Mechanical and Thermal Behavior of Hemp-Reinforced Starch/Agar Biocomposites: Insights from Finite Element Simulation and Machine Learning Models

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation and Sourcing of Raw Materials

2.2. Preparation and Pretreatment of Hemp Fiber

2.3. Preparation of Biocomposite Films

2.4. Evaluation of Samples

2.4.1. Thickness and Density

2.4.2. Tensile Test and Finite Element Simulation

2.4.3. Machine Learning Models

2.4.4. Impact Test and Finite Element Simulation

2.4.5. Thermal Tests and Finite Element Simulation

- Transient Thermal Analysis

- Steady-State Thermal Analysis

3. Results and Discussion

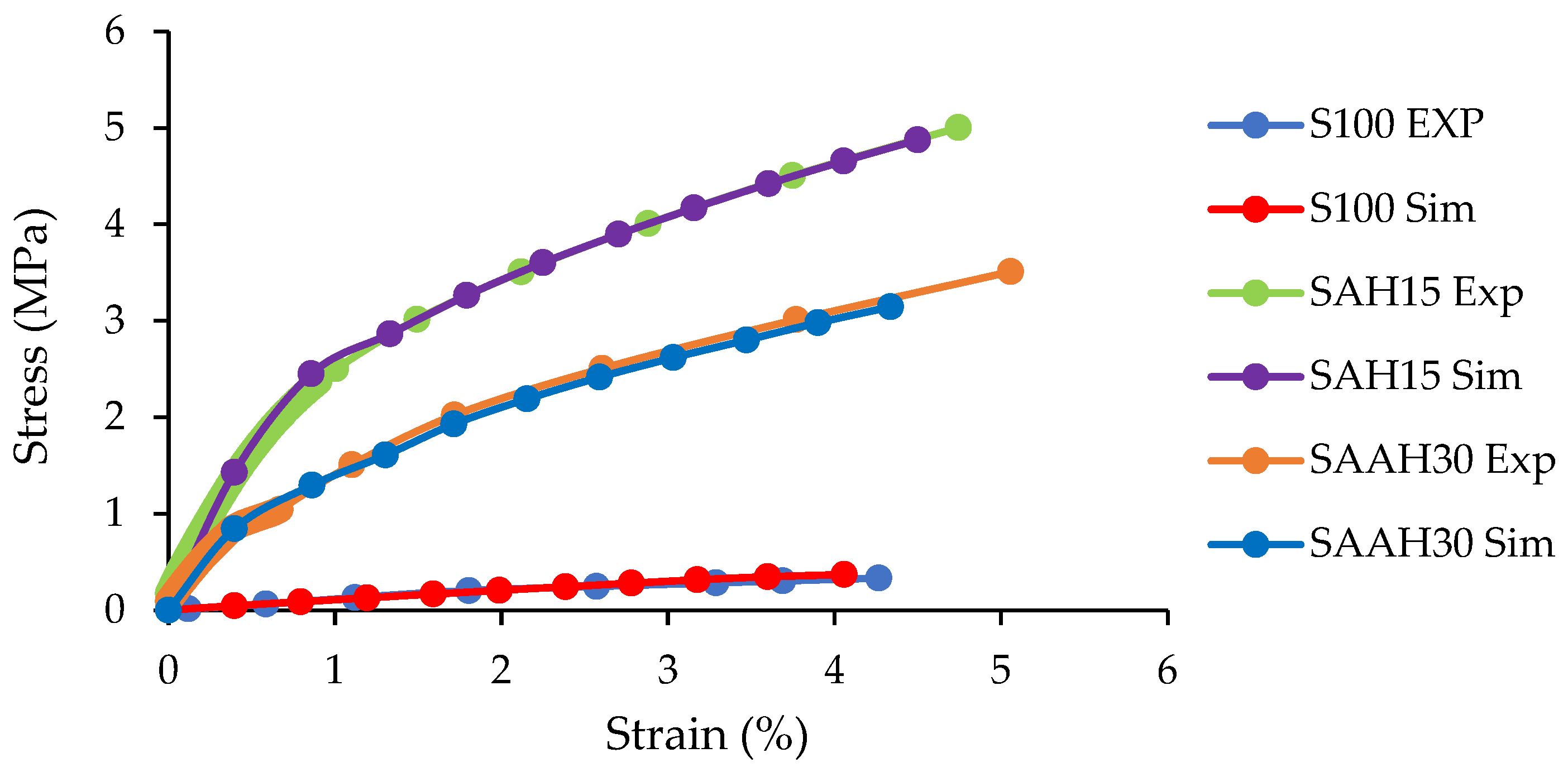

3.1. Tensile Test Results and Finite Element Simulation

3.2. Machine Learning Results for Predicting Tensile Strength Data

3.3. Results of Impact Test

3.3.1. Impact Test Results and Finite Element Simulation

3.3.2. Strain Energy Variations

3.3.3. Plastic Dissipation Energy Variations

3.4. Results of Thermal Analysis

3.4.1. Steady-State Thermal Analysis

3.4.2. Transient Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nabels-Sneiders, M.; Platnieks, O.; Grase, L.; Gaidukovs, S. Lamination of cast hemp paper with bio-based plastics for sustainable packaging: Structure—Thermomechanical properties relationship and biodegradation studies. J. Compos. Sci. 2022, 6, 246. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Gopi, J.A.; Radoor, S.; Krishnasamy, S.; Deshmukh, K.; Hameed, N.; Sienkiewicz, N. Turning waste plant fibers into advanced plant fiber reinforced polymer composites: A comprehensive review. Compos. Part C Open Access 2023, 10, 100333. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, Y.; Zhang, X.; Liu, J. Development of active and intelligent packaging by incorporating betalains from red pitaya (Hylocereus polyrhizus) peel into starch/polyvinyl alcohol films. Food Hydrocoll. 2020, 100, 105410. [Google Scholar] [CrossRef]

- Amariei, S.; Ursachi, F.; Petraru, A. Development of new biodegradable agar-alginate membranes for food packaging. Membranes 2022, 12, 576. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef]

- Terzioğlu, P.; Güney, F.; Parın, F.N.; Şen, İ.; Tuna, S. Biowaste orange peel incorporated chitosan/polyvinyl alcohol composite films for food packaging applications. Food Packag. Shelf Life 2021, 30, 100742. [Google Scholar] [CrossRef]

- Trociński, A.; Wieruszewski, M.; Bartkowiak, M.; Dziurka, D.; Mirski, R. The influence of hemp fibers (Cannabis sativa L.) on the mechanical properties of fiber–gypsum boards reinforcing the gypsum matrix. Polymers 2024, 16, 2644. [Google Scholar] [CrossRef] [PubMed]

- Rekha, C.; Zhongxiang, F. Hemp macromolecules: Crafting sustainable solutions for food and packaging innovation. Int. J. Biol. Macromol. 2024, 273, 132823. [Google Scholar] [CrossRef]

- Voicea, I.; Găgeanu, I.; Cujbescu, D.; Persu, C.; Dumitru, I.; Oprescu, R.; Voicu, G.; Ungureanu, N.; Dilea, M. Energetic capitalization of biomass residues resulted after extracting fibers from Cannabis Sativa L. In Proceedings of the International Symposium ISB-INMATEH—Agricultural and Mechanical Engineering, Bucharest, Romania, 26–28 October 2017; pp. 241–246. [Google Scholar]

- Malabadi, R.B.; Kolkar, K.P.; Chalannavar, R.K. Cannabis sativa: Ethnobotany and phytochemistry. Int. J. Innov. Sci. Res. Rev. 2023, 5, 3990–3998. [Google Scholar]

- Rupasinghe, H.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Finley, S.J.; Javan, G.T.; Green, R.L. Bridging disciplines: Applications of forensic science and industrial hemp. Front. Microbiol. 2022, 13, 760374. [Google Scholar] [CrossRef] [PubMed]

- Manea, D.; Stroescu, G.; Popa, L.; Ionescu, A.; Zaica, A. Management practices in industrial hemp harvesting and storage. INMATEH–Agric. Eng. 2023, 69, 520–526. [Google Scholar] [CrossRef]

- Arumugam, G.S.; Arumugam, C.; Damodharan, K.; Kumar, R.S.; Gummadi, S.N.; Muthusamy, S. Thermal and mechanical properties of high-performance polyester nanobiocomposites reinforced with pre-treated sunn hemp fiber for automotive applications. Int. J. Biol. Macromol. 2024, 280, 135591. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Haque, A.N.M.A.; Naebe, M. Lignin–cellulose nanocrystals from hemp hurd as light-coloured ultraviolet (UV) functional filler for enhanced performance of polyvinyl alcohol nanocomposite films. Nanomaterials 2021, 11, 3425. [Google Scholar] [CrossRef]

- Dixit, S.; Mishra, G.; Yadav, V.L. Optimization of novel bio-composite packaging film based on alkali-treated Hemp fiber/polyethylene/polypropylene using response surface methodology approach. Polym. Bull. 2022, 79, 2559–2583. [Google Scholar] [CrossRef]

- Bahsaine, K.; El Allaoui, B.; Benzeid, H.; El Achaby, M.; Zari, N.; Bouhfid, R. Hemp cellulose nanocrystals for functional chitosan/polyvinyl alcohol-based films for food packaging applications. RSC Adv. 2023, 13, 33294–33304. [Google Scholar] [CrossRef]

- Gupta, A.; Shohel, S.M.; Singh, M.; Singh, J. Study on mechanical properties of natural fiber (Jute)/synthetic fiber (Glass) reinforced polymer hybrid composite by representative volume element using finite element analysis: A numerical approach and validated by experiment. Hybrid Adv. 2024, 6, 100239. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.; Liu, W.; Fu, T.; Qiu, R.; Wu, S. Tensile performance mechanism for bamboo fiber-reinforced, palm oil-based resin bio-composites using finite element simulation and machine learning. Polymers 2023, 15, 2633. [Google Scholar] [CrossRef] [PubMed]

- Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of hemp hurds as bio-sourced additives in PLA-based biocomposites. Polymers 2021, 13, 3786. [Google Scholar] [CrossRef]

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. Organization of Standardization: Geneva, Switzerland, 2012.

- Biriș, S.Ș.; Maican, E.; Paraschiv, G.; Vlăduț, V.; Bungescu, S. A model for prediction of stress state in soil below agricultural tyres using the finite element method. Sci. Bull. UPB Ser. D 2007, 69, 19–28. [Google Scholar]

- Altarazi, S.; Allaf, R.; Alhindawi, F. Machine learning models for predicting and classifying the tensile strength of polymeric films fabricated via different production processes. Materials 2019, 12, 1475. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; He, D.; Liu, X.; Wang, E.; Li, S.; Liu, T.; Yang, S. Strain characteristics and energy dissipation laws of gas-bearing coal during impact fracture process. Energy 2022, 242, 123028. [Google Scholar] [CrossRef]

- Guo, S.; Wang, L.; Shao, G.; Shao, H.; Jiang, J.; Chen, N. Mechanical behavior and energy dissipation of woven and warp-knitted PVC membrane materials under multistage cyclic loading. Polymers 2022, 14, 1666. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhao, H.; Liu, C.; Chen, J.; Liu, C.; Zhang, T.; Gong, W. Transient heat transfer characteristics in a flat plate heat sink with mini-channels for cooling high heat flux IGBT. Micromachines 2022, 13, 1417. [Google Scholar] [CrossRef] [PubMed]

- Leila, A.; Jean-Yves, M.; Sid-Ahmed, R.; Thierry, M.; Luc, G.; Stephane, C.; Zoulikha, M.R. Prediction of thermal conductivity and specific heat of native maize starch and comparison with HMT treated starch. J. Renew. Mater. 2019, 7, 535–546. [Google Scholar] [CrossRef]

- Cao, W.; Cheng, X.; Gong, L.; Li, Y.; Zhang, R.; Zhang, H. Thermal conductivity of highly porous ceramic foams with different agar concentrations. Mater. Lett. 2015, 139, 66–69. [Google Scholar] [CrossRef]

- Myers, E.; Piazza, M.; Owkes, M.; June, R.K. Heat conduction simulation of chondrocyte-embedded agarose gels suggests negligible impact of viscoelastic dissipation on temperature change. J. Biomech. 2024, 176, 112307. [Google Scholar] [CrossRef]

- Gaujena, B.; Agapovs, V.; Borodinecs, A.; Strelets, K. Analysis of thermal parameters of hemp fiber insulation. Energies 2020, 13, 6385. [Google Scholar] [CrossRef]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. Part I: Physical and thermal properties. J. Build. Eng. 2019, 24, 100540. [Google Scholar] [CrossRef]

- He, M.J.; Qi, H.; Wang, Y.F.; Ren, Y.T.; Cai, W.H.; Ruan, L.M. Near-field radiative heat transfer in multilayered graphene system considering equilibrium temperature distribution. Opt. Express 2019, 27, A953–A966. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Z.; Zhou, S.; Wang, L.; Liu, X.; Xue, R. Facile fabrication of densely packed ammoniated alumina/MXene/bacterial cellulose composite films for enhancing thermal conductivity and photothermal conversion performance. J. Mater. Sci. Technol. 2025, 213, 162–173. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, T.; Yin, C.; Sun, H.; Zhang, C.; Zhang, Y.; Chi, Q. Significantly enhanced high-temperature energy storage performance for polymer composite films with gradient distribution of organic fillers. J. Chem. Eng. 2024, 497, 154546. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Arpitha, G.R.; Gopinath, V. Effect of hybridization on properties of hemp-carbon fibre-reinforced hybrid polymer composites using experimental and finite element analysis. World J. Eng. 2019, 16, 248–259. [Google Scholar] [CrossRef]

- Singh, S.P.; Dutt, A.; Hirwani, C.K. Mechanical, modal and harmonic behavior analysis of jute and hemp fiber reinforced polymer composite. J. Nat. Fibers 2023, 20, 2140328. [Google Scholar] [CrossRef]

- Asumani, O.M.L.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- del Borrello, M.; Mele, M.; Campana, G.; Secchi, M. Manufacturing and characterization of hemp-reinforced epoxy composites. Polym. Compos. 2020, 41, 2316–2329. [Google Scholar] [CrossRef]

- Gheribi, R.; Taleb, Y.; Perrin, L.; Segovia, C.; Brosse, N.; Desobry, S. Development of chitosan green composites reinforced with hemp fibers: Study of mechanical and barrier properties for packaging application. Molecules 2023, 28, 4488. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Lee, J.S.; Choi, I.; Han, J. Mathematical modeling of cinnamon (Cinnamomum verum) bark oil release from agar/PVA biocomposite film for antimicrobial food packaging: The effects of temperature and relative humidity. Food Chem. 2021, 363, 130306. [Google Scholar] [CrossRef]

- Zhang, Y.; Remadevi, R.; Hinestroza, J.P.; Wang, X.; Naebe, M. Transparent ultraviolet (UV)-shielding films made from waste hemp hurd and polyvinyl alcohol (PVA). Polymers 2020, 12, 1190. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Machine learning tensile strength and impact toughness of wheat straw reinforced composites. Mach. Learn. Appl. 2021, 6, 100188. [Google Scholar] [CrossRef]

- Natrayan, L.; Bhaskar, A.; Patil, P.P.; Kaliappan, S.; Dineshkumar, M.; Esakkiraj, E.S. Optimization of Filler Content and Size on Mechanical Performance of Graphene/Hemp/Epoxy-Based Hybrid Composites using Taguchi with ANN Technique. J. Nanomater. 2023, 2023, 8235077. [Google Scholar] [CrossRef]

- Perumal, A.B.; Sellamuthu, P.S.; Nambiar, R.B.; Sadiku, E.R.; Phiri, G.; Jayaramudu, J. Effects of multiscale rice straw (Oryza sativa) as reinforcing filler in montmorillonite-polyvinyl alcohol biocomposite packaging film for enhancing the storability of postharvest mango fruit (Mangifera indica L.). Appl. Clay Sci. 2018, 158, 1–10. [Google Scholar] [CrossRef]

- Promhuad, K.; Srisa, A.; San, H.; Laorenza, Y.; Wongphan, P.; Sodsai, J.; Harnkarnsujarit, N. Applications of hemp polymers and extracts in food, textile and packaging: A review. Polymers 2022, 14, 4274. [Google Scholar] [CrossRef]

| Diameter (mm) | Density (g/cm3) | Young’s Modulus (MPa) | Yield Stress (MPa) |

|---|---|---|---|

| 20 | 1.2 | 2000 | 70 |

| S100 | SH15 | SH30 | SAH0 | SAH15 | SAH30 | SAAH 0 | SAAH 15 | SAAH 30 | |

|---|---|---|---|---|---|---|---|---|---|

| Conductiviy (20 °C) | 0.05 | 0.0506 | 0.0511 | 0.0530 | 0.0532 | 0.0534 | 0.0538 | 0.0540 | 0.0541 |

| Conductivity (100 °C) | 0.19 | 0.175 | 0.163 | 0.196 | 0.180 | 0.168 | 0.198 | 0.182 | 0.171 |

| Specific heat (20 °C) | 1.8 | 1.73 | 1.68 | 1.93 | 1.85 | 1.78 | 1.97 | 1.88 | 1.82 |

| Specific heat (100 °C) | 2.33 | 2.24 | 2.18 | 2.50 | 2.40 | 2.31 | 2.55 | 2.44 | 2.36 |

| Expansion (20 °C) | 3 × 10−5 | 3.3 × 10−5 | 3.1 × 10−5 | 4 × 10−5 | 3.7 × 10−5 | 3.3 × 10−5 | 4.1 × 10−5 | 3.8 × 10−5 | 3.6 × 10−5 |

| Expansion (100 °C) | 6.5 × 10−5 | 6.1 × 10−5 | 5.9 × 10−5 | 6.6 × 10−5 | 6.3 × 10−5 | 6 × 10−5 | 6.7 × 10−5 | 6.3 × 10−5 | 6.1 × 10−5 |

| Sample | Thickness (mm) | Density (g/cm3) | Young’s Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| S100 | 0.30 | 1.14 | 7.68 | 0.511 | 9.90 |

| SH15 | 0.35 | 1.10 | 28.51 | 0.407 | 2.77 |

| SH30 | 0.40 | 1.04 | 48.03 | 0.556 | 2.14 |

| SAH0 | 0.42 | 0.93 | 322.11 | 11.53 | 22.16 |

| SAH15 | 0.45 | 0.95 | 343.72 | 7.07 | 9.60 |

| SAH30 | 0.45 | 4.10 | 399.70 | 10.86 | 7.91 |

| SAAH0 | 0.50 | 0.89 | 142.73 | 5.78 | 22.30 |

| SAAH15 | 0.50 | 4.87 | 184.82 | 5.28 | 14.20 |

| SAAH30 | 0.60 | 1.22 | 234.37 | 6.46 | 13.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fartash Naeimi, E.; Selvi, K.Ç.; İnanç, İ.; Ungureanu, N. Mechanical and Thermal Behavior of Hemp-Reinforced Starch/Agar Biocomposites: Insights from Finite Element Simulation and Machine Learning Models. Polymers 2025, 17, 855. https://doi.org/10.3390/polym17070855

Fartash Naeimi E, Selvi KÇ, İnanç İ, Ungureanu N. Mechanical and Thermal Behavior of Hemp-Reinforced Starch/Agar Biocomposites: Insights from Finite Element Simulation and Machine Learning Models. Polymers. 2025; 17(7):855. https://doi.org/10.3390/polym17070855

Chicago/Turabian StyleFartash Naeimi, Ehsan, Kemal Çağatay Selvi, İbrahim İnanç, and Nicoleta Ungureanu. 2025. "Mechanical and Thermal Behavior of Hemp-Reinforced Starch/Agar Biocomposites: Insights from Finite Element Simulation and Machine Learning Models" Polymers 17, no. 7: 855. https://doi.org/10.3390/polym17070855

APA StyleFartash Naeimi, E., Selvi, K. Ç., İnanç, İ., & Ungureanu, N. (2025). Mechanical and Thermal Behavior of Hemp-Reinforced Starch/Agar Biocomposites: Insights from Finite Element Simulation and Machine Learning Models. Polymers, 17(7), 855. https://doi.org/10.3390/polym17070855