Automotive Application of Chemically Foamed rPET

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Material Properties

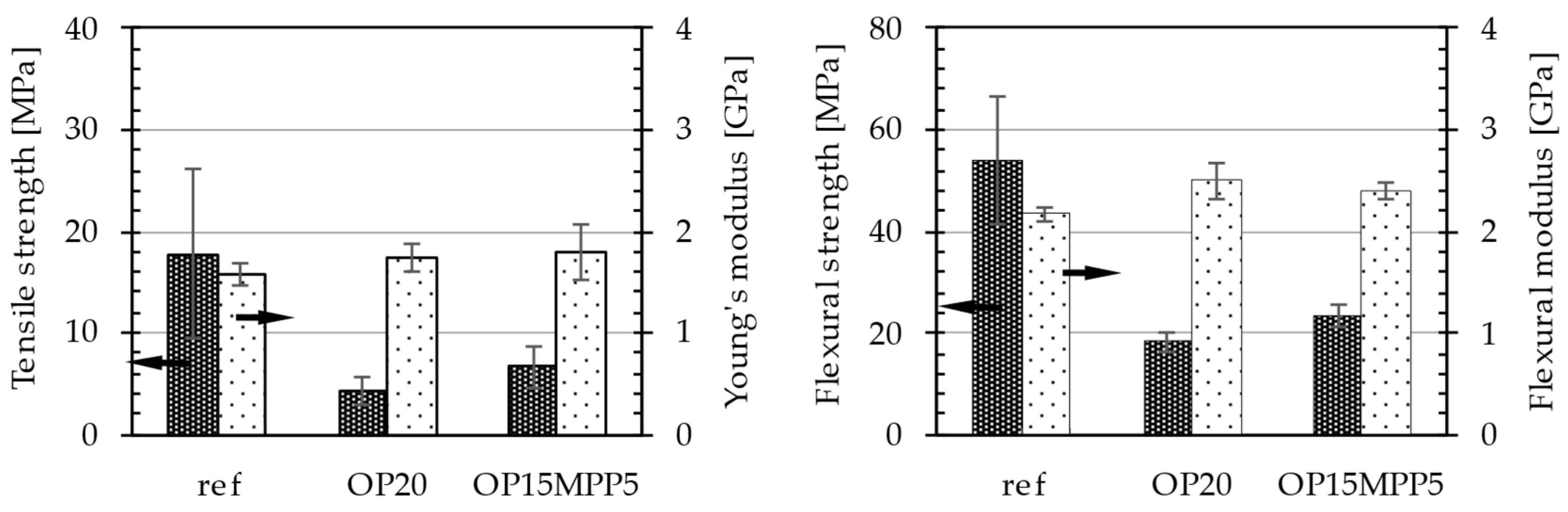

3.1. Mechanical Tests

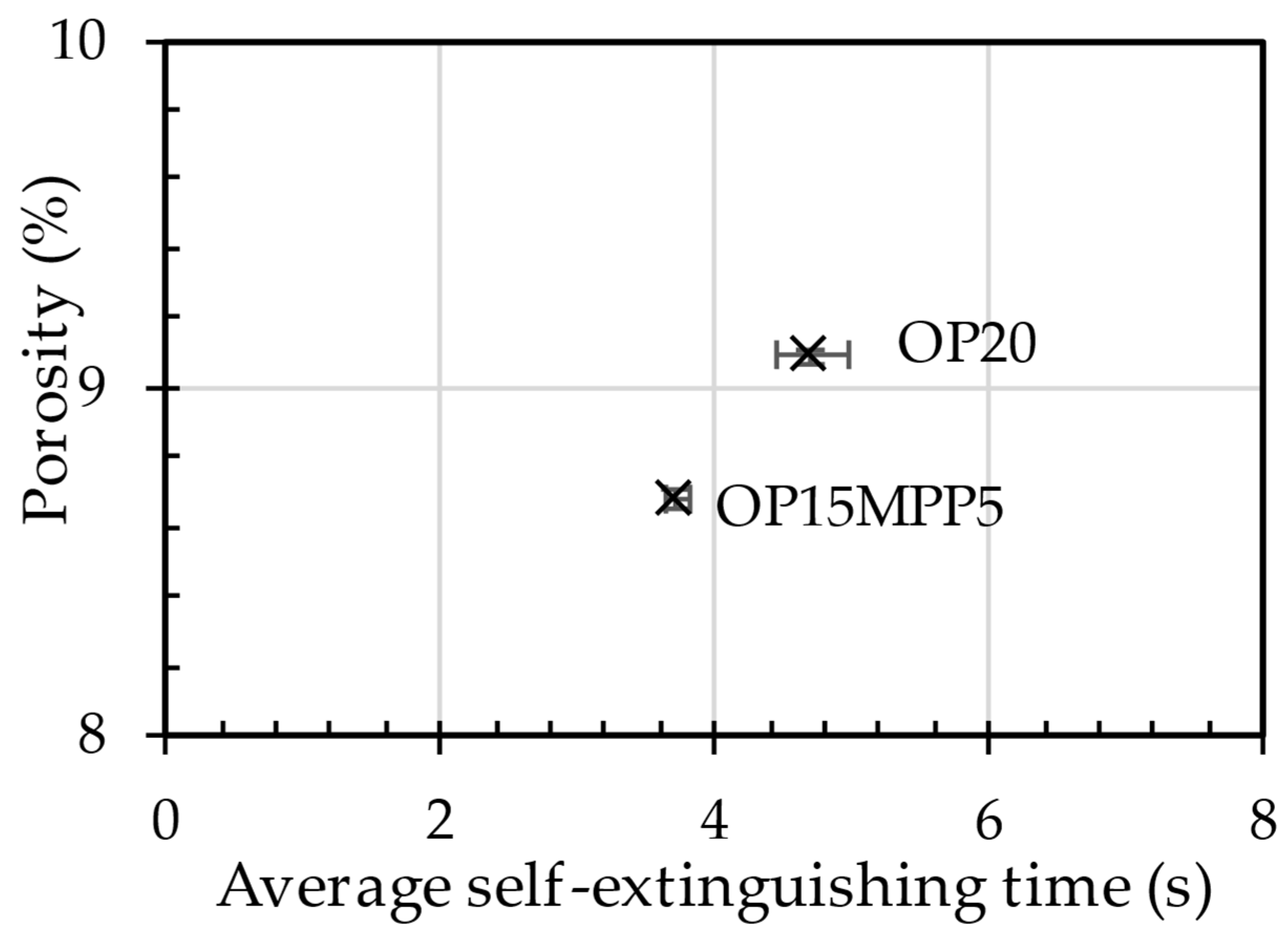

3.2. Flammability

3.3. TGA

4. Applicability Testing

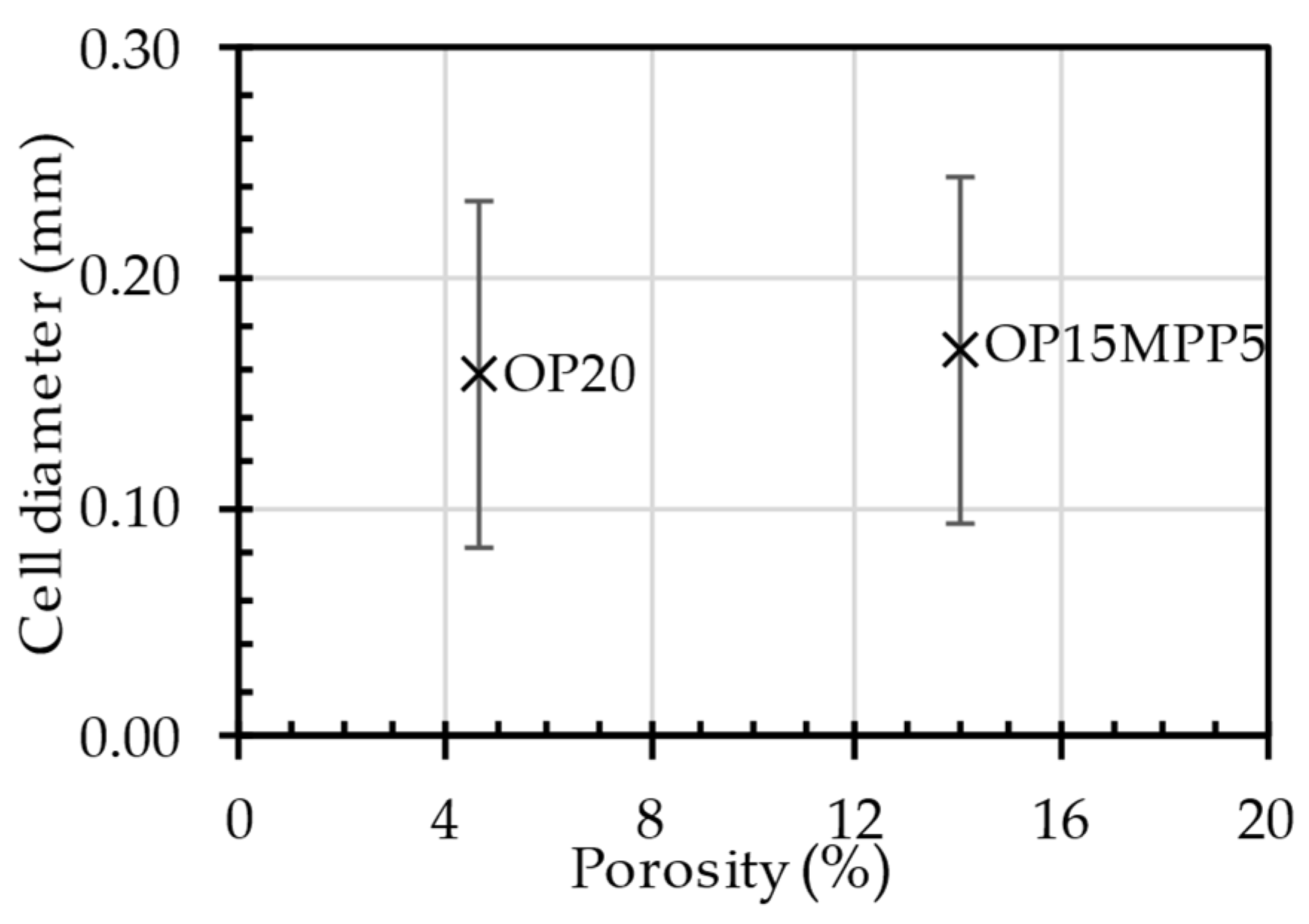

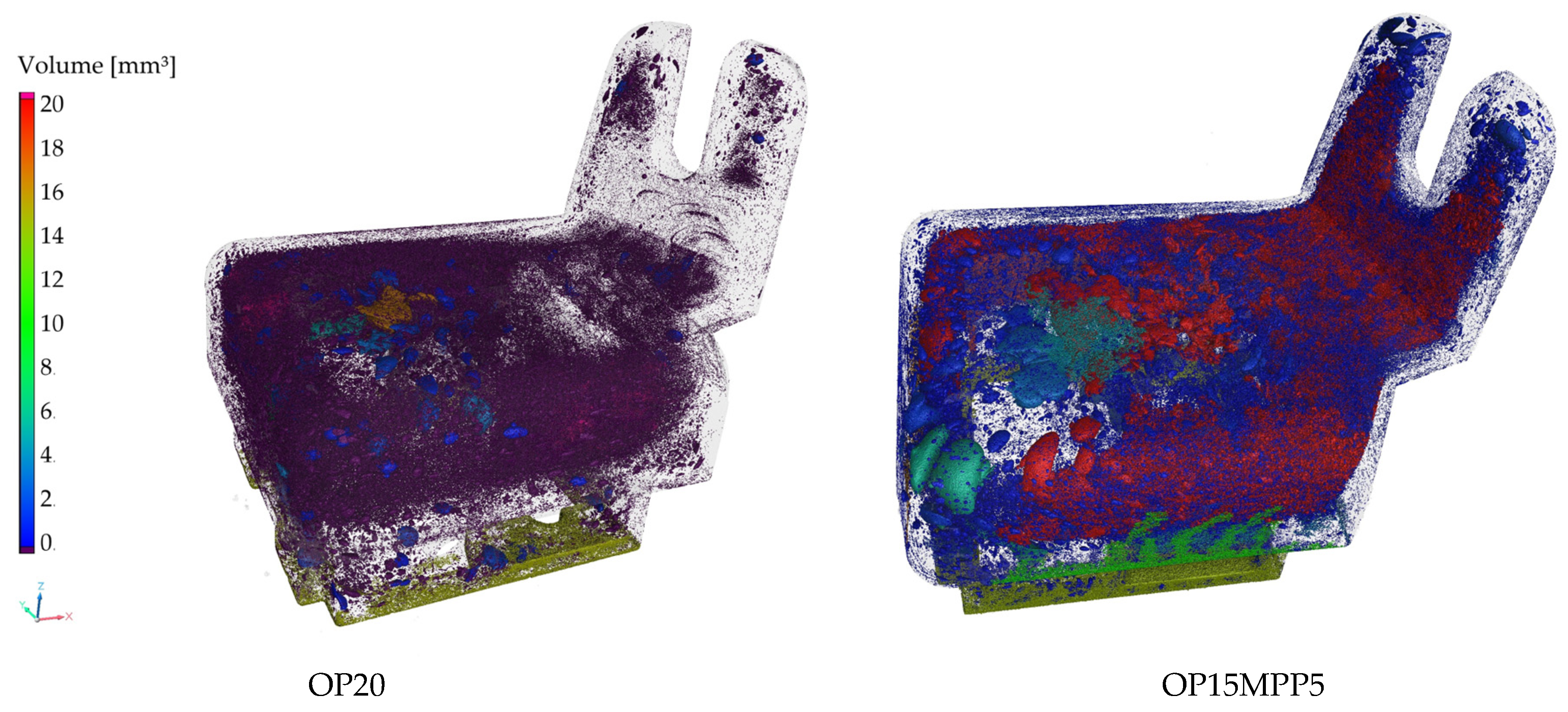

4.1. CT Scans of the Automotive Component

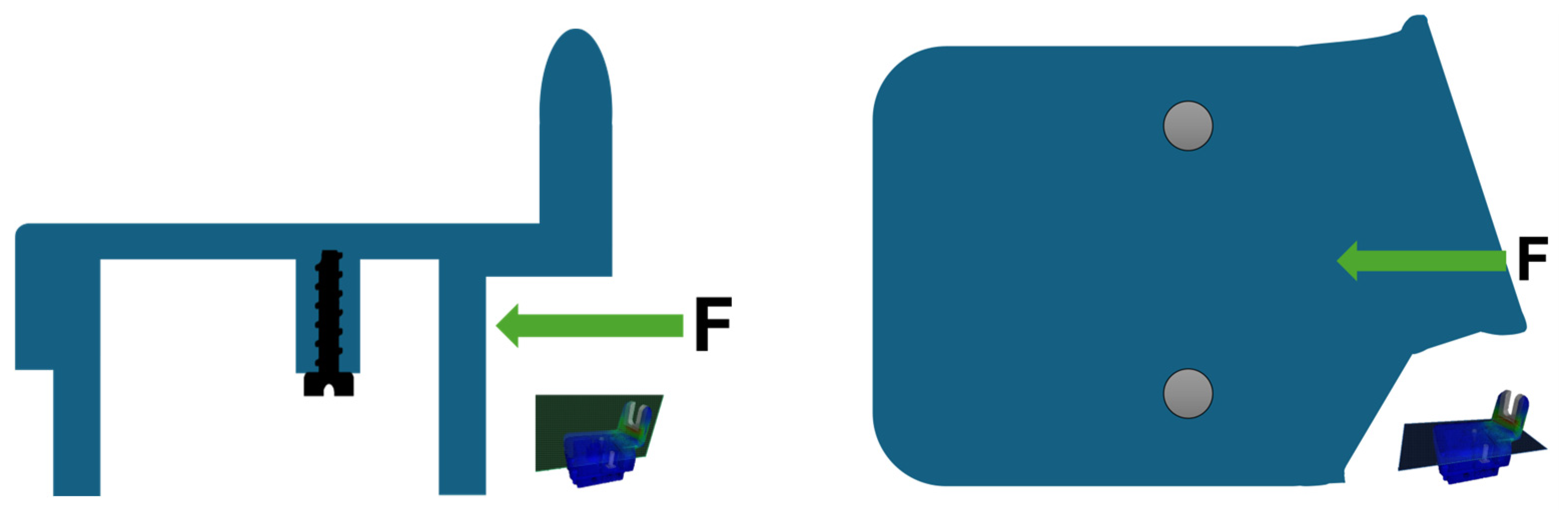

4.2. Testing the Applicability of an Automotive Product Using Finite Element Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization, and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Thompson, R.C.; Moore, C.J.; vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Lukács, N.; Ronkay, F.; Molnár, B.; Marosfői, B.; Bocz, K. Characterisation of flame retarded recycled PET foams produced by batch foaming. Polym. Test. 2023, 124, 108104. [Google Scholar] [CrossRef]

- Bocz, K.; Ronkay, F.; Vadas, D.; Molnár, B.; Gere, D.; Czigány, T.; Marosi, G. Flame retardancy of PET foams manufactured from bottle waste. J. Therm. Anal. Calorim. 2022, 148, 217–228. [Google Scholar] [CrossRef]

- Szabó, V.A.; Dogossy, G. Structure and properties of closed-cell foam prepared from rPET. IOP Conf. Ser. Mater. Sci. Eng. 2018, 426, 012043. [Google Scholar] [CrossRef]

- Eaves, D. Polymer Foams: Trends in Use and Technology; Rapra Technology Limited: Shawbury, UK, 2001; pp. 33–34. [Google Scholar]

- Xing, J.; He, L.; Jiang, T. Effect of hardness on the foaming behavior, surface quality, and mechanical properties of thermoplastic polyurethane foams by chemical foaming injection molding. Polym. Eng. Sci. 2024, 64, 5929–5939. [Google Scholar] [CrossRef]

- Mendoza-Cedeno, S.; Kweon, M.S.; Newby, S.; Shivokhin, M.; Pehlert, G.; Lee, P.C. Improved cell morphology and surface roughness in high-temperature foam injection molding using a long-chain branched polypropylene. Polymers 2021, 13, 2404. [Google Scholar] [CrossRef] [PubMed]

- Szabó, V.A.; Fekete, G.; Dogossy, G. Endothermic–Exothermic Hybrid Foaming of Recycled PET Blends. J. Compos. Sci. 2024, 8, 383. [Google Scholar] [CrossRef]

- Szabó, V.A. Építőipari szigetelőblokk fejlesztése hulladékpalackból. Műszaki Katonai Közlöny 2020, 30, 77–84. [Google Scholar] [CrossRef]

- European Parliament and Council of the European Union. Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of-life vehicles. Off. J. Eur. Union 2000, L269, 34–43. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32000L0053 (accessed on 31 March 2025).

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Jiang, Q.; Chen, G.; Kumar, A.; Mills, A.; Jani, K.; Rajamohan, V.; Venugopal, B.; Rahatekar, S. Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core. J. Compos. Sci. 2021, 5, 2. [Google Scholar] [CrossRef]

- Bedell, M.; Simon, B.; Kiziltas, A.; Herrington, R.; Hock, M. A case for closed-loop recycling of post-consumer PET for automotive foams. Waste Manag. 2017, 95, 388–398. [Google Scholar] [CrossRef]

- Szabó, V.A.; Jakab, S.K.; Kovács, A.; Böcz, T.Z.; Dogossy, G. Use of Hybrid Flame Retardants in Chemically Foamed rPET Blends. Crystals 2025, 15, 80. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, G.; Wang, J.; Wang, G.; Zhang, W. Effects of process parameters on core-back foam injection molding process. Express Polym. Lett. 2019, 13, 390–405. [Google Scholar] [CrossRef]

- ISO 527; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2019.

- ISO 178; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- ISO 179; Plastics—Determination of Charpy impact properties. ISO: Geneva, Switzerland, 2019.

- ISO 9772; Cellular Plastics—Determination of Horizontal Burning Characteristics of Small Specimens Exposed to a Small Flame Ignition Source. ISO: New York, NY, USA, 2020.

- ISO 9773; Plastics—Determination of Burning Behaviour of Thin Flexible Vertical Specimens in Contact with a Small Flame Ignition Source. ISO: New York, NY, USA, 2024.

- Brueckner, E.; Georgi, W.; Gehde, M.; Mayr, P. Relaxation Behavior of Metal-Polymer Hybrid Structures Mechanically Joined by Clinching. In Proceedings of the 75th Annual Technical Conference and Exhibition of the Society of Plastics Engineers, ANTEC 2017, Anaheim, CA, USA, 8–10 May 2017. ISBN 978-0-692-88309-9. [Google Scholar]

- Gómez-Monterde, J. Characterization of Microcellular Plastics for Weight Reduction in Automotive Interior Parts. Ph.D. Thesis, Universitat Politècnica de Catalunya-BarcelonaTech, Barcelona, Spain, 2017; p. 276. [Google Scholar] [CrossRef]

- Matsuura, M.; Tabata, T.; Matsukawa, M.; Hori, M. Biomechanics and Mechanobiology of Trabecular Bone: A Review. J. Biomech. Eng. 2015, 137, 010802. [Google Scholar] [CrossRef]

- Saini, A.; Yadav, C.; Lyu, M.-Y. Cavity Pressure Profile Study during Foam Injection Molding and Its Effect on Cell Formation of Polypropylene/Chemical Blowing Agent Foam. J. Appl. Polym. Sci. 2023, 140, e53643. [Google Scholar] [CrossRef]

| rPET | Calriant CESA Extend | Du-Pont Elovaloy PTW | Tracel IM 7200 | Tracel IM 3170 MS | Clariant Exolit OP 1240 | Budenheim Budit 342 | |

|---|---|---|---|---|---|---|---|

| OP20 | 100 | 2 | 10 | 3 | 1 | 20 | 0 |

| OP15MPP5 | 100 | 2 | 10 | 3 | 1 | 15 | 5 |

| Description | Unit | Value |

|---|---|---|

| Clamping force | kN | 150 |

| Nozzle temperature | °C | 260 |

| Injection pressure | bar | 650 |

| Injection speed | cm3/s | 30 |

| Holding pressure | bar | 150–50–20 |

| Holding pressure time | s | 2–1 |

| Intermediate mold opening | mm | 0.5 |

| Residual cooling after mold opening | s | 20 |

| Mold temperature | °C | 35 |

| Tonset [%] | T-50% [%] | dTGmax [%/°C] | Char Yield [%] | |

|---|---|---|---|---|

| ref | 410 | 469 | 1.93 | 3.8 |

| OP20 | 401 | 464 | 1.59 | 22.1 |

| OP15MPP5 | 371 | 458 | 1.39 | 23.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabó, V.A.; Kovács, A.; Jakab, S.K.; Böcz, T.Z.; Dogossy, G. Automotive Application of Chemically Foamed rPET. Polymers 2025, 17, 1251. https://doi.org/10.3390/polym17091251

Szabó VA, Kovács A, Jakab SK, Böcz TZ, Dogossy G. Automotive Application of Chemically Foamed rPET. Polymers. 2025; 17(9):1251. https://doi.org/10.3390/polym17091251

Chicago/Turabian StyleSzabó, Veronika Anna, András Kovács, Sándor Kálmán Jakab, Tamara Zsuzsanna Böcz, and Gábor Dogossy. 2025. "Automotive Application of Chemically Foamed rPET" Polymers 17, no. 9: 1251. https://doi.org/10.3390/polym17091251

APA StyleSzabó, V. A., Kovács, A., Jakab, S. K., Böcz, T. Z., & Dogossy, G. (2025). Automotive Application of Chemically Foamed rPET. Polymers, 17(9), 1251. https://doi.org/10.3390/polym17091251