Cellulose Extraction from Soybean Hulls and Hemp Waste by Alkaline and Acidic Treatments: An In-Depth Investigation on the Effects of the Chemical Treatments on Biomass

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Extraction of Cellulose from Soybean Hulls

3.1.1. Purification Steps and Yield Measurement

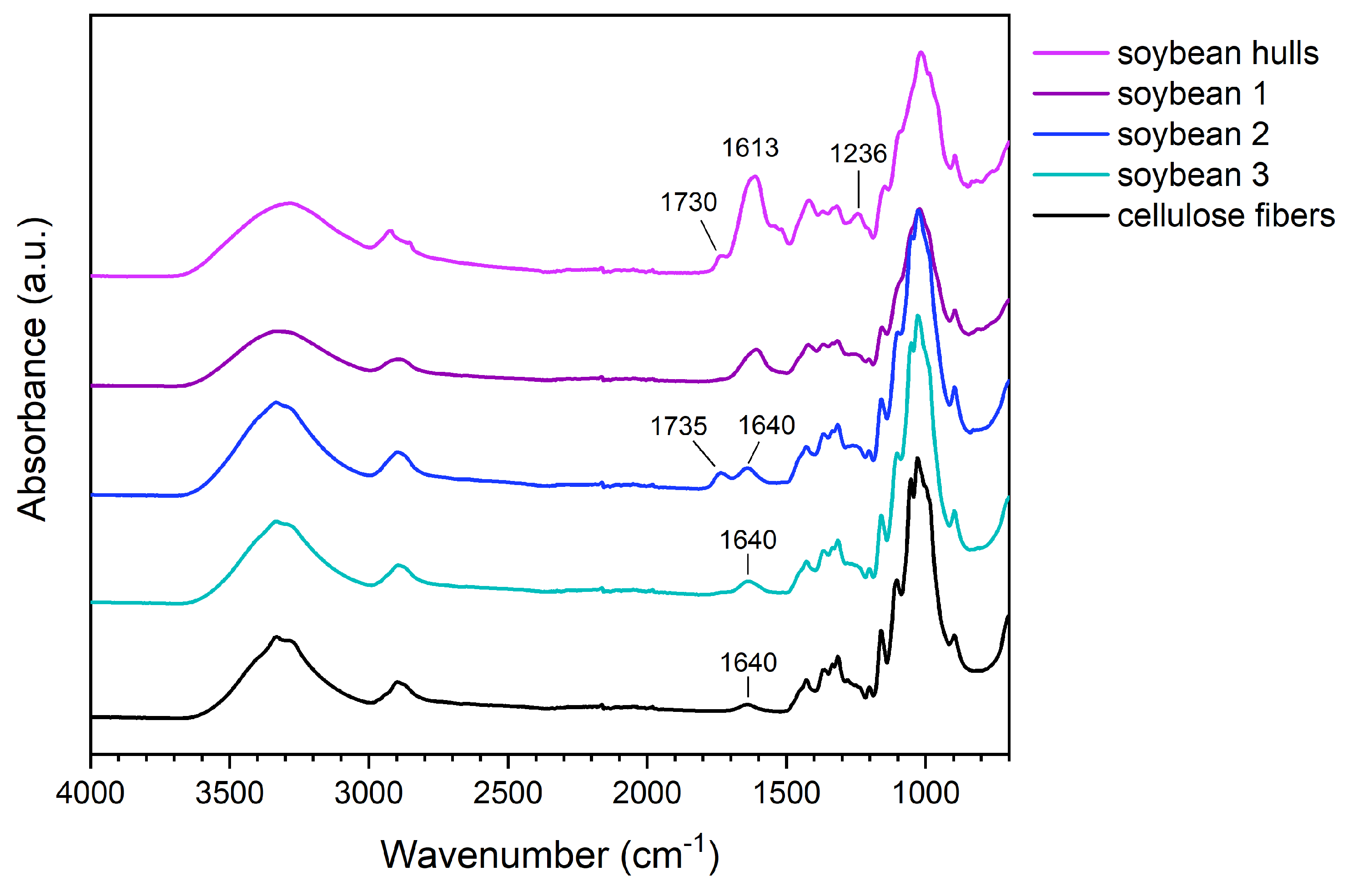

3.1.2. FTIR Spectroscopy

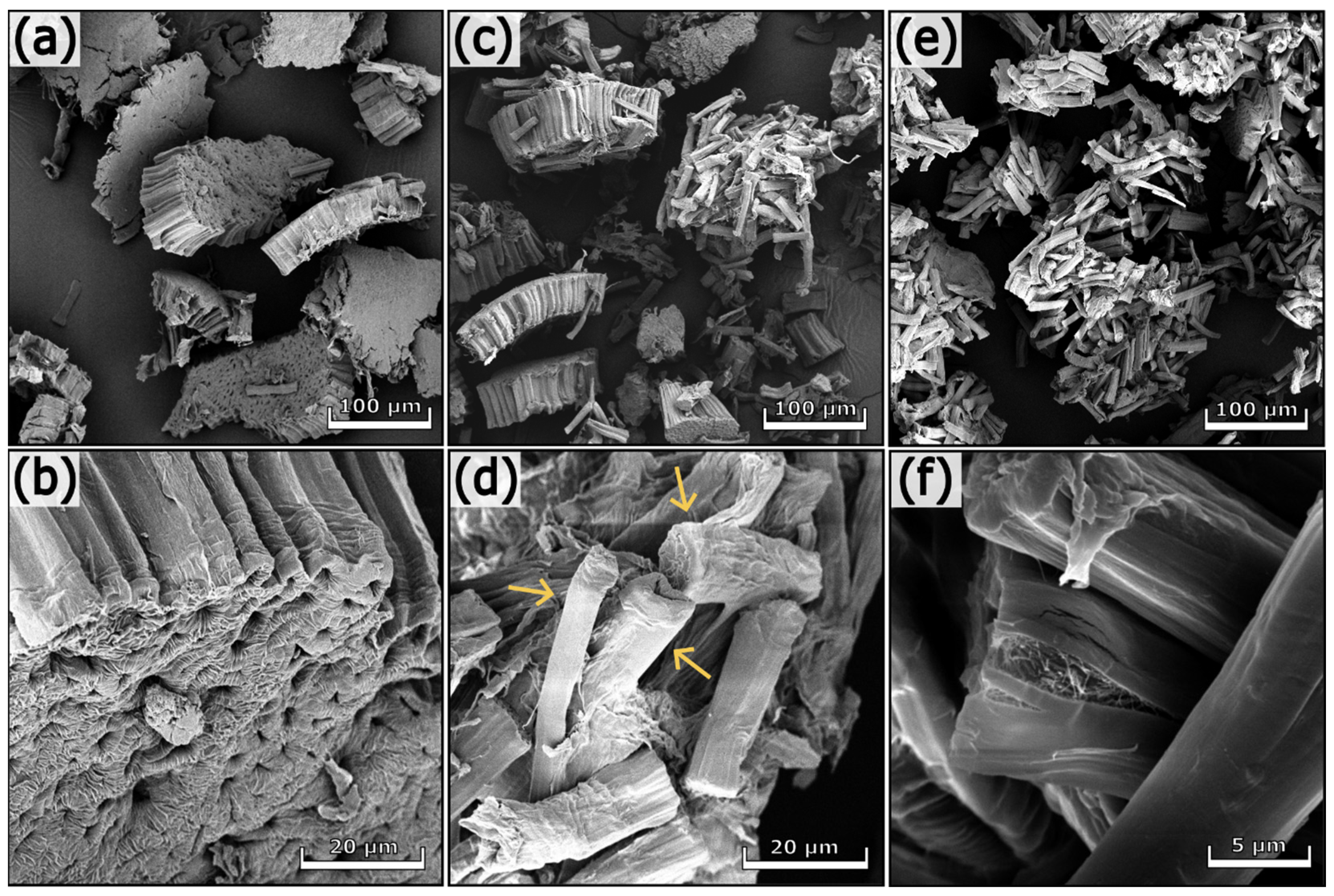

3.1.3. Morphological Analyses

3.1.4. Chemical Composition

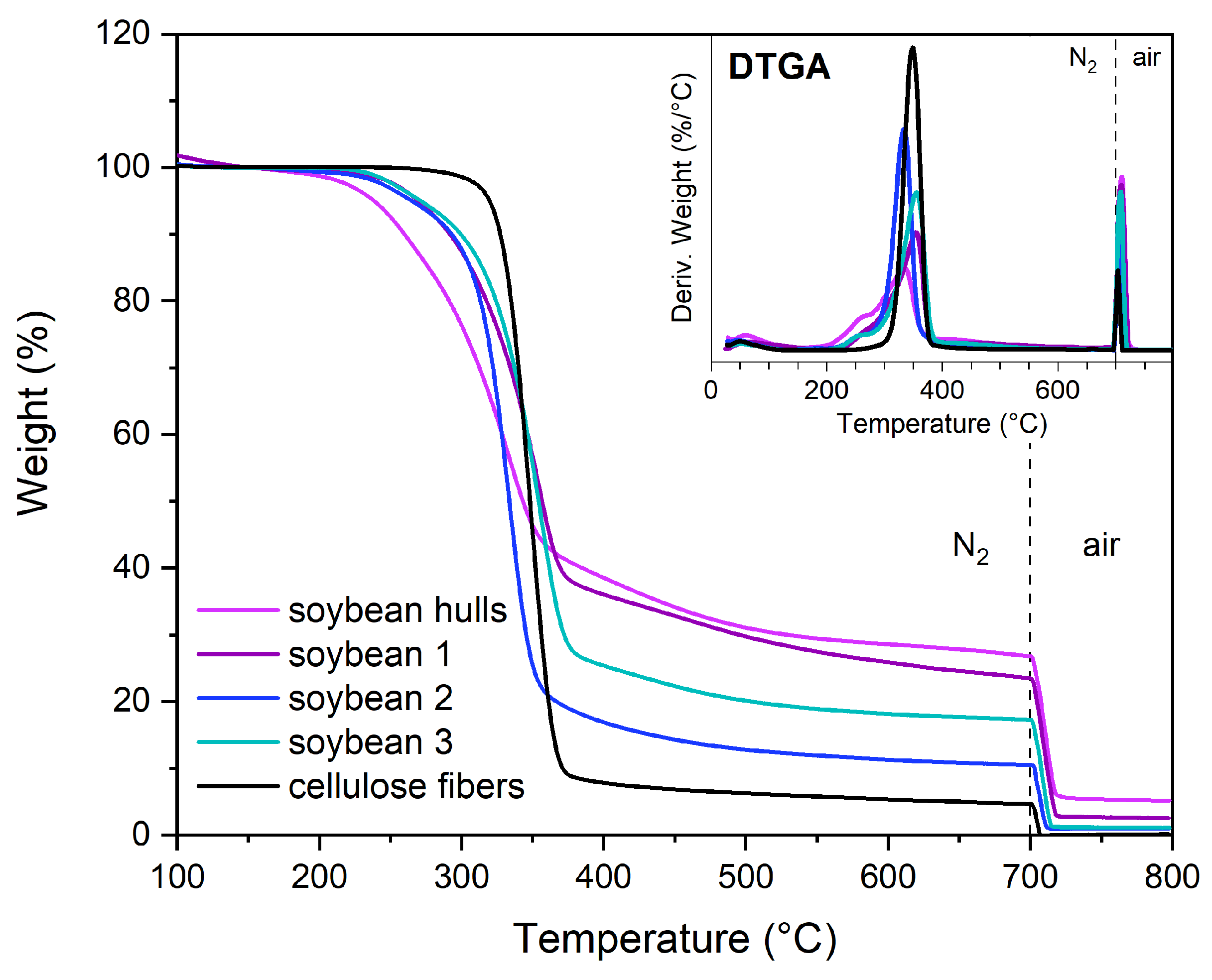

3.1.5. Thermogravimetric Analyses

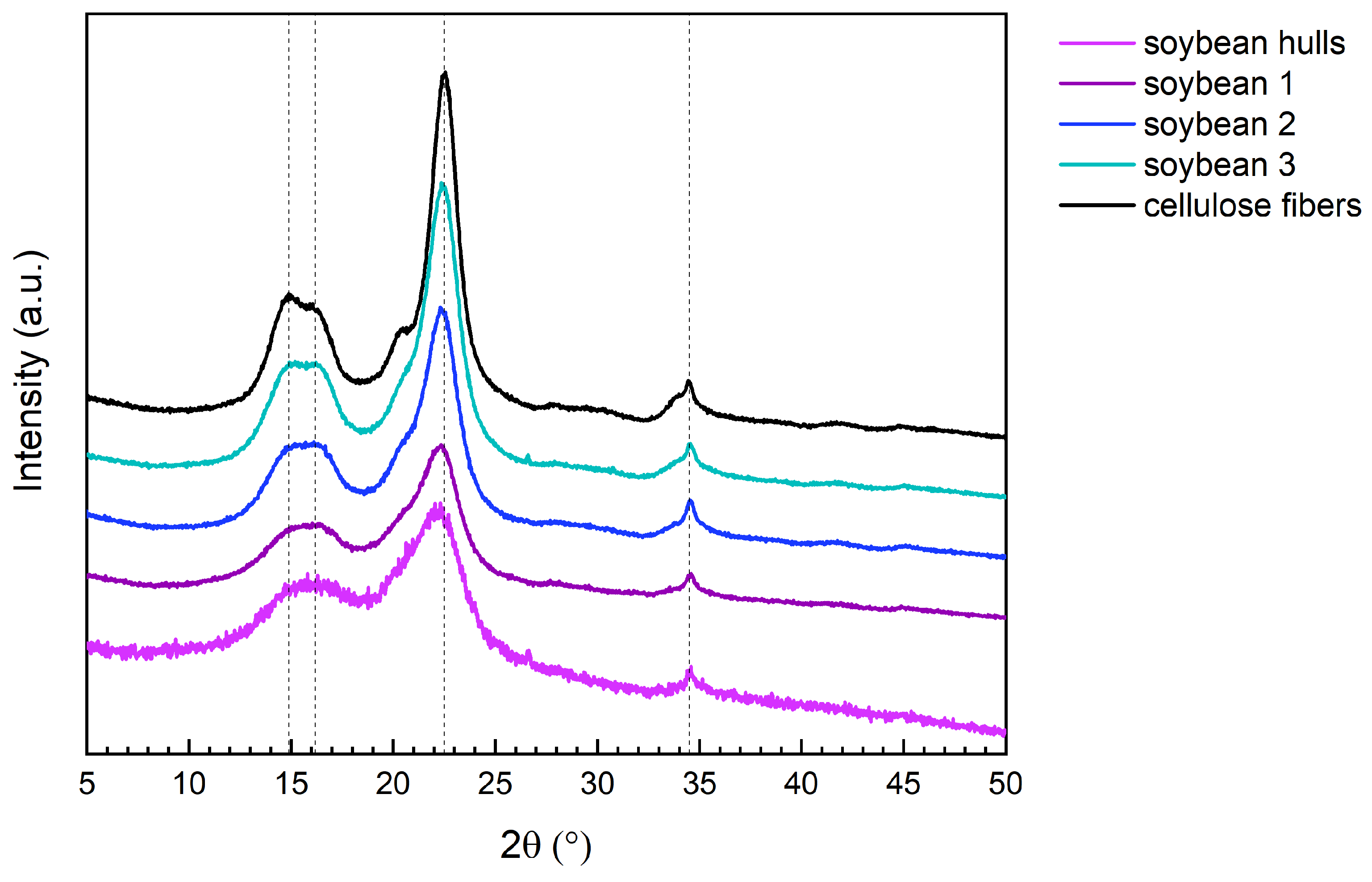

3.1.6. X-Ray Diffraction Results

3.2. Extraction of Cellulose from Hemp Waste

3.2.1. Purification Steps and Yield Measurement

3.2.2. FTIR Spectroscopy

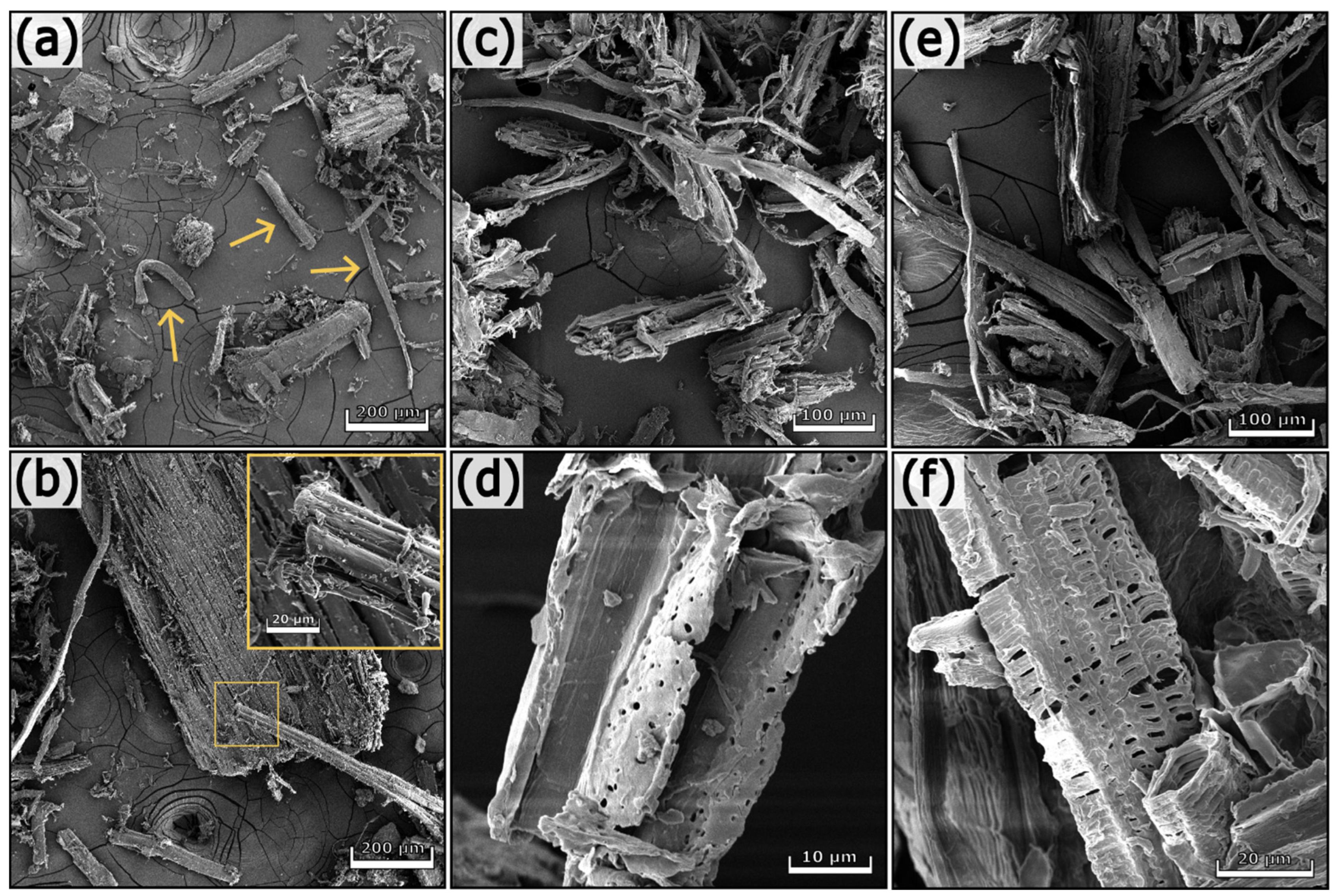

3.2.3. Morphological Analyses

3.2.4. Chemical Composition

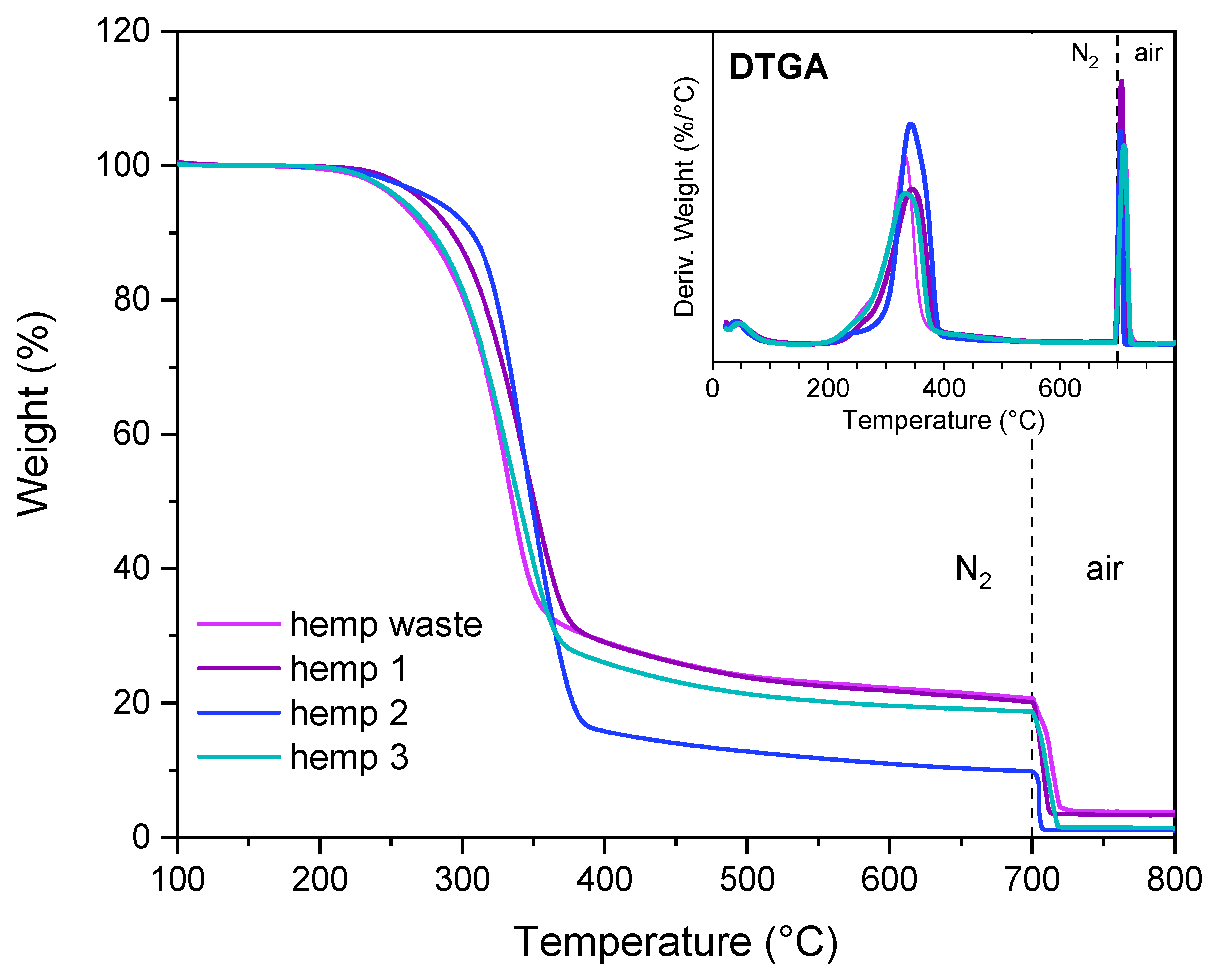

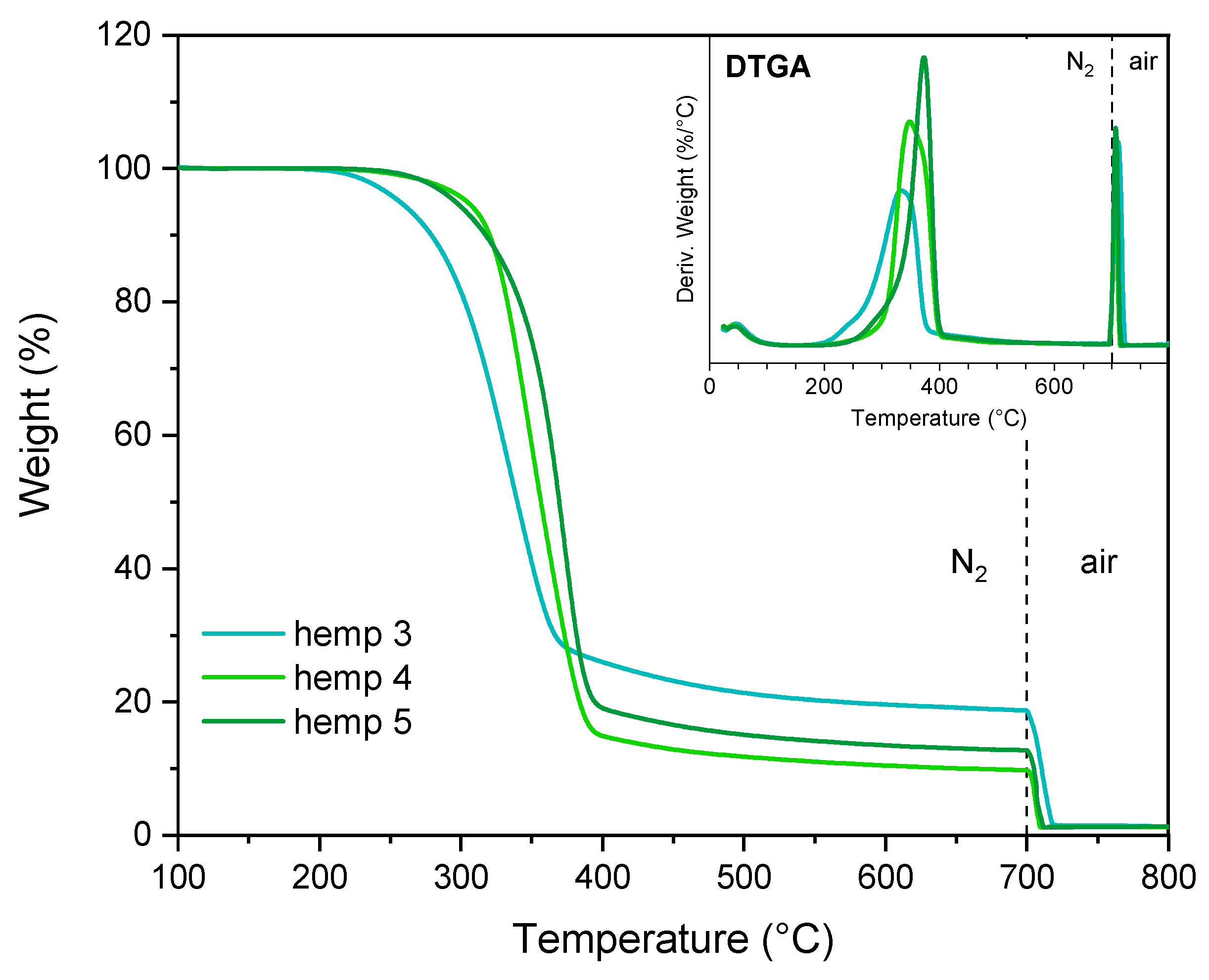

3.2.5. Thermogravimetric Analyses

3.2.6. Lignin Quantification

3.2.7. X-Ray Diffraction Results

4. Perspectives and Challenges

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Spear, M.J.; Eder, A.; Carus, M. Wood Polymer Composites. In Wood Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 195–249. [Google Scholar]

- Alemdar, A.; Sain, M. Isolation and Characterization of Nanofibers from Agricultural Residues—Wheat Straw and Soy Hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef]

- Cao, Y.; Shibata, S.; Fukumoto, I. Mechanical Properties of Biodegradable Composites Reinforced with Bagasse Fibre before and after Alkali Treatments. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 423–429. [Google Scholar] [CrossRef]

- Thomas, S.; Paul, S.A.; Pothan, L.A.; Deepa, B. Natural Fibres: Structure, Properties and Applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–42. [Google Scholar]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted Pre-Treatment of Hemp Bast Fibres for Optimal Performance in Biocomposite Materials: A Review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Zimniewska, M.; Wladyka-Przybylak, M.; Mankowski, J. Cellulosic Bast Fibers, Their Structure and Properties Suitable for Composite Applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 97–119. [Google Scholar]

- Harris, P.J. Nonwood Fibers. In Encyclopedia of Applied Plant Sciences; Elsevier: Amsterdam, The Netherlands, 2017; Volume 1, pp. 198–202. [Google Scholar]

- Carrillo-López, A.; Yahia, E.M. Morphology and Anatomy. In Postharvest Physiology and Biochemistry of Fruits and Vegetables; Elsevier: Amsterdam, The Netherlands, 2019; pp. 113–130. [Google Scholar]

- Hamad, S.F.; Stehling, N.; Holland, C.; Foreman, J.P.; Rodenburg, C. Low-Voltage SEM of Natural Plant Fibers: Microstructure Properties (Surface and Cross-Section) and Their Link to the Tensile Properties. Procedia Eng. 2017, 200, 295–302. [Google Scholar] [CrossRef]

- Heinze, T. Cellulose: Structure and Properties. In Advances in Polymer Science; Springer: New York, NY, USA, 2015; Volume 271, pp. 1–52. [Google Scholar]

- Popescu, C.M. Wood as Bio-Based Building Material. In Performance of Bio-based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 21–96. [Google Scholar]

- Scheller, H.V.; Ulvskov, P. Hemicelluloses. Annu. Rev. Plant Biol. 2010, 61, 263–289. [Google Scholar] [CrossRef]

- Santiago, R.; Barros-Rios, J.; Malvar, R. Impact of Cell Wall Composition on Maize Resistance to Pests and Diseases. Int. J. Mol. Sci. 2013, 14, 6960–6980. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Abdou Alio, M.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.-D.; Callois, J.-M.; Vial, C.; Michaud, P.; et al. Wood-Lignin: Supply, Extraction Processes and Use as Bio-Based Material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Bian, J.; Peng, F.; Peng, X.P.; Xu, F.; Sun, R.C.; Kennedy, J.F. Isolation of Hemicelluloses from Sugarcane Bagasse at Different Temperatures: Structure and Properties. Carbohydr. Polym. 2012, 88, 638–645. [Google Scholar] [CrossRef]

- Farsi, M. Thermoplastic Matrix Reinforced with Natural Fibers: A Study on Interfacial Behavior. In Some Critical Issues for Injection Molding; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural Fiber Eco-Composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Debiagi, F.; Faria-Tischer, P.C.S.; Mali, S. A Green Approach Based on Reactive Extrusion to Produce Nanofibrillated Cellulose from Oat Hull. Waste Biomass Valorization 2021, 12, 1051–1060. [Google Scholar] [CrossRef]

- Merci, A.; Urbano, A.; Grossmann, M.V.E.; Tischer, C.A.; Mali, S. Properties of Microcrystalline Cellulose Extracted from Soybean Hulls by Reactive Extrusion. Food Res. Int. 2015, 73, 38–43. [Google Scholar] [CrossRef]

- Yang, W.; Feng, Y.; He, H.; Yang, Z. Environmentally-Friendly Extraction of Cellulose Nanofibers from Steam-Explosion Pretreated Sugar Beet Pulp. Materials 2018, 11, 1160. [Google Scholar] [CrossRef]

- Osong, S.H.; Norgren, S.; Engstrand, P. Processing of Wood-Based Microfibrillated Cellulose and Nanofibrillated Cellulose, and Applications Relating to Papermaking: A Review. Cellulose 2016, 23, 93–123. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated Cellulose and New Nanocomposite Materials: A Review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Mateo, S.; Peinado, S.; Morillas-Gutiérrez, F.; La Rubia, M.D.; Moya, A.J. Nanocellulose from Agricultural Wastes: Products and Applications—A Review. Processes 2021, 9, 1594. [Google Scholar] [CrossRef]

- Melro, E.; Filipe, A.; Sousa, D.; Valente, A.J.M.; Romano, A.; Antunes, F.E.; Medronho, B. Dissolution of Kraft Lignin in Alkaline Solutions. Int. J. Biol. Macromol. 2020, 148, 688–695. [Google Scholar] [CrossRef]

- Ventura-Cruz, S.; Tecante, A. Nanocellulose and Microcrystalline Cellulose from Agricultural Waste: Review on Isolation and Application as Reinforcement in Polymeric Matrices. Food Hydrocoll. 2021, 118, 106771. [Google Scholar] [CrossRef]

- USDA. Production–Soybeans. Available online: https://www.fas.usda.gov/data/production/commodity/2222000 (accessed on 3 February 2025).

- Liu, H.-M.; Li, H.-Y. Application and Conversion of Soybean Hulls. In Soybean—The Basis of Yield, Biomass and Productivity; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Rosso, D.F.; Negrão, D.R.; Driemeier, C. Unveiling the Variability and Multiscale Structure of Soybean Hulls for Biotechnological Valorization. Waste Biomass Valorization 2022, 13, 2095–2108. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- EU Hemp. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 3 February 2025).

- Teirumnieka, E.; Patel, N.; Laktuka, K.; Dolge, K.; Veidenbergs, I.; Blumberga, D. Sustainability Dilemma of Hemp Utilization for Energy Production. Energy Nexus 2023, 11, 100213. [Google Scholar] [CrossRef]

- Väisänen, T.; Kilpeläinen, P.; Kitunen, V.; Lappalainen, R.; Tomppo, L. Effect of Steam Treatment on the Chemical Composition of Hemp (Cannabis sativa L.) and Identification of the Extracted Carbohydrates and Other Compounds. Ind. Crops Prod. 2019, 131, 224–233. [Google Scholar] [CrossRef]

- Simpson, M.G. Plant Anatomy and Physiology. In Plant Systematics; Elsevier: Amsterdam, The Netherlands, 2019; pp. 537–566. [Google Scholar]

- Bhatnagar, A.; Sain, M. Processing of Cellulose Nanofiber-Reinforced Composites. J. Reinf. Plast. Compos. 2005, 24, 1259–1268. [Google Scholar] [CrossRef]

- Flauzino Neto, W.P.; Silvério, H.A.; Dantas, N.O.; Pasquini, D. Extraction and Characterization of Cellulose Nanocrystals from Agro-Industrial Residue—Soy Hulls. Ind. Crops Prod. 2013, 42, 480–488. [Google Scholar] [CrossRef]

- Sinclair, A.; Jiang, L.; Bajwa, D.; Bajwa, S.; Tangpong, S.; Wang, X. Cellulose Nanofibers Produced from Various Agricultural Residues and Their Reinforcement Effects in Polymer Nanocomposites. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Rigoletto, M.; Calza, P.; Santuchi da Cunha, A.; Sederino, V.; Fabbri, D.; Tummino, M.L.; Laurenti, E. Soybean Peroxidase Immobilised on Cellulose-Alginate Hydrogels for Removal of Recalcitrant Organic Pollutants in Water. React. Chem. Eng. 2023, 8, 1629–1637. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry. TAPPI T222 om-02 Acid-Insoluble Lignin in Wood and Pulp; Official Test Method 2006. Available online: https://scirp.org/reference/referencespapers?referenceid=2951782 (accessed on 4 April 2025).

- Lu, F.; Wang, C.; Chen, M.; Yue, F.; Ralph, J. A Facile Spectroscopic Method for Measuring Lignin Content in Lignocellulosic Biomass. Green. Chem. 2021, 23, 5106–5112. [Google Scholar] [CrossRef]

- de Souza, A.G.; Junqueira, M.T.; de Lima, G.F.; Rangari, V.K.; Rosa, D.S. A New Proposal of Preparation of Different Polymorphs of Nanocellulose from Eucalyptus Citriodora. J. Polym. Environ. 2020, 28, 1150–1159. [Google Scholar] [CrossRef]

- Huang, C.; Yu, H.; Abdalkarim, S.Y.H.; Li, Y.; Chen, X.; Yang, X.; Zhou, Y.; Zhang, L. A Comprehensive Investigation on Cellulose Nanocrystals with Different Crystal Structures from Cotton via an Efficient Route. Carbohydr. Polym. 2022, 276, 118766. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose Crystallinity Index: Measurement Techniques and Their Impact on Interpreting Cellulase Performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- Dence, C.W. The Determination of Lignin. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 33–61. [Google Scholar] [CrossRef]

- Chatjigakis, A.K.; Pappas, C.; Proxenia, N.; Kalantzi, O.; Rodis, P.; Polissiou, M. FT-IR Spectroscopic Determination of the Degree of Esterification of Cell Wall Pectins from Stored Peaches and Correlation to Textural Changes. Carbohydr. Polym. 1998, 37, 395–408. [Google Scholar] [CrossRef]

- Kostryukov, S.G.; Matyakubov, H.B.; Masterova, Y.Y.; Kozlov, A.S.; Pryanichnikova, M.K.; Pynenkov, A.A.; Khluchina, N.A. Determination of Lignin, Cellulose, and Hemicellulose in Plant Materials by FTIR Spectroscopy. J. Anal. Chem. 2023, 78, 718–727. [Google Scholar] [CrossRef]

- Poletto, M.; Pistor, V.; Santana, R.M.C.; Zattera, A.J. Materials Produced from Plant Biomass: Part II: Evaluation of Crystallinity and Degradation Kinetics of Cellulose. Mater. Res. 2012, 15, 421–427. [Google Scholar] [CrossRef]

- Sain, M.M.; Bhatnagar, A. Manufacturing of Nano-Fibrils from Natural Fibres, Agro Based Fibres and Root Fibres. CA 2437616, 4 February 2005.

- Liu, Q.; He, W.-Q.; Aguedo, M.; Xia, X.; Bai, W.-B.; Dong, Y.-Y.; Song, J.-Q.; Richel, A.; Goffin, D. Microwave-Assisted Alkali Hydrolysis for Cellulose Isolation from Wheat Straw: Influence of Reaction Conditions and Non-Thermal Effects of Microwave. Carbohydr. Polym. 2021, 253, 117170. [Google Scholar] [CrossRef] [PubMed]

- Shao, S.; Meyer, C.J.; Ma, F.; Peterson, C.A.; Bernards, M.A. The Outermost Cuticle of Soybean Seeds: Chemical Composition and Function during Imbibition. J. Exp. Bot. 2007, 58, 1071–1082. [Google Scholar] [CrossRef]

- Tummino, M.L.; Laurenti, E.; Bracco, P.; Cecone, C.; Parola, V.L.; Vineis, C.; Testa, M.L. Antibacterial Properties of Functionalized Cellulose Extracted from Deproteinized Soybean Hulls. Cellulose 2023, 30, 7805–7824. [Google Scholar] [CrossRef]

- Kawamoto, H. Lignin Pyrolysis Reactions. J. Wood Sci. 2017, 63, 117–132. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi, H.; Zattera, A. Native Cellulose: Structure, Characterization and Thermal Properties. Materials 2014, 7, 6105–6119. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Kukuruzović, J.; Matin, A.; Kontek, M.; Krička, T.; Matin, B.; Brandić, I.; Antonović, A. The Effects of Demineralization on Reducing Ash Content in Corn and Soy Biomass with the Goal of Increasing Biofuel Quality. Energies 2023, 16, 967. [Google Scholar] [CrossRef]

- Asadieraghi, M.; Wan Daud, W.M.A. Characterization of Lignocellulosic Biomass Thermal Degradation and Physiochemical Structure: Effects of Demineralization by Diverse Acid Solutions. Energy Convers. Manag. 2014, 82, 71–82. [Google Scholar] [CrossRef]

- Penttilä, P. Structural Characterisation of Cellulosic Materials Using X-Ray and Neutron. Scattering.Ph.D. Thesis, University of Helsinki, Helsinki, Finland, 1 November 2013. [Google Scholar]

- Hyman, D.; Sluiter, A.; Crocker, D.; Johnson, D.; Sluiter, J.; Black, S.; Scarlata, C. Determination of Acid Soluble Lignin Concentration Curve by UV-Vis Spectroscopy: Laboratory Analytical Procedure (LAP); Technical Report (NREL/TP-510-42617); National Renewable Energy Laboratory: Denver, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP); Technical Report (NREL/TP-510-42618); National Renewable Energy Laboratory: Denver, CO, USA, 2012. [Google Scholar]

- Martelli-Tosi, M.; Assis, O.B.G.; Silva, N.C.; Esposto, B.S.; Martins, M.A.; Tapia-Blácido, D.R. Chemical Treatment and Characterization of Soybean Straw and Soybean Protein Isolate/Straw Composite Films. Carbohydr. Polym. 2017, 157, 512–520. [Google Scholar] [CrossRef]

- Lu, N.; Swan, R.H.; Ferguson, I. Composition, Structure, and Mechanical Properties of Hemp Fiber Reinforced Composite with Recycled High-Density Polyethylene Matrix. J. Compos. Mater. 2012, 46, 1915–1924. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. Cellulose Reinforced Polymer Composites and Nanocomposites: A Critical Review. Cellulose 2013, 20, 2221–2262. [Google Scholar] [CrossRef]

- Testa, M.L.; Pandoli, O.G.; Cecone, C.; Laurenti, E.; La Parola, V.; Vineis, C.; Tummino, M.L. Sustainable Grafting of (Ligno)Cellulose-Based Powders with Antibacterial Functionalities: Effect of Biomass Type and Synthesis Conditions. Adv. Sustain. Syst. 2025, 9, 2400710. [Google Scholar] [CrossRef]

| Recovered Biomass (%) | Step Yield% (Wet Biomass) | Step Yield% (Dry Biomass *) | |

|---|---|---|---|

| Soybean 1 | 53 | 53 | 57 |

| Soybean 2 | 46 | 86 | 85 |

| Soybean 3 | 35 | 76 | 77 |

| N (%) | C (%) | H (%) | |

|---|---|---|---|

| soybean hulls | 1.60 ± 0.03 a | 40.58 ± 0.12 a | 5.95 ± 0.03 a |

| soybean 1 | 0.18 ± 0.01 b | 40.89 ± 0.09 b | 6.07 ± 0.05 b |

| soybean 2 | 0.16 ± 0.01 b | 42.45 ± 0.09 c | 6.18 ± 0.02 c |

| soybean 3 | 0.16 ± 0.04 b | 42.13 ± 0.12 d | 6.13 ± 0.01 b |

| cellulose fibers | - | 42.86 ± 0.08 e | 6.27 ± 0.07 c |

| CI (%) | |

|---|---|

| soybean hulls | 64 |

| soybean 1 | 74 |

| soybean 2 | 84 |

| soybean 3 | 87 |

| cellulose fibers | 92 |

| Recovered Biomass (%) | Step Yield% | |

|---|---|---|

| Hemp 1 | 75 | 75 |

| Hemp 2 | 67 | 88 |

| Hemp 3 | 57 | 86 |

| Hemp 4 | 53 | 92 |

| Hemp 5 | 47 | 88 |

| N (%) | C (%) | H (%) | |

|---|---|---|---|

| hemp waste | 0.65 ± 0.01 a | 43.11 ± 0.03 a | 5.92 ± 0.13 a,b |

| hemp 1 | 0.22 ± 0.01 b | 42.73 ± 0.12 b | 5.82 ± 0.03 a |

| hemp 2 | 0.21 ± 0.01 b | 44.22 ± 0.14 c | 5.95 ± 0.04 b |

| hemp 3 | 0.17 ± 0.01 c | 43.91 ± 0.08 d | 5.98 ± 0.07 b |

| hemp 4 | 0.18 ± 0.01 c | 44.35 ± 0.14 c,e | 5.95 ± 0.07 b |

| hemp 5 | 0.17 ± 0.01 c | 44.48 ± 0.07 e | 5.95 ± 0.05 b |

| CI (%) | |

|---|---|

| hemp waste | 79 |

| hemp 1 | 84 |

| hemp 2 | 86 |

| hemp 3 | 86 |

| hemp 4 | 87 |

| hemp 5 | 87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moramarco, A.; Ricca, E.; Acciardo, E.; Laurenti, E.; Bracco, P. Cellulose Extraction from Soybean Hulls and Hemp Waste by Alkaline and Acidic Treatments: An In-Depth Investigation on the Effects of the Chemical Treatments on Biomass. Polymers 2025, 17, 1220. https://doi.org/10.3390/polym17091220

Moramarco A, Ricca E, Acciardo E, Laurenti E, Bracco P. Cellulose Extraction from Soybean Hulls and Hemp Waste by Alkaline and Acidic Treatments: An In-Depth Investigation on the Effects of the Chemical Treatments on Biomass. Polymers. 2025; 17(9):1220. https://doi.org/10.3390/polym17091220

Chicago/Turabian StyleMoramarco, Antonella, Edoardo Ricca, Elisa Acciardo, Enzo Laurenti, and Pierangiola Bracco. 2025. "Cellulose Extraction from Soybean Hulls and Hemp Waste by Alkaline and Acidic Treatments: An In-Depth Investigation on the Effects of the Chemical Treatments on Biomass" Polymers 17, no. 9: 1220. https://doi.org/10.3390/polym17091220

APA StyleMoramarco, A., Ricca, E., Acciardo, E., Laurenti, E., & Bracco, P. (2025). Cellulose Extraction from Soybean Hulls and Hemp Waste by Alkaline and Acidic Treatments: An In-Depth Investigation on the Effects of the Chemical Treatments on Biomass. Polymers, 17(9), 1220. https://doi.org/10.3390/polym17091220