Study on Viscoelastic Characteristics of Polymer Solution Formation and Their Effect on Oil Displacement Efficiency

Abstract

1. Introduction

2. Viscoelastic Characteristics of Polymers Under Reservoir Conditions

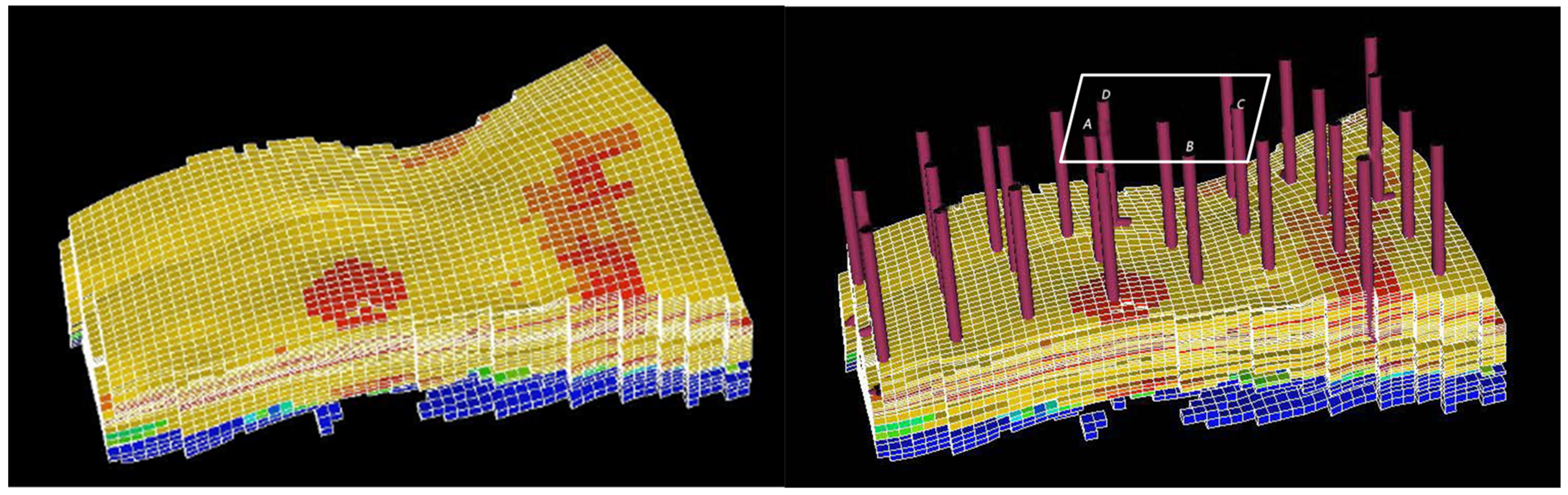

2.1. Characteristics of Changes in Polymer Solution Concentration and Shear Rate Under Injection Conditions

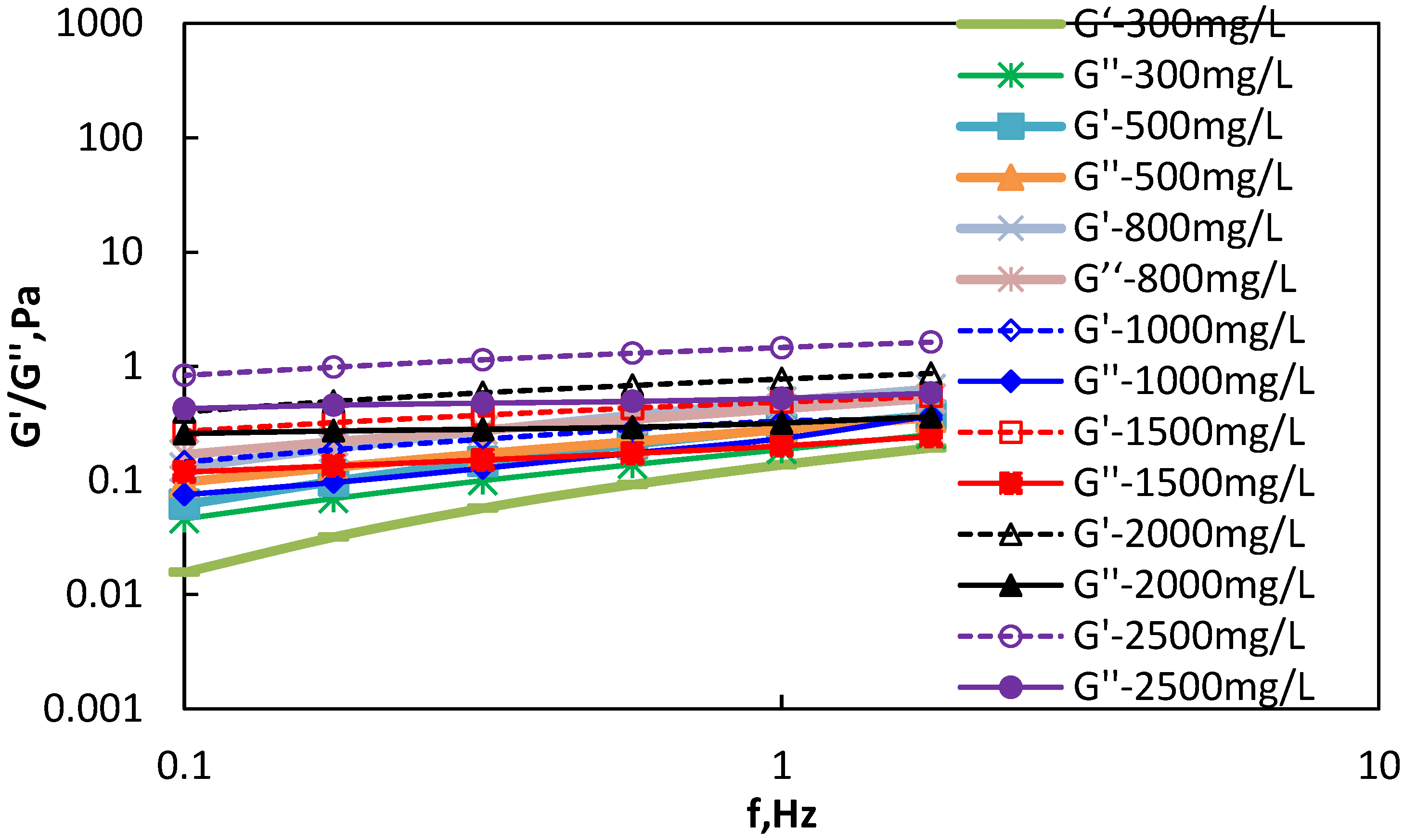

2.2. Viscoelastic Characteristics of Polymer Solutions

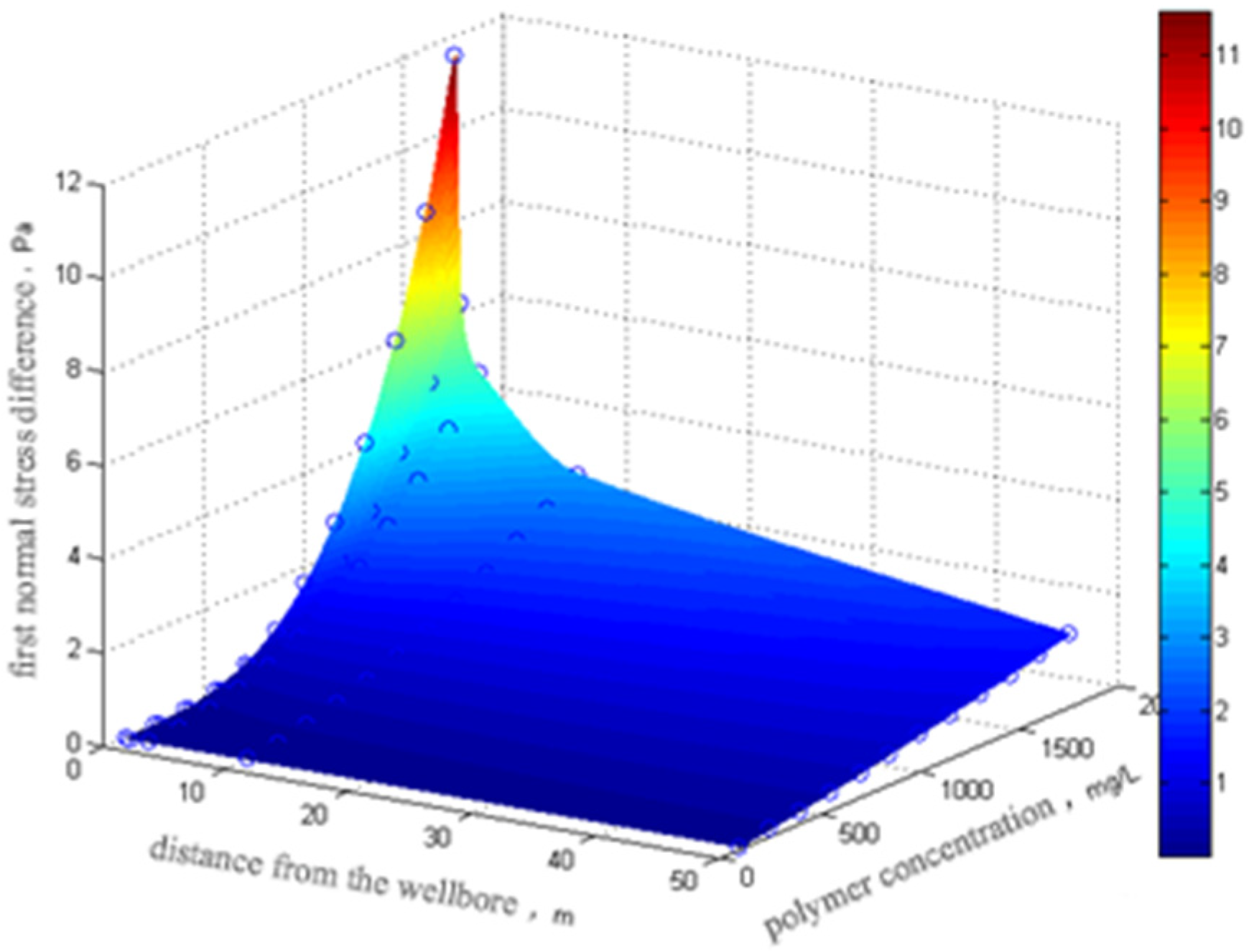

2.3. Characterization of Viscoelasticity of Polymer Solutions at Different Locations and Injection Concentrations

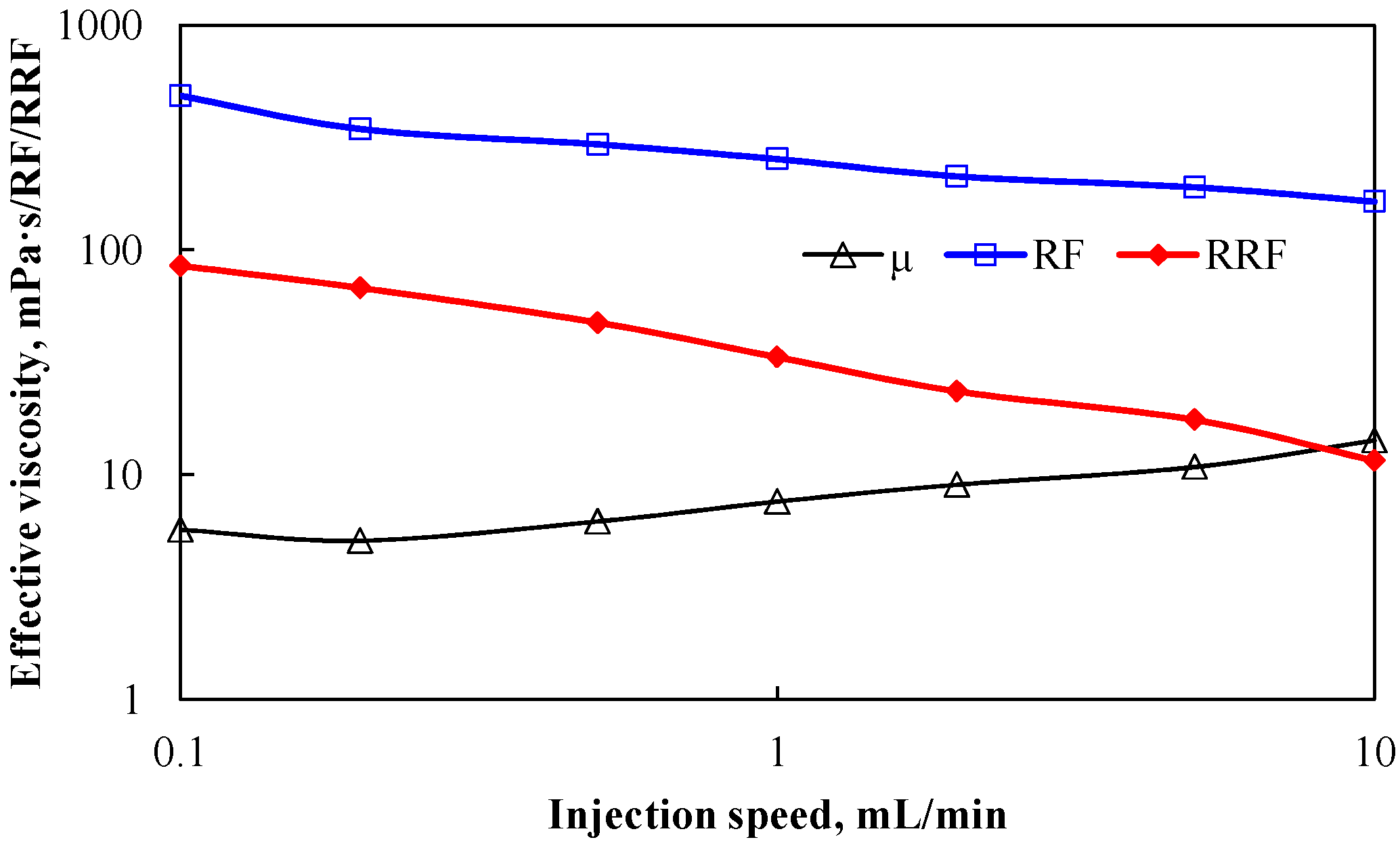

3. Viscoelastic Characteristics of Polymers Under Infiltration Experiments

3.1. Pressure Characteristics of Viscoelastic Polymers in Porous Media

3.2. Seepage Characteristics of Polymer Solutions Under Variable Velocity Conditions

4. Study on Influence of Viscoelasticity on Oil Displacement Effect

4.1. Oil Displacement Experiment Design

4.2. The Influence of Viscoelasticity on Oil Displacement Effect

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Levitt, D.; Jouenne, S.; Bondino, I.; Santanach-Carreras, E.; Bourrel, M. Polymer Flooding of Heavy Oil Under Adverse Mobility Conditions. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 2–4 July 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013; p. SPE165267. [Google Scholar]

- Wang, S.; Shi, L.; Ye, Z.; Wang, Y.; Liu, C.; Xue, X. Microscopic experimental study on the sweep and displacement efficiencies in heterogeneous heavy oil reservoirs. Energy Rep. 2021, 7, 1627–1635. [Google Scholar] [CrossRef]

- Guo, M.; Yu, H.; Zhou, C.; Jia, Z.; Huang, W.; Guo, S.; Zhang, P.; Pan, B.; Wang, Y. Seepage flow characteristics and ability for enhanced oil recovery based on ultra high molecular weight partially hydrolysed polyacrylamide. Int. J. Oil Gas Coal Technol. 2017, 14, 216–231. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Subbotin, A.V.; Kulichikhin, V.G. Stability of polymer jets in extension: Physicochemical and rheological mechanisms. Russ. Chem. Rev. 2020, 89, 811–823. [Google Scholar] [CrossRef]

- Baumgaertel, M.; Schausberger, A.; Winter, H.H. The relaxation of polymers with linear flexible chains of uniform length. Rheol. Acta 1990, 29, 400–408. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H. Anovel model sensitivity analysis for viscoelastic polymer flooding in offshore oilfield. J. Ind. Eng. Chem. 2014, 20, 656–667. [Google Scholar] [CrossRef]

- Subbotin, A.V.; Malkin, A.Y.; Kulichikhin, V.G. The Elasticity of Polymer Melts and Solutions in Shear and Extension Flows. Polymers 2023, 15, 1051. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Malkin, A.Y. Rheology of Polymers; Springer: Berlin/Heidelberg, Germany, 1980. [Google Scholar]

- Malkin, A.Y.; Petrie, C.J.S. Some conditions for rupture of polymer liquids in extension. J. Rheol. 1997, 41, 1–25. [Google Scholar] [CrossRef]

- Münstedt, H. Extensional Rheology and Processing of Polymeric Materials. Int. Polym. Process. 2018, 33, 594–618. [Google Scholar] [CrossRef]

- Malkin, A.; Arinstein, A.; Kulichikhin, V. Polymer extension flows and instabilities. Prog. Polym. Sci. 2014, 39, 959–978. [Google Scholar] [CrossRef]

- Kulichikhin, V.G.; Malkin, A.Y. The Role of Structure in Polymer Rheology: Review. Polymers 2022, 14, 1262. [Google Scholar] [CrossRef]

- Anurag, P.; Qamar, S.F.; Das, S.; Basu, S.; Kesarwani, H.; Saxena, A.; Sharma, S.; Sarkar, J. Advanced multi-wall carbon nanotube-optimized surfactant-polymer flooding for enhanced oil recovery. Fuel 2024, 355, 129463. [Google Scholar]

- Cheng, Y.; Chang, H.; Du, Z.; Yuan, B.; Dandekar, A.; Zhang, Y. A laboratory investigation of CO2 influence on solvent-assisted polymer flooding for improving viscous oil recovery on Alaska North Slope. Geoenergy Sci. Eng. 2023, 229, 212053. [Google Scholar] [CrossRef]

- Cao, J.; Hu, M.; Cheng, Y.; Wang, Z.; Zhang, H.; Chen, R.; Guo, J. Design of high-temperature salt-responsive hydrogel based on W/O/W double emulsion. Colloids Surf. A Physicochem. Eng. Asp. 2025, 717, 136852. [Google Scholar] [CrossRef]

- Mohsen, M.Y.; Pouyan, E.B.; Pacelli, Z. Fundamentals and Recent Progress in the Flow of Water-Soluble Polymers in Porous Media for Enhanced Oil Recovery. Energies 2022, 15, 8575. [Google Scholar] [CrossRef]

- Siegbert, R.; Behr, M.; Elgeti, S. Die swell as an objective in the design of polymer extrusion dies. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016; Volume 1769, p. 140003. [Google Scholar] [CrossRef]

- Zhang, J.; Dan, L.; Wang, L. Application of horizontal well discontinuous chemical flooding technology in Bohai Oilfield. Front. Energy Res. 2023, 10, 1036835. [Google Scholar] [CrossRef]

- Hao, H.; Tan, L. The Characteristic of Oil and Gas Accumulation and Main Factors of Reservoir Enrichment in SZ36-1 Region. Appl. Mech. Mater. 2015, 737, 859–862. [Google Scholar]

- Liu, Y.; Meng, X.; Zhang, Y.; Xia, H.; Cao, B.; Luo, Y. Numerical simulation of separate-layer injection-production effect and its influencing factors in offshore oilfield -by taking SZ36-1 oilfield in Bohai sea as an example. Pet. Geol. Eng. 2020, 34, 95–101. [Google Scholar]

- Xue, X.; Zhu, S.; Ma, X.; Zhang, S.; Yang, S.; Huang, Z.; Xu, M.; Huang, H. Enhancing heavy-oil displacement efficiency through viscoelasticity of polymer solution by investigating the viscosity limit of crude oil: An experimental study. Energy Sci. Eng. 2024, 12, 2493–2504. [Google Scholar] [CrossRef]

- Xue, X. Study on the Influence of Rheological Properties of Polymer Solutions on Enhanced Oil Recovery. Doctoral Thesis, Southwest Petroleum University, Chengdu, China, 2009. [Google Scholar]

- Tedde, G.M.; Santo, L.; Bellisarbo, D.; Quandini, F. Frozen Stresses in Shape Memory Polymer Composites. Mater. Plast. 2022, 55, 2018494. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, F.; Xie, X.; Kang, X.D.; Li, B.Z. Reservoir technical-economic limit of polymer flooding and classification in Bohai Sea. China Offshore Oil Gas 2014, 26, 51–54. [Google Scholar]

- Zhu, S.; Xu, M.; Yang, S.; Huang, Z.; Wang, Y.; Zhu, Y. Evaluation of shear resistance of dendritic hydrophobic association polymers. J. Polym. Res. 2024, 31, 318. [Google Scholar] [CrossRef]

- Jiao, G.; Zhu, S.; Wang, J.; Huang, Z.; Xu, M. Feasibility of Oil Mud Reinjection from Offshore Platforms in Bohai Oilfield. J. Basic Appl. Sci. 2023, 19, 68–76. [Google Scholar] [CrossRef]

- Alves, M.; Oliveira, P.; Pinho, F. Numerical Methods for Viscoelastic Fluid Flows. Annu. Rev. Fluid Mech. 2021, 53, 509–541. [Google Scholar] [CrossRef]

- Wang, S.; Shi, L.; Ye, Z.; Zhang, X.; Zhang, L.; Li, X. Experimental study on improving oil recovery in fluvial reservoir with polymer solutions. AIP Adv. 2021, 11, 055121. [Google Scholar] [CrossRef]

- Browne, C.A.; Datta, S.S. Elastic turbulence generates anomalous flow resistance in porous media. Sci. Adv. 2021, 7, eabj2619. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, S.; Xue, X.; Zhang, J.; Xu, J.; Liu, Z. Influencing factors for effective establishment of residual resistance factor of polymer solution in porous media. J. Polym. Res. 2022, 29, 210. [Google Scholar] [CrossRef]

- Shi, L.; Zhu, S.; Zou, J.; Xue, X.; Zhao, W.; Ye, Z. Research on the Time Range and Influencing Factors of Effective Flow Control in Polymer Flooding. Pet. Reserv. Eval. Dev. 2019, 9, 31–35. [Google Scholar]

- Zang, L.; Hu, M.; Cao, J.; Cheng, Y.; Li, P.; Guo, J.; Zhang, H. Design of Janus Nanoparticles for Mobility Control in Heterogeneous Reservoirs. ACS Omega 2024, 9, 16536–16546. [Google Scholar] [CrossRef] [PubMed]

| Type | Parameters |

|---|---|

| Injection Schemes | 1. Waterflood baseline: 0.06 PV·a−1 injection rate. 2. Polymer flood: 0.3 PV slug size at 1750 mg/L concentration, 0.06 PV·a−1 injection rate |

| Reservoir Properties | 1. Thickness: 200–400 m. 2. Initial pressure: 14.2 MPa. 3. Permeability: 2500 mD, coefficient of variation VK = 0.6. 4. Porosity: 32% average. 5. Initial oil saturation: 56%. |

| Fluid Properties | 1. Crude oil viscosity: 65 mPa·s. 2. Oil formation volume factor: 1.11. 3. Injection water salinity: 9374 mg/L. 4. Temperature: 65 °C. |

| Segmentation | Perforated Interval | Near-Well Zone | Exceeding 6 m | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Distance from the bottom of the well | 0.01 m | 0.3 m | 0.5 m | 0.8 m | 1 m | 2 m | 6 m | 20 m | 56 m | 104 m |

| Linear velocity | 318.471 | 10.616 | 6.369 | 3.981 | 3.185 | 2.588 | 1.127 | 0.758 | 0.377 | 0.242 |

| shear rate | 171.502 | 5.717 | 3.430 | 2.144 | 1.715 | 1.394 | 0.607 | 0.408 | 0.203 | 0.13 |

| Differential Pressure, MPa | Injection Rate, mL/min | ||

|---|---|---|---|

| 0.1 | 1 | 10 | |

| Glycerol | 0.0087 | 0.087 | 0.87 |

| SNF3640C | 0.4 | 2.16 | 11.5 |

| Core Number | Pore Volume | Saturated Oil Quantity | Displacing Velocity, mL/min | Porosity | Oil Saturation | Displacement Fluid System |

|---|---|---|---|---|---|---|

| 2# | 12.246 | 10.5 mL | 0.1 | 32.20% | 0.86 | glycerol |

| 13# | 11.8 | 9.9 mL | 0.5 | 30.00% | 0.84 | glycerol |

| 15# | 11.3 | 9.4 mL | 0.01 | 28.80% | 0.83 | glycerol |

| 21# | 12 | 10.1 mL | 1 | 32.20% | 0.84 | glycerol |

| 22# | 11.2 | 9.4 mL | 5 | 28.50% | 0.84 | glycerol |

| 14# | 12.2 | 10.8 mL | 0.5 | 31.08% | 0.89 | SNF3640C |

| 16# | 12.3 | 10.7 mL | 0.01 | 31.30% | 0.87 | SNF3640C |

| 27# | 11.2 | 9 mL | 5 | 31.08% | 0.8 | SNF3640C |

| 25# | 11.5 | 9.8 mL | 1 | 31.30% | 0.85 | SNF3640C |

| 16# | 12.3 | 10.7 mL | 0.01 | 31.30% | 0.87 | SNF3640C |

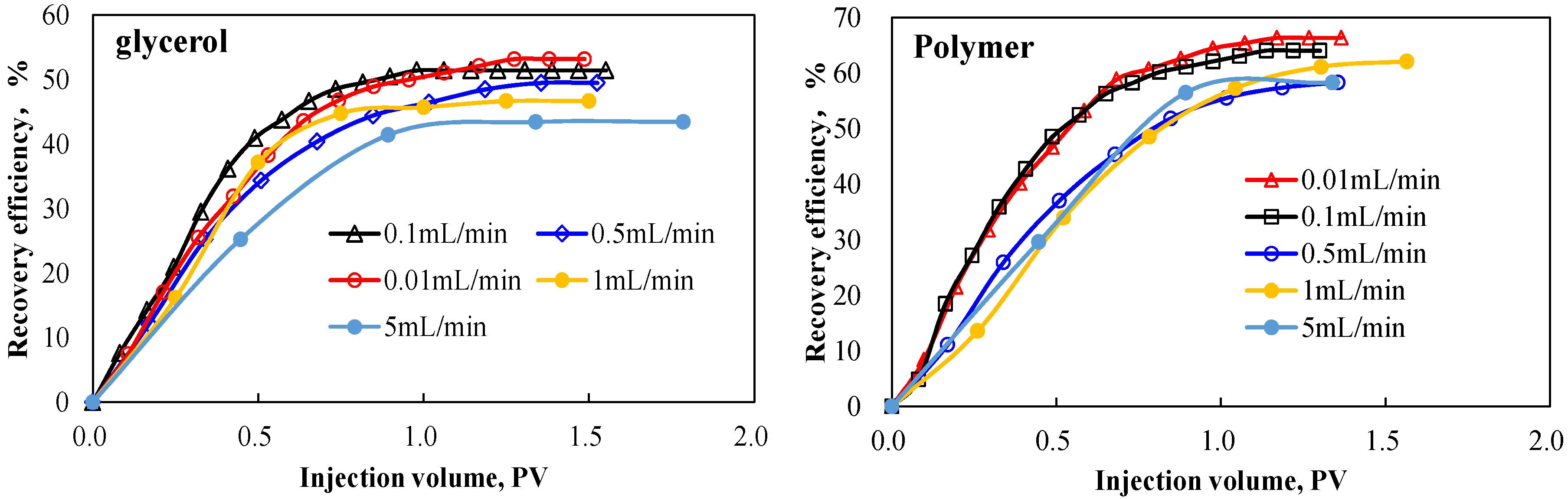

| Displacing Velocity, mL/min | Oil Displacement Efficiency of Glycerol | Oil Displacement Efficiency of Polymer | Difference |

|---|---|---|---|

| 0.01 | 53.19% | 66.36% | 13.17% |

| 0.1 | 51.43% | 64.08% | 12.65% |

| 0.5 | 49.49% | 58.33% | 8.84% |

| 1 | 46.67% | 62.14% | 15.47% |

| 5 | 43.43% | 58.33% | 14.90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhu, S.; Zhu, Y.; Chen, L.; Zhang, J.; Duan, X.; Cai, Y.; Jiang, X. Study on Viscoelastic Characteristics of Polymer Solution Formation and Their Effect on Oil Displacement Efficiency. Polymers 2026, 18, 2. https://doi.org/10.3390/polym18010002

Zhu S, Zhu Y, Chen L, Zhang J, Duan X, Cai Y, Jiang X. Study on Viscoelastic Characteristics of Polymer Solution Formation and Their Effect on Oil Displacement Efficiency. Polymers. 2026; 18(1):2. https://doi.org/10.3390/polym18010002

Chicago/Turabian StyleZhu, Shijie, Yong Zhu, Lijun Chen, Jie Zhang, Xueli Duan, Yunxiong Cai, and Xinsheng Jiang. 2026. "Study on Viscoelastic Characteristics of Polymer Solution Formation and Their Effect on Oil Displacement Efficiency" Polymers 18, no. 1: 2. https://doi.org/10.3390/polym18010002

APA StyleZhu, S., Zhu, Y., Chen, L., Zhang, J., Duan, X., Cai, Y., & Jiang, X. (2026). Study on Viscoelastic Characteristics of Polymer Solution Formation and Their Effect on Oil Displacement Efficiency. Polymers, 18(1), 2. https://doi.org/10.3390/polym18010002