Enhanced Electrothermal Properties of Core–Sheath Lignin-Derived Carbon Nanotube Yarns with UHMWPE Insulation

Abstract

1. Introduction

2. Experimental Section

2.1. Preparation of CP Yarn and Fabric

2.2. Characterizations and Mechanical Testing

2.3. Determination of Electrothermal Properties

2.4. Durability Testing

3. Results and Discussion

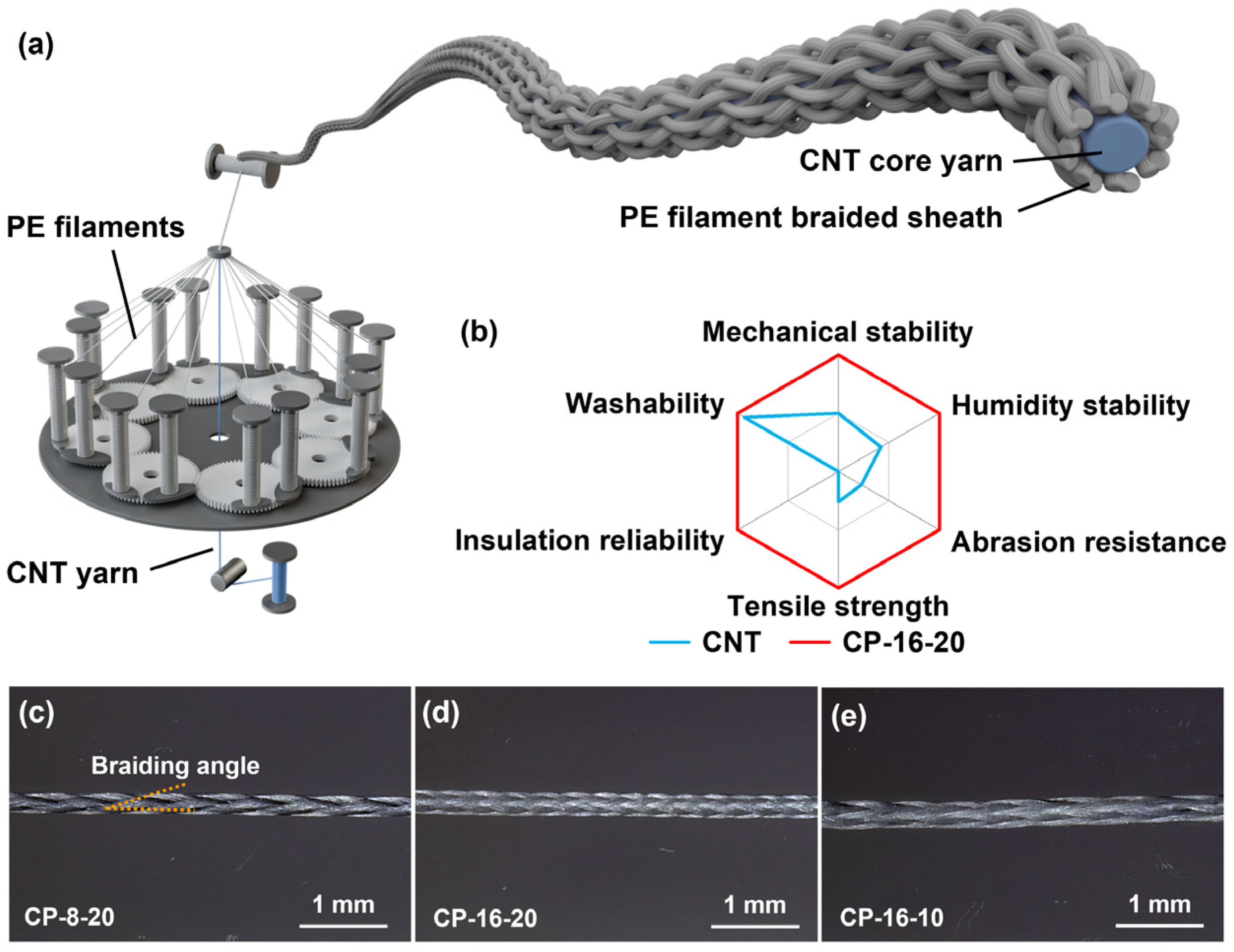

3.1. Material Structures and Morphology

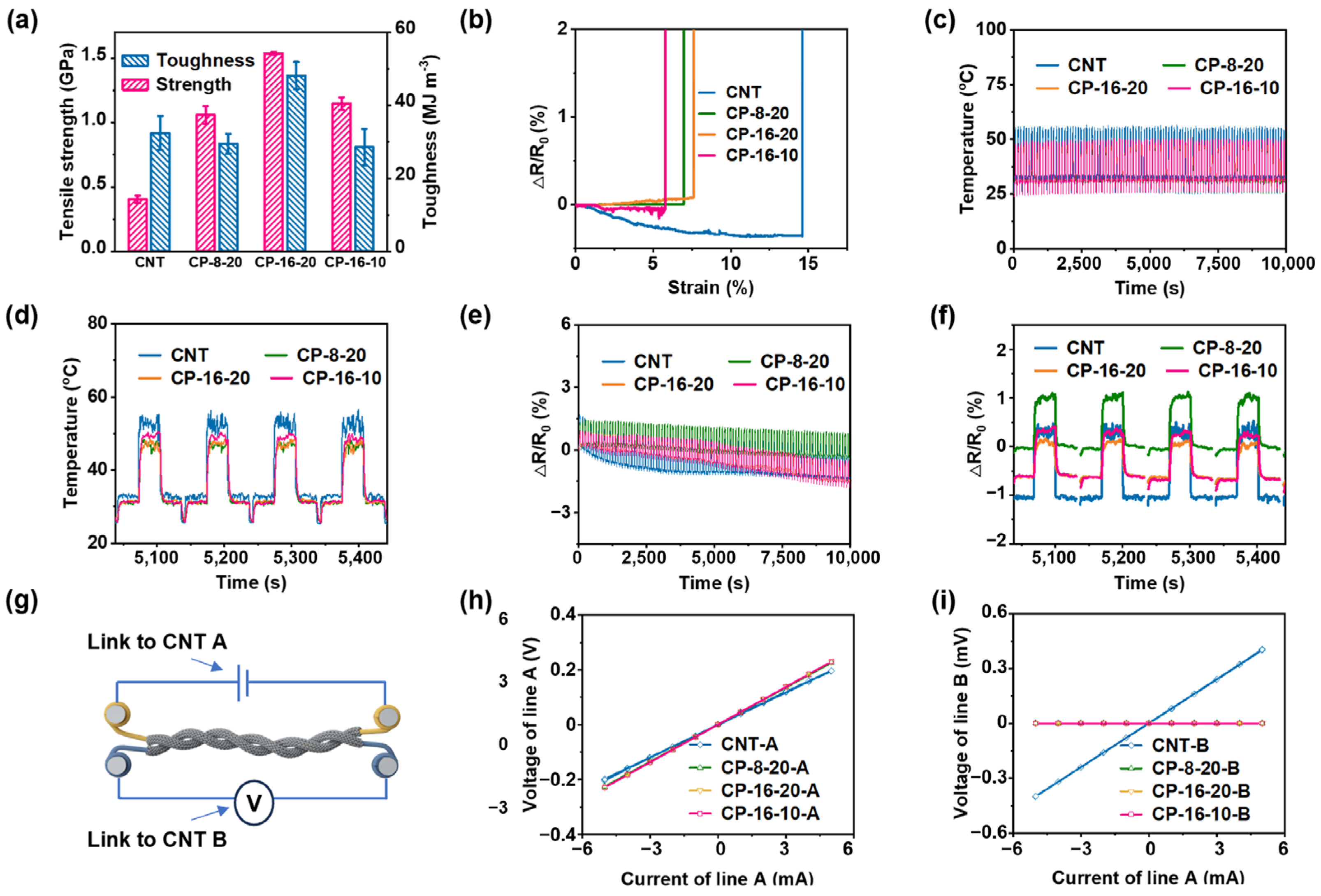

3.2. Mechanical, Electrical, and Electrothermal Behavior of CP Yarns

3.3. Flexibility and Durability of CP Yarns

3.4. Abrasion and Wash Resistance of CP Yarns

3.5. Application Performance of CP Yarns

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, J.; Llerena Zambrano, B.; Woo, J.; Yoon, K.; Lee, T. Recent advances in 1D stretchable electrodes and devices for textile and wearable electronics: Materials, fabrications, and applications. Adv. Mater. 2020, 32, 1902532. [Google Scholar] [CrossRef]

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; Van Langenhove, L. Integration of conductive materials with textile structures, an overview. Sensors 2020, 20, 6910. [Google Scholar] [CrossRef]

- Duan, L.Y.; D’hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Jia, J.; Pu, J.H.; Liu, J.H.; Zhao, X.; Ke, K.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Surface structure engineering for a bionic fiber-based sensor toward linear, tunable, and multifunctional sensing. Mater. Horiz. 2020, 7, 2450–2459. [Google Scholar] [CrossRef]

- Son, W.; Lee, J.M.; Kim, S.H.; Kim, H.W.; Cho, S.B.; Suh, D.; Chun, S.; Choi, C. High-power hydro-actuators fabricated from biomimetic carbon nanotube coiled yarns with fast electrothermal recovery. Nano Lett. 2022, 22, 2470–2478. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xia, K.; Wang, H.; Liang, X.; Yin, Z.; Zhang, Y. Advanced carbon for flexible and wearable electronics. Adv. Mater. 2019, 31, 1801072. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, K.R.; Fan, H.W.; Hou, C.Y.; Li, Y.G.; Zhang, Q.H.; Wang, H.Z. Reduced graphene oxide functionalized stretchable and multicolor electrothermal chromatic fibers. J. Mater. Chem. C 2017, 5, 11448–11453. [Google Scholar] [CrossRef]

- Luo, J.C.; Gao, S.J.; Luo, H.; Wang, L.; Huang, X.W.; Guo, Z.; Lai, X.J.; Lin, L.W.; Li, R.K.Y.; Gao, J.F. Superhydrophobic and breathable smart MXene-based textile for multifunctional wearable sensing electronics. Chem. Eng. J. 2021, 406, 126898. [Google Scholar] [CrossRef]

- Pu, J.H.; Zhao, X.; Zha, X.J.; Bai, L.; Ke, K.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. Multilayer structured AgNW/WPU-MXene fiber strain sensors with ultrahigh sensitivity and a wide operating range for wearable monitoring and healthcare. J. Mater. Chem. A 2019, 7, 15913–15923. [Google Scholar] [CrossRef]

- Eom, J.; Jaisutti, R.; Lee, H.; Lee, W.; Heo, J.S.; Lee, J.Y.; Park, S.K.; Kim, Y.H. Highly sensitive textile strain sensors and wireless user-interface devices using all-polymeric conducting fibers. ACS Appl. Mater. Interfaces 2017, 9, 10190–10197. [Google Scholar] [CrossRef]

- Pu, J.H.; Zha, X.J.; Zhao, M.; Li, S.; Bao, R.Y.; Liu, Z.Y.; Xie, B.H.; Yang, M.B.; Guo, Z.; Yang, W. 2D end-to-end carbon nanotube conductive networks in polymer nanocomposites: A conceptual design to dramatically enhance the sensitivities of strain sensors. Nanoscale 2018, 10, 2191–2198. [Google Scholar] [CrossRef]

- Falco, A.; Loghin, F.C.; Becherer, M.; Lugli, P.; Salmeron, J.F.; Rivadeneyra, A. Low-cost gas sensing: Dynamic self-compensation of humidity in CNT-based devices. ACS Sens. 2019, 4, 3141–3146. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Liu, Y.; Fang, Z.; Kuang, Y.; Zhang, Y.; Peng, C.; Chen, G. Flexible and highly sensitive humidity sensor based on cellulose nanofibers and carbon nanotube composite film. Langmuir 2019, 35, 4834–4842. [Google Scholar] [CrossRef] [PubMed]

- Tajin, A.S.; Levitt, A.S.; Liu, Y.; Amanatides, C.E.; Schauer, C.L.; Dion, G.; Dandekar, K.R. On the effect of sweat on sheet resistance of knitted conductive yarns in wearable antenna design. IEEE AWPL 2020, 19, 542–546. [Google Scholar] [CrossRef] [PubMed]

- Walker, J.M.; Akbar, S.A.; Morris, P.A. Synergistic effects in gas sensing semiconducting oxide nano-heterostructures: A review. Sens. Actuators B 2019, 286, 624–640. [Google Scholar] [CrossRef]

- Hossain, M.M.; Lubna, M.M.; Bradford, P.D. Multifunctional and washable carbon nanotube-wrapped textile yarns for wearable e-textiles. ACS Appl. Mater. Interfaces 2023, 15, 3365–3376. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Xu, F.J.; Liu, W.; Gao, Y.; Zhang, K.; Zhang, X.H.; Qiu, Y.P. Flexible strain sensor based on aerogel-spun carbon nanotube yarn with a core-sheath structure. Compos. Part A 2018, 108, 107–113. [Google Scholar] [CrossRef]

- Yang, S.; Liu, S.; Ding, X.J.; Zhu, B.; Shi, J.D.; Yang, B.; Liu, S.R.; Chen, W.; Tao, X.M. Permeable and washable electronics based on polyamide fibrous membrane for wearable applications. Compos. Sci. Technol. 2021, 207, 108729. [Google Scholar] [CrossRef]

- Pan, J.J.; Hao, B.W.; Xu, P.J.; Li, D.Q.; Luo, L.; Li, J.Q.; Xia, Z.G.; Cheng, D.S.; Xu, A.C.; Cai, G.M.; et al. Highly robust and durable core-sheath nanocomposite yarns for electro-thermochromic performance application. Chem. Eng. J. 2020, 384, 123376. [Google Scholar] [CrossRef]

- Yin, Z.; Jian, M.; Wang, C.; Xia, K.; Liu, Z.; Wang, Q.; Zhang, M.; Wang, H.; Liang, X.; Liang, X.; et al. Splash-resistant and light-weight silk-sheathed wires for textile electronics. Nano Lett. 2018, 18, 7085–7091. [Google Scholar] [CrossRef]

- Cai, G.; Yang, M.; Pan, J.; Cheng, D.; Xia, Z.; Wang, X.; Tang, B. Large-scale production of highly stretchable CNT/cotton/spandex composite yarn for wearable applications. ACS Appl. Mater. Interfaces 2018, 10, 32726–32735. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; An, J.; Wang, A.C.; Luo, J.; Sun, B.; Wang, J.; Wang, Z.L. Shape adaptable and highly resilient 3D braided triboelectric nanogenerators as e-textiles for power and sensing. Nat. Commun. 2020, 11, 2868. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Li, Z.; Xu, B.; Li, M.; Jiang, C.; Guan, X.; Yang, Y. Scalable core–spun coating yarn-based triboelectric nanogenerators with hierarchical structure for wearable energy harvesting and sensing via continuous manufacturing. Nano Energy 2022, 91, 106672. [Google Scholar] [CrossRef]

- Sofronova, D.; Angelova, R.A.; Sofronov, Y. Design and development of an e-textile mat for assuring the comfort of bedridden persons. Materials 2021, 14, 5437. [Google Scholar] [CrossRef]

- Li, Y.F.; Liu, H.; Li, X.J. Thermal-electrical properties and resistance stability of silver coated yarns. Adv. Mater. Mach. Electron. I 2017, 1820, 020009. [Google Scholar] [CrossRef]

- Dai, H.M.; Gao, J.L.; Jia, C.; Liu, F.Y.; Zhai, G.X.; Wang, X.F.; Xiang, H.X.; Zhu, M.F. High-performance electrothermal fabrics enabled by lignin-derived carbon nanotube yarns. Chem. Eng. J. 2024, 482, 149157. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Highly elastic and transparent multiwalled carbon nanotube/polydimethylsiloxane bilayer films as electric heating materials. Mater. Des. 2015, 86, 72–79. [Google Scholar] [CrossRef]

- Singh, N.; Sheikh, J. Multifunctional linen fabric obtained through finishing with chitosan-gelatin microcapsules loaded with cinnamon oil. J. Nat. Fibers 2022, 19, 4780–4790. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, X.; Qu, L.; Miao, J. Smart fibers and textiles for personal thermal management in emerging wearable applications. Adv. Mater. Technol. 2023, 8, 2201137. [Google Scholar] [CrossRef]

- Kyosev, Y. Braiding Technology for Textiles: Principles, Design and Processes; Elsevier: Cambridge, UK, 2014. [Google Scholar]

- Gholami, A.; Melenka, G.W. Studying the geometrical models of tubular braided composite using micro computed tomography and particle swarm optimization. Compos. Part. B-Eng. 2023, 260, 110758. [Google Scholar] [CrossRef]

- Zhai, J.; Zeng, T.; Xu, G.D.; Wang, Z.H.; Cheng, S.; Fang, D.N. A multi-scale finite element method for failure analysis of three-dimensional braided composite structures. Compos. Part B 2017, 110, 476–486. [Google Scholar] [CrossRef]

- Liu, Y.T.; Hou, Y.L.; Sapanathan, T.; Nie, R.J.; Meng, L.; Xu, Y.J. A multiscale strategy for exploring the mechanical behavior of 3D braided composite thin-walled cylinders. Thin Wall Struct. 2024, 198, 111705. [Google Scholar] [CrossRef]

- Wei, X.; Wang, J.; Ma, H.; Farha, F.I.; Bi, S.; Zhang, Q.; Xu, F. Super-strong CNT composite yarn with tight CNT packing via a compress-stretch process. Nanoscale 2022, 14, 9078–9085. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.D.; Ma, Q.Q.; Liang, T.; Yao, Y.M.; Li, J.H.; Zeng, X.L.; Xu, J.B.; Sun, R. A facile strategy to densify aligned CNT films with significantly enhanced thermal conductivity and mechanical strength. Adv. Mater. Technol. 2022, 7, 9. [Google Scholar] [CrossRef]

- Zhan, H.; Chen, Y.W.; Shi, Q.Q.; Zhang, Y.; Mo, R.W.; Wang, J.N. Highly aligned and densified carbon nanotube films with superior thermal conductivity and mechanical strength. Carbon 2022, 186, 205–214. [Google Scholar] [CrossRef]

- Tran, T.Q.; Fan, Z.; Liu, P.; Myint, S.M.; Duong, H.M. Super-strong and highly conductive carbon nanotube ribbons from post-treatment methods. Carbon 2016, 99, 407–415. [Google Scholar] [CrossRef]

- Liu, P.; Hu, D.C.M.; Tran, T.Q.; Jewell, D.; Duong, H.M. Electrical property enhancement of carbon nanotube fibers from post treatments. Colloid. Surface A 2016, 509, 384–389. [Google Scholar] [CrossRef]

- Dini, Y.; Rouchon, D.; Faure-Vincent, J.; Dijon, J. Large improvement of CNT yarn electrical conductivity by varying chemical doping and annealing treatment. Carbon 2020, 156, 38–48. [Google Scholar] [CrossRef]

- Taylor, L.W.; Dewey, O.S.; Headrick, R.J.; Komatsu, N.; Peraca, N.M.; Wehmeyer, G.; Kono, J.; Pasquali, M. Improved properties, increased production, and the path to broad adoption of carbon nanotube fibers. Carbon 2021, 171, 689–694. [Google Scholar] [CrossRef]

- Gao, E.L.; Lu, W.B.; Xu, Z.P. Strength loss of carbon nanotube fibers explained in a three-level hierarchical model. Carbon 2018, 138, 134–142. [Google Scholar] [CrossRef]

- Jung, Y.; Cho, Y.S.; Lee, J.W.; Oh, J.Y.; Park, C.R. How can we make carbon nanotube yarn stronger? Compos. Sci. Technol. 2018, 166, 95–108. [Google Scholar] [CrossRef]

- Wang, J.N.; Luo, X.G.; Wu, T.; Chen, Y. High-strength carbon nanotube fibre-like ribbon with high ductility and high electrical conductivity. Nat. Commun. 2014, 5, 3848. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, H.; Jia, C.; Hu, Z.; Yu, S.; Xiang, H.; Wang, X.; Zhu, M. Enhanced Electrothermal Properties of Core–Sheath Lignin-Derived Carbon Nanotube Yarns with UHMWPE Insulation. Polymers 2025, 17, 537. https://doi.org/10.3390/polym17040537

Dai H, Jia C, Hu Z, Yu S, Xiang H, Wang X, Zhu M. Enhanced Electrothermal Properties of Core–Sheath Lignin-Derived Carbon Nanotube Yarns with UHMWPE Insulation. Polymers. 2025; 17(4):537. https://doi.org/10.3390/polym17040537

Chicago/Turabian StyleDai, Hongmei, Chao Jia, Zexu Hu, Senlong Yu, Hengxue Xiang, Xuefen Wang, and Meifang Zhu. 2025. "Enhanced Electrothermal Properties of Core–Sheath Lignin-Derived Carbon Nanotube Yarns with UHMWPE Insulation" Polymers 17, no. 4: 537. https://doi.org/10.3390/polym17040537

APA StyleDai, H., Jia, C., Hu, Z., Yu, S., Xiang, H., Wang, X., & Zhu, M. (2025). Enhanced Electrothermal Properties of Core–Sheath Lignin-Derived Carbon Nanotube Yarns with UHMWPE Insulation. Polymers, 17(4), 537. https://doi.org/10.3390/polym17040537