Preparation and Characterization of Quaternized Chitosan Coated Alginate Microspheres for Blue Dextran Delivery

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Quaternary Ammonium CS (QAC)

2.3. Preparation of BD-Loaded ALG, CS/ALG and QAC/ALG Microspheres

2.4. Characterizations

2.5. In Vitro Drug Release

2.5.1. Drug Encapsulation Efficiency

2.5.2. Cumulative Drug Release

2.6. Statistical Analysis

3. Results and Discussion

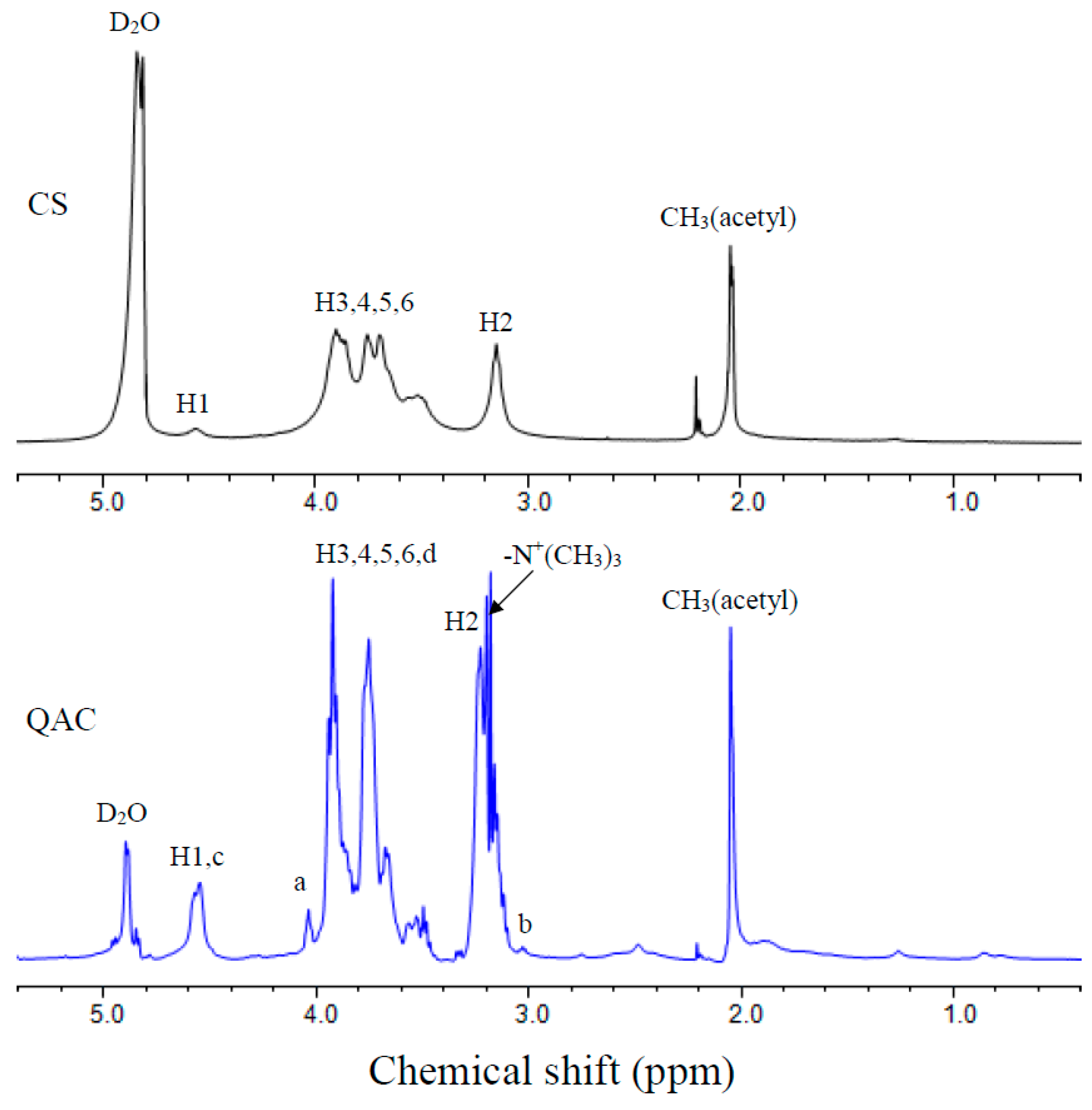

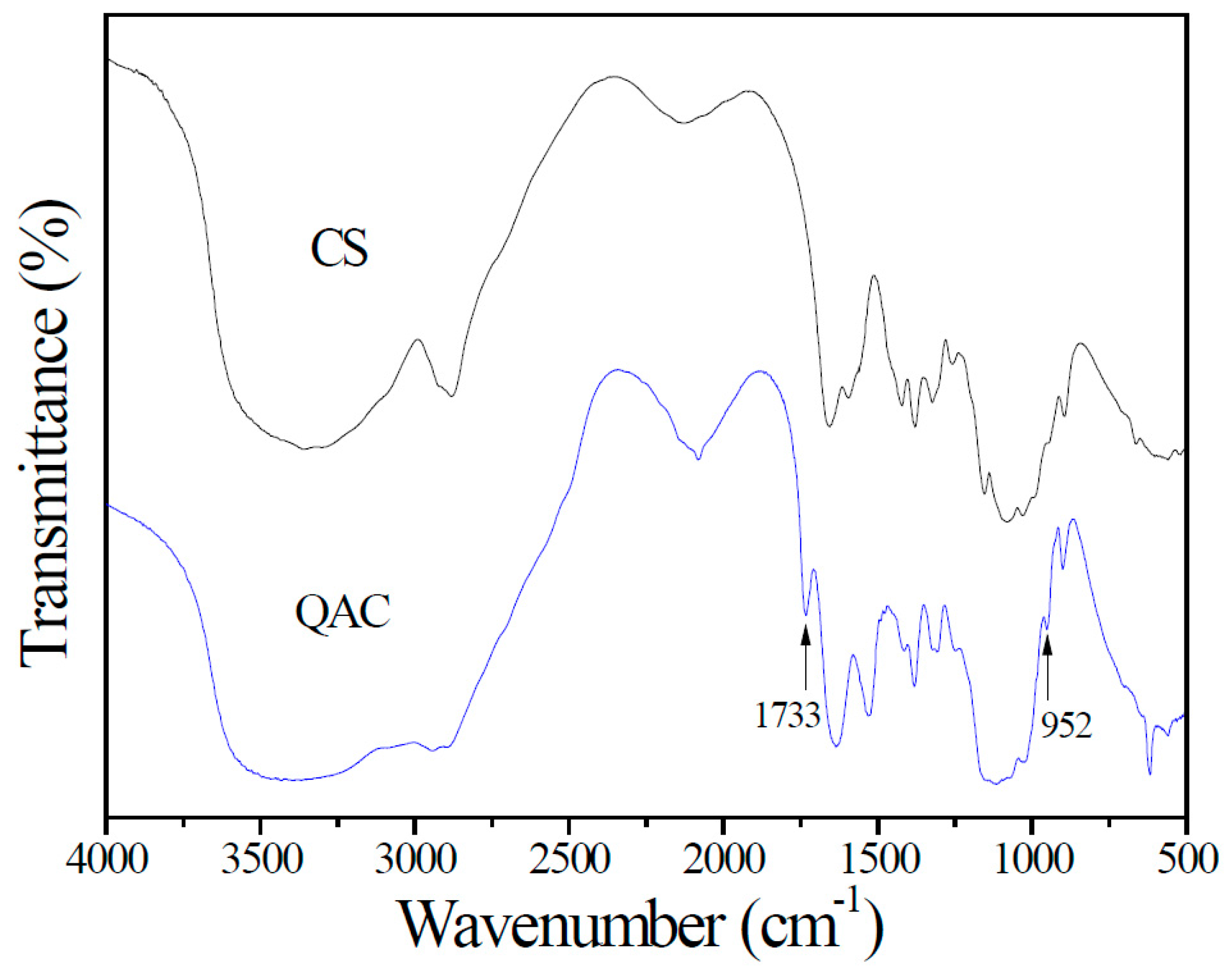

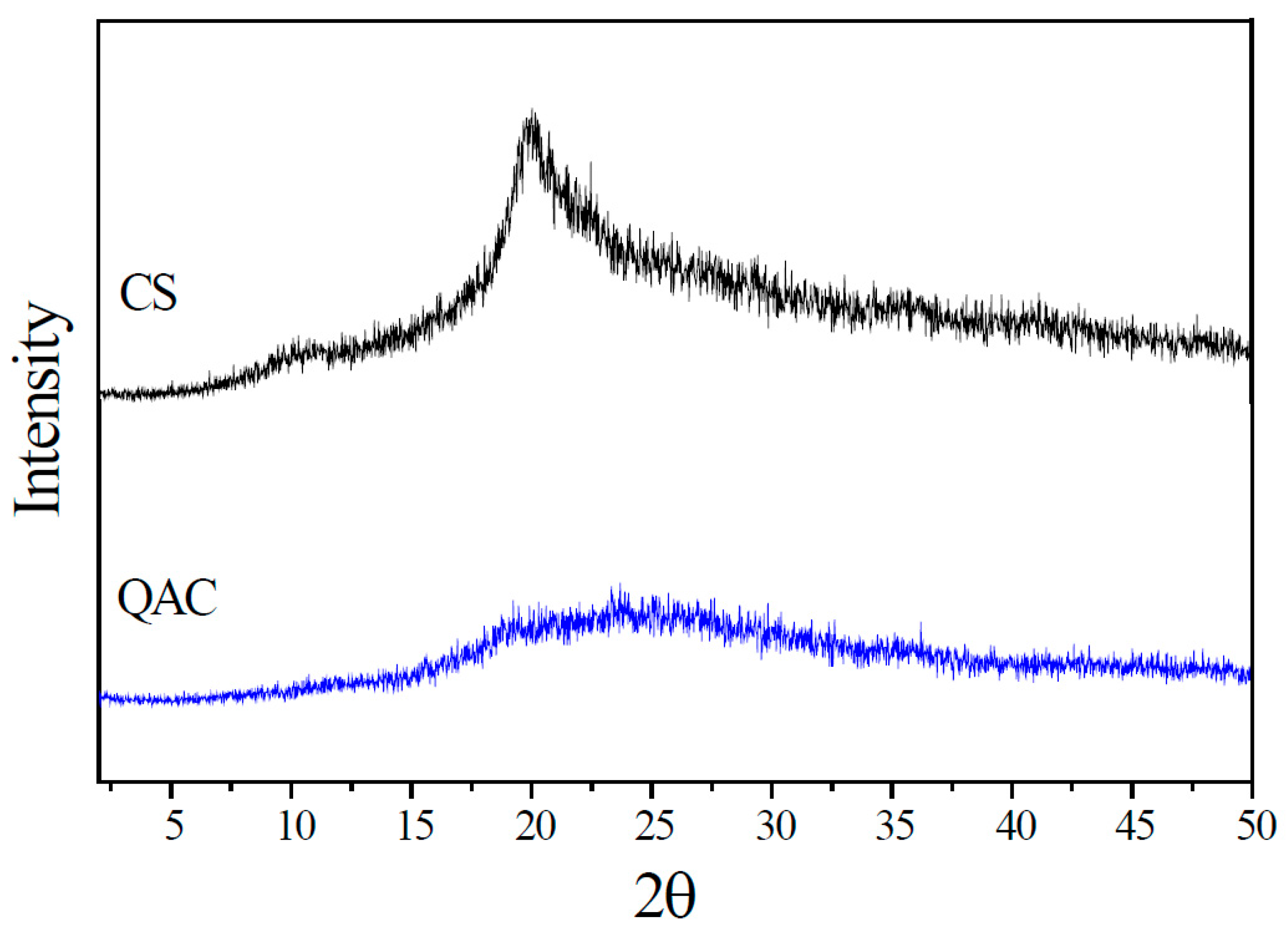

3.1. QAC Characteristics

3.2. Microspheres Characteristics

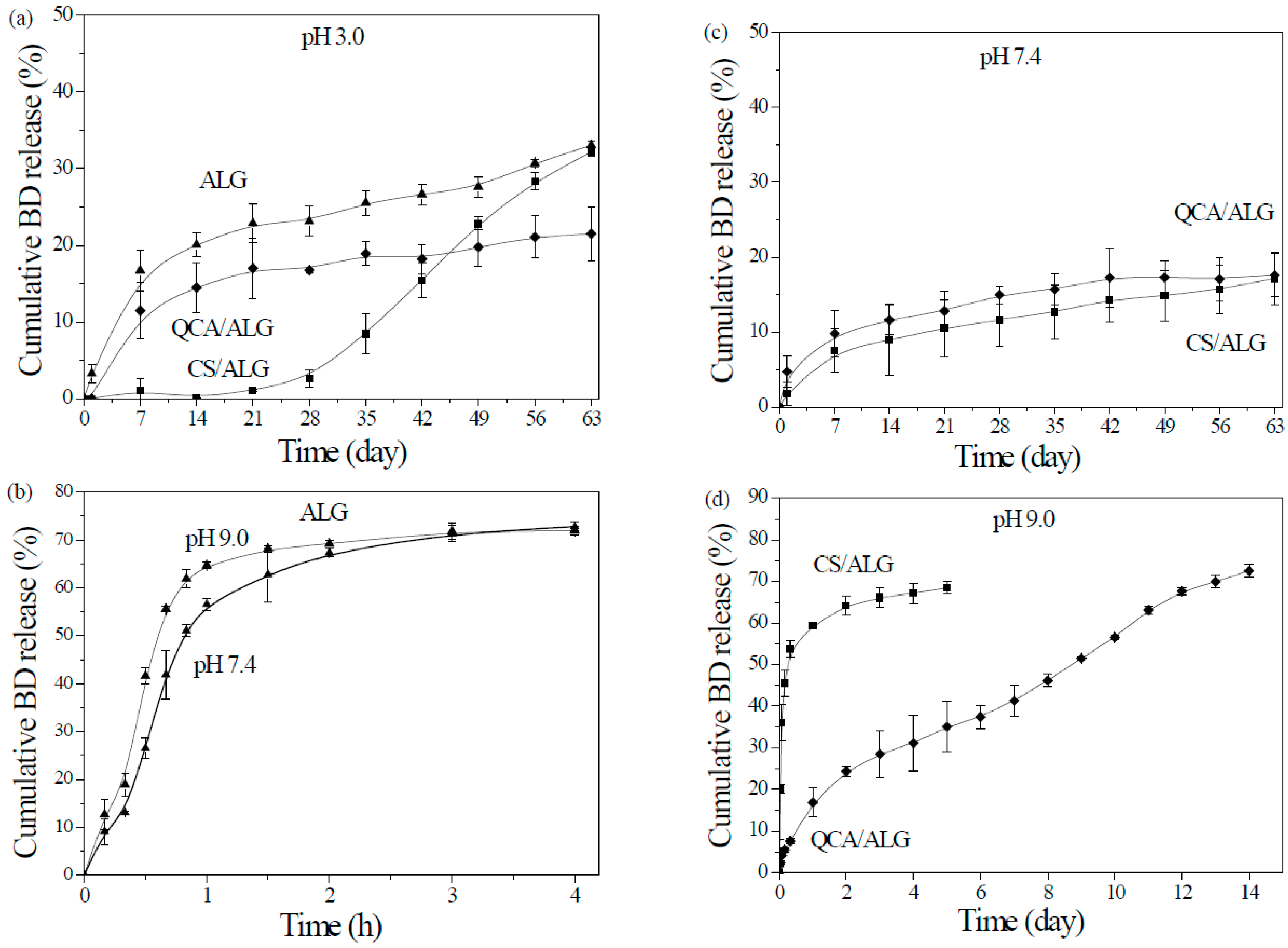

3.3. BD Release Prolife

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rizwan, M.; Yahya, R.; Hassan, A.; Yar, M.; Azzahari, A.D.; Selvanathan, V.; Sonsudin, F.; Abouloula, C.N. pH Sensitive hydrogels in drug delivery: Brief history, properties, swelling, and release mechanism, material selection and applications. Polymers 2017, 9, 137. [Google Scholar] [CrossRef]

- Martín, M.J.; Calpena, A.C.; Fernández, F.; Mallandrich, M.; Gálvez, P.; Clares, B. Development of alginate microspheres as nystatin carriers for oral mucosa drug delivery. Carbohydr. Polym. 2015, 117, 140–149. [Google Scholar] [CrossRef] [PubMed]

- Omer, A.M.; Tamer, T.M.; Hassan, M.A.; Rychter, P.; Mohy Eldin, M.S.; Koseva, N. Development of amphoteric alginate/aminated chitosan coated microbeads for oral protein delivery. Int. J. Biol. Macromol. 2016, 92, 362–370. [Google Scholar] [CrossRef] [PubMed]

- Suksamran, T.; Ngawhirunpat, T.; Rojanarata, T.; Sajomsang, W.; Pitaksuteepong, T.; Opanasopit, P. Methylated N-(4-N,N-dimethylaminocinnamyl) chitosan-coated electrospray OVA-loaded microparticles for oral vaccination. Int. J. Pharm. 2013, 448, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Saludas, L.; Pascual-Gil, S.; Prósper, F.; Garbayo, E.; Blanco-Prieto, M. Hydrogel based approaches for cardiac tissue engineering. Int. J. Pharm. 2017, 523, 454–475. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.; Ahuja, N.; Ma, C.; Liu, X. Injectable scaffolds: Preparation and application in dental and craniofacial regeneration. Mater. Sci. Eng. R 2017, 111, 1–26. [Google Scholar] [CrossRef]

- Deng, K.L.; Zhong, H.B.; Tian, T.; Gou, Y.B.; Li, Q.; Dong, L.R. Drug release behavior of a pH/temperature sensitive calcium alginate/poly(N-acryloylglycine) bead with core-shelled structure. Express Polym. Lett. 2010, 4, 773–780. [Google Scholar] [CrossRef]

- Krishna Rao, K.S.V.; Ha, C.S. pH Sensitive hydrogels based on acryl amides and their swelling and diffusion characteristics with drug delivery behavior. Polym. Bull. 2009, 62, 167–181. [Google Scholar] [CrossRef]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed]

- Baimark, Y.; Srisuwan, Y. Preparation of alginate microspheres by water–in–oil emulsion method for drug delivery: Effect of Ca2+ post-cross-linking. Adv. Powder Technol. 2014, 25, 1541–1546. [Google Scholar] [CrossRef]

- Moya, M.L.; Morley, M.; Khanna, O.; Opara, E.C.; Brey, E.M. Stability of alginate microbead properties in vitro. J. Mater. Sci. Mater. Med. 2012, 23, 903–912. [Google Scholar] [CrossRef] [PubMed]

- Anal, A.K.; Bhopatkar, D.; Tokura, S.; Tamura, H.; Stevens, W.F. Chitosan-alginate multilayer beads for gastric passage and controlled intestinal release of protein. Drug Dev. Ind. Pharm. 2003, 29, 713–724. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.X.; Wang, L.; Du, L.; Guo, S.R.; Wang, X.Q.; Tang, T.T. Adjustment of the antibacterial activity and biocompatibility of hydroxypropyltrimethyl ammonium chloride chitosan by varying the degree of substitution of quaternary ammonium. Carbohydr. Polym. 2010, 81, 275–283. [Google Scholar] [CrossRef]

- He, M.; Chu, C.H. Dual stimuli responsive glycidyl methacrylate chitosan-quaternary ammonium hybrid hydrogel and its bovine serum albumin release. J. Appl. Polym. Sci. 2013, 130, 3736–3745. [Google Scholar] [CrossRef]

- Shi, X.W.; Du, Y.M.; Li, J.; Su, X.L.; Yang, J.H. Release characteristics of brilliant blue from calcium-alginate beads coated with quaternized chitosan. J. Microencapsul. 2006, 23, 405–415. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.M. Binding of a quaternary ammonium polymer-grafted-chitosan onto a chemically modified wool fabric surface: Assessment of mechanical, antibacterial and antifungal properties. RSC Adv. 2015, 5, 35497–35505. [Google Scholar] [CrossRef]

- Viet, D.; Beck-Candanedo, S.; Gray, D.G. Synthesis and characterization of blue dextrans. Carbohydr. Polym. 2008, 74, 372–378. [Google Scholar]

- Sriamornsak, P.; Kennedy, R.A. Effect of sodium fluorescein on release characteristics of a macromolecule from calcium alginate beads. Carbohydr. Polym. 2011, 84, 1208–1212. [Google Scholar] [CrossRef]

- Endo, K.; Anada, T.; Yamada, M.; Seki, M.; Sasaki, K.; Suzuki, O. Enhancement of osteoblastic differentiation in alginate gel beads with bioactive octacalcium phosphate particles. Biomed. Mater. 2015, 10, 065019. [Google Scholar] [CrossRef] [PubMed]

- Sobol, M.; Bartkowiak, A.; de Haan, B.; de Vos, P. Cytotoxicity study of novel water-soluble chitosan derivatives applied as membrane material of alginate microcapsules. J. Biomed. Mater. Res. Part A 2013, 101, 1907–1914. [Google Scholar] [CrossRef]

- Song, H. Synthesis and application of cationic starch graft polymer by using the complex initiation system. Carbohydr. Polym. 2010, 82, 768–771. [Google Scholar] [CrossRef]

- Igberase, E.; Osifo, P.; Ofomaja, A. The adsorption of copper (II) ions by polyaniline graft chitosan beads from aqueous solution: Equilibrium, kinetic and desorption studies. J. Environ. Chem. Eng. 2014, 2, 362–369. [Google Scholar] [CrossRef]

- Liu, W.; Huang, Y.; Liu, H.; Hu, Y. Composite structure of temperature sensitive chitosan microgel and anomalous behavior in alcohol solutions. J. Colloid Interface Sci. 2007, 313, 117–121. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.L.; Yu, W.D. Preparation and characterization of CS-g-PNIPAAm microgels and application in a water vapour-permeable fabric. Carbohydr. Polym. 2015, 127, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Umar, A.; Abu Naim, A.; Sanagi, M.M. Synthesis and characterization of chitosan grafted with polystyrene using ammonium persulfate initiator. Mater. Lett. 2014, 124, 12–14. [Google Scholar] [CrossRef]

- Lim, S.H.; Hudson, S.M. Synthesis and antimicrobial activity of a water-soluble chitosan derivative with a fiber-reactive group. Carbohydr. Res. 2004, 339, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Rivas, B.L.; del Carmen Aguirre, M.; Pereira, E.; Moutet, J.C.; Aman, E.S. Capability of cationic water-soluble polymers in conjunction with ultrafiltration membranes to remove arsenate ions. Polym. Eng. Sci. 2007, 47, 1256–1261. [Google Scholar] [CrossRef]

- Sashiwa, H.; Yamamori, N.; Ichinose, Y.; Sunamoto, J.; Aiba, S. Michael reaction of chitosan with various acryl reagents in water. Biomacromolecules 2003, 4, 1250–1254. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.L.; An, Q.F.; Zhao, F.Y.; Gao, C.J. Fabrication of chitosan/PDMCHEA blend positively charged membranes with improved mechanical properties and high nanofiltration performances. Desalination 2015, 357, 8–15. [Google Scholar] [CrossRef]

- Hu, H.; Yu, L.; Tan, S.; Tu, K.; Wang, L.Q. Novel complex hydrogels based on N-carboxyethyl chitosan and quaternized chitosan and their controlled in vitro protein release property. Carbohydr. Res. 2010, 345, 462–468. [Google Scholar]

- Li, Z.; Yang, F.; Yang, R. Synthesis and characterization of chitosan derivatives with dual-antibacterial functional groups. Int. J. Biol. Macromol. 2015, 75, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.H.; Kim, J.C.; Lee, H.Y.; Kim, J.D.; Yang, J.H. Release property of temperature-sensitive alginate beads containing poly(N-isopropylacrylamide). Colloids Surf. B. Biointerfaces 2005, 46, 57–61. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Shi, J.; Xu, X.; Cao, S. Chitosan coated alginate/poly(N-isopropylacrylamide) beads for dual responsive drug delivery. Int. J. Biol. Macromol. 2013, 59, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Wyss, A.; von Stockar, U.; Marison, I.W. Production and characterization of liquid-core capsules made from cross-linked acrylamide copolymers for biotechnological applications. Biotechnol. Bioeng. 2004, 86, 563–572. [Google Scholar] [CrossRef] [PubMed]

- Dehousse, V.; Garbacki, N.; Colige, A.; Evrard, B. Development of pH–responsive nanocarriers using trimethylchitosans and methacrylic acid copolymer for siRNA delivery. Biomaterials 2010, 31, 1839–1849. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.-Y.; Zeng, S.-Y. Preparation and Characterization of Quaternized Chitosan Coated Alginate Microspheres for Blue Dextran Delivery. Polymers 2017, 9, 210. https://doi.org/10.3390/polym9060210

Chen K-Y, Zeng S-Y. Preparation and Characterization of Quaternized Chitosan Coated Alginate Microspheres for Blue Dextran Delivery. Polymers. 2017; 9(6):210. https://doi.org/10.3390/polym9060210

Chicago/Turabian StyleChen, Kuo-Yu, and Si-Ying Zeng. 2017. "Preparation and Characterization of Quaternized Chitosan Coated Alginate Microspheres for Blue Dextran Delivery" Polymers 9, no. 6: 210. https://doi.org/10.3390/polym9060210

APA StyleChen, K.-Y., & Zeng, S.-Y. (2017). Preparation and Characterization of Quaternized Chitosan Coated Alginate Microspheres for Blue Dextran Delivery. Polymers, 9(6), 210. https://doi.org/10.3390/polym9060210