Enhancing the Physicochemical, Thermal, and Technological Properties of Freeze-Dried Welsh Onion Leaf Juice: Influence of Maltodextrin and Gum Arabic as Carrier Agents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material and Reagents

2.2. Juice Extraction

2.3. Preparation of Dispersions

2.4. Freeze Drying

2.5. Color Analysis

2.6. Scanning Electron Microscopy

2.7. Fourier-Transform Infrared Spectroscopy (FTIR)

2.8. Total Polyphenol Content and DPPH• Scavenging Activity

2.9. Thermogravimetric Analysis

2.10. Moisture Content, Water Activity, and Water Solubility

2.11. Flow Properties

2.12. Statistical Analysis

3. Results and Discussion

3.1. Juice Properties

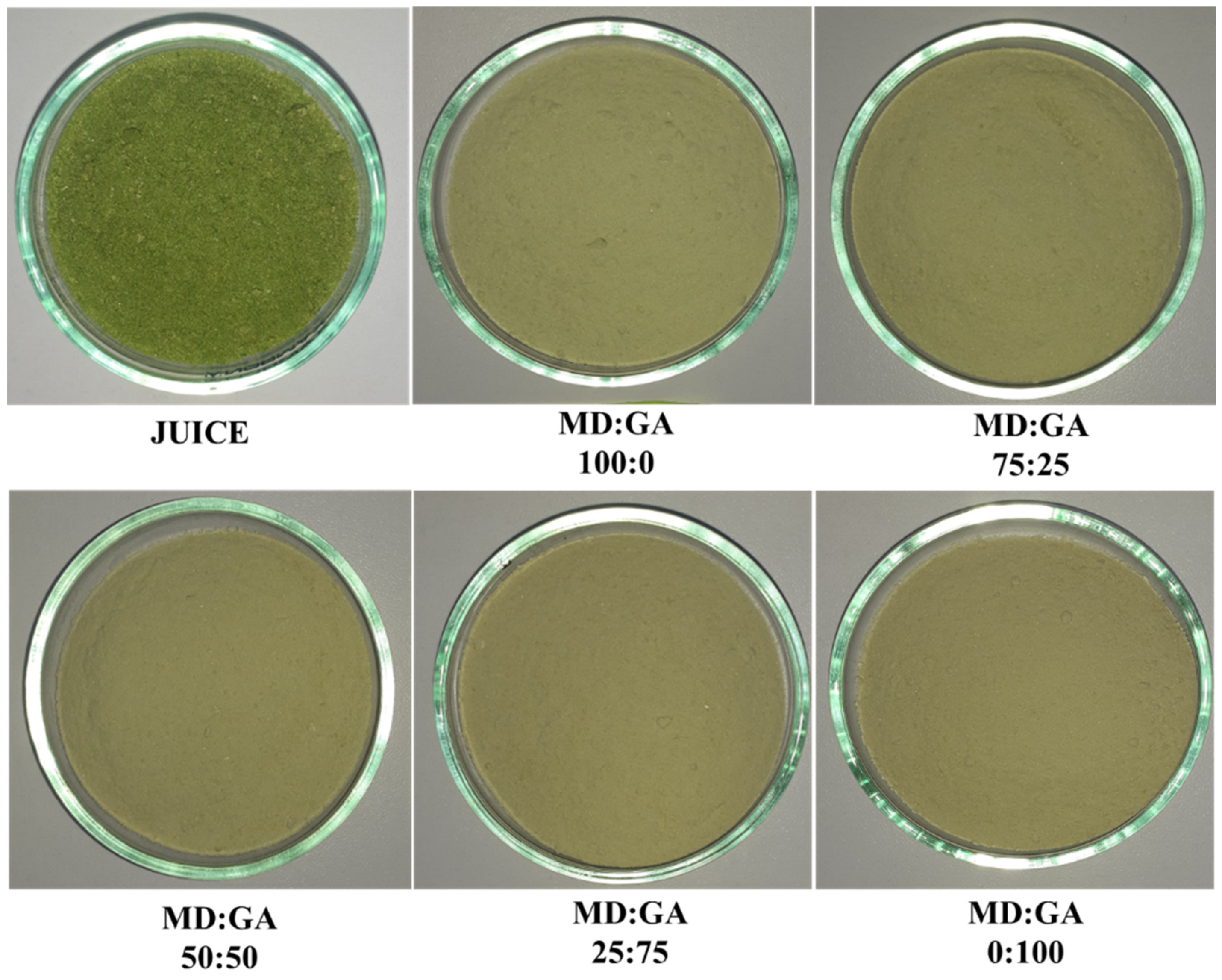

3.2. Appearance and Color Attributes of the Freeze-Dried Welsh Onion Leaf Juice

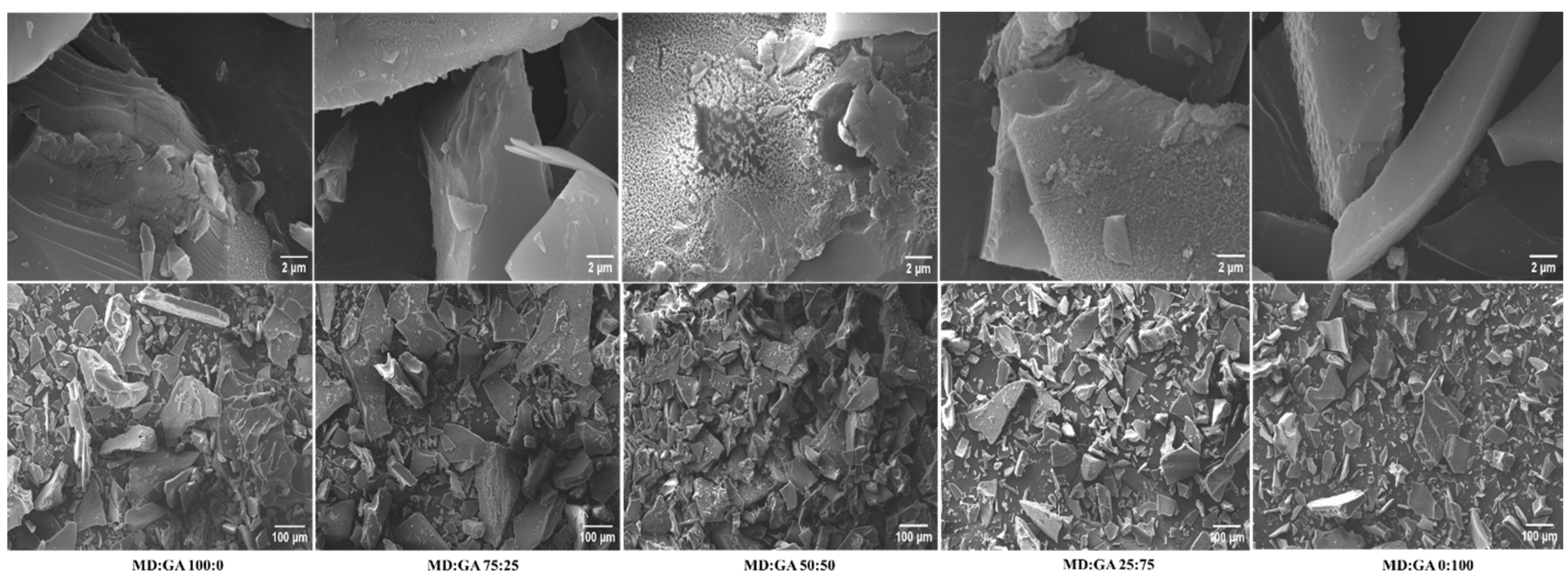

3.3. Morphological Properties of the Freeze-Dried WELSH Onion Leaf Juice

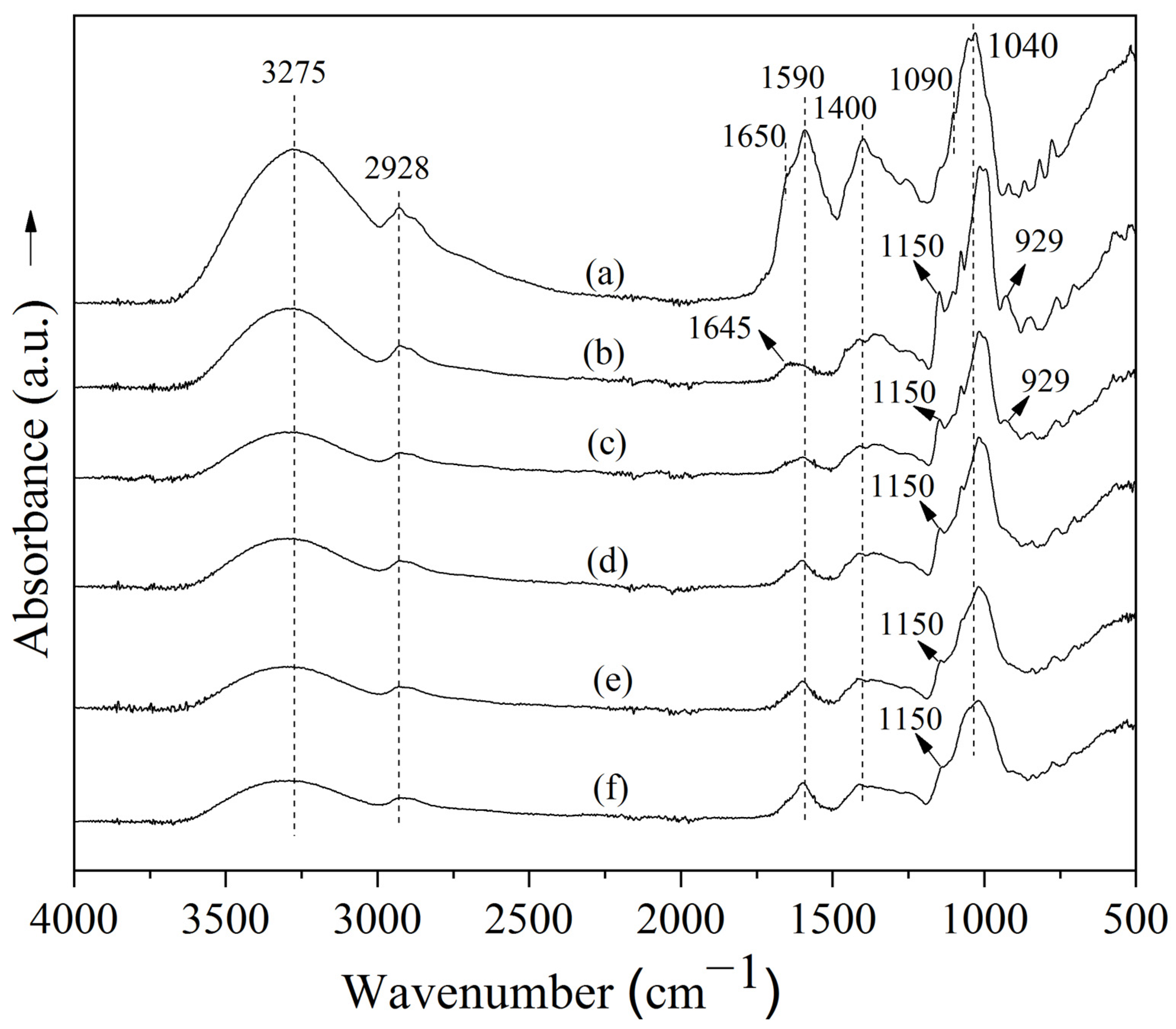

3.4. FTIR Spectra Analysis

3.5. Polyphenol Content and DPPH• Scavenging Activity of the Freeze-Dried Welsh Onion Leaf Juice

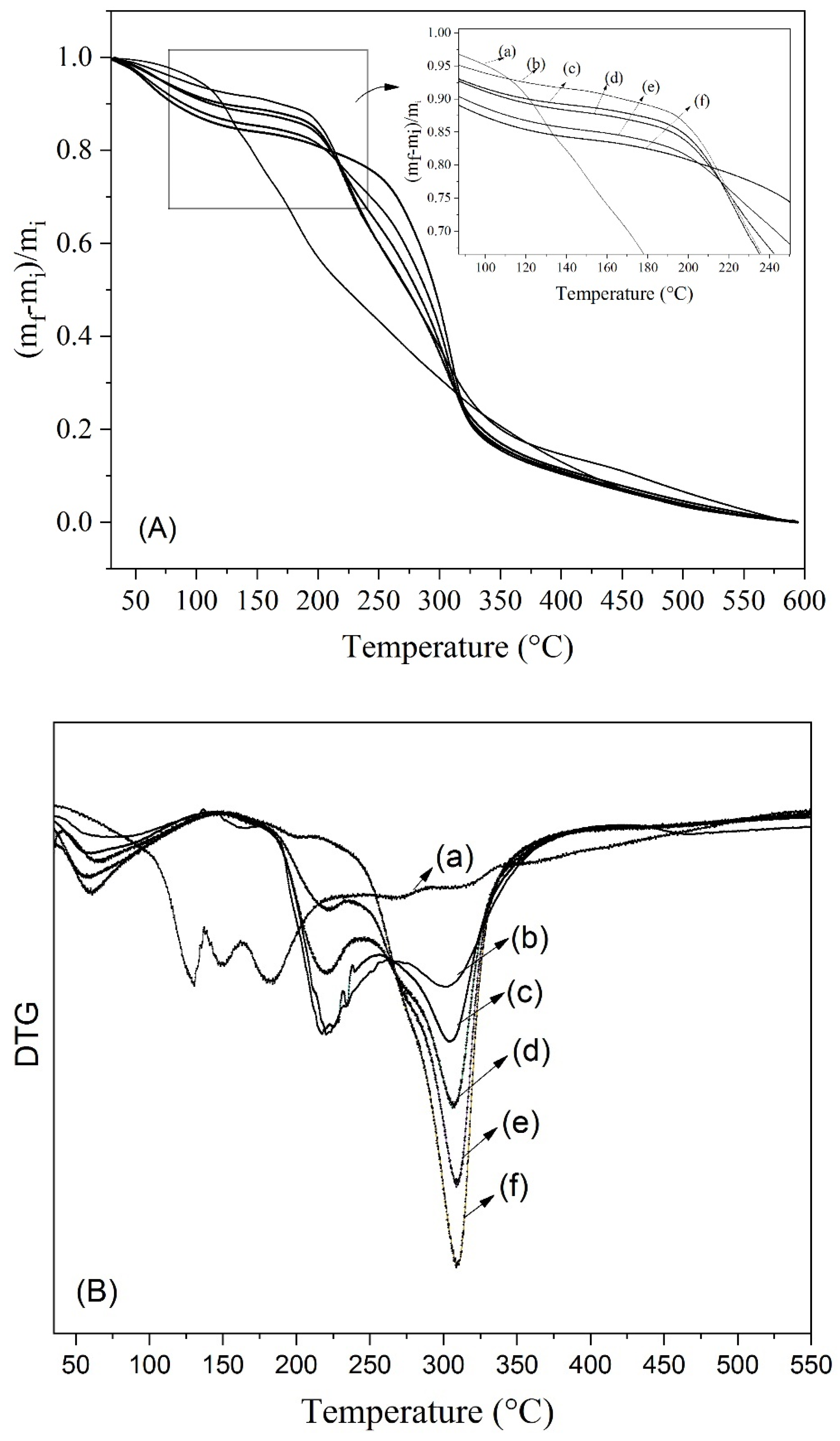

3.6. Thermogravimetric Analysis of the Freeze-Dried Welsh Onion Leaf Juice

3.7. Moisture Content, Water Activity, and Water Solubility

3.8. Flowability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ramírez Monsalve, J.; Jaramillo Gaviria, L.; Arango Correa, A. Use of Freeze-Dried Aromatic Herbs with Quality Organoleptic Characteristics in Gastronomic Products. Int. J. Gastron. Food Sci. 2021, 24, 100341. [Google Scholar] [CrossRef]

- Gupta, A.; Sanwal, N.; Bareen, M.A.; Barua, S.; Sharma, N.; Joshua Olatunji, O.; Prakash Nirmal, N.; Sahu, J.K. Trends in Functional Beverages: Functional Ingredients, Processing Technologies, Stability, Health Benefits, and Consumer Perspective. Food Res. Int. 2023, 170, 113046. [Google Scholar] [CrossRef]

- Kim, S.H.; Yoon, J.B.; Han, J.; Seo, Y.A.; Kang, B.H.; Lee, J.; Ochar, K. Green Onion (Allium fistulosum): An Aromatic Vegetable Crop Esteemed for Food, Nutritional and Therapeutic Significance. Foods 2023, 12, 4503. [Google Scholar] [CrossRef] [PubMed]

- Medina-Jaramillo, C.; Usgame-Fagua, K.; Franco-González, N.; López-Córdoba, A. Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions. Foods 2022, 11, 641. [Google Scholar] [CrossRef]

- Goyal, R.; Thakur, A.; Nanda, V. Comparative Analysis of Nutritional, Functional, and Antioxidant Properties of Botanical Parts (Bulb, Pseudostem, Leaves) of Spring Onion (Allium fistulosum) Varieties for Exploring Its Waste Utilization Potential. Food Biosci. 2025, 66, 106239. [Google Scholar] [CrossRef]

- Balkrishna, A.; Sharma, H.; Srivastava, D.; Kukreti, A.; Kumar, A.; Arya, V.; Chaudhary, M. Phytochemistry, Pharmacology, and Medicinal Aspects of Allium fistulosum L.: A Narrative Review. J. Appl. Pharm. Sci. 2023, 13, 107–118. [Google Scholar] [CrossRef]

- Medina-Jaramillo, C.; Gomez-Delgado, E.; López-Córdoba, A. Improvement of the Ultrasound-Assisted Extraction of Polyphenols from Welsh Onion (Allium fistulosum) Leaves Using Response Surface Methodology. Foods 2022, 11, 2425. [Google Scholar] [CrossRef] [PubMed]

- Yıkmış, S.; Erdal, B.; Doguer, C.; Levent, O.; Türkol, M.; Tokatlı Demirok, N. Thermosonication Processing of Purple Onion Juice (Allium cepa L.): Anticancer, Antibacterial, Antihypertensive, and Antidiabetic Effects. Processes 2024, 12, 517. [Google Scholar] [CrossRef]

- Yoo, K.S.; Lee, E.J.; Hamilton, B.K.; Patil, B.S. A Comparison of Juice Extraction Methods in the Pungency Measurement of Onion Bulbs. J. Sci. Food Agric. 2016, 96, 735–741. [Google Scholar] [CrossRef]

- Nasri, S.; Anoush, M.; Khatami, N. Evaluation of Analgesic and Anti-Inflammatory Effects of Fresh Onion Juice in Experimental Animals. Afr. J. Pharm. Pharmacol. 2012, 6, 1679–1684. [Google Scholar] [CrossRef]

- Laureanti, E.J.G.; Paiva, T.S.; de Matos Jorge, L.M.; Jorge, R.M.M. Microencapsulation of Bioactive Compound Extracts Using Maltodextrin and Gum Arabic by Spray and Freeze-Drying Techniques. Int. J. Biol. Macromol. 2023, 253, 126969. [Google Scholar] [CrossRef] [PubMed]

- Delshadi, R.; Bahrami, A.; Tafti, A.G.; Barba, F.J.; Williams, L.L. Micro and Nano-Encapsulation of Vegetable and Essential Oils to Develop Functional Food Products with Improved Nutritional Profiles. Trends Food Sci. Technol. 2020, 104, 72–83. [Google Scholar] [CrossRef]

- Banožić, M.; Filipović, A.; Ištuk, J.; Kovač, M.; Ivanković, A.; Kajić, N.; Puljić, L.; Aladić, K.; Jokić, S. Valorization of Underutilized Mandarin Juice Byproduct Through Encapsulation of Flavonoids Using Freeze-Drying Technique. Appl. Sci. 2025, 15, 380. [Google Scholar] [CrossRef]

- Hay, T.O.; Nastasi, J.R.; Prakash, S.; Fitzgerald, M.A. Comparison of Gidyea Gum, Gum Arabic, and Maltodextrin in the Microencapsulation and Colour Stabilisation of Anthocyanin-Rich Powders Using Freeze-Drying and Spray-Drying Techniques. Food Hydrocoll. 2025, 163, 111023. [Google Scholar] [CrossRef]

- Telis, V.R.N.; Martínez-Navarrete, N. Biopolymers Used as Drying Aids in Spray- Drying and Freeze-Drying of Fruit Juices and Pulps. In Biopolymer Engineering in Food Processing; CRC Press: Boca Raton, FL, USA, 2012; pp. 279–325. [Google Scholar]

- Lachowicz, S.; Michalska-Ciechanowska, A.; Oszmiański, J. The Impact of Maltodextrin and Inulin on the Protection of Natural Antioxidants in Powders Made of Saskatoon Berry Fruit, Juice, and Pomace as Functional Food Ingredients. Molecules 2020, 25, 1805. [Google Scholar] [CrossRef]

- Pudziuvelyte, L.; Marksa, M.; Sosnowska, K.; Winnicka, K.; Morkuniene, R.; Bernatoniene, J. Freeze-Drying Technique for Microencapsulation of Elsholtzia Ciliata Ethanolic Extract Using Different Coating Materials. Molecules 2020, 25, 2237. [Google Scholar] [CrossRef]

- Alves, E.S.; Ferreira, C.S.R.; Souza, P.R.; Bruni, A.R.S.; Castro, M.C.; Saqueti, B.H.F.; Santos, O.O.; Madrona, G.S.; Visentainer, J.V. Freeze-Dried Human Milk Microcapsules Using Gum Arabic and Maltodextrin: An Approach to Improving Solubility. Int. J. Biol. Macromol. 2023, 238, 124100. [Google Scholar] [CrossRef] [PubMed]

- Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. New Freeze-Dried Andean Blueberry Juice Powders for Potential Application as Functional Food Ingredients: Effect of Maltodextrin on Bioactive and Morphological Features. Molecules 2020, 25, 5635. [Google Scholar] [CrossRef]

- Luna-Finkler, C.L.; Gomes, A.d.C.; de Aguiar Júnior, F.C.A.; Ribeiro, E.; de Melo Barbosa, R.; Severino, P.; Santini, A.; Souto, E.B. From Extraction to Stabilization: Employing a 22 Experimental Design in Developing Nutraceutical-Grade Bixin from Bixa orellana L. Foods 2024, 13, 1622. [Google Scholar] [CrossRef]

- Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. Evaluation of Mixtures of Maltodextrin and Gum Arabic for the Encapsulation of Andean Blueberry (Vaccinium meridionale) Juice by Freeze-drying. Int. J. Food Sci. Technol. 2022, 57, 7379–7390. [Google Scholar] [CrossRef]

- Abarghoei, M.; Goli, M.; Shahi, S. Investigation of Cold Atmospheric Plasma Effects on Functional and Physicochemical Properties of Wheat Germ Protein Isolate. LWT 2023, 177, 114585. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- López-Córdoba, A.; Deladino, L.; Agudelo-Mesa, L.; Martino, M. Yerba Mate Antioxidant Powders Obtained by Co-Crystallization: Stability during Storage. J. Food Eng. 2014, 124, 158–165. [Google Scholar] [CrossRef]

- Pino, J.A.; Sosa-Moguel, O.; Sauri-Duch, E.; Cuevas-Glory, L. Microencapsulation of Winter Squash (Cucurbita moschata Duchesne) Seed Oil by Spray Drying. J. Food Process Preserv. 2019, 43, e14136. [Google Scholar] [CrossRef]

- Aniesrani Delfiya, D.S.; Thangavel, K.; Natarajan, N.; Kasthuri, R.; Kailappan, R. Microencapsulation of Turmeric Oleoresin by Spray Drying and in Vitro Release Studies of Microcapsules. J. Food Process Eng. 2015, 38, 37–48. [Google Scholar] [CrossRef]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of Water Activity (an) on Microbial Stability: As a Hurdle in Food Preservation. In Water Activity in Foods; Barbosa-Cánovas, G.V., Fontana, A.J., Schmidt, S.J., Labuza, T.P., Eds.; Wiley-Blackwell: Hoboken, NJ, USA, 2007; pp. 239–271. [Google Scholar] [CrossRef]

- Abney, K.R.; Kopsell, D.A.; Sams, C.E.; Zivanovic, S.; Kopsell, D.E. UV-B Radiation Impacts Shoot Tissue Pigment Composition in Allium fistulosum L. Cultigens. Sci. World J. 2013, 2013, 513867. [Google Scholar] [CrossRef]

- Lee, E.J.; Patil, B.S.; Yoo, K.S. Antioxidants of 15 Onions with White, Yellow, and Red Colors and Their Relationship with Pungency, Anthocyanin, and Quercetin. LWT 2015, 63, 108–114. [Google Scholar] [CrossRef]

- Duqueyroix, A.; Ait Aider-Kaci, F.; Aider, M. Impact of the Anodic and Cathodic Electro-Activation Treatment on the Physico-Chemical and Antioxidant Capacity of Red Beetroot Juice. ACS Omega 2022, 7, 42456–42466. [Google Scholar] [CrossRef]

- Chang, L.S.; Karim, R.; Abdulkarim, S.M.; Ghazali, H.M. Production and Characterization of Enzyme-Treated Spray-Dried Soursop (Annona muricata L.) Powder. J. Food Process Eng. 2018, 41, e12688. [Google Scholar] [CrossRef]

- Aquino, G.; Basilicata, M.G.; Crescenzi, C.; Vestuto, V.; Salviati, E.; Cerrato, M.; Ciaglia, T.; Sansone, F.; Pepe, G.; Campiglia, P. Optimization of Microwave-Assisted Extraction of Antioxidant Compounds from Spring Onion Leaves Using Box–Behnken Design. Sci. Rep. 2023, 13, 14923. [Google Scholar] [CrossRef]

- Sethuraman, S.; Rajendran, K. Is Gum Arabic a Good Emulsifier Due to CH...ΠInteractions? How Urea Effectively Destabilizes the Hydrophobic CH...ΠInteractions in the Proteins of Gum Arabic than Amides and GuHCl? ACS Omega 2019, 4, 16418–16428. [Google Scholar] [CrossRef]

- Akhavan Mahdavi, S.; Jafari, S.M.; Assadpoor, E.; Dehnad, D. Microencapsulation Optimization of Natural Anthocyanins with Maltodextrin, Gum Arabic and Gelatin. Int. J. Biol. Macromol. 2016, 85, 379–385. [Google Scholar] [CrossRef]

- Tang, L.; Liu, H.; Huang, G.; Yuan, Z.; Fu, M.; Bu, Z.; Wen, J.; Xu, Y. The Structural Characterization, Physicochemical Properties, and Stability of Gardenia Yellow Pigment Microcapsules. LWT 2022, 162, 113507. [Google Scholar] [CrossRef]

- Karaduman, U.; Sakin-Yilmazer, M.; Balkir, P. Artichoke Leaf Extract Powder: Sustainable Production and Potential Culinary Applications. Int. J. Gastron. Food Sci. 2025, 39, 101113. [Google Scholar] [CrossRef]

- Damodaran, S.; Parkin, K.L. Fennema’s Food Chemistry, 5th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Barbosa Canovas, G.V.; Ortega Rivas, E.; Juliano, P.; Yan, H. Food Powders: Physical Properties, Processing, and Functionality; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2005; ISBN 0-306-47806-4. [Google Scholar]

- López-Córdoba, A.; Goyanes, S. Food Powder Properties. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Carr, R.L. Evaluating Flow Properties of Solids. Chem. Eng. 1965, 72, 163–168. [Google Scholar]

| Physicochemical Properties | Value |

|---|---|

| Soluble solids content (°Brix) | 3.46 ± 0.06 |

| Dry solid content (%) | 3.45 ± 0.04 |

| Water activity | 1.01 ± 0.05 |

| pH | 5.80 ± 0.01 |

| Color coordinates (CIELAB) | L* = 41.95 ± 1.70 |

| a* = −24.22 ± 3.89 | |

| b* = 47.10 ± 0.29 | |

| h = 117.11 ± 3.58 | |

| c = 53.04 ± 2.04 | |

| Total polyphenol content (mg GAE/g dw) | 20.73 ± 0.90 |

| DPPH• scavenging activity (mg GAE/g dw) | 2.16 ± 0.05 |

| MD/GA Concentration (%) | L* | a* | b* | h | Chroma | ΔE |

|---|---|---|---|---|---|---|

| Juice * | 52.35 ± 0.07 c | −13.95 ± 0.49 a | 39.90 ± 2.68 a | 109.28 ± 0.56 a | 42.26 ± 2.64 a | - |

| 100/0 | 60.01 ± 1.38 a | −5.54 ± 2.75 b | 17.45 ± 3.36 b | 106.78 ± 5.93 a | 21.26 ± 2.06 b | 25.26 ± 3.86 a |

| 75/25 | 59.05 ± 1.62 a,b | −4.47 ± 1.81 b | 17.13 ± 2.73 b | 104.36 ± 4.59 a | 19.63 ± 1.58 b,c | 25.64 ± 2.83 a |

| 50/50 | 57.11 ± 2.34 c,a,b | −3.68 ± 1.59 b | 18.41 ± 1.51 b | 101.28 ± 4.82 a | 18.83 ± 1.55 b,c | 24.43 ± 1.46 a |

| 25/75 | 56.92 ± 2.54 c,a,b | −4.24 ± 2.17 b | 17.64 ± 1.46 b | 103.24 ± 6.23 a | 18.23 ± 1.71 b,c | 24.88 ± 1.79 a |

| 0/100 | 55.90 ± 2.68 c,b | −4.18 ± 1.71 b | 17.9 ± 2.95 b | 102.75 ± 3.89 a | 16.43 ± 1.14 c | 24.45 ± 3.37 a |

| MD/GA Concentration (%) | Total Phenolic Content (mg GAE g−1) | Total Polyphenol Recovery (%) | DPPH Radical Scavenging Capacity (mg GAE g−1) |

|---|---|---|---|

| Juice * | 19.45 ± 0.56 a | 93.7 ± 1.3 a | 3.28 ± 0.12 a |

| 100/0 | 2.60 ± 0.11 e | 93.7 ± 3.5 a | 0.55 ± 0.14 b |

| 75/25 | 2.92 ± 0.06 d | 95.3 ± 9.5 a | 0.56 ± 0.08 b |

| 50/50 | 3.20 ± 0.21 c,d | 95.3 ± 9.1 a | 0.50 ± 0.13 b |

| 25/75 | 3.27 ± 0.11 b,c | 98.0 ± 5.9 a | 0.50 ± 0.09 b |

| 0/100 | 3.53 ± 0.17 b | 99.1 ± 7.1 a | 0.54 ± 0.08 b |

| MD/GA Concentration (%) | Moisture Content (%) | Water Activity (aw) | Water Solubility (%) |

|---|---|---|---|

| Juice * | 6.55 ± 0.07 a | 0.27 ± 0.01 a | 72.42 ± 1.85 b |

| 100/0 | 5.63 ± 0.49 a,b | 0.35 ± 0.06 a | 88.68 ± 0.78 a |

| 75/25 | 4.94 ± 0.32 b | 0.30 ± 0.09 a | 88.62 ± 0.55 a |

| 50/50 | 6.50 ± 0.63 a | 0.37 ± 0.01 a | 87.78 ± 0.64 a |

| 25/75 | 5.84 ± 0.56 a,b | 0.33 ± 0.02 a | 87.37 ± 0.34 a |

| 0/100 | 6.36 ± 0.51 a | 0.30 ± 0.02 a | 87.55 ± 0.82 a |

| MD:GA Concentration (%) | Loose-Bulk Density (kg m−3) | Tapped-Bulk Density (kg m−3) | Hausner Ratio | Carr Index (%) |

|---|---|---|---|---|

| Juice * | 385.93 ± 0.12 a | 472.26 ± 7.71 a | 1.22 ± 0.02 a | 18.26 ± 1.36 a |

| 100/0 | 392.51 ± 13.89 a | 461.66 ± 15.75 a | 1.17 ± 0.02 a,b | 14.96 ± 1.78 a,b |

| 75/25 | 396.36 ± 15.53 a | 467.32 ± 22.36 a | 1.18 ± 0.02 a,b | 15.14 ± 1.66 a,b |

| 50/50 | 413. 94 ± 13.21 a | 474.36 ± 17.08 a | 1.14 ± 0.01 b | 12.72 ± 0.85 b |

| 25/75 | 390.50 ± 30.82 a | 452.82 ± 31.48 a | 1.16 ± 0.02 b | 13.80 ± 1.71 b |

| 0/100 | 393.83 ± 13.45 a | 474.52 ± 17.04 a | 1.20 ± 0.02 a | 16.98 ± 1.80 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Jaramillo, C.; López-Córdoba, A. Enhancing the Physicochemical, Thermal, and Technological Properties of Freeze-Dried Welsh Onion Leaf Juice: Influence of Maltodextrin and Gum Arabic as Carrier Agents. Polymers 2025, 17, 801. https://doi.org/10.3390/polym17060801

Medina-Jaramillo C, López-Córdoba A. Enhancing the Physicochemical, Thermal, and Technological Properties of Freeze-Dried Welsh Onion Leaf Juice: Influence of Maltodextrin and Gum Arabic as Carrier Agents. Polymers. 2025; 17(6):801. https://doi.org/10.3390/polym17060801

Chicago/Turabian StyleMedina-Jaramillo, Carolina, and Alex López-Córdoba. 2025. "Enhancing the Physicochemical, Thermal, and Technological Properties of Freeze-Dried Welsh Onion Leaf Juice: Influence of Maltodextrin and Gum Arabic as Carrier Agents" Polymers 17, no. 6: 801. https://doi.org/10.3390/polym17060801

APA StyleMedina-Jaramillo, C., & López-Córdoba, A. (2025). Enhancing the Physicochemical, Thermal, and Technological Properties of Freeze-Dried Welsh Onion Leaf Juice: Influence of Maltodextrin and Gum Arabic as Carrier Agents. Polymers, 17(6), 801. https://doi.org/10.3390/polym17060801