A Review on Additive Manufactured Engineering Materials for Enhanced Road Safety and Transportation Applications

Abstract

1. Introduction

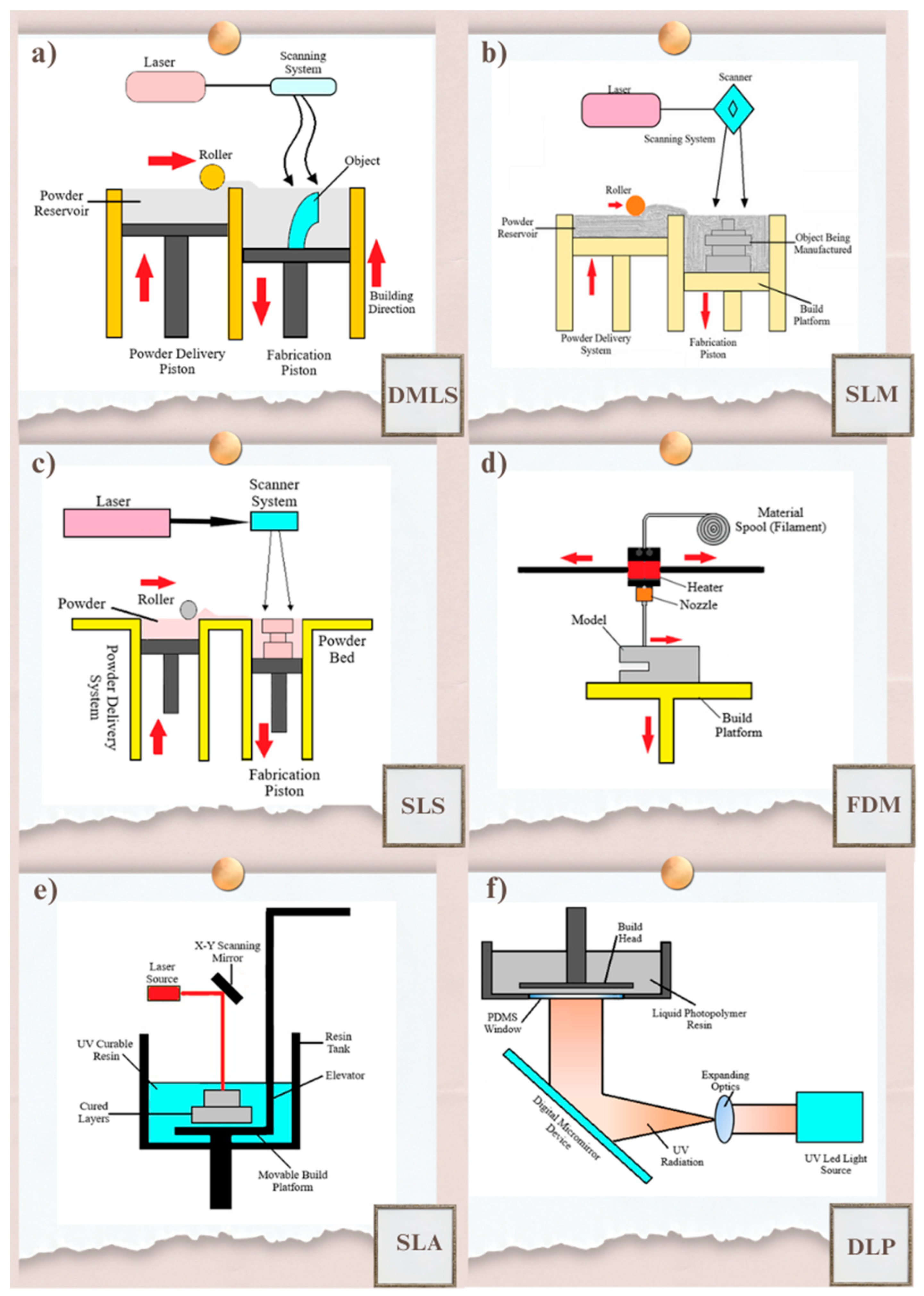

2. Additive Manufacturing Technologies in Road Safety Elements

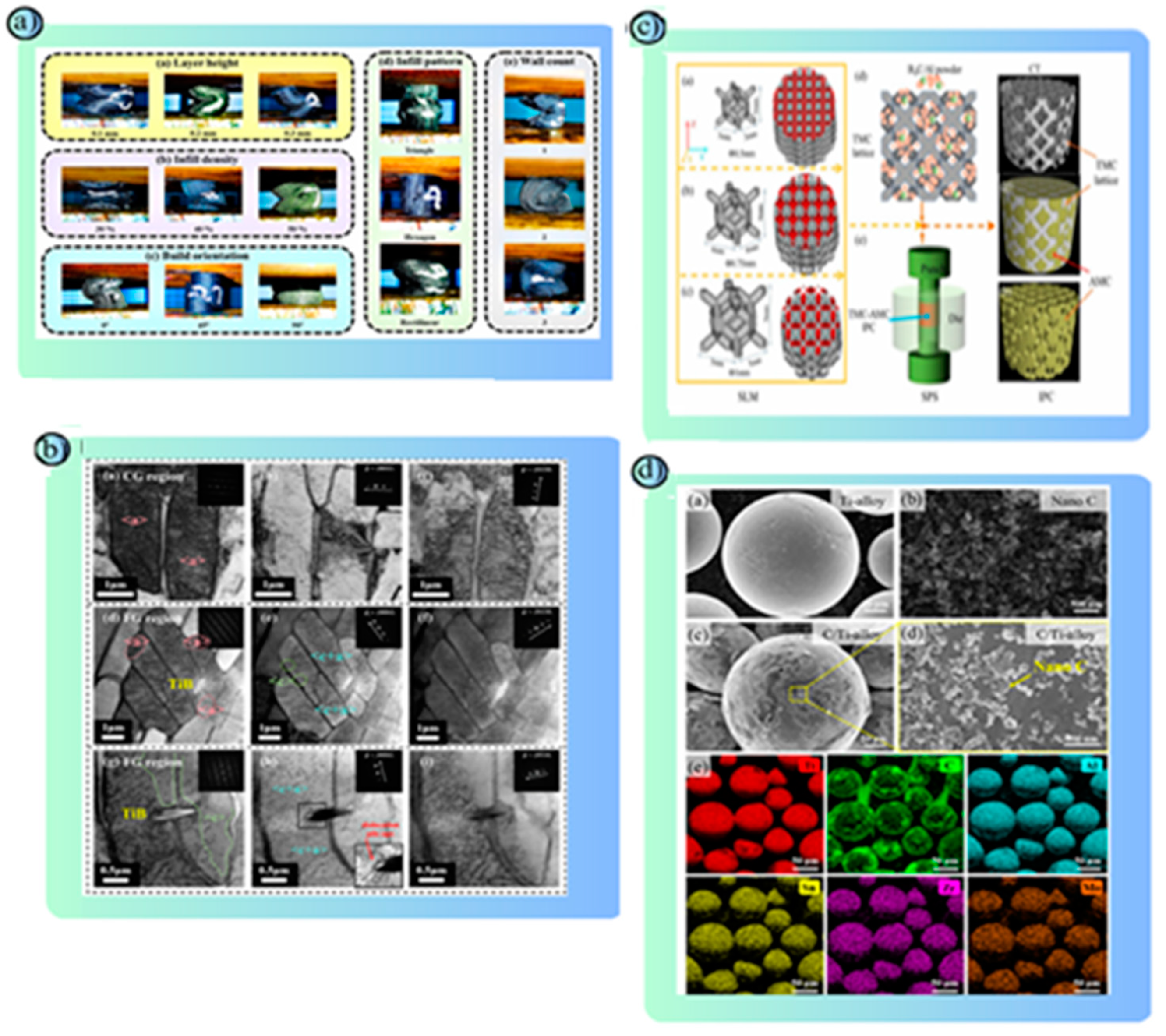

3. Materials Used in Road Safety and Transportation Applications

3.1. Polymers

| Year | Materials | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2022 | Recycled tire rubber and Polypropylene (PP) [67] | Energy and carbon analysis of recycled materials in road safety barriers |

| Option B achieved 38% less CO2 and 47% less non-renewable energy consumption. Option C showed a 69% CO2 reduction and 86% less energy consumption. |

| 2023 | Flexible polymer barrier [69] | Develop a flexible and reusable barrier system for runaway vehicles |

| The proposed system ensured passenger safety while successfully stopping runaway vehicles. It is also cost-effective as it is reusable. |

| 2024 | Ethylene-Vinyl Acetate (EVA) foam [70] | Design optimization of roadside safety barriers |

| EVA foam improved the crash performance of the barrier by reducing impact energy by 30%. Better design parameters were developed through parallel Bayesian optimization. |

| 2023 | Modular Rotating Polymer Barrier [71] | Analyzing the crash performance of the new mountable roll barrier |

| The rotating barrier caused less damage than conventional steel barriers, increased energy absorption and improved passenger safety. |

| 2021 | Assembled Anti-Collision Barrier (Polymer Composite) [72] | Analyzing the crash impact of a new erected barrier |

| The new barrier provided better energy absorption than traditional steel barriers and prevented vehicles from driving off the bridge. |

| 2019 | Water Filled Plastic Barrier (MDPE) [73] | Evaluating the crash performance of water-filled barriers |

| MDPE plastic barriers were effective at low speeds (≤20 km/h) but did not provide sufficient safety at high speeds (>50 km/h). |

3.2. Metals

| Year | Material | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2022 | Three-wave steel beam [86] | Increase crashworthiness. |

| Improved strength with new design. Maximum displacement 568.48 mm meeting Class 8 standards. |

| 2023 | Steel barrier [87] | Improving safety in freight car collisions |

| Absorbed 60% of the momentum. Reduced accident severity transferred to passengers. |

| 2023 | Q690 material [88] | Developing a passage system without a wing wall |

| Successful transition reducing the risk of snagging. Absorbed 280 KJ of crash energy. SB class protection. |

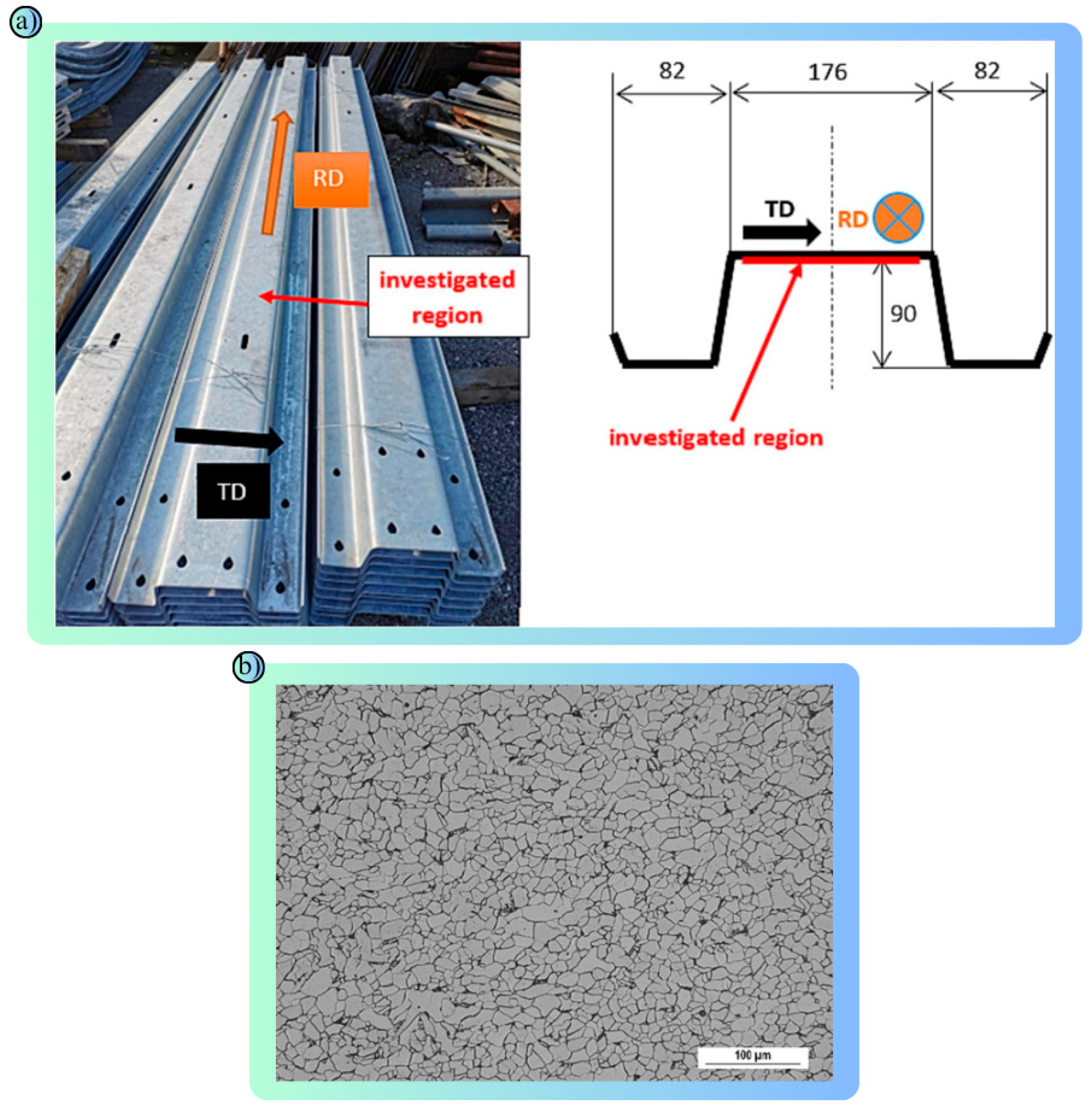

| 2023 | Ti-Nb Microalloyed steel [91] | Matching microstructure properties to crash loads. Microalloyed steel analyzed by laboratory tests |

| Microstructure developed for crash loads. Yield strength 729 MPA, tensile strength 813 MPa. |

| 2024 | Steel flange (Figure 6a,b) [92] | Reliably measure the load-bearing capacity. Material properties were evaluated with the non-destructive Barkhausen method |

| The load-bearing capacity was reliably assessed. A correlation was found between notch toughness and magnetic hardness. |

| 2024 | Crash barriers [93] | Optimizing barrier design and reducing impact in derailments of high-speed trains. Modeling with ABAQUS |

| Optimized design for high-speed trains. Effective in terms of dynamic damage prevention. |

| 2022 | W-beam barrier [95] | Poles in metal sleeves were evaluated. |

| Comparable performance to buried poles, compliant with MASH standards. |

| 2024 | Al 6061-T6 material [96] | Increase deformation resistance and moment of inertia. Beam optimization using LS-DYNA software |

| Higher inertia and reduced deformation. Deformation reduced by 12.8%, moment of inertia increased by 28.6%. |

| 2022 | Triple beam barrier [98] | Making bridge barrier connections safe. Crash tests were conducted in accordance with MASH standards. |

| Safe and effective bridge barrier connection. Compliant with MASH TL-3 standards, prevents vehicle entrapment. |

| 2024 | Movable steel barrier [99] | Improving highway safety with fast opening and closing barriers. |

| Fast installation for highway safety. Installation speed 12 m/min, closing speed 2 min. |

| 2021 | Cable barriers and strong post barriers [100] | Analyzing crash outcomes with cable barriers and pole barriers. Data analysis was performed with mixed logit models. |

| Cable barriers have the lowest share of fatal/injury accidents with 24%. |

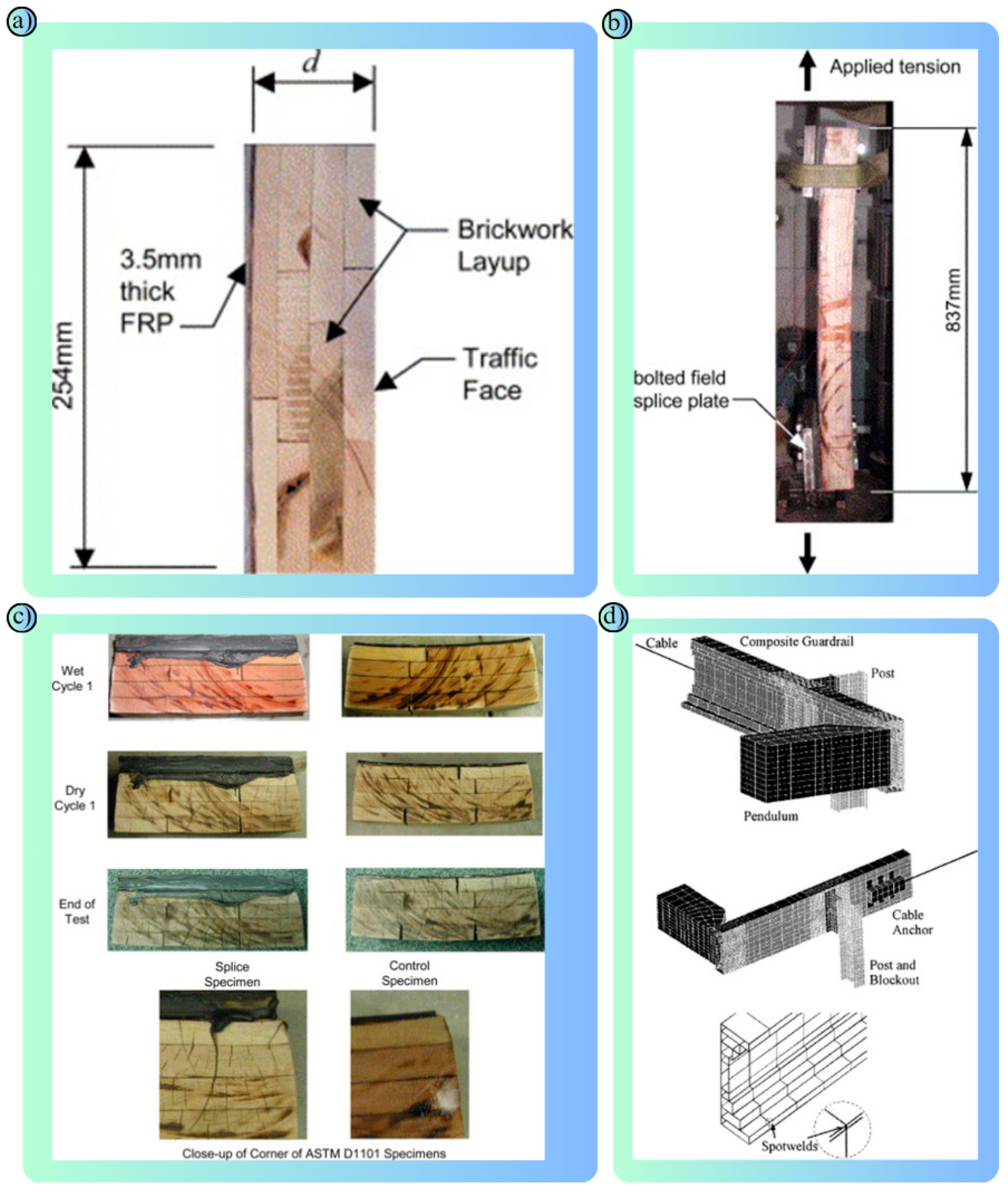

3.3. Composites

| Year | Material | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2024 | Glass fiber/LDPE composite [119] | Production and characterization for W-beam barrier |

| Glass fiber-reinforced barriers have better energy absorption capacity compared to the steel alternative. |

| 2023 | Natural stem (Stipa tenacissima) composite [122] | Increase impact energy absorption |

| The composite barrier absorbed 67.7% more impact energy than steel. |

| 2021 | Basalt fiber reinforced polymer [125] | Improving crash performance |

| It absorbed more energy than steel barriers, keeping vehicle acceleration under 200%. |

| 2022 | Composite blocks [126] | W-beam barrier height increase |

| MASH Test 3-11 standard was found compliant, passenger safety was increased. |

| 2023 | Composite-steel double-layer barrier [127] | Increasing the crashworthiness of bridge barriers |

| The double-layer barrier provided energy absorption equivalent to 59.1% of the concrete barrier. |

| 2023 | Carbon/Epoxy and Fiber Metal Laminated [128] | Compare the impact resistance of different barriers |

| The FML-B barrier was found to have the highest energy absorption capacity. |

| 2023 | Renewable hybrid barrier (RHB) [129] | Impact resistance of innovative hybrid barrier systems |

| The hybrid barrier was found to be as safe as steel and as comfortable as concrete. |

| 2022 | Hybrid barrier with waste materials (Figure 8b) [118] | To investigate the usability of waste materials in barriers |

| An environmentally friendly barrier compliant with EN 1317 tests was proposed. |

| 2024 | Recycled foam concrete [130] | Increasing energy absorption in road barriers |

| Reduced impact force by 54.46%, reduced cost by 5.5%. |

| 2021 | Steel-concrete composite beam [131] | Analyzing the effect of parapets | Simple beam composite bridge model | A 26.92% lower load distribution was detected with the parapet effect. |

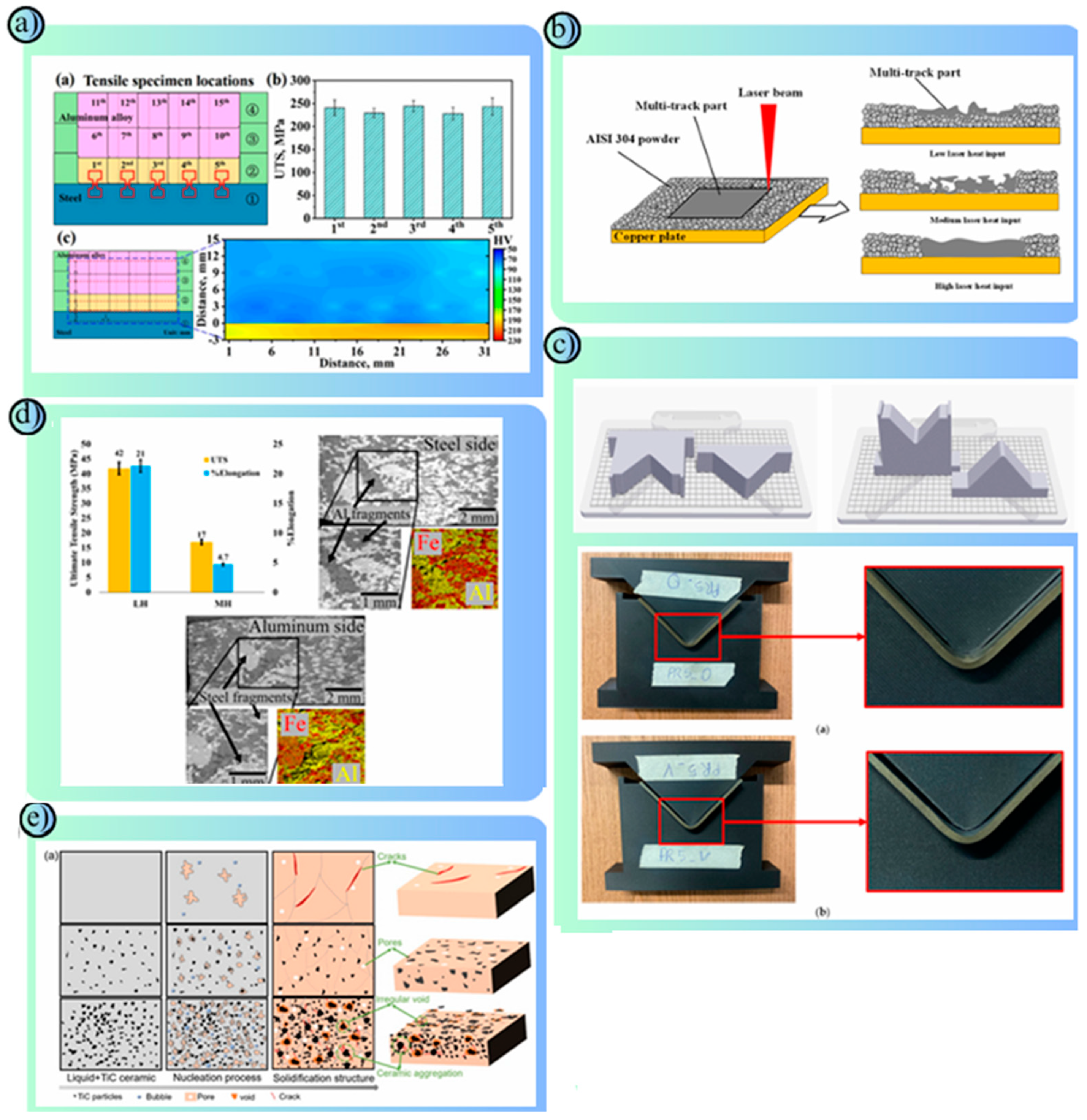

4. AMed Materials and Its Road Safety and Transportation Structures

4.1. Polymer-Based Materials

4.2. Metal Materials

4.3. Composite Materials

5. Challenges and Future Perspectives

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Health Organization. Pedestrian Safety: A Road Safety Manual for Decision-Makers and Practitioners; World Health Organization: Geneva, Switzerland, 2023. [Google Scholar]

- Meesmann, U.; Wardenier, N.; Torfs, K.; Pires, C.; Delannoy, S.; Van den Berghe, W. A Global Look at Road Safety: Synthesis from the ESRA2 Survey in 48 Countries. ESRA Project (E-Survey of Road Users’ Attitudes); Vias Institute: Brussels, Belgium, 2022. [Google Scholar]

- Khan, M.N.; Das, S. Advancing Traffic Safety through the Safe System Approach: A Systematic Review. Accid. Anal. Prev. 2024, 199, 107518. [Google Scholar] [PubMed]

- Mára, M.; Konrád, P.; Fornůsek, J.; Zatloukal, J.; Frydrýn, M.; Nouzovský, L.; Sovják, R. Development of Mobile Road Barrier Made of Ultra-High-Performance Fibre-Reinforced Concrete. Mater. Today Proc. 2020, 32, 162–167. [Google Scholar]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A Comparison of Traditional Manufacturing vs Additive Manufacturing, The Best Method for the Job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar]

- Alparslan, C.; Bayraktar, Ş.; Gupta, K. A Comparative Study on Mechanical Performance of PLA, ABS, and CF Materials Fabricated by Fused Deposition Modeling. Facta Univ. Ser. Mech. Eng. 2024. [Google Scholar]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing Over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar]

- Eickhoff, R.; Antusch, S.; Nötzel, D.; Probst, M.; Hanemann, T. Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts. Polymers 2024, 16, 2548. [Google Scholar] [CrossRef]

- Economides, A.L.; Islam, M.N.; Baxevanakis, K.P. Additively Manufactured Carbon Fibre PETG Composites: Effect of Print Parameters on Mechanical Properties. Polymers 2024, 16, 3336. [Google Scholar] [CrossRef]

- Shapiro, A.A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive Manufacturing for Aerospace Flight Applications. J. Spacecr. Rocket. 2016, 53, 952–959. [Google Scholar]

- Schiller, G.J. Additive Manufacturing for Aerospace. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–8. [Google Scholar]

- Vasco, J.C. Additive Manufacturing for the Automotive Industry. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 505–530. [Google Scholar]

- Schuhmann, D.; Rockinger, C.; Merkel, M.; Harrison, D.K. A Study on Additive Manufacturing for Electromobility. World Electr. Veh. J. 2022, 13, 154. [Google Scholar] [CrossRef]

- De, A.; Ramasubramian, B.; Ramakrishna, S.; Chellappan, V. Advances in Additive Manufacturing Techniques for Electrochemical Energy Storage. Adv. Mater. Technol. 2024, 9, 2301439. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive Manufacturing in Unmanned Aerial Vehicles (UAVs): Challenges and Potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Tanwar, R.S.; Jhavar, S. Ti-Based Alloys for Aerospace and Biomedical Applications Fabricated through Wire+Arc Additive Manufacturing (WAAM). Mater. Today Proc. 2024, 98, 226–232. [Google Scholar]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder Characterisation Techniques and Effects of Powder Characteristics on Part Properties in Powder-Bed Fusion Processes. Virtual Phys. Prototyp. 2017, 12, 3–29. [Google Scholar] [CrossRef]

- Gibbons, D.W.; Govender, P.; van der Merwe, A.F. Metal Powder Feedstock Evaluation and Management for Powder Bed Fusion: A Review of Literature, Standards, and Practical Guidelines. Prog. Addit. Manuf. 2024, 9, 805–833. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Ishfaq, K.; Abdullah, M.; Mahmood, M.A. A State-of-the-Art Direct Metal Laser Sintering of Ti6Al4V and AlSi10Mg Alloys: Surface Roughness, Tensile Strength, Fatigue Strength and Microstructure. Opt. Laser Technol. 2021, 143, 107366. [Google Scholar] [CrossRef]

- Bayraktar, Ş.; Alparslan, C. Comparison of the SLM, SLS, and DLMS Techniques in Additive Manufacture of AlSi10Mg Alloys. In Innovation and Sustainable Manufacturing; Woodhead Publishing: Cambridge, UK, 2023; pp. 231–253. [Google Scholar]

- Bayraktar, Ş.; Şentürk, E. Machinability of 3D Printed Materials. In Innovations in Additive Manufacturing; Springer International Publishing: Cham, Switzerland, 2022; pp. 297–319. [Google Scholar]

- Malashin, I.; Martysyuk, D.; Tynchenko, V.; Nelyub, V.; Borodulin, A.; Galinovsky, A. Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches. Polymers 2024, 16, 737. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Saenz-Nuno, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2021, 12, 9. [Google Scholar] [CrossRef]

- Yehia, H.M.; Hamada, A.; Sebaey, T.A.; Abd-Elaziem, W. Selective Laser Sintering of Polymers: Process Parameters, Machine Learning Approaches, and Future Directions. J. Manuf. Mater. Process. 2024, 8, 197. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, S.; He, L.; Yang, Z.; Liu, T. 3D Printing of High-Stiffness and High-Strength Glass Fiber Reinforced PEEK Composites by Selective Laser Sintering. Compos. Part A Appl. Sci. Manuf. 2024, 187, 108470. [Google Scholar]

- Hira, F.; Asif, M.; Ullah, H.; Khan, I.; Hussain, G.; Amir, M.; Alkahtani, M. Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples. Polymers 2025, 17, 426. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhao, P.; Lu, Q.; Zhang, Y.; Lei, H.; Yu, C.; Yu, J. Multi-Physical Honeycomb Metastructure Fabricated by Fused Deposition Modeling with Broadband Radar Absorption and Mechanical Resistance for Drones. Polym. Compos. 2024, 45, 1278–1287. [Google Scholar]

- Liu, K. Driving Towards a Greener Future: The Role of Artificial Intelligence and 3D Printing in Advancing Energy-Efficient Vehicles. In Proceedings of the 2024 International Conference on Mechanical, Electronic, and Automation Engineering (ICMEEA 2024), Singapore, 26 July 2024; Atlantis Press: Dordrecht, The Netherlands, 2024; pp. 688–703. [Google Scholar]

- Khoo, H.; Allen, W.S.; Arroyo-Currás, N.; Hur, S.C. Rapid Prototyping of Thermoplastic Microfluidic Devices via SLA 3D Printing. Sci. Rep. 2024, 14, 17646. [Google Scholar]

- Tuvshinbayar, K.; Mpofu, N.S.; Berger, T.; Storck, J.L.; Büsgen, A.; Ehrmann, A. Comparison of FDM and SLA Printing on Woven Fabrics. Commun. Dev. Assem. Text. Prod. 2024, 5, 169–177. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Jamil, M.; Gupta, M.K. Digital Light Processing 3D Printing of Ceramic Materials: A Review on Basic Concept, Challenges, and Applications. Int. J. Adv. Manuf. Technol. 2024, 130, 2241–2267. [Google Scholar] [CrossRef]

- Chaudhary, R.; Akbari, R.; Antonini, C. Rational Design and Characterization of Materials for Optimized Additive Manufacturing by Digital Light Processing. Polymers 2023, 15, 287. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar]

- Attar, H.; Ehtemam-Haghighi, S.; Soro, N.; Kent, D.; Dargusch, M.S. Additive Manufacturing of Low-Cost Porous Titanium-Based Composites for Biomedical Applications: Advantages, Challenges and Opinion for Future Development. J. Alloys Compd. 2020, 827, 154263. [Google Scholar]

- Walter, A.; Marcham, C.L. Environmental Advantages in Additive Manufacturing. Prof. Saf. 2020, 65, 34–38. [Google Scholar]

- Dalla Chiara, B.; Pellicelli, M. Sustainable Road Transport from the Energy and Modern Society Points of View: Perspectives for the Automotive Industry and Production. J. Clean. Prod. 2016, 133, 1283–1301. [Google Scholar] [CrossRef]

- Jiang, W.; Huang, Y.; Sha, A. A Review of Eco-Friendly Functional Road Materials. Constr. Build. Mater. 2018, 191, 1082–1092. [Google Scholar] [CrossRef]

- Yentimur, M.F.; Kütük, T.; Kütük, S. Bor ve Bor Atığının İnşaat Yıkıntı Atığı ile Normal Beton Üzerindeki Etkileri. J. Innov. Civ. Eng. Technol. 2022, 4, 47–60. [Google Scholar]

- Babić, D.; Babić, D.; Fiolic, M.; Ferko, M. Road Markings and Signs in Road Safety. Encyclopedia 2022, 2, 1738–1752. [Google Scholar] [CrossRef]

- Molan, A.M.; Moomen, M.; Ksaibati, K. The Impact of Traffic Barrier Geometric Features on Crash Frequency and Injury Severity of Non-Interstate Highways. J. Saf. Res. 2020, 75, 155–165. [Google Scholar]

- Moon, W.; Milailidis, P.; Chau, T. Safe System Roadsides: Putting Clear Zones in Their Place. Transp. Res. Circ. 2016, 28–37. [Google Scholar]

- Molan, A.M.; Rezapour, M.; Ksaibati, K. Investigating the Relationship Between Crash Severity, Traffic Barrier Type, and Vehicle Type in Crashes Involving Traffic Barrier. J. Traffic Transp. Eng. (Eng. Ed.) 2020, 7, 125–136. [Google Scholar]

- Xu, F.; Zhang, X.; Zhang, H. A Review on Functionally Graded Structures and Materials for Energy Absorption. Eng. Struct. 2018, 171, 309–325. [Google Scholar]

- Croll, S.G. Surface Roughness Profile and Its Effect on Coating Adhesion and Corrosion Protection: A Review. Prog. Org. Coat. 2020, 148, 105847. [Google Scholar] [CrossRef]

- Chhipa, S.M.; Sharma, S.; Bagha, A.K. Recent Development in Polymer Coating to Prevent Corrosion in Metals: A Review. Mater. Today Proc. 2024, in press. [Google Scholar]

- Fan, J.; Njuguna, J. An Introduction to Lightweight Composite Materials and Their Use in Transport Structures. In Lightweight Composite Structures in Transport; Woodhead Publishing: Sawston, UK, 2016; pp. 3–34. [Google Scholar]

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R. Matrix Materials Used in Composites: A Comprehensive Study. Mater. Today Proc. 2020, 21, 1559–1562. [Google Scholar]

- Garner, D.M.; Barnes, G.; Coles, I.; Roberts, R.; Adams, D.O. Crash Safety Assurances Strategies for Future Plastic and Composite Intensive Vehicles (PCIVs); U.S. Department of Transportation: Washington, DC, USA, 2010.

- Yang, J.; Xu, G.; Cai, C.S.; Kareem, A. Crash Performance Evaluation of a New Movable Median Guardrail on Highways. Eng. Struct. 2019, 182, 459–472. [Google Scholar]

- Lin, H.; Chen, F.; Zhang, H. Active Luminous Road Markings: A Comprehensive Review of Technologies, Materials, and Challenges. Constr. Build. Mater. 2023, 363, 129811. [Google Scholar]

- Chen, J.; Li, R.; Zhang, Y.; Wu, Y.; He, H. Study on the Reflective Principle and Long-Term Skid Resistance of a Sustainable Hydrophobic Hot-Melt Marking Paint. Sustainability 2023, 15, 9950. [Google Scholar] [CrossRef]

- Sengoz, B.; Topal, A.; Isikyakar, G. Morphology and Image Analysis of Polymer Modified Bitumens. Constr. Build. Mater. 2009, 23, 1986–1992. [Google Scholar]

- Yan, K.; Chen, J.; You, L.; Tian, S. Characteristics of Compound Asphalt Modified by Waste Tire Rubber (WTR) and Ethylene Vinyl Acetate (EVA): Conventional, Rheological, and Microstructural Properties. J. Clean. Prod. 2020, 258, 120732. [Google Scholar]

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A Review of Polymer-Modified Asphalt Binder: Modification Mechanisms and Mechanical Properties. Clean. Mater. 2024, 12, 100255. [Google Scholar]

- Kamal, I.; Bas, Y. Materials and Technologies in Road Pavements-An Overview. Mater. Today Proc. 2021, 42, 2660–2676. [Google Scholar]

- Wallqvist, V.; Kjell, G.; Cupina, E.; Kraft, L.; Deck, C.; Willinger, R. New Functional Pavements for Pedestrians and Cyclists. Accid. Anal. Prev. 2017, 105, 52–63. [Google Scholar]

- Boyce, P. Lighting for Driving: Roads, Vehicles, Signs, and Signals; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Thiyahuddin, M.I.; Gu, Y.; Thambiratnam, D.P.; Thilakarathna, H.M. Impact and Energy Absorption of Portable Water-Filled Road Safety Barrier System Fitted with Foam. Int. J. Impact Eng. 2014, 72, 26–39. [Google Scholar] [CrossRef]

- Gover, R.B.; Oloyede, A.; Thambiratnam, D.P.; Thiyahuddin, M.I.; Morris, A. Experimental and Numerical Study of Polymeric Foam Efficacy in Portable Water-Filled Barriers. Int. J. Impact Eng. 2015, 76, 83–97. [Google Scholar] [CrossRef]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable Polymers and Plastics: Performance Beyond the Green. New Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M. Plastic Waste and Its Management Strategies for Environmental Sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar]

- Amulya, K.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Low Carbon Biodegradable Polymer Matrices for Sustainable Future. Compos. Part C Open Access 2021, 4, 100111. [Google Scholar] [CrossRef]

- Tejaswini, M.S.S.R.; Pathak, P.; Ramkrishna, S.; Ganesh, P.S. A Comprehensive Review on Integrative Approach for Sustainable Management of Plastic Waste and Its Associated Externalities. Sci. Total Environ. 2022, 825, 153973. [Google Scholar] [CrossRef]

- Monteiro, H.; Ribeiro, I.; Gonçalves, M.; Iten, M.; Caetano, N.S. Life Cycle Energy and Carbon Analysis of a Road-Safety Barrier Produced Using Recycled Tire Rubber. Energy Rep. 2022, 8, 270–276. [Google Scholar] [CrossRef]

- ISO 14040/14044:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Xu, X.; Zhang, H.; Zhao, X.; Du, X.; Lian, D.; Liu, Z. Development of a Runaway Vehicle Protective Barrier System Using Simulation and Full-Scale Crash Testing. Sustainability 2023, 15, 1925. [Google Scholar] [CrossRef]

- Xia, F.; Le, V.H.; Ruan, D.; Tsang, H.H.; Wheatland, J.; Xu, S. Design Optimisation of Roadside Safety Roller Barriers. Eng. Struct. 2024, 317, 118602. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, J.; Huang, L.; Xu, J. Analysis of Anti-Collision Performance of a New Assembled Rolling Guardrail. Structures 2023, 47, 246–259. [Google Scholar] [CrossRef]

- Yao, J.; Wang, B.; Hou, Y.; Huang, L. Analysis of Vehicle Collision on an Assembled Anti-Collision Guardrail. Sensors 2021, 21, 5152. [Google Scholar] [CrossRef] [PubMed]

- Yuan, D.; Luo, Y.; Peng, Y. Research on the Crashworthiness of Regular Centurion 2M Barrier Based on the Arbitrary Lagrange-Euler Method. Int. J. Automot. Technol. 2019, 20, 549–558. [Google Scholar]

- EN 1317:2010; European Standard for Road Restraint Systems. European Committee for Standardization: Brussels, Belgium, 2010.

- Soltani, M.; Moghaddam, T.B.; Karim, M.R.; Sulong, N.R. Analysis of Developed Transition Road Safety Barrier Systems. Accid. Anal. Prev. 2013, 59, 240–252. [Google Scholar] [PubMed]

- Martin, J.L.; Mintsa-Eya, C.; Goubel, C. Long-Term Analysis of the Impact of Longitudinal Barriers on Motorway Safety. Accid. Anal. Prev. 2013, 59, 443–451. [Google Scholar] [CrossRef]

- Bruski, D.; Burzyński, S.; Chróścielewski, J.; Jamroz, K.; Pachocki, Ł.; Witkowski, W.; Wilde, K. Experimental and Numerical Analysis of the Modified TB32 Crash Tests of the Cable Barrier System. Eng. Fail. Anal. 2019, 104, 227–246. [Google Scholar]

- Song, J.; Hu, D.; Luo, S.; Liu, W.; Wang, D.; Sun, Q.; Zhang, G. Energy-Absorption Behavior of Metallic Hollow Sphere Structures Under Impact Loading. Eng. Struct. 2021, 226, 111350. [Google Scholar]

- Baddoo, N.R. Stainless Steel in Construction: A Review of Research, Applications, Challenges and Opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206. [Google Scholar]

- Sarıkaya, M.; Önler, D.B.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A Review on Aluminum Alloys Produced by Wire Arc Additive Manufacturing (WAAM): Applications, Benefits, Challenges and Future Trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar]

- Ortega-Iguña, M.; Chludzinski, M.; Sánchez-Amaya, J.M. Comparative Mechanical Study of Pressure Sensitive Adhesives Over Aluminium Substrates for Industrial Applications. Polymers 2022, 14, 4783. [Google Scholar] [CrossRef]

- Paul, P.; Tota-Maharaj, K. Laboratory Studies on Granular Filters and Their Relationship to Geotextiles for Stormwater Pollutant Reduction. Water 2015, 7, 1595–1609. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Formisano, A.; Terracciano, G.; Landolfo, R. Iron Alloys and Structural Steels from XIX Century Until Today: Evolution of Mechanical Properties and Proposal of a Rapid Identification Method. Constr. Build. Mater. 2021, 302, 124132. [Google Scholar]

- Olabi, A.G.; Morris, E.; Hashmi, M.S.J. Metallic Tube Type Energy Absorbers: A Synopsis. Thin-Walled Struct. 2007, 45, 706–726. [Google Scholar]

- Biswas, S.; Williams, K.; Jones, M. Development of a Constitutive Model for Erosion Based on Dissipated Particle Energy to Predict the Wear Rate of Ductile Metals. Wear 2018, 404, 166–175. [Google Scholar]

- Guo, K.; Wang, C.; Shen, L. An Experimental Study on the Impact Resistance of a New Three-Wave Beam Steel Guardrail. Front. Mater. 2022, 9, 942099. [Google Scholar]

- Jaber, M.M.; Ali, M.H.; Abd, S.K.; Abosinnee, A.S.; Malik, R.Q. Simulation Research on the Collision Between Freight Cars and Expressway Three-Wave Beam Steel Guardrail. Multimed. Tools Appl. 2023, 1, 1–22. [Google Scholar]

- Shen, L.; Hu, R.; Wang, T. Research and Design of a Wing-Wall-Free Guardrail in Transition Between the Subgrade and the Bridge. Front. Mater. 2022, 9, 918107. [Google Scholar]

- JTG B05-01-2013; Standard for Safety Performance Evaluation of Highway Barriers. Ministry of Transport of the People’s Republic of China: Beijing, China, 2013.

- JTG/T D81-2017; Design Guidelines for Highway Safety Facilities. Ministry of Transport of the People’s Republic of China: Beijing, China, 2017.

- Liu, Y.; Gan, X.; Wang, S.; Yang, H.; Li, Y.; Xu, G. Effect of Coiling Temperature on Microstructure and Properties of a Ti–Nb Microalloyed High-Speed Guardrail Steel. Steel Res. Int. 2023, 94, 2200840. [Google Scholar]

- Neslušan, M.; Minárik, P.; Čep, R.; Ondruš, J.; Pitoňák, M.; Zgútová, K. Measurement of Bearing Capacity of Steel Road Barrier Flange via Barkhausen Noise Emission. Eng. Fail. Anal. 2024, 156, 107804. [Google Scholar]

- Qian, K.; Wang, G.; Ma, H.; Zeng, H. Study on Dynamic Damage of Crash Barrier Under Impact Load of High-Speed Train. Sustainability 2024, 16, 3147. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Sheikh, N.; Bligh, R. Evaluation of W-Beam Guardrail and Terminal Posts Installed in Metal Sleeves. Transp. Res. Rec. 2022, 2676, 355–362. [Google Scholar]

- Wang, L.; Huang, X.; Li, R.; Tang, Z.; Li, J.; Chen, D. Collision Study on New Aluminum Alloy W-Beam Guardrail. Appl. Sci. 2024, 14, 5266. [Google Scholar] [CrossRef]

- JTG/T F83-01-2004; Test Methods for Safety Performance of Highway Safety Barriers. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Rasmussen, J.D.; Rosenbaugh, S.K.; Faller, R.K.; Bielenberg, R.W. Development of a Test Level 3 Approach Guardrail Transition to Steel Tube Bridge Rail. Transp. Res. Rec. 2022, 2676, 74–89. [Google Scholar]

- Zhang, A.; Bu, Q.; Zhang, W.; He, G.; Deng, Y. Test and Application of Movable Steel Barrier with Grade SB Light Composite Corrugated Beam. J. Meas. Eng. 2024, 12, 1–22. [Google Scholar]

- Hosseinpour, M.; Haleem, K. Examining Crash Injury Severity and Barrier-Hit Outcomes from Cable Barriers and Strong-Post Guardrails on Alabama’s Interstate Highways. J. Saf. Res. 2021, 78, 155–169. [Google Scholar]

- Davids, W.G.; Botting, J.K.; Peterson, M. Development and Structural Testing of a Composite-Reinforced Timber Highway Guardrail. Constr. Build. Mater. 2006, 20, 733–743. [Google Scholar]

- Bank, L.C.; Gentry, T.R. Development of a Pultruded Composite Material Highway Guardrail. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1329–1338. [Google Scholar]

- Gebremichael, Y.M.; Li, W.; Boyle, W.J.O.; Meggitt, B.T.; Grattan, K.T.V.; McKinley, B.; Luke, S. Integration and Assessment of Fibre Bragg Grating Sensors in an All-Fibre Reinforced Polymer Composite Road Bridge. Sens. Actuators A Phys. 2005, 118, 78–85. [Google Scholar]

- Canning, L.; Hodgson, J.; Jarman, A.; Karuna, R.; Luke, S. The Analysis, Design and Optimisation of an Advanced Composite Bridge Deck. In Advances in Polymer Composites Structures and Applications in Construction; Thomas Telford Publishing: London, UK, 2002; p. 405. [Google Scholar]

- Yanagimoto, J.; Ikeuchi, K. Sheet Forming Process of Carbon Fiber Reinforced Plastics for Lightweight Parts. CIRP Ann. 2012, 61, 247–250. [Google Scholar]

- Masilamani, R.; Dhandapani, N.V.; Kumar, K.V.; Mani, K.T. A Review on Usage of Carbon Fiber Reinforced Plastics in Automobiles. Int. J. Pure Appl. Math. 2017, 117, 537–544. [Google Scholar]

- Li, Z.; Meng, Z. A Review of the Radio Frequency Non-Destructive Testing for Carbon-Fibre Composites. Meas. Sci. Rev. 2016, 16, 68–76. [Google Scholar]

- Visal, S.; Deokar, S.U. A Review Paper on Properties of Carbon Fiber Reinforced Polymers. Int. J. Innov. Res. Sci. Technol. 2016, 2, 238–243. [Google Scholar]

- Firmo, J.P.; Correia, J.R.; França, P. Fire Behaviour of Reinforced Concrete Beams Strengthened with CFRP Laminates: Protection Systems with Insulation of the Anchorage Zones. Compos. Part B Eng. 2012, 43, 1545–1556. [Google Scholar]

- Hegde, S.; Shenoy, B.S.; Chethan, K.N. Review on Carbon Fiber Reinforced Polymer (CFRP) and Their Mechanical Performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar]

- Chen, Y.; Li, M.; Yang, X.; Wei, K. Durability and Mechanical Behavior of CFRP/Al Structural Joints in Accelerated Cyclic Corrosion Environments. Int. J. Adhes. Adhes. 2020, 102, 102695. [Google Scholar]

- Khan, M.S.; Din, I.U.; Khan, K.A.; Shah, S.A.; Jan, A. A Review of Design, Materials, and Manufacturing Techniques in Bumper Beam System. Compos. Part C Open Access 2024, 14, 100496. [Google Scholar]

- Shubhra, Q.T.; Alam, A.M.; Quaiyyum, M.A. Mechanical Properties of Polypropylene Composites: A Review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar]

- Mohanty, A.K.; Misra, M. Studies on Jute Composites—A Literature Review. Polym. Plast. Technol. Eng. 1995, 34, 729–792. [Google Scholar]

- Hou, S.; Li, Q.; Long, S.; Yang, X.; Li, W. Crashworthiness Design for Foam-Filled Thin-Wall Structures. Mater. Des. 2009, 30, 2024–2032. [Google Scholar]

- Bi, J.; Fang, H.; Wang, Q.; Ren, X. Modeling and Optimization of Foam-Filled Thin-Walled Columns for Crashworthiness Designs. Finite Elem. Anal. Des. 2010, 46, 698–709. [Google Scholar]

- Santosa, S.P.; Wierzbicki, T.; Hanssen, A.G.; Langseth, M. Experimental and Numerical Studies of Foam-Filled Sections. Int. J. Impact Eng. 2000, 24, 509–534. [Google Scholar]

- Yumrutaş, H.İ.; Ali, Z.O. Experimental Performance Evaluation of an Innovative Hybrid Barrier System Filled with Waste Materials. Constr. Build. Mater. 2022, 316, 125231. [Google Scholar]

- Leitlands, V.; Skruls, V.; Andersons, J. Production and Characterization of Glass Fiber/LDPE Composite Material for W-Beam Guardrail. AIP Conf. Proc. 2024, 3158, 060001. [Google Scholar]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6641/D6641M-16; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2016.

- Helaili, S.; Bettaieb, S.; Tarhouni, R. Road Guardrail Beam Made of Natural Stem (Stipa tenacissima L.) Eco-Composite: Impact Energy Absorption Improvement by Stems and Pre-Tensioning. J. Compos. Mater. 2023, 57, 1833–1844. [Google Scholar]

- BS EN 1317-2:2010; Road Restraint Systems—Part 2: Performance Classes, Impact Test Acceptance Criteria and Test Methods for Safety Barriers. British Standards Institution: London, UK, 2010.

- ASTM E23-18; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018.

- Sun, S.; Li, H.; Zhu, C.; Mei, K.; Jiang, H.; Sun, Y.; Huang, H. Study on the Anti-Collision Performance of Basalt Fiber Reinforced Polymer Beam–Column Guardrail. Compos. Struct. 2021, 276, 114588. [Google Scholar]

- Dobrovolny, C.S.; Bligh, R.; Kiani, M.; Hangul, A. Investigation and MASH Full-Scale Crash Testing of the Practice of Raising Blockouts on W-Beam Rail Systems. Transp. Res. Rec. 2022, 2676, 776–789. [Google Scholar]

- Li, J.; Wang, Y.; Ma, Z.; Liang, D. Simulation and Performance Analysis of Passenger Bus Collision with Rigid Guardrail of Expressway Bridge. Bridge Struct. 2023, 19, 41–55. [Google Scholar]

- Mohammadi, I.; Haghighi-Yazdi, M.; Safarabadi, M.; Yousefi, A. Crashworthiness Analysis of a Composite Guardrail Under Impact Loading. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 1651–1664. [Google Scholar]

- Yumrutas, H.I.; Ozcanan, S.; Apak, M.Y.; Anwer, M.J. Experimental and Numerical Comparative Crashworthiness Analysis of Innovative Renewable Hybrid Barrier with Conventional Roadside Barriers. Int. J. Crashworthiness 2023, 28, 334–350. [Google Scholar]

- Jiang, L.; Wang, K.; Fang, H.; Chen, B.; Zhu, L.; Zhang, Q.; Zhang, X. Protection Performance of a Novel Anti-Collision Guardrail with Recycled Foamed Concrete Under Vehicle Collision. Eng. Struct. 2024, 305, 117795. [Google Scholar]

- Zhang, Z.; Liu, Y.; Feng, B.; Ma, Y.; Zhang, G. Analytical Solutions for Girder Distribution Factor in Steel-Concrete Composite Girders with the Effect of Parapets. Adv. Civ. Eng. 2021, 2021, 8471801. [Google Scholar]

- Aghaee, K.; Li, L.; Roshan, A.; Namakiaraghi, P. Additive Manufacturing Evolution in Construction: From Individual Terrestrial to Collective, Aerial, and Extraterrestrial Applications. J. Build. Eng. 2024, 96, 110389. [Google Scholar]

- Kakarla, A.B.; Kong, I.; Patel, V.I. Additive Manufacturing for Building and Constructions: Overview, Applications and Challenges. In Additive Manufacturing: Novel Materials, Process, Properties, Applications; Scrivener Publishing LLC: Beverly, MA, USA, 2024; pp. 485–508. [Google Scholar]

- Cecchel, S.; Ferraresi, R.; Magni, M.; Guerini, L.; Cornacchia, G. Evolution of Prototyping in Automotive Engineering: A Comprehensive Study on the Reliability of Additive Manufacturing for Advanced Powertrain Components. Frat. Ed Integrità Strutt. 2024, 18, 109–126. [Google Scholar]

- Radhika, C.; Shanmugam, R.; Ramoni, M.; Gnanavel, B.K. A Review on Additive Manufacturing for Aerospace Application. Mater. Res. Express 2024, 11, 022001. [Google Scholar]

- Kumar, S.A.; Prasad, R.V.S. Basic Principles of Additive Manufacturing: Different Additive Manufacturing Technologies. In Additive Manufacturing; Woodhead Publishing: Sawston, UK, 2021; pp. 17–35. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021; Volume 17, pp. 160–186. [Google Scholar]

- Fu, H.; Kaewunruen, S. State-of-the-Art Review on Additive Manufacturing Technology in Railway Infrastructure Systems. J. Compos. Sci. 2022, 6, 7. [Google Scholar]

- Pollicino, A.G. Additive Manufacturing and Metal Replacement in the Automotive Field: The Case Study of a Headlight Protection Grid. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2023. [Google Scholar]

- Niknazar, M.; Haley, P.V.; Ramanan, L.; Truong, S.T.; Shrinivasan, Y.; Bhowmick, A.K.; Sundararajan, S. Building a Domain-Specific Guardrail Model in Production. arXiv 2024, arXiv:2408.01452. [Google Scholar]

- Baruffi, D.; Costella, M.F.; Chamberlain Pravia, Z.M. Experimental Analysis of Guardrail Structures for Occupational Safety in Construction. Open Constr. Build. Technol. J. 2021, 15, 141–151. [Google Scholar]

- Gardner, L. Metal Additive Manufacturing in Structural Engineering–Review, Advances, Opportunities and Outlook. Structures 2023, 47, 2178–2193. [Google Scholar]

- Raja, S.; Al-Tmimi, H.M.; Ghadir, G.K.; Mustafa, M.A.; Alani, Z.K.; Rusho, M.A.; Rajeswari, N. An Analysis of Polymer Material Selection and Design Optimization to Improve Structural Integrity in 3D Printed Aerospace Components. Appl. Chem. Eng. 2024, 7, 1875. [Google Scholar]

- Subramani, R.; Mustafa, M.A.; Ghadir, G.K.; Al-Tmimi, H.M.; Alani, Z.K.; Rusho, M.A.; Kumar, A.P. Exploring the Use of Biodegradable Polymer Materials in Sustainable 3D Printing. Appl. Chem. Eng. 2024, 7, 3870. [Google Scholar]

- Hassan, H.; Hallez, H.; Thielemans, W.; Vandeginste, V. A Review of Electro-Active Shape Memory Polymer Composites: Materials Engineering Strategies for Shape Memory Enhancement. Eur. Polym. J. 2024, 208, 112861. [Google Scholar]

- Kumar, A.; Dixit, S.; Singh, S.; Sreenivasa, S.; Bains, P.S.; Sharma, R. Recent Developments in the Mechanical Properties and Recycling of Fiber-Reinforced Polymer Composites. Polym. Compos. 2024, 1–26. [Google Scholar] [CrossRef]

- Tripathi, L.; Singh, O.; Behera, B.K. 3-D Woven Honeycomb Structures and Their Composites. Text. Prog. 2024, 56, 231–322. [Google Scholar] [CrossRef]

- Alqahtani, S.; Alqahtani, T.; Ali, H.M.; Farukh, F.; Kandan, K. The Effect of Lattice Topology on the Thermal and Mechanical Performance of Additively Manufactured Polymer Lattices. Results Eng. 2024, 21, 101905. [Google Scholar] [CrossRef]

- de Winter, J.; Manzaneque, T.; Ghatkesar, M.K. Damping of 3D-Printed Polymer Microbeam Resonators. J. Micromech. Microeng. 2023, 34, 015004. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive Manufacturing in Polymer Research: Advances, Synthesis, and Applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Safi Jahanshahi, A.; Akhoundi, B.; Quagliato, L. Investigation of Compressive Strength of 3D-Printed PLA/Continuous Glass Fibers Composites Manufactured by Simultaneous Impregnation Extrusion-Based Additive Manufacturing. Eng. Res. Express 2024, 7, 015403. [Google Scholar] [CrossRef]

- Orisekeh, D.K.; Corti, G.; Jahan, M.P. Enhancing Thermo-Mechanical Properties of Additively Manufactured PLA Using Eggshell Microparticle Fillers. J. Manuf. Process. 2025, 133, 782–797. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 23, 100529. [Google Scholar] [CrossRef]

- Maguire, A.; Pottackal, N.; Saadi, M.A.S.R.; Rahman, M.M.; Ajayan, P.M. Additive Manufacturing of Polymer-Based Structures by Extrusion Technologies. Oxf. Open Mater. Sci. 2021, 1, itaa004. [Google Scholar] [CrossRef]

- Daminabo, S.C.; Goel, S.; Grammatikos, S.A.; Nezhad, H.Y.; Thakur, V.K. Fused Deposition Modeling-Based Additive Manufacturing (3D Printing): Techniques for Polymer Material Systems. Mater. Today Chem. 2020, 16, 100248. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar]

- Chen, M.T.; Gong, Z.; Zhang, T.; Zuo, W.; Zhao, Y.; Zhao, O.; Wang, Z. Mechanical Behavior of Austenitic Stainless Steels Produced by Wire Arc Additive Manufacturing. Thin-Walled Struct. 2024, 196, 111455. [Google Scholar]

- Zadi-Maad, A.; Rohib, R.; Irawan, A. Additive Manufacturing for Steels: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 285, 012028. [Google Scholar]

- Tan, Q.; Zhang, M. Recent Advances in Inoculation Treatment for Powder-Based Additive Manufacturing of Aluminium Alloys. Mater. Sci. Eng. R Rep. 2024, 158, 100773. [Google Scholar]

- Su, J.L.; Jiang, F.L.; Teng, J.; Chen, L.Q.; Requena, G.; Yan, M.; Tan, C.L. Laser Additive Manufacturing of Titanium Alloys: Process, Materials and Post-Processing. Rare Met. 2024, 43, 6288–6328. [Google Scholar]

- Cheng, X.; Xu, J.; Yang, Z.; Guo, Q.; Li, C.; Zhou, J.; Ma, Z. A Novel Nickel-Based Superalloy with Excellent High-Temperature Performance Designed for Laser Additive Manufacturing. Mater. Sci. Eng. A 2024, 911, 146926. [Google Scholar]

- Mahamood, R.M. Laser Metal Deposition Process of Metals, Alloys, and Composite Materials; Springer: Cham, Switzerland, 2018; Volume 10. [Google Scholar]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar]

- Peng, J.; Zhang, T.; Xu, L.; Chen, G.; Hu, D.; Zhu, Z.; Kindo, S. Effect of C-Mn-Cu on Microstructure and Properties of Wire Arc Additive Manufacturing of High-Manganese Steels. Mater. Sci. Technol. 2024, 40, 02670836241242566. [Google Scholar]

- Zhang, M.; Liu, F.C.; Xue, P.; Zhang, H.; Wu, L.H.; Ni, D.R.; Ma, Z.Y. Fabrication of Large-Scale Steel-Aluminum Components with Homogeneously Distributed Amorphous Interfacial Layer and Enhanced Bonding Strength Using Modified Friction Stir Additive Manufacturing. J. Mater. Sci. Technol. 2024, 194, 151–166. [Google Scholar] [CrossRef]

- Wessels, H.; Weißenfels, C.; Wriggers, P. Metal Particle Fusion Analysis for Additive Manufacturing Using the Stabilized Optimal Transportation Meshfree Method. Comput. Methods Appl. Mech. Eng. 2018, 339, 91–114. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing Transportation: An Overview of 3D Printing in Aviation, Automotive, and Space Industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Fabrication of Mesh Patterns Using a Selective Laser-Melting Process. Appl. Sci. 2019, 9, 1922. [Google Scholar] [CrossRef]

- Giorleo, L.; Deniz, K.I. Polymer Tools Produced by Fused Filament Fabrication for Steel-Bending Process: Effect of Layering Orientation. J. Manuf. Mater. Process. 2024, 8, 243. [Google Scholar] [CrossRef]

- Wang, H.; He, L.; Zhang, Q.; Yuan, Y. Influence of Ni Contents on Microstructure and Mechanical Performance of AlSi10Mg Alloy by Selective Laser Melting. Materials 2023, 16, 4679. [Google Scholar] [CrossRef]

- Ozlati, A.; Movahedi, M.; Ramezani, H. Wire Arc Additive Manufacturing of Stainless Steel/Aluminum Bi-Metal Using Roll-Bonded Transition Joint. Manuf. Lett. 2025, 43, 6–11. [Google Scholar] [CrossRef]

- Li, Y.; Guan, X.; Liu, X.; Gu, H. The Effect of TiC Addition on the Mechanical Properties and Thermal Expansion Coefficient During Laser Metal Deposition of Invar 36 Alloy. Eng. Fail. Anal. 2024, 169, 109198. [Google Scholar] [CrossRef]

- Katsuyama, Y.; Hui, J.; Thiel, M.; Haba, N.; Yang, Z.; Kaner, R.B. 3D-Printed Carbon Scaffold for Structural Lithium Metal Batteries. Small Methods 2024, 8, 2400831. [Google Scholar] [CrossRef]

- Yang, Y.; Lin, H.; Dong, P.; Li, Y.; Li, Q. An Analytical Temperature–Based Thermomechanical Finite Element Model for Process Modeling of Metal Additive Manufacturing. J. Mech. Sci. Technol. 2025, 39, 1–12. [Google Scholar] [CrossRef]

- Latte, M.; Mazzarisi, M.; Guerra, M.G.; Campanelli, S.L.; Galantucci, L.M. Key Performance Indexes for the Evaluation of Geometrical Characteristics and Subsurface Defects Through Laser Line Monitoring of Laser Metal Deposition Process. Opt. Laser Technol. 2025, 182, 112085. [Google Scholar] [CrossRef]

- Wu, H.; Guo, A.; Kong, D.; Sheng, X.; Liu, C.; Wu, J.; Chen, Z. Additive Manufacturing of Bionic Layered Ceramic-Metal Composites for Enhanced Toughness and Damage Resistance. Virtual Phys. Prototyp. 2025, 20, e2443102. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A. Additive Manufacturing of Composite Materials: An Overview. In Proceedings of the 6th International Conference on Virtual Machining Process Technology (VMPT), Montréal, QC, Canada, 29 May–2 June 2017. [Google Scholar]

- Yi, H.; Jia, L.; Ding, J.; Li, H. Achieving Material Diversity in Wire Arc Additive Manufacturing: Leaping from Alloys to Composites via Wire Innovation. Int. J. Mach. Tools Manuf. 2024, 194, 104103. [Google Scholar]

- Regassa, Y.; Lemu, H.G.; Sirabizuh, B. Trends of Using Polymer Composite Materials in Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 659, 012021. [Google Scholar]

- Del Rey, G.R.; de Lucas Salgado, J.; Hernández, A.A.G.; Tanarro, E.C. Design, Manufacturing and Experimental Validation of Additive Manufacturing Cores for Bearing Seats in Carbon Fibre Reinforced Polymer Structures. Heliyon 2024, 10, e35652. [Google Scholar]

- Tang, S.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z. Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review. Adv. Eng. Mater. 2021, 23, 2100053. [Google Scholar]

- Sun, J.; Ye, D.; Zou, J.; Chen, X.; Wang, Y.; Yuan, J.; Bai, J. A Review on Additive Manufacturing of Ceramic Matrix Composites. J. Mater. Sci. Technol. 2023, 138, 1–16. [Google Scholar]

- Garmabi, M.M.; Jalali, A.; Manzoor, A.; Malik, R.; Sain, M. Driving Sustainability and Performance: 3D-Printing of Lightweight Functional Components Using Recycled Carbon Fiber Reinforced Polyphenylene Sulfide Composites for Automotive Industry. Prog. Addit. Manuf. 2025, 10, 2397–2409. [Google Scholar] [CrossRef]

- Zhai, C.; Chen, Y.; Zhao, Y.; Li, Q.; Zhang, Z.; Yang, W.; Li, Y. A Review on Process Parameter Influence and Optimization for 3D Printing of Fiber-Reinforced Thermoplastic Composites. J. Reinf. Plast. Compos. 2024, 07316844241273038. [Google Scholar] [CrossRef]

- Sivakumar, N.K.; Palaniyappan, S.; Basavarajappa, S.; Hashem, M.I.; Bodaghi, M.; Sekar, V. Study on the Impact of Material Extrusion Factors on the Compressive Characteristics of Honeycomb Lattice-Structured Onyx™ Composites. Mater. Today Commun. 2023, 37, 107317. [Google Scholar]

- Yu, R.; Bai, X.; Yu, X.; Zhang, H. WC-Reinforced Iron Matrix Composites Fabricated by Wire Arc Additive Manufacturing Combined with Gravity-Driven Powder Feeding: Particle Transportation and Size Effects. Rapid Prototyp. J. 2023, 29, 1014–1028. [Google Scholar]

- Landrie, D.M.; Tekinalp, H.; Hassen, A.; Theodore, M.; Vaidya, U. Ballistic Characterization of Additively Manufactured Extrusion Deposited Thermoplastic Composite Plates. Polym. Polym. Compos. 2023, 31, 09673911231171043. [Google Scholar]

- Chaves Figueiredo, S.; Romero Rodríguez, C.; Ahmed, Y.; Bos, D.H.; Xu, Y.; Salet, T.M.; Bos, F.P. Mechanical Behavior of Printed Strain Hardening Cementitious Composites. Materials 2020, 13, 2253. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Han, Y.; Cheng, D.; Liu, H.; Chen, F.; Le, J.; Lu, W. Dual Hetero-Structured Ti Composites by Manipulating Self-Assembled Powder Embedded with Nano-Reinforcements. Compos. Part B Eng. 2025, 291, 111999. [Google Scholar]

- Xiong, Y.; Zhang, F.; Huang, Y.; Dai, T.; Wan, Q.; Chen, Y.; Yin, S. A Novel Composites of Laser 3D Printed CoCrFeNiMn/Ti6Al4V Lattice Structure with B4C/AlSi10Mg Interpenetrating Phases. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108579. [Google Scholar]

- Wang, Y.; Fan, W.; Zhou, F.; Prashanth, K.G.; Feng, Z.; Zhang, S.; Lin, X. The Influence of Process Parameters on the Microstructure and Properties of the TiC/Ti-Alloy Composites Fabricated by the Directed Energy Deposition Process. J. Mater. Res. Technol. 2025, 34, 164–174. [Google Scholar]

- Sikora, P.; Chougan, M.; Cuevas, K.; Liebscher, M.; Mechtcherine, V.; Ghaffar, S.H.; Stephan, D. The Effects of Nano-and Micro-Sized Additives on 3D Printable Cementitious and Alkali-Activated Composites: A Review. Appl. Nanosci. 2022, 12, 805–823. [Google Scholar]

- Mingione, E.; Salvi, D.; Almonti, D.; Ponticelli, G.S. Improvement of Thermal, Electrical, and Tribological Performances of GnPs Composites Produced by Selective Laser Sintering. Polym. Compos. 2025, 2025, 29467. [Google Scholar]

- Cuccarollo, P.; Pontefisso, A.; Carraro, P.A.; Quaresimin, M. Characterization and Modelling of the Microstructural and Mechanical Properties of Additively Manufactured Continuous Fiber Polymer Composites. Compos. Sci. Technol. 2025, 260, 110986. [Google Scholar]

- Li, G.; Li, H.; Liu, Q.; Sun, H.; Nie, Y.; Li, Q.; Ren, L. 4D Printing of Polycarbonate Ternary Composites and the Biomimetic Folding Deployment Mechanisms. Adv. Compos. Hybrid Mater. 2025, 8, 54. [Google Scholar]

- Zhang, X.; Wei, G.; Huang, X.; Zhang, H.; Hao, X.; Tan, S.; Ji, G. Optimized Pyramidal Honeycomb PEEK/CF Composites Metastructure Through 3D Printing for Broadband Electromagnetic Wave Absorption. Mater. Today Phys. 2025, 50, 101620. [Google Scholar]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef]

| Technique | Accuracy | Surface Finish | Material Range | Cost | Production Speed | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

| FDM | Low–Medium | Rough | Thermoplastics | Low | Fast | Low cost, easy to use, rapid prototyping | Poor surface finish, limited material strength |

| SLA | High | Excellent | Photopolymers | Medium | Slow | High detail, smooth surfaces | Brittle parts, limited material types |

| DLP | High | Excellent | Photopolymers | Medium | Fast | High resolution, faster than SLA | Limited build volume, costly resins |

| SLS | Medium | Good | Polymers, Composites | Medium–High | Medium | No support needed, good mechanical properties | Rough surface, powder handling required |

| SLM | High | Good | Metals | High | Slow | High strength, dense metal parts | Expensive, requires post-processing |

| DMLS | High | Good | Metals | High | Slow | Excellent detail and strength | High cost, slow process |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alparslan, C.; Yentimur, M.F.; Kütük-Sert, T.; Bayraktar, Ş. A Review on Additive Manufactured Engineering Materials for Enhanced Road Safety and Transportation Applications. Polymers 2025, 17, 877. https://doi.org/10.3390/polym17070877

Alparslan C, Yentimur MF, Kütük-Sert T, Bayraktar Ş. A Review on Additive Manufactured Engineering Materials for Enhanced Road Safety and Transportation Applications. Polymers. 2025; 17(7):877. https://doi.org/10.3390/polym17070877

Chicago/Turabian StyleAlparslan, Cem, Muhammed Fatih Yentimur, Tuba Kütük-Sert, and Şenol Bayraktar. 2025. "A Review on Additive Manufactured Engineering Materials for Enhanced Road Safety and Transportation Applications" Polymers 17, no. 7: 877. https://doi.org/10.3390/polym17070877

APA StyleAlparslan, C., Yentimur, M. F., Kütük-Sert, T., & Bayraktar, Ş. (2025). A Review on Additive Manufactured Engineering Materials for Enhanced Road Safety and Transportation Applications. Polymers, 17(7), 877. https://doi.org/10.3390/polym17070877