Enhancing Polypropylene Biodegradability Through Additive Integration for Sustainable and Reusable Laboratory Applications

Abstract

1. Introduction

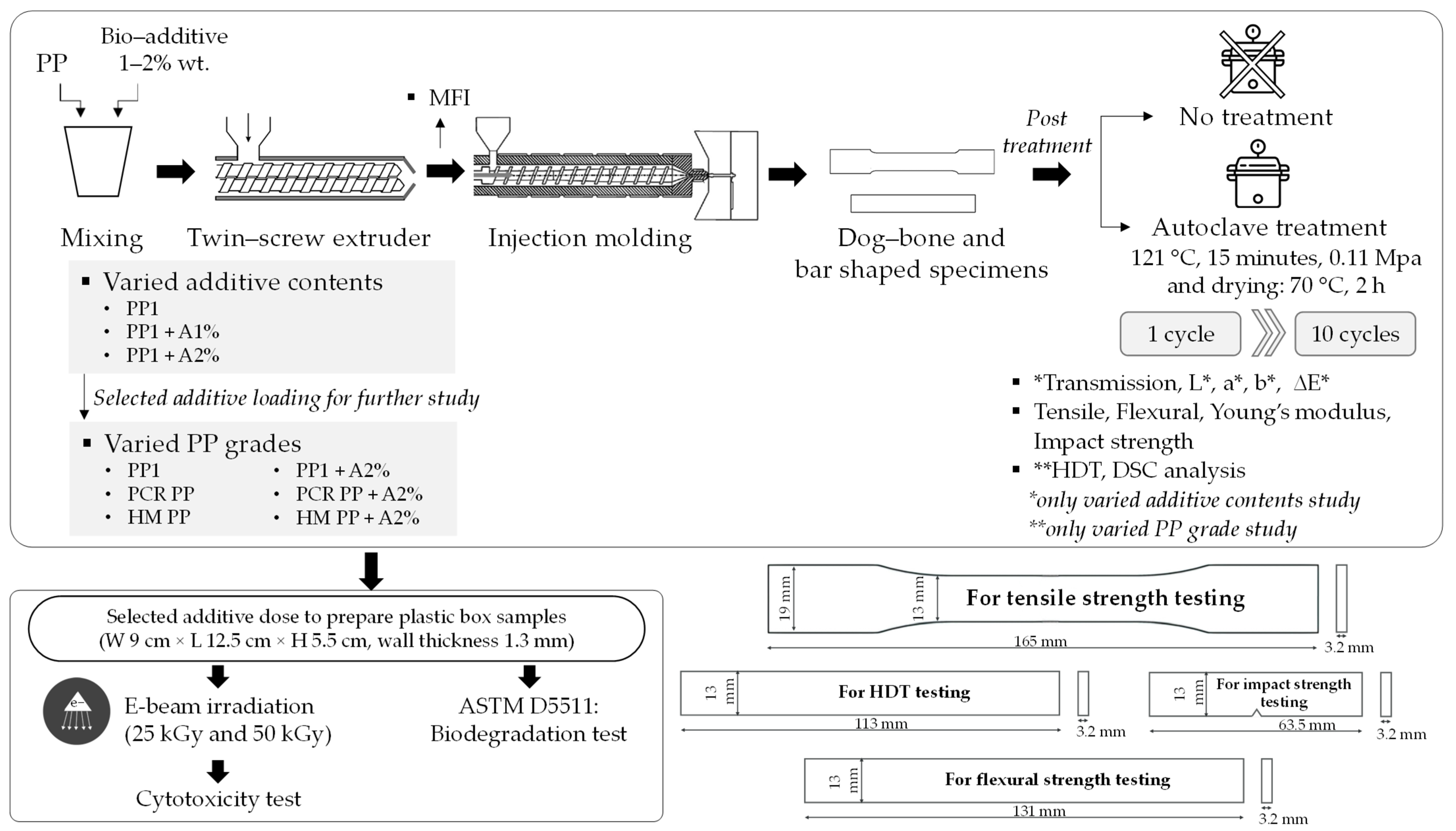

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Autoclave Sterilization Treatment

2.4. Characterization and Mechanical Properties Testing

2.5. E-Beam Irradiation and Cytotoxicity Test

2.6. Biodegradation Test

3. Results and Discussion

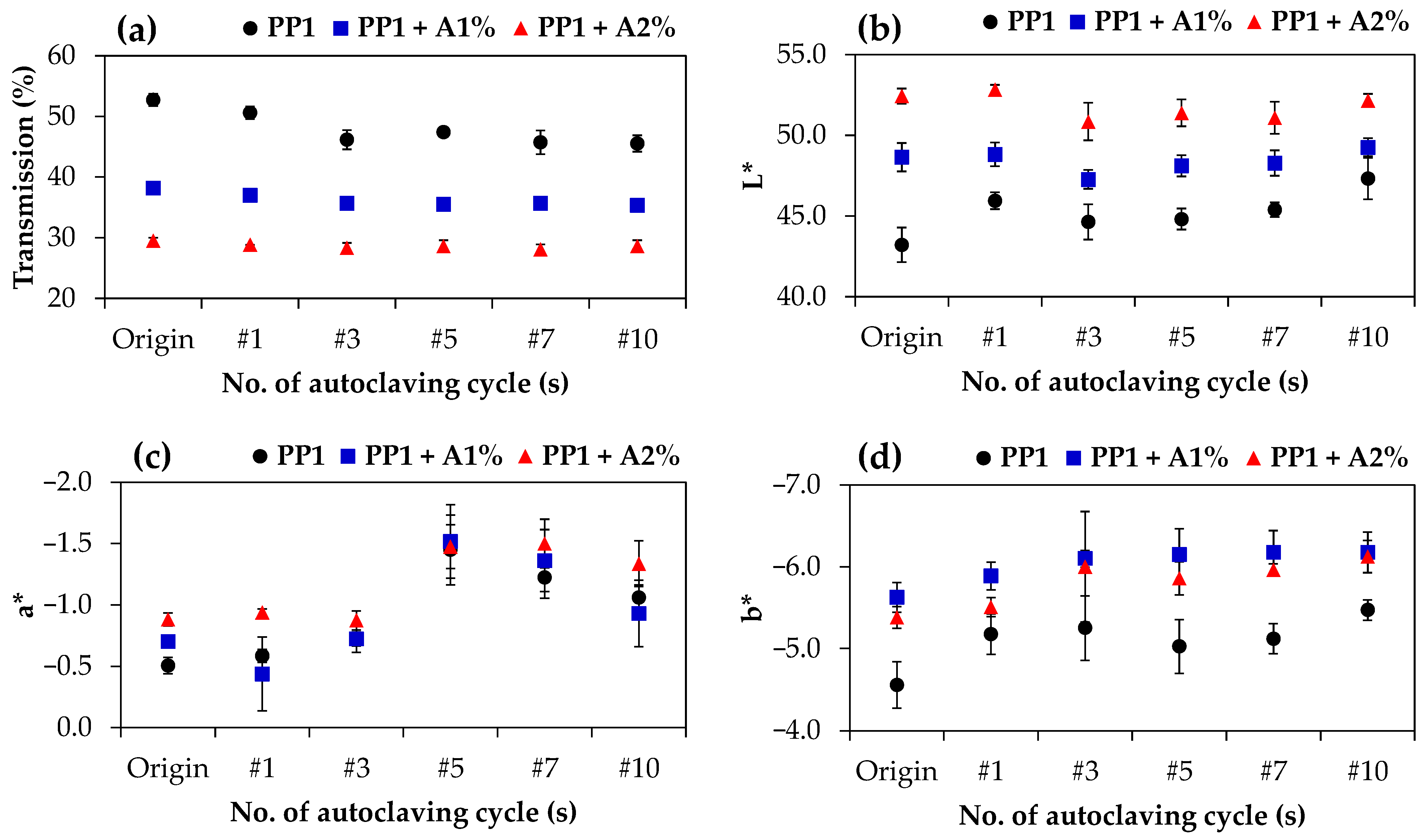

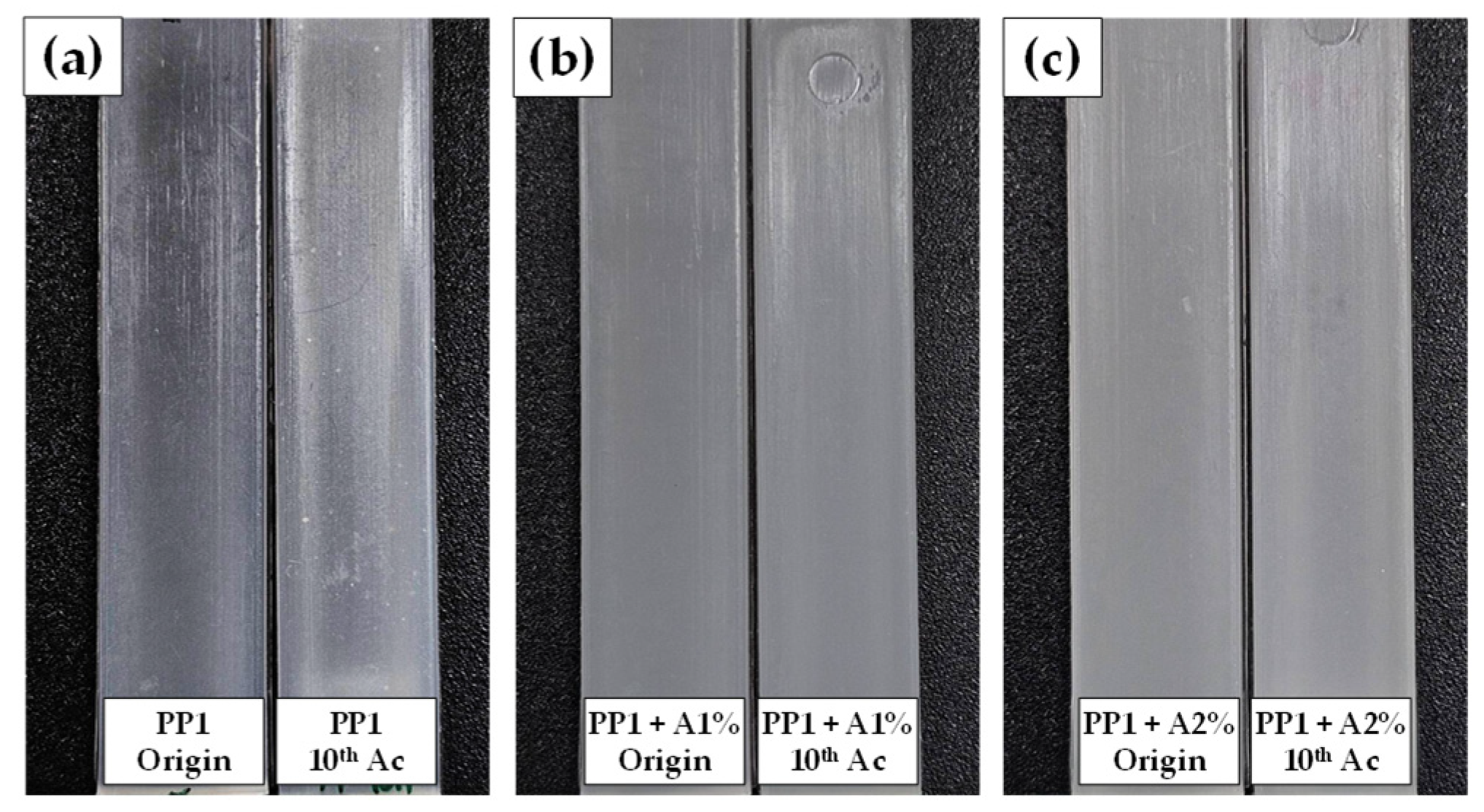

3.1. Effect of Biodegradable Additive Content and Repeated Autoclaving on PP1 Optical Properties

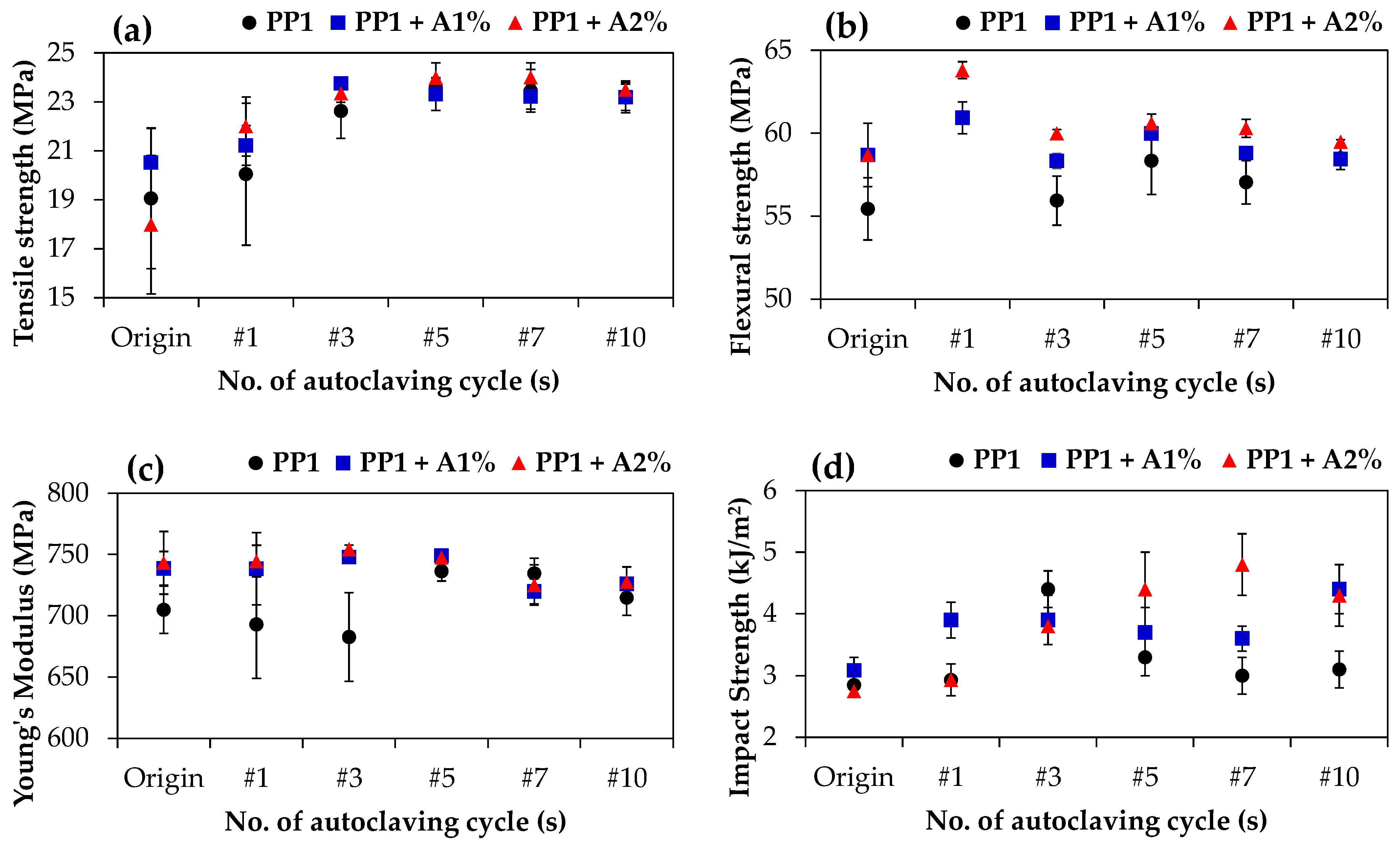

3.2. Effect of Biodegradable Additive Content and Repeated Autoclaving on PP1 Mechanical Properties

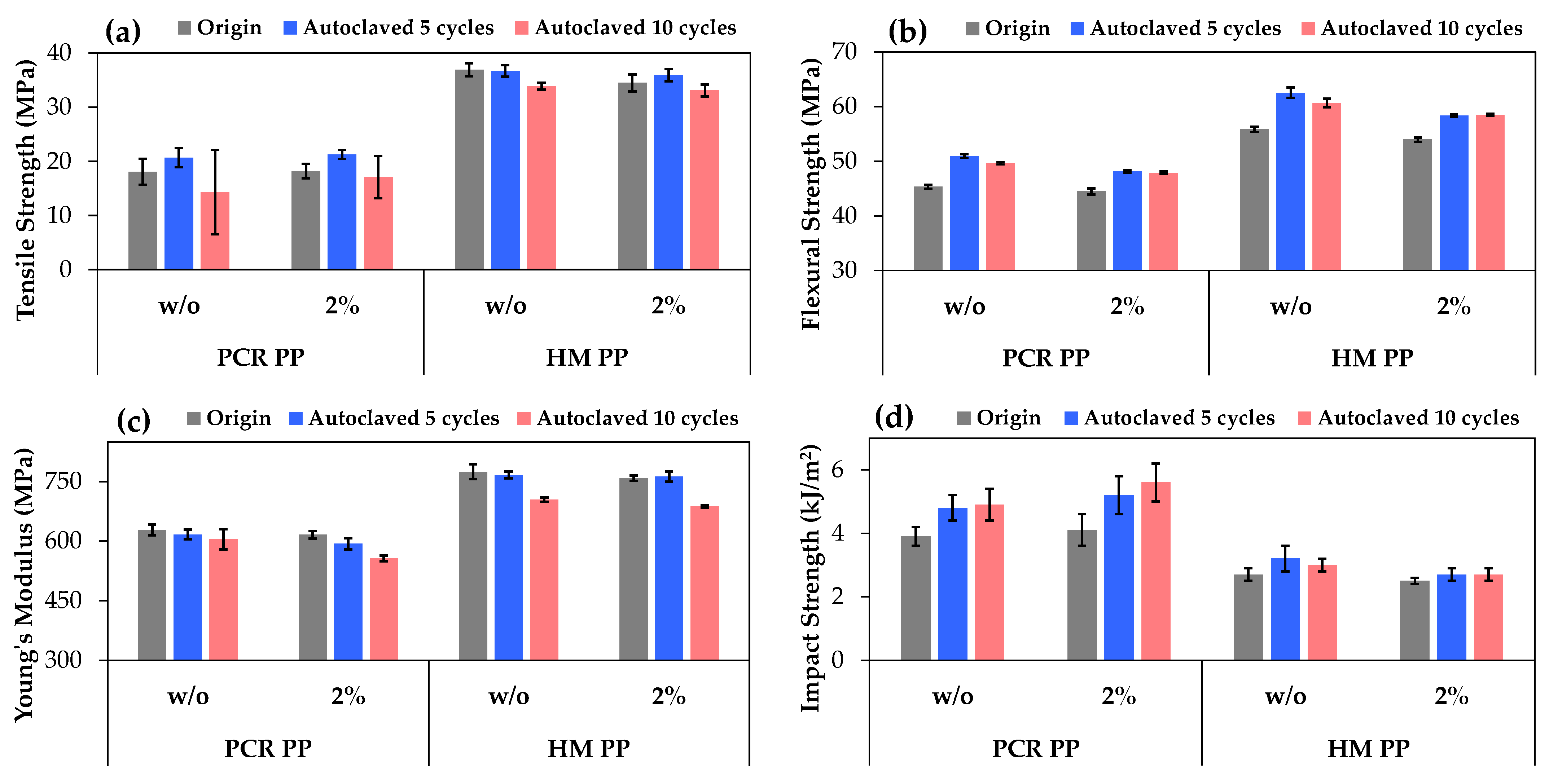

3.3. Effect of Biodegradable Additive and Repeated Autoclaving on Different PP Grades

3.4. Effect of Biodegradable Additive and Repeated Autoclaving on Thermal Properties

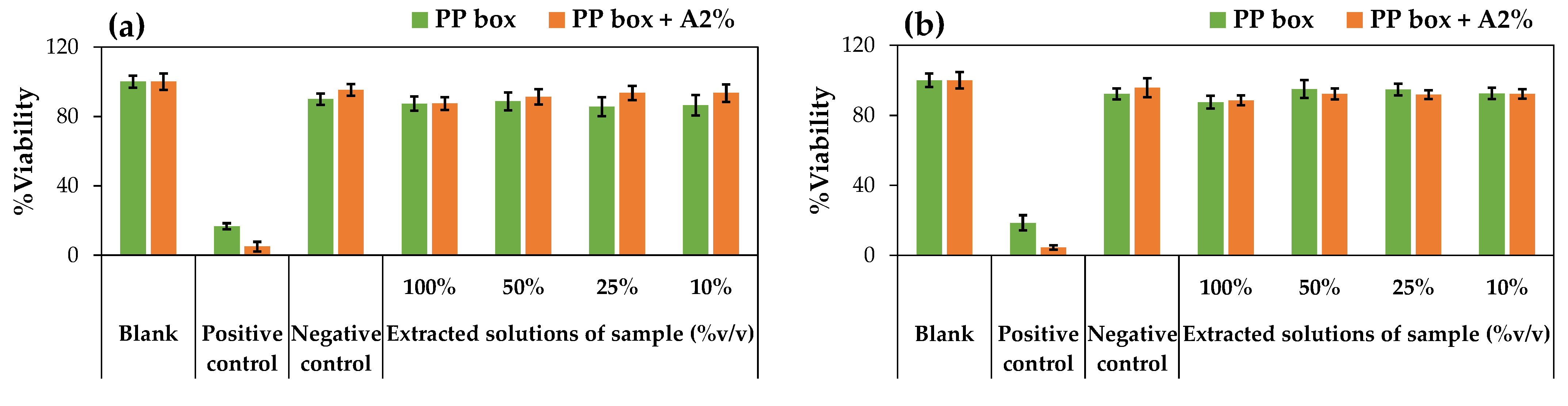

3.5. Cytotoxicity

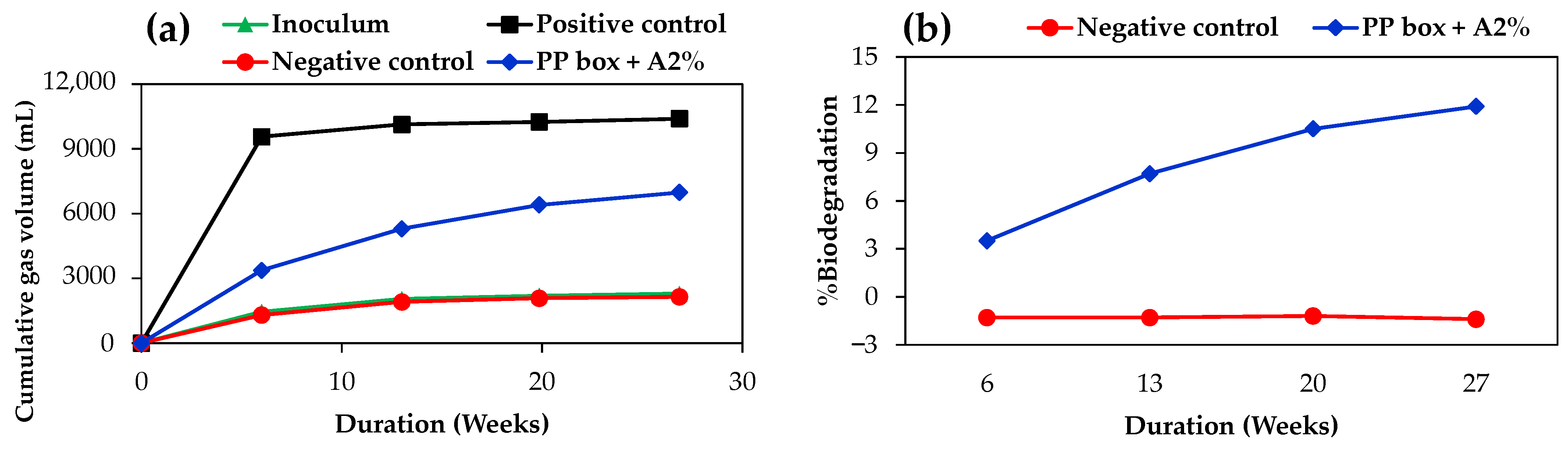

3.6. Biodegradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Freeland, B.; McCarthy, E.; Balakrishnan, R.; Fahy, S.; Boland, A.; Rochfort, K.D.; Dabros, M.; Marti, R.; Kelleher, S.M.; Gaughran, J. A Review of Polylactic Acid as a Replacement Material for Single-Use Laboratory Components. Materials 2022, 15, 2989. [Google Scholar] [CrossRef] [PubMed]

- Sover, A.; Ermster, K.; Riess, A.K.-M.; Martin, A. Recycling of Laboratory Plastic Waste—A Feasibility Study on Cell Culture Flasks. In Proceedings of the 5th International Conference, Business Meets Technology, Valencia, Spain, 13–15 July 2023; Editorial Universitat Politècnica de València: València, Spain, 2023. [Google Scholar]

- ISO 7218:2007; Microbiology of Food and Animal Feeding Stuffs—General Requirements and Guidance for Microbiological Examinations. ISO: Geneva, Switzerland, 2007.

- Kumar, A.; Prajapati, V.D.; Prajapati, B.G.; Pramanik, J.; Paliwal, H.; Kadlag, S.C.; Patel, S.K. 9—PVC/Polycarbonate Blends, IPNs, and Gels. In Poly(Vinyl Chloride)-Based Blends, Interpenetrating Polymer Networks (IPNs), and Gels; Thomas, S., Akhina, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 229–254. ISBN 978-0-323-99474-3. [Google Scholar]

- Murariu, M.; Laoutid, F.; Paint, Y.; Murariu, O.; Raquez, J.-M.; Dubois, P. Balancing the Strength–Impact Relationship and Other Key Properties in Polypropylene Copolymer–Natural CaSO4 (Anhydrite)-Filled Composites. Int. J. Mol. Sci. 2023, 24, 2659. [Google Scholar] [CrossRef] [PubMed]

- Serbetci, K.; Kulacoglu, H.; Devay, A.O.; Hasirci, N. Effects of Resterilization on Mechanical Properties of Polypropylene Meshes. Am. J. Surg. 2007, 194, 375–379. [Google Scholar] [CrossRef] [PubMed]

- Coda, A.; Bendavid, R.; Botto-Micca, F.; Bossotti, M.; Bona, A. Structural Alterations of Prosthetic Meshes in Humans. Hernia 2003, 7, 29–34. [Google Scholar] [CrossRef]

- Fiebig, J.; Gahleitner, M.; Paulik, C.; Wolfschwenger, J. Ageing of Polypropylene: Processes and Consequences. Polym. Test 1999, 18, 257–266. [Google Scholar] [CrossRef]

- O’kane, W.J.; Young, R.J.; Ryan, A.J. The Effect of Annealing on the Structure and Properties of Isotactic Polypropylene Films. J. Macromol. Sci. Part B 1995, 34, 427–458. [Google Scholar] [CrossRef]

- Gahleitner, M.; Fiebig, J.; Wolfschwenger, J.; Dreiling, G.; Paulik, C. Post-Crystallization and Physical Aging of Polypropylene: Material and Processing Effects. J. Macromol. Sci. Part B 2002, 41, 833–849. [Google Scholar] [CrossRef]

- Gahleitner, M.; Wolfschwenger, J.; Fiebig, J.; Dobianer, K.; Hametner, C. Sterilization Effects on Polypropylene: Technology and Polymer Type Effects. In Proceedings of the 9th EUROPLACE Conference, Brussels, Belgium, 9 April 2003; Volume 25. [Google Scholar]

- Bobori, D.C.; Feidantsis, K.; Dimitriadi, A.; Datsi, N.; Ripis, P.; Kalogiannis, S.; Sampsonidis, I.; Kastrinaki, G.; Ainali, N.M.; Lambropoulou, D.A.; et al. Dose-Dependent Cytotoxicity of Polypropylene Microplastics (PP-MPs) in Two Freshwater Fishes. Int. J. Mol. Sci. 2022, 23, 3878. [Google Scholar] [CrossRef]

- ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity. International Organization for Standardization: Geneva, Switzerland, 2009; Volume 34.

- Rafiq, A.; Xu, J.-L. Microplastics in Waste Management Systems: A Review of Analytical Methods, Challenges and Prospects. Waste Manag. 2023, 171, 54–70. [Google Scholar] [CrossRef]

- Sin, L.T.; Rahman, A.R.; Rahman, W.A.W.A. Polylactic Acid: PLA Biopolymer Technology and Applications, 1st ed.; Elsevier Science: Oxford, UK, 2012; ISBN 9781437744590. [Google Scholar]

- ASTM D883; Standard Terminology Relating to Plastics. ASTM International: West Conshohocken, PA, USA, 2012.

- Siracusa, V. Microbial Degradation of Synthetic Biopolymers Waste. Polymers 2019, 11, 1066. [Google Scholar] [CrossRef]

- Kelesoglu, N. The First PLA Plastic Plates Offered for Tissue Culture. Available online: https://www.labconscious.com/blog/the-first-pla-plastic-tissue-culture-plates (accessed on 20 August 2024).

- ASTM D6400-21; Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D5511-18; Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions. ASTM International: West Conshohocken, PA, USA, 2018.

- Greene, J. Biodegradation of Compostable Plastics in Green Yard-Waste Compost Environment. J. Polym. Environ. 2007, 15, 269–273. [Google Scholar] [CrossRef]

- Itävaara, M.; Karjomaa, S.; Selin, J.-F. Biodegradation of Polylactide in Aerobic and Anaerobic Thermophilic Conditions. Chemosphere 2002, 46, 879–885. [Google Scholar] [CrossRef] [PubMed]

- Nghiem, L.D.; Iqbal, H.M.N.; Zdarta, J. The Shadow Pandemic of Single Use Personal Protective Equipment Plastic Waste: A Blue Print for Suppression and Eradication. Case Stud. Chem. Environ. Eng. 2021, 4, 100125. [Google Scholar] [CrossRef] [PubMed]

- Wiesinger, H.; Klotz, M.; Wang, Z.; Zhao, Y.; Haupt, M.; Hellweg, S. The Identity of Oxo-Degradable Plastics and Their Use in Switzerland; Federal Office for the Environment (FOEN): Zurich, Switzerland, 2020. [Google Scholar]

- Devalla, S. Review of Evidence on Oxo-Biodegradable Plastic Products; James Hutton Institute: Aberdeen, UK, 2022. [Google Scholar]

- BioSphere Plastic, LLC. How BioSphere Works. Available online: https://biosphereplastic.com/how-biosphere-works (accessed on 20 September 2024).

- Zafiu, C.; Binner, E.; Höck, L.; Świechowski, K.; Huber-Humer, M. Study on the Degradability of Plastics with Prodegradant Additives during Anaerobic and Aerobic Biological Waste Treatment Processes. J. Mater. Cycles Waste Manag. 2023, 25, 3545–3556. [Google Scholar] [CrossRef]

- Mubarak, Y.A. Effects of Biodegradable Polypropylene Additive on the Impact Strength and Spherulites Growth Rate of Isotactic Polypropylene. Int. J. Mech. Eng. Technol. 2018, 9, 109–121. [Google Scholar]

- Mubarak, Y.A. Thermal and Mechanical Properties of Biodegradable Isotactic Polypropylene. J. Thermoplast. Compos. Mater. 2022, 35, 2371–2394. [Google Scholar] [CrossRef]

- BioSphere Plastic, LLC. BioSphere Reveals Novel Additive Formulation to Speed up Biodegradation in Polymers. Addit. Polym. 2012, 2012, 2–3. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D256-24; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2025.

- ASTM D648-18; Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position. ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2022; Edition 2.

- Schmeling, M.; Sartori, N.; Monteiro, S., Jr.; Baratieri, L. Color Stability of Shade Guides after Autoclave Sterilization. Int. J. Periodontics Restor. Dent. 2014, 34, 689–693. [Google Scholar] [CrossRef]

- Pande, N.; Kulkarni, S.; Jaiswal, P.; Chahande, J. Comparative Evaluation of the Effect of Three Medications on the Color Stability of Two Commercially Available Acrylic Resin Denture Teeth after Thermocycling—An in Vitro Study. Indian J. Multidiscip. Dent. 2019, 9, 9–17. [Google Scholar] [CrossRef]

- Nimeroff, I. Colorimetry; National Bureau of Standards: Washington, DC, USA, 1968; Volume 104, pp. 1–47. [Google Scholar]

- Liu, J.; Li, Y. Annealing-Induced High Impact Toughness of Isotactic Polypropylene Realized by Introducing Ultra-High Molecular Weight Polyethylene. Polym. Bull. 2024. [Google Scholar] [CrossRef]

- Junaedi, H.; Baig, M.; Dawood, A.; Albahkali, E.; Almajid, A. Effect of the Matrix Melt Flow Index and Fillers on Mechanical Properties of Polypropylene-Based Composites. Materials 2022, 15, 7568. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Cutts, W.D.; Ning, H.; Pillay, S.; Liu, S. Effects of Chemical and Autoclave Sterilization Treatments on Medical Personal Protective Equipment Made of Nonwoven Polypropylene Fibers for Recycling. J. Polym. Res. 2022, 29, 360. [Google Scholar] [CrossRef]

- Yadav, Y.S.; Jain, P.C. Melting Behaviour of Isotactic Polypropylene Isothermally Crystallized from the Melt. Polymers 1986, 27, 721–727. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation Behavior of Polypropylene during Reprocessing and Its Biocomposites: Thermal and Oxidative Degradation Kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef]

- Han, L.; Li, X.; Li, Y.; Huang, T.; Wang, Y.; Wu, J.; Xiang, F. Influence of Annealing on Microstructure and Physical Properties of Isotactic Polypropylene/Calcium Carbonate Composites with β-Phase Nucleating Agent. Mater. Sci. Eng. A 2010, 527, 3176–3185. [Google Scholar] [CrossRef]

- Biosphere Safety Data Sheet. Available online: https://www.sbsasiagroup.com/files/Sbs/Product/MSDS-BioSphere-Pellet-Additive.pdf (accessed on 14 February 2025).

| Sample | ΔE* After Autoclave Treatment(s) | ||||

|---|---|---|---|---|---|

| 1 Cycle | 3 Cycles | 5 Cycles | 7 Cycles | 10 Cycles | |

| PP1 | 2.8 | 1.6 | 1.9 | 2.4 | 4.2 |

| PP1 + A1% | 0.4 | 1.5 | 1.1 | 0.9 | 0.9 |

| PP1 + A2% | 0.4 | 1.7 | 1.3 | 1.6 | 0.9 |

| MFI (g/10 min) | Without Additive | With 2% by Weight of Additive |

|---|---|---|

| PP1 | 10.36 ± 0.07 | 11.23 ± 0.05 |

| PCR PP | 6.49 ± 0.03 | 6.54 ± 0.03 |

| HM PP | 56.49 ± 0.43 | 62.80 ± 0.66 |

| Sample | HDT (°C) | Tm (°C) | Tc (°C) | % Crystallinity | |||||

|---|---|---|---|---|---|---|---|---|---|

| PP | PP + A2% | PP | PP + A2% | PP | PP + A2% | PP | PP + A2% | ||

| PP1 | Origin | 101 | 103 | 165.8 | 166.7 | 120.8 | 120.5 | 50.6 | 50.8 |

| Autoclaved 5 cycles | 122 | 125 | 166.9 | 165.7 | 120.0 | 120.4 | 47.8 | 48.2 | |

| Autoclaved 10 cycles | 127 | 125 | 166.4 | 167.0 | 120.2 | 120.6 | 49.2 | 48.8 | |

| PCR PP | Origin | 104 | 99 | 162.0 | 161.5 | 124.7 | 122.8 | 41.2 | 42.2 |

| Autoclaved 5 cycles | 119 | 118 | 162.2 | 162.6 | 124.2 | 122.0 | 44.2 | 40.0 | |

| Autoclaved 10 cycles | 119 | 122 | 161.6 | 161.8 | 124.2 | 122.2 | 43.1 | 40.6 | |

| HM PP | Origin | 120 | 117 | 159.3 | 158.8 | 129.8 | 128.2 | 47.4 | 46.9 |

| Autoclaved 5 cycles | 129 | 127 | 159.3 | 158.8 | 129.3 | 127.4 | 47.0 | 45.1 | |

| Autoclaved 10 cycles | 130 | 127 | 159.1 | 157.2 | 129.1 | 120.3 | 45.1 | 44.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samneingjam, K.; Mahajaroensiri, J.; Kanathananun, M.; Aranda, C.V.; Muñoz, M.; Limwongsaree, S. Enhancing Polypropylene Biodegradability Through Additive Integration for Sustainable and Reusable Laboratory Applications. Polymers 2025, 17, 639. https://doi.org/10.3390/polym17050639

Samneingjam K, Mahajaroensiri J, Kanathananun M, Aranda CV, Muñoz M, Limwongsaree S. Enhancing Polypropylene Biodegradability Through Additive Integration for Sustainable and Reusable Laboratory Applications. Polymers. 2025; 17(5):639. https://doi.org/10.3390/polym17050639

Chicago/Turabian StyleSamneingjam, Kanittika, Juthamas Mahajaroensiri, Maysinee Kanathananun, Cristina Velasco Aranda, Mario Muñoz, and Somchoke Limwongsaree. 2025. "Enhancing Polypropylene Biodegradability Through Additive Integration for Sustainable and Reusable Laboratory Applications" Polymers 17, no. 5: 639. https://doi.org/10.3390/polym17050639

APA StyleSamneingjam, K., Mahajaroensiri, J., Kanathananun, M., Aranda, C. V., Muñoz, M., & Limwongsaree, S. (2025). Enhancing Polypropylene Biodegradability Through Additive Integration for Sustainable and Reusable Laboratory Applications. Polymers, 17(5), 639. https://doi.org/10.3390/polym17050639