A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Sample Production

2.2.2. Optimization of Recycling Process

2.2.3. Testing Methods

3. Results and Discussion

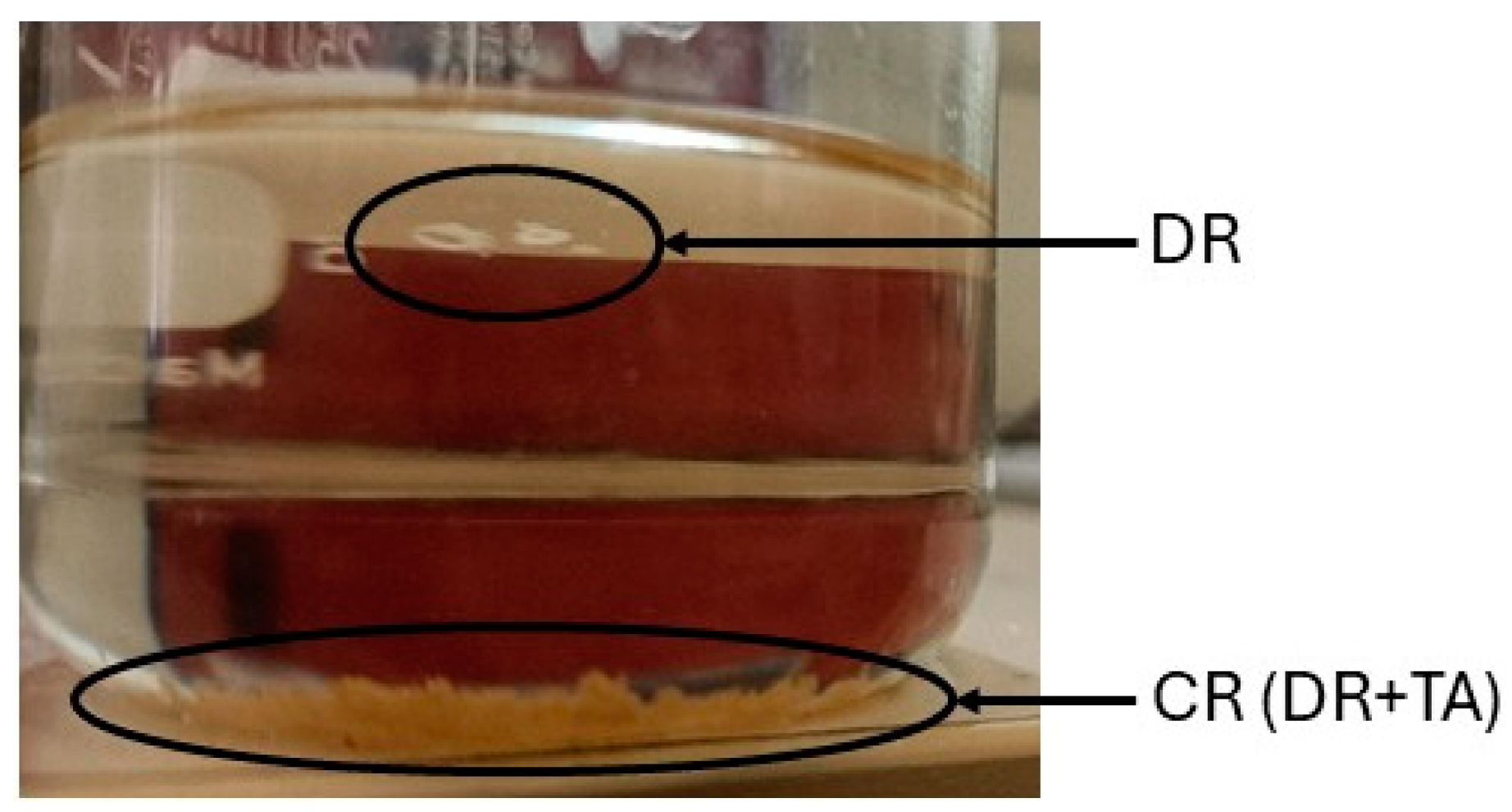

3.1. Recycling Process

3.2. FTIR and H-NMR Analysis

3.3. Thermal Characterization

3.4. Mechanical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Cho, C.M.; Wang, X.; Tsumura, S.K.; Thitsartarn, W.; Tay, S.W. Reusing Bisphenol—A Type of Epoxy Polymer Recyclates from the Solvolysis of CFRP. J. Compos. Sci. 2024, 8, 2. [Google Scholar] [CrossRef]

- Deng, J.; Xu, L.; Liu, J.; Peng, J.; Han, Z.; Shen, Z.; Guo, S. Efficient method of recycling carbon fiber from the waste of carbon fiber reinforced polymer composites. Polym. Degrad. Stab. 2020, 182, 109419. [Google Scholar] [CrossRef]

- Al-Lami, A.; Hilmer, P.; Sinapius, M. Eco-efficiency assessment of manufacturing carbon fiber reinforced polymers (CFRP) in aerospace industry. Aerosp. Sci. Technol. 2018, 79, 669–678. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Klose, L.; Meyer-Heydecke, N.; Wongwattanarat, S.; Chow, J.; Pérez García, P.; Carré, C.; Streit, W.; Antranikian, G.; Romero, A.M.; Liese, A. Towards Sustainable Recycling of Epoxy-Based Polymers: Approaches and Challenges of Epoxy Biodegradation. Polymers 2023, 15, 2653. [Google Scholar] [CrossRef]

- Long, Y.; Tian, F.; Bai, L.; An, W.; Zhao, X.; Du, R.; Liu, X.; Zhou, X.; Xu, S.; Wang, Y.Z. A mild and efficient oxidative degradation system of epoxy thermosets: Full recovery and degradation mechanism. Green Chem. 2022, 24, 7082. [Google Scholar] [CrossRef]

- Yang, K.; Wu, S.; Guan, J.; Shao, Z.; Ritchie, R.O. Enhancing the Mechanical Toughness of Epoxy-Resin Composites Using Natural Silk Reinforcements. Sci. Rep. 2017, 7, 11939. [Google Scholar] [CrossRef]

- Chen, P.Y.; Feng, R.; Xu, Y.; Zhu, J.H. Recycling and Reutilization of Waste Carbon Fiber Reinforced Plastics: Current Status and Prospects. Polymers 2023, 15, 3508. [Google Scholar] [CrossRef]

- Sokoli, H.U.; Simonsen, M.E.; Nielsen, P.R.; Arturi, K.R.; Sogaard, E.G. Conversion of the matrix in glass fiber reinforced composites into a high heating value oil and other valuable feedstocks. Fuel Process Technol. 2016, 149, 29–39. [Google Scholar] [CrossRef]

- Tavares de Moraes, V.; Jermoloviciusb, L.A.; Soares Tenórioc, J.A.; Marraccini Giampietri Lebrãoa, S.; Wolf Lebrão, G. Microwave-Assisted Recycling Process to Recover Fiber from Fiberglass Polyester Composites. Mater. Res. 2020, 22 (Suppl. S1), e20190389. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B 2020, 193, 108053–108067. [Google Scholar] [CrossRef]

- Zhu, J.H.; Chen, P.Y.; Su, M.N.; Pei, C.; Xing, F. Recycling of carbon fibre reinforced plastics by electrically driven heterogeneous catalytic degradation of epoxy resin. Green Chem. 2019, 21, 1635. [Google Scholar] [CrossRef]

- Navarro, C.A.; Kedzie, E.A.; Ma, Y.; Michael, K.H.; Nutt, S.R.; Williams, T.J. Mechanism and Catalysis of Oxidative Degradation of Fiber-Reinforced Epoxy Composites. Top. Catal. 2018, 61, 704–709. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J.M.; Robertson, M.L. The future of plastics recycling. Science 2017, 358, 870–872. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S. Recycling of carbon fiber with epoxy composites by chemical recycling for future perspective: A review. Chem. Pap. 2020, 74, 3785–3807. [Google Scholar] [CrossRef]

- Navarro, C.A.; Giffin, C.R.; Zhang, B.; Yu, Z.; Nutt, S.R.; Williams, T.J. A structural chemistry look at composites recycling. Mater. Horiz. 2020, 7, 2479. [Google Scholar] [CrossRef]

- Shen, M.; Cao, H.; Robertson, M.L. Hydrolysis and Solvolysis as Benign Routes for the End-of-Life Management of Thermoset Polymer Waste. Annu. Rev. Chem. Biomol. Eng. 2020, 11, 183–201. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Liu, C.; Mahmoodi, R.; Li, Q.; Naebe, M. Development of a low cost and green microwave assisted approach towards the circular carbon fibre composites. Compos. Part B 2020, 184, 107750. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Mysore Prabhakara, H.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Anastas, P.; Eghbali, N. Green Chemistry: Principles and Practice. Chem. Soc. Rev. 2010, 39, 301–312. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Latteri, A.; Cicala, G. Recycling treatment of carbon fibre/epoxy composites: Materials recovery and characterization and environmental impacts through life cycle assessment. Compos. Part B 2016, 104, 17–25. [Google Scholar] [CrossRef]

- Thomas, J.; Patil, R.S.; Patil, M.; John, J. Navigating the Labyrinth of Polymer Sustainability in the Context of Carbon Footprint. Coatings 2024, 14, 774. [Google Scholar] [CrossRef]

- Das, M.; Chacko, R.; Varughese, S. An Efficient Method of Recycling of CFRP Waste Using Peracetic Acid. ACS Sustain. Chem. Eng. 2018, 6, 1564–1571. [Google Scholar] [CrossRef]

- Huang, K.; Zheng, J.; Yuan, W.; Wang, X.; Song, Q.; Li, Y.; Crittenden, J.C.; Wang, L.; Wang, J. Microwave-assisted chemical recovery of glass fiber and epoxy resin from non-metallic components in waste printed circuit boards. Waste Manag. 2021, 124, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, X.L.; Tian, F.; An, W.L.; Xu, S.; Wang, Y.Z. A fast and mild closed-loop recycling of anhydride-cured epoxy through microwave-assisted catalytic degradation by trifunctional amine and subsequent reuse without separation. Green Chem. 2019, 21, 2487. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of sustainable microwave-based approach to recover glass fibers for wind turbine blades composite waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Patre, R.; Rani, M.; Zafar, S. Insights into environmental sustainability of microwave assisted chemical recycling of CFRP waste using life cycle assessment. Waste Manag. Bull. 2025, 3, 100194. [Google Scholar] [CrossRef]

- Saitta, L.; Rizzo, G.; Tosto, C.; Cicala, G.; Blanco, I.; Pergolizzi, E.; Ciobanu, R.; Recca, G. Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach. Polymers 2023, 15, 2809. [Google Scholar] [CrossRef]

- Pegoretti, A. Towards sustainable structural composites: A review on the recycling of continuous-fiber-reinforced thermoplastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 105–115. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Silverstein, R.M.; Bassler, G.C. Spectrometric Identification of Organic Compounds, 5th ed.; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Pawar, M.; Kadam, A.; Yemul, O.; Thamke, V.; Kodam, K. Biodegradable bioepoxy resins based on epoxidized natural oil (cottonseed & algae) cured with citric and tartaric acids through solution polymerization: A renewable approach. Ind. Crops Prod. 2016, 89, 434–447. [Google Scholar] [CrossRef]

- Ferrari, F.; Esposito Corcione, C.; Striani, R.; Saitta, L.; Gianluca Cicala, G.; Greco, A. Fully Recyclable Bio-Based Epoxy Formulations Using Epoxidized Precursors from Waste Flour: Thermal and Mechanical Characterization. Polymers 2021, 13, 2768 . [Google Scholar] [CrossRef] [PubMed]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Greco, A.; Ferrari, F.; Maffezzoli, A. Compression behavior of soft PVC foams obtained by cardanol-derived plasticizer. J. Cell Plast. 2020, 56, 515–530. [Google Scholar] [CrossRef]

| Samples | VIR [wt%] | CR/GR [wt%] | IPDA [phr on VIR] |

|---|---|---|---|

| VIR_CR_1 | 90 | 10 | 22 |

| VIR_CR_2 | 80 | 20 | 22 |

| VIR_CR_3 | 70 | 30 | 22 |

| VIR_CR_4 | 60 | 40 | 22 |

| VIR_GR_1 | 90 | 10 | 22 |

| VIR_GR_2 | 80 | 20 | 22 |

| VIR_GR_3 | 70 | 30 | 22 |

| VIR_GR_4 | 60 | 40 | 22 |

| Microwave Power [W] | Total Process Time [min] | Number of Cycles |

|---|---|---|

| 160 | 115 | 10 |

| 240 | 55.5 | 10 |

| 320 | 36.2 (no yeast) | 10 |

| 320 | 33 | 10 |

| 400 | 28.5 | 11 |

| Samples | Tg [°C] |

|---|---|

| CR | 32.6 |

| VIR | 127.2 |

| DR | 82.5 |

| VIR_CR_1 | 110.3 |

| VIR_CR_2 | 91.5 |

| VIR_CR_3 | 85.1 |

| VIR_CR_4 | 82.3 |

| VIR_GR_1 | 132.6 |

| VIR_GR_2 | 139.6 |

| VIR_GR_3 | 141.7 |

| VIR_GR_4 | 142.5 |

| (a) | Degrees of Freedom | Mean Square | p |

| Factor 1 (type of recyclate) | 1 | 389 | 2.74 × 10−4 |

| Factor 2 (amount of recyclate) | 4 | 1370 | 2.74 × 10−16 |

| Interaction | 4 | 88.4 | 1.31 × 10−2 |

| Error | 40 | 24.2 | |

| (b) | Degrees of Freedom | Mean Square | p |

| Factor 1 (type of recyclate) | 1 | 5 × 10−3 | 0.75 |

| Factor 2 (amount of recyclate) | 4 | 7.9 × 10−1 | 4.84 × 10−8 |

| Interaction | 4 | 7.2 × 10−1 | 1.57 × 10−7 |

| Error | 40 | 4.8 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cafaro, F.; Ferrari, F.; Carallo, G.A.; Greco, A.; Maffezzoli, A. A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices. Polymers 2025, 17, 989. https://doi.org/10.3390/polym17070989

Cafaro F, Ferrari F, Carallo GA, Greco A, Maffezzoli A. A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices. Polymers. 2025; 17(7):989. https://doi.org/10.3390/polym17070989

Chicago/Turabian StyleCafaro, Fabrizio, Francesca Ferrari, Gloria Anna Carallo, Antonio Greco, and Alfonso Maffezzoli. 2025. "A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices" Polymers 17, no. 7: 989. https://doi.org/10.3390/polym17070989

APA StyleCafaro, F., Ferrari, F., Carallo, G. A., Greco, A., & Maffezzoli, A. (2025). A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices. Polymers, 17(7), 989. https://doi.org/10.3390/polym17070989