Deformation of Polyethylene Subjected to Static and Nonstatic Stresses and Krypton Ions Irradiation

Abstract

1. Introduction

2. Experimental Methods

3. Research Results

4. Conclusions

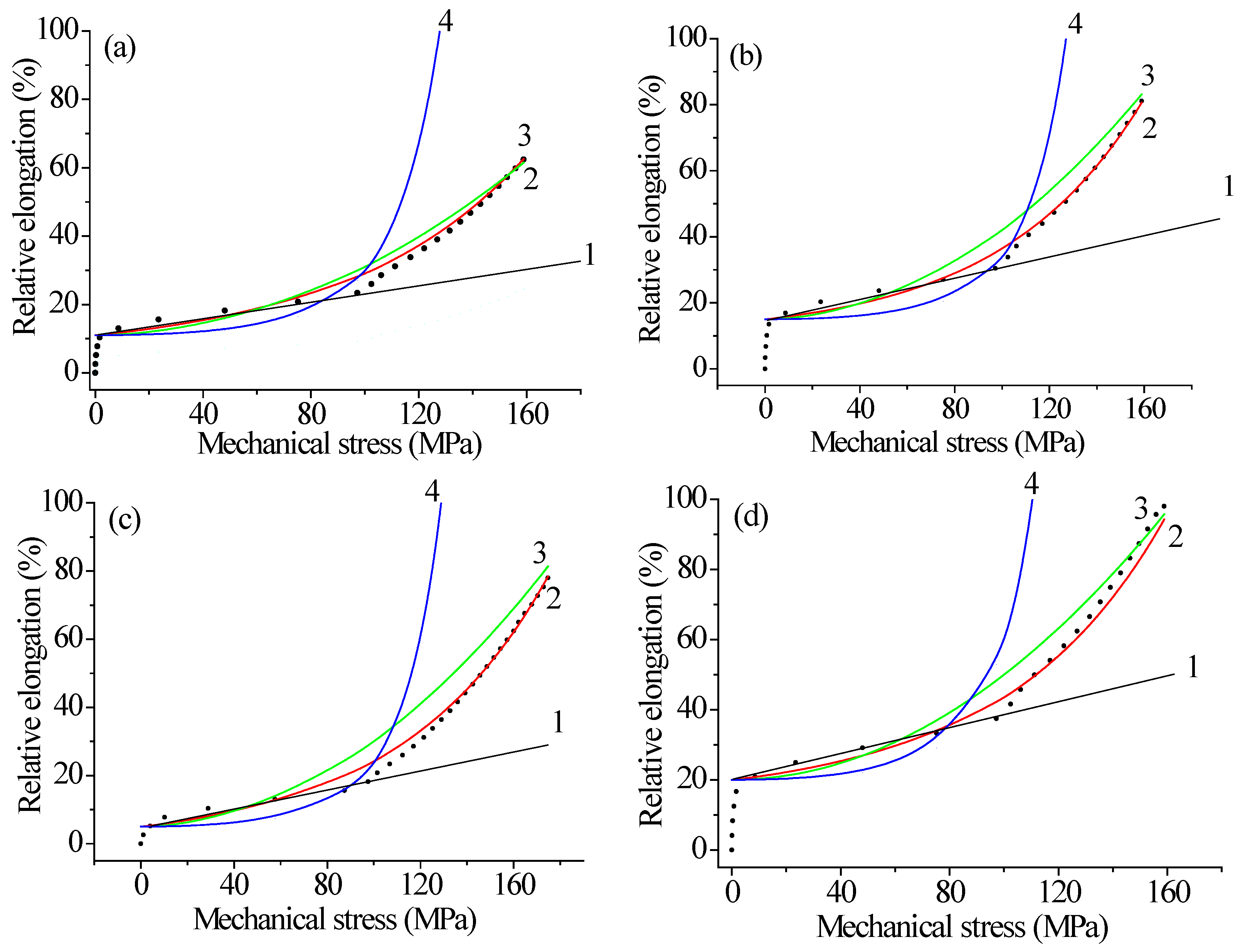

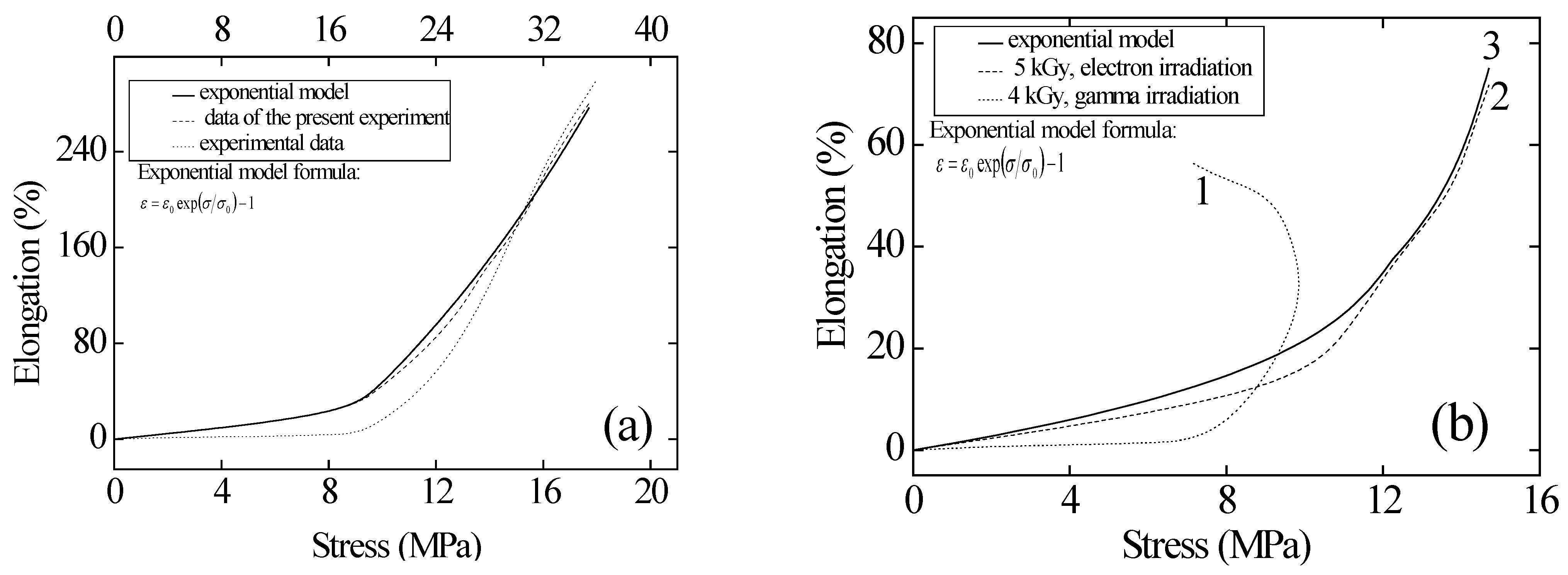

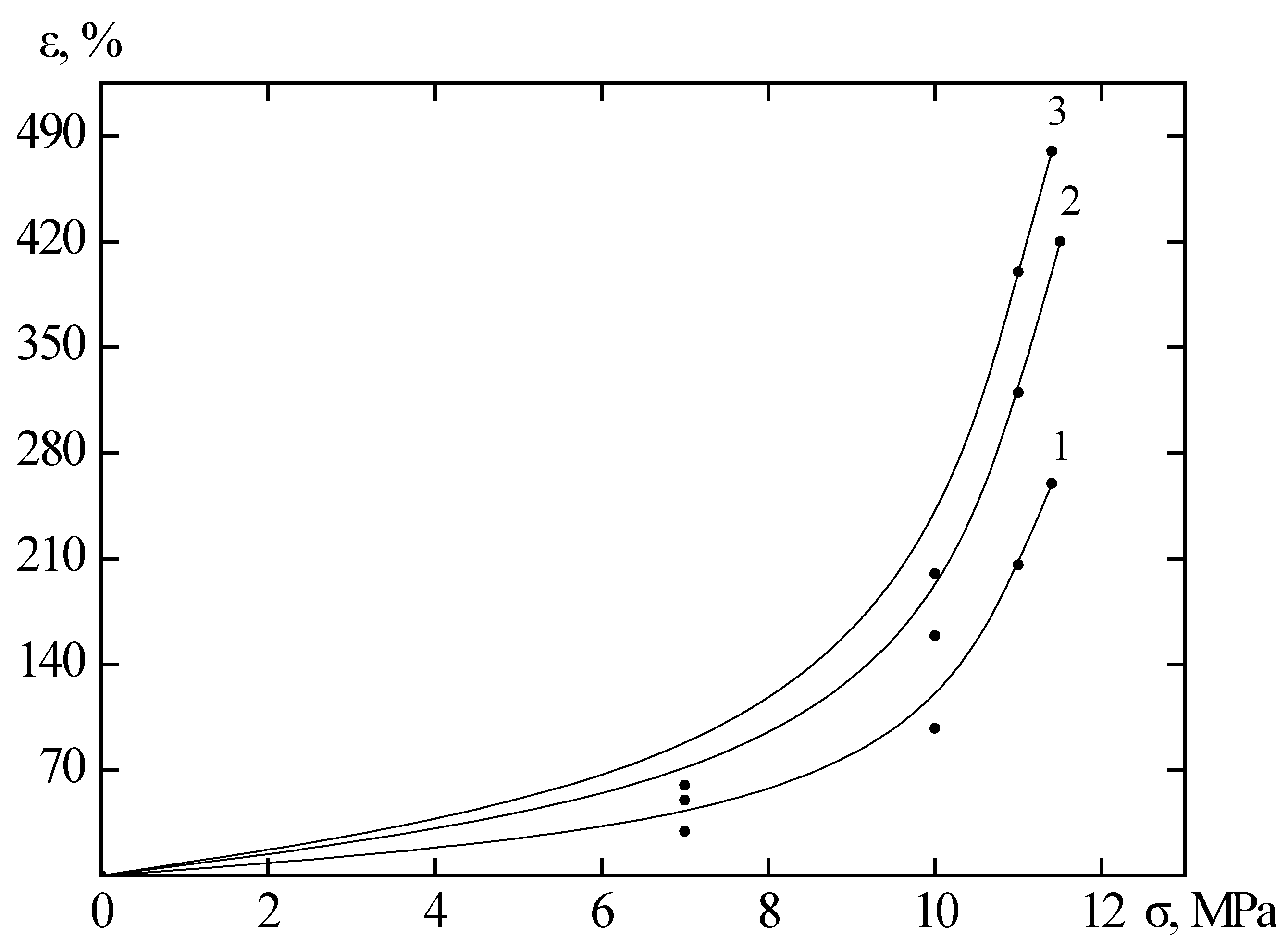

- Tensile tests conducted on irradiated and unirradiated polyethylene (PE) samples demonstrated a clear relationship between deformation and mechanical stress. Within the elastic range, deformation increases linearly following Hooke’s law before transitioning to exponential growth as stress rises. Irradiation significantly influences the deformation and strength properties of polyethylene.

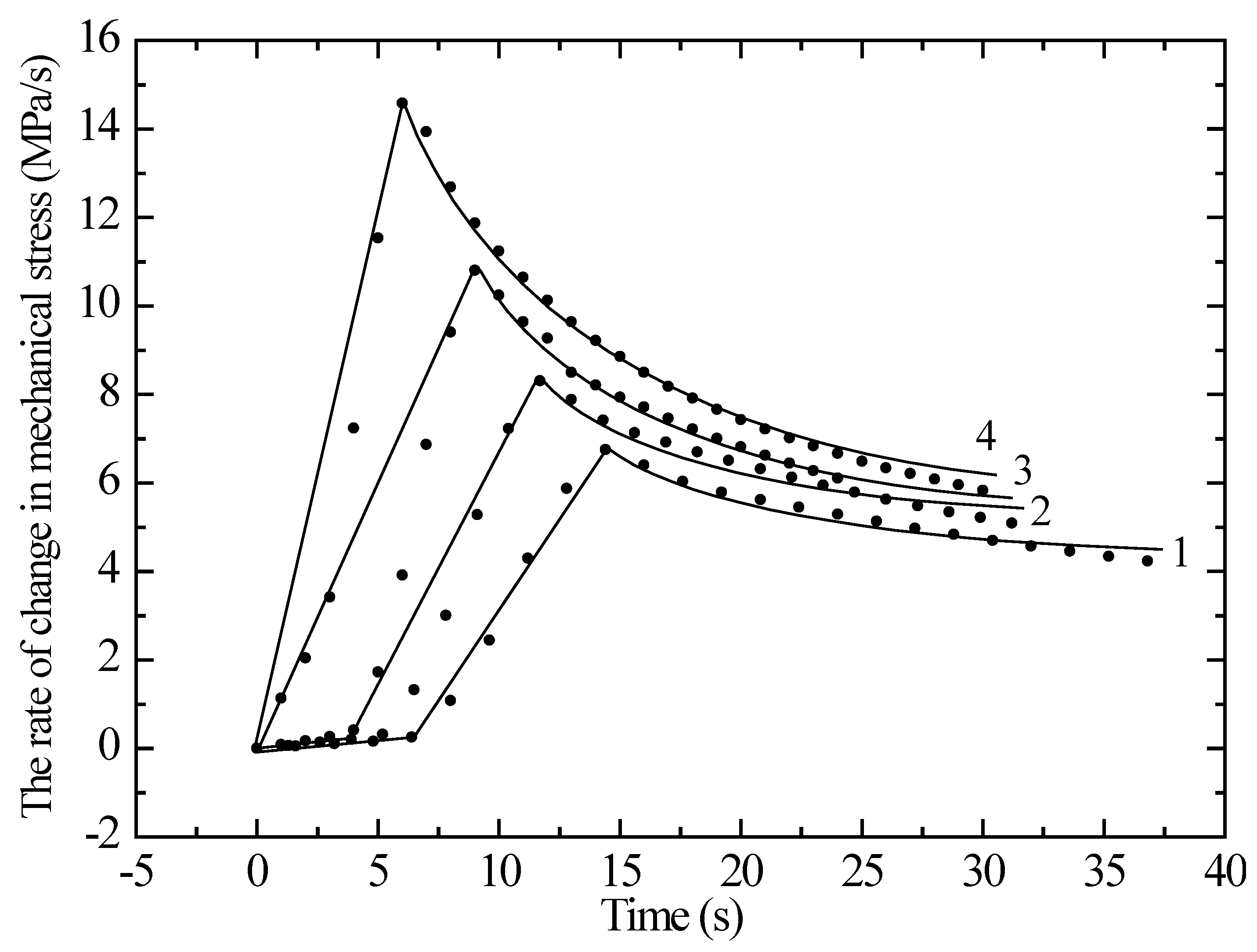

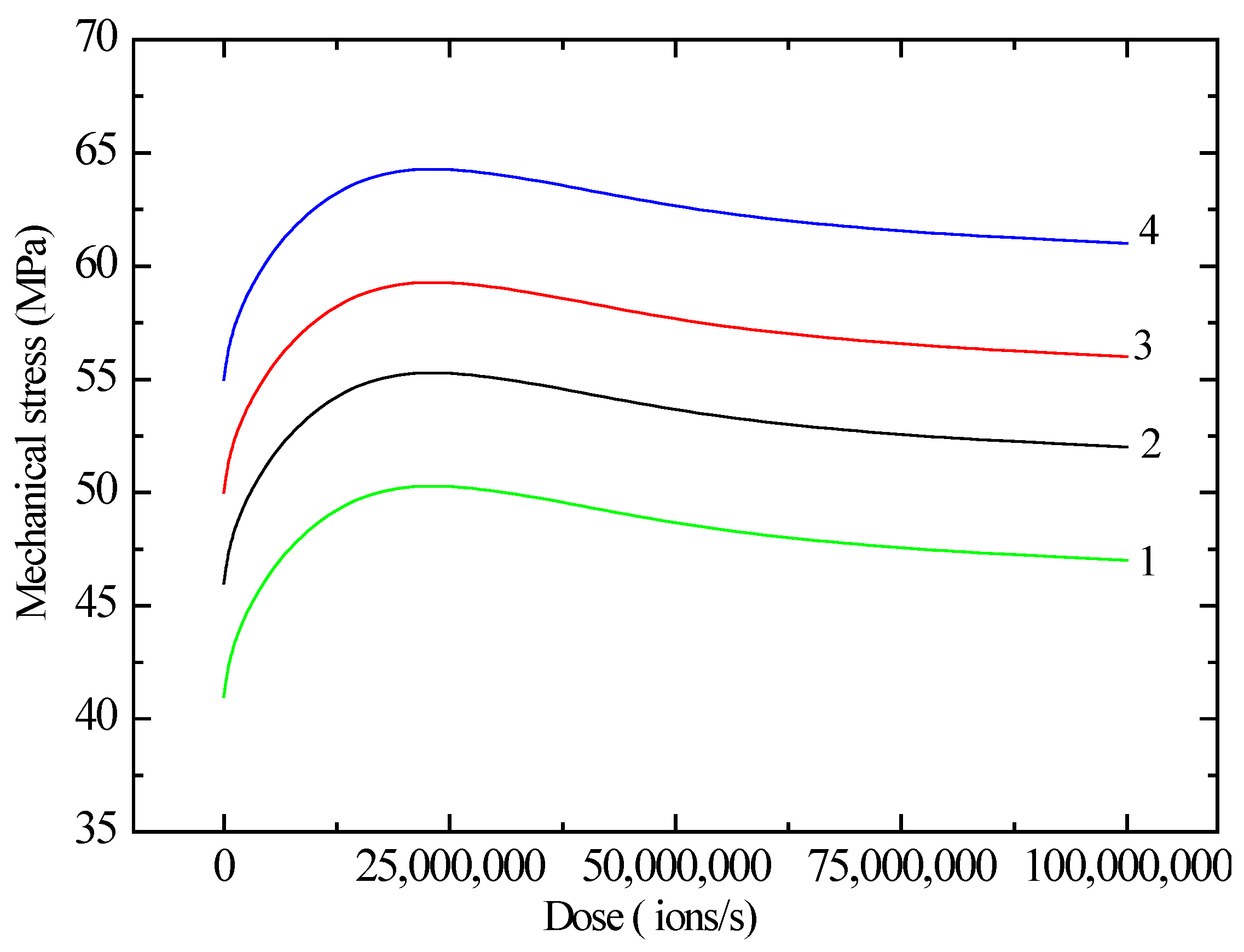

- Plots illustrating the rate of mechanical stress over time for control and irradiated samples (with a working length of 5 cm) aligned well with the predictive models proposed in this study. A notable finding was the 2.5-fold increase in the mechanical stress rate with higher radiation doses.

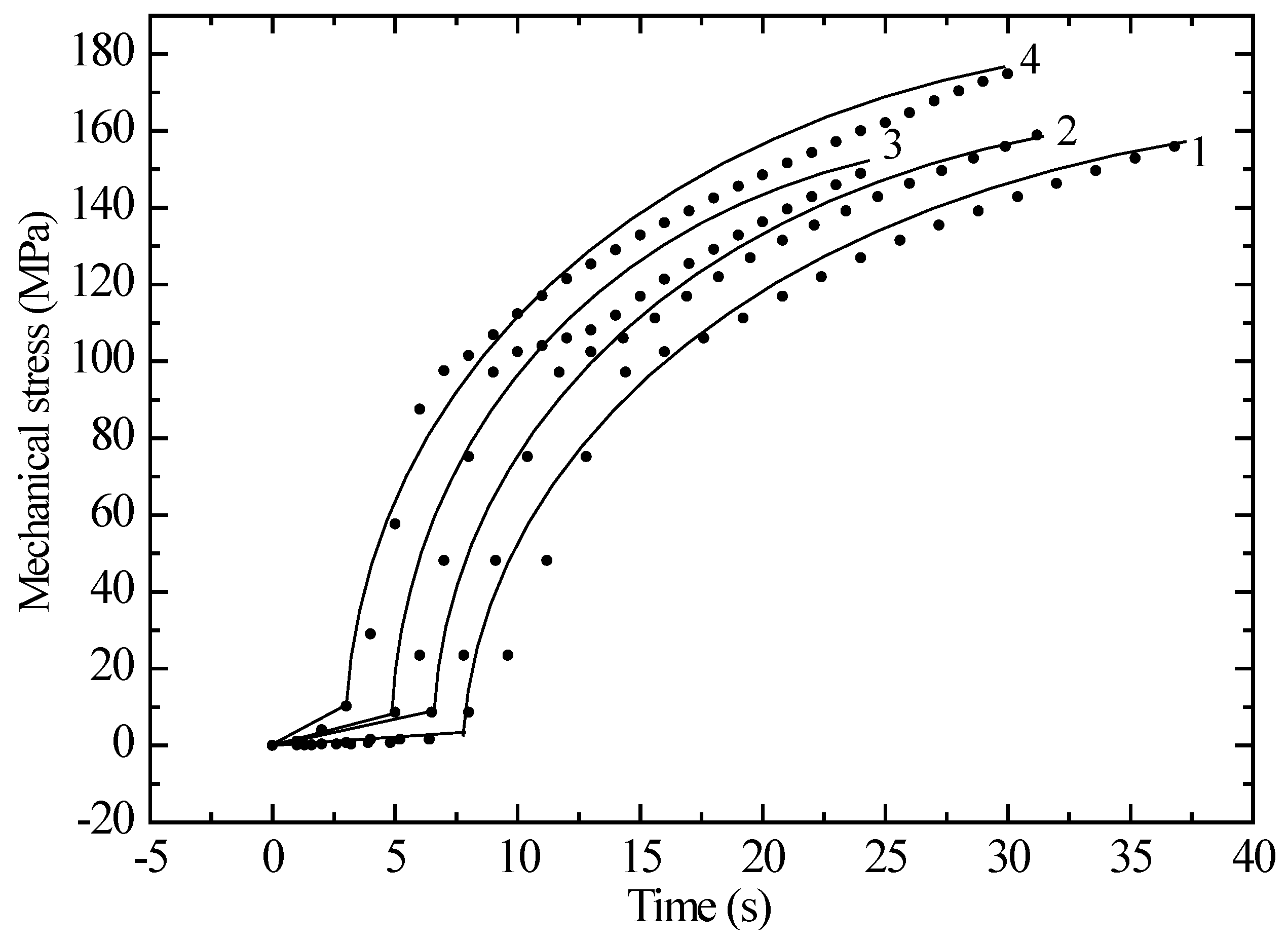

- The temporal evolution of mechanical stress revealed an intense increase during the first 15 s of loading, followed by saturation. This behavior is likely due to atomic-scale structural changes in the irradiated material, such as increased interatomic distances.

- When examining deformation under various radiation doses, the qualitative stress–strain behavior of polyethylene remained consistent; however, significant changes were observed in the material’s deformation and strength characteristics.

- The relationship between mechanical stress and irradiation dose suggests that stretching increases interatomic and intermolecular distances, enhancing the strength of the polymer and promoting stronger intermolecular forces.

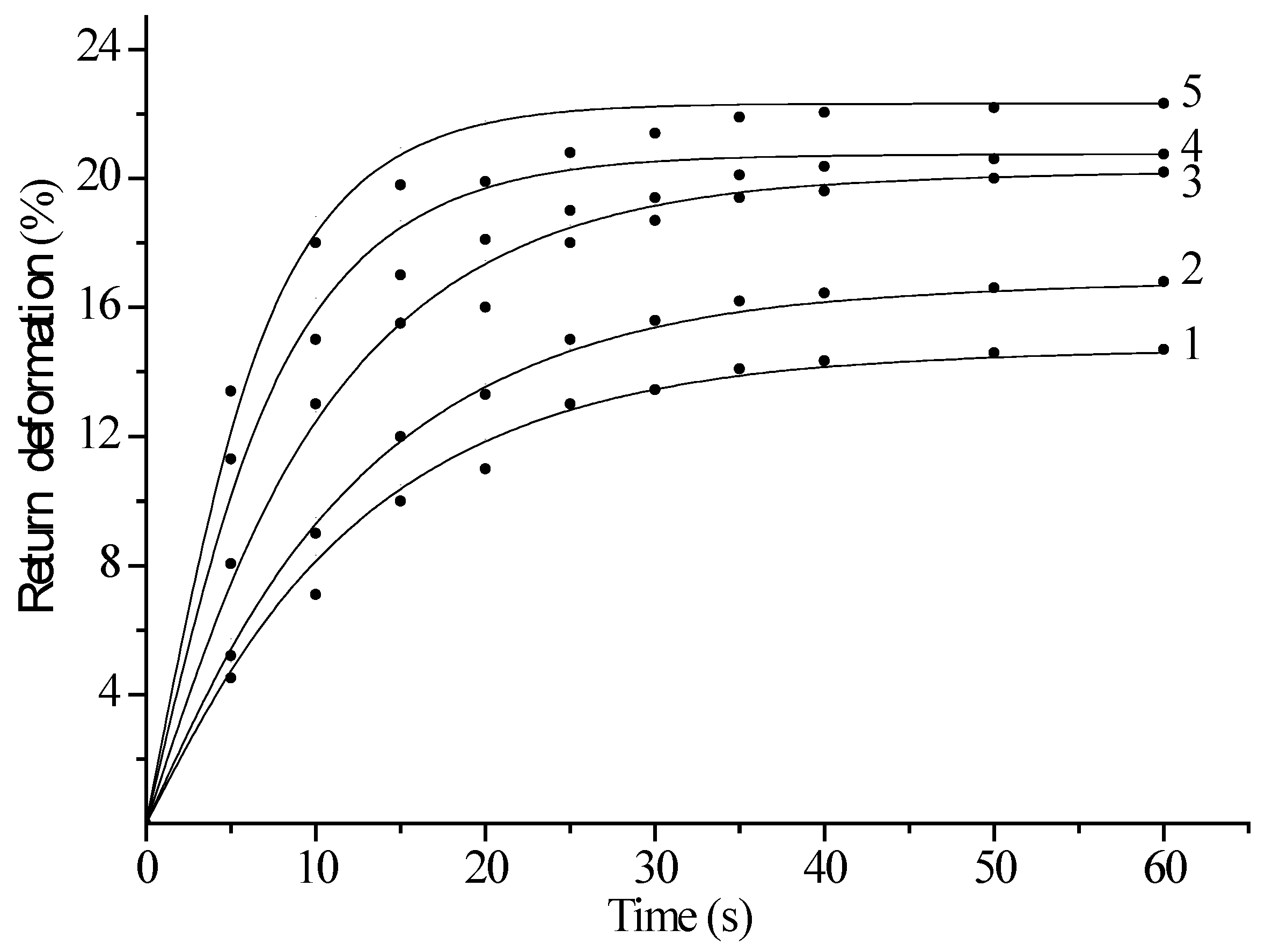

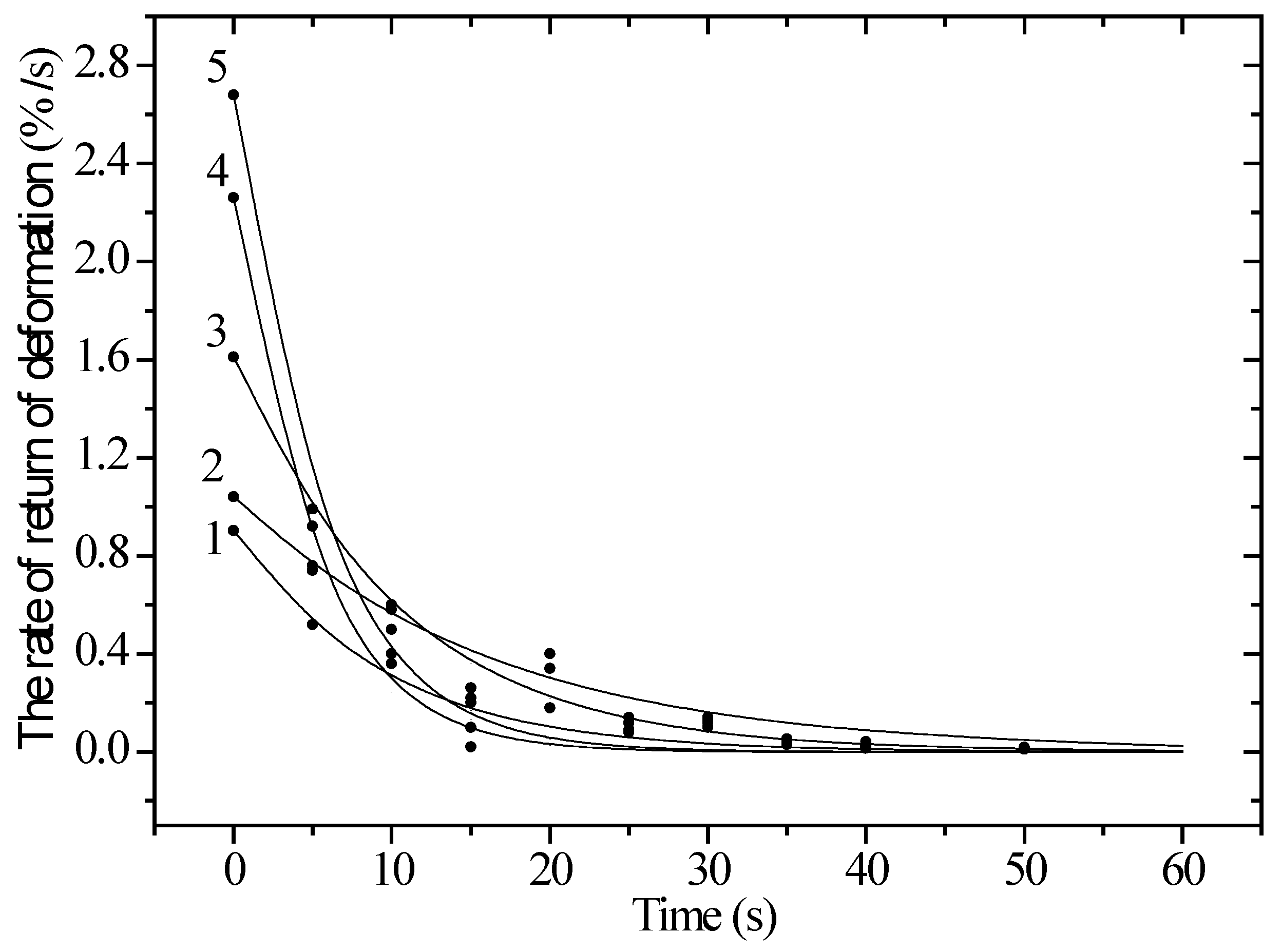

- Recovery deformation increased rapidly during the first 20 s of loading before decelerating and halting. This is attributed to the partial retention of elasticity in irradiated samples, where macromolecules strive to revert to their original configuration due to molecular interactions.

- The recovery deformation rate depends on time, static stress, and radiation dose. Ion irradiation reduced the recovery deformation rate, indicating significant changes to the materials’ viscoelastic behavior.

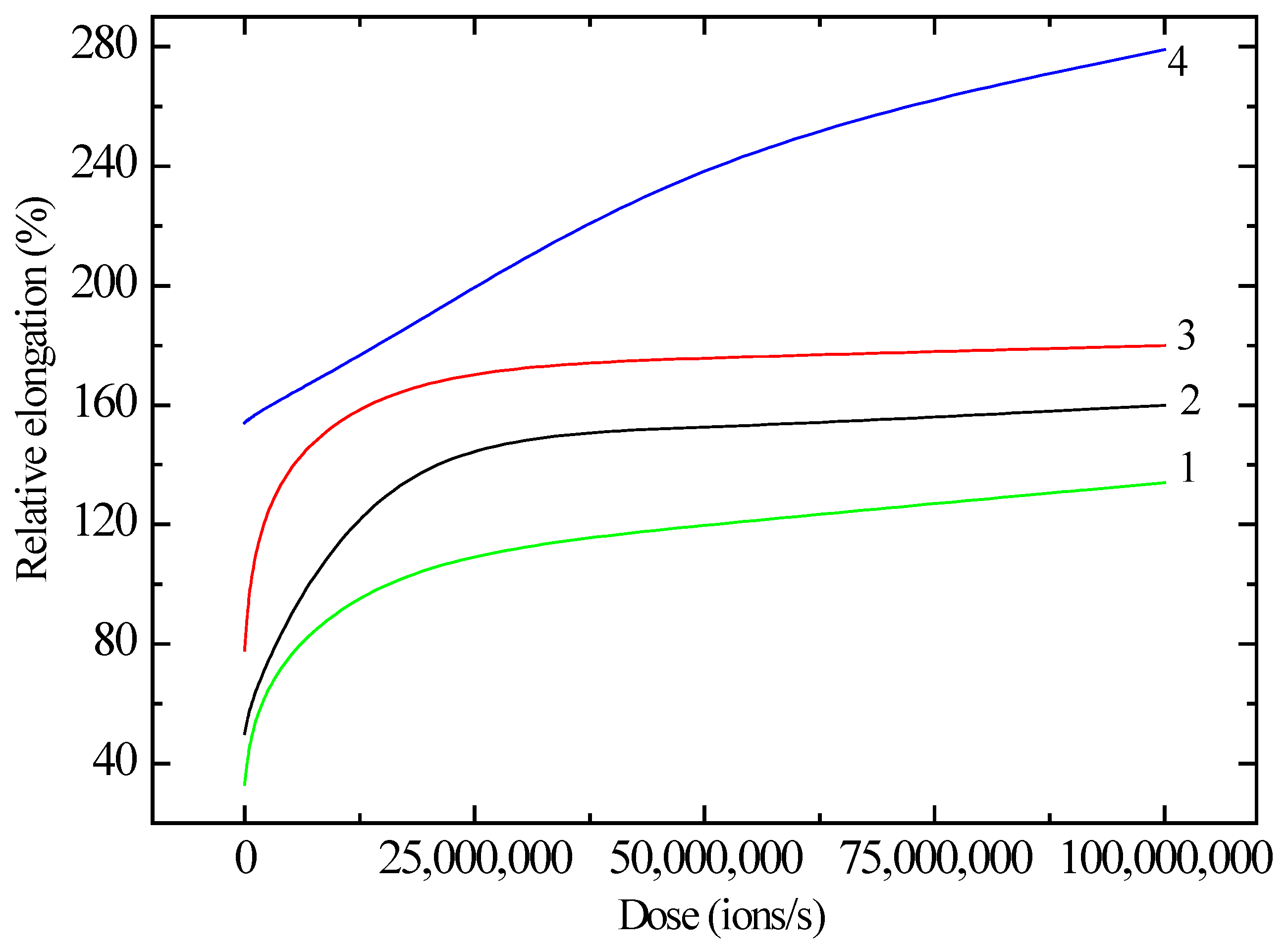

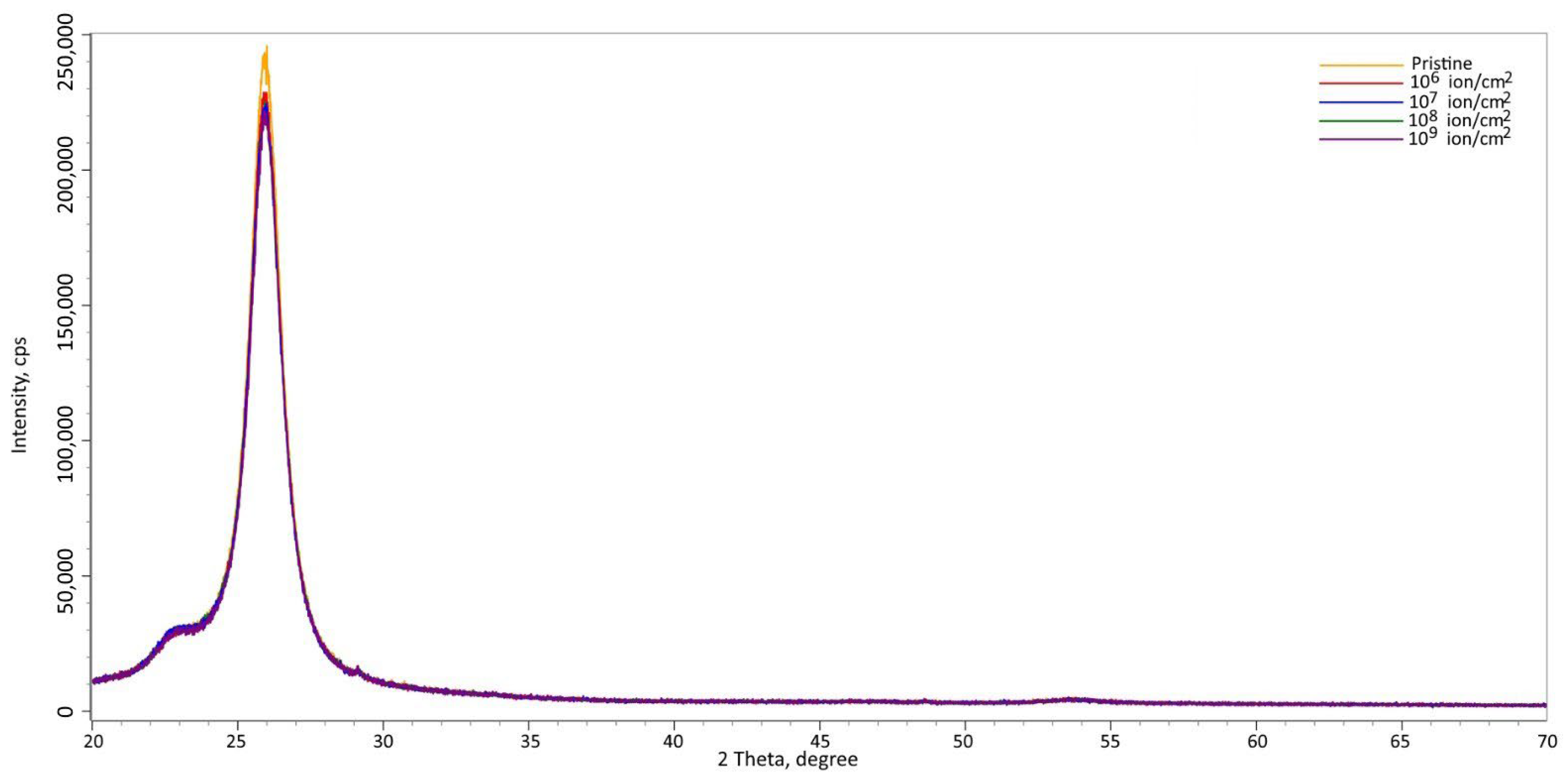

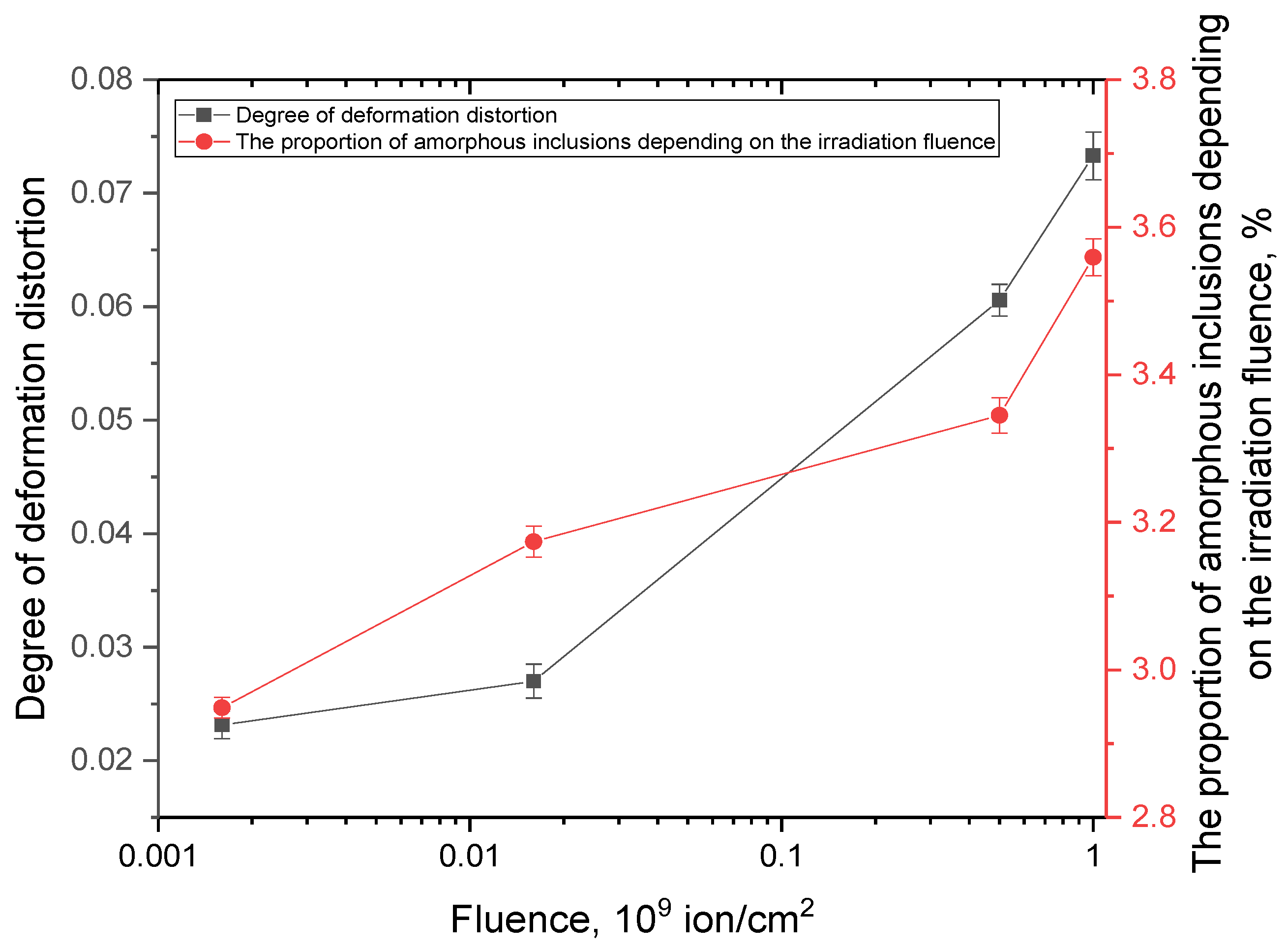

- Deformation distortions in molecular chains caused by irradiation with heavy Kr15+ ions were evaluated as a function of irradiation fluence. A slight increase in deformation distortion was observed when the fluence increased from 106 ions/cm2 to 107 ions/cm2, likely due to the isolation of latent tracks and corresponding changes in electron density.

- Comparative analysis of electron- and ion-irradiated polymer materials showed that Teflon films lose plasticity post-irradiation, whereas polyethylene films exhibit enhanced elongation and failure at higher deformation values compared to unirradiated samples. High-energy electron irradiation degrades polyethylene strength, while krypton ion irradiation at 147 MeV maintains mechanical strength, underscoring the suitability of krypton ions for irradiation processes.

- The findings highlight the potential of irradiated polyethylene films for practical applications in wire insulation, construction materials, and the aerospace industry. Additionally, these results contribute to a deeper understanding of deformation mechanisms in irradiated polymers, paving the way for advanced material design in high-performance environments.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Amanzhulov, B.; Ivanov, I.; Uglov, V.; Zlotski, S.; Ryskulov, A.; Kurakhmedov, A.; Sapar, A.; Ungarbayev, Y.; Koloberdin, M.; Zdorovets, M. Radiation Resistance of High-Entropy Alloys CoCrFeNi and CoCrFeMnNi, Sequentially Irradiated with Kr and He Ions. Materials 2024, 17, 4751. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Zhang, X.; Li, J.; Peng, S.; Wan, Q.; Xue, J.; Yi, X. Effects of Ion Irradiation and Temperature on Mechanical Properties of GaN Single Crystals under Nanoindentation. Materials 2023, 16, 7537. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Kan, Y.; Wu, C.; Chen, H. Irradiation-Assisted Microstructure Evolution and Mechanical Properties Loss of 310S Welded Joints. Metals 2023, 13, 858. [Google Scholar] [CrossRef]

- Kurbanova, B.; Aimaganbetov, K.; Ospanov, K.; Abdrakhmanov, K.; Zhakiyev, N.; Rakhadilov, B.; Sagdoldina, Z.; Almas, N. Effects of Electron Beam Irradiation on Mechanical and Tribological Properties of PEEK. Polymers 2023, 15, 1340. [Google Scholar] [CrossRef]

- Akilbekov, A.; Kenbayev, D.; Dauletbekova, A.; Polisadova, E.; Yakovlev, V.; Karipbayev, Z.; Shalaev, A.; Elsts, E.; Popov, A.I. The Effect of Fast Kr Ion Irradiation on the Optical Absorption, Luminescence, and Raman Spectra of BaFBr Crystals. Crystals 2023, 13, 1260. [Google Scholar] [CrossRef]

- Qian, B.; Dai, Y.; Xin, L.; Yao, C.; Wang, G.; Chang, S. Mechanical and thermal stability properties improvement of polyethylene wax-coated tungsten carbide/high-density polyethylene γ-rays shielding composites through irradiation-induced crosslinking. Radiat. Phys. Chem. 2025, 226, 112174. [Google Scholar] [CrossRef]

- Barbosa, A.S.; Biancolli, A.L.G.; Santos, B.P.S.; Bonvent, J.-J.; Hermida-Merino, D.; Santiago, E.I. Advancements in radiation-induced grafted anion-exchange membranes: Controlling pre-irradiation parameters of high-density polyethylene for enhanced fuel cell performance and durability. React. Funct. Polym. 2025, 208, 106149. [Google Scholar] [CrossRef]

- Huang, G.; Lv, W.; Zhu, Y.; Zhang, Z.; Jin, X.; Liu, H.; Zhang, T.; Yang, F.; Lua, M.; Zhao, Y. Investigation of the effects of irradiation and aging on the tribological behavior of ultra-high molecular weight polyethylene/graphene oxide composites under water lubrication. RSC Adv. 2024, 14, 18161–18170. [Google Scholar] [CrossRef]

- Kupchishin, A.I.; Muradov, A.D.; Taipova, B.G.; Voronova, N.A. Catastrophic model of destruction and experimental research o polymer materials irradiated by electrons. Eurasian Phys. Teh. J. 2009, 6, 16. [Google Scholar]

- Mohammadian-Kohol, M.; Asgari, M.; Shakur, H.R. Effect of gamma irradiation on the structural, mechanical and optical properties of polytetrafluoroethylene sheet. Radiat. Phys. Chem. 2018, 145, 11–18. [Google Scholar] [CrossRef]

- Kupchishin, A.I.; Taipova, B.G.; Kupchishin, A.A.; Voronova, N.A.; Kirdyashkin, V.I.; Fursa, T.V. Catastrophic models of materials destruction. IOP Conf. Ser. Mater. Sci. Eng. 2016, 110, 012037. [Google Scholar] [CrossRef]

- Prasad, S.G.; De, A.; De, U. Structural and optical investigations of radiation damage in transparent PET polymer films. Int. J. Spectrosc. 2011, 11, 7. [Google Scholar] [CrossRef]

- Sharma, T.; Aggarwal, S.; Kumar, S.; Mitta, V.K.; Kalsi, P.C.; Manchanda, V.K. Effect of gamma irradiation on the optical properties of Cr-39 polymer. J. Mater. Sci. 2007, 42, 1127–1130. [Google Scholar] [CrossRef]

- Hedman, T.D.; Demko, A.R.; Kalman, J. Enhanced ignition of milled boron-polytetrafluoroethylene mixtures. Combust. Flame 2018, 198, 112–119. [Google Scholar] [CrossRef]

- Shao, Y.; Zhu, L.; Li, W.; Liu, H. Anti-asphalt properties of PPS/PTFE composite coatings at high temperature. Surf. Eng. 2018, 34, 877–883. [Google Scholar] [CrossRef]

- Komarov, F.F.; Kupchishin, A.I.; Pivovarov, S.P.; Tlebaev, K.B.; Kusainov, A.T.; Rukhin, A.B.; Pozdeeva, T.V. Influence of γ-irradiation on the conformation of free radicals in polytetrafluoeroethylene. J. Eng. Phys. Thermophys. 2012, 85, 455–458. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Buranich, V.V.; Horodek, P.D.; Budzunski, P.E.; Amekura, H.G.; Okubo, N.H.; Ishikawa, N.H.; Bagdasaryan, A.A.; Rakhadilov, B.I.; Tarelnik, V.J.; et al. Evaluation of Phase stability, Microstructure and Defect structure in High-Entropy Ceramics after High-Energy Implantation. High Temp. Mater. Process. Int. Q. High-Technol. Plasma Process. 2022, 26, 77–93. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Webster, R.F.; Tilley, R.D.; Buranich, V.V.; Ivashchenko, V.I.; Takeda, Y.; Oyoshi, K.; Sakenova, R.; Piotrowska, K.; Zukowski, P.; et al. Formation of Si-Rich Interfaces by Radiation-Induced Diffusion and Microsegregation in CrN/ZrN Nanoscale Coatings. ACS Appl. Mater. Interfaces 2021, 13, 16928–16938. [Google Scholar] [CrossRef]

- Lavrentiev, V.I.; Pogrebnjak, A.D. High-dose ion implantation into metal. Surf. Coat. Technol. 1998, 99, 24–32. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Tolopa, A.M. A review of High-dose implantation and Production of ion mixed structures. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1990, 52, 25–43. [Google Scholar] [CrossRef]

- El-Diasty, F.; Bakry, A.M. Spectroscopic and sub-bandgap optical properties of gamma-irradiated cellulose triacetate polymer. J. Phys. D Appl. Phys. 2009, 42, 145413. [Google Scholar] [CrossRef]

- Standard Test Method for Tensile Properties of Thin Plastic Sheeting. Available online: https://store.astm.org/d0882-18.html (accessed on 20 February 2025).

- Brownell, M.; Nair, A.K. Deformation mechanisms of polytetrafluoroethylene at the nano- and microscales. R. Soc. Chem. 2019, 21, 490–503. [Google Scholar] [CrossRef] [PubMed]

- Polykandriotis, E.; Besrour, F.; Arkudas, A.; Ruppe, F.; Zetzmann, K.; Braeuer, L.; Horch, R.E. Flexor tendon repair with a polytetrafluoroethylene (PTFE) suture material. Arch. Orthop. Trauma Surg. 2019, 173, 46–51. [Google Scholar] [CrossRef] [PubMed]

- Cheng, B.; Inoue, Y.; Ishihara, K. Surface functionalization of polytetrafluoroethylene substrate with hybrid processes comprising plasma treatment and chemical reactions. American Society of Mechanical Engineers (ASME). Colloids Surf. B Biointerfaces 2019, 173, 77–84. [Google Scholar] [CrossRef]

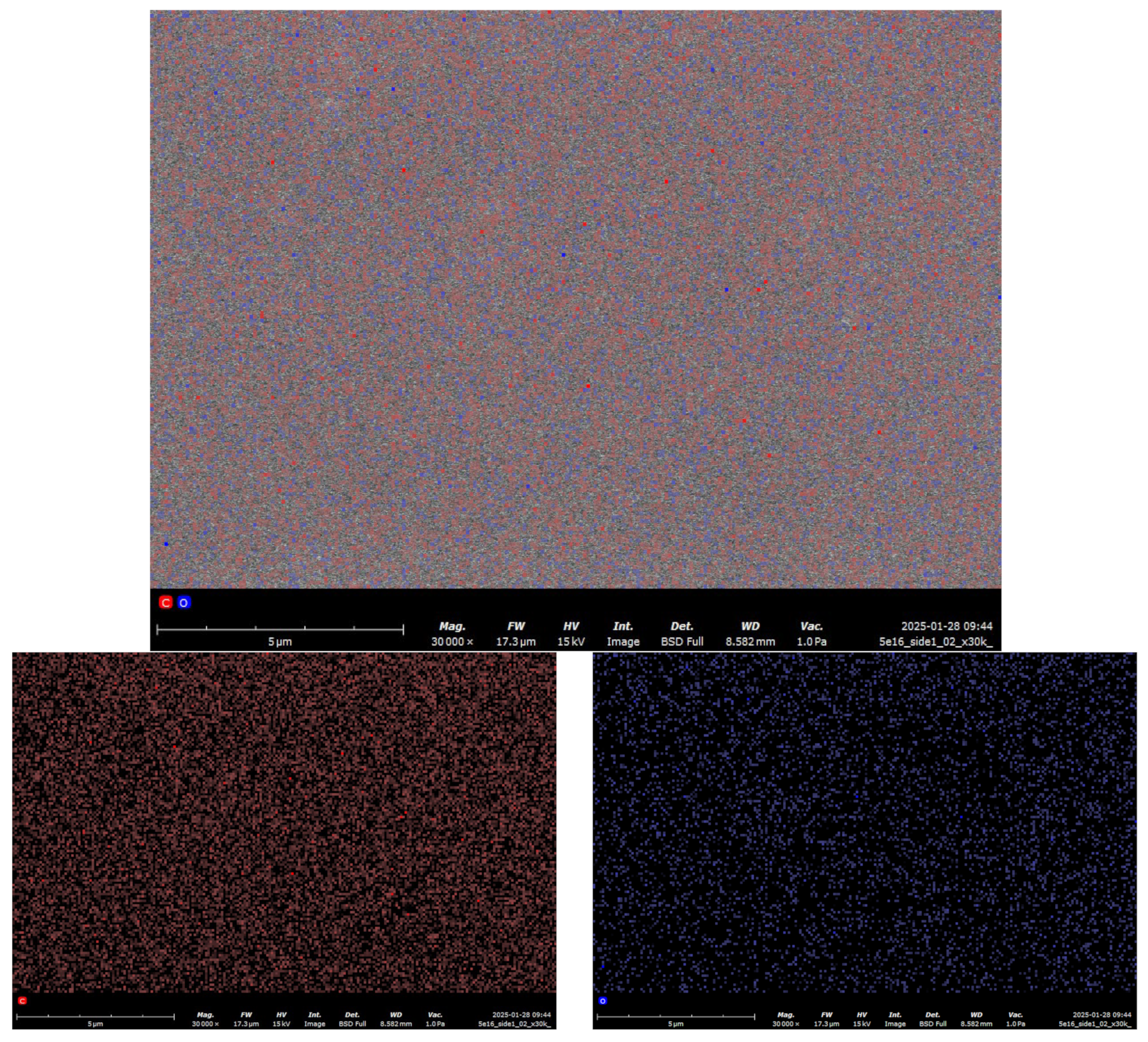

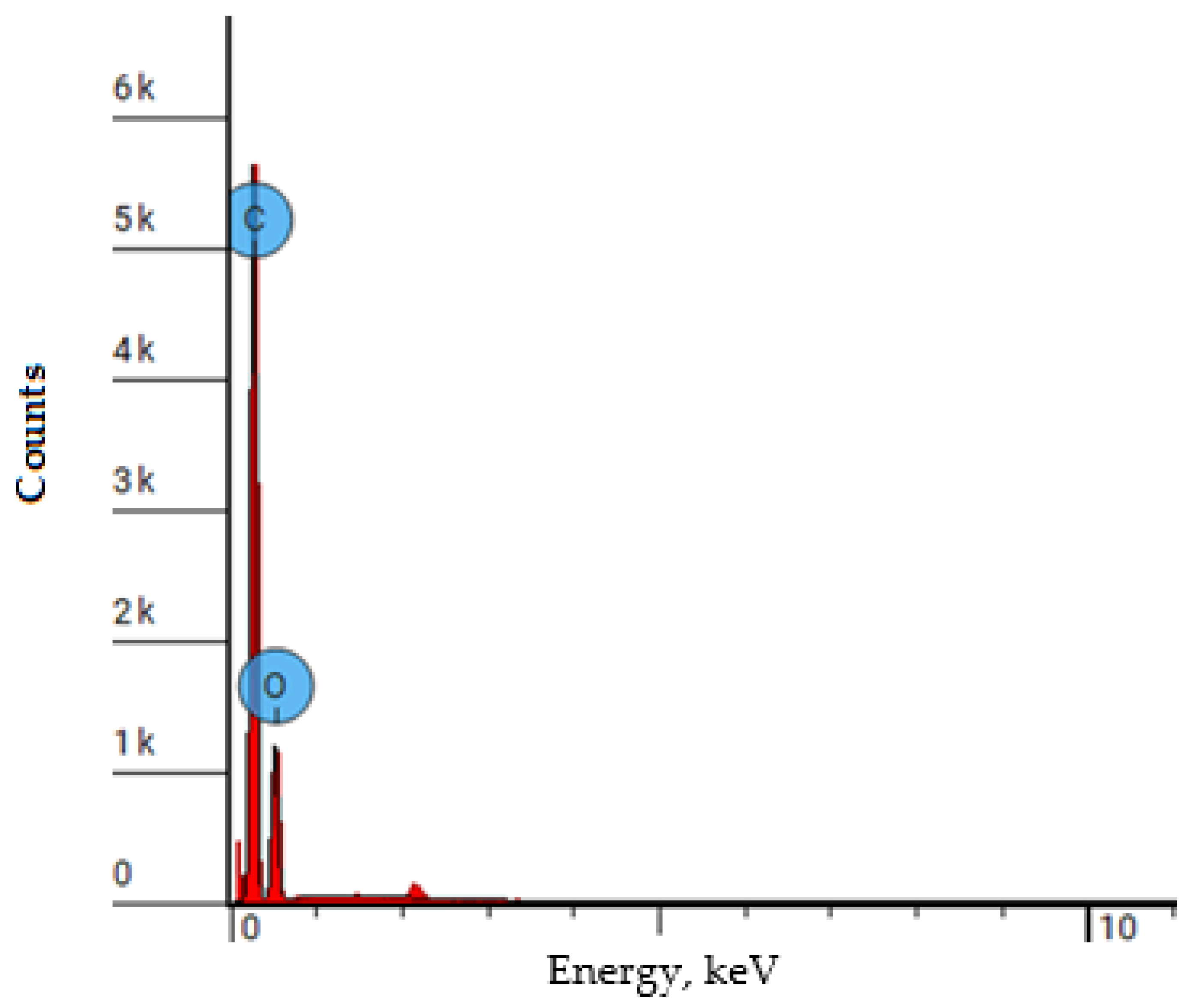

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

|---|---|---|---|---|

| 6 | C | Carbon | 72.025 | 65.900 |

| 8 | O | Oxygen | 27.975 | 34.100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupchishin, A.I.; Kozlovsky, A.L.; Niyazov, M.N.; Tlebaev, K.B.; Bondar, O.V.; Pogrebnjak, A.D. Deformation of Polyethylene Subjected to Static and Nonstatic Stresses and Krypton Ions Irradiation. Polymers 2025, 17, 1081. https://doi.org/10.3390/polym17081081

Kupchishin AI, Kozlovsky AL, Niyazov MN, Tlebaev KB, Bondar OV, Pogrebnjak AD. Deformation of Polyethylene Subjected to Static and Nonstatic Stresses and Krypton Ions Irradiation. Polymers. 2025; 17(8):1081. https://doi.org/10.3390/polym17081081

Chicago/Turabian StyleKupchishin, Anatoliy I., Artem L. Kozlovsky, Marat N. Niyazov, Kairat B. Tlebaev, Oleksandr. V. Bondar, and Alexander D. Pogrebnjak. 2025. "Deformation of Polyethylene Subjected to Static and Nonstatic Stresses and Krypton Ions Irradiation" Polymers 17, no. 8: 1081. https://doi.org/10.3390/polym17081081

APA StyleKupchishin, A. I., Kozlovsky, A. L., Niyazov, M. N., Tlebaev, K. B., Bondar, O. V., & Pogrebnjak, A. D. (2025). Deformation of Polyethylene Subjected to Static and Nonstatic Stresses and Krypton Ions Irradiation. Polymers, 17(8), 1081. https://doi.org/10.3390/polym17081081