NaOH-Only Pretreated Wood Densification: A Simplified Sulfite-Free Route Across Wood Species

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Chemical Treatment

2.4. Densification

2.5. SEM

2.6. Chemical Characterization

2.6.1. Extractives

2.6.2. Klason Lignin

2.6.3. Chemical Composition

2.6.4. FTIR

2.7. Physical-Mechanical Properties

2.7.1. Density

2.7.2. Three-Point Bending

2.8. Statistic

3. Results

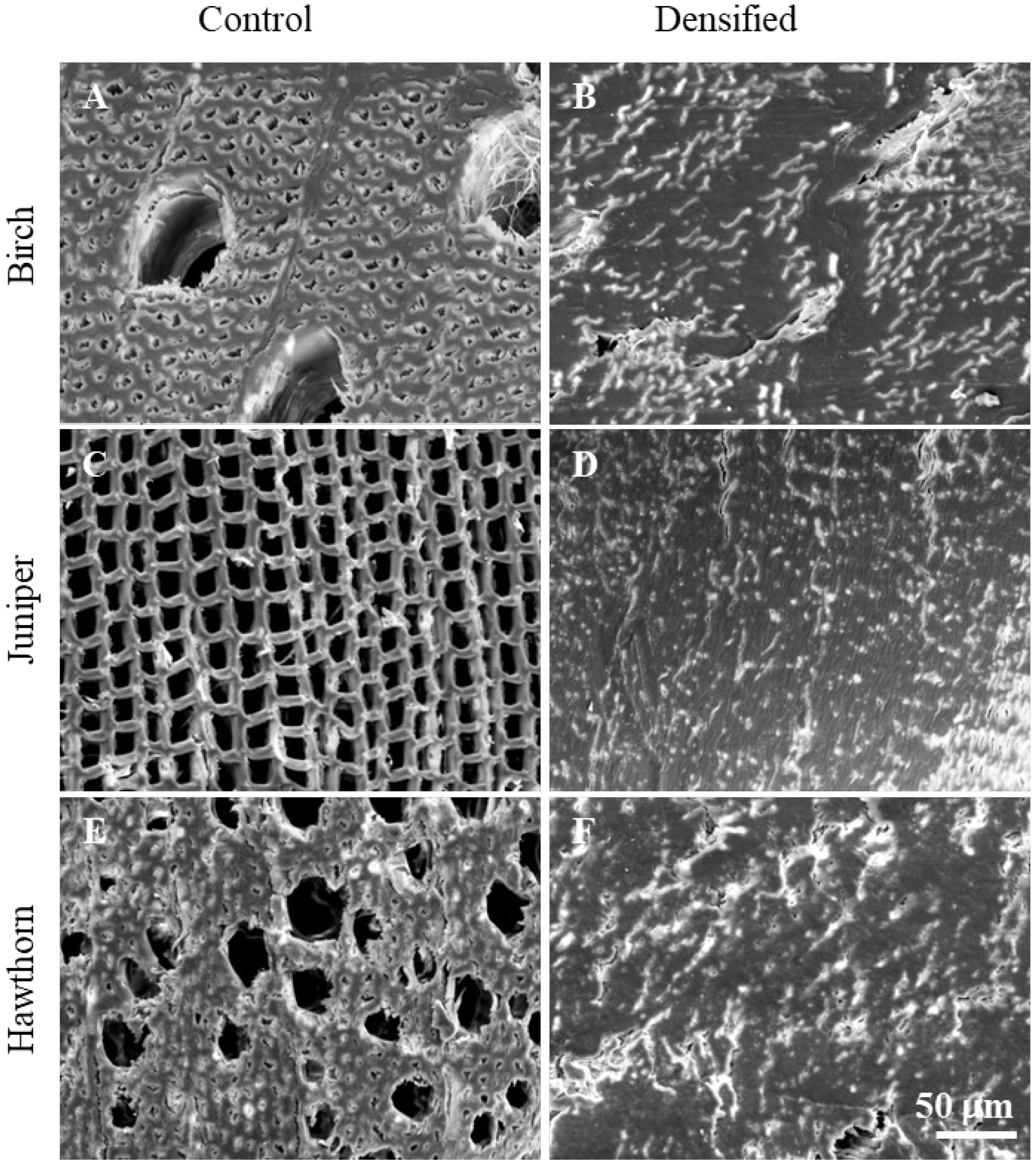

3.1. SEM

3.2. Chemical Characterization

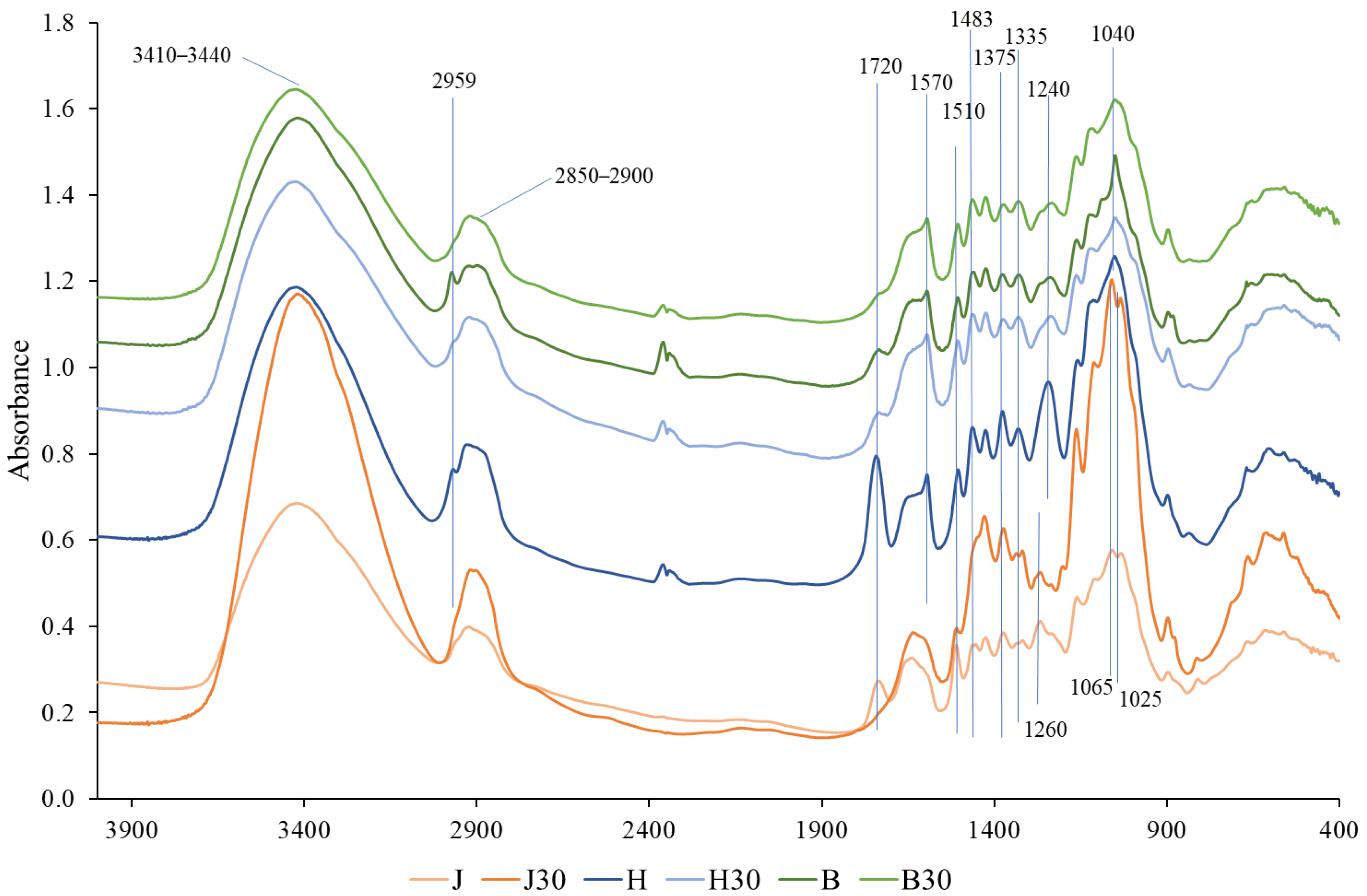

3.3. FTIR

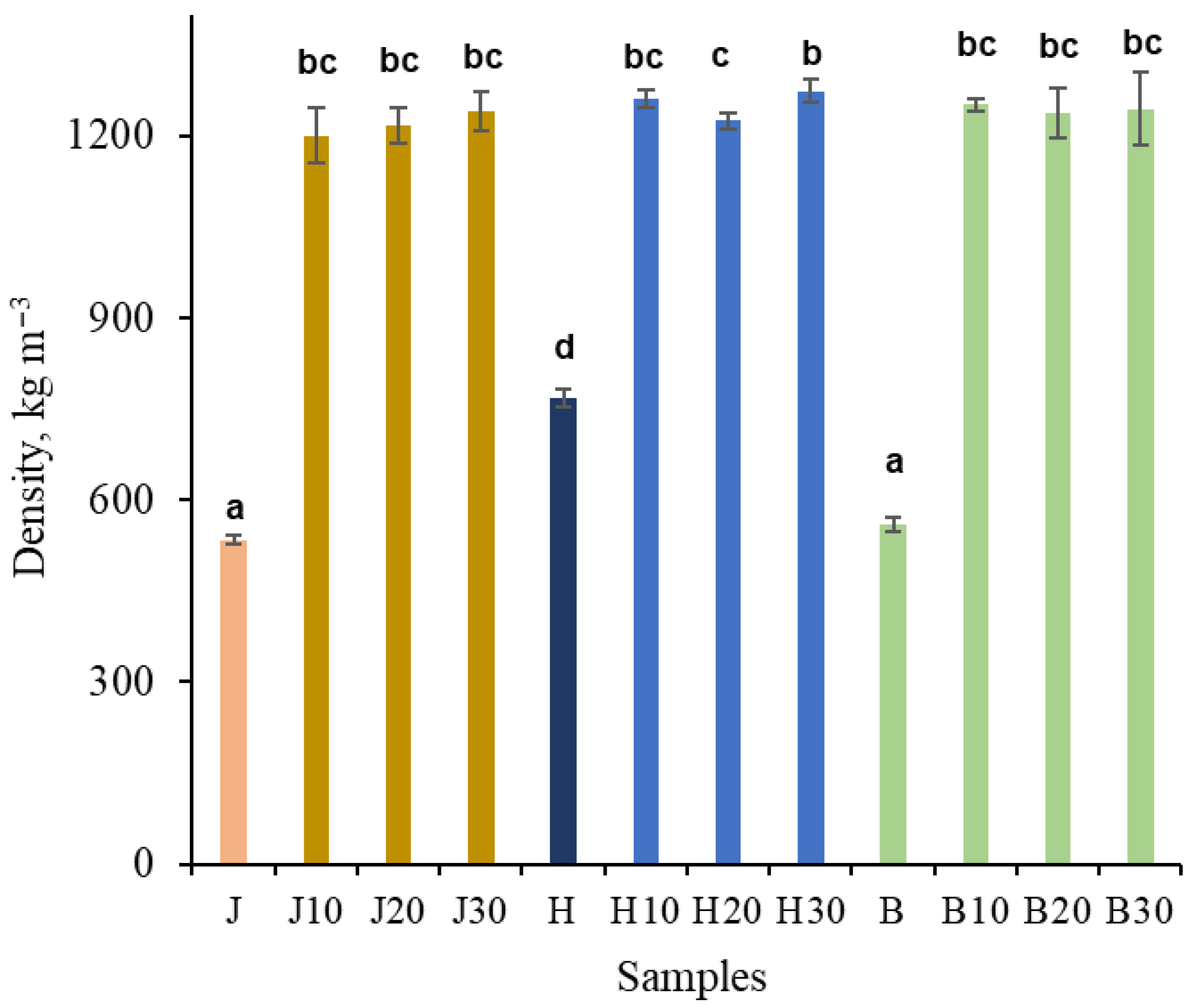

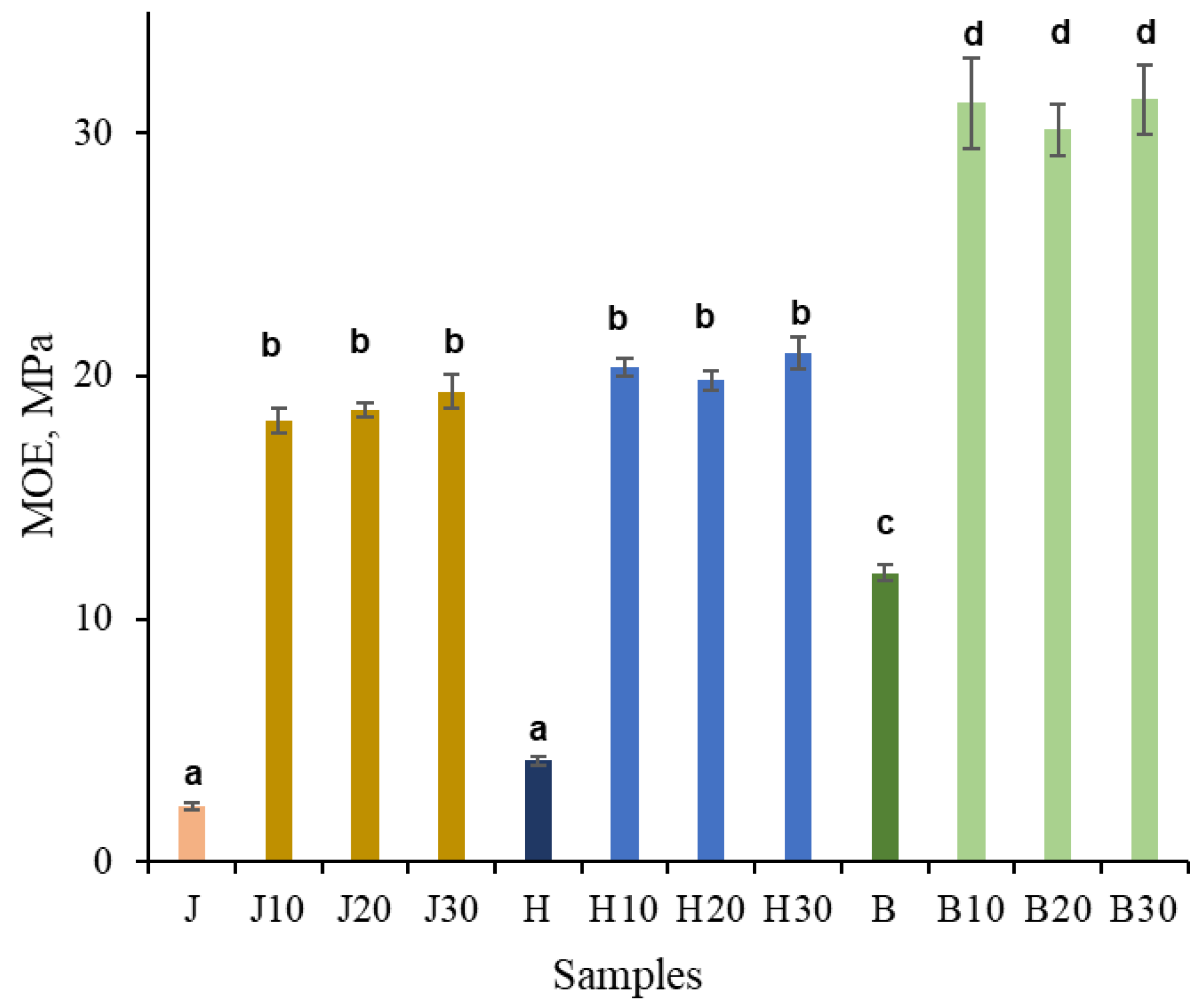

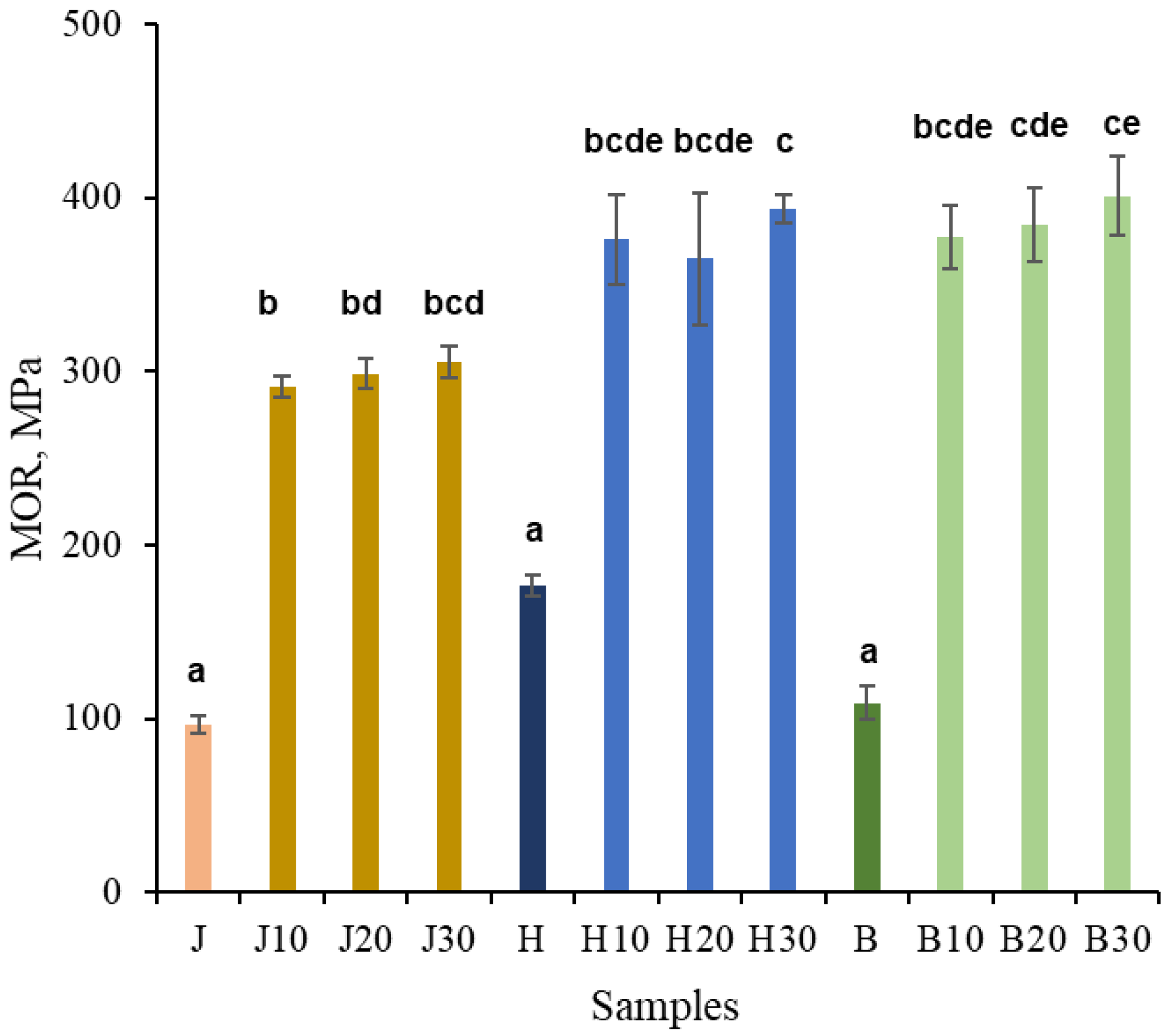

3.4. Mechanical Properties

4. Discussion

4.1. Microstructural Observations After NaOH Pretreatment and Densification

4.2. Chemical Activation of the Cell-Wall Matrix

4.3. Relationship Between Microstructural Consolidation, Chemical Modification, and Mechanical Performance

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| J | Untreated juniper wood |

| J10; J20; J30 | NaOH treated juniper wood in different time (10; 20; 30 min) |

| H | Untreated hawthorn wood |

| H10; H20; H30 | NaOH treated hawthorn wood in different time (10; 20; 30 min) |

| B | Untreated birch wood |

| B10; B20; B30 | NaOH treated birch wood in different time (10; 20; 30 min) |

| MOE | Modulus of elasticity |

| MOR | Modulus of rapture |

| SEM | Scanning Electron Microscopy |

| FTIR | Fourier Transform Infrared Spectroscopy |

| SE | Standard error |

References

- Yan, W.; Liu, J.; Zheng, X.; Zhang, J.; Tang, K. Wood-Derived High-Performance Cellulose Structural Materials. E-Polymers 2023, 23, 20230010. [Google Scholar] [CrossRef]

- Gondaliya, A.M.; Hoque, M.; Raghunath, S.; Foster, E.J. Green and Sustainable Fabrication of DES-Pretreated High-Strength Densified Wood. Wood Sci. Technol. 2024, 58, 1901–1923. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Lu, Y.; Wu, G.; Bai, L.; Barker-Rothschild, D.; Lyu, J.; Liu, S.; Rojas, O.J. Wood Elasticity and Compressible Wood-Based Materials: Functional Design and Applications. Prog. Mater. Sci. 2025, 147, 101354. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Petrič, M. Delignified Wood from Understanding the Hierarchically Aligned Cellulosic Structures to Creating Novel Functional Materials: A Review. Adv. Sustain. Syst. 2021, 5, 2000251. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, K.; Xu, L.; Zhang, Y.; Xiao, Y.; Yuan, Y.; Wang, W. Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications. Polymers 2025, 17, 2677. [Google Scholar] [CrossRef]

- Malaga-Toboła, U.; Łapka, M.; Tabor, S.; Niesłony, A.; Findura, P. Influence of Wood Anisotropy on Its Mechanical Properties in Relation to the Scale Effect. Int. Agrophys. 2019, 33, 337–345. [Google Scholar] [CrossRef]

- Kuai, B.; Wang, Z.; Gao, J.; Tong, J.; Zhan, T.; Zhang, Y.; Lu, J.; Cai, L. Development of Densified Wood with High Strength and Excellent Dimensional Stability by Impregnating Delignified Poplar by Sodium Silicate. Constr. Build. Mater. 2022, 344, 128282. [Google Scholar] [CrossRef]

- Cabral, J.P.; Kafle, B.; Subhani, M.; Reiner, J.; Ashraf, M. Densification of Timber: A Review on the Process, Material Properties, and Application. J. Wood Sci. 2022, 68, 20. [Google Scholar] [CrossRef]

- Sarwar, M.A.; Irfan, M.; Tabish, A.N.; Mahmood Khan, H.; Waqas Iqbal, M.; Fatima, H.; Iqbal, T. Effect of Pretreatment Parameters and Binder Concentration on the Densification of Wood Residue. Environ. Prog. Sustain. Energy 2023, 42, e14196. [Google Scholar] [CrossRef]

- Blanchet, P.; Cabral, M.R.; Silva, J.V.F.; García-Jaca, J.; Ridley-Ellis, D.; McGetrick, P.J.; Nocetti, M.; Pommier, R. A Decade Review on Hardwood Composites and Their Research Developments. Eur. J. Wood Wood Prod. 2025, 83, 65. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing Bulk Natural Wood into a High-Performance Structural Material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Gullo, F.; Marangon, A.; Croce, A.; Gatti, G.; Aceto, M. From Natural Woods to High Density Materials: An Ecofriendly Approach. Sustainability 2023, 15, 2055. [Google Scholar] [CrossRef]

- Andze, L.; Dubnika, A.; Nefjodovs, V.; Andzs, M.; Skute, M.; Zoldners, J.; Kapickis, M.; Locs, J.; Vetra, J. Chemically Pretreated Densification of Juniper Wood for Potential Use in Osteosynthesis Bone Implants. J. Funct. Biomater. 2024, 15, 287. [Google Scholar] [CrossRef] [PubMed]

- Maturana, J.C.; Guindos, P.; Lagos, J.; Arroyave, C.; Echeverría, F.; Correa, E. Two-Step Hot Isostatic Pressing Densification Achieved Non-Porous Fully-Densified Wood with Enhanced Physical and Mechanical Properties. Sci. Rep. 2023, 13, 14324. [Google Scholar] [CrossRef]

- Ran, Y.; Lu, D.; Jiang, J.; Huang, Y.; Wang, W.; Jinzhen, C. Deep Eutectic Solvents-Assisted Wood Densification: A Promising Strategy for Shape-Fixation. Chem. Eng. J. 2023, 471, 144476. [Google Scholar] [CrossRef]

- Sansone, L.; Cigliano, C.; Lopresto, V.; Papa, I.; Russo, P.; Antonucci, V.; Ricciardi, M.R. Hydrothermal Densification of Oak Wood: A Microstructural, Physical, and Chemical Study Toward Structural Applications. Appl. Sci. 2025, 15, 12618. [Google Scholar] [CrossRef]

- Fang, C.H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of Wood Veneers by Compression Combined with Heat and Steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Yang, B.; Hu, L. Wood Composite as an Energy Efficient Building Material: Guided Sunlight Transmittance and Effective Thermal Insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Vattikuti, S.V.P.; Rosaiah, P.; Shim, J.; Sudhani, H.P.K.; Thi, N.N.; Dao, T.-B.-N.; Nguyen Dang, N. Wood-Derived Supercapacitors: A Sustainable Energy Storage Solution. J. Energy Storage 2024, 103, 114237. [Google Scholar] [CrossRef]

- Mariani, A.; Malucelli, G. Transparent Wood-Based Materials: A New Step toward Sustainability and Circularity. Next Mater. 2024, 5, 100255. [Google Scholar] [CrossRef]

- Meng, T.; Ding, Y.; Liu, Y.; Xu, L.; Mao, Y.; Gelfond, J.; Li, S.; Li, Z.; Salipante, P.F.; Kim, H.; et al. In Situ Lignin Adhesion for High-Performance Bamboo Composites. Nano Lett. 2023, 23, 8411–8418. [Google Scholar] [CrossRef]

- Kilumets, C.; Kallakas, H.; Ralph, S.; Zhu, J.Y.; Hunt, C.G.; Rohumaa, A.; Kers, J. Effect of Lignin on Veneer Densification and Set-Recovery. Constr. Build. Mater. 2024, 451, 138795. [Google Scholar] [CrossRef]

- Terzopoulou, P.; Vouvoudi, E.C.; Achilias, D.S. Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications. Forests 2025, 16, 993. [Google Scholar] [CrossRef]

- Rowell, R.M. (Ed.) Handbook of Wood Chemistry and Wood Composite; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Lawoko, M.; Henriksson, G.; Gellerstedt, G. Structural Differences between the Lignin−Carbohydrate Complexes Present in Wood and in Chemical Pulps. Biomacromolecules 2005, 6, 3467–3473. [Google Scholar] [CrossRef] [PubMed]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. Bioresources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Mosiner, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A Review on Alkaline Pretreatment Technology for Bioconversion of Lignocellulosic Biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- Lehto, J.T.; Alén, R.J. Chemical Pretreatments of Wood Chips Prior to Alkaline Pulping—A Review of Pretreatment Alternatives, Chemical Aspects of the Resulting Liquors, and Pulping Outcomes. Bioresources 2014, 10, 8604–8656. [Google Scholar] [CrossRef]

- Jahan, M.S.; Rahman, M.M.; Ni, Y. Alternative Initiatives for Non-Wood Chemical Pulping and Integration with the Biorefinery Concept: A Review. Biofuels Bioprod. Bioref. 2021, 15, 100–118. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Hui, L. Pulping and Papermaking of Non-Wood Fibers. In Pulp and Paper Processing; Kazi, S.N., Ed.; InTechOpen: London, UK, 2018. [Google Scholar]

- T222 om-98; Acid-Insoluble Lignin in Wood and Pulp. TAPPI Press: Atlanta, GA, USA, 1998.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass—NREL/TP-510-42618; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008. [Google Scholar]

- EN 310:1993; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. CEN: Brussels, Belgium, 1993.

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of Densified Wood via Synergy of Chemical Pretreatment, Hot-Pressing and Post Mechanical Fixation. J. Wood Sci. 2020, 66, 5. [Google Scholar] [CrossRef]

- Bogolitsyn, K.G.; Zubov, I.N.; Gusakova, M.A.; Chukhchin, D.G.; Krasikova, A.A. Juniper Wood Structure under the Microscope. Planta 2015, 241, 1231–1239. [Google Scholar] [CrossRef] [PubMed]

- Owens, F.C.; Ravindran, P.; Costa, A.; Shmulsky, R.; Wiedenhoeft, A.C. Predicting Hardwood Porosity Domains: Toward Cascading Computer-Vision Wood Identification Models. Bioresources 2024, 19, 9741–9772. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M. Effects of Short-Term Thermomechanical Densification on the Structure and Properties of Wood Veneers. Wood Mater. Sci. Eng. 2017, 12, 40–54. [Google Scholar] [CrossRef]

- Biziks, V.; Andersons, B.; Beļkova, Ļ.; Kapača, E.; Militz, H. Changes in the Microstructure of Birch Wood after Hydrothermal Treatment. Wood Sci. Technol. 2013, 47, 717–735. [Google Scholar] [CrossRef]

- Adams, S.J.; Estupiñán-Pérez, L.; González-Anduaga, G.M.; Navarrete, A.; Khan, I.A. Anatomical Markers for Identification and Standardization of Crataegus mexicana, Commercially Marketed as “Raíz de Tejocote”. Plants 2025, 14, 3607. [Google Scholar] [CrossRef]

- Wang, S.-Y.; Zhang, Y.-Q.; Wei, Q.; Cui, D.-Z.; Fu, X.-S.; Liu, Z.-L.; Zheng, Z.-A. Pulsed Vacuum Drying (PVD) of Hawthorn (Crataegus Spp.) Slices: Effects on Drying Characteristics and Physicochemical Quality. Food Bioproc. Technol. 2024, 17, 5410–5422. [Google Scholar] [CrossRef]

- Najjoum, N.; Grimi, N.; Benali, M.; Chadni, M.; Castignolles, P. Extraction and Chemical Features of Wood Hemicelluloses: A Review. Int. J. Biol. Macromol. 2025, 311, 143681. [Google Scholar] [CrossRef]

- Andze, L.; Andzs, M.; Skute, M.; Nefjodovs, V.; Kapickis, M.; Tupciauskas, R. Preliminary Study of Chemically Pretreated Densification of Juniper Wood for Use in Bone Implants. Mater. Sci. Forum 2022, 1071, 101–108. [Google Scholar] [CrossRef]

- Antczak, A.; Skręta, A.; Kamińska-Dwórznicka, A.; Rząd, K.; Matwijczuk, A. Study on the Structure of Lignin Isolated from Wood Under Acidic Conditions. Molecules 2025, 30, 4705. [Google Scholar] [CrossRef]

- Geng, W.; Narron, R.; Jiang, X.; Pawlak, J.J.; Chang, H.; Park, S.; Jameel, H.; Venditti, R.A. The Influence of Lignin Content and Structure on Hemicellulose Alkaline Extraction for Non-Wood and Hardwood Lignocellulosic Biomass. Cellulose 2019, 26, 3219–3230. [Google Scholar] [CrossRef]

- Md Salim, R.; Asik, J.; Sarjadi, M.S. Chemical Functional Groups of Extractives, Cellulose and Lignin Extracted from Native Leucaena leucocephala Bark. Wood Sci. Technol. 2021, 55, 295–313. [Google Scholar] [CrossRef]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Sharma, V.; Yadav, J.; Kumar, R.; Tesarova, D.; Ekielski, A.; Mishra, P.K. On the Rapid and Non-Destructive Approach for Wood Identification Using ATR-FTIR Spectroscopy and Chemometric Methods. Vib. Spectrosc. 2020, 110, 103097. [Google Scholar] [CrossRef]

- Mania, P.; Kupfernagel, C.; Curling, S. Densification of Delignified Wood: Influence of Chemical Composition on Wood Density, Compressive Strength, and Hardness of Eurasian Aspen and Scots Pine. Forests 2024, 15, 892. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Vasile, C.; Popescu, M.-C.; Singurel, G.H.; Popa, V.I.; Munteanu, B.S. Analytical Methods for Lignin Characterization. II. Spectroscopic Studies. Cellul. Chem. Technol. 2006, 40, 597–621. [Google Scholar]

- Chen, H.; Ferrari, C.; Angiuli, M.; Yao, J.; Raspi, C.; Bramanti, E. Qualitative and Quantitative Analysis of Wood Samples by Fourier Transform Infrared Spectroscopy and Multivariate Analysis. Carbohydr. Polym. 2010, 82, 772–778. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Chao, Y.; Nawawi, D.S.; Akiyama, T.; Yokoyama, T.; Matsumoto, Y. Analysis of Lignin Aromatic Structure in Wood Based on the IR Spectrum. J. Wood Chem. Technol. 2012, 32, 294–303. [Google Scholar] [CrossRef]

- Suota, M.J.; da Silva, T.A.; Zawadzki, S.F.; Sassaki, G.L.; Hansel, F.A.; Paleologou, M.; Ramos, L.P. Chemical and Structural Characterization of Hardwood and Softwood LignoForceTM Lignins. Ind. Crops Prod. 2021, 173, 114138. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Martínez Cortizas, A. Differentiation between Pine Woods According to Species and Growing Location Using FTIR-ATR. Wood Sci. Technol. 2018, 52, 487–504. [Google Scholar] [CrossRef]

- Shimizu, S.; Yokoyama, T.; Akiyama, T.; Matsumoto, Y. Reactivity of Lignin with Different Composition of Aromatic Syringyl/Guaiacyl Structures and Erythro/Threo Side Chain Structures in β-O-4 Type during Alkaline Delignification: As a Basis for the Different Degradability of Hardwood and Softwood Lignin. J. Agric. Food Chem. 2012, 60, 6471–6476. [Google Scholar] [CrossRef]

- Tripetch, P.; Lekhavat, S.; Devahastin, S.; Chiewchan, N.; Borompichaichartkul, C. Antioxidant Activities of Konjac Glucomannan Hydrolysates of Different Molecular Weights at Different Values of PH. Foods 2023, 12, 3406. [Google Scholar] [CrossRef]

- Björklund, J.; Fonti, M.V.; Fonti, P.; Van den Bulcke, J.; von Arx, G. Cell Wall Dimensions Reign Supreme: Cell Wall Composition Is Irrelevant for the Temperature Signal of Latewood Density/Blue Intensity in Scots Pine. Dendrochronologia 2021, 65, 125785. [Google Scholar] [CrossRef]

- Alqrinawi, H.; Ahmed, B.; Wu, Q.; Lin, H.; Kameshwar, S.; Shayan, M. Effect of Partial Delignification and Densification on Chemical, Morphological, and Mechanical Properties of Wood: Structural Property Evolution. Ind. Crops Prod. 2024, 213, 118430. [Google Scholar] [CrossRef]

- Modenbach, A.A.; Nokes, S.E. Effects of Sodium Hydroxide Pretreatment on Structural Components of Biomass. Trans. ASABE 2014, 57, 1187–1198. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J. Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review. Molecules 2023, 28, 1868. [Google Scholar] [CrossRef]

- Mania, P.; Wróblewski, M.; Wójciak, A.; Roszyk, E.; Moliński, W. Hardness of Densified Wood in Relation to Changed Chemical Composition. Forests 2020, 11, 506. [Google Scholar] [CrossRef]

- Raman, V.; Liew, K.C. Density of Densified Paraserianthes falcataria Wood Pre-Treated with Alkali. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kota Bharu, Malaysia, 10–11 August 2020; Volume 549, p. 549. [Google Scholar]

- Wang, J.; Fishwild, S.J.; Begel, M.; Zhu, J.Y. Properties of Densified Poplar Wood through Partial Delignification with Alkali and Acid Pretreatment. J. Mater. Sci. 2020, 55, 14664–14676. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of Thermo-Hydro-Mechanical Densification on Microstructure and Properties of Poplar Wood (Populus tomentosa). J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

- Wang, J.; Chai, Y.; Liu, J.; Zhu, J.Y. The Viscoelastic and Hygroscopicity Behavior of Delignified and Densified Poplar Wood. Forests 2023, 14, 1721. [Google Scholar] [CrossRef]

- Raina, R.; Verma, P.K.; Peshin, R.; Kour, H. Potential of Juniperus Communis L as a Nutraceutical in Human and Veterinary Medicine. Heliyon 2019, 5, e02376. [Google Scholar] [CrossRef]

- Uçar, G.; Balaban, M. The Composition of Volatile Extractives from the Wood of Juniperus excelsa, Juniperus foetidissima and Juniperus oxycedrus. Holz als Roh-und Werkst. 2002, 60, 356–362. [Google Scholar] [CrossRef]

- Sokół-Łetowska, A.; Oszmiański, J.; Wojdyło, A. Antioxidant Activity of the Phenolic Compounds of Hawthorn, Pine and Skullcap. Food Chem. 2007, 103, 853–859. [Google Scholar] [CrossRef]

- Janzen, P.; Zimmer, K.; Appelt, J. Extractable Compounds in a Birch Tree—Variations in Composition and Yield Potentials. Forests 2023, 14, 1279. [Google Scholar] [CrossRef]

- Martins, J.R.; Llanos, J.H.R.; Botaro, V.; Gonçalves, A.R.; Brienzo, M. Hemicellulose Biomass Degree of Acetylation (Natural Versus Chemical Acetylation) as a Strategy for Based Packaging Materials. Bioenergy Res. 2024, 17, 877–896. [Google Scholar] [CrossRef]

- Zhu, X.; Xue, Y.; Qian, L.; Mei, C.; Gao, Y. Fabrication of Self-Bonding Laminated Bamboo via a Dual-Treatment Method Combining Alkali Treatment and Hot Pressing. Constr. Build. Mater. 2025, 490, 142553. [Google Scholar] [CrossRef]

- Xu, B.H.; Wang, B.L.; Yu, K.B.; Bouchaïr, A. An Optional Connection Material in Timber Structures: Densified Poplar. J. Mater. Sci. 2021, 56, 14114–14125. [Google Scholar] [CrossRef]

- Wehsener, J.; Bremer, M.; Haller, P.; Fischer, S. Bending Tests of Delignified and Densified Poplar. Wood Mater. Sci. Eng. 2023, 18, 42–50. [Google Scholar] [CrossRef]

| Sample | J | J10 | J20 | J30 | H | H10 | H20 | H30 | B | B10 | B20 | B30 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Component | Quantity, % | |||||||||||

| Extractives | 3.01 | 2.81 | 0.53 | 0.75 | 1.00 | 1.03 | 1.01 | 1.02 | 1.52 | 1.03 | 1.04 | 1.03 |

| Glucose | 38.85 | 42.61 | 44.75 | 44.92 | 40.77 | 45.93 | 47.39 | 46.90 | 37.56 | 40.68 | 41.40 | 42.32 |

| Xylose | 8.43 | 8.58 | 8.61 | 8.60 | 23.15 | 22.70 | 22.62 | 22.66 | 25.15 | 24.91 | 24.92 | 24.75 |

| Ather hemicelluloses | 12.7 | 11.87 | 11.69 | 11.71 | 5.61 | 3.42 | 2.50 | 2.51 | 7.52 | 7.11 | 7.11 | 6.92 |

| Acid-soluble lignin | 0.9 | 0.87 | 0.90 | 0.88 | 0.62 | 1.84 | 1.73 | 1.83 | 0.56 | 0.59 | 0.54 | 0.60 |

| Acid-insoluble lignin | 31.49 | 30.32 | 30.39 | 30.32 | 22.54 | 21.65 | 21.60 | 21.22 | 23.46 | 22.51 | 22.64 | 22.59 |

| Inorganic part | 1.96 | 1.98 | 1.97 | 1.98 | 1.53 | 1.18 | 1.13 | 1.20 | 1.23 | 1.02 | 1.04 | 0.66 |

| Acetic acid | 1.78 | 0.15 | 0.10 | 0.10 | 3.59 | 1.69 | 1.13 | 1.17 | 2.15 | 0.92 | 0.84 | 0.80 |

| Others | 1.36 | 1.20 | 1.28 | 1.50 | 2.15 | 1.29 | 1.30 | 1.74 | 1.23 | 1.51 | 1.22 | 1.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Andze, L.; Nefjodovs, V.; Zoldners, J.; Milbreta, U.; Skute, M.; Vecbiskena, L.; Filipova, I.; Andzs, M. NaOH-Only Pretreated Wood Densification: A Simplified Sulfite-Free Route Across Wood Species. Polymers 2026, 18, 312. https://doi.org/10.3390/polym18030312

Andze L, Nefjodovs V, Zoldners J, Milbreta U, Skute M, Vecbiskena L, Filipova I, Andzs M. NaOH-Only Pretreated Wood Densification: A Simplified Sulfite-Free Route Across Wood Species. Polymers. 2026; 18(3):312. https://doi.org/10.3390/polym18030312

Chicago/Turabian StyleAndze, Laura, Vadims Nefjodovs, Juris Zoldners, Ulla Milbreta, Marite Skute, Linda Vecbiskena, Inese Filipova, and Martins Andzs. 2026. "NaOH-Only Pretreated Wood Densification: A Simplified Sulfite-Free Route Across Wood Species" Polymers 18, no. 3: 312. https://doi.org/10.3390/polym18030312

APA StyleAndze, L., Nefjodovs, V., Zoldners, J., Milbreta, U., Skute, M., Vecbiskena, L., Filipova, I., & Andzs, M. (2026). NaOH-Only Pretreated Wood Densification: A Simplified Sulfite-Free Route Across Wood Species. Polymers, 18(3), 312. https://doi.org/10.3390/polym18030312