1. Introduction

Additive manufacturing (AM) has emerged as a promising technique in industry, manufacturing customised 3D parts in a cost-effective manner. In this context, fused deposition modelling (FDM) is an economical and flexible process that consists of forming parts by extrusion of melted filament deposited layer by layer, to create the designed geometry without wasting material as in other technologies like moulding or casting [

1]. In the biomedical field, FDM has been shown to be a potential alternative for manufacturing medical devices as it can print 3D unique fully adapted to the patient products, even with complex geometries, such as synthetic bone models [

2,

3], dentistry products [

4] and tissue scaffolds [

5]. Moreover, FDM allows for the use of a wide variety of biocompatible materials compared to other AM techniques, which makes it possible to choose the material with the most optimal properties for the desired application, as long as the melting point and viscosity are low enough to enable extrusion [

1,

6], reducing the FDM market mainly to thermoplastics. At a time when the environment is an important issue, this technology also allows for the use of sustainable and environmental materials, including biodegradable and bio-based materials. In this field, polylactic acid (PLA) stands out among all the FDM materials as one of the most promising and used biodegradable polymers [

4,

6,

7,

8,

9,

10].

PLA is a bioabsorbable and biocompatible thermoplastic made of natural resources such as corn or sugar cane [

11,

12]. Among its features, it is recognised as a safe material for clinical use [

3], approved by the U.S. Food and Drug Administration [

13], which highlights its thermal stability, elasticity and non-toxicity [

12]. However, this semi-crystalline polymer presents some drawbacks, such as high hydrophobicity, poor bioactivity, low degradation rate and, although the mechanical properties are favourable with an elastic module similar to bone, they are not sufficient for functionality [

6,

12,

13,

14,

15]. In addition, taking into account the weak bonds created during the material deposition [

7], most of the 3D printed parts are used only for prototypes and not as a final part [

1,

16]. Due to the optimal relation between the ease of printing PLA and the quality of the parts, even for complex geometries, there are multiple manufacturers of filament spools and printers for this widely used material, which leads to the fact that there is no well-established method to extrude PLA [

8]. Therefore, different authors agree that controlling the composition, sintering process, crystallinity and molecular weight of PLA is key to optimising its properties, demonstrating that small variations have a direct impact on the main properties of this widespread polymer, in particular mechanical strength, degradation rate and bioactivity [

10,

17,

18,

19]. Among the different alternatives for finding the improvement, adjusting the formula of PLA composites seems to be a method to find a biomechanical improvement [

18], therefore, different authors have tested different combinations, such as PLA with Zirconium Dioxide (ZrO

2) [

4], poly(ε-caprolactone) (PCL) [

11] and poly(3-hydroxybutyrate) (PHB) [

8]. Two of the most promising combinations are PLA–Hydroxyapatite [

18] and PLA–Magnesium [

13,

15]. These two materials are particularly interesting for bone regeneration applications, as they are resorbable by the human body, promote bone regeneration and can be 3D printed using FDM methods, allowing professionals to obtain cost-effective and customised parts for technical applications such as orthopaedic implants [

3,

15].

Hydroxyapatite (HA) is a biocompatible ceramic obtained from natural resources. Its surface simulates the appearance of bones and teeth [

6], is highly bioactive and promotes the adhesion of proteins [

6]. Nevertheless, it exhibits poor mechanical strength, brittleness and a slow degradation rate [

12,

14]. However, when mixed in a PLA matrix, it might create a biocompatible and resorbable composite and stands out as one of the most exciting combinations in the medical field, as it enhances osteoconduction and bone formation [

2,

3,

14]. Regarding internal geometry, the introduction of HA reduces the accumulation of defects of PLA [

2], without generating internal porosity [

12]. In terms of functionality, it increases bioactivity and osteoinductivity, presenting good absorbability, hydrophilicity and biocompatibility [

1,

3,

14]. Finally, regarding mechanical properties, it increases the crack resistance, compressive strength, bending strength and elastic modulus [

12,

18,

20]. Despite the improvements of this material, the optimum properties are not yet achieved [

14]. In particular, it is estimated that for simulating the human cortical bone, the HA wt. should be higher [

2,

3,

12], a complicated parameter as it leads to an increase in porosity that deteriorates mechanical resistance [

12] and printing is more challenging when the wt.% of HA is increased [

2,

3].

On the other hand, magnesium (Mg) is a biodegradable and biocompatible metal that is essential in the human body, as it plays a key role in the metabolism [

15]. Although Mg shows a high mechanical strength and stiffness, with an antibacterial property to prevent infections [

21], it is limited by its high degradation rate. Accordingly, some authors have found that the mixture of PLA with Mg is favourable; Mg neutralises the hydrolysis of the PLA matrix while PLA stabilises Mg and controls its degradation rate and corrosion, thus demonstrating the combination of Mg-reinforced PLA (PLA–Mg) composite as a powerful alternative [

13,

21,

22,

23]. In terms of mechanical properties, the composite improves compressive strength and stiffness [

15]. Regarding functionality, PLA–Mg improves osteoconduction and osteointegration [

23]. However, although Mg could be used as a multifunctional filler, increasing mechanical, degradation and biological properties [

24], this material still has certain disadvantages, because the presence of Mg still produces cracks in the structure, releasing oxygen that can cause irritation and the loss of 60% of mechanical strength in only 28 days [

21].

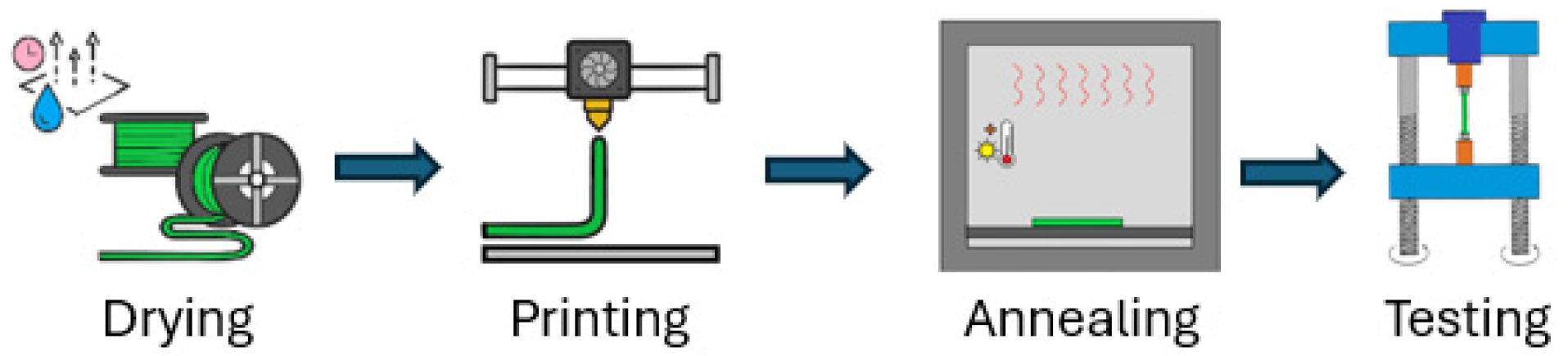

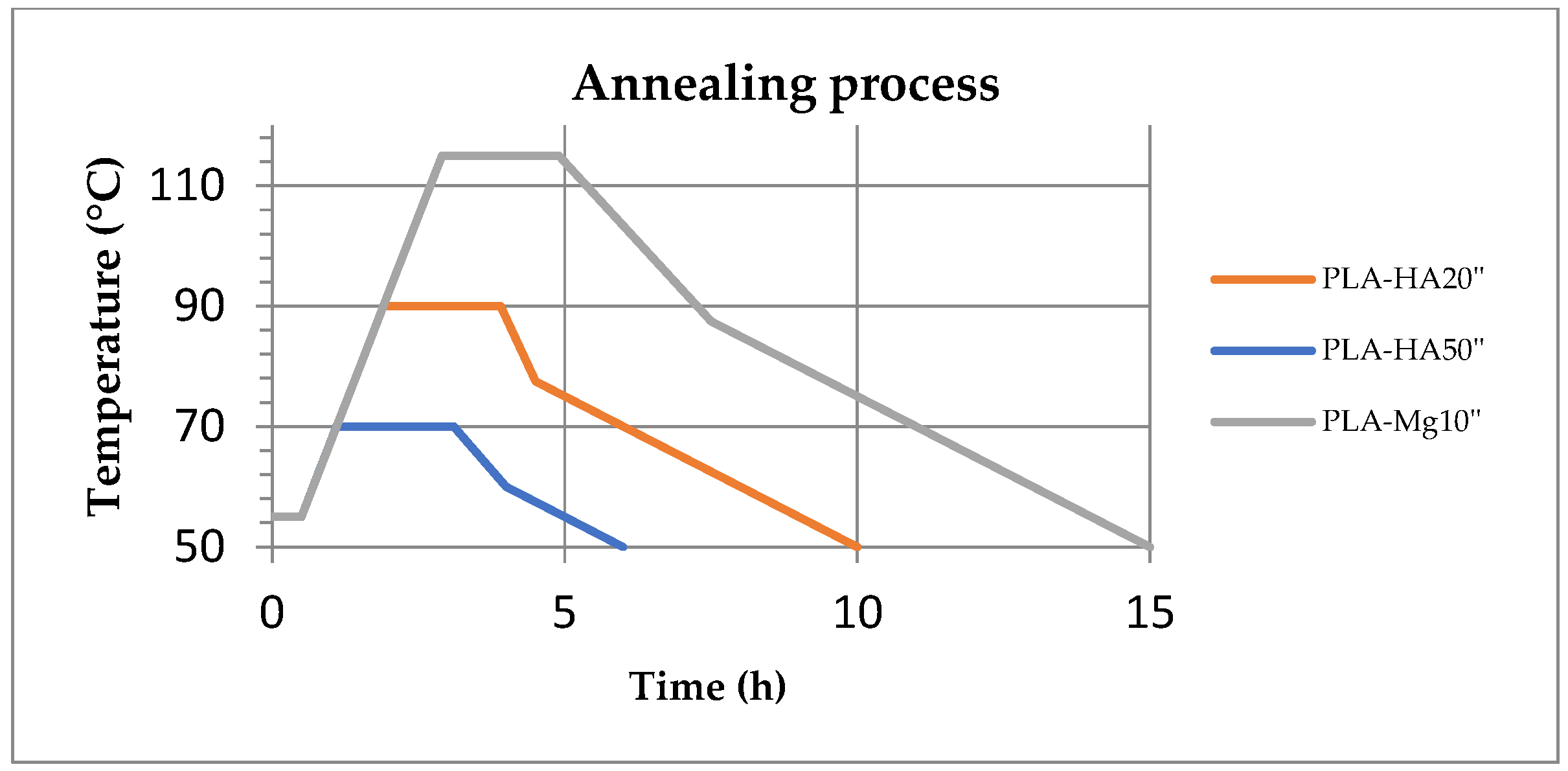

Although the composites introduced improve the performance of final pieces in comparison to raw PLA, a feasible material has not been found yet. As a result, post-processing seems to be required for improving the properties [

8], thermal annealing being a simple and highly efficient method [

17]. Annealing consists of heating the polymer at a temperature higher than the glass transition (Tg) and lower than the melting point (Tm) for a specific time [

16] to boost diffusion between particles, which leads to molecular reorganisation, decreasing imperfections between layers [

16] and increasing the degree of crystallinity [

3,

8,

17], which is directly related to mechanical properties because of the semicrystalline structure of these materials [

25,

26]. As a result, it reduces the residual stress caused during the manufacturing process [

7], leading to modification of the chemical and physical properties, including optical, thermal, electrical, mechanical and rheological performance, as well as hydrolysis and degradation rate [

7,

17,

27].

Some authors highlight the benefits of composites of PLA–Mg and PLA–HA over pure material [

3,

12,

13,

14,

15,

18,

20,

21], while others focus on optimising the manufacturing process or the post-processing of composites [

8,

16]. However, although in the literature it is mentioned that composites with concretions higher than 5% should be improved, as well as the FDM process optimised [

17], not many articles that combine both techniques have been found at the time of writing, and other authors agree that these materials are not yet thoroughly studied [

3,

22]. The crystallisation process of polylactic acid chains is a widely studied topic, since different methods, among which the controlled cooling rate after annealing and the introduction of nanoparticles stand out, have been used to increase the degree of crystallinity of these monomer units. In particular, changes in composition caused by these treatments, as well as the improvement of physical and chemical properties, are well-known and documented, but the reference to the mechanical properties that will directly determine which material can be used for each application and working conditions is often lost [

5,

7,

9]. Therefore, the aim of this study is to evaluate the effects of annealing on the mechanical properties of the composites made of PLA mixed with HA and Mg, both with concentrations higher than 5%, to find an improvement in their mechanical performance to optimise the use of these composites in medical applications.

4. Conclusions

This study focuses on the mechanical analysis of two composites with a high filler concentration of nanocomposites, PLA–HA and PLA–Mg, under different annealing conditions, which are of interest for medical applications in which temporary resorbable implants are required.

On the one hand, it can be determined that the composition of the PLA mixture has a stronger influence on the mechanical performance than the thermal treatment of the polymer, since it is observed that the wt.% of HA added has a direct effect on the performance, worsening the mechanical properties when exceeding the concentration of this ceramic. As a result, PLA with 50% HA presents worse mechanical properties than the 20% HA composite, being a much more fragile material even though the osteosynthesis may be considered better due to the higher concentration of hydroxyapatite. In terms of cooling rate and mechanical properties, in the flexure, compressive radial and tensile analyses of PLA–HA20, it has been observed that the mechanical behaviour is consistent with the physical and chemical behaviour described in the literature since controlled cooling gives better results than cooling at room temperature after annealing. As a conclusion, it seems advisable to define heating and cooling rates for each combination of polymers.

Thus, we have been able to verify that annealing is detrimental to the PLA and Mg composite, making it more fragile and worsening its tensile and flexural strength, as well as the radial force supported.

In conclusion, it can be determined that there is no gold standard combination of material composition and an annealing process that enhances all mechanical properties at the same time. Therefore, it will be necessary to define the desired properties and requirements for each application in order to determine the material with the most optimal composition and treatment, according to mechanical and functional needs.