Sustainable Manufacturing of Lightweight Hybrid Nanocomposites for Electric Vehicle Battery Enclosures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

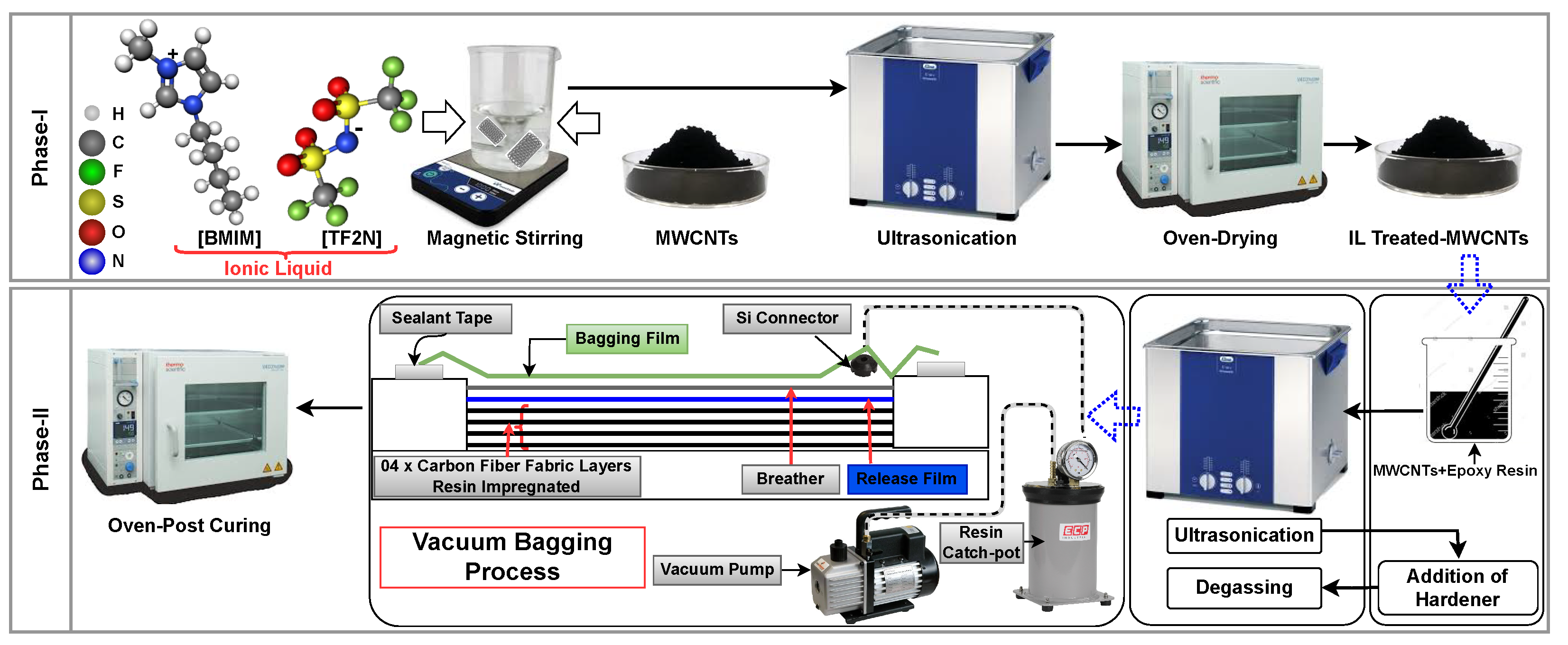

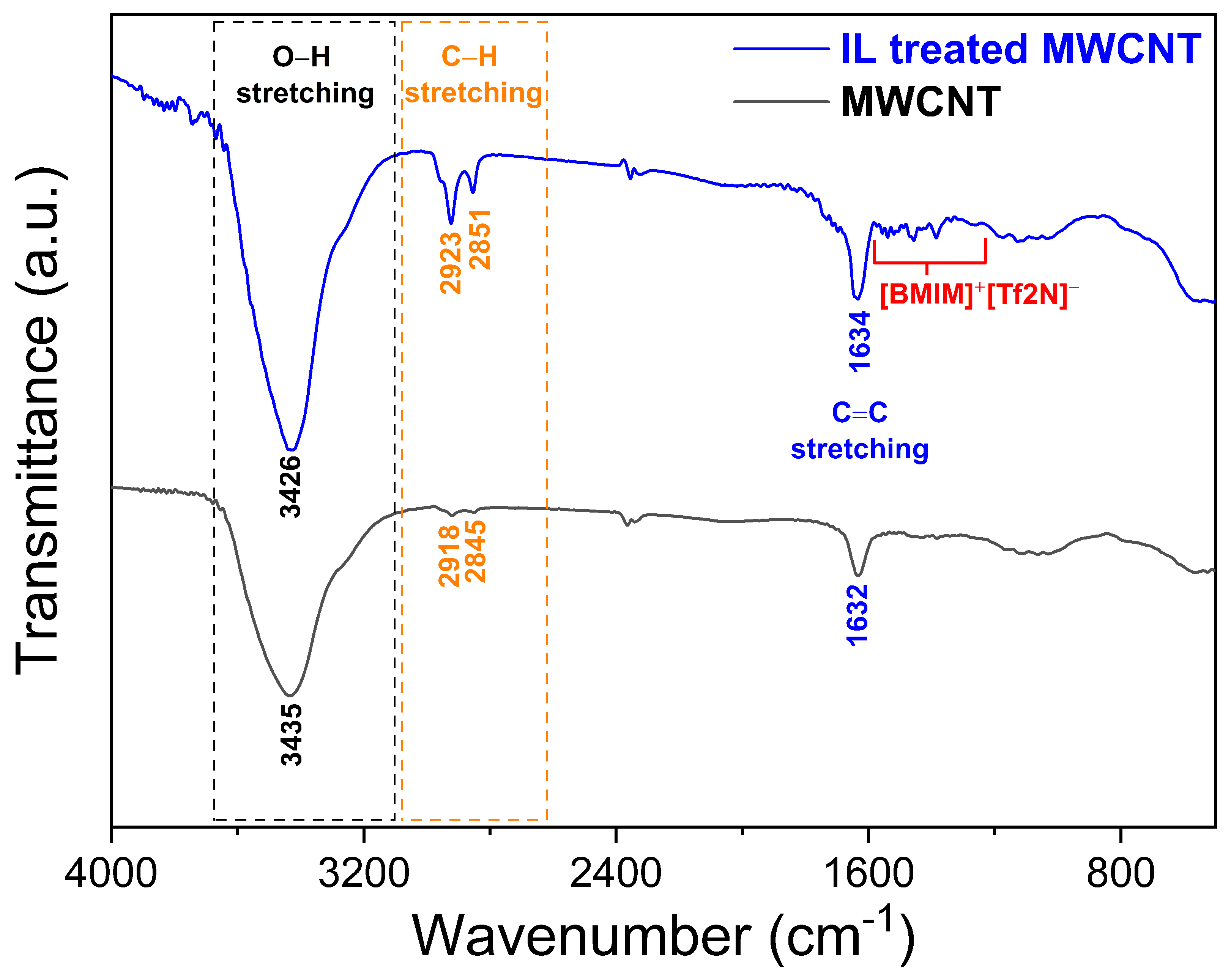

2.2.1. Phase I: Surface Treatment of MWCNTs

2.2.2. Phase II: Fabrication of CFRP Laminates

2.3. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Takahashi, J. Development of carbon fiber-reinforced thermoplastics for mass-produced automotive applications in japan. J. Compos. Sci. 2021, 5, 86. [Google Scholar] [CrossRef]

- Kishore, K.S.; Subbaiah, K.V. Carbon Fiber and Carbon Fiber Reinforced Epoxy Composites for Automotive Applications—A Review. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 29, 272–282. [Google Scholar] [CrossRef]

- Patel, K.; Potluri, P.; Yousaf, Z.; Wilkinson, A. Multi-scale reinforcement of epoxy composites-Use of carbon fibre fabrics coated with an epoxy binder containing MWCNTs for improved interlaminar fracture resistance. Compos. Part B Eng. 2019, 165, 109–119. [Google Scholar] [CrossRef]

- Ren, X.; Sherif, M.M.; Wei, Y.; Lyu, Y.; Sun, Y.; Ozbulut, O.E. Effect of corrosion on the tensile and fatigue performance of CFRP strand Sheet/Steel double strap joints. Eng. Struct. 2022, 260, 114240. [Google Scholar] [CrossRef]

- Moyer, K.; Meng, C.; Marshall, B.; Assal, O.; Eaves, J.; Perez, D.; Karkkainen, R.; Roberson, L.; Pint, C.L. Carbon fiber reinforced structural lithium-ion battery composite: Multifunctional power integration for CubeSats. Energy Storage Mater. 2020, 24, 676–681. [Google Scholar] [CrossRef]

- Choi, J.; Zabihi, O.; Varley, R.J.; Fox, B.; Naebe, M. High performance carbon fiber structural batteries using cellulose nanocrystal reinforced polymer electrolyte. ACS Appl. Mater. Interfaces 2022, 14, 45320–45332. [Google Scholar] [CrossRef] [PubMed]

- Simões, S. High-performance advanced composites in multifunctional material design: State of the art, challenges, and future directions. Materials 2024, 17, 5997. [Google Scholar] [CrossRef]

- Pernice, M.F.; Qi, G.; Senokos, E.; Anthony, D.B.; Nguyen, S.; Valkova, M.; Greenhalgh, E.S.; Shaffer, M.S.; Kucernak, A.R. Mechanical, electrochemical and multifunctional performance of a CFRP/carbon aerogel structural supercapacitor and its corresponding monofunctional equivalents. Multifunct. Mater. 2022, 5, 025002. [Google Scholar] [CrossRef]

- Zafeiropoulou, K.; Kostagiannakopoulou, C.; Geitona, A.; Tsilimigkra, X.; Sotiriadis, G.; Kostopoulos, V. On the multi-functional behavior of graphene-based nano-reinforced polymers. Materials 2021, 14, 5828. [Google Scholar] [CrossRef]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J. Thermoplast. Compos. Mater. 2025, 38, 754–780. [Google Scholar] [CrossRef]

- Senthil Kumar, M.; Sakthivel, G.; Jagadeeshwaran, R.; Lakshmipathi, J.; Vanmathi, M.; Mohanraj, T.; Admassu, Y. Development of Eco-Sustainable Silica-Reinforced Natural Hybrid Polymer Composites for Automotive Applications. Adv. Mater. Sci. Eng. 2022, 2022, 5924457. [Google Scholar] [CrossRef]

- Choudhary, S.; Sain, M.K.; Kumar, V.; Saraswat, P.; Jindal, M.K. Advantages and applications of sisal fiber reinforced hybrid polymer composites in automobiles: A literature review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Lightweight structural materials in open access: Latest trends. Materials 2021, 14, 6577. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, M.; Ghosh, A.; Roy, A. Renewable and sustainable materials in automotive industry. Encycl. Renew. Sustain. Mater. 2020, 2020, 162–179. [Google Scholar]

- Hao, M.; Qian, X.; Zhang, Y.; Yang, J.; Li, C.; Gong, H.; Wang, X.; Wang, P.; Liu, L.; Huang, Y. Thermal conductivity enhancement of carbon fiber/epoxy composites via constructing three-dimensionally aligned hybrid thermal conductive structures on fiber surfaces. Compos. Sci. Technol. 2023, 231, 109800. [Google Scholar] [CrossRef]

- Adeoti, M.O.; Jamiru, T.; Adegbola, T.A.; Suleiman, I.; Abdullahi, M.; Aramide, B.P. Selection criteria of polymer nanocomposites for electrical energy storage applications: A concise review. Express Polym. Lett. 2025, 19, 208. [Google Scholar] [CrossRef]

- Antony Jose, S.; Cowan, N.; Davidson, M.; Godina, G.; Smith, I.; Xin, J.; Menezes, P.L. A Comprehensive Review on Cellulose Nanofibers, Nanomaterials, and Composites: Manufacturing, Properties, and Applications. Nanomaterials 2025, 15, 356. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Asyraf, M.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.; et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Wu, Z.; Zhao, Y.; Yang, K.; Guan, J.; Wang, S.; Gu, Y.; Li, M.; Feng, Y.; Feng, W.; Ritchie, R.O. Enhancing the mechanical performance of fiber-reinforced polymer composites using carbon nanotubes as an effective nano-phase reinforcement. Adv. Mater. Interfaces 2023, 10, 2201935. [Google Scholar] [CrossRef]

- Shah, V.; Bhaliya, J.; Patel, G.M.; Deshmukh, K. Advances in polymeric nanocomposites for automotive applications: A review. Polym. Adv. Technol. 2022, 33, 3023–3048. [Google Scholar] [CrossRef]

- Chen, R.; Zhou, Y.; Li, X. Cotton-derived Fe/Fe3C-encapsulated carbon nanotubes for high-performance lithium–sulfur batteries. Nano Lett. 2022, 22, 1217–1224. [Google Scholar] [CrossRef]

- Dhanaraju, G.; Pittala, R.K.; Ben, B.S.; Atgur, V.; Banapurmath, N.; Umarfarooq, M.; Khan, T.; Singh, B. Enhanced mechanical performance and damping behavior of CFRP composites through exfoliated MWCNT functionalization. Nanocomposites 2024, 10, 184–200. [Google Scholar] [CrossRef]

- Brown, A.D.; Bakis, C.E.; Smith, E.C. Effect of carbon nanotube surface treatment on the dynamic mechanical properties of a hybrid carbon/epoxy composite laminate. Compos. Sci. Technol. 2023, 231, 109807. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, A.; Tiwari, M. Numerical and analytical modelling of effective thermal conductivity of multi-walled carbon nanotubes polymer nanocomposites including the effect of nanotube orientation and interfacial thermal resistance. Nanocomposites 2023, 9, 30–42. [Google Scholar] [CrossRef]

- Chen, J. Electrical and thermal properties of epoxy matrix composite materials reinforced with multi-walled carbon nanotubes under different weight fraction conditions. Authorea Prepr. 2023. [Google Scholar] [CrossRef]

- Spinelli, G.; Guarini, R.; Guadagno, L.; Vertuccio, L.; Romano, V. Thermo-Mechanical and Thermo-Electric Properties of a Carbon-Based Epoxy Resin: An Experimental, Statistical, and Numerical Investigation. Materials 2024, 17, 3596. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Ling, Y.; Zhang, X.; Liang, M.; Zou, H. Ultra-thin carbon fiber reinforced carbon nanotubes modified epoxy composites with superior mechanical and electrical properties for the aerospace field. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107197. [Google Scholar] [CrossRef]

- Sabet, M. Advanced Functionalization Strategies for Carbon Nanotube Polymer Composites: Achieving Superior Dispersion and Compatibility. Polym.-Plast. Technol. Mater. 2025, 64, 465–494. [Google Scholar] [CrossRef]

- Nurazzi, N.; Sabaruddin, F.; Harussani, M.; Kamarudin, S.; Rayung, M.; Asyraf, M.; Aisyah, H.; Norrrahim, M.; Ilyas, R.; Abdullah, N.; et al. Mechanical performance and applications of cnts reinforced polymer composites—A review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Mozaffarinasab, H.; Jamshidi, M. Surface modification of carbon nanotubes by a bifunctional amine silane; effects on physical/mechanical/thermal properties of epoxy nanocomposite. Prog. Org. Coatings 2023, 179, 107521. [Google Scholar] [CrossRef]

- Salahuddin, B.; Faisal, S.N.; Baigh, T.A.; Alghamdi, M.N.; Islam, M.S.; Song, B.; Zhang, X.; Gao, S.; Aziz, S. Carbonaceous materials coated carbon fibre reinforced polymer matrix composites. Polymers 2021, 13, 2771. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Farouk, N.; Mortezaei, N.; Yumashev, A.V.; Akhtar, M.N.; Arabmarkadeh, A. Investigation on microwave absorption characteristics of ternary MWCNTs/CoFe2O4/FeCo nanocomposite coated with conductive PEDOT-Polyaniline Co-polymers. Ceram. Int. 2021, 47, 12244–12251. [Google Scholar] [CrossRef]

- Raja, M.A.Z.; Sabati, M.; Parveen, N.; Awais, M.; Awan, S.E.; Chaudhary, N.I.; Shoaib, M.; Alquhayz, H. Integrated intelligent computing application for effectiveness of Au nanoparticles coated over MWCNTs with velocity slip in curved channel peristaltic flow. Sci. Rep. 2021, 11, 22550. [Google Scholar] [CrossRef]

- Idumah, C.I. Novel advancements in green and sustainable polymeric nanocomposites coatings. Curr. Res. Green Sustain. Chem. 2021, 4, 100173. [Google Scholar] [CrossRef]

- Domagała, K.; Borlaf, M.; Traber, J.; Kata, D.; Graule, T. Purification and functionalisation of multi-walled carbon nanotubes. Mater. Lett. 2019, 253, 272–275. [Google Scholar] [CrossRef]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, mechanical, and thermal properties of natural fiber-reinforced epoxy composites for construction and automotive applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Aslam, M.M.A.; Kuo, H.W.; Den, W.; Usman, M.; Sultan, M.; Ashraf, H. Functionalized carbon nanotubes (CNTs) for water and wastewater treatment: Preparation to application. Sustainability 2021, 13, 5717. [Google Scholar] [CrossRef]

- Sun, X.; Bao, J.; Li, K.; Argyle, M.D.; Tan, G.; Adidharma, H.; Zhang, K.; Fan, M.; Ning, P. Advance in using plasma technology for modification or fabrication of carbon-based materials and their applications in environmental, material, and energy fields. Adv. Funct. Mater. 2021, 31, 2006287. [Google Scholar] [CrossRef]

- Jung, H.; Choi, H.K.; Oh, Y.; Hong, H.; Yu, J. Enhancement of thermo-mechanical stability for nanocomposites containing plasma treated carbon nanotubes with an experimental study and molecular dynamics simulations. Sci. Rep. 2020, 10, 405. [Google Scholar] [CrossRef]

- Yu, S.; Wu, Y.; Xue, Q.; Zhu, J.J.; Zhou, Y. A novel multi-walled carbon nanotube-coupled CoNi MOF composite enhances the oxygen evolution reaction through synergistic effects. J. Mater. Chem. A 2022, 10, 4936–4943. [Google Scholar] [CrossRef]

- Hayyan, M.; Abed, K.M.; Azzouz, A.; Hayyan, A.; AL-Mashhadani, M.K. Natural deep eutectic solvent-functionalized multiwall carbon nanotubes for lead removal from wastewater. Chem. Eng. Process.-Process Intensif. 2024, 205, 109961. [Google Scholar] [CrossRef]

- Uthaman, A.; Lal, H.M.; Li, C.; Xian, G.; Thomas, S. Mechanical and water uptake properties of epoxy nanocomposites with surfactant-modified functionalized multiwalled carbon nanotubes. Nanomaterials 2021, 11, 1234. [Google Scholar] [CrossRef]

- Fikri, M.A.; Pandey, A.; Samykano, M.; Kadirgama, K.; George, M.; Saidur, R.; Selvaraj, J.; Abd Rahim, N.; Sharma, K.; Tyagi, V. Thermal conductivity, reliability, and stability assessment of phase change material (PCM) doped with functionalized multi-wall carbon nanotubes (FMWCNTs). J. Energy Storage 2022, 50, 104676. [Google Scholar] [CrossRef]

- Turan, F.; Guclu, M.; Gurkan, K.; Durmus, A.; Taskin, Y. The effect of carbon nanotubes loading and processing parameters on the electrical, mechanical, and viscoelastic properties of epoxy-based composites. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 93. [Google Scholar] [CrossRef]

- Kazemi, A.S.; Nataj, Z.E.; Abdi, Y.; Abdol, M.A. Tuning wettability and surface order of MWCNTs by functionalization for water desalination. Desalination 2021, 508, 115049. [Google Scholar] [CrossRef]

- Dutta, V.; Verma, R.; Gopalkrishnan, C.; Yuan, M.H.; Batoo, K.M.; Jayavel, R.; Chauhan, A.; Lin, K.Y.A.; Balasubramani, R.; Ghotekar, S. Bio-inspired synthesis of carbon-based nanomaterials and their potential environmental applications: A state-of-the-art review. Inorganics 2022, 10, 169. [Google Scholar] [CrossRef]

- Guo, K.W. Carbon Nanotubes Synthesized by Green/Eco-friendly Technique Potential for Bioenergy Applications. In Nanomaterials in Biofuels Research; Springer: Singapore, 2020; pp. 251–274. [Google Scholar]

- Ezzatzadeh, E.; Sheikholeslami-Farahani, F.; Yadollahzadeh, K.; Rezayati, S. Highly efficient reusable carboxy group functionalized imidazolium salts for a simple and cost-effective preparation of pyrano [2, 3-d] pyrimidinone derivatives. Comb. Chem. High Throughput Screen. 2021, 24, 1465–1475. [Google Scholar] [CrossRef]

- Abaide, E.R.; Muller, C.C.; Draszewski, C.P.; Tres, M.V.; Mazutti, M.A.; Zabot, G.L. Chemistry of ionic liquid, switchable solvents, supercritical carbon dioxide and sub/supercritical water. In Advanced Nanotechnology and Application of Supercritical Fluids; Springer: Cham, Switzerland, 2020; pp. 165–198. [Google Scholar]

- Meshksar, M.; Afshariani, F.; Rahimpour, M.R. Industrial applications of green solvents for sustainable development of technologies in organic synthesis. In Applications of Nanotechnology for Green Synthesis; Springer: Cham, Switzerland, 2020; pp. 435–455. [Google Scholar]

- Tzani, A.; Karadendrou, M.A.; Kalafateli, S.; Kakokefalou, V.; Detsi, A. Current trends in green solvents: Biocompatible ionic liquids. Crystals 2022, 12, 1776. [Google Scholar] [CrossRef]

- Shamshina, J.L.; Berton, P. Ionic liquids as designed, multi-functional plasticizers for biodegradable polymeric materials: A mini-review. Int. J. Mol. Sci. 2024, 25, 1720. [Google Scholar] [CrossRef]

- Mishra, K.; Devi, N.; Siwal, S.S.; Zhang, Q.; Alsanie, W.F.; Scarpa, F.; Thakur, V.K. Ionic liquid-based polymer nanocomposites for sensors, energy, biomedicine, and environmental applications: Roadmap to the future. Adv. Sci. 2022, 9, 2202187. [Google Scholar] [CrossRef]

- Ray, P.; Pilania, M. The application and influence of ionic liquids in nanotechnology. Mater. Today Proc. 2021, 47, 2835–2838. [Google Scholar] [CrossRef]

- Wei, L.; Wang, L.; Cui, Z.; Liu, Y.; Du, A. Multifunctional applications of ionic liquids in polymer materials: A brief review. Molecules 2023, 28, 3836. [Google Scholar] [CrossRef] [PubMed]

- Matuszek, K.; Piper, S.L.; Brzęczek-Szafran, A.; Roy, B.; Saher, S.; Pringle, J.M.; MacFarlane, D.R. Unexpected energy applications of ionic liquids. Adv. Mater. 2024, 36, 2313023. [Google Scholar] [CrossRef] [PubMed]

- Peng, K.; Lin, J.; Yang, D.; Fu, F.; Dai, Z.; Zhou, G.; Yang, Z. Molecular-level insights into interfacial interaction–nanostructure relationships of imidazolium-based ionic liquids around carbon nanotube electrodes. Ind. Eng. Chem. Res. 2022, 61, 14051–14065. [Google Scholar] [CrossRef]

- ASTM D7264/D7264M-21; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D7028-20; Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E1530-19; Standard Test Method for Evaluating the Resistance to Thermal Transmission of Materials by the Guarded Heat Flow Meter Technique. ASTM International: West Conshohocken, PA, USA, 2019.

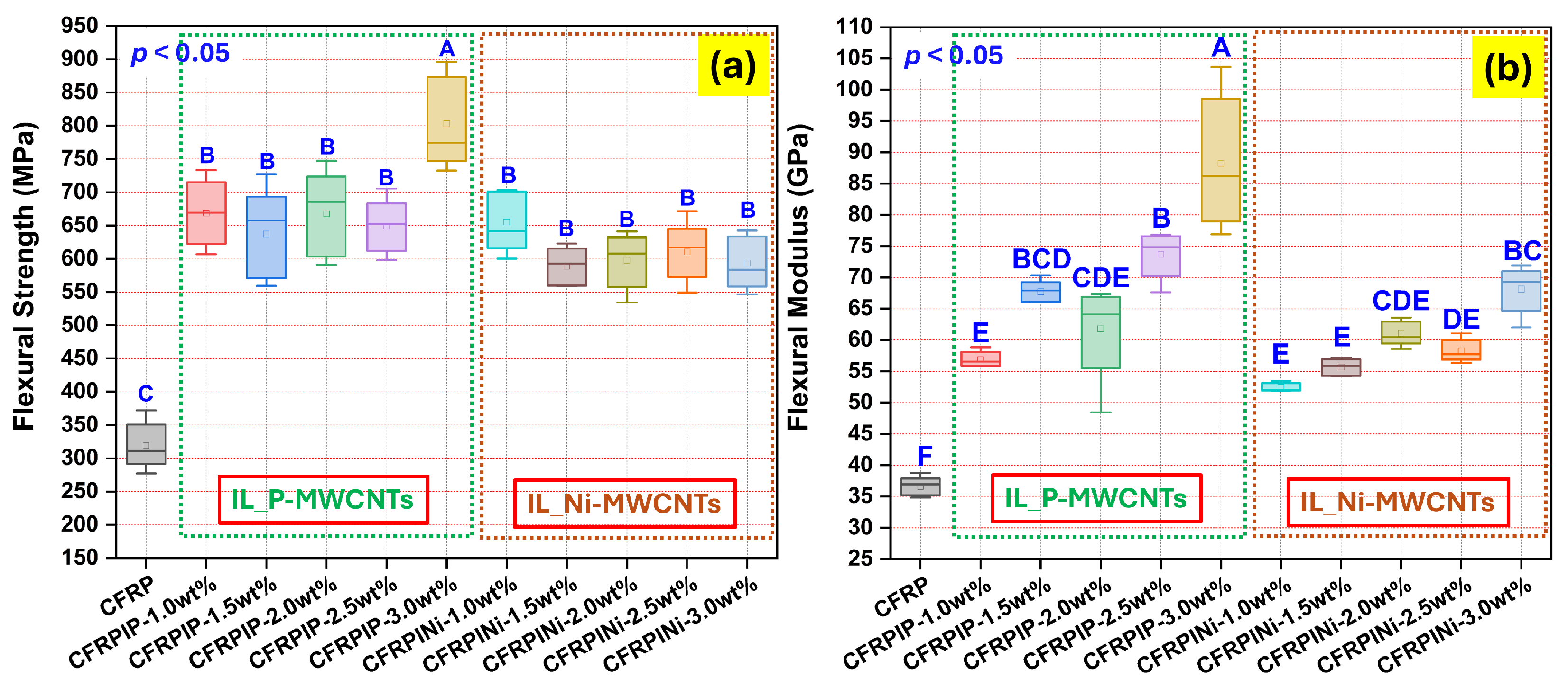

| Sample ID | Flexural Strength (MPa) | S.D. | Flexural Modulus (GPa) | S.D. |

|---|---|---|---|---|

| CFRP | 319 | 35 | 36.6 | 1.5 |

| CFRPIP-1.0wt% | 668.7 | 49.3 | 56.89 | 1.2 |

| CFRPIP-1.5wt% | 637.1 | 67.2 | 67.71 | 1.7 |

| CFRPIP-2.0wt% | 667.8 | 63.7 | 61.78 | 7.6 |

| CFRPIP-2.5wt% | 648.5 | 40.2 | 73.67 | 3.7 |

| CFRPIP-3.0wt% | 802.8 | 67.7 | 88.21 | 1 |

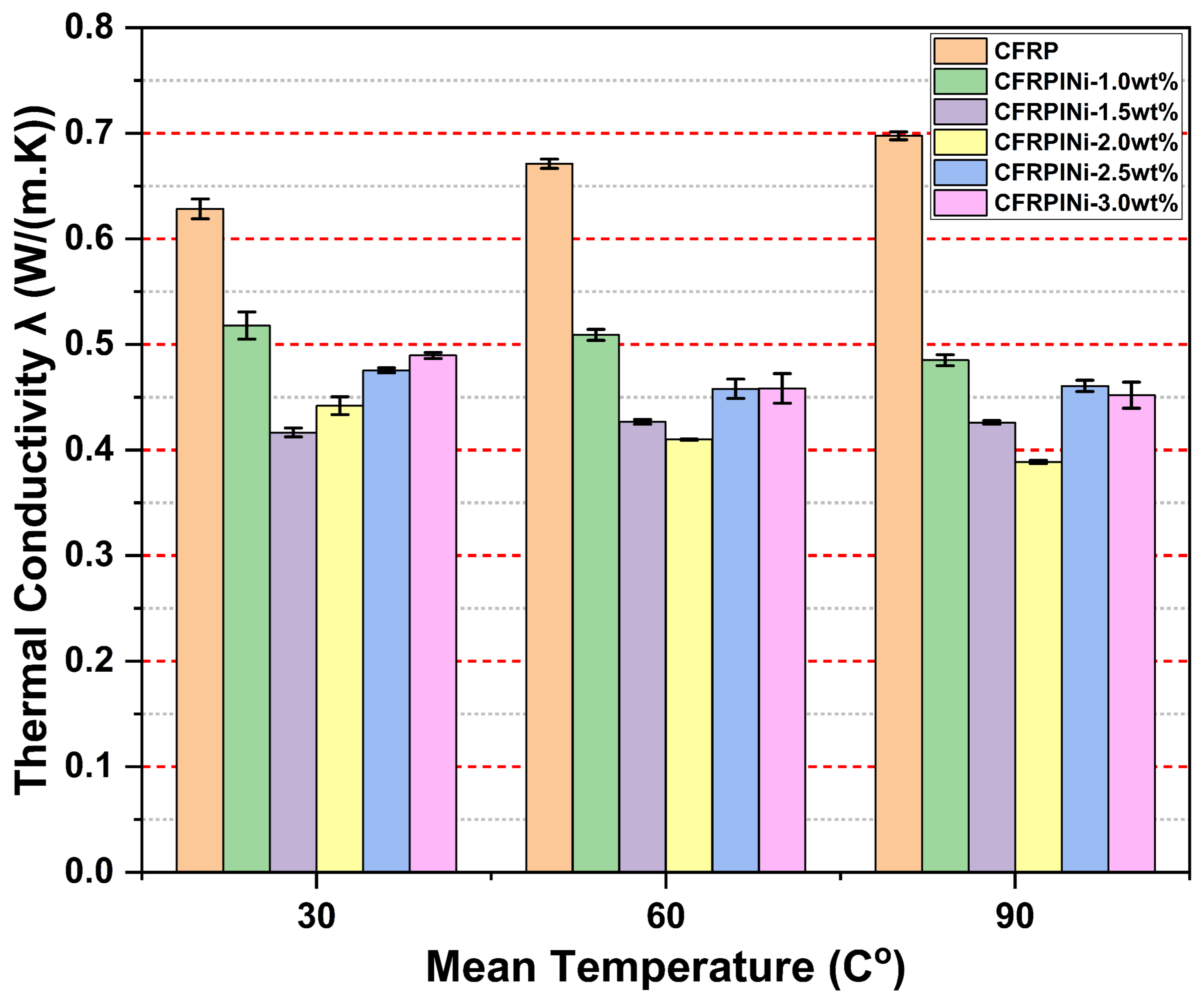

| CFRPINi-1.0wt% | 655 | 44.6 | 52.41 | 6.8 |

| CFRPINi-1.5wt% | 588.5 | 28.4 | 55.67 | 1.3 |

| CFRPINi-2.0wt% | 597.5 | 41.8 | 61.05 | 1.9 |

| CFRPINi-2.5wt% | 610.3 | 44.2 | 58.29 | 1.7 |

| CFRPINi-3.0wt% | 593.2 | 39.5 | 68.13 | 3.7 |

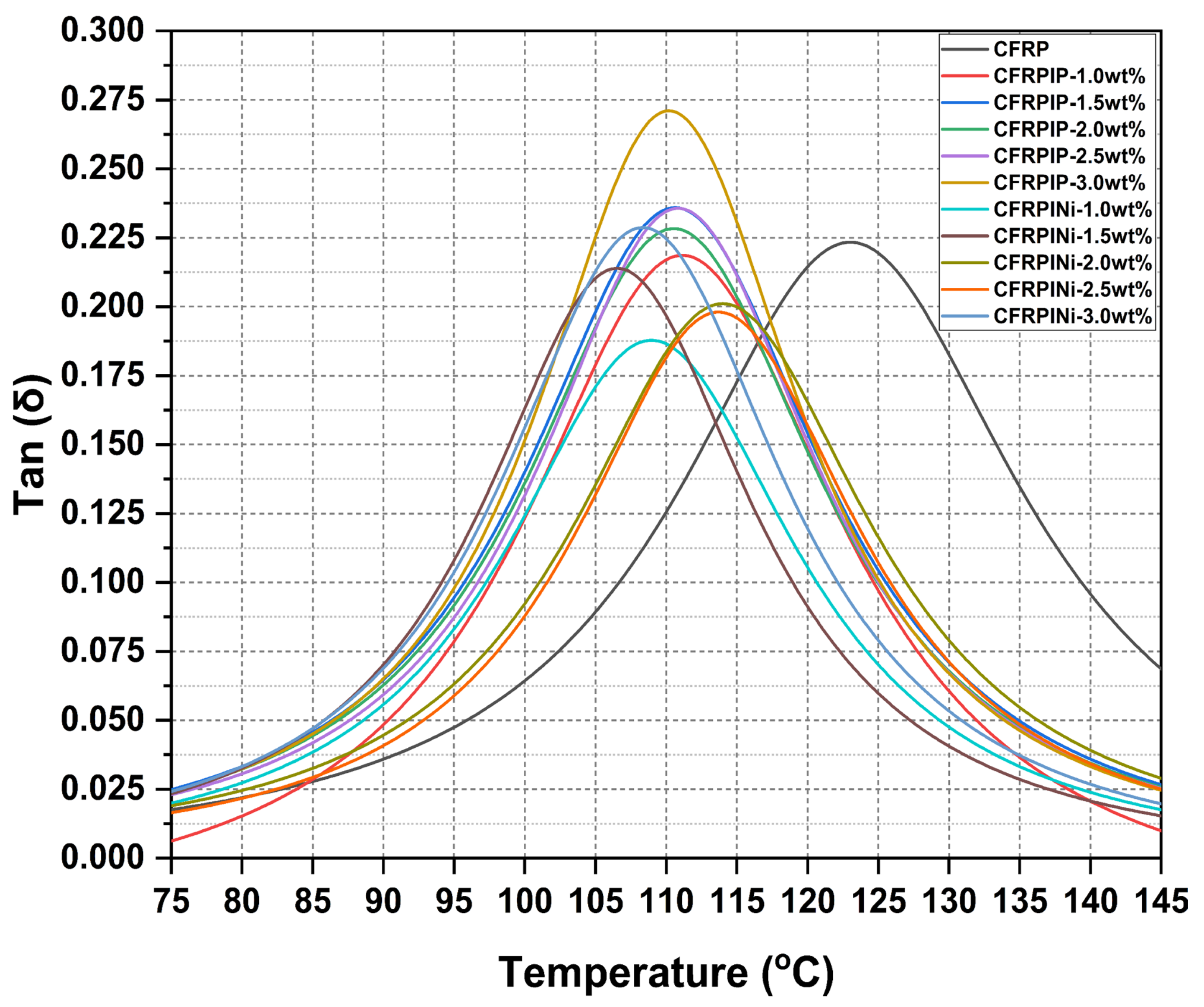

| Sample ID | Tg (°C) |

|---|---|

| CFRP | 123 |

| CFRPIP-1.0wt% | 111 |

| CFRPIP-1.5wt% | 110 |

| CFRPIP-2.0wt% | 110 |

| CFRPIP-2.5wt% | 110 |

| CFRPIP-3.0wt% | 110 |

| CFRPINi-1.0wt% | 108 |

| CFRPINi-1.5wt% | 106 |

| CFRPINi-2.0wt% | 113 |

| CFRPINi-2.5wt% | 113 |

| CFRPINi-3.0wt% | 108 |

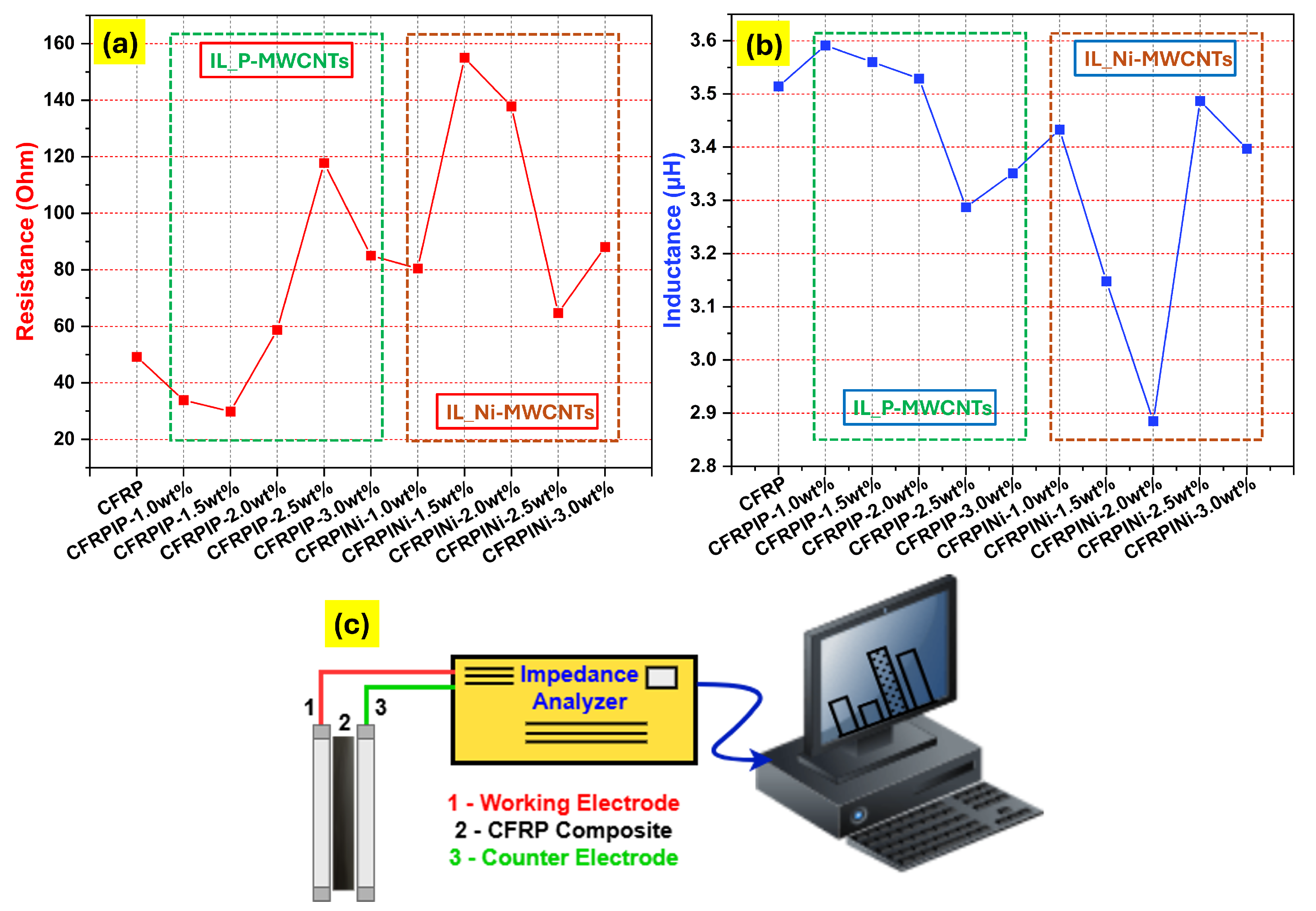

| Sample ID | %Error | %Error | Equivalent Circuit | ||

|---|---|---|---|---|---|

| CFRP | 49.2 | 0.069 | 0.3514 | 0.764 | |

| CFRPIP-1.0wt% | 33.9 | 0.055 | 0.3591 | 0.426 | |

| CFRPIP-1.5wt% | 29.89 | 0.058 | 0.3560 | 0.410 | |

| CFRPIP-2.0wt% | 58.7 | 0.067 | 0.3529 | 0.861 | |

| CFRPIP-2.5wt% | 117.8 | 0.084 | 0.3287 | 2.237 | |

| CFRPIP-3.0wt% | 85.0 | 0.078 | 0.3351 | 1.482 | |

| CFRPINi-1.0wt% | 80.5 | 0.075 | 0.3433 | 1.318 | |

| CFRPINi-1.5wt% | 155.0 | 0.087 | 0.3148 | 3.149 | |

| CFRPINi-2.0wt% | 137.8 | 0.089 | 0.2885 | 3.120 | |

| CFRPINi-2.5wt% | 64.7 | 0.071 | 0.3487 | 1.010 | |

| CFRPINi-3.0wt% | 88.1 | 0.079 | 0.3397 | 1.543 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, U.; Bertana, V.; Mossotti, G.; Ferrero, S.; Scaltrito, L. Sustainable Manufacturing of Lightweight Hybrid Nanocomposites for Electric Vehicle Battery Enclosures. Polymers 2025, 17, 1056. https://doi.org/10.3390/polym17081056

Farooq U, Bertana V, Mossotti G, Ferrero S, Scaltrito L. Sustainable Manufacturing of Lightweight Hybrid Nanocomposites for Electric Vehicle Battery Enclosures. Polymers. 2025; 17(8):1056. https://doi.org/10.3390/polym17081056

Chicago/Turabian StyleFarooq, Umar, Valentina Bertana, Giulia Mossotti, Sergio Ferrero, and Luciano Scaltrito. 2025. "Sustainable Manufacturing of Lightweight Hybrid Nanocomposites for Electric Vehicle Battery Enclosures" Polymers 17, no. 8: 1056. https://doi.org/10.3390/polym17081056

APA StyleFarooq, U., Bertana, V., Mossotti, G., Ferrero, S., & Scaltrito, L. (2025). Sustainable Manufacturing of Lightweight Hybrid Nanocomposites for Electric Vehicle Battery Enclosures. Polymers, 17(8), 1056. https://doi.org/10.3390/polym17081056