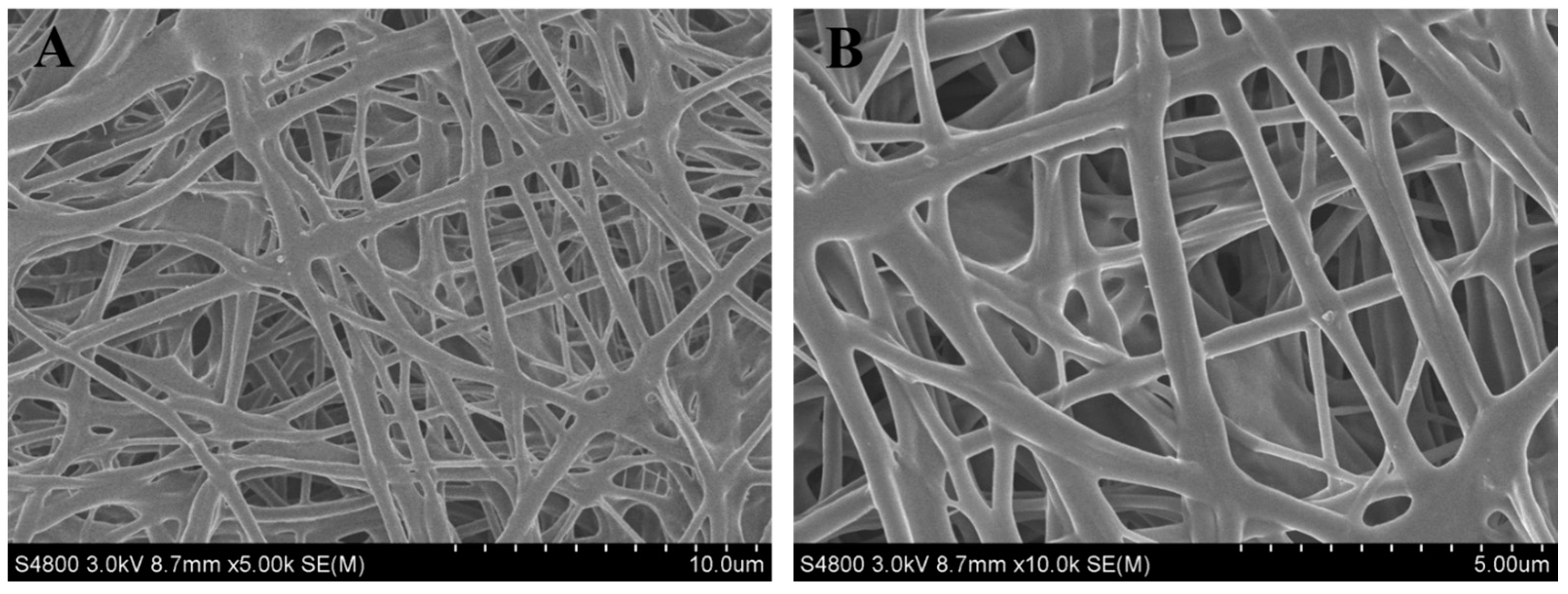

Properties of Electrospun Nanofibers of Multi-Block Copolymers of [Poly-ε-caprolactone-b-poly(tetrahydrofuran-co-ε-caprolactone)]m Synthesized by Janus Polymerization

Abstract

1. Introduction

2. Experimental

2.1. Materials

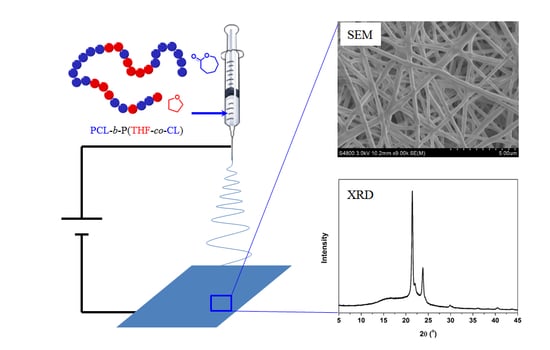

2.2. Electrospinning

2.3. Annealing

2.4. Mechanical Test

2.5. Characterization

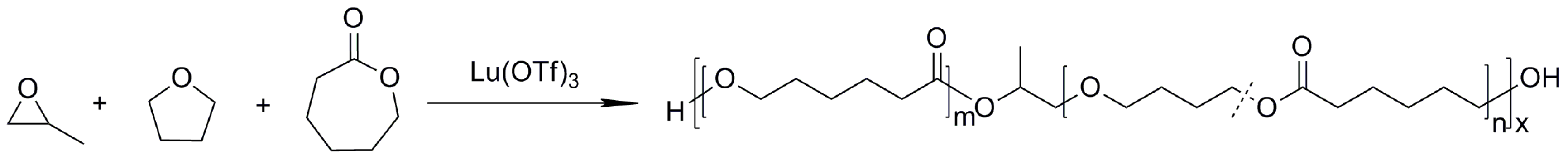

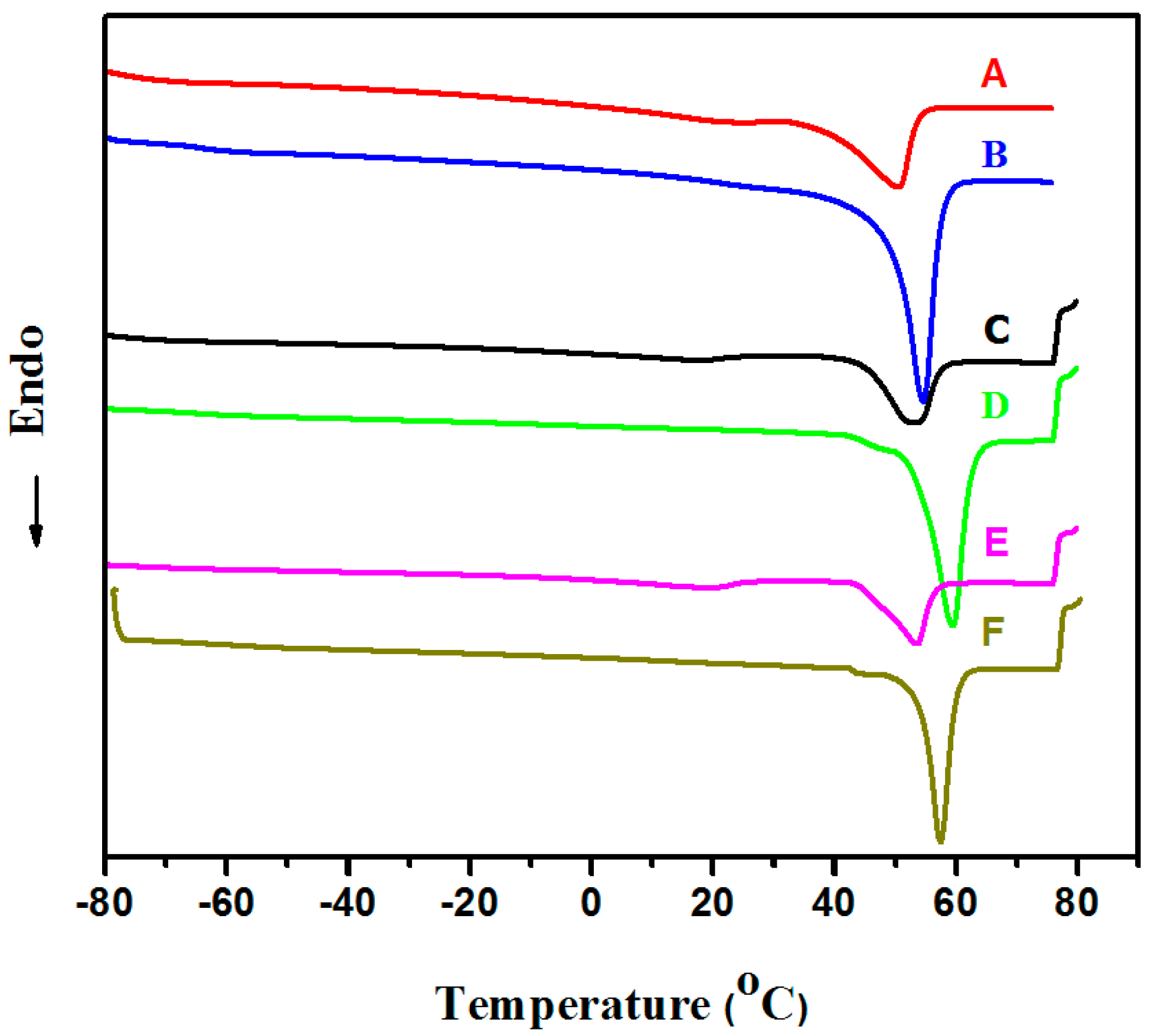

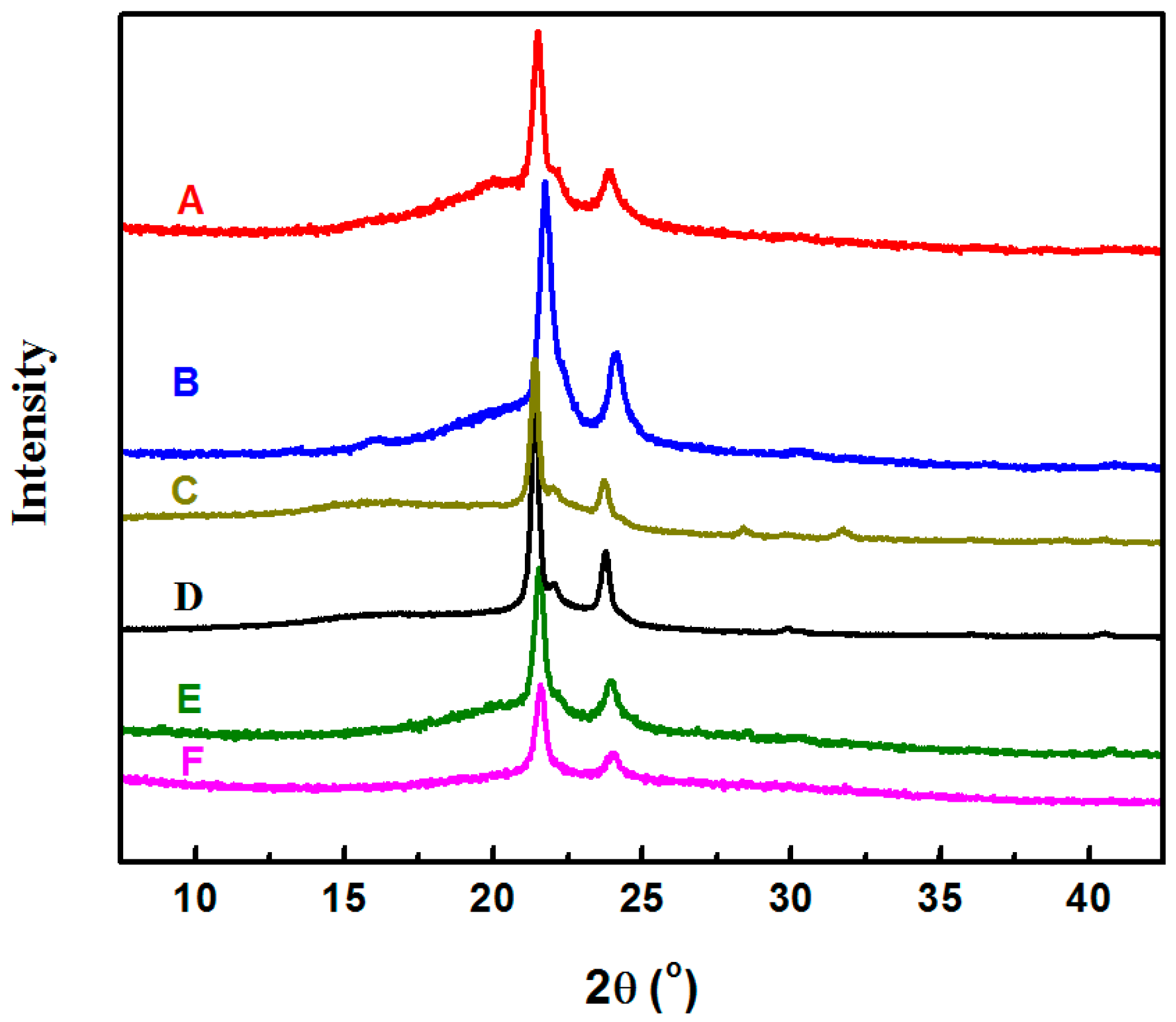

3. Results and Discussion

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guascito, M.R.; Chirizzi, D.; Malitesta, C.; Giotta, L.; Mastrogiacomo, D.; Valli, L.; Stabili, L. Development and characterization of a novel bioactive polymer with antibacterial and lysozyme-like activity. Biopolymers 2014, 101, 461–470. [Google Scholar] [CrossRef] [PubMed]

- Neppalli, R.; Marega, C.; Marigo, A.; Bajgai, M.P.; Kim, H.Y.; Causin, V. Poly(ε-caprolactone) filled with electrospun nylon fibres: A model for a facile composite fabrication. Eur. Polym. J. 2010, 46, 968–976. [Google Scholar] [CrossRef]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of electrospinning technique for biomedical applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef]

- Venugopal, J.; Zhang, Y.; Ramakrishna, S. Fabrication of modified and functionalized polycaprolactone nanofiber scaffolds for vascular tissue engineering. Nanotechnology 2005, 16, 2138. [Google Scholar] [CrossRef] [PubMed]

- Li, W.J.; Cooper, J.A.; Mauck, R.L.; Tuan, R.S. Fabrication and characterization of six electrospun poly (α-hydroxy ester)-based fibrous scaffolds for tissue engineering applications. Acta Biomater. 2006, 2, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Pitt, C.G. Poly-ε-caprolactone and its copolymers. In Biodegradable Polymers as Drug Delivery Systems; Chasin, M.P., Langer, R., Eds.; Marcel Dekker: New York, NY, USA, 1990; Volume 45, pp. 71–120. [Google Scholar]

- Van der Schueren, L.; De Schoenmaker, B.; Kalaoglu, Ö.I.; De Clerck, K. An alternative solvent system for the steady state electrospinning of polycaprolactone. Eur. Polym. J. 2011, 47, 1256–1263. [Google Scholar] [CrossRef]

- Lee, K.; Kim, H.; Khil, M.; Ra, Y.; Lee, D. Characterization of nano-structured poly(ε-caprolactone) nonwoven mats via electrospinning. Polymer 2003, 44, 1287–1294. [Google Scholar] [CrossRef]

- Duan, Y.; Jia, J.; Wang, S.; Yan, W.; Jin, L.; Wang, Z. Preparation of antimicrobial poly(ε-caprolactone) electrospun nanofibers containing silver-loaded zirconium phosphate nanoparticles. J. Appl. Polym. Sci. 2007, 106, 1208–1214. [Google Scholar] [CrossRef]

- Moghe, A.; Hufenus, R.; Hudson, S.; Gupta, B. Effect of the addition of a fugitive salt on electrospinnability of poly(ɛ-caprolactone). Polymer 2009, 50, 3311–3318. [Google Scholar] [CrossRef]

- Shimomura, O.; Lee, B.S.; Meth, S.; Suzuki, H.; Mahajan, S.; Nomura, R.; Janda, K.D. Synthesis and application of polytetrahydrofuran-grafted polystyrene (PS-PTHF) resin supports for organic synthesis. Tetrahedron 2005, 61, 12160–12167. [Google Scholar] [CrossRef]

- Aouissi, A.; Al-Deyab, S.S.; Al-Shahri, H. The cationic ring-opening polymerization of tetrahydrofuran with 12-tungstophosphoric acid. Molecules 2010, 15, 1398–1407. [Google Scholar] [CrossRef] [PubMed]

- Stephen Clark, J.; Elustondo, F.; Trevitt, G.P.; Boyall, D.; Robertson, J.; Blake, A.J.; Wilson, C.; Stammen, B. Preparation of cyclic ethers for polyether synthesis by catalytic ring-closing enyne metathesis of alkynyl ethers. Tetrahedron 2002, 58, 1973–1982. [Google Scholar] [CrossRef]

- Jayakannan, M.; Ramakrishnan, S. Recent developments in polyether synthesis. Macromol. Rapid Commun. 2001, 22, 1463–1473. [Google Scholar] [CrossRef]

- Chow, H.F.; Chan, I.Y.K.; Mak, C.C.; Man-Kit, N. Synthesis and properties of a new class of polyether dendritic fragments: Useful building blocks for functional dendrimers. Tetrahedron 1996, 52, 4277–4290. [Google Scholar] [CrossRef]

- Dale, J. The contrasting behaviour of oxirane and oxetane in cationic cyclooligomerization and polymerization. Tetrahedron 1993, 49, 8707–8725. [Google Scholar] [CrossRef]

- Klein, R.; Wurm, F.R. Aliphatic polyethers: Classical polymers for the 21st century. Macromol. Rapid Commun. 2015, 36, 1147–1165. [Google Scholar] [CrossRef] [PubMed]

- Rachmawati, R.; de Gier, H.D.; Woortman, A.J.; Loos, K. Synthesis of telechelic and three-arm polytetrahydrofuran-block-amylose. Macromol. Chem. Phys. 2015, 216, 1091–1102. [Google Scholar] [CrossRef]

- You, L.; Hogen-Esch, T.E.; Zhu, Y.; Ling, J.; Shen, Z. Brønsted acid-free controlled polymerization of tetrahydrofuran catalyzed by recyclable rare earth triflates in the presence of epoxides. Polymer 2012, 53, 4112–4118. [Google Scholar] [CrossRef]

- Gonzalez-Rodriguez, D.; Guevorkian, K.; Douezan, S.; Brochard-Wyart, F. Soft matter models of developing tissues and tumors. Science 2012, 338, 910–917. [Google Scholar] [CrossRef] [PubMed]

- You, L.; Ling, J. Janus polymerization. Macromolecules 2014, 47, 2219–2225. [Google Scholar] [CrossRef]

- Li, Y.; Bai, T.; Li, Y.; Ling, J. Branched polytetrahydrofuran and poly(tetrahydrofuran-co-ε-caprolactone) synthesized by Janus polymerization: A novel self-healing material. Macromol. Chem. Phys. 2016, 218, 1600450. [Google Scholar] [CrossRef]

- Qiu, H.; Yang, Z.; Shah, M.I.; Mao, Z.; Ling, J. [PCL-b-P(THF-co-CL)]m multiblock copolymer synthesized by Janus polymerization. Polymer 2017, 128, 71–77. [Google Scholar] [CrossRef]

- Xie, J.; Li, X.; Xia, Y. Putting electrospun nanofibers to work for biomedical research. Macromol. Rapid Commun. 2008, 29, 1775–1792. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.C.; Baji, A.; Leng, S. Effect of fiber diameter on tensile properties of electrospun poly(ε-caprolactone). Polymer 2008, 49, 4713–4722. [Google Scholar] [CrossRef]

- Darrell, H.R.; Iksoo, C. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216. [Google Scholar]

- Baji, A.; Mai, Y.W.; Wong, S.C.; Abtahi, M.; Chen, P. Electrospinning of polymer nanofibers: Effects on oriented morphology, structures and tensile properties. Compos. Sci. Technol. 2010, 70, 703–718. [Google Scholar] [CrossRef]

- Zhu, G.; Ling, J.; Shen, Z. Isothermal crystallization of random copolymers of ε-caprolactone with 2,2-dimethyltrimethylene carbonate. Polymer 2003, 44, 5827–5832. [Google Scholar] [CrossRef]

| Sample | CL Content (wt %) a | Mn b (kg/mol) | Đ b | Tm (°C) | ΔH (J/g) | χDSC (%) | χXRD (%) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|---|---|---|

| P1-nanofiber | 53.3 | 97 | 2.09 | 51.0 | 32.64 | 43 | 17.4 | 8.1 | 161 |

| P1-annealed | 53.2 | 24.45 | 32 | 21.1 | 10.2 | 267 | |||

| P1-cast film | 53.5 | 26.60 | 35 | 17.4 | - | - | |||

| P1-thermal-molded film | 50.0 | 21.18 | 28 | 5.7 | 20.0 | 2610 | |||

| P2-nanofiber | 88.4 | 131 | 2.06 | 54.0 | 40.57 | 32 | 22.5 | 10.4 | 123 |

| P2-annealed | 60.0 | 50.80 | 41 | 31.2 | 12.5 | 338 | |||

| P2-cast film | 55.5 | 43.06 | 35 | 19.3 | - | - | |||

| P2-thermal-molded film | 55.0 | 37.09 | 30 | 7.1 | 17.1 | 1020 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, M.I.; Yang, Z.; Li, Y.; Jiang, L.; Ling, J. Properties of Electrospun Nanofibers of Multi-Block Copolymers of [Poly-ε-caprolactone-b-poly(tetrahydrofuran-co-ε-caprolactone)]m Synthesized by Janus Polymerization. Polymers 2017, 9, 559. https://doi.org/10.3390/polym9110559

Shah MI, Yang Z, Li Y, Jiang L, Ling J. Properties of Electrospun Nanofibers of Multi-Block Copolymers of [Poly-ε-caprolactone-b-poly(tetrahydrofuran-co-ε-caprolactone)]m Synthesized by Janus Polymerization. Polymers. 2017; 9(11):559. https://doi.org/10.3390/polym9110559

Chicago/Turabian StyleShah, Muhammad Ijaz, Zhening Yang, Yao Li, Liming Jiang, and Jun Ling. 2017. "Properties of Electrospun Nanofibers of Multi-Block Copolymers of [Poly-ε-caprolactone-b-poly(tetrahydrofuran-co-ε-caprolactone)]m Synthesized by Janus Polymerization" Polymers 9, no. 11: 559. https://doi.org/10.3390/polym9110559

APA StyleShah, M. I., Yang, Z., Li, Y., Jiang, L., & Ling, J. (2017). Properties of Electrospun Nanofibers of Multi-Block Copolymers of [Poly-ε-caprolactone-b-poly(tetrahydrofuran-co-ε-caprolactone)]m Synthesized by Janus Polymerization. Polymers, 9(11), 559. https://doi.org/10.3390/polym9110559