Functionalization of Phenolic Aldehydes for the Preparation of Sustainable Polyesters and Polyurethanes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. General Synthesis of Phenoxy Diols (Diols 1–3)

2.3. General Synthesis of Bis(Phenolic Alcohols) (Diols 4–5)

2.4. General Preparation of PUs

2.5. General Preparation of PEs

2.6. General Preparation of PE Polyols

2.7. Preparation of PU Foams

2.7.1. PU Foam Premix

2.7.2. PU Foam Free Rises

2.7.3. PU Foam Plaque Moulds

2.8. Characterization Methods

2.9. Mechanical Testing of PU Foams

3. Results

3.1. Synthesis and Characterization of Organic Diols

3.1.1. Phenoxy Diols

3.1.2. Bis(Phenolic Alcohols)

3.2. Synthesis and Characterization of PUs

3.3. Synthesis and Characterization of PEs

3.4. Preparation and Characterization of PE Polyols

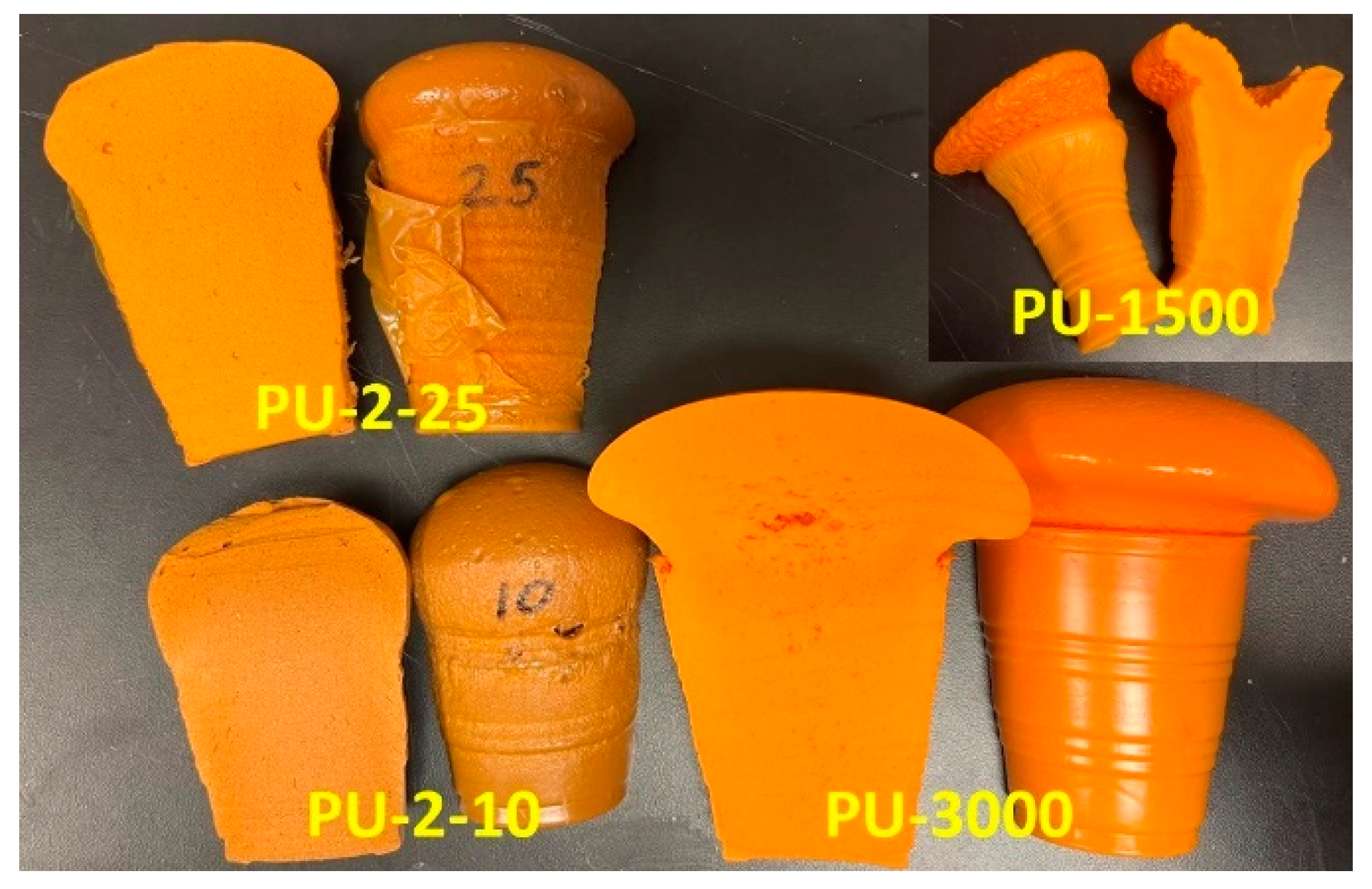

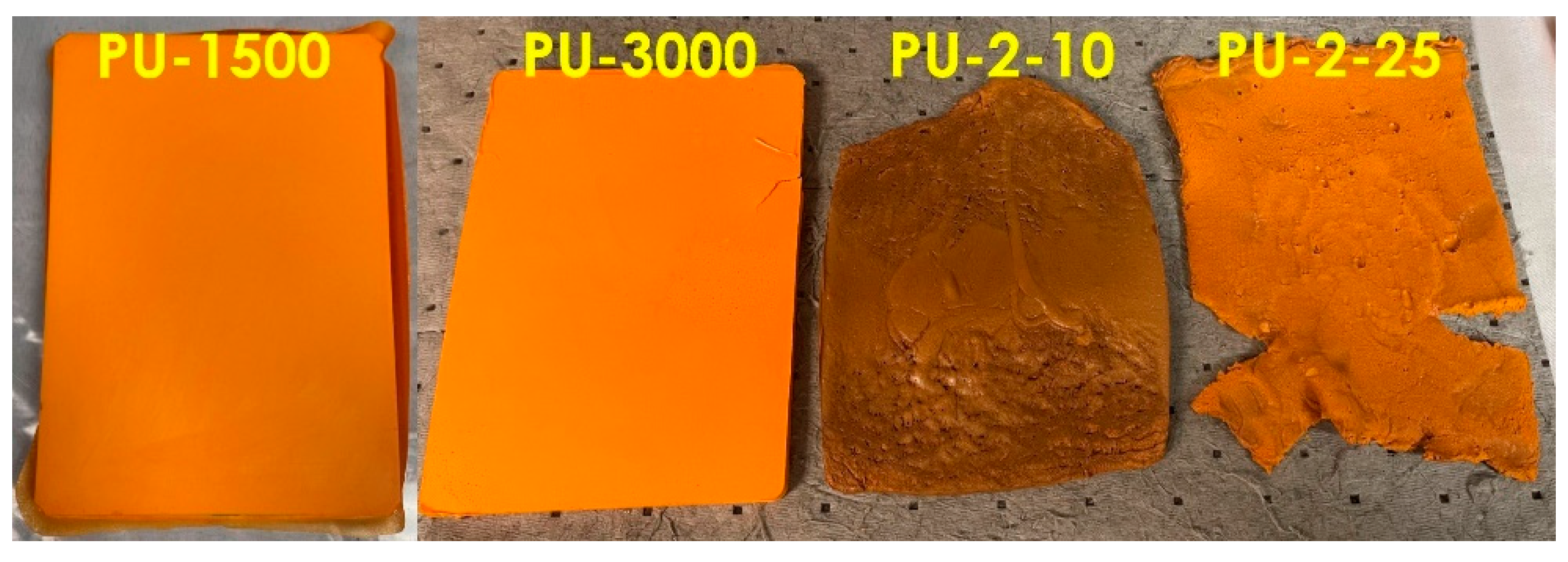

3.5. Preparation and Characterization of PU Foams

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delidovich, I.; Hausoul, P.J.C.; Deng, L.; Pfützenreuter, R.; Rose, M.; Palkovits, R. Alternative Monomers Based on Lignocellulose and Their Use for Polymer Production. Chem. Rev. 2016, 116, 1540–1599. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable Polymers from Renewable Resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Nakajima, H.; Dijkstra, P.; Loos, K. The Recent Developments in Biobased Polymers toward General and Engineering Applications: Polymers That Are Upgraded from Biodegradable Polymers, Analogous to Petroleum-Derived Polymers, and Newly Developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable Polymers and Plastics: Performance beyond the Green. N. Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic Biomass: A Sustainable Platform for the Production of Bio-Based Chemicals and Polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Carafa, R.N.; Foucher, D.A.; Sacripante, G.G. Biobased Polymers from Lignocellulosic Sources. Green. Chem. Lett. Rev. 2023, 16, 2153087. [Google Scholar] [CrossRef]

- Rico-García, D.; Ruiz-Rubio, L.; Pérez-Alvarez, L.; Hernández-Olmos, S.L.; Guerrero-Ramírez, G.L.; Vilas-Vilela, J.L. Lignin-Based Hydrogels: Synthesis and Applications. Polymers 2020, 12, 81. [Google Scholar] [CrossRef]

- Fache, M.; Boutevin, B.; Caillol, S. Vanillin Production from Lignin and Its Use as a Renewable Chemical. ACS Sustain. Chem. Eng. 2016, 4, 35–46. [Google Scholar] [CrossRef]

- Rao, S.R.; Ravishankar, G.A. Vanilla Flavour: Production by Conventional and Biotechnological Routes. J. Sci. Food Agric. 2000, 80, 289–304. [Google Scholar] [CrossRef]

- Pandey, M.P.; Kim, C.S. Lignin Depolymerization and Conversion: A Review of Thermochemical Methods. Chem. Eng. Technol. 2011, 34, 29–41. [Google Scholar] [CrossRef]

- Foyer, G.; Chanfi, B.H.; Virieux, D.; David, G.; Caillol, S. Aromatic Dialdehyde Precursors from Lignin Derivatives for the Synthesis of Formaldehyde-Free and High Char Yield Phenolic Resins. Eur. Polym. J. 2016, 77, 65–74. [Google Scholar] [CrossRef]

- Rubens, M.; Van Wesemael, M.; Feghali, E.; Luntadila Lufungula, L.; Blockhuys, F.; Vanbroekhoven, K.; Eevers, W.; Vendamme, R. Exploring the Reactivity of Aliphatic and Phenolic Hydroxyl Groups in Lignin Hydrogenolysis Oil towards Urethane Bond Formation. Ind. Crops Prod. 2022, 180, 114703. [Google Scholar] [CrossRef]

- Furtwengler, P.; Avérous, L. Renewable Polyols for Advanced Polyurethane Foams from Diverse Biomass Resources. Polym. Chem. 2018, 9, 4258–4287. [Google Scholar] [CrossRef]

- Caschera, A.; Calayan, T.; Piccolo, N.; Kakroodi, A.; Robinson, J.J.; Sacripante, G. Degradation of Bioderived Polyurethane Composites by Spectroscopy in ISO20200 Composting Conditions. Polymers 2024, 16, 2071. [Google Scholar] [CrossRef] [PubMed]

- McKenna, S.T.; Hull, T.R. The Fire Toxicity of Polyurethane Foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef]

- Sardon, H.; Pascual, A.; Mecerreyes, D.; Taton, D.; Cramail, H.; Hedrick, J.L. Synthesis of Polyurethanes Using Organocatalysis: A Perspective. Macromolecules 2015, 48, 3153–3165. [Google Scholar] [CrossRef]

- Amran, U.A.; Zakaria, S.; Chia, C.H.; Roslan, R.; Jaafar, S.N.S.; Salleh, K.M. Polyols and Rigid Polyurethane Foams Derived from Liquefied Lignocellulosic and Cellulosic Biomass. Cellulose 2019, 26, 3231–3246. [Google Scholar] [CrossRef]

- Palacios-Mateo, C.; van der Meer, Y.; Seide, G. Analysis of the Polyester Clothing Value Chain to Identify Key Intervention Points for Sustainability. Environ. Sci. Eur. 2021, 33, 2. [Google Scholar] [CrossRef]

- Sokolsky-Papkov, M.; Langer, R.; Domb, A.J. Synthesis of Aliphatic Polyesters by Polycondensation Using Inorganic Acid as Catalyst. Polym. Adv. Technol. 2011, 22, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Chung, H. Synthesis and Characterization of Lignin-Graft-Poly(Ethylene Brassylate): A Biomass-Based Polyester with High Mechanical Properties. ACS Sustain. Chem. Eng. 2021, 9, 14766–14776. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, Z.; Zeng, S.; Li, G.; Xiong, J.; Ding, L.; Gauthier, M. Synthesis and Characterization of Renewable Polyesters Based on Vanillic Acid. J. Appl. Polym. Sci. 2020, 137, 4–13. [Google Scholar] [CrossRef]

- Jeong, H.; Park, J.; Kim, S.; Lee, J.; Ahn, N.; Roh, H. Preparation and Characterization of Thermoplastic Polyurethanes Using Partially Acetylated Kraft Lignin. Fibers Polym. 2013, 14, 1082–1093. [Google Scholar] [CrossRef]

- Zhang, X.; Jeremic, D.; Kim, Y.; Street, J.; Shmulsky, R. Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams. Polymers 2018, 10, 706. [Google Scholar] [CrossRef] [PubMed]

- Kühnel, I.; Podschun, J.; Saake, B.; Lehnen, R. Synthesis of Lignin Polyols via Oxyalkylation with Propylene Carbonate. Holzforschung 2015, 69, 531–538. [Google Scholar] [CrossRef]

- Kühnel, I.; Saake, B.; Lehnen, R. Oxyalkylation of Lignin with Propylene Carbonate: Influence of Reaction Parameters on the Ensuing Bio-Based Polyols. Ind. Crops Prod. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, C.; Chen, Q.; Ingram, I.D.V.; Zeng, X.; Ren, T.; Xie, H. Sustainable Aromatic Aliphatic Polyesters and Polyurethanes Prepared from Vanillin-Derived Diols via Green Catalysis. Polymers 2020, 12, 586. [Google Scholar] [CrossRef]

- Canceill, J.; Collet, A. ChemInform Abstract: Two-Step Synthesis of D3 and C3h Cryptophanes. J. Chem. Soc. Chem. Commun. 1988, 19, 582–584. [Google Scholar] [CrossRef]

- Mouren, A.; Avérous, L. Aromatic Thermoplastic Polyurethanes Synthesized from Different Potential Sustainable Resources. Eur. Polym. J. 2023, 197, 112338. [Google Scholar] [CrossRef]

- Tarnchompoo, B.; Chitnumsub, P.; Jaruwat, A.; Shaw, P.J.; Vanichtanankul, J.; Poen, S.; Rattanajak, R.; Wongsombat, C.; Tonsomboon, A.; Decharuangsilp, S.; et al. Hybrid Inhibitors of Malarial Dihydrofolate Reductase with Dual Binding Modes That Can Forestall Resistance. ACS Med. Chem. Lett. 2018, 9, 1235–1240. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.-K.; Han, Y.; Chen, C.-F. Guest-Dependent Complexation of Triptycene-Derived Macrotricyclic Host Containing One Anthracene Moiety with Paraquat Derivatives: Construction of [2]Rotaxanes. Supramol. Chem. 2015, 27, 357–363. [Google Scholar] [CrossRef]

- ASTM E1899-08; Standard Test Method for Hydroxyl Groups Using Reaction with p-Toluenesulfonyl Isocyanate (TSI) and Potentiometric Titration with Tetrabutylammonium Hydroxide. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D412; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D3574; Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. ASTM International: West Conshohocken, PA, USA, 2017.

- Sacripante, G.G.; Zhou, K.; Farooque, M. Sustainable Polyester Resins Derived from Rosins. Macromolecules 2015, 48, 6876–6881. [Google Scholar] [CrossRef]

- Fowler, R.G. Microscale Reactions of Vanillin. J. Chem. Educ. 1992, 69, 43–45. [Google Scholar] [CrossRef]

- Song, J.; Xie, C.; Xue, Z.; Wang, T. Strong Oxophilicity of Zr Species in Zr4+-Exchanged Montmorillonite Boosted Meerwein-Ponndorf-Verley Reduction of Renewable Carbonyl Compounds. ACS Sustain. Chem. Eng. 2022, 10, 12197–12206. [Google Scholar] [CrossRef]

- Alinejad, M.; Henry, C.; Nikafshar, S.; Gondaliya, A.; Bagheri, S.; Chen, N.; Singh, S.K.; Hodge, D.B.; Nejad, M. Lignin-Based Polyurethanes: Opportunities for Bio-Based Foams, Elastomers, Coatings and Adhesives. Polymers 2019, 11, 1202. [Google Scholar] [CrossRef] [PubMed]

- Hanson, K.G.; Lin, C.H.; Abu-Omar, M.M. Preparation and Properties of Renewable Polyesters Based on Lignin-Derived Bisphenol. Polymers 2021, 233, 124202. [Google Scholar] [CrossRef]

- Robinson, J.J.; Sacripante, G.G.; Vicol, R.L.; Ghalia, M.A.; Wang, Y.; Mullick, S. Polyurethane Elastomer Compositions, and Processes Thereof. U.S. Patent 10,934,384 B1, 2021. [Google Scholar]

- Robinson, J.J.; Ghalia, M.A.; Vicol, R.L.; Sacripante, G.G. Plasticizer Lignin Compositions. U.S. Patent 2022/095182 A1, 23 July 2022. [Google Scholar]

- Omisol, C.J.M.; Aguinid, B.J.M.; Abilay, G.Y.; Asequia, D.M.; Tomon, T.R.; Sabulbero, K.X.; Erjeno, D.J.; Osorio, C.K.; Usop, S.; Malaluan, R.; et al. Flexible Polyurethane Foams Modified with Novel Coconut Monoglycerides-Based Polyester Polyols. ACS Omega 2024, 9, 4497–4512. [Google Scholar] [CrossRef]

- Zieglowski, M.; Trosien, S.; Rohrer, J.; Mehlhase, S.; Weber, S.; Bartels, K.; Siegert, G.; Trellenkamp, T.; Albe, K.; Biesalski, M. Reactivity of Isocyanate-Functionalized Lignins: A Key Factor for the Preparation of Lignin-Based Polyurethanes. Front. Chem. 2019, 7, 562. [Google Scholar] [CrossRef] [PubMed]

- Liszkowska, J.; Moraczewski, K.; Borowicz, M.; Paciorek-Sadowska, J.; Czupryński, B.; Isbrandt, M. The Effect of Accelerated Aging Conditions on the Properties of Rigid Polyurethane-Polyisocyanurate Foams Modified by Cinnamon Extract. Appl. Sci. 2019, 9, 2663. [Google Scholar] [CrossRef]

- Robinson, J.J.; Carafa, R.N.; Li, J.; Sacripante, G.G. Polyurethane Elastomer Composition Comprising Lignin. U.S. Patent 17/958266, 30 September 2022. [Google Scholar]

| Sample | Diol | Diisocyanate | Yield (%) | Tg (°C) | Td (5%) (°C) | Td (50%) (°C) | MW (Da) | Mn (Da) | Ð (MW/Mn) |

|---|---|---|---|---|---|---|---|---|---|

| PU-1M | 1 | MDI | 23 | 128.6 | 235 | 467 | 3186 | 2477 | 1.3 |

| PU-1P | 1 | PDI | 18 | 21.0 | 187 | 346 | 65,500 | 36,700 | 1.8 |

| PU-2M | 2 | MDI | 98 | 163.8 | 205 | 438 | 158,000 | 71,200 | 2.3 |

| PU-2P | 2 | PDI | 40 | −1.7 | 196 | 337 | 48.400 | 32,600 | 1.5 |

| PU-3M | 3 | MDI | 40 | 153.3 | 256 | 386 | 12,460 | 4645 | 2.7 |

| PU-3P | 3 | PDI | 31 | 34.3 | 201 | 332 | 61,000 | 34,700 | 1.8 |

| PU-4M | 4 | MDI | 97 | 183.8 | 167 | 372 | - | - | - |

| PU-4P | 4 | PDI | 63 | 62.2 | 231 | 406 | 10,700 | 3910 | 2.7 |

| PU-5M | 5 | MDI | 95 | 103.8 | 164 | 389 | - | - | - |

| PU-5P | 5 | PDI | 86 | 18.3 | 202 | 367 | - | - | - |

| Sample | Diol | Yield (%) | Tg (°C) | Td (5%) (°C) | Td (50%) (°C) |

|---|---|---|---|---|---|

| PE-1 | 1 | 56 | - | 127 | 311 |

| PE-2 | 2 | 58 | 20.4 | 138 | 329 |

| PE-3 | 3 | 50 | −5.1 | 151 | 364 |

| PE-4 | 4 | 79 | - | 176 | 395 |

| PE-5 | 5 | 70 | 40.4 | 192 | 398 |

| Sample | Viscosity (cps) | AV # (mg KOH/g) | OH # (mg KOH/g) | MW (g/mol) |

|---|---|---|---|---|

| PSA 3000 | 4335 | 0.9 | 39.0 | 2875 |

| PSA 1500 | 940 | 0.5 | 73.7 | 1520 |

| 2–10 | 3547 | 3.2 | 63.0 | 1780 |

| 2–25 | 2332 | 9.2 | 78.3 | 1433 |

| Sample | Cream Time (s) | Rise Time (min:s) | Tack Free Time (min:s) |

|---|---|---|---|

| PU-3000 | 15 | 1:30 | 3:30 |

| PU-1500 | 20 | 1:47 | 2:55 |

| PU-2-10 | 16 | 1:00 | 0:50 |

| PU-2-25 | 15 | 1:30 | 2:50 |

| Sample | 33LV Amount (pphp) | Hardness (Benchtop) | Resiliency (%) (Ball) | Tensile Strength (kg/cm2) | Elongation (%) | Tear | |

|---|---|---|---|---|---|---|---|

| Die-C (N/mm) | Split (N/mm) | ||||||

| PU-3000 | 0.8 | 35 | 33 | 12.1 | 399 | 6.5 | 2.0 |

| PU-1500 | 0.8 | 25 | 22 | 10.3 | 277 | 7.8 | 1.5 |

| PU-2-10 | 0.8 | - | - | 7.5 | 103 | 3.9 | - |

| PU-2-10 | 0.6 | 35 | 13 | 11.9 | 119 | 5.0 | 0.8 |

| PU-2-10 | 0.4 | 35 | 13 | 12.4 | 117 | 4.8 | 0.7 |

| PU-3000 | 0.8 | 35 | 33 | 12.1 | 399 | 6.5 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carafa, R.N.; Fernandes, B.V.; Repiquet, C.; Rana, S.; Foucher, D.A.; Sacripante, G.G. Functionalization of Phenolic Aldehydes for the Preparation of Sustainable Polyesters and Polyurethanes. Polymers 2025, 17, 643. https://doi.org/10.3390/polym17050643

Carafa RN, Fernandes BV, Repiquet C, Rana S, Foucher DA, Sacripante GG. Functionalization of Phenolic Aldehydes for the Preparation of Sustainable Polyesters and Polyurethanes. Polymers. 2025; 17(5):643. https://doi.org/10.3390/polym17050643

Chicago/Turabian StyleCarafa, Rachele N., Brigida V. Fernandes, Clara Repiquet, Sidrah Rana, Daniel A. Foucher, and Guerino G. Sacripante. 2025. "Functionalization of Phenolic Aldehydes for the Preparation of Sustainable Polyesters and Polyurethanes" Polymers 17, no. 5: 643. https://doi.org/10.3390/polym17050643

APA StyleCarafa, R. N., Fernandes, B. V., Repiquet, C., Rana, S., Foucher, D. A., & Sacripante, G. G. (2025). Functionalization of Phenolic Aldehydes for the Preparation of Sustainable Polyesters and Polyurethanes. Polymers, 17(5), 643. https://doi.org/10.3390/polym17050643