Creep and Recovery Behaviour of Polyolefin-Rubber Nanocomposites Developed for Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Thermomechanical Properties

3. Results and Discussion

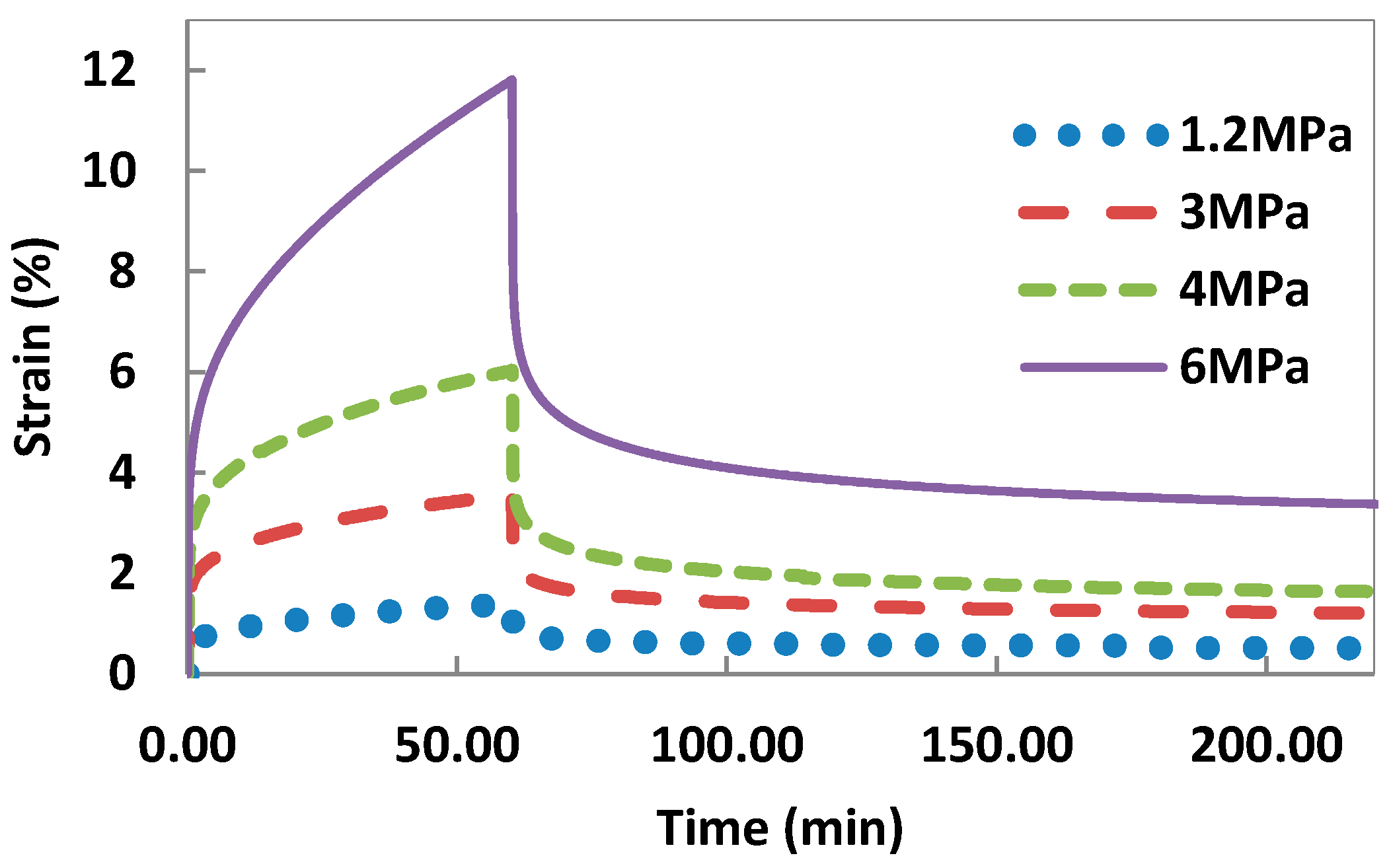

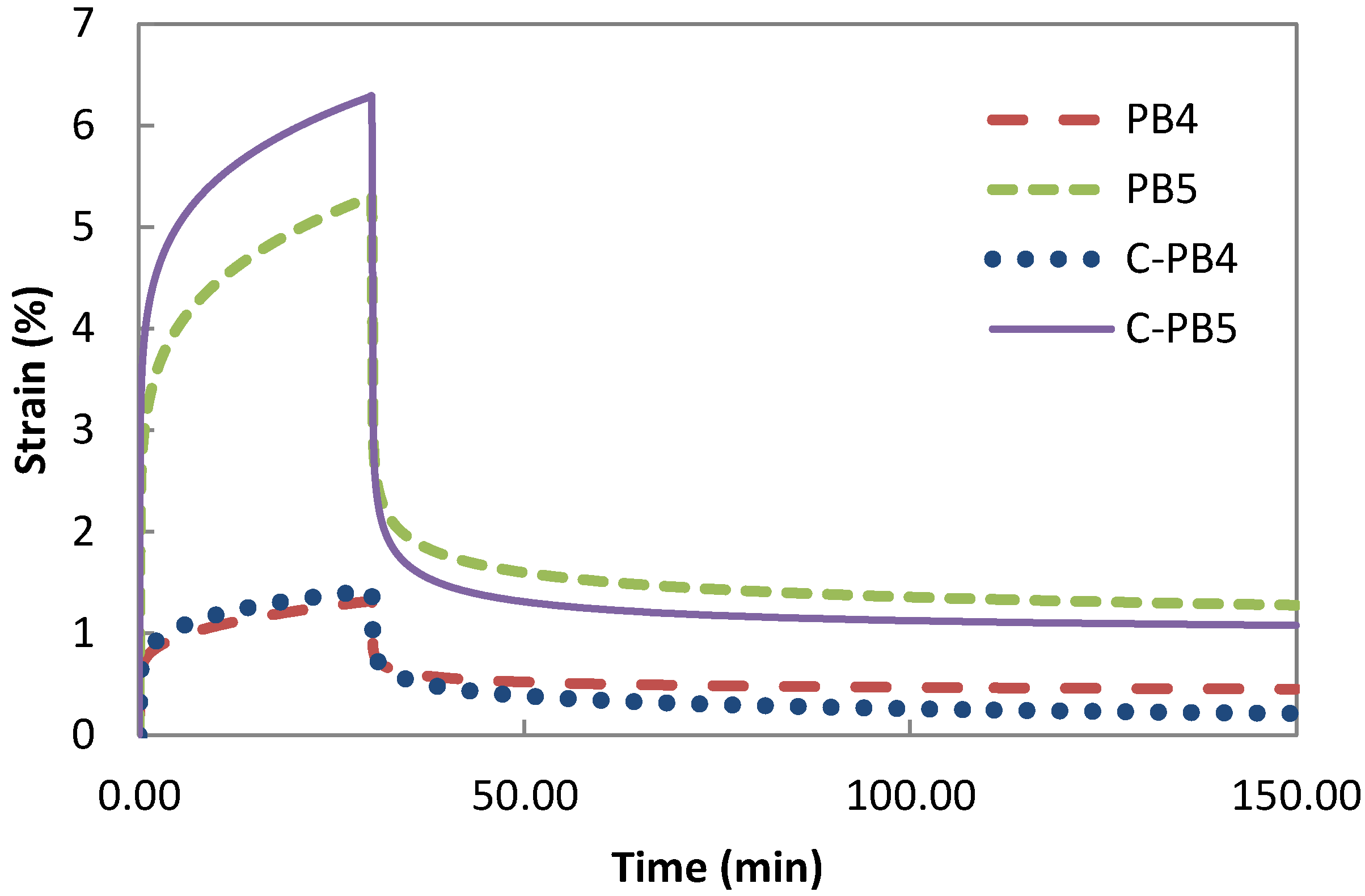

3.1. Strain Response of Composites with Creep Stress

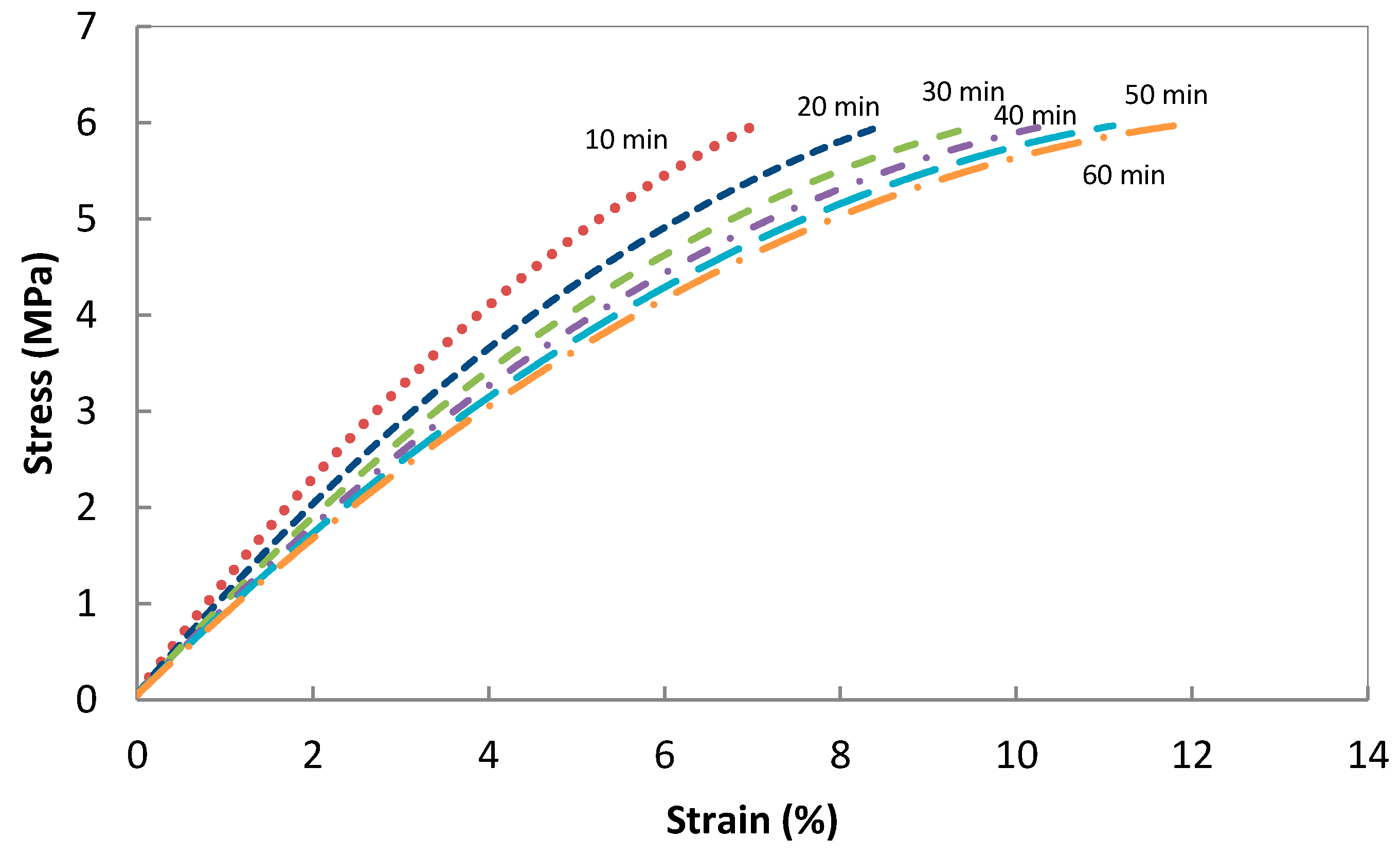

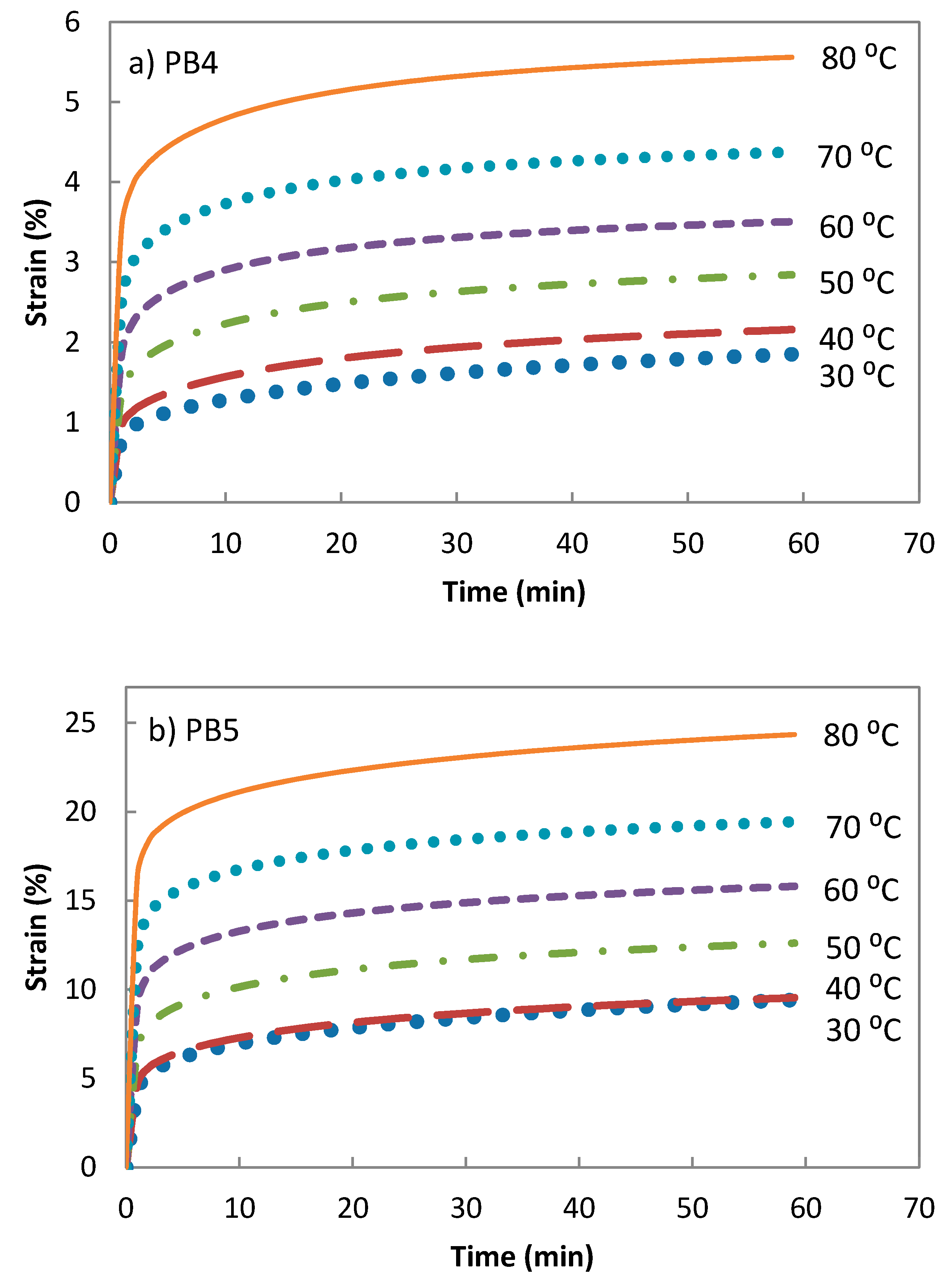

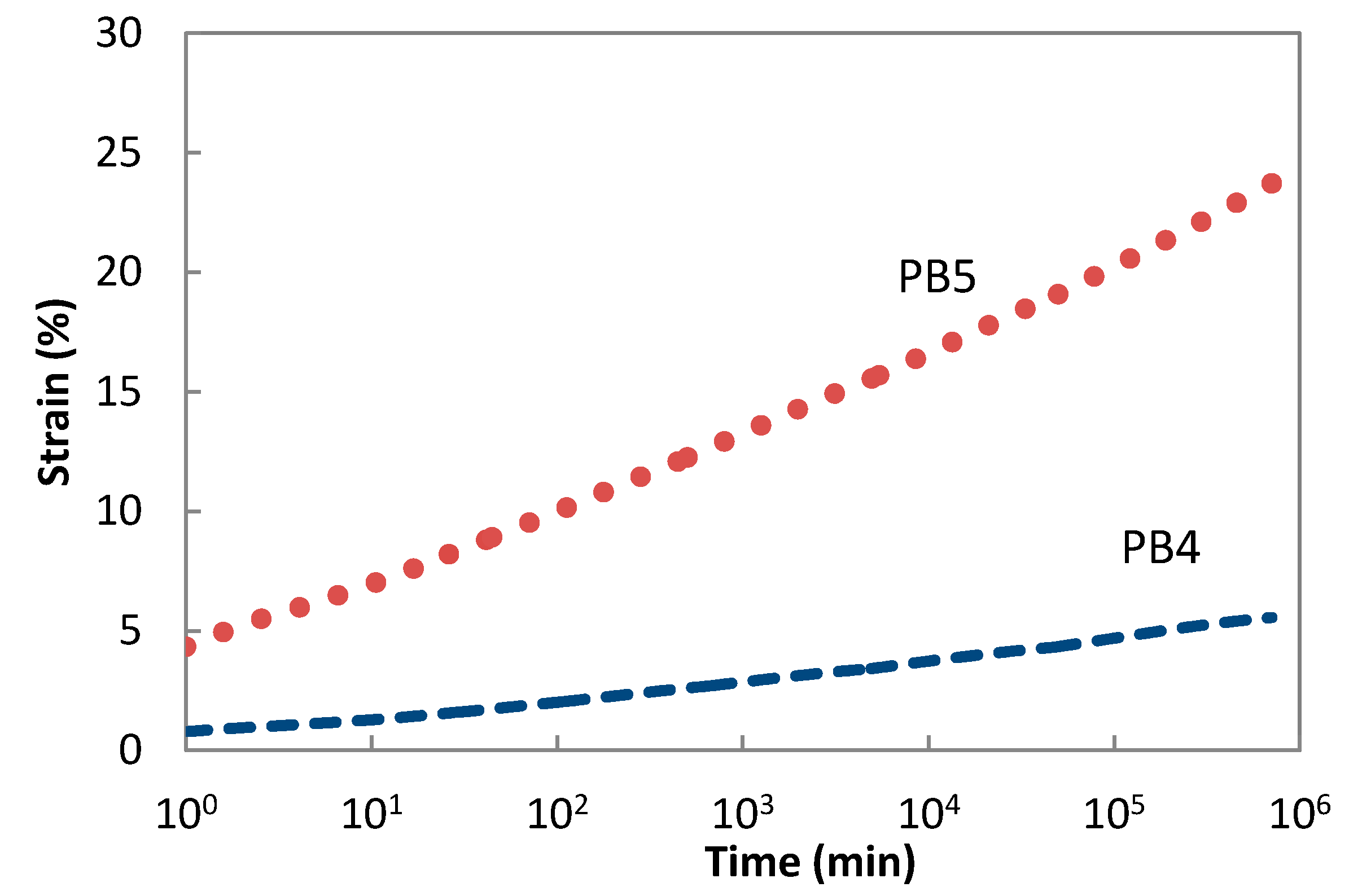

3.2. Application of Time-Temperature Superposition for Long Term Deformation Behaviour

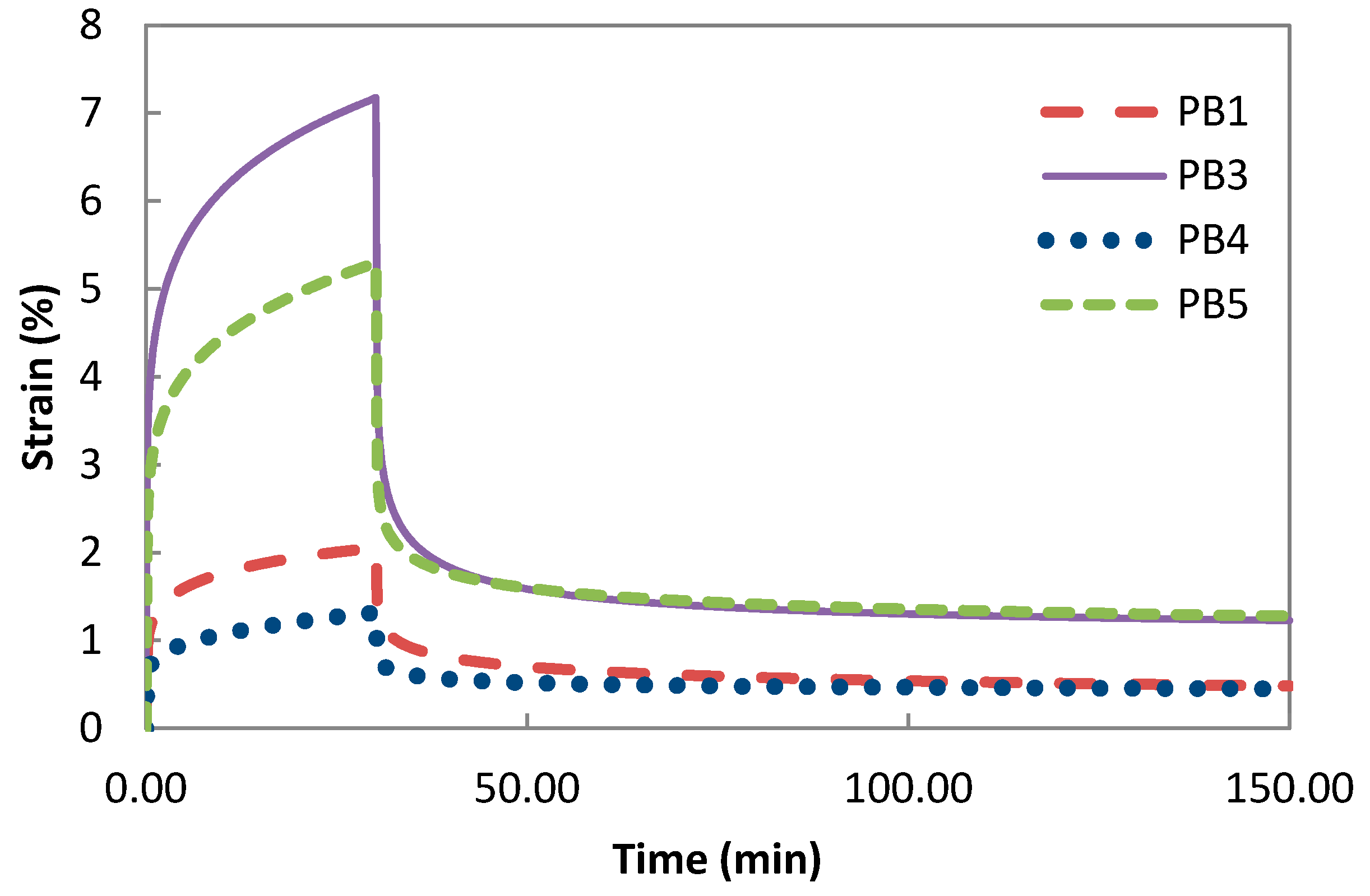

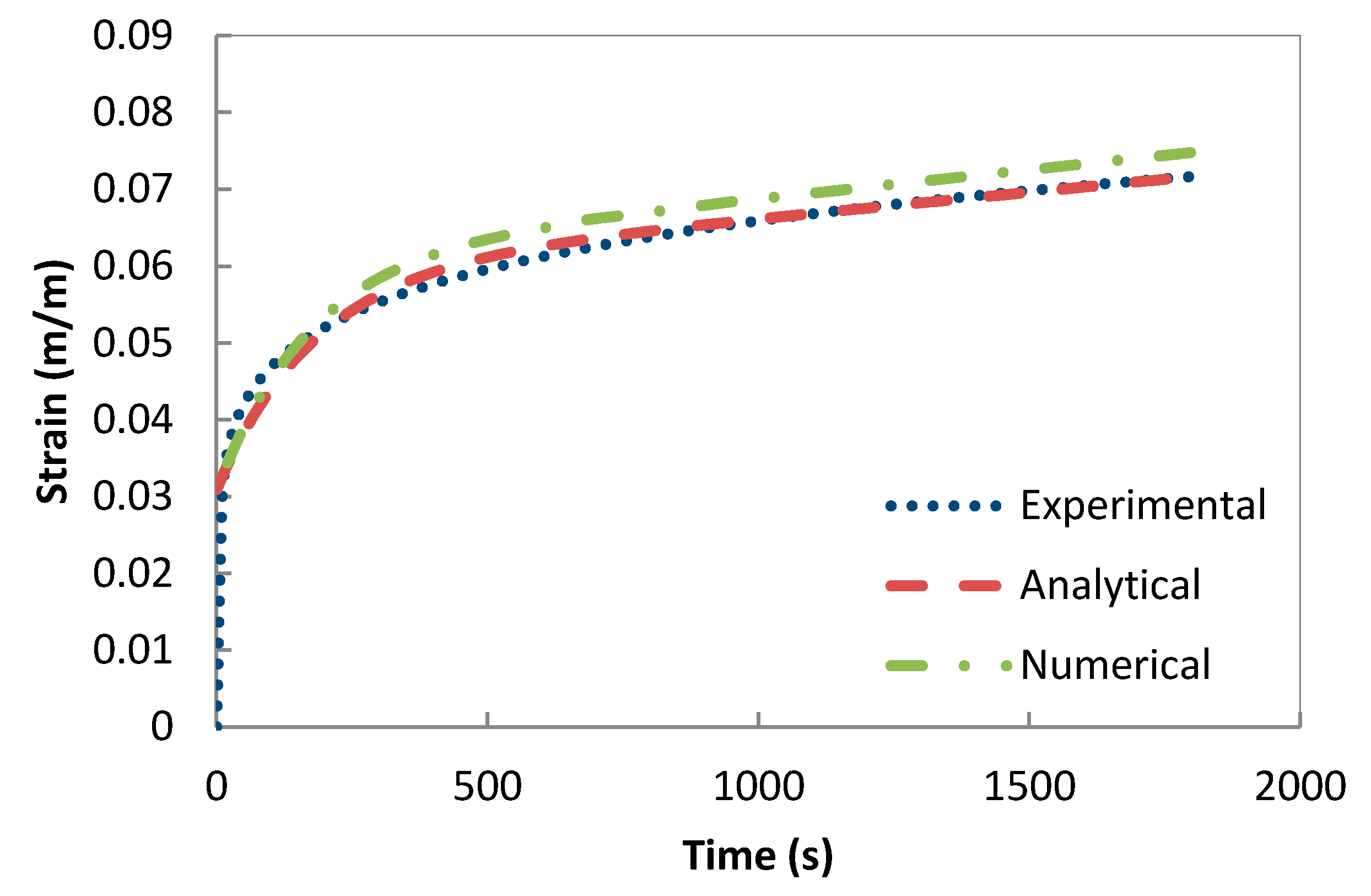

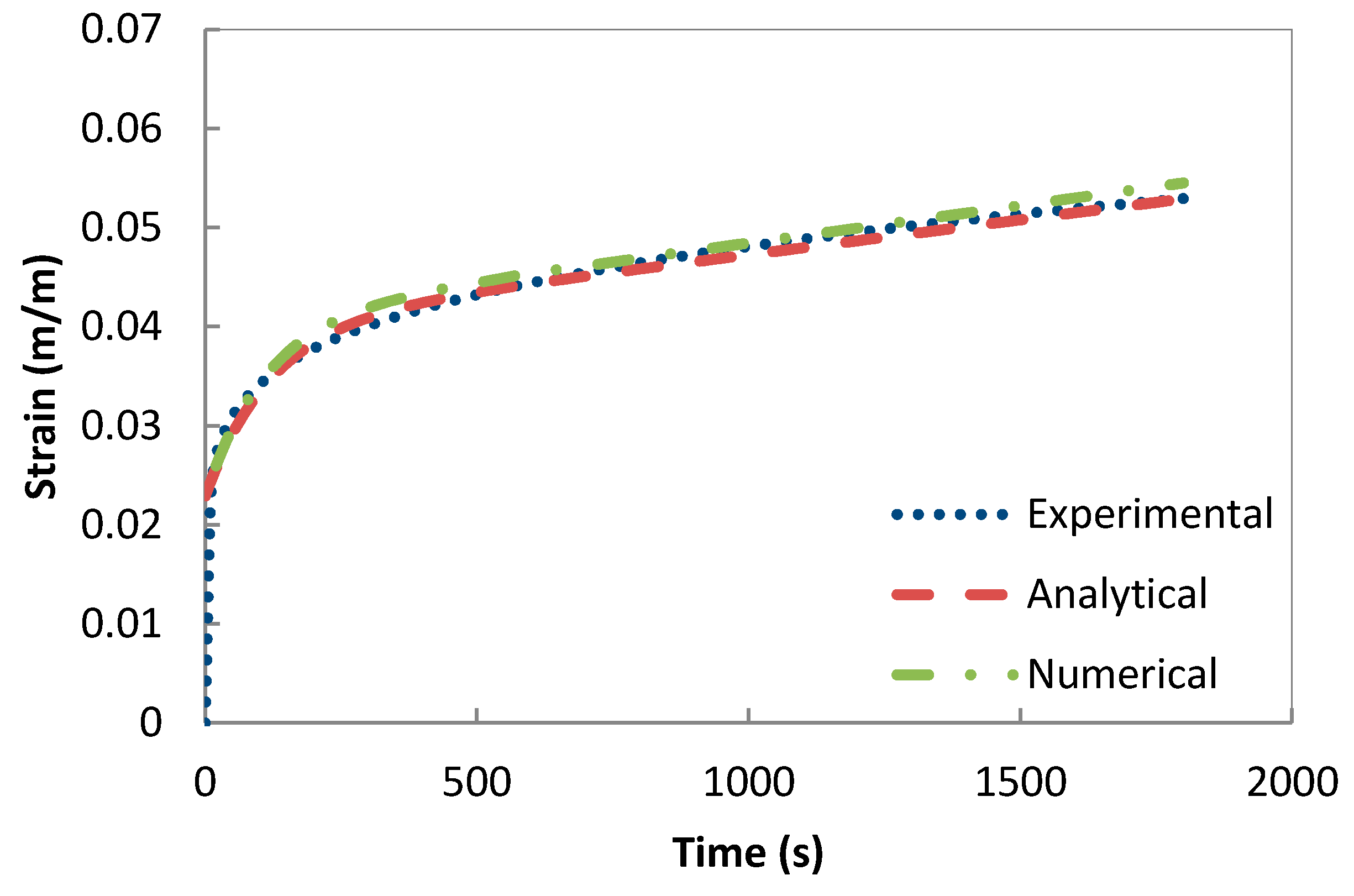

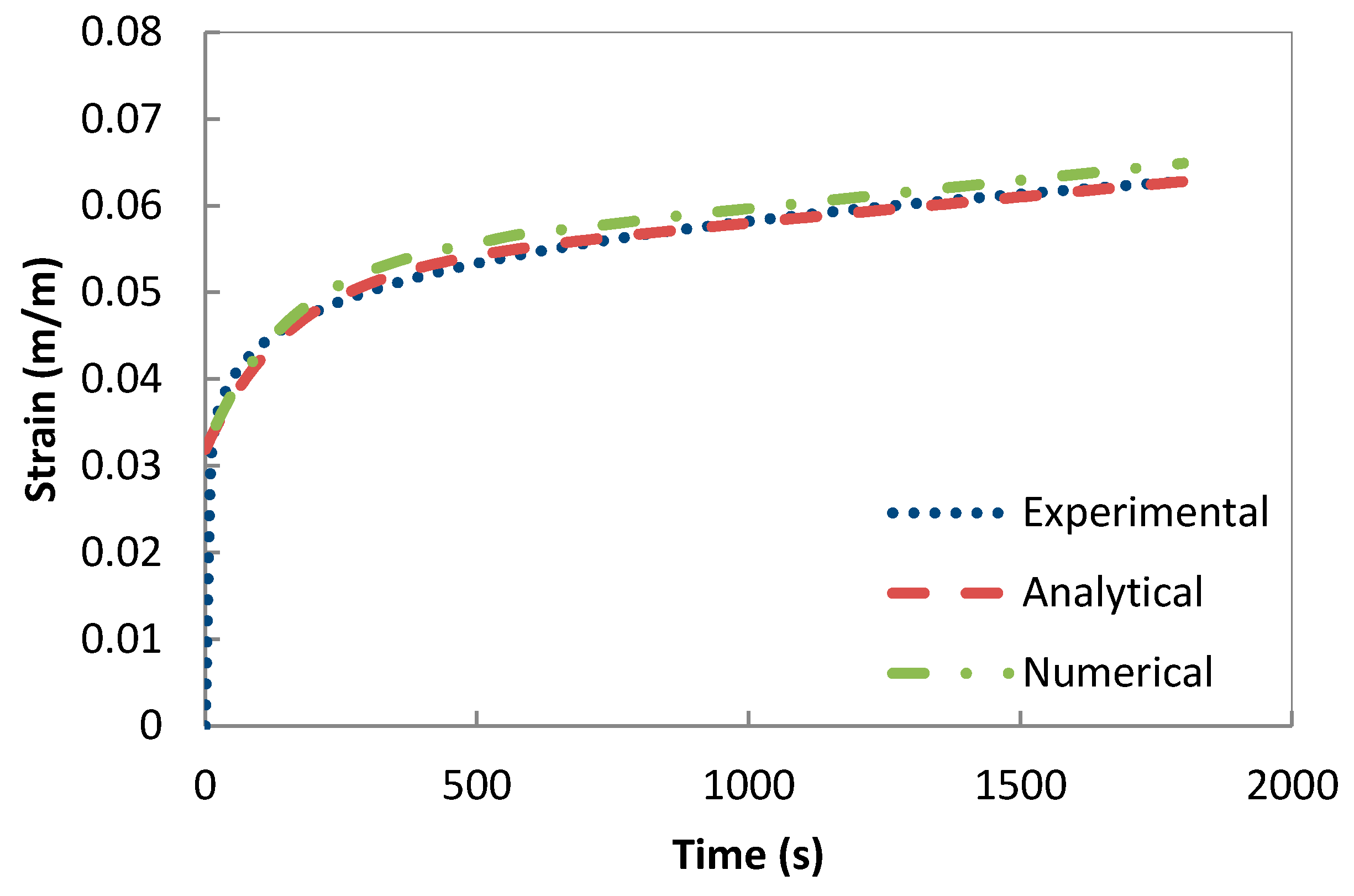

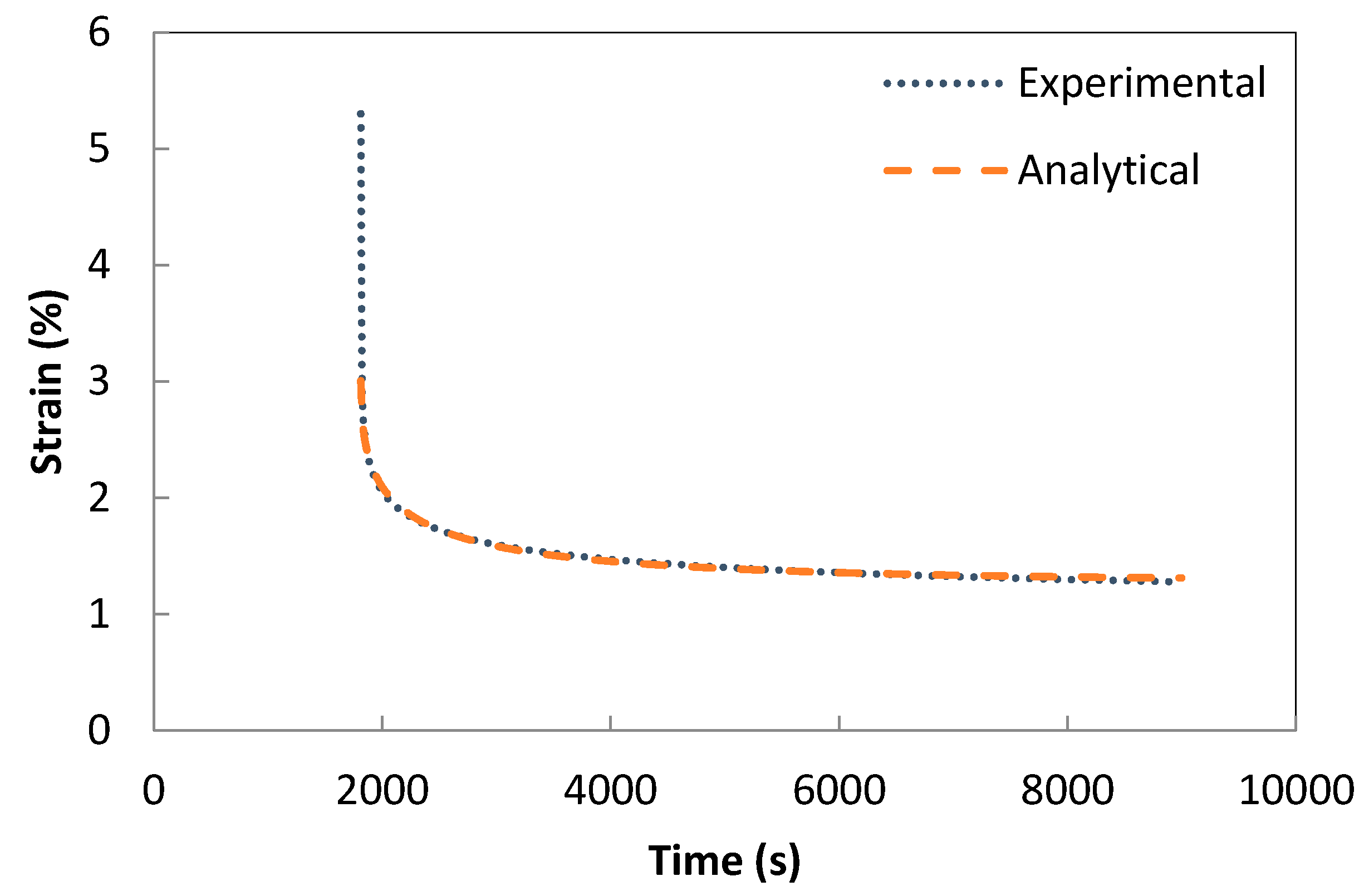

3.3. Modelling of the Creep Phase of Composites via a Four Element Burger Model

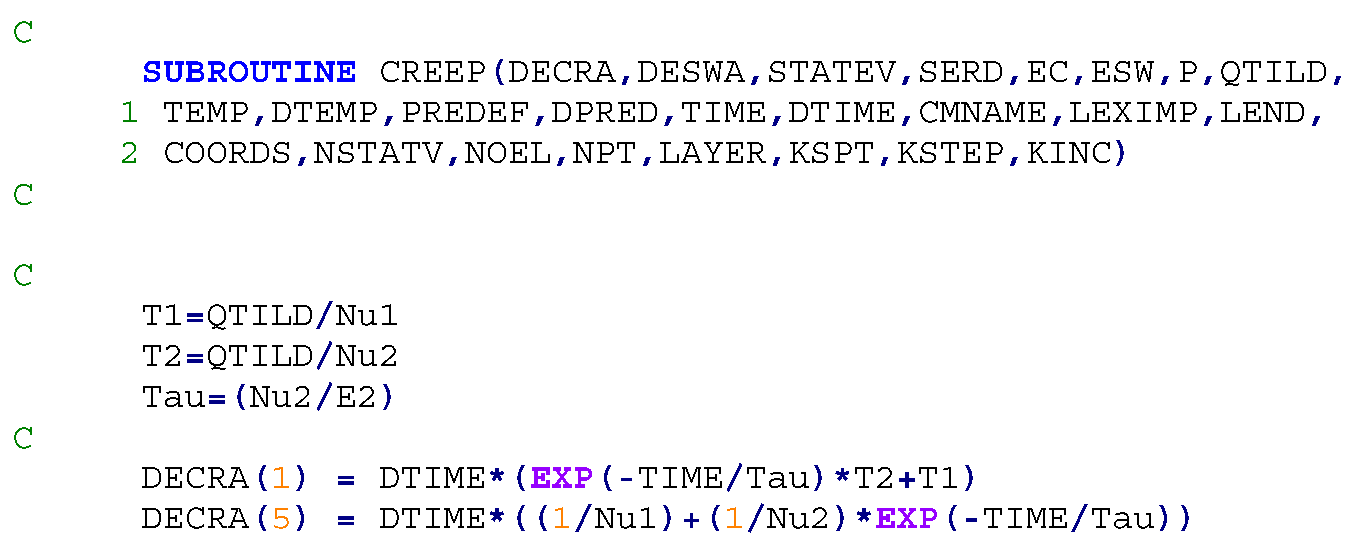

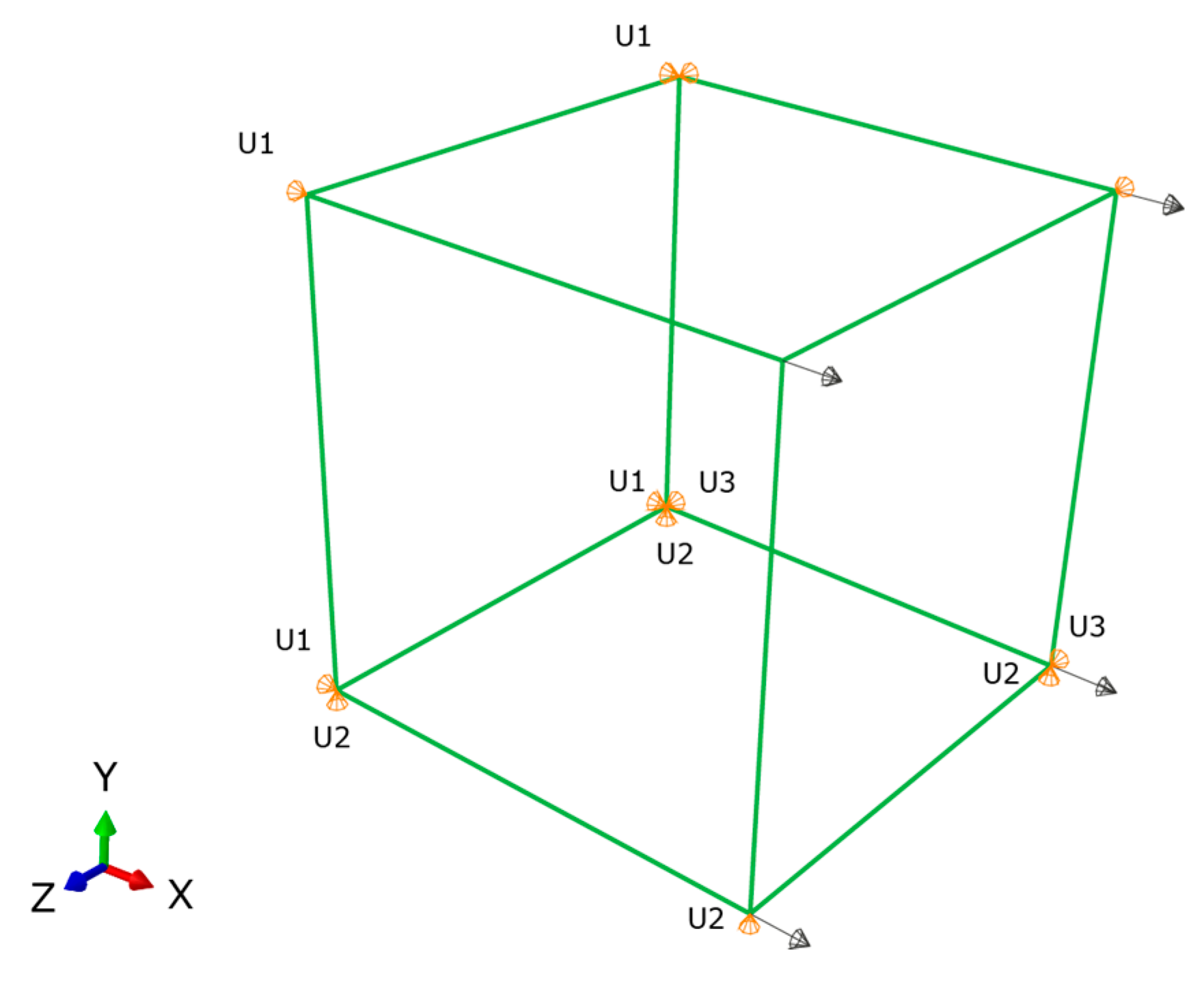

3.4. ABAQUS Implementation of the Four Element Burger Model

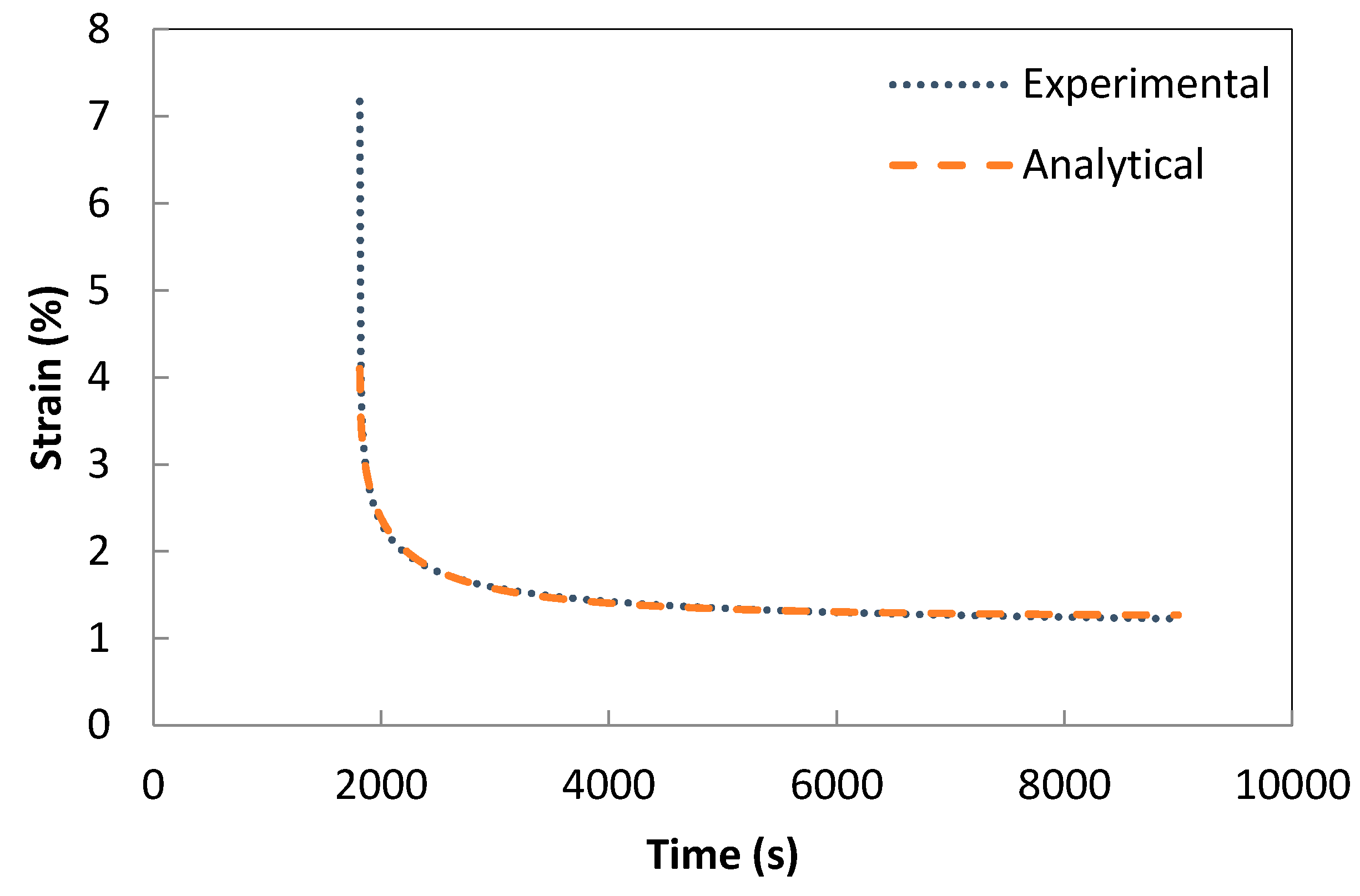

3.5. Modelling of the Recovery Phase of Composites via a Weibull Distribution Function

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Spoljaric, S.; Genovese, A.; Shanks, R.A. Novel elastomer-dumbbell functionalized POSS composites: Thermomechanical and morphological properties. J. Appl. Polym. Sci. 2012, 123, 585–600. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wang, X.; Gong, L.-X.; Peng, K.; Zhao, L.; Chen, Q.; Wu, L.-B.; Jiang, J.-X.; La, G.-Q. Creep and recovery of polystyrene composites filled with graphene additives. Compos. Sci. Technol. 2014, 91, 63–70. [Google Scholar] [CrossRef]

- Starkova, O.; Buschhorn, S.T.; Mannov, E.; Schulte, K.; Aniskevich, A. Creep and recovery of epoxy/MWCNT nanocomposites. Compos. A Appl. Sci. Manuf. 2012, 43, 1212–1218. [Google Scholar] [CrossRef]

- Jia, Y.; Peng, K.; Gong, X.L.; Zhang, Z. Creep and recovery of polypropylene/carbon nanotube composites. Int. J. Plast. 2011, 27, 1239–1251. [Google Scholar] [CrossRef]

- Ward, I.M. Mechanical Properties of Solid Polymers; John Wiley and Sons Ltd.: Weinheim, Germany, 1983. [Google Scholar]

- Guedes, R.M. Creep and Fatigue in Polymer Matrix Composites—Front Matter. Woodhead Publishing, 2011. Available online: http://app.knovel.com/hotlink/pdf/id:kt009390G3/creep-fatigue-in-polymer/front-matter (accessed on 1 December 2016).

- Findley, W.N.; Lai, J.S.; Onaran, K. Creep and Relaxation of Nonlinear Viscoelastic Materials: With an Introduction to Linear Viscoelasticity; DoverPublications Inc.: New York, NY, USA, 1989. [Google Scholar]

- Spoljaric, S.; Genovese, A.; Shanks, R.A. Polypropylene-microcrystalline cellulose composites with enhanced compatibility and properties. Compos. A Appl. Sci. Manuf. 2009, 40, 791–799. [Google Scholar] [CrossRef]

- Wong, S.; Shanks, R. Creep behaviour of biopolymers and modified flax fibre composites. Compos. Interfaces 2008, 15, 131–145. [Google Scholar] [CrossRef]

- Fancey, K.S. A mechanical model for creep, recovery and stress relaxation in polymeric materials. J. Mater. Sci. 2005, 40, 4827–4831. [Google Scholar] [CrossRef]

- Dai, Z.; Gao, Y.; Liu, L.; Pötschke, P.; Yang, J.; Zhang, Z. Creep-resistant behaviour of MWCNT-polycarbonate melt spun nanocomposite fibers at elevated temperature. Polymer 2013, 54, 3723–3729. [Google Scholar] [CrossRef]

- Wang, X.; Gong, L.-X.; Tang, L.-C.; Peng, K.; Pei, Y.B.; Zhao, L.; Wu, L.-B.; Jiang, J.-X. Temperature dependence of creep and recovery behaviours of polymer composites filled with chemically reduced graphene oxide. Compos. A Appl. Sci. Manuf. 2014, 69, 288–298. [Google Scholar] [CrossRef]

- Daver, F.; Baez, E.; Shanks, R.A.; Brandt, M. Conductive polyolefin-rubber nanocomposites with carbon nanotubes. Compos. A Appl. Sci. Manuf. 2016, 80, 13–20. [Google Scholar] [CrossRef]

- Nanocyl Carbon Nanotube Specialist. Technical Data Sheet of Plasticyl LDPE2001. Available online: www.nanocyl.com (accessed on 30 March 2013).

- ASTM D2990-09. Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics; ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 13 January 2015).

- Dassault Systems. ABAQUS User Manual, CREEP User-subroutine, Section 1.1.1 of the ABAQUS User Subroutine Reference Guide. 2015. [Google Scholar]

- Kim, Y.J. Contour integral calculations for generalised creep laws within ABAQUS. Int. J. Press. Vessel. Pip. 2001, 78, 661–666. [Google Scholar] [CrossRef]

- Lin, J.; Ho, K.C.; Dean, T.A. An integrated process for modelling of precipitation hardening and springback in creep age-forming. Int. J. Mach. Tools Manuf. 2006, 46, 1266–1270. [Google Scholar] [CrossRef]

- Gao, H.M.; Chen, G.X. Creep model of EPS composite soil and secondary development in FEM. In Forensic Engineering 2012: Gateway to a Better Tomorrow, Proceedings of the 6th Congress on Forensic Engineering, San Francisco, CA, USA, 31 October–3 November 2012; ASCE: Reston, VA, USA; pp. 692–699.

- Georgiopoulos, P.; Kontou, E.; Christopoulos, A. Short-term creep behaviour of a biodegradable polymer reinforced with wood-fibers. Compos. B Eng. 2015, 80, 134–144. [Google Scholar] [CrossRef]

- Lobo, H.; Hurtado, J. Characterization and modeling of nonlinear behaviour of plastics. In Proceedings of the ABAQUS User Conference, Boston, MA, USA, 23–25 May 2006.

| Composite code | Composition (%·w/w) | |||

|---|---|---|---|---|

| LLDPE | FRP | MA-g-PE | MWCNT | |

| PB1 | 70 | 30 | - | - |

| PB3 | 30 | 70 | - | - |

| PB4 | 65 | 30 | 5 | - |

| PB5 | 25 | 70 | 5 | - |

| C-PB4 | 62 | 30 | 5 | 3 |

| C-PB5 | 22 | 70 | 5 | 3 |

| Composite code | E1 (MPa) | E2 (MPa) | η1 (MPa·s) | η2 (MPa·s) | τ (s) |

|---|---|---|---|---|---|

| PB1 | 192 | 127 | 448,200 | 8730 | 69 |

| PB3 | 39 | 42 | 176,829 | 7409 | 176 |

| PB4 | 258 | 299 | 479,916 | 13,287 | 44 |

| PB5 | 52 | 69 | 169,956 | 8293 | 120 |

| C-PB4 | 226 | 177 | 1,020,917 | 40,838 | 231 |

| C-PB5 | 38 | 59 | 201,237 | 9177 | 154 |

| Composite code | εmax (%) | εe (%) | εve (%) | ε∞ (%) | ηr (s) | βr |

|---|---|---|---|---|---|---|

| PB1 | 2.56 | 0.64 | 0.95 | 0.47 | 591.18 | 0.48 |

| PB3 | 7.17 | 3.07 | 2.85 | 1.25 | 221.77 | 0.47 |

| PB4 | 1.32 | 0.46 | 0.40 | 0.45 | 340.34 | 0.46 |

| PB5 | 5.30 | 2.29 | 1.73 | 1.28 | 356.55 | 0.45 |

| C-PB4 | 1.42 | 0.55 | 0.68 | 0.19 | 720.60 | 0.49 |

| C-PB5 | 6.29 | 3.17 | 2.02 | 1.10 | 186.31 | 0.46 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daver, F.; Kajtaz, M.; Brandt, M.; Shanks, R.A. Creep and Recovery Behaviour of Polyolefin-Rubber Nanocomposites Developed for Additive Manufacturing. Polymers 2016, 8, 437. https://doi.org/10.3390/polym8120437

Daver F, Kajtaz M, Brandt M, Shanks RA. Creep and Recovery Behaviour of Polyolefin-Rubber Nanocomposites Developed for Additive Manufacturing. Polymers. 2016; 8(12):437. https://doi.org/10.3390/polym8120437

Chicago/Turabian StyleDaver, Fugen, Mladenko Kajtaz, Milan Brandt, and Robert A. Shanks. 2016. "Creep and Recovery Behaviour of Polyolefin-Rubber Nanocomposites Developed for Additive Manufacturing" Polymers 8, no. 12: 437. https://doi.org/10.3390/polym8120437

APA StyleDaver, F., Kajtaz, M., Brandt, M., & Shanks, R. A. (2016). Creep and Recovery Behaviour of Polyolefin-Rubber Nanocomposites Developed for Additive Manufacturing. Polymers, 8(12), 437. https://doi.org/10.3390/polym8120437