1. Introduction

Edible packaging films made from milk proteins are a “green” potential solution to replace some petroleum-based food-packaging films and improve the quality and preservation of food, while at the same time reducing waste, since the films biodegrade and can be eaten with the food they are protecting. Casein (Cas), the main protein of cow’s milk, is precipitated from milk by acidification and then neutralized with Ca(OH)

2 or NaOH base to re-solubilize and form calcium caseinate (CaCas) or sodium caseinate (NaCas) before spray-drying. The caseinates have a random-coil structure due to the presence of many ring-shaped proline residues that stiffen the backbone and prevent the formation of tertiary structures, through steric hindrance [

1]. The proline residues are also hydrophobic and their distribution pattern along the proteins contributes to the caseinates’ amphiphilic character that is exploited in the film-making process. Films manufactured from CaCas or NaCas blended with glycerol (Gly) are strong, transparent, tasteless and excellent oxygen barriers [

2], but their mechanical properties vary strongly with the ambient humidity present during their manufacture, storage and utilization [

3]. To date, edible films intended for food packaging applications have been prepared from a variety of proteins, carbohydrates, and protein/carbohydrate combinations, and are generally highly hydrophilic, soluble in water and extremely sensitive to moisture during storage and utilization; however, the tensile properties of hydrophilic edible films are typically measured at normal temperature (

T) and relative humidity (RH) conditions (23 ± 2 °C and 50% ± 5% RH) only. For example, Cas/Gly film strips are stored in normal conditions for at least 40 h according to the standard ASTM method for testing tensile properties of thin films [

4], then mounted on an Instron-type texture analyzer or an opened dynamic mechanical analyzer (DMA), in a room or chamber also controlled at ~50% ± 5% RH and 23 ± 2 °C, to measure the stress-strain curves of Cas/Gly films in normal conditions [

5,

6,

7]. In order to measure the stress-strain curves under different RH conditions and obtain the Young’s modulus,

Y, tensile strength,

TS, and elongation at break,

D (%), of casein films as a function of RH, films have been left to equilibrate in the open in the laboratory and tested at different times of the year, with RH varying from as low as ~10% to as high as ~70% RH [

3,

8]. At constant film thickness, the elongation at break of CaCas/Gly films increased considerably with RH, while the tensile strength and elastic modulus decreased somewhat linearly with RH and could in theory be extrapolated to ~0 MPa at ~80% RH [

3]. Using casein films grafted with acrylonitrile, Somanathan

et al. found that the transient tensile properties (

i.e., stress-strain curves) of casein-based films were strongly affected by the amount of moisture absorbed by the films [

9]. During the DMA measurement of stress-strain curves of beta-casein films preconditioned in an environmental chamber at 50% RH, Mauer

et al. postulated that the 10 min needed to test each sample at the variable ambient RH present in the laboratory at the time of measurement had a negligible effect on the moisture-content of the films, and that the tensile properties measured were representative of the properties at 50% RH [

7].

Environmental conditions (

T and RH) are known to affect the mechanical properties of biopolymer films in several ways. For instance, hydrophilic soy-protein/Gly films were found to possess high moisture-sorption rates and to absorb increasing amounts of water when RH rises [

10]. Because the humidity (

H) in the air increases near-exponentially with temperature at constant RH [

11], variations in either

T or RH can considerably affect the films' water-content, which acts as a plasticizer and generally reduces the tensile strength and increases the elongation at break of the films [

10]. Protein-based thermoplastics resemble semi-crystalline polymers and can have several structural relaxations and transition temperatures, including a glass transition (

Tg) and a melting point (

Tm), as well as various secondary transition temperatures that correspond to different changes in protein-protein interactions, or partial denaturation of the tertiary or secondary structure of the proteins. Unlike polymers,

Tg and

Tm do not necessarily imply complete unfolding of the proteins into a fully amorphous structure, as α-helices and β-sheets can remain [

12]. The thermal behaviors of casein or whey protein films—plasticized with Gly or not—have been determined at 0% RH at a wide range of temperatures using differential scanning calorimetry (DSC) or dynamic mechanical analysis (DMA; also termed dynamic thermo-mechanical analysis, DMTA) [

13,

14,

15]. Recently, the dynamic thermo-mechanical behaviors of soy-protein/Gly films were characterized with DMA from −100 to 150 °C with a heating rate of 5 °C/min at 0% RH [

16].

However, since water strongly plasticizes protein networks, relative humidity values above 0% are expected to heavily influence the different transition temperatures of protein-based films. Different levels of moisture absorbed into casein films during thermo-mechanical analyses are expected to lower

Tg and

Tm to different extents, as well as trigger new unfolding and reconfiguration patterns for the proteins, that may be indicated by new, or shifted, secondary transition temperatures. To date, the thermo-mechanical properties of milk-based films have not been measured other than in dry (0% RH) conditions, and few other edible films and bioplastics have been characterized with DMA after equilibrating under varied RH conditions. In order to measure the RH-dependent thermo-mechanical properties of hydrophilic films and bioplastics, materials have been left to equilibrate for at least a week at ~23 °C in air-tight chambers containing different saturated salt solutions, such as: LiCl, CH

3COOK, MgCl

2, K

2CO

3, Mg(NO

3)

2, NaNO

2, NaCl or KCl, which generate constant RH conditions of 11%, 24%, 33%, 44%, 54%, 66%, 76% or 85%, respectively [

17], then loaded onto a DMA for thermo-mechanical analysis with a

T-ramp at 0% RH. For example, Hochstetter

et al. evaluated uncoated wheat gluten/Gly sheets from −150 to 50 °C at 0% RH with a

T-ramp of 2 °C/min at different frequencies of 1, 2.5, 5, 10 and 20 Hz [

17]. Wongsasulak

et al. found that the moisture content played a key role in the thermo-mechanical properties and microstructure of egg albumen/cassava starch composite films and added a wet cotton ball in the DMA chamber to reduce moisture-loss during

T-ramps. After ramping

T from 25 to 130 °C at a rate of 2.5 °C/min, water loss in the samples was reduced to ~5% in the presence of wet cotton, compared to 20% without it [

18]. The effective RH created within the DMA chamber was not tracked and most certainly fluctuated with

T during the experiment, from a low or normal RH at 25 °C, to ~100% RH once water in the cotton vaporized above 100 °C, possibly affecting the thermo-mechanical results in different ways. A different technique employed to perform DMA

T-ramps at specific moisture contents consists of coating samples with silicone oil or silicone-based hydrophobic grease after equilibration at the desired RH, to limit water evaporation during heating and maintain a constant moisture content within the film or thin sheet. Using this technique, Zárate-Ramírez

et al. characterized the thermal properties of wheat gluten bioplastics, preconditioned at 53% RH (14% moisture content), from −30 to 160 °C while keeping the moisture content hypothetically constant [

19,

20]. Ditudompo

et al. employed three different RH levels to precondition extruded starch ribbons at 33%, 75% and 98% RH to yield moisture-contents of ~13%, 19% and 31%, then coated the samples with silicon grease to perform DMA

T-ramps; the grease was found to effectively keep water-loss below 5% [

21].

In this paper, we assess a novel technology called DMA-RH that precisely controls the relative humidity inside the DMA chamber during a test by balancing the flow rates of dry and water-saturated nitrogen flowing through the test chamber to produce any desired value of RH between 0% and 80% at 5–90 °C. RH is a strong function of temperature: the mass of water per unit volume of air is termed “humidity”, H(

T); at constant pressure, the mass of water at saturation (the dew point,

Hs(

T)) increases nearly exponentially with

T [

11]; the relative humidity is defined as RH = H(

T)/

Hs(

T), and therefore, at constant RH, H(

T) increases exponentially with

T. The DMA-RH technology is able to perform isohume (iso-RH)

T-ramps, as well as isothermal (iso-

T) changes in RH, both in transient and dynamic mode. Isohume

T-ramps at different RH values and isothermal RH-steps or RH-ramps are expected to provide new information on the thermo-mechanical properties of hydrophilic thin films, since the broad variations of H(

T) in the atmosphere around the sample may profoundly affect the moisture-content, protein configuration, network structure and molecular mobility of the films. Although DMA-RH has recently been employed to characterize some of the humidity-dependent properties of different green food-packaging materials, including Kraft and Clupak papers, biodegradable polyesters, and carboxymethylcellulose-based films [

22,

23,

24], it has not yet been applied to edible and/or protein-based films. CaCas/Gly films with a constant composition and physical attributes were chosen as a template for method-development using the DMA-RH technology to evaluate its performance and usefulness to characterize the hydro-thermo-mechanical properties of hydrophilic, protein-based thin films. Exploratory transient and dynamic tensile tests were performed under a wide variety of (

T, RH) conditions by designing various experimental programs to simulate potential real-life conditions during the fabrication, storage and/or utilization of the films, such as refrigeration, “normal” handling conditions, heating, cold/dry or hot/humid climates,

etc., which may be encountered during the life of food packaging films.

3. Results and Discussion

3.1. Stress-Strain Tests

3.1.1. Open Tests

Transient stress-strain tests at ambient RH and

T were performed by letting samples equilibrate in the laboratory for at least 30 min, then leaving the test chamber opened and deflecting the continuous flow of dry N

2 away from the sample by inserting a small cardboard shield in front of the N

2 inlet. RH values with a stability of ±2% were obtained around the tensile clamp, and the daily RH ranged from 10% to 60% over the course of a year, with

T = 20–23 °C. The averaged tensile strength (

TS) and Young’s Modulus (

Y) as a function of ambient RH are reported in

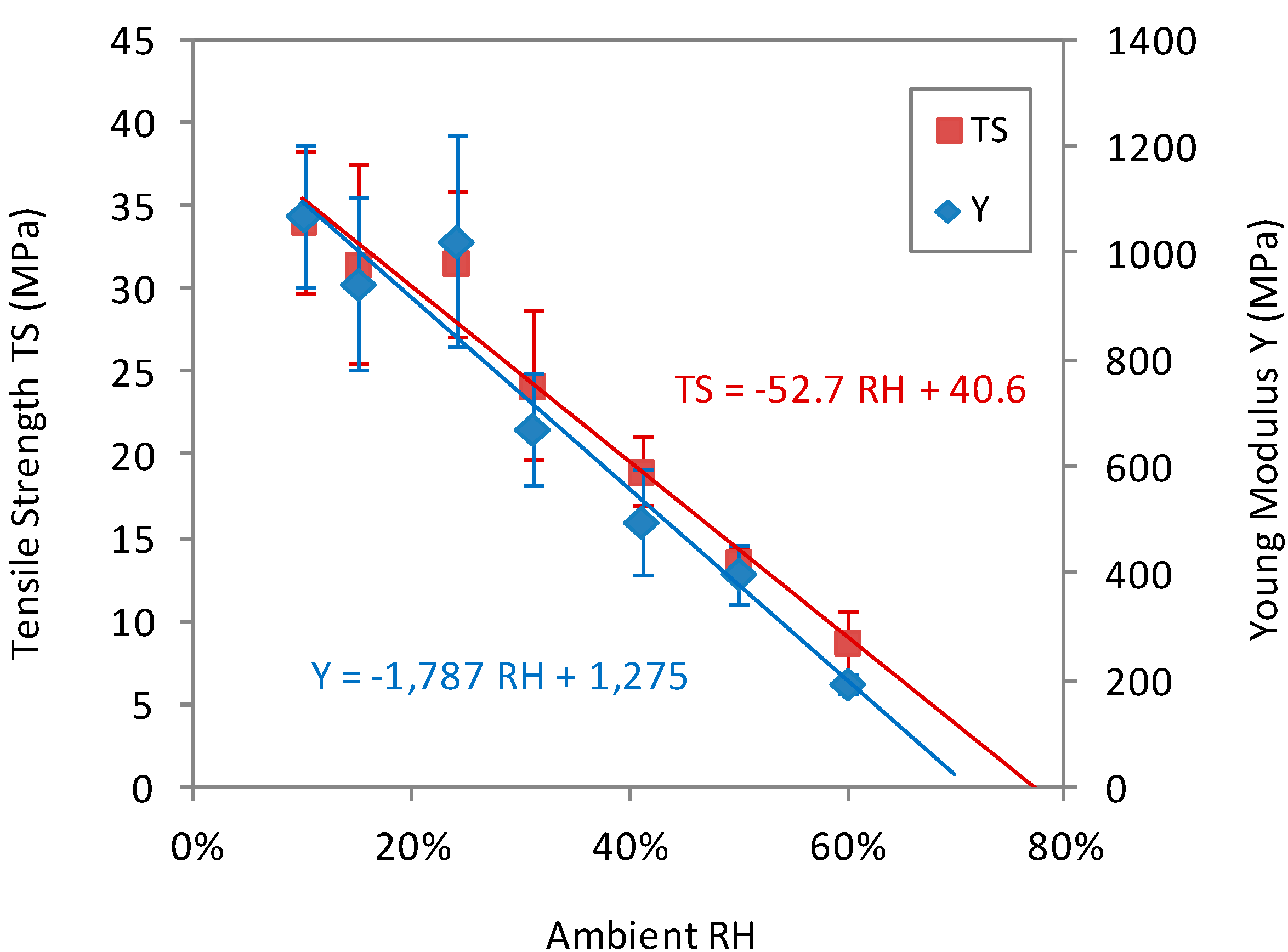

Figure 1.

Figure 1.

Tensile properties of ~0.04 mm CaCas/Gly films measured in transient stress-strain mode with the DMA chamber opened to ambient conditions (~20 °C and varying RH depending on the day). Samples were stored at 60% RH for 5–12 days before testing.

Figure 1.

Tensile properties of ~0.04 mm CaCas/Gly films measured in transient stress-strain mode with the DMA chamber opened to ambient conditions (~20 °C and varying RH depending on the day). Samples were stored at 60% RH for 5–12 days before testing.

At the extension rate of 1 N/min, CaCas/Gly films appeared strong and stiff and highly sensitive to ambient moisture.

TS and

Y decreased linearly when RH increased and ambient moisture plasticized the films, comparable to the results of Bonnaillie

et al. [

3]. The elongation at break (

D) was low and varied from

D ~ 8% at 10% RH to

D ~ 27% at 60% RH. Linear extrapolation of

TS and

Y to zero suggests the existence of a point of null strength for the films between 70% and 80% RH, where the protein network becomes “fluid”, similarly to a heat-induced melting point.

In normal conditions (50% RH), the films showed a high modulus of

Y = 400 MPa, and a high strength of

TS = 13.6 MPa, with a low elongation at break of

D ~ 20%. These results cannot readily be compared with literature data for other Cas/Gly films, as the sample geometry and extension rate greatly affect the tensile properties of viscoelastic materials [

25]:

TS and

Y typically increase, while

D decreases, with shorter and/or thinner film strips and higher extension rates, as in this study, compared to Bonnaillie

et al. [

3] and others [

2].

For example, in prior works, Tomasula

et al. reported values of

TS = 1.6, 1.9, or 7.0 MPa and

D = 67%, 76%, or 66% for CaCas/Gly films (2.33:1 ratio) of thicknesses 0.11, 0.15, or 0.10 mm, respectively, at 23 °C and 50% RH [

26,

27]; in two other studies, CaCas/Gly films (2:1 ratio), or beta-Cas/Gly films (also 2:1 ratio), with similar ~0.11 mm thickness, reportedly possessed

TS ~ 4.25 MPa and

D ~ 1.45% [

28], or

TS ~ 6.0 MPa and

D ~ 274% [

7], respectively, also in normal environmental conditions. With a ratio of 4:1, slightly thinner (0.085 mm) NaCas/Gly films reportedly possessed

TS ~ 17–27 MPa and

D ~ 10.5% [

29], also in normal conditions, which is more similar to the values obtained in this work.

Repeatability of the stress-strain tests was good at high RH (

Figure 1). Data scattering increased at low RH when the films became brittle and tended to break early in the presence of any defect.

Opened stress–strain tests at ambient RH are quick and enable testing and comparing multiple film strips in a same day at approximately the same environmental conditions; this can be useful to screen different film compositions and formulations. Since CaCas films are highly moisture-sensitive, small changes in RH would render difficult the observation of more subtle formulation- or composition-induced property-changes unless T and RH are carefully kept constant.

3.1.2. Closed Tests

Stress-strain tests were performed with the DMA-RH chamber closed to maintain both a constant RH and T. The selected set of (T, RH) may correspond to “normal” conditions (i.e., ~23 °C and 50% RH), or may match any other desired value, such as the conditions during storage, to evaluate the mechanical properties of films in various storage conditions.

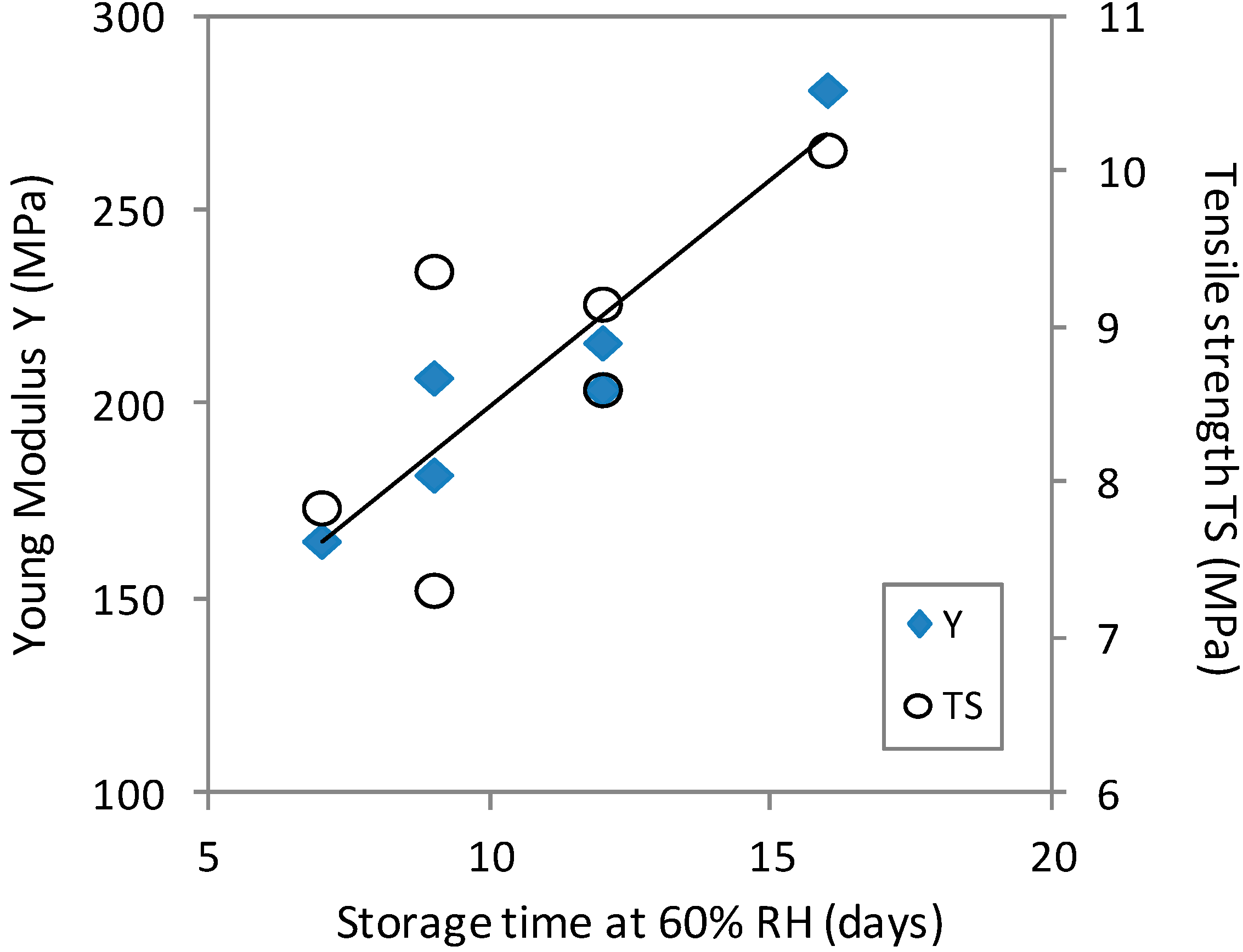

In a prefatory shelf-life study, CaCas/Gly films were stored at 20 °C and 60% RH for 21 days to evaluate the effect of high moisture on the integrity of the films with time. Beginning on day 7, films were removed from storage every few days to cut strips; each strip was then mounted onto the tensile clamp inside the DMA-RH chamber and allowed to re-equilibrate to 60% RH before performing stress-strain measurements (

Figure 2). Because DMA-RH programs always begin at 0% RH, 30 min were necessary to reach 60% RH, during which the film strip stiffened and shrank due to drying. Lengthwise shrinkage was clearly observed through negative clamp “displacement” (

d) readings on the DMA-RH control panel, which tracked the position of the mobile half of the tension clamp, in μm. A re-equilibration time of 1–2 h after reaching 60% RH was allotted for each strip tested. Film strips were considered equilibrated when d plateaued for at least 30 min. Because of the 1–2 h equilibration time needed, only 3–5 strips were tested on a given day.

Figure 2.

Isohume stress-strain tests of ~0.04 mm CaCas/Gly films in the closed DMA-RH chamber: TS and Y as a function of length-of-storage at 60% RH.

Figure 2.

Isohume stress-strain tests of ~0.04 mm CaCas/Gly films in the closed DMA-RH chamber: TS and Y as a function of length-of-storage at 60% RH.

Figure 2 shows that the tensile strength and modulus of CaCas/Gly films stored and measured at 60% RH tended to increase with time from 7 to 16 days in storage, signifying that the films became stiffer and more brittle with time, hypothetically due to bacterial-degradation at the high water activity, since the films and environmental chamber were not sterile. At 21 days, films became too brittle to cut into strips and could not be tested, suggesting a shelf-life of less than three weeks for CaCas/Gly films under humid conditions.

According to these results, CaCas/Gly films were subsequently stored at 50% RH and 20 °C and tested within two weeks of manufacture. Fresh films were made periodically so the age of each film tested remained between 4 and 14 days at 50% RH.

3.2. Rate of Moisture-Sorption

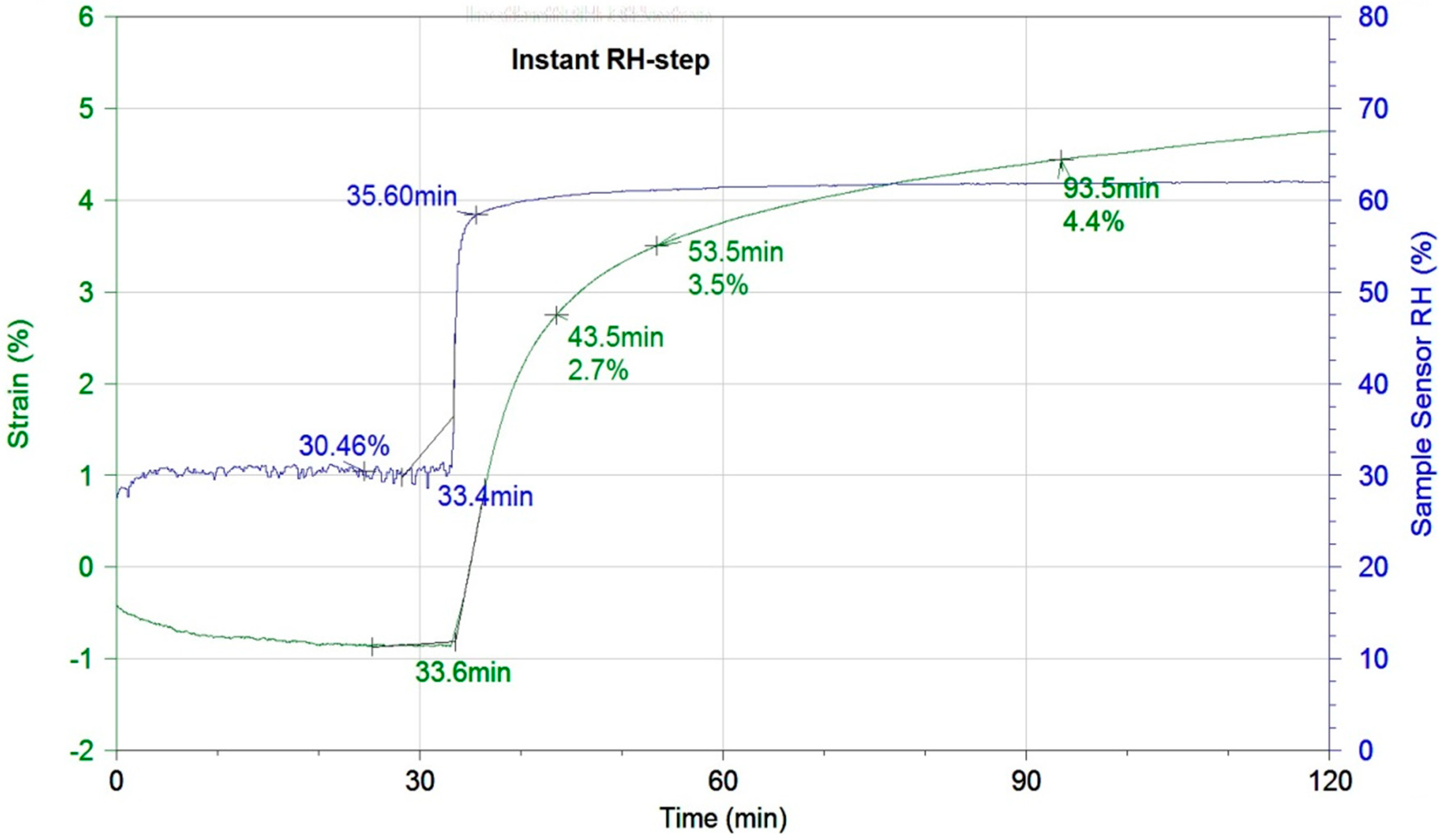

Figure 3 presents the variations of strain for a CaCas/Gly film strip held statically during an instant RH-step from 30% RH (ambient) to 62% RH (N

2 inlet). The film strip was well equilibrated at 30.5% RH and the strain was plateauing near −0.8% for ~30 min. Once the DMA-RH chamber was closed at

t = 33.4 min, moist N

2 flushed the atmosphere in approximately 2 min. The film strip began absorbing water immediately, as indicated by a sharp increase in strain at

t = 33.6 min indicative of water-swelling. CaCas/Gly films are highly hygroscopic; swelling is not only rapid, but substantial: after 10 min, the sample gained 3.5% in length; after 1 h, the sample’s length increased by 5.2%. Thermogravimetric moisture-sorption analyses will be necessary to determine the water-sorption kinetics of casein films as a function of changing environmental conditions, as well as the equilibrium water content and stoichiometric water-to-casein ratio as a function of

T and RH.

Figure 3.

Instant RH-step at 20 °C, for a ~0.04 mm CaCas/Gly film stored at RHs = 50%: step from RHa = 30% to RH1 = 62%. Legend: Blue = RH; Green = Strain% (sample elongation).

Figure 3.

Instant RH-step at 20 °C, for a ~0.04 mm CaCas/Gly film stored at RHs = 50%: step from RHa = 30% to RH1 = 62%. Legend: Blue = RH; Green = Strain% (sample elongation).

Figure 3 reveals that atmospheric humidity changes cause rapid and pronounced swelling of casein films, and thus have a strong effect on the moisture content of the films, and environmental conditions before and during mechanical analyses, therefore having critical effects on the results. For example, the length (and moisture content) of film strips changes if they are taken out of storage for only a few minutes to be tested under an ambient RH value (RH

a) different from the storage RH (RH

s). If RH

s and RH

a are different, casein-based films should be equilibrated for at least 1–2 h at RH

a (see next section) or the effective water content of the films will be unknown and somewhere between the equilibrium values at RH

s and RH

a.

3.3. Sample Equilibration at (T, RH) before Mechanical Testing

Because film strips typically shrank before the beginning of a test, a pre-conditioning step was added to every test-program to allow samples to equilibrate after closing the DMA-RH chamber.

Figure 4 presents the typical pre-conditioning pattern for CaCas/Gly film strips. Shrinkage and swelling of the sample were monitored via strain changes as a function of time and RH around the sample. The sample was stored at RH

s = 50%; ambient relative humidity was RH

a = 23%; and target testing conditions were RH

1 = 62%, all at ~20 °C.

Figure 4.

Pre-conditioning of a ~0.05 mm CaCas/Gly film sample inside the DMA-RH chamber: storage at RHs = 50%; ambient RHa = 23%; target RH1 = 60%. Legend: Blue = RH, Green = Strain% (sample elongation).

Figure 4.

Pre-conditioning of a ~0.05 mm CaCas/Gly film sample inside the DMA-RH chamber: storage at RHs = 50%; ambient RHa = 23%; target RH1 = 60%. Legend: Blue = RH, Green = Strain% (sample elongation).

When RH

a < RH

s, film strips initially dried and shrunk (negative Δ-strain) during and after installation on the tensile clamp (

Figure 4,

t < 12 min). The chamber was kept opened until RH

1 = RH

a (23%) to minimize shrinkage while RH

1 automatically rose from 0% to 23%. After closing the chamber (

t = 12 min), RH

1 increased to 59% at a rate of 2%/min and the sample quickly reverted to swelling (positive Δ-strain). Swelling was fast and near-linear while RH

1 increased linearly, and slowed when RH

1 stabilized. After equilibrium (Δ-strain ~ 0) is considered reached at

t = 240 min, the sample was re-measured to initialize the strain and the test-program began.

All the film strips were pre-conditioned similarly. The time required to reach a strain (or displacement, d) plateau strongly depended on RH1 and T and required from 30 min to >12 h. The time needed for equilibration increased when |RH1 − RHs| increased, T decreased, or RH1 decreased; in general, hydration of film strips was faster than drying.

The adequate equilibration time needed for each program type was determined and then kept constant for all samples, to minimize variations between samples.

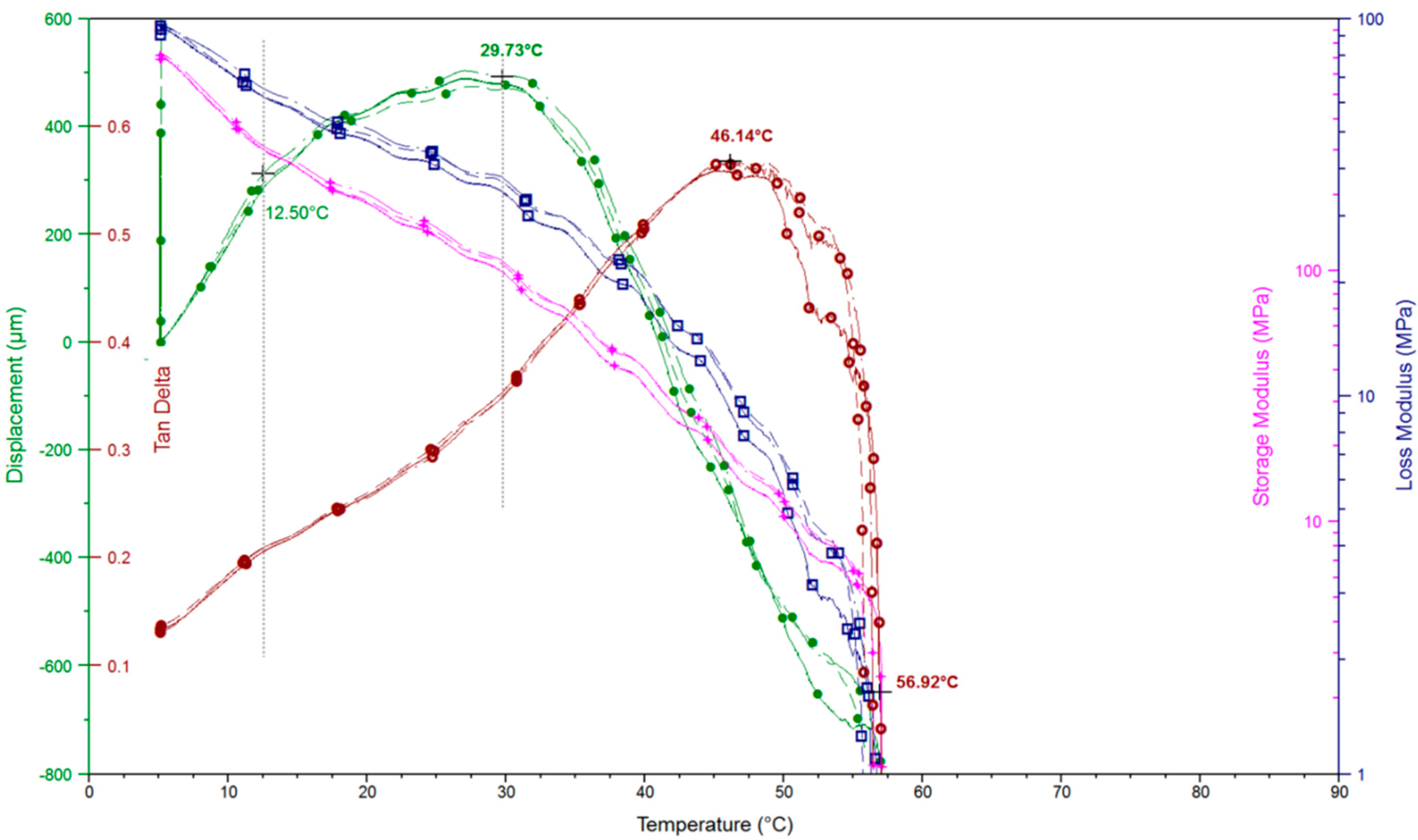

3.4. Dynamic Isohume Temperature Ramps

Film strips were pre-conditioned for 2 h inside the DMA-RH chamber, in dynamic (oscillating) mode, to equilibrate at 5 °C and 50% RH. At

t = 120 min,

T was ramped slowly and linearly to 90 °C while RH was automatically maintained at 50%. Because the humidity, H(

T), increases exponentially with

T at constant RH, the flow rates of wet and dry N

2 were constantly adjusted by the software, causing small undulations of RH with time with an amplitude of ±0.5% that translated into small undulations of other signals monitored: the clamp displacement (

d), storage modulus (

E') and loss modulus (

E''), as seen on

Figure 5.

Figure 5.

Dynamic temperature ramp, from 5 to 90 °C, at 50% RH: independent triplicate using three strips from the same CaCas/Gly film (~0.04 mm), tested on three consecutive days. Legend: green (●) = clamp displacement (d); pink (+) = storage modulus (E'); dark blue (□) = loss modulus (E''); brown (○) = Tan Delta (δ).

Figure 5.

Dynamic temperature ramp, from 5 to 90 °C, at 50% RH: independent triplicate using three strips from the same CaCas/Gly film (~0.04 mm), tested on three consecutive days. Legend: green (●) = clamp displacement (d); pink (+) = storage modulus (E'); dark blue (□) = loss modulus (E''); brown (○) = Tan Delta (δ).

Triplicate measurements of the same film on three consecutive days showed an excellent repeatability (

Figure 5). After equilibration at 5 °C and 50% RH, the samples’ dynamic properties were: Tanδ = 0.1335 ± 0.0029,

E' = 711 ± 11 MPa and

E'' = 95.8 ± 1 MPa. When

T increased, the combined effects of heat and increased humidity H(

T) plasticized the CaCas/Gly network, which swelled, as indicated by the positive clamp displacement (

d).

E' and

E'' dropped when

T rose, signifying a loss of elasticity as well as a loss of resistance to plastic deformation, also demonstrated by the rise of Tanδ that is significant of a less crystalline and/or a more rubbery network.

While a traditional glass-transition (Tg) is not observed under these test conditions, different slope changes indicate intermediate transition temperatures (Ti) that may possibly correspond to changes in the conformation of casein proteins; or, reconfiguration of the casein-glycerol-water network as more water molecules are absorbed and heat further enhances molecular mobility; or, even the loss of certain bonds between the casein proteins as water expands the network and heat activates a wide variety of chain-motions. The first change of slope was consistently observed around T1 = 12.5 °C at 50% RH in the E', Tanδ and d curves, corresponding to a minor transition of the CaCas/Gly network. Around T2 = 30 °C, the rise of Tanδ and drop of E' and E'' accelerated, while the sample length abruptly shifted from swelling to shrinking. This surprising phenomenon was observed consistently; as more water and heat were added into the film strip and the casein network continued to soften, we expected that the film’s expansion would also accelerate due to swelling and the gentle tugging of the dynamic oscillations. Two possible explanations for the opposite, shrinking behavior observed, may be that: (a) the network has become sufficiently liquid-like for surface-tension forces to cause the softened film to contract with each dynamic oscillation, in order to minimize the surface-area of the sample; or (b) the casein proteins may be adopting more tightly-coiled configurations.

The peak of Tanδ around 46 °C was adopted as the traditional “melting temperature”, Tm.

While the T-ramp was programed to continue until 90 °C, CaCas/Gly films typically broke between 40 and 60 °C at 50% RH. The knowledge of the mechanical behavioral changes of CaCas/Gly films as a function of T in humid conditions is useful to investigate potential food packaging applications; for example, at 50% RH, the films are most soft and pliable around 30–40 °C and could possibly be shrink-wrapped, but lose their structural integrity and may possibly become sticky above 40 °C; thus, CaCas/Gly films may not be suited for manufacture, handling, storage and utilization in humid climates where T routinely exceed 40 °C.

Using a new batch of film, a series of isohume

T-ramps was performed on the entire range of RH available (0%, 10%, 20%, 40%, 50%, 60% and 70%) to map the thermo-mechanical properties of CaCas/Gly films as a function of both

T and RH.

Figure 6 presents the storage modulus,

E', and the sample-length variation (swelling/stretching and shrinkage),

D, during seven different isohume

T-ramps.

Figure 6.

Storage modulus (E') and variation in sample length (D) vs. T, at 0%–70% RH, for 0.04–0.05 mm CaCas/Gly films. The dashed line represent E'; solid lines represent D.

Figure 6.

Storage modulus (E') and variation in sample length (D) vs. T, at 0%–70% RH, for 0.04–0.05 mm CaCas/Gly films. The dashed line represent E'; solid lines represent D.

Similarly to

Figure 5,

E' dropped and samples initially swelled when

T (and H(

T)) increased. After pre-conditioning at 5 °C for 1–6 h (depending on RH), the initial value of

E' became considerably lower as RH increased. At a given constant temperature greater than

Tg, which is the case here,

E' of a polymer is proportional to its degree of crystallinity [

30], thus an increasing moisture content in the film was assumed to render the CaCas/Gly/water network increasingly amorphous. In this series of

T-ramps, several samples broke immediately above the melting point indicated by the peak of Tanδ; thus,

Tm was considered the temperature at break.

Table 1 lists

Tm as well as several secondary transition temperatures (

T1,

T2,

T3) as a function of RH, and the values for

E'(RH) at 20 °C.

Table 1.

Transition temperatures of CaCas/Gly films during isohume

T-ramps at 0%–70% RH. Data extracted from the

E' curves (

E') or

D curves (

D) of

Figure 6.

Table 1.

Transition temperatures of CaCas/Gly films during isohume T-ramps at 0%–70% RH. Data extracted from the E' curves (E') or D curves (D) of Figure 6.

| RH | 1st Inflexion Point (Reduced Slope) T1 | 2nd Inflexion Point (Increased Slope) T2 | Sample Shrinkage, T3 | Melting Point, Tm | E' at 20 °C (MPa) |

|---|

| 0% | ~25 °C (E') | ~50 °C (E') | – | >90 °C | 3,277 |

| 10% | ~35 °C (E') | ~50 °C (E') | – | >90 °C | 2,150 |

| 20% | ~22 °C (E') | ~42 °C (E'), 60 °C (D) | – | >90 °C | 1,450 |

| 40% | 12.5 °C (E' and D) | 41 °C (E' and D) | 56 °C (D) | 65 °C | 780 |

| 50% | 12.5°C (E' and D) | – | 39 °C (D) | 40 °C | 344 |

| 60% | 12.5 °C (E') | – | 16 °C (D) | 34 °C | 75 |

| 70% | – | – | 10 °C (D) | 12 °C | – |

The strength of CaCas/Gly films dropped extremely rapidly at 70% RH, with a low

Tm of 12 °C. The films were less and less affected by

T as RH decreased, with slower drops in

E' and higher

Tm values. At 60% RH and lower, three types of secondary transitions temperatures (

Ti) were observed during

T-ramps:

Around T1 = 12.5 °C, the rapid, linear drop of E' (and linear rise of D) slowed, indicated by a reduced slope (or even a plateau) for both E' and D, similar to a rubbery plateau. T1 increased to 22–35 °C below 20% RH;

At low RH (≤40%), T2 marks an inflexion point where the slope of the E' and/or D curves increased, signifying a greater effect of T (and H(T)) on the structure and integrity of the casein network;

At high RH (≥40%), samples reverted from swelling to shrinking around T3.

The four transition temperatures generally decreased with higher RH: the plasticization and microstructure of the CaCas/Gly network being a function of water content and heat-induced molecular mobility, greater water contents in the films may diminish the amount of heat needed to trigger the different transitions.

According to

Table 1 and

Figure 6, CaCas/Gly films have rubbery-plateau-type behavior and may be useful for the manufacture and utilization of food packaging between conditions of ~12.5–40 °C and 10%–50% RH, which provide a combination of strength, pliability, and low sensitivity to

T changes (up to 40 °C). At lower

T and RH, the films may be too crystalline and brittle for handling and folding, but may be stored for prolonged shelf-life; on the other hand, excessive

T and RH may compromise the strength and integrity of the casein network and impair use as well as shorten the shelf-life (

Section 3.1.2).

3.5. Dynamic Isothermal Humidity Ramps

Because T-ramps raise both the amount of heat provided to the sample and the amount of moisture, H(T), in the atmosphere around the sample, isothermal RH-ramps were performed to isolate the effect of moisture on the dynamic mechanical properties of CaCas/Gly films at constant T.

After closing the DMA-RH, samples were equilibrated for 6 h at 20% RH and 20 °C; longer equilibration times were necessary than with T-ramps because the hygroscopic casein films tended to dry slowly at 20% RH.

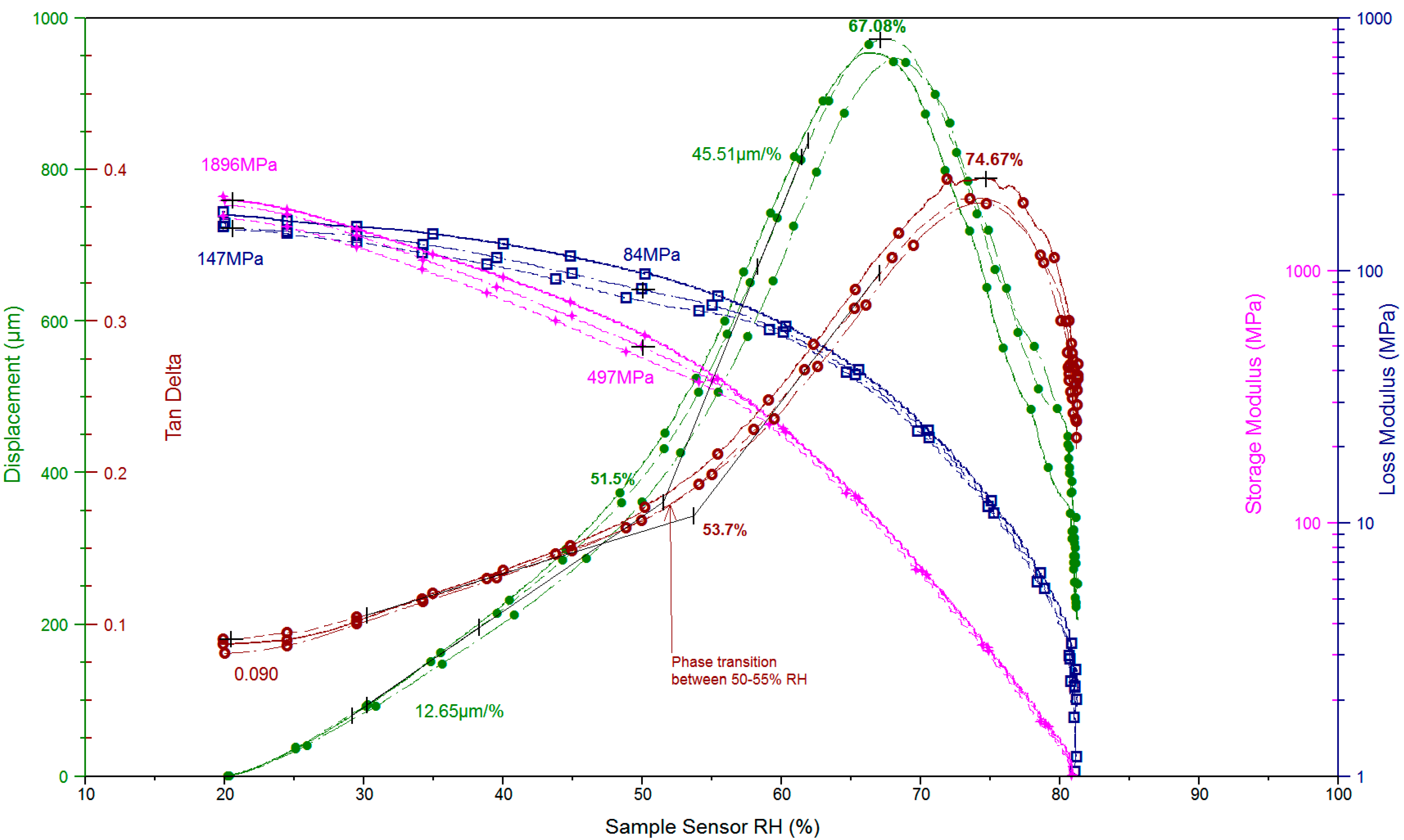

Figure 7 presents the clamp displacement (

d), storage modulus (

E'), loss modulus (

E'') and Tanδ for three RH-ramps of the same film, performed on three consecutive days.

Figure 7.

Isothermal RH-ramp on ~0.04 mm CaCas/Gly films after 6 h equilibration at 20 °C and 20% RH; triplicate performed after 4, 5 and 6 days in storage at 20 °C and 50% RH. Legend: green (●) = d; pink (+) = E'; dark blue (□) = E''; brown (○) = Tanδ.

Figure 7.

Isothermal RH-ramp on ~0.04 mm CaCas/Gly films after 6 h equilibration at 20 °C and 20% RH; triplicate performed after 4, 5 and 6 days in storage at 20 °C and 50% RH. Legend: green (●) = d; pink (+) = E'; dark blue (□) = E''; brown (○) = Tanδ.

As RH slowly and linearly increased from 20% to 80%, d and Tanδ increased while E' and E'' dropped, all being synonymous to water absorption and plasticization of the casein network. Between 20% and 50% RH, Tanδ and the rate of swelling of the film, indicated by d, were proportional to RH, suggesting that the amount of water absorbed in the film is proportional to the amount of water present in the atmosphere around the film. Around 50%–55% RH, a first transition, indicated by an inflexion of all the curves, was observed: above 55% RH, the rise of Tanδ and the rate of swelling accelerated greatly, while E' and E'' began to plummet. The rate of linear swelling almost quadrupled, from 12.65 μm/% between 25% and 50% RH, to 45.51 μm/% between 55% and 65% RH. This first transition humidity, RH1, appears to correspond to a critical water-content inside the CaCas/Gly films that triggered a reconfiguration within either the casein proteins themselves (e.g., loosening of the random-coil structure), or within the CaCas/Gly/water network, to form a looser structure that absorbs more water molecules per unit of water present in the atmosphere. Around RH1, the casein proteins hypothetically uncoiled, or some of the hydrogen or ionic bonds within the network broke, resulting in the plummeting of E' and a loss of crystallinity of the network and accelerated rise of Tanδ. The inflexion point on the Tanδ curve (53.7%) is slightly higher than that on the displacement curve (51.5%), suggestive of a delay (similar to super-saturation) between the physical absorption of water molecules inside the film and the reconfiguration of the casein network once the critical water content has been reached.

A second transition humidity, RH

2, was observed around 67.0% when sample swelling sharply reverted to shrinkage as the moisture content of the films reached a critical fraction that enabled contraction of the network, possibly due to surface tension, or coiling of the caseins (similar to polymer annealing), as with

T-ramps. A melting-point, RH

m, indicated by the peak of Tanδ, lastly occurred near 74.7% RH when the films began to behave more like liquids than solids. In a prior study, Mauer

et al. found that glycerol migrated out of beta-Cas/Gly films around 76% RH [

7].

Although the strength (

E' and

E'') of the film was very low at the end of each test, the three samples in

Figure 7 continued to shrink and soften after reaching 81% RH but did not rupture.

For further study, the different critical moisture contents related to RH1, RH2 and RHm, and the corresponding water-to-casein stoichiometric ratios, may be determined with thermo-gravimetric moisture-sorption analysis.

The repeatability of RH-ramps experiments was excellent for samples cut from the same film and tested on consecutive days using an identical pre-conditioning (equilibration) program (as in

Figure 7). Repeatability was also good between samples cut from separate films of identical composition that were manufactured and then tested on different days.

Table 2 lists the equilibration values for

E',

E'' and Tanδ of eight independent samples, after pre-conditioning at 20% RH and 20 °C for 6 h and measuring the equilibrated length.

Table 2.

E', E'' and Tanδ of eight independent samples equilibrated at 20 °C and 20% RH for 6 h.

Table 2.

E', E'' and Tanδ of eight independent samples equilibrated at 20 °C and 20% RH for 6 h.

| Sample # | E' (MPa) | E'' (MPa) | Tanδ |

|---|

| 1 | 2,196 | 158.8 | 0.072 |

| 2 | 1,995 | 161.2 | 0.081 |

| 3 | 1,985 | 152.8 | 0.077 |

| 4 | 1,899 | 165.1 | 0.087 |

| 5 | 1,608 | 145.0 | 0.091 |

| 6 | 1,810 | 146.9 | 0.081 |

| 7 | 1,588 | 138.4 | 0.089 |

| 8 | 1,772 | 159.2 | 0.090 |

| Average | 1,857 | 153.4 | 0.083 |

| Standard deviation | 206 | 9.2 | 0.007 |

| Error | ±11.1% | ±6.0% | ±8.0% |

In

Table 2 and in general, possible sources of data scattering were identified as variations in the age of the films (from 3 days to 3 weeks), differing film thickness and crosslink density due to gradients formed during drying, user-error (e.g., slack; poor vertical alignment) when mounting film strips, and structural defects in the strip (e.g., air bubble, rough edge,

etc.).

3.6. Effects of Equilibration Time before T-Ramps and RH-Ramps

Equilibration of film strips to RH values lower than the storage RH (50%) required several hours, depending on the equilibration RH and

T. Insufficient pre-conditioning times retained excessive moisture within the film samples, which corrupted the mechanical measurements.

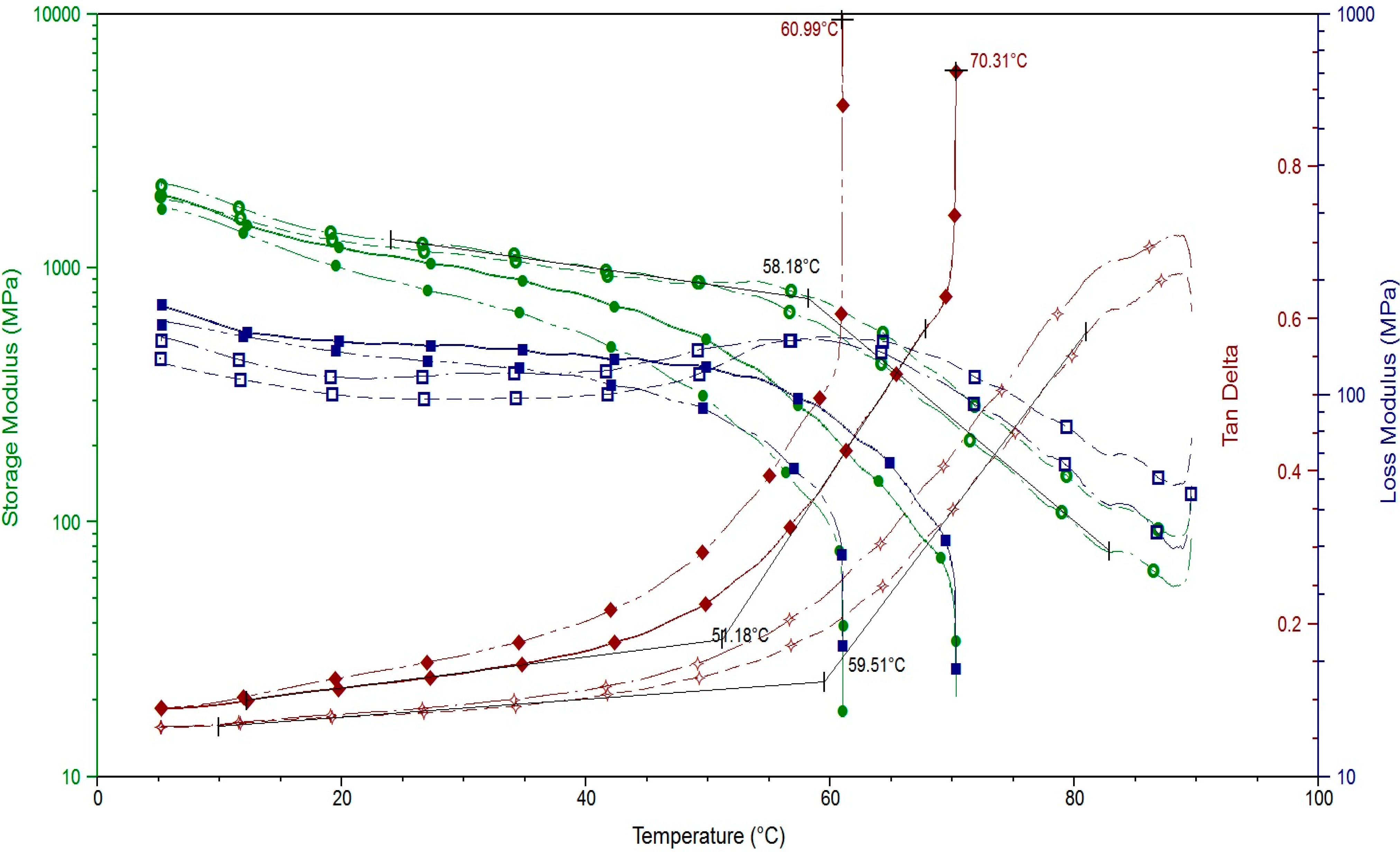

Figure 8 presents

T-ramps at 30% RH performed with four different samples stored at 50% RH, then equilibrated at 5 °C and 30% RH for either 4 h or 6 h. While all four samples had similar initial

E' and

E'' values after pre-conditioning, the two samples equilibrated for only 4 h retained more moisture and possessed a less crystalline structure, as indicated by an artificially higher (~30% higher) initial value of Tanδ. Additionally, when

T increased,

E' and

E'' began decreasing, and Tanδ rising, at lower

T and with a higher rate than for samples equilibrated for 6 h. Samples equilibrated for 6 h underwent a first transition around

T1 ~59 °C and did not break at 90 °C; the two samples equilibrated for 4 h had inflexion points of ~47 °C and ~51 °C, and broke at ~61 °C and ~70 °C, respectively, due to the excess moisture present within the film. Thus, it is critical to allow adequate equilibration time before beginning each test program.

Figure 8.

T-ramp duplicates at 30% RH for 0.04–0.05 mm CaCas/Gly films after pre-conditioning for four hours (green (●) = E'; dark blue (■) = E''; brown (♦) = Tanδ) or six hours (green (○) = E'; dark blue (□) = E''; brown (✧) = Tanδ

Figure 8.

T-ramp duplicates at 30% RH for 0.04–0.05 mm CaCas/Gly films after pre-conditioning for four hours (green (●) = E'; dark blue (■) = E''; brown (♦) = Tanδ) or six hours (green (○) = E'; dark blue (□) = E''; brown (✧) = Tanδ

3.7. Dynamic Humidity-Steps

At constant

T = 20 °C, samples were cycled from normal conditions (50%) to high (≥60%) then low (20%–40%) RH for 3–6 h each, to simulate normal, humid and dry storage and utilization conditions that may be encountered by casein films. The rate of change and equilibrium values of the dynamic mechanical properties and sample length were studied for each RH-step.

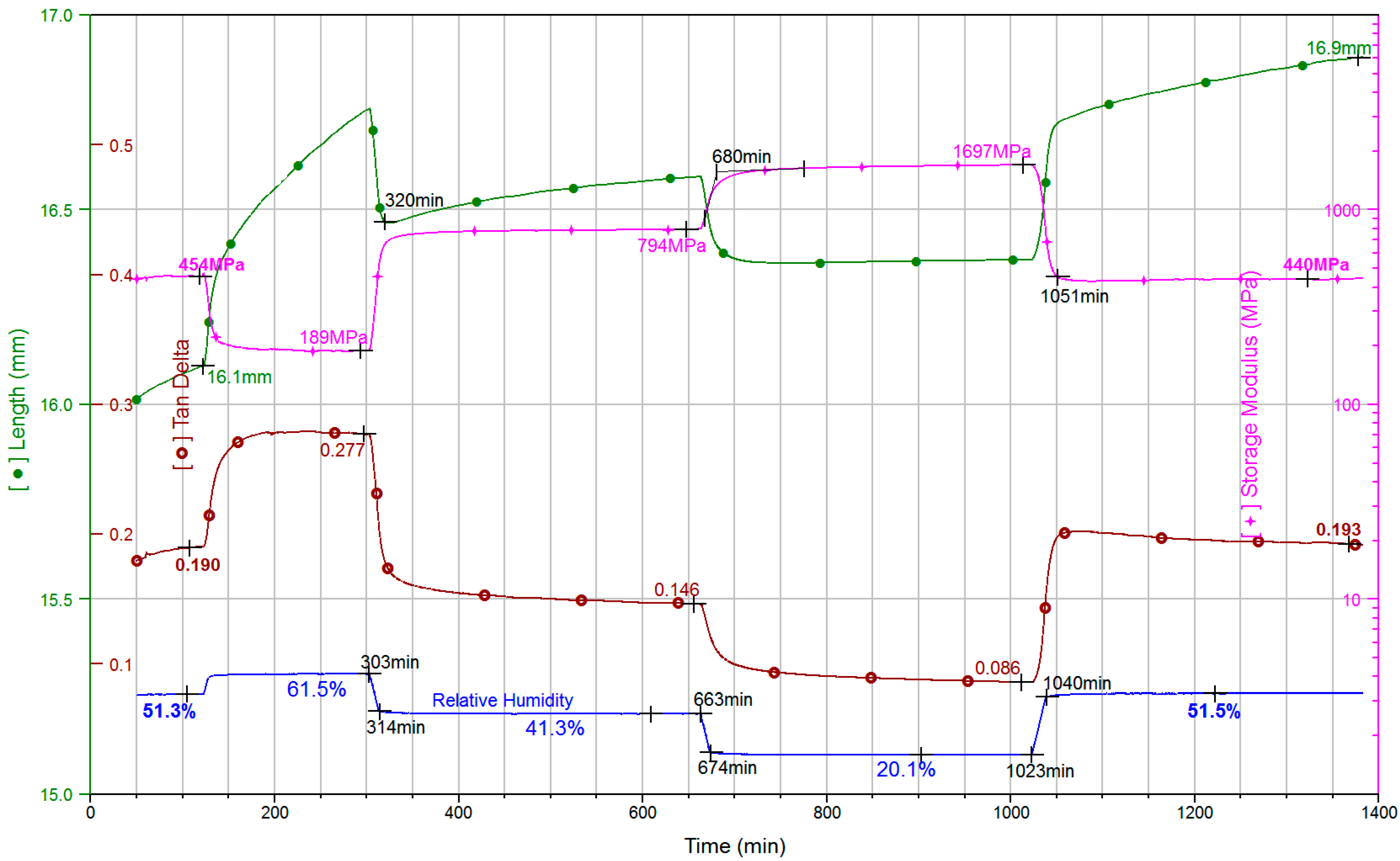

Figure 9 presents the storage modulus (

E'), Tanδ, and the sample length (

L) as a function of time during a 23 h-long RH-steps program.

During each step,

E' greatly dropped and Tanδ and

L rose when RH increased, due to the absorption of plasticizing water molecules into the film. When RH decreased, water-desorption caused the opposite changes. Changes in

E', Tanδ and

L occurred simultaneously to each RH steps and tapered within 1–10 min of RH stabilization, signifying that both water sorption and desorption into/from casein films were rapid between 20% and 61% RH. The inflexion point for each signal (

E', Tanδ and

L) during each RH step was measured using the “onset point” function of the Universal Analysis 2000 software; an example is shown at 680 min for

E' (

Figure 9). The stabilization delays, calculated from: delay =

t(inflexion point) −

t(RH stabilization), are listed in

Table 3.

Figure 9.

RH steps at 20 °C for 0.042 mm CaCas/Gly films: dynamic mechanical variations due to fast humidity changes between 20% and 61.5% RH. Legend: green (●) = sample length, L; pink (+) = E'; blue (−) = RH; brown (○) = Tanδ.

Figure 9.

RH steps at 20 °C for 0.042 mm CaCas/Gly films: dynamic mechanical variations due to fast humidity changes between 20% and 61.5% RH. Legend: green (●) = sample length, L; pink (+) = E'; blue (−) = RH; brown (○) = Tanδ.

Table 3.

Delay (min) between RH-stabilization and inflexion of the

E', Tanδ and

L curves during RH-steps of

Figure 9.

Table 3.

Delay (min) between RH-stabilization and inflexion of the E', Tanδ and L curves during RH-steps of Figure 9.

| RH Step | E' Delay | Tanδ Delay | L Delay |

|---|

| 51.3% to 61.5% | 4.9 min | 10.3 min | 9.0 min |

| 61.5% to 41.3% | 2.6 min | 5.2 min | 1.4 min |

| 41.3% to 20.1% | 6.0 min | 8.7 min | 5.5 min |

| 20.1% to 51.5% | 3.5 min | 4.0 min | 3.5 min |

Equilibrium for E' was considered reached ~50 min after each RH step. However, Tanδ slowly and continually decreased after E' leveled off and did not reach a plateau after 6 h at 20%, 41% and 51% RH. This suggests a slow tightening phenomenon during which the casein network progressively adopted a more crystalline configuration with each new water-content.

In-between RH steps, the length of the film increased continuously, not due to swelling since H is constant, but because the sample was stretched by a fraction of 1 μm during each dynamic oscillation. The rate of stretching was minimal at 20% RH (0.03 μm/min) and increased greatly with RH as additional moisture increased the mobility of the network, with stretching rates of 0.22, 0.35, and 2.0 μm/min at 41%, 51%, and 61% RH, respectively. As a result, L increased by ~5% during the whole test.

The values of E' and Tanδ after equilibration at 51.3% and 51.5% RH at the beginning and end of the test were almost identical: E' = 454 MPa and Tanδ = 0.190 in the beginning; E' = 440 MPa and Tanδ = 0.193 at the end; which means that although application of high and low humidity altered the water-content of CaCas/Gly films radically and changed their configuration, the change was fully reversible. Thus, storage or utilization of casein films under temporary abuse conditions (such as, high RH) or temporary uncontrolled atmosphere should not affect the mechanical properties of the films after normal storage conditions are restored.

The equilibrium values of

E' and Tanδ obtained with the RH-steps program matched the transient values obtained with the RH-ramp program well (

Table 4), suggesting a good repeatability and accuracy of both testing methods, with less than 11% difference between the two; thus, either method may be used, depending on whether discrete sorption kinetics and equilibrium data are desired, or near-equilibrium values and transition points on the entire RH-range are of interest.

Table 4.

Comparison of values of

E' and Tanδ obtained with the RH-ramp and RH-step methods of

Figure 7 and

Figure 9.

Table 4.

Comparison of values of E' and Tanδ obtained with the RH-ramp and RH-step methods of Figure 7 and Figure 9.

| T and RH conditions | RH-steps | RH-ramp | Difference |

|---|

| 20 °C and 20% RH (6 h equilibration) | E' = 1,697 MPa, Tanδ = 0.086 | E' = 1,896 MPa, Tanδ = 0.090 | 11%, 4.6% |

| 20 °C and 51.5% RH | E' = 440 MPa, Tanδ = 0.193 (6 h equilibration) | E' = 454 MPa, Tanδ = 0.177 (no equilibration) | 3.2%, 9% |

| 20 °C and 61.5% RH | E' = 189 MPa, Tand = 0.277 (3h equilibration) | E' = 203 MPa, Tand = 0.266 (no equilibration) | 7.4%, 4.1% |

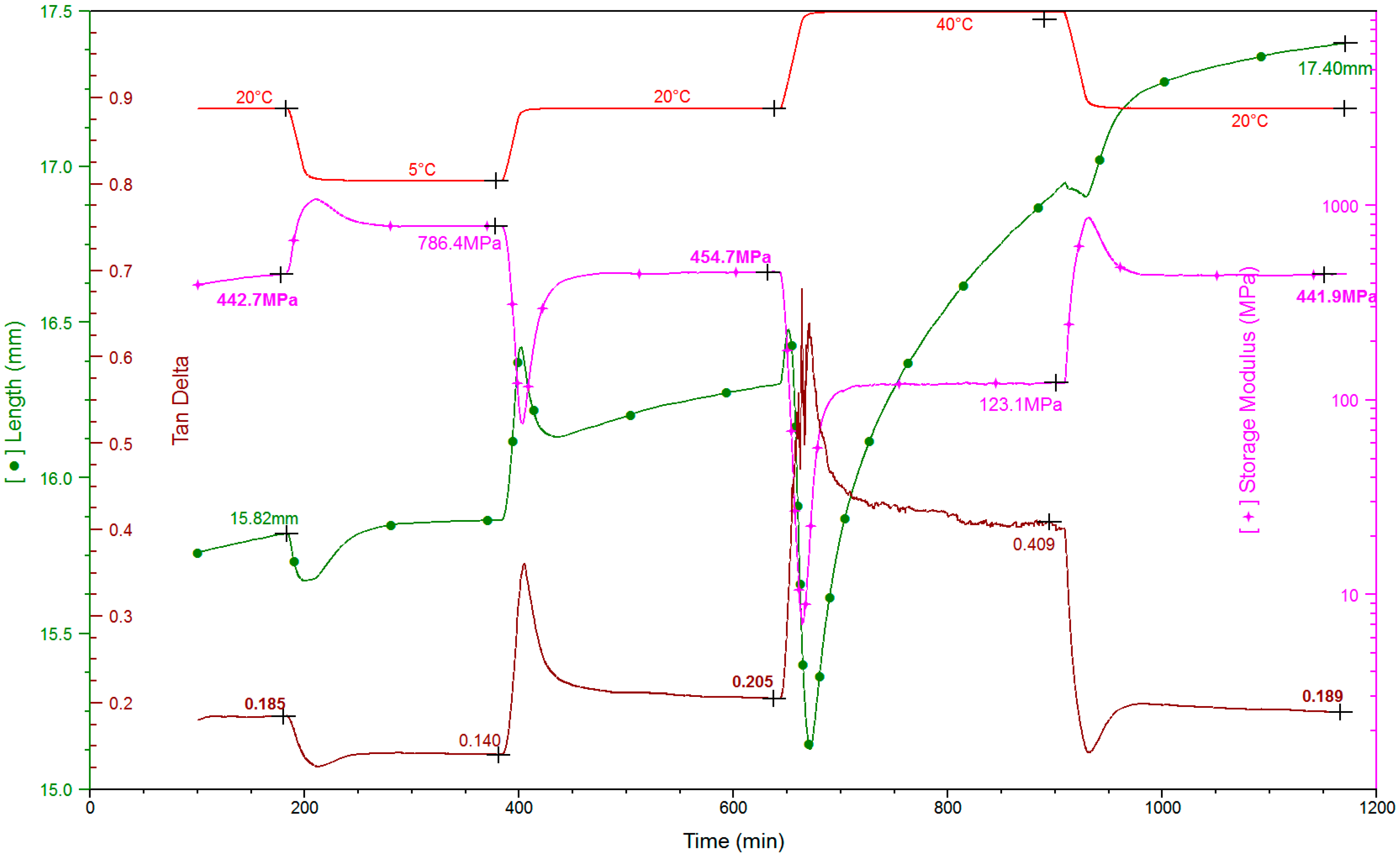

3.8. Dynamic Temperature-Steps

At constant 50% RH, the sample was cycled from normal conditions (20 °C) to refrigeration (5 °C) and warm climate (40 °C) to observe the effects of the combined variation of

T and H(

T) on moisture sorption and mechanical properties (

Figure 10).

Similarly to RH-steps, the mechanical changes caused by moisture desorption at 5 °C and moisture absorption at 40 °C were reversible, with near identical equilibrated values of E' and Tanδ at the beginning and end of the test program. The CaCas/Gly network seemed to adopt the same equilibrium configuration at 20 °C and 50% RH independently of its temperature history up to 40 °C.

When

T was reduced (at

t = 180 min, and

t = 910 min in

Figure 10) and H(

T) lowered exponentially, CaCas/Gly films instantly stiffened (

E' increase and drop of Tanδ) and shrank (

L reduction). An overshoot of

E' and undershoot of

L and Tanδ occurred as the film cooled and water molecules desorbed from the casein network, hypothetically placing it into a temporary, stoichiometrically-unstable configuration. This was followed by a decrease of

E' and increase of Tanδ and

L after

T and H(

T) stabilized and the network adopted a new equilibrium configuration, suggesting that the rates of cooling and water-desorption are faster than reconfiguration of the casein network. Inversely, when

T and H(

T) were raised (at

t = 383 min, and

t = 643 min), the immediate water-sorption and warming of the network caused an undershoot of

E' and overshoot of Tanδ and

L, as the network became supersaturated with water and over-plasticized. Once

T and H(

T) stabilized, the casein network rearranged into a more stable configuration involving the new water molecules, and

E' increased while Tanδ and

L decreased, before equilibration. Each

T-step, from

Ti to

Ti+1, occurred within 19 min (15 °C-amplitude) or 23 min (20 °C-amplitude), whereas equilibration of the film’s network at

Ti+1 required ~70 min, corresponding to a ~50 min delay caused by slow rearranging of the casein network to adapt to the new water content and the different chain-mobility imparted by

Ti+1. This equilibration time is much shorter than that recommended in prior literature: the “Standard Test Method for Tensile Properties of Thin Plastic Sheeting” recommends an equilibration time of 40 h at 23 ± 2 °C and 50% ± 5% RH before testing films (ASTM, [

4]); while Mauer

et al. found that β-casein films reached equilibrium relative humidity within 48 h inside an environmental chamber [

7].

During each temperature plateau, the film length (

L) increased continuously due to dynamic oscillations, as described in

Section 3.8. The rate of stretching was minimal at 5 °C then increased greatly with

T, as added heat and moisture increased the mobility of the network.

Around

t = 650 min, the expected overshoot of

L during the

T-step from 20 °C to 40 °C, was interrupted and became a sharp and pronounced undershoot instead, signifying shrinkage of the film. It is hypothesized that, when

T reached ~25 °C, “over-plasticizing” of the casein network reached the critical point that triggers film contraction, as described in

Section 3.4 and

Section 3.5; the film’s liquid-like behavior also appears in the jagged shape of the Tanδ peak between

t = 660 and 670 min, and the very low minimum value of 7.2 MPa for

E'.

As with RH-steps, the equilibrium values of E' and Tanδ at 50% RH and 20 °C obtained with the T-step program approximately match the results of the T-ramp program at 20 °C. Since equilibrium was reached in ~70 min with a T-step amplitude of 20 °C, more accurate T-ramps may be obtained by reducing the ramping rate to 20/70 = 0.28 °C/min or less, instead of the 0.33 °C/min used in this work, to produce constant equilibrium condition.

Figure 10.

T-steps at 50% RH for a 0.042 mm CaCas/Gly film: dynamic mechanical variations due to fast T and H(T) changes between 5 and 40 °C. Legend: green (●) = L; pink (+) = E'; red (−) = T; brown (−) = Tanδ.

Figure 10.

T-steps at 50% RH for a 0.042 mm CaCas/Gly film: dynamic mechanical variations due to fast T and H(T) changes between 5 and 40 °C. Legend: green (●) = L; pink (+) = E'; red (−) = T; brown (−) = Tanδ.