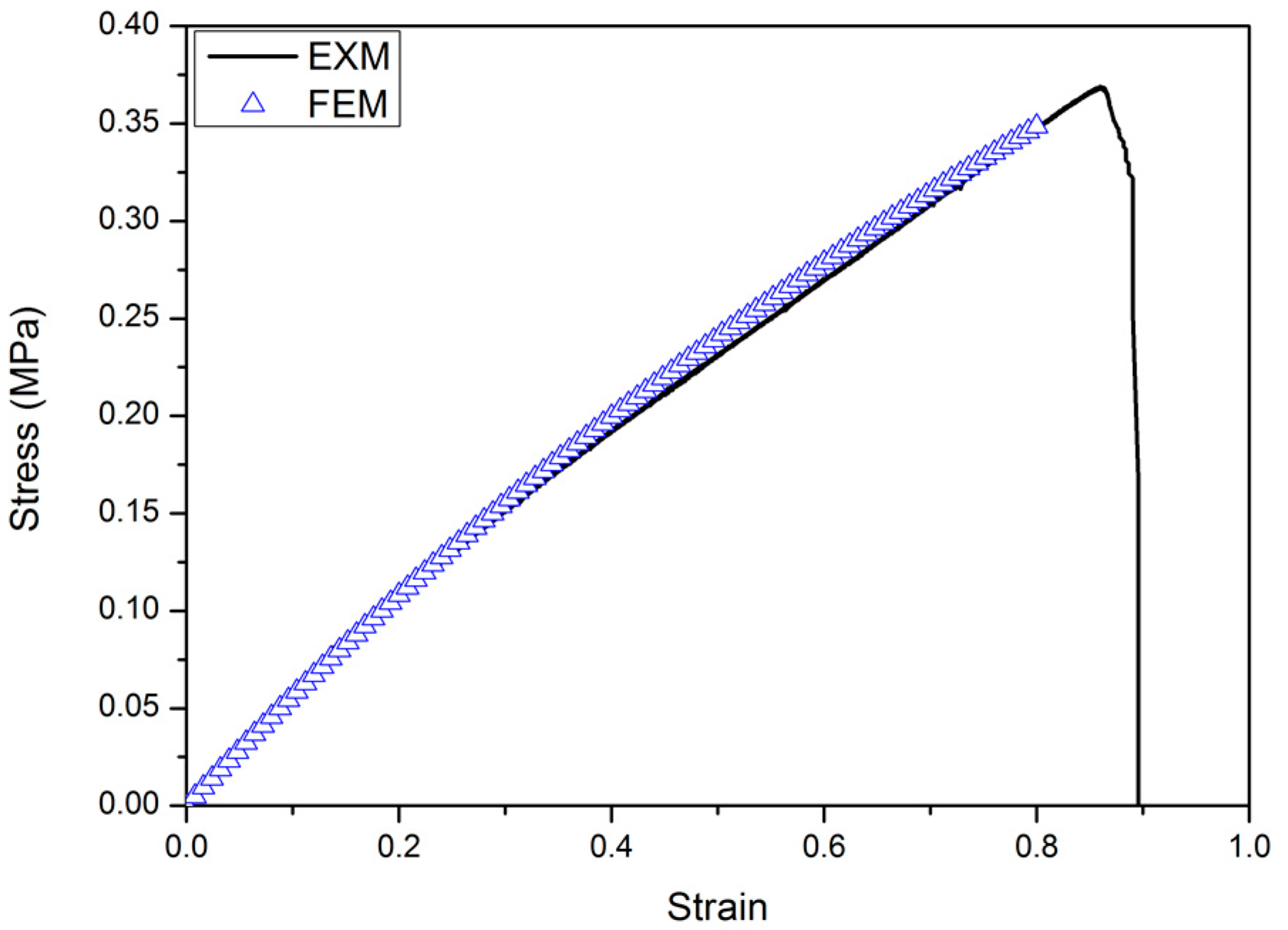

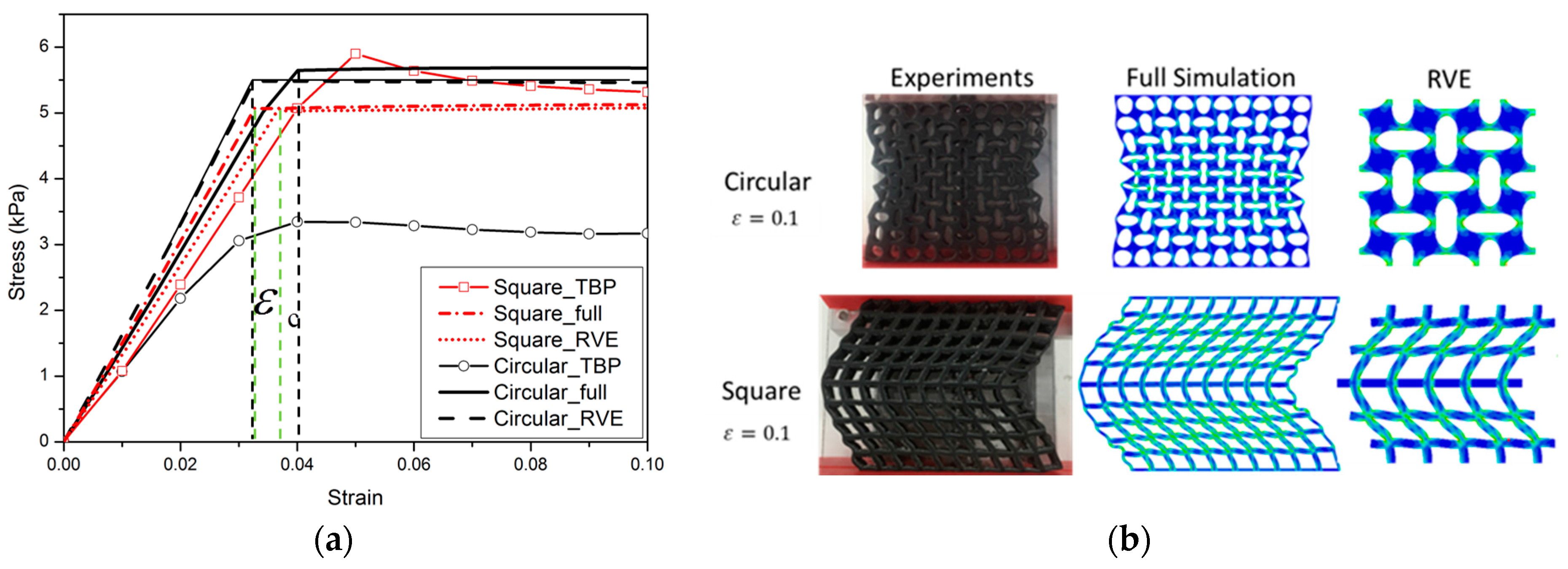

2.1.1. TangoBlackPlus®-3D Printing Material for the Cellular Structure

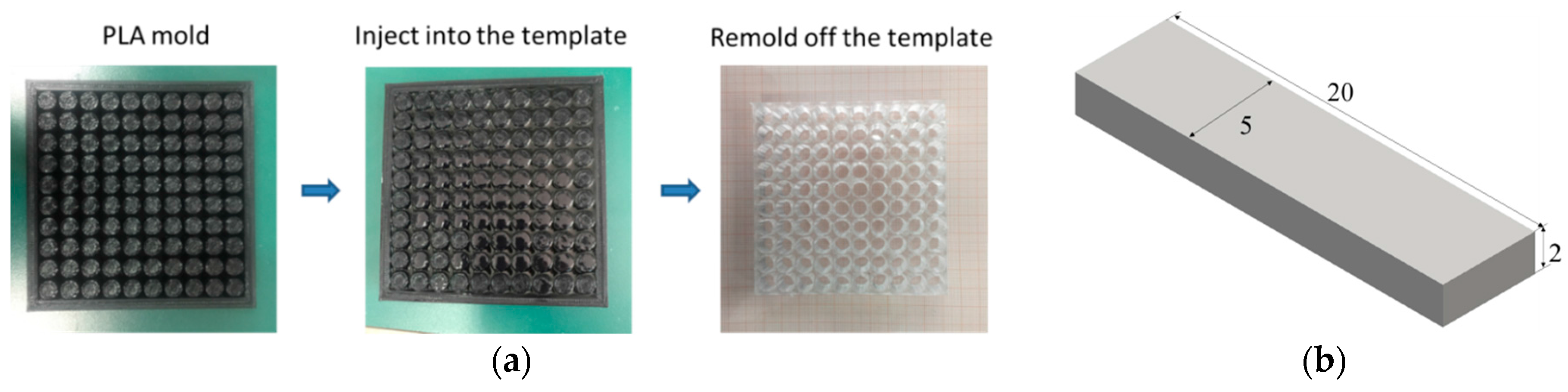

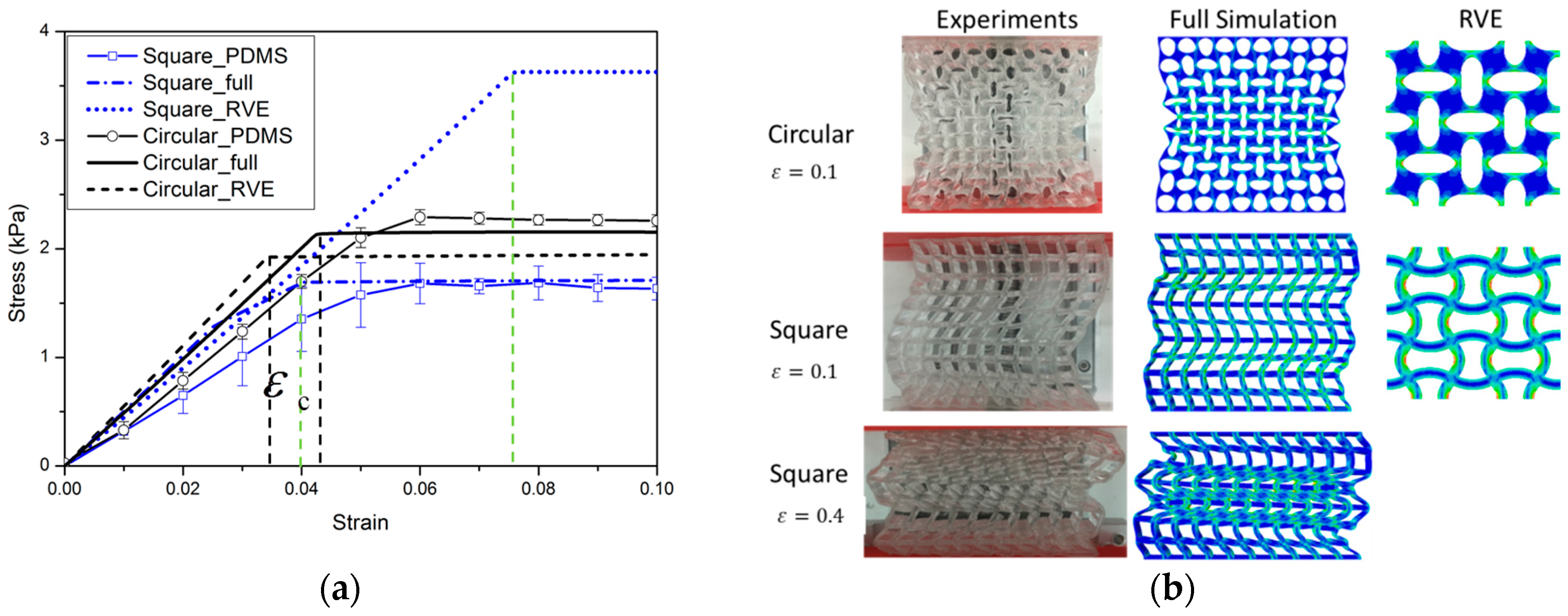

2.1.2. PDMS for the Cellular Structure

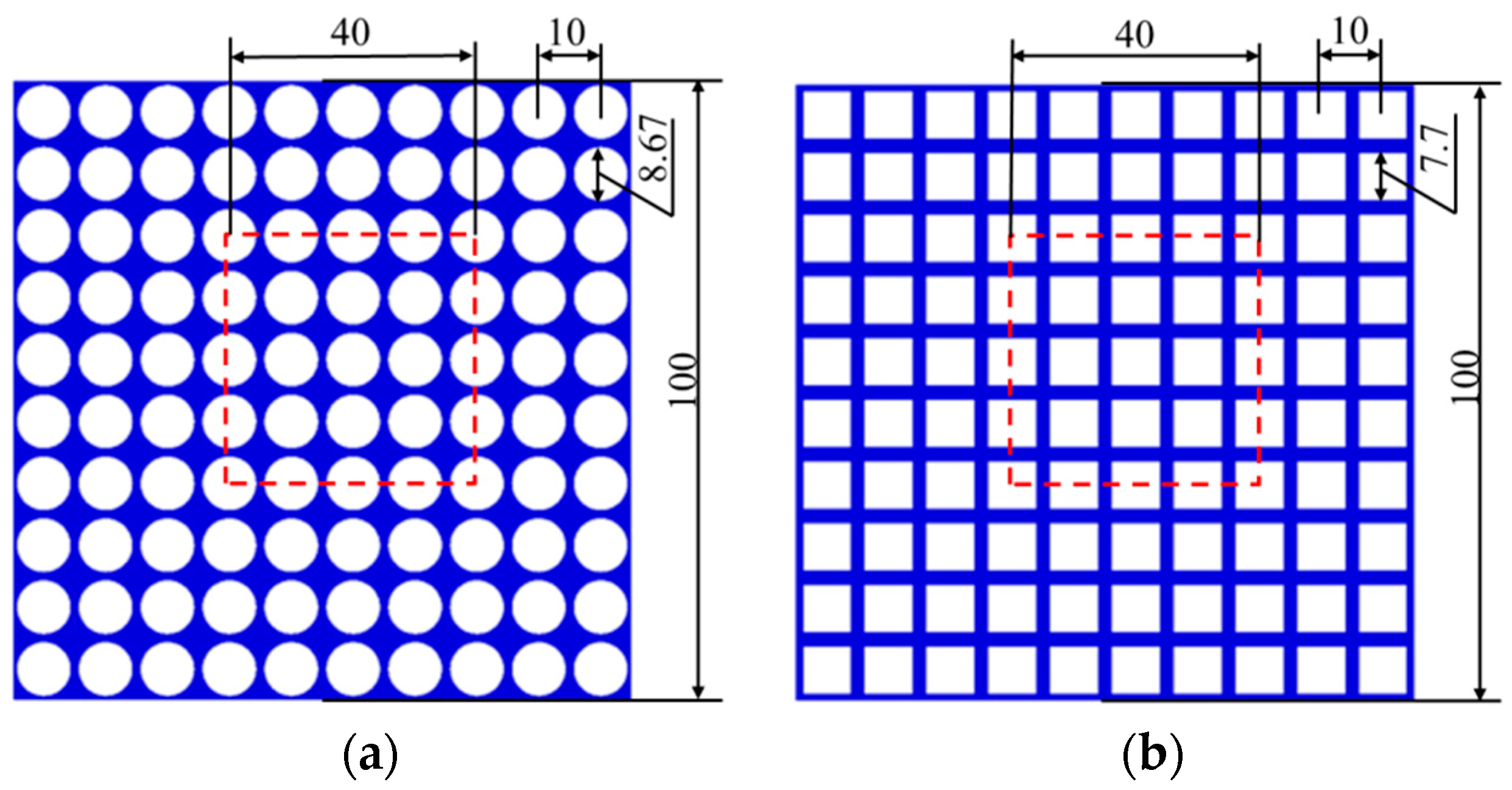

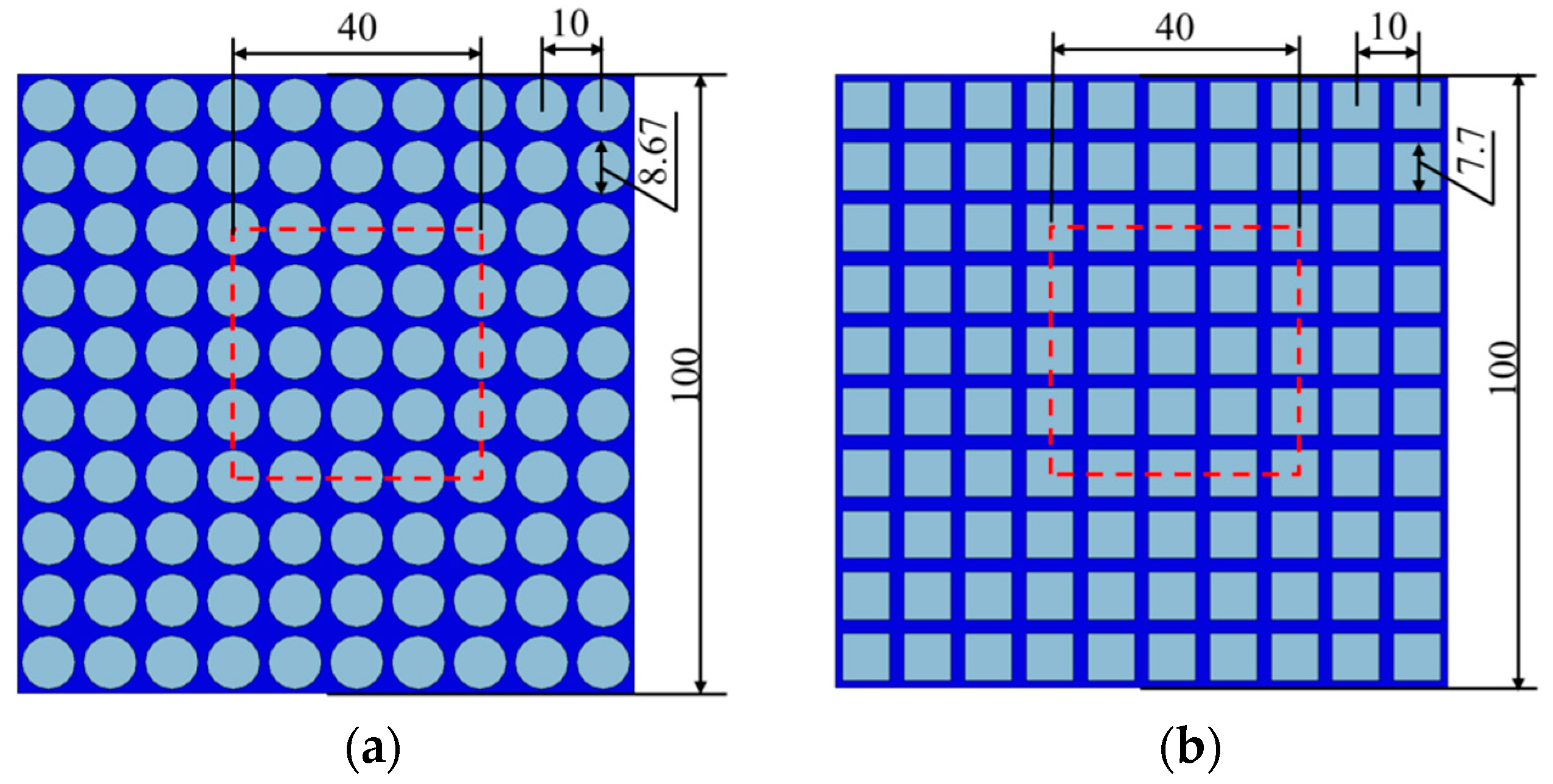

2.2. Experiments and Modeling for Soft Cellular Solids

2.2.1. Experimental Protocol

2.2.2. Modeling

2.3. Results and Discussion for Soft Cellular Solids

3. Novel Mechanical Behavior of the Composite Gel Material under Compression

3.1. Material Characterization of Polyacrylamide Hydrogel

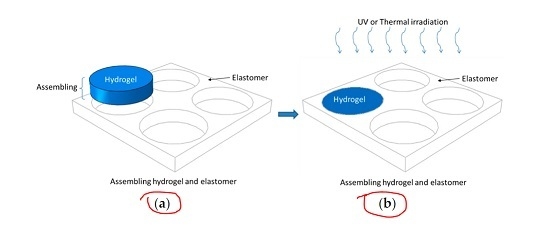

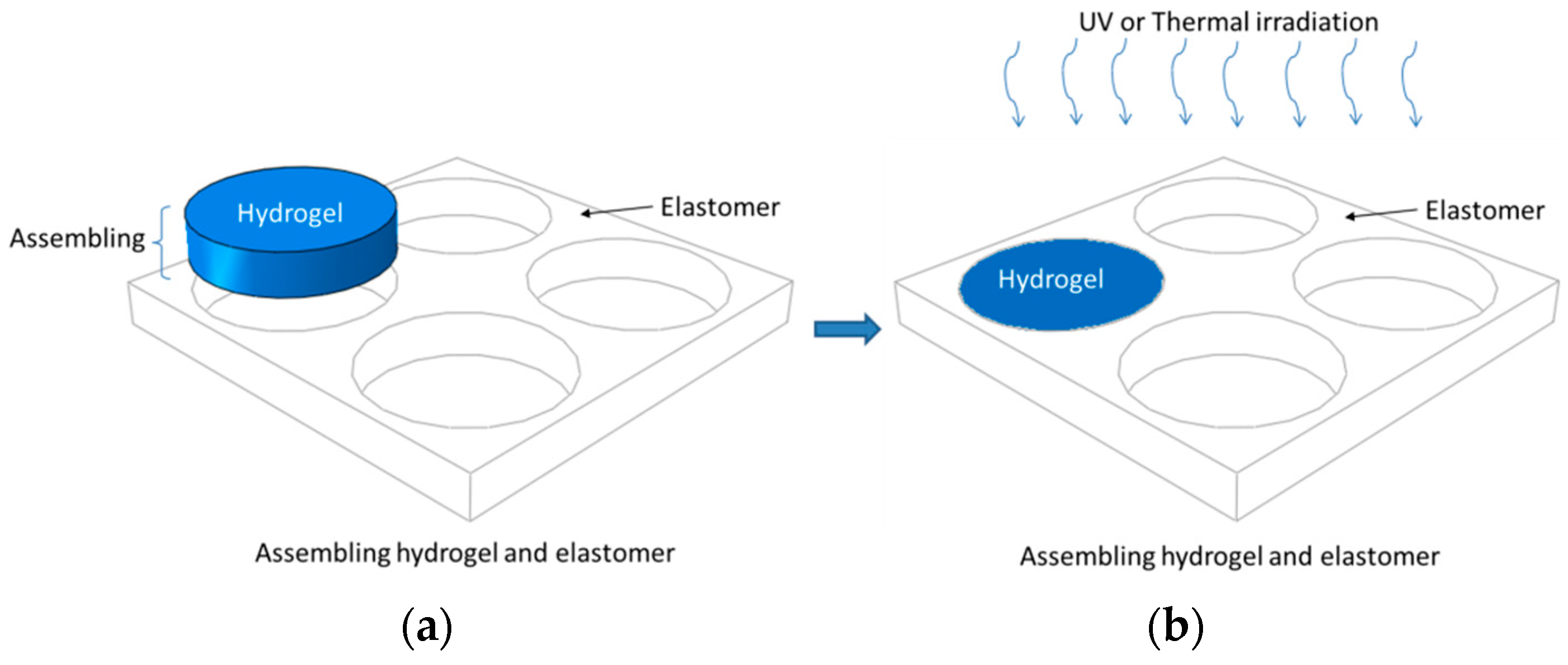

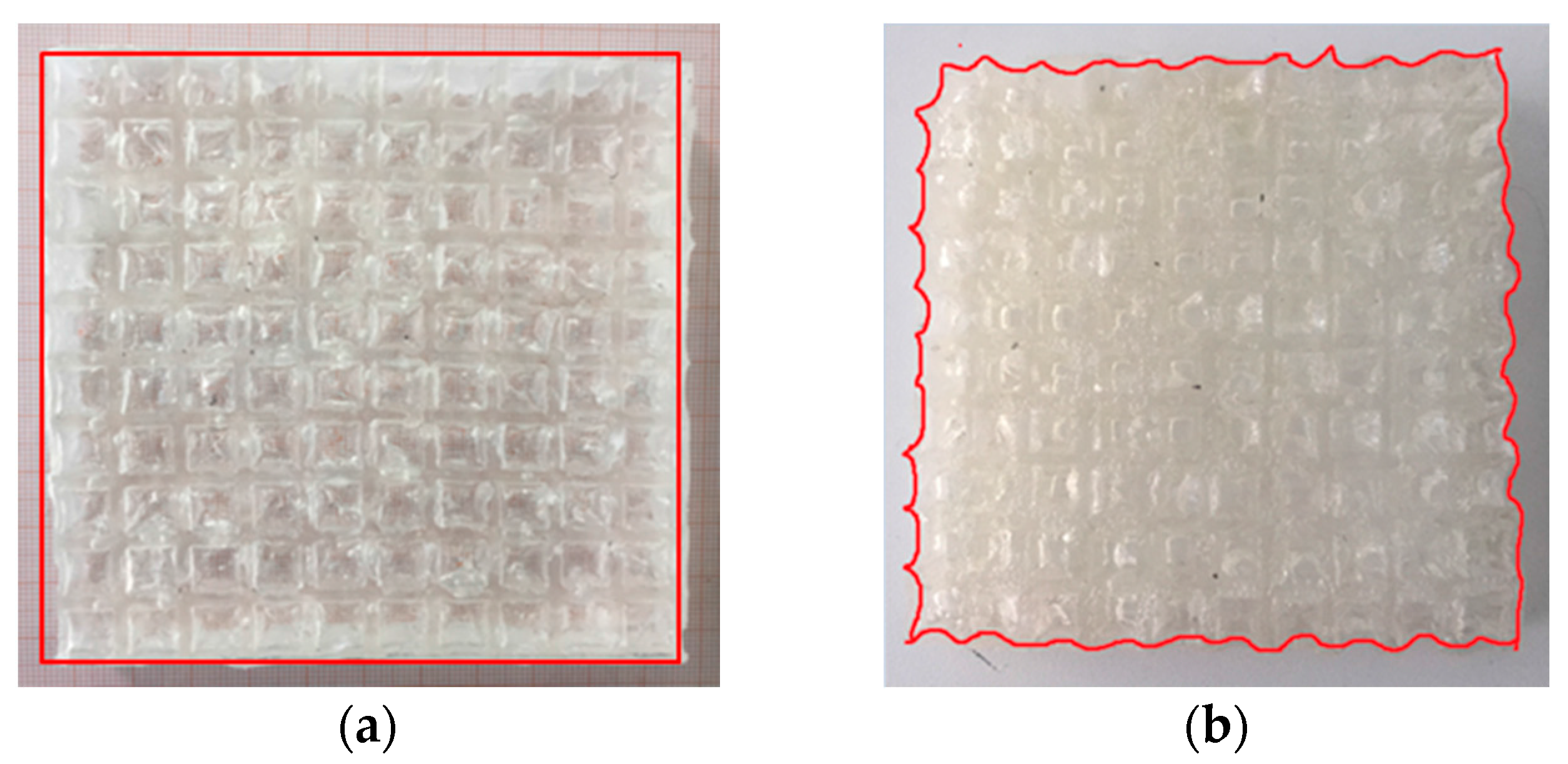

3.2. Weak or Robust Interface of the Hydrogel–Elastomer Composite Material

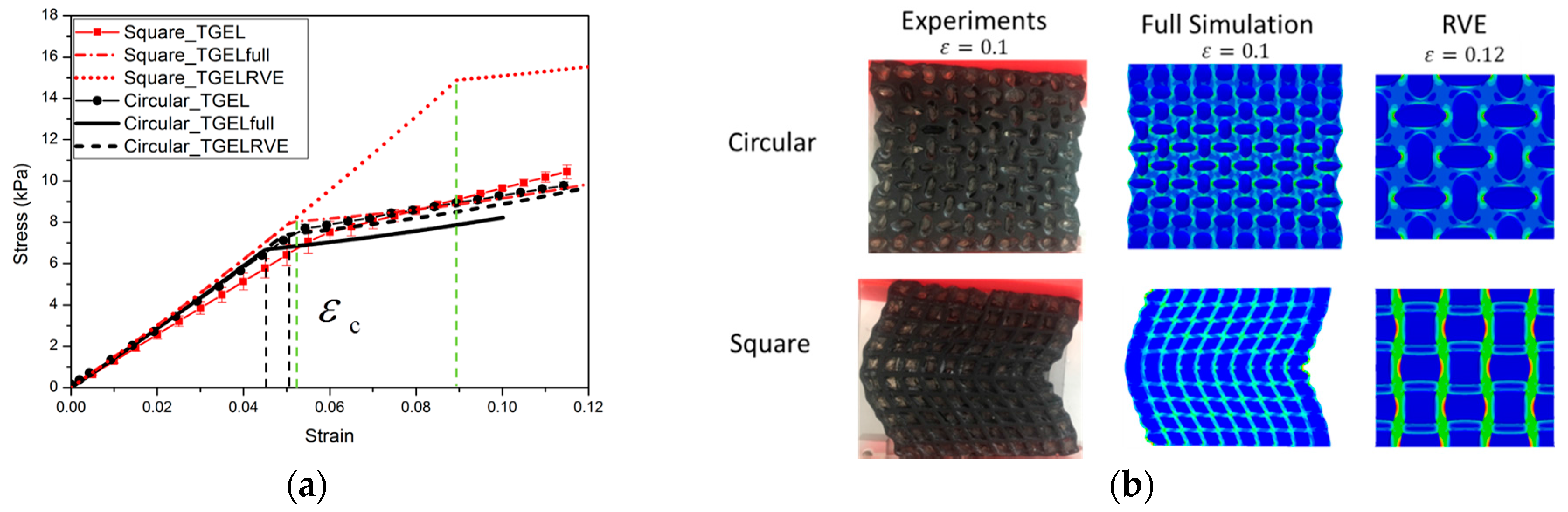

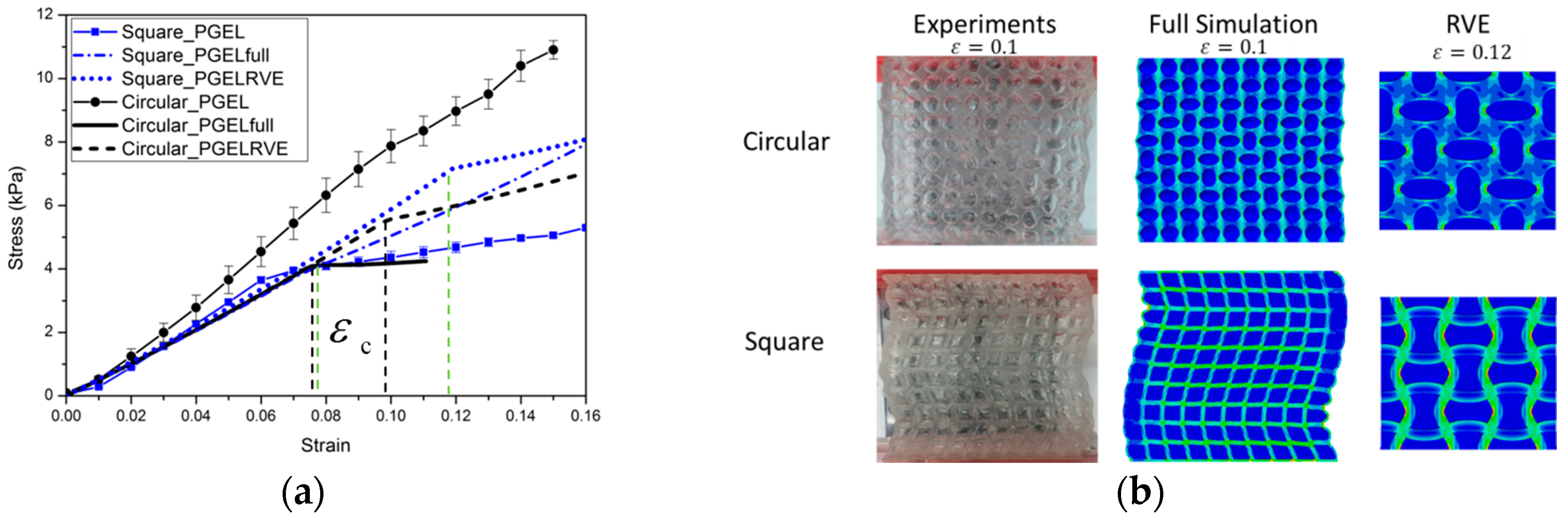

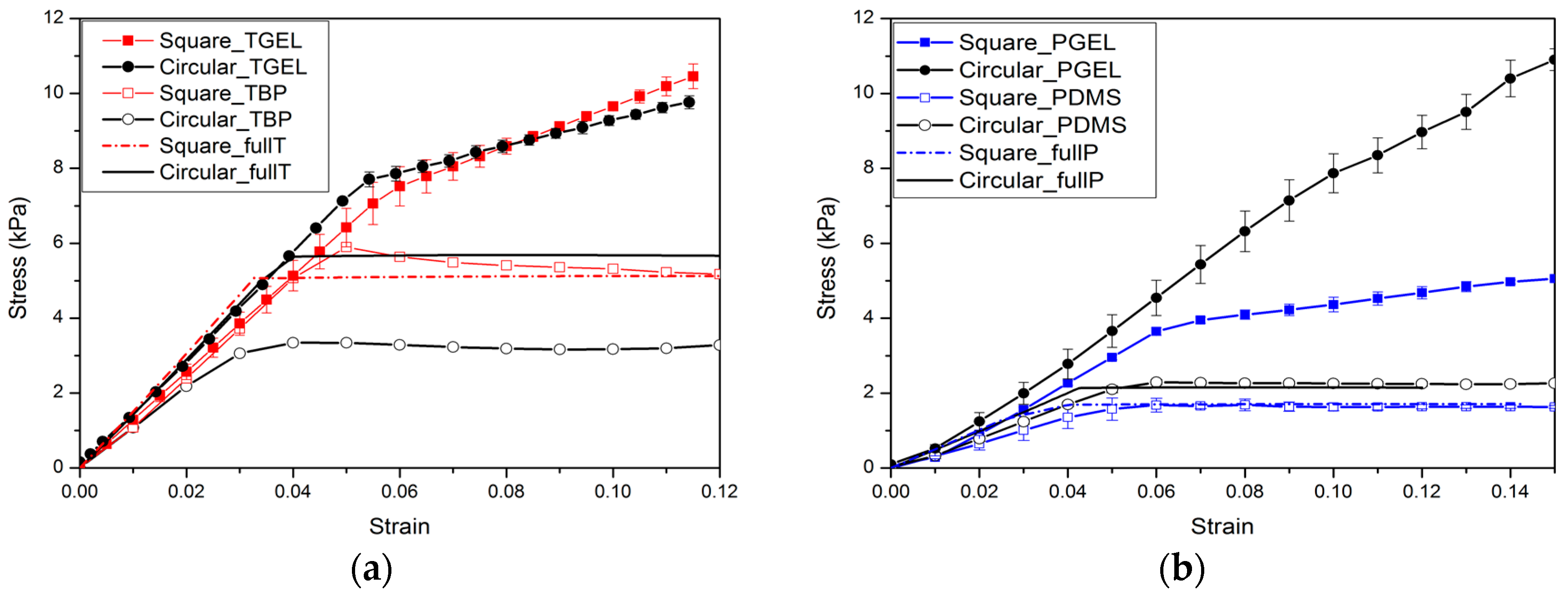

3.3. Results and Discussion of Composite Material

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Friis, E.A.; Lakes, R.S.; Park, J.B. Negative Poisson’s ratio polymeric and metallic foams. J. Mater. Sci. 1988, 23, 4406–4414. [Google Scholar] [CrossRef]

- Grima, J.N.; Alderson, A.; Evans, K.E. An Alternative Explanation for the Negative Poisson’s Ratios in Auxetic Foams. J. Phys. Soc. Jpn. 2005, 74, 1341–1342. [Google Scholar] [CrossRef]

- Pozniak, A.A.; Smardzewski, J.; Wojciechowski, K.W. Computer simulations of auxetic foams in two dimensions. Smart Mater. Struct. 2013, 22, 084009. [Google Scholar] [CrossRef]

- Williams, J.L.; Lewis, J.L. Properties and an anisotropic model of cancellous bone from the proximal tibial epiphysis. Trans. ASME J. Biomech. Eng. 1982, 104, 5–56. [Google Scholar] [CrossRef]

- Evans, K.E.; Alderson, K.L. The static and dynamic moduli of auxetic microporous polyethylene. J. Mater. Sci. Lett. 1992, 11, 1721–1724. [Google Scholar] [CrossRef]

- Caddock, B.D.; Evans, K.E. Microporous materials with negative Poisson’s ratios. I. Microstructure and mechanical properties. J. Phys. D 1989, 22, 1877–1882. [Google Scholar] [CrossRef]

- Wang, L.; Lau, J.; Thomas, E.L.; Boyce, M.C. Co-Continuous Composite Materials for Stiffness, Strength, and Energy Dissipation. Adv. Mater. 2011, 23, 1524–1529. [Google Scholar] [CrossRef] [PubMed]

- Evans, K.E.; Alderson, K.L. Auxetic materials: The positive side of being negative. Eng. Sci. Educ. J. 2000, 9, 148–154. [Google Scholar] [CrossRef]

- Shan, S.; Kang, S.H.; Zhao, Z.; Fang, L.; Bertoldi, K. Design of planar isotropic negative Poisson’s ratio structures. Extreme Mech. Lett. 2015, 4, 96–102. [Google Scholar] [CrossRef]

- Hughes, T.P.; Marmier, A.; Evans, K.E. Auxetic frameworks inspired by cubic crystals. Int. J. Solids Struct. 2010, 47, 1469–1476. [Google Scholar] [CrossRef]

- Chen, Y.J.; Scarpa, F.; Liu, Y.J.; Leng, J.S. Elasticity of anti-tetrachiral anisotropic lattices. Int. J. Solids Struct. 2013, 50, 996–1004. [Google Scholar] [CrossRef]

- Gaspar, N.; Smith, C.W.; Alderson, A.; Grima, J.N.; Evans, K.E. A generalised three-dimensional tethered-nodule model for auxetic materials. J. Mater. Sci. 2011, 46, 372–384. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K.L.; Attard, D.; Evans, K.E.; Gatt, R.; Grima, J.N.; Miller, W.; Ravirala, N.; Smith, C.W.; Zied, K. Elastic constants of 3-, 4- and 6-connected chiral and anti-chiral honeycombs subject to uniaxial in-plane loading. Compos. Sci. Technol. 2010, 70, 1042–1048. [Google Scholar] [CrossRef]

- Babaee, S.; Shim, J.; Weaver, J.C.; Chen, E.R.; Patel, N.; Bertoldi, K. 3D soft metamaterials with negative Poisson’s ratio. Adv. Mater. 2013, 25, 5044–5049. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Shen, F.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. 3D soft auxetic lattice structures fabricated by selective laser sintering: TPU powder evaluation and process optimization. Mater. Des. 2017, 120, 317–327. [Google Scholar] [CrossRef]

- Willshaw, S.; Mullin, T. Pattern switching in two and three-dimensional soft solids. Soft Matter 2012, 8, 1747. [Google Scholar] [CrossRef]

- Yang, D.; Jin, L.; Martinez, R.V.; Bertoldi, K.; Whitesides, G.M.; Suo, Z. Phase-transforming and switchable metamaterials. Extreme Mech. Lett. 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Yang, D.; Mosadegh, B.; Ainla, A.; Lee, B.; Khashai, F.; Suo, Z.; Bertoldi, K.; Whitesides, G.M. Buckling of Elastomeric Beams Enables Actuation of Soft Machines. Adv. Mater. 2015, 27, 6323–6327. [Google Scholar] [CrossRef] [PubMed]

- Bertoldi, K.; Reis, P.M.; Willshaw, S.; Mullin, T. Negative Poisson’s Ratio Behavior Induced by an Elastic Instability. Adv. Mater. 2010, 22, 361–366. [Google Scholar] [CrossRef] [PubMed]

- Bertoldi, K.; Boyce, M.C. Mechanics of the hysteretic large strain behavior of mussel byssus threads. J. Mater. Sci. 2007, 42, 8943–8956. [Google Scholar] [CrossRef]

- Bertoldi, K.; Boyce, M.C.; Deschanel, S.; Prange, S.M.; Mullin, T. Mechanics of deformation-triggered pattern transformations and superelastic behavior in periodic elastomeric structures. J. Mech. Phys. Solids 2008, 56, 2642–2668. [Google Scholar] [CrossRef]

- Mullin, T.; Deschanel, S.; Bertoldi, K.; Boyce, M.C. Pattern Transformation Triggered by Deformation. Phys. Rev. Lett. 2007, 99, 084301. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Guo, S.; Liu, Z.; Liew, K.M. Pattern transformation of thermo-responsive shape memory polymer periodic cellular structures. Int. J. Solids Struct. 2015, 71, 194–205. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, Y.; Ellyin, F. A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 2003, 40, 1907–1921. [Google Scholar] [CrossRef]

- Li, J.; Shim, J.; Deng, J.; Overvelde, J.T.B.; Zhu, X.; Bertoldi, K.; Yang, S. Switching periodic membranes via pattern transformation and shape memory effect. Soft Matter 2012, 8, 10322. [Google Scholar] [CrossRef]

- Xiao, R. Modeling Mismatch Strain Induced Self-Folding of Bilayer Gel Structures. Int. J. Appl. Mech. 2016, 8, 164004. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Wang, J.; Zheng, Y. Anisotropic Swelling in Fiber-Reinforced Hydrogels: An Incremental Finite Element Method and Its Applications in Design of Bilayer Structures. Int. J. Appl. Mech. 2016, 8, 1640003. [Google Scholar] [CrossRef]

- Zhang, Y.; Matsumoto, E.A.; Peter, A.; Lin, P.-C.; Kamien, R.D.; Yang, S. One-step nanoscale assembly of complex structures via harnessing of an elastic instability. Suppl. Inf. 2008, 8, 1192–1196. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-H.; Wang, L.; Boyce, M.C.; Thomas, E.L. Periodic Bicontinuous Composites for High Specific Energy Absorption. Nano Lett. 2012, 12, 4392–4396. [Google Scholar] [CrossRef] [PubMed]

- Bertoldi, K.; Boyce, M.C. Mechanically triggered transformations of phononic band gaps in periodic elastomeric structures. Phys. Rev. B 2008, 77, 052105. [Google Scholar] [CrossRef]

- Wang, K.; Chang, Y.-H.; Chen, Y.; Zhang, C.; Wang, B. Designable dual-material auxetic metamaterials using three-dimensional printing. Mater. Des. 2015, 67, 159–164. [Google Scholar] [CrossRef]

- Hu, J.; He, Y.; Lei, J.; Liu, Z.; Swaddiwudhipong, S. Mechanical behavior of composite gel periodic structures with the pattern transformation. Struct. Eng. Mech. 2014, 50, 605–616. [Google Scholar] [CrossRef]

- Michel, J.; Lopezpamies, O.; Pontecastaneda, P.; Triantafyllidis, N. Microscopic and macroscopic instabilities in finitely strained porous elastomers. J. Mech. Phys. Solids 2007, 55, 900–938. [Google Scholar] [CrossRef]

- Mullin, T.; Willshaw, S.; Box, F. Pattern switching in soft cellular solids under compression. Soft Matter 2013, 9, 4951. [Google Scholar] [CrossRef]

- Hong, W.; Liu, Z.S.; Suo, Z.G. Inhomogeneous swelling of a gel in equilibrium with a solvent and mechanical load. Int. J. Solids Struct. 2009, 46, 3282–3289. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J., Jr. Statistical Mechanics of Cross-Linked Polymer Networks I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Li, J. Mechanical Behavior of Hydrogels for the Use of Ionic Devices; Harvard University: Cambridge, MA, USA, 2015. [Google Scholar]

- Yuk, H.; Zhang, T.; Parada, G.A.; Liu, X.Y.; Zhao, X.H. Skin-inspired hydrogel–elastomer hybrids with robust interfaces and functional microstructures. Nat. Commun. 2016, 7, 12028. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.H.; Shan, S.; Noorduin, W.L.; Khan, M.; Aizenberg, J.; Bertoldi, K. Buckling-Induced Reversible Symmetry Breaking and Amplification of Chirality Using Supported Cellular Structures. Adv. Mater. 2013, 25, 3380–3385. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.-H.; Koh, C.Y.; Bertoldi, K.; Boyce, M.C.; Thomas, E.L. Combining Pattern Instability and Shape-Memory Hysteresis for Phononic Switching. Nano Lett. 2009, 9, 2113–2119. [Google Scholar] [CrossRef] [PubMed]

- Singamaneni, S.; Bertoldi, K.; Chang, S.; Jang, J.-H.; Thomas, E.L.; Boyce, M.C.; Tsukruk, V.V. Instabilities and Pattern Transformation in Periodic, Porous Elastoplastic Solid Coatings. ACS Appl. Mater. Interfaces 2009, 1, 42–47. [Google Scholar] [CrossRef] [PubMed]

- Bertoldi, K.; Gei, M. Instabilities in multilayered soft dielectrics. J. Mech. Phys. Solids 2011, 59, 18–42. [Google Scholar] [CrossRef]

- Efimenko, K.; Wallace, W.E.; Genzer, J. Surface Modification of Sylgard-184 Poly(dimethyl siloxane) Networks by Ultraviolet and Ultraviolet/Ozone Treatment. J. Colloid Interface Sci. 2002, 254, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Schnyder, B.; Lippert, T.; Kötz, R.; Wokaun, A.; Graubner, V.-M.; Nuyken, O. UV-irradiation induced modification of PDMS films investigated by XPS and spectroscopic ellipsometry. Surf. Sci. 2003, 532–535, 1067–1071. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Zhou, Y.; Liu, Z.; Ng, T.Y. Pattern Switching in Soft Cellular Structures and Hydrogel-Elastomer Composite Materials under Compression. Polymers 2017, 9, 229. https://doi.org/10.3390/polym9060229

Hu J, Zhou Y, Liu Z, Ng TY. Pattern Switching in Soft Cellular Structures and Hydrogel-Elastomer Composite Materials under Compression. Polymers. 2017; 9(6):229. https://doi.org/10.3390/polym9060229

Chicago/Turabian StyleHu, Jianying, Yu Zhou, Zishun Liu, and Teng Yong Ng. 2017. "Pattern Switching in Soft Cellular Structures and Hydrogel-Elastomer Composite Materials under Compression" Polymers 9, no. 6: 229. https://doi.org/10.3390/polym9060229

APA StyleHu, J., Zhou, Y., Liu, Z., & Ng, T. Y. (2017). Pattern Switching in Soft Cellular Structures and Hydrogel-Elastomer Composite Materials under Compression. Polymers, 9(6), 229. https://doi.org/10.3390/polym9060229