The Effect of Fiber Weight Fraction on Tribological Behavior for Glass Fiber Reinforced Polymer

Abstract

1. Introduction

2. Materials and Methods

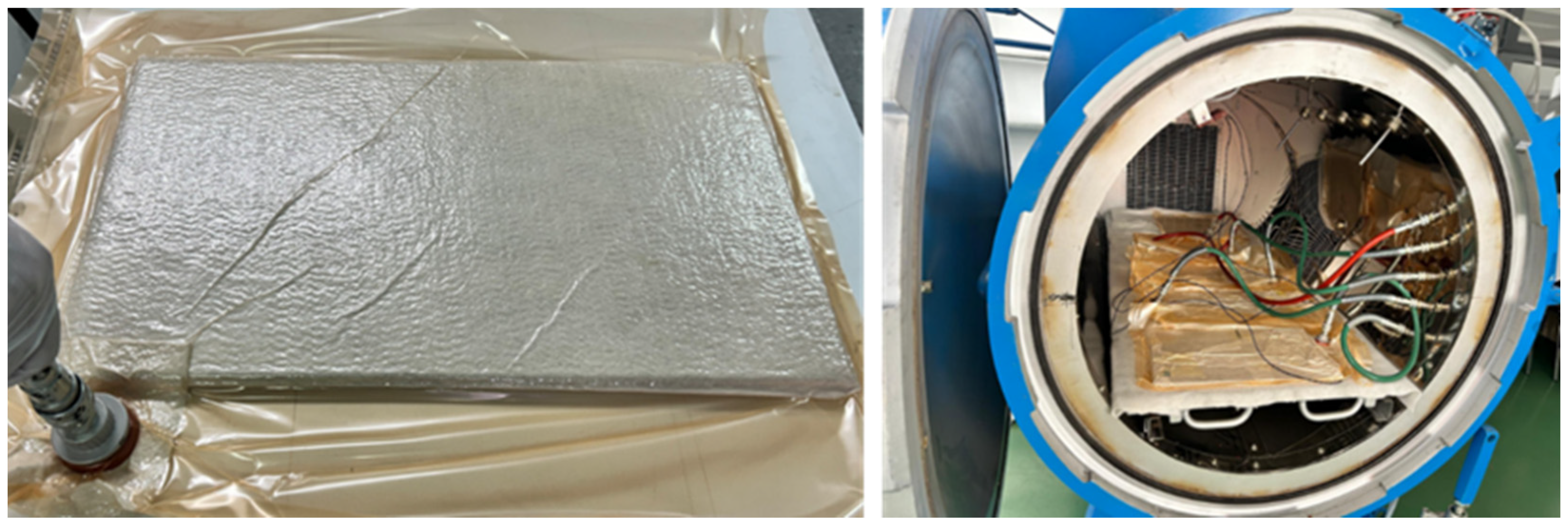

2.1. Materials and Samples Manufacturing

2.2. Mechanical Tests

2.3. Wear Tests

- Vdisk—wear volume of the disc (mm3);

- Vball—wear volume of the ball (mm3);

- F—normal force (N);

- Lsliding—total sliding distance (m);

- Kdisk, Kball—wear factors of the disc and ball (mm3/Nm).

2.4. Design of the Experiments and Statistical Method

2.5. Morphological Analysis

3. Results and Discussion

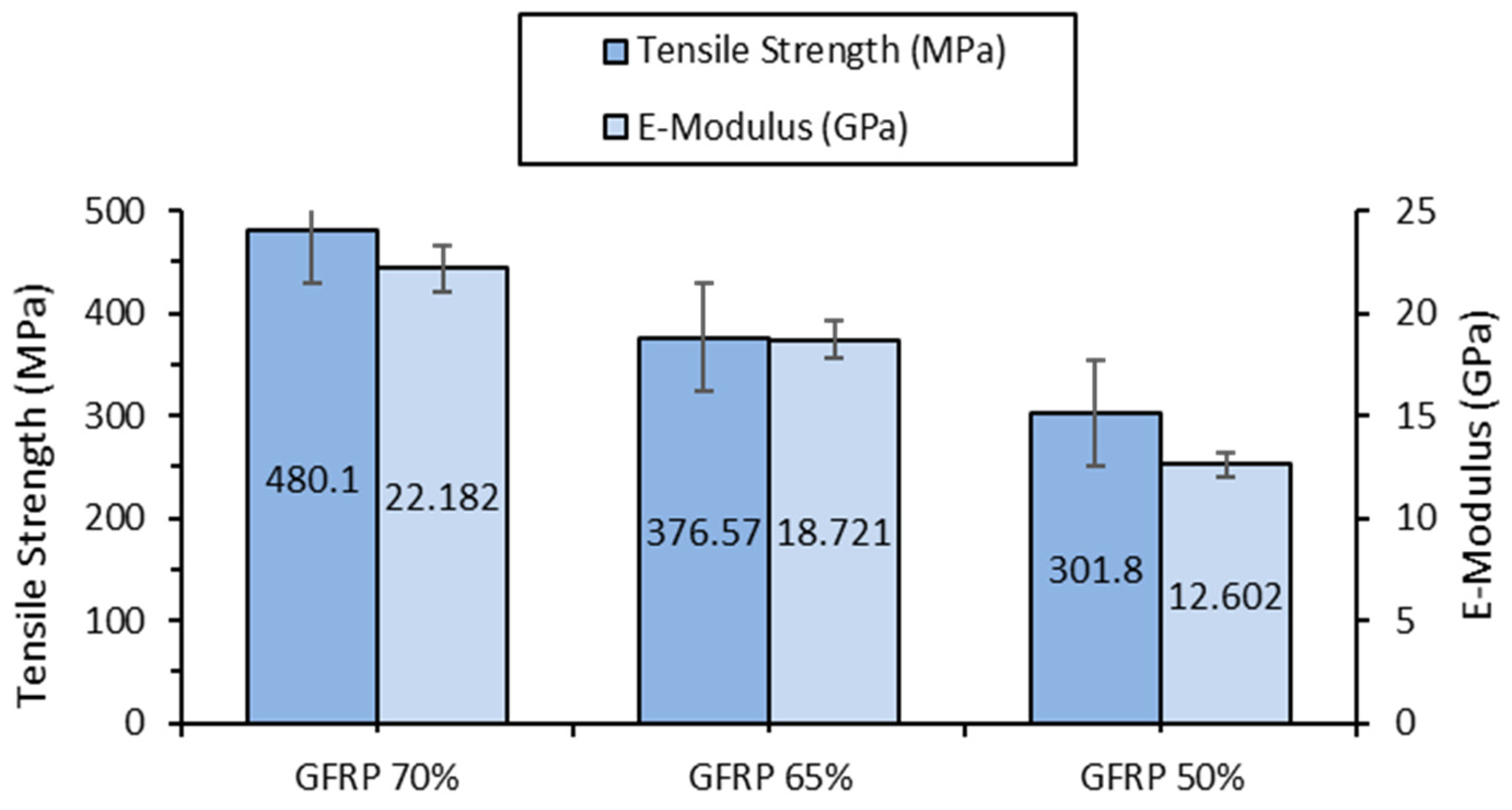

3.1. Results of Mechanical Testing

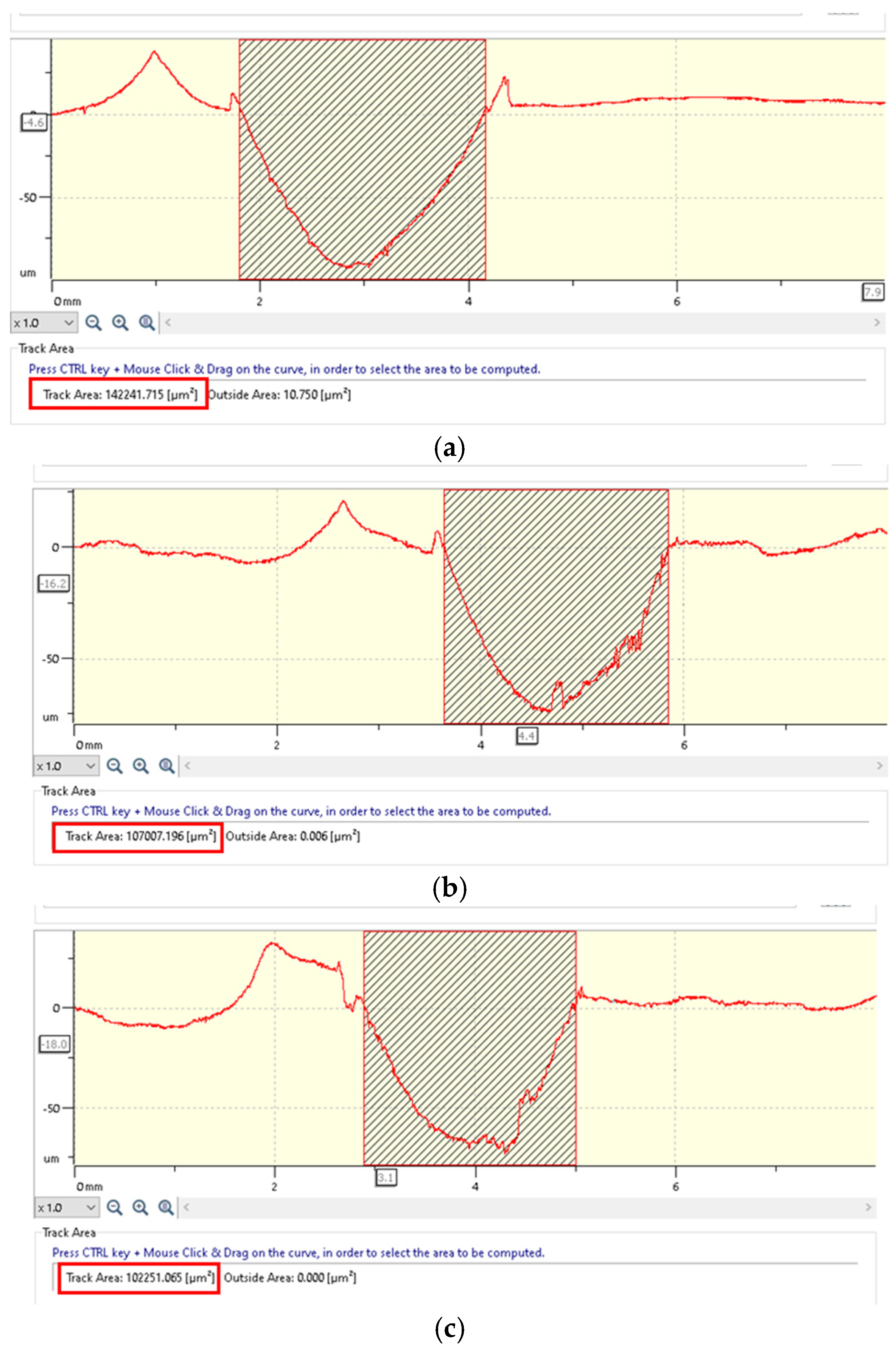

3.2. Tribological Testing Results

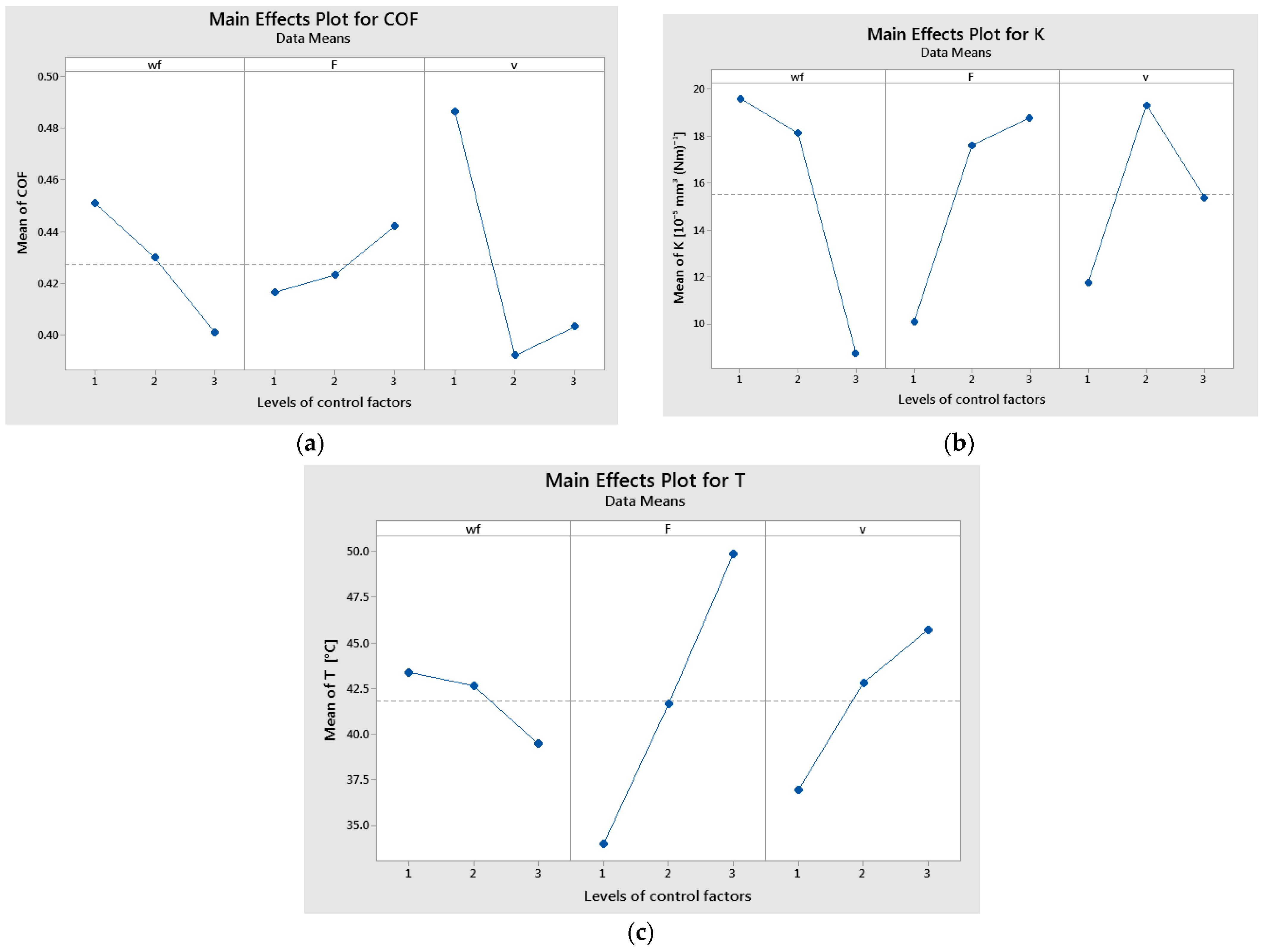

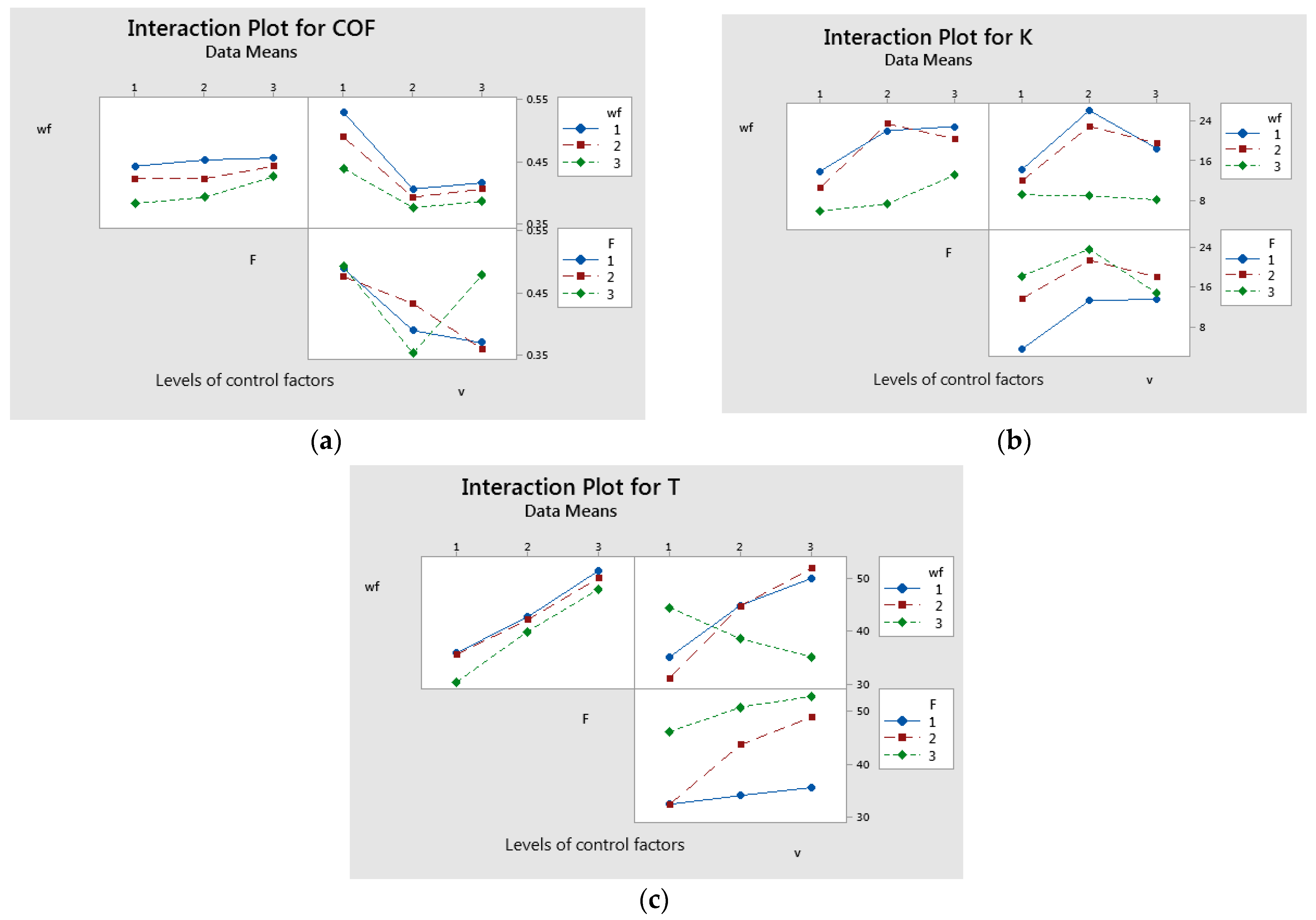

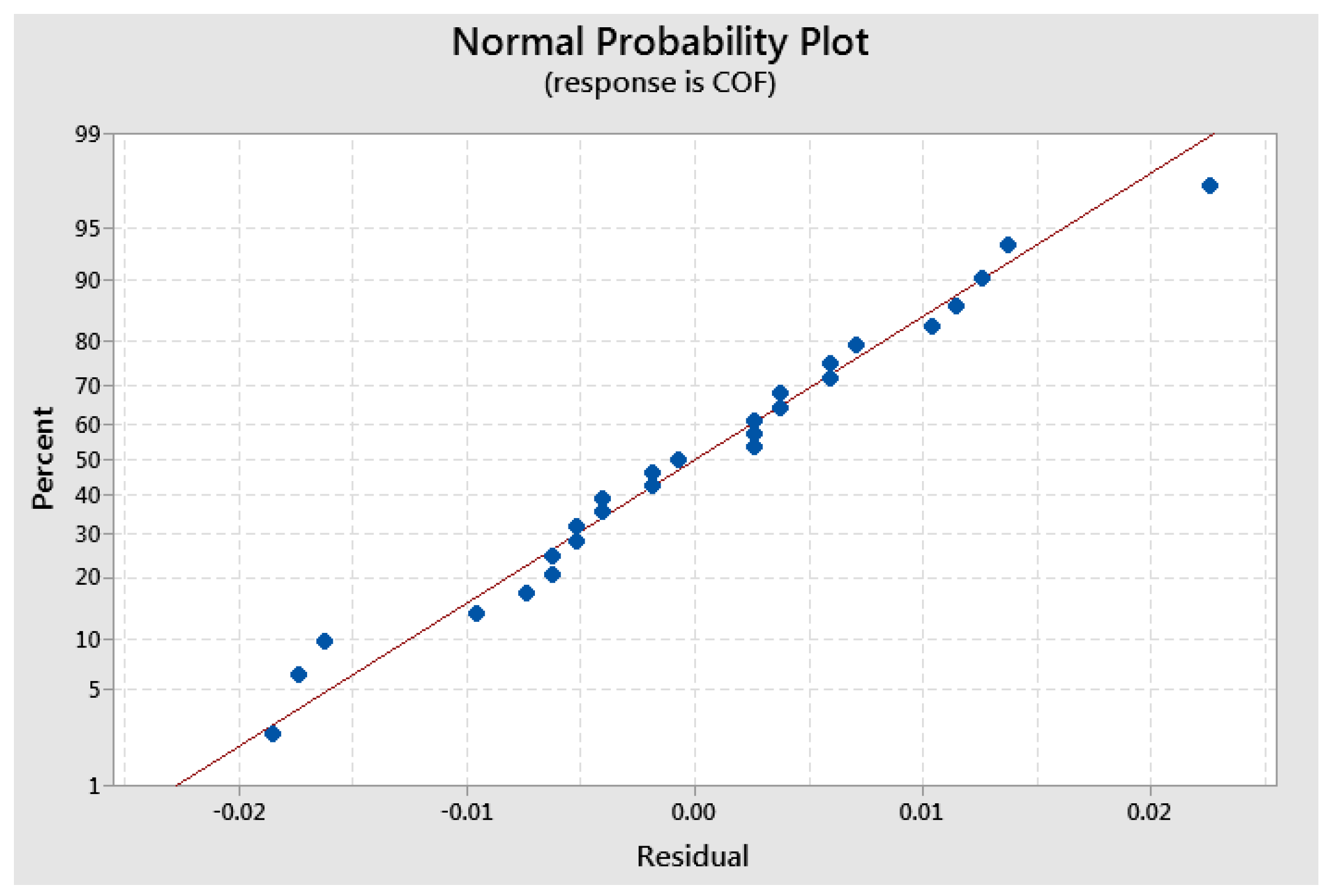

3.3. Results of Statistical Analysis

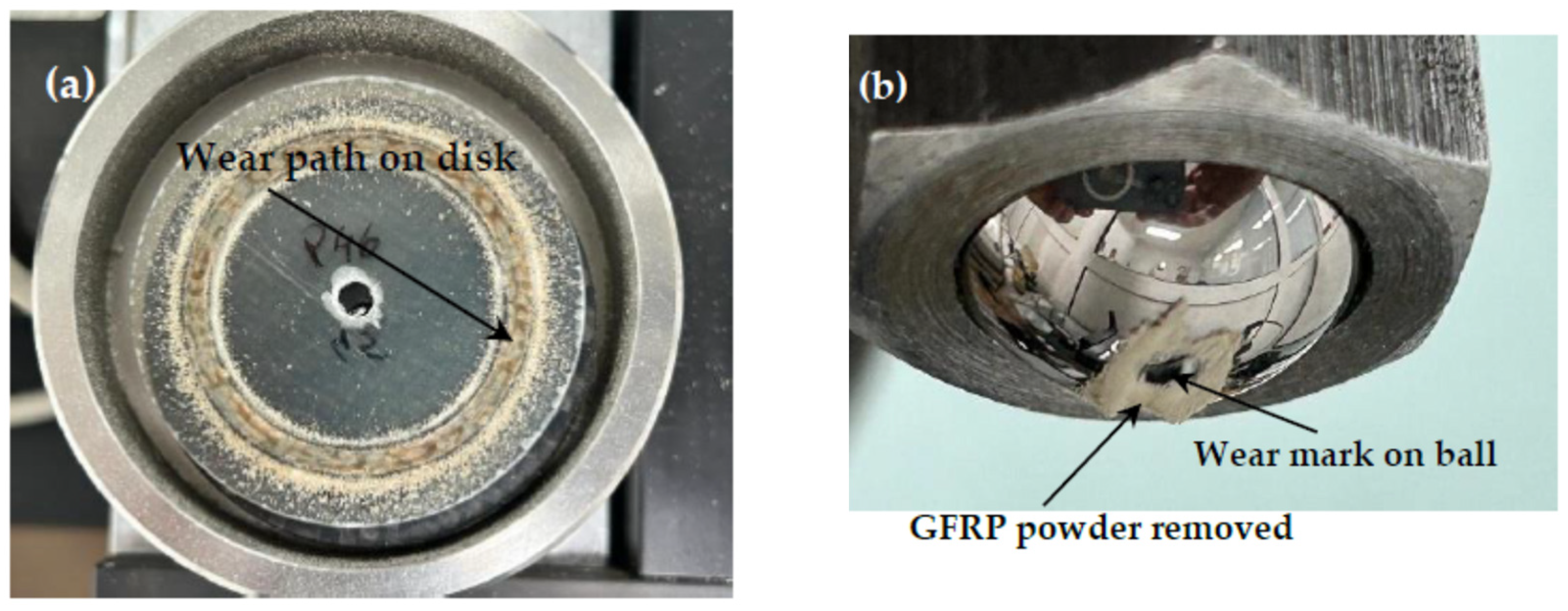

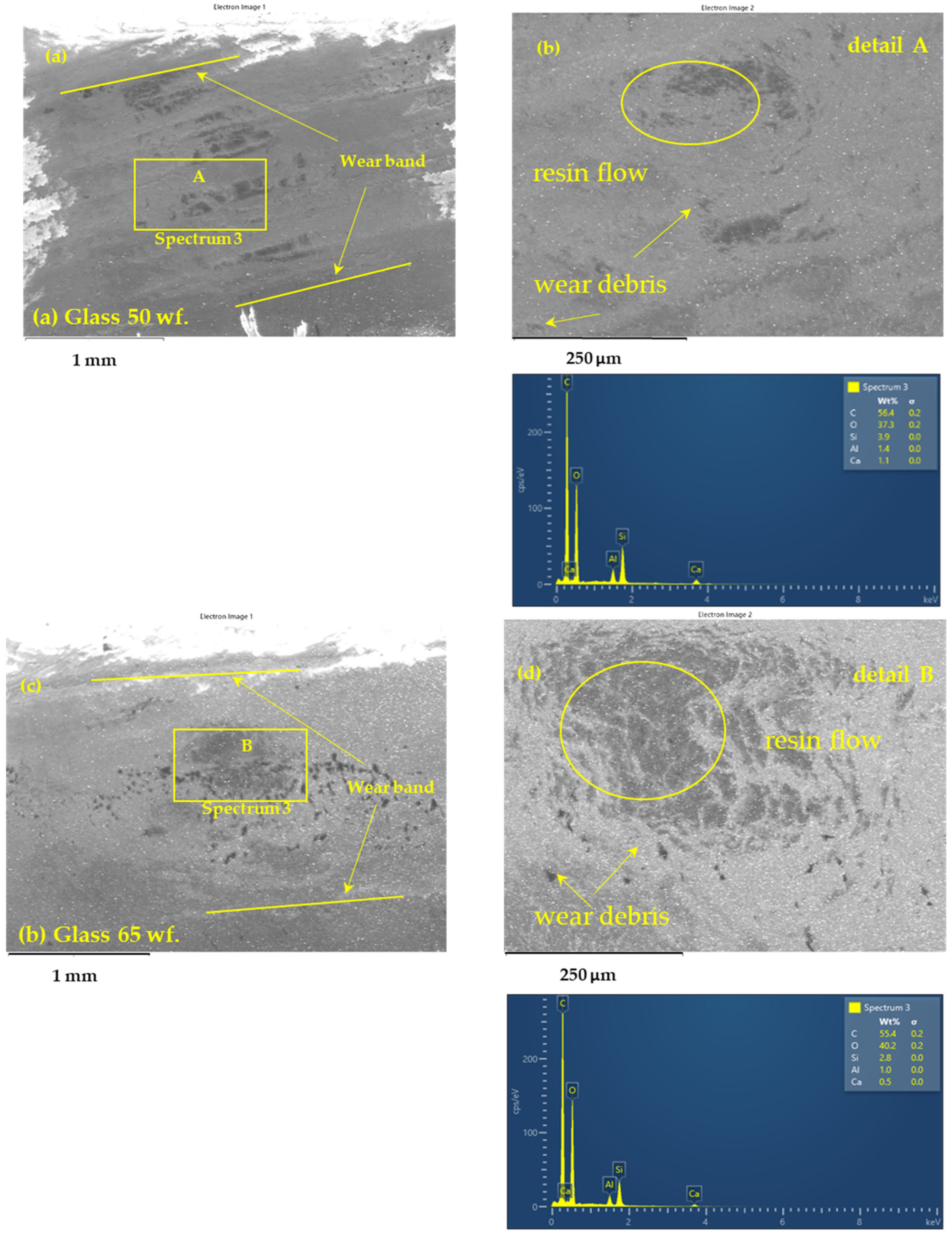

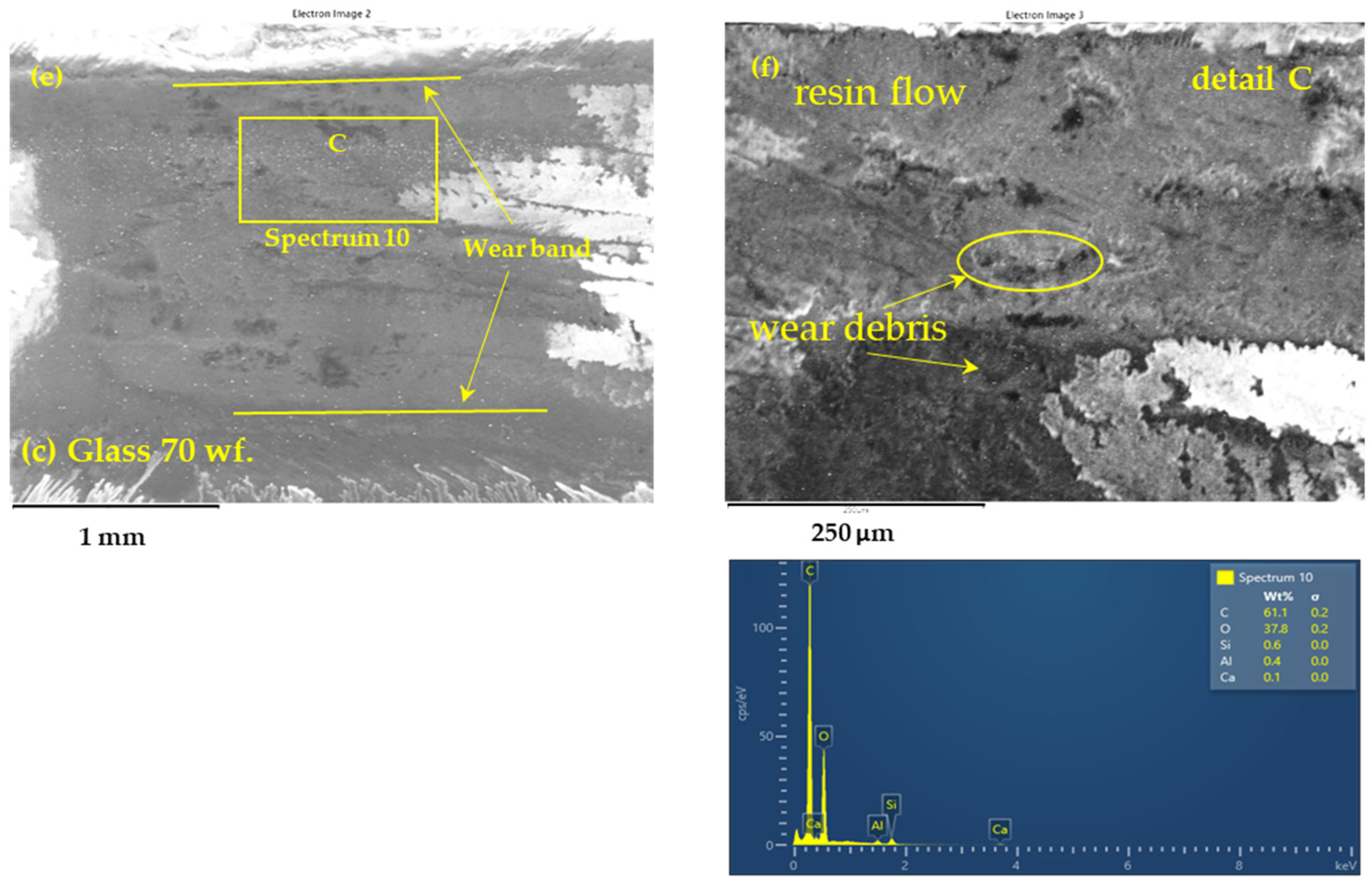

3.4. Results of the Morphological Analysis

3.5. Interactions and Transformations Between Wear Mechanisms

3.6. Correlation Between Structural Changes and Tribological Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Palanikumar, K.; Ramesh, M.; Hemachandra Reddy, K. Experimental investigation on the mechanical properties of green hybrid sisal and glass fiber reinforced polymer composites. J. Nat. Fibers 2016, 13, 321–331. [Google Scholar] [CrossRef]

- Landesmann, A.; Seruti, C.A.; Batista ED, M. Mechanical properties of glass fiber reinforced polymers members for structural applications. Mater. Res. 2015, 18, 1372–1383. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; El-Elamy, M.I.; Zoalfakar, S.H. Mechanical properties of glass fiber reinforced polyester composites. Int. J. Appl. Sci. Eng. 2017, 14, 121–131. [Google Scholar]

- Davallo, M.; Pasdar, H. Comparison of mechanical properties of glass-polyester composites formed by resin transfer molding and hand lay-up technique. Int. J. ChemTech Res. 2009, 1, 470–475. [Google Scholar]

- Abdullah, E.T. A study of bending properties of unsaturated polyester/glass fiber reinforced composites. Al-Nahrain J. Sci. 2013, 16, 129–132. [Google Scholar] [CrossRef]

- Talib AA, A.; Jumahat, A.; Jawaid, M.; Sapiai, N.; Leao, A.L. Effect of wear conditions, parameters and sliding motions on tribological characteristics of basalt and glass fibre reinforced epoxy composites. Materials 2021, 14, 701. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T.; Yung, D.-L. Effect of temperature on sliding and erosive wear of fiber reinforced polyimide hybrids. Tribol. Int. 2015, 82, 525–533. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T. Friction and wear of fiber reinforced polyimide composites. Wear 2013, 301, 122–129. [Google Scholar] [CrossRef]

- Karsli, N.G.; Demirkol, S.; Yilmaz, T. Thermal aging and reinforcement type effects on the tribological, thermal, thermomechanical, physical and morphological properties of poly(ether ether ketone) composites. Compos. Part B Eng. 2016, 88, 253–263. [Google Scholar] [CrossRef]

- Birleanu, C.; Cioaza, M.; Serdean, F.; Pustan, M.; Bere, P.; Contiu, G. Tribological investigation of glass fiber reinforced polymer composites against 52100 chrome alloy steel based on ELECTRE decision-making method. Polymers 2023, 16, 62. [Google Scholar] [CrossRef]

- Asyraf, M.R.; Ishak, M.R.; Syamsir, A.; Amir, A.L.; Nurazzi, N.M.; Norrrahim, M.N.F.; Asrofi, M.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Filament-wound glass-fibre reinforced polymer composites: Potential applications for cross arm structure in transmission towers. Polym. Bull. 2023, 80, 1059–1084. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Sanjay, M.; Yogesha, B. Studies on natural/glass fiber reinforced polymer hybrid composites: An evolution. Mater. Today Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- Collar, E.P.; García-Martínez, J.M. Mechanical Behavior of Polymeric Materials: Recent Studies. Polymers 2024, 16, 2821. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Torabizadeh, M.; Eisazadeh, H. Experimental study of the effect of strain rate on the mechanical behavior of assorted thermoplastic polymers. J. Mater. Eng. Perform. 2024, 33, 6942–6951. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical performance and applications of cnts reinforced polymer composites—A review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Bazli, M.; Abolfazli, M. Mechanical properties of fibre reinforced polymers under elevated temperatures: An overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef]

- Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A review on mechanical properties of natural fibre reinforced polymer composites under various strain rates. J. Compos. Sci. 2021, 5, 130. [Google Scholar] [CrossRef]

- Kukureka, S.N.; Hooke, C.J.; Rao, M.; Liao, P.; Chen, Y.K. The effect of fibre reinforcement on the friction and wear of polyamide 66 under dry rolling–sliding contact. Tribol. Int. 1999, 32, 107–116. [Google Scholar] [CrossRef]

- Dearn, K.D.; Kukureka, S.N.; Walton, D. Engineering polymers and composites for machine elements. In Handbook of Polymer Tribology; World Scientific: Singapore, 2018; pp. 441–479. [Google Scholar]

- Zaghloul MM, Y.; Steel, K.; Veidt, M.; Heitzmann, M.T. Mechanical and tribological performances of thermoplastic polymers reinforced with glass fibres at variable fibre volume fractions. Polymers 2023, 15, 694. [Google Scholar] [CrossRef]

- Yaşar, İ.; Arslan, F. Effects of fiber volume fraction and fiber orientation on the tribological behaviour of unidirectionally oriented glass fiber-polyester composites. Turk. J. Eng. Environ. Sci. 2000, 24, 181–192. [Google Scholar]

- Abdurohman, K.; Pratomo, R.A.; Hidayat, R.; Ramadhan, R.A.; Nurtiasto, T.S.; Ardiansyah, R.; Pribadi Putra Pratama, M.G. A comparison of vacuum infusion, vacuum bagging, and hand lay-up process on the compressive and shear properties of GFRP materials. Indones. J. Aerosp. 2023, 21, 39–50. [Google Scholar] [CrossRef]

- Ali, F.A.; Choudhary, V.; Priya, I.M.I. Experimental study on the tribological properties of polymer composites. In AIP Conference Proceedings; AIP Publishing: Mellville, NY, USA, 2022; Volume 2460. [Google Scholar]

- Sun, X.; Chi, M.; Yu, Y.; Wu, Y.; Zhang, X.; Chen, Q.; Shi, J.; Lan, D. High temperature resistance oil-paper insulation with polyimide: A study on dielectric properties. IEEE Trans. Dielectr. Electr. Insul. 2024. [Google Scholar] [CrossRef]

- Available online: https://www.astm.org/d3039_d3039m-17.html (accessed on 6 March 2025).

- Udroiu, R. Quality Analysis of Micro-Holes Made by Polymer Jetting Additive Manufacturing. Polymers 2023, 16, 32. [Google Scholar] [CrossRef] [PubMed]

- Birleanu, C.; Cioaza, M.; Udroiu, R.; Pustan, M.; Bere, P.; Lazarescu, L. Enhanced Tribological and Mechanical Properties of Copper-Modified Basalt-Reinforced Epoxy Composites. Polymers 2005, 17, 91. [Google Scholar] [CrossRef]

- Popișter, F.; Dragomir, M.; Ciudin, P.; Goia, H.Ș. Empowering Rehabilitation: Design and Structural Analysis of a Low-Cost 3D-Printed Smart Orthosis. Polymers 2024, 16, 1303. [Google Scholar] [CrossRef]

- Cioaza, M.; Birleanu, C.; Pustan, M.; Bere, P.; Contiu, G. Evaluation the Tribological Properties of Different Fiber Reinforced Polymers. In International Tribology Symposium of IFToMM; Springer Nature: Cham, Switzerland, 2024; pp. 85–95. [Google Scholar]

| Laminated Composite Symbolization | Fiber (%) | Epoxy Resin (%) |

|---|---|---|

| Laminated epoxy/glass fiber composite (wf. 50%)—GFRP_50 | 50 | 50 |

| Laminated epoxy/glass fiber composite (wf. 65%)—GFRP_65 | 65 | 35 |

| Laminated epoxy/glass fiber composite (wf. 70%)—GFRP_70 | 70 | 30 |

| Parameters | Operating Conditions |

|---|---|

| Load (Force) | 10, 20, 30 N |

| Sliding Speed | 0.1, 0.25, 0.36 m/s |

| Rotational Speed (RPM) | Max 215 (±3) rpm |

| Relative Humidity | 40 (±5)% |

| Initial Temperature | 20 (±2) °C |

| Test Duration | 120 min |

| Conditions | Dry friction |

| Materials Disc and Ball | GFRP composites and 52100-chromium-alloyed carbon steel balls |

| Roughness of the Disc and Ball [Ra] | 0.32 µm and 0.04 µm |

| Targets | Glass Fiber, wf. | Applied Load, F | Sliding Speed, v | |||

|---|---|---|---|---|---|---|

| Symbol | Value [%] | Symbol | Value [N] | Symbol | Value [m/s] | |

| Coefficient of friction Specific wear rate Temperature | 1 | 50 | 1 | 10 | 1 | 0.10 |

| 2 | 65 | 2 | 20 | 2 | 0.25 | |

| 3 | 70 | 3 | 30 | 3 | 0.36 | |

| Specimen | Tensile Strength [MPa]/ SD [MPa]/CV [%] | Tensile Strain at Maximum Load [%]/ SD [%]/CV [%] | Elastic Modulus E [MPa]/ SD [MPa]/CV [%] |

|---|---|---|---|

| GFRP 70% | 480.1/(25.92)/5.39 | 2.94/(0.03)/1.02 | 22,181.7/(253.2)/1.14 |

| GFRP 65% | 376.57/(24.37)/6.47 | 2.63/(0.02)/0.76 | 18,720.6/(316.36)/1.73 |

| GFRP 50% | 318.8/(22.45)/7.04 | 2.41/(0.02)/0.82 | 14,602/(301.25)/2.06 |

| Specimen | Flexural Strength [MPa]/ SD [MPa]/CV [%] | Flexural Strain [%]/ SD [%]/CV [%] | Elastic Modulus E [MPa]/ SD [MPa]/CV [%] |

|---|---|---|---|

| GFRP 70% | 464.8/(11.47)/2.46 | 3.77/(0.16)/4.24 | 21,009/(392)/1.52 |

| GFRP 65% | 415.5/(21.56)/5.18 | 3.08/(0.13)/4.22 | 18,218/(484)/2.65 |

| GFRP 50% | 388.6/(36.8)/9.46 | 2.36/(0.25)/9.59 | 14,935/(199)/2.94 |

| Experimental Parameters | Mean of Measured Parameters | |||||

|---|---|---|---|---|---|---|

| Exp.nr. | Applied Load F [N] | Sliding Speed v [m/s] | Glass Fiber wf. [%] | Specific Wear Rate K [10−5 mm3 × (Nm)−1] | Coefficient of Friction [µ] Average of the Last 60 min | Temperature Average of the Last 60 min [°C] |

| 1 | 10 | 0.1 | 50 | 5.758 | 0.54 | 32.7 |

| 2 | 10 | 0.1 | 65 | 3.42 | 0.5 | 29.4 |

| 3 | 10 | 0.1 | 70 | 1.5488 | 0.43 | 35.1 |

| 4 | 10 | 0.25 | 50 | 20.985 | 0.4 | 35 |

| 5 | 10 | 0.25 | 65 | 12.267 | 0.39 | 36.2 |

| 6 | 10 | 0.25 | 70 | 6.4267 | 0.38 | 31 |

| 7 | 10 | 0.36 | 50 | 14.907 | 0.39 | 40.2 |

| 8 | 10 | 0.36 | 65 | 16.022 | 0.38 | 41.4 |

| 9 | 10 | 0.36 | 70 | 9.59 | 0.34 | 25.1 |

| 10 | 20 | 0.1 | 50 | 15.208 | 0.54 | 32 |

| 11 | 20 | 0.1 | 65 | 14.189 | 0.48 | 29.2 |

| 12 | 20 | 0.1 | 70 | 11.456 | 0.41 | 35.9 |

| 13 | 20 | 0.25 | 50 | 24.906 | 0.45 | 47.5 |

| 14 | 20 | 0.25 | 65 | 32.737 | 0.43 | 45.7 |

| 15 | 20 | 0.25 | 70 | 6.12 | 0.42 | 37.8 |

| 16 | 20 | 0.36 | 50 | 26.019 | 0.37 | 48.7 |

| 17 | 20 | 0.36 | 65 | 23.291 | 0.36 | 51.7 |

| 18 | 20 | 0.36 | 70 | 4.42 | 0.35 | 46.3 |

| 19 | 30 | 0.1 | 50 | 21.671 | 0.51 | 40.8 |

| 20 | 30 | 0.1 | 65 | 18.256 | 0.49 | 34.9 |

| 21 | 30 | 0.1 | 70 | 14.426 | 0.48 | 62.7 |

| 22 | 30 | 0.25 | 50 | 32.385 | 0.37 | 52.4 |

| 23 | 30 | 0.25 | 65 | 23.727 | 0.36 | 52.7 |

| 24 | 30 | 0.25 | 70 | 14.341 | 0.33 | 47.1 |

| 25 | 30 | 0.36 | 50 | 14.488 | 0.49 | 61.3 |

| 26 | 30 | 0.36 | 65 | 19.191 | 0.48 | 62.7 |

| 27 | 30 | 0.36 | 70 | 10.492 | 0.47 | 34.2 |

| COF | K | T | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Source | F-Value | p-Value | PC [%] | F-Value | p-Value | PC [%] | F-Value | p-Value | PC [%] |

| wf | 18.17 | 0.001 | 11 | 17.08 | 0.001 | 34.15 | 0.84 | 0.466 | 2.71 |

| F | 5.07 | 0.038 | 3.07 | 10.94 | 0.005 | 21.87 | 12.13 | 0.004 | 39.08 |

| v | 76.85 | <0.001 | 46.51 | 7.05 | 0.017 | 14.11 | 3.85 | 0.068 | 12.39 |

| wf*F | 0.81 | 0.551 | 0.98 | 1.47 | 0.296 | 5.89 | 0.06 | 0.992 | 0.4 |

| wf*v | 2.90 | 0.094 | 3.51 | 2.07 | 0.177 | 8.28 | 4.23 | 0.039 | 27.24 |

| F*v | 26.86 | <0.001 | 32.51 | 1.92 | 0.200 | 7.7 | 0.82 | 0.546 | 5.3 |

| Error | - | - | 2.42 | - | - | 8 | - | - | 12.88 |

| Total | - | - | 100 | - | - | 100 | - | - | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birleanu, C.; Udroiu, R.; Cioaza, M.; Pustan, M.; Paul, B.; Vilau, C. The Effect of Fiber Weight Fraction on Tribological Behavior for Glass Fiber Reinforced Polymer. Polymers 2025, 17, 720. https://doi.org/10.3390/polym17060720

Birleanu C, Udroiu R, Cioaza M, Pustan M, Paul B, Vilau C. The Effect of Fiber Weight Fraction on Tribological Behavior for Glass Fiber Reinforced Polymer. Polymers. 2025; 17(6):720. https://doi.org/10.3390/polym17060720

Chicago/Turabian StyleBirleanu, Corina, Razvan Udroiu, Mircea Cioaza, Marius Pustan, Bere Paul, and Cristian Vilau. 2025. "The Effect of Fiber Weight Fraction on Tribological Behavior for Glass Fiber Reinforced Polymer" Polymers 17, no. 6: 720. https://doi.org/10.3390/polym17060720

APA StyleBirleanu, C., Udroiu, R., Cioaza, M., Pustan, M., Paul, B., & Vilau, C. (2025). The Effect of Fiber Weight Fraction on Tribological Behavior for Glass Fiber Reinforced Polymer. Polymers, 17(6), 720. https://doi.org/10.3390/polym17060720