Abstract

This paper presents the potential for an alternative use of structural polymer composite reinforcement, made from natural industrial hemp (Cannabis sativa L.) fibres, in the manufacture of selected products in the shipbuilding industry. This research used fabrics made from unmodified and chemically modified industrial hemp fibres. The primary research focus was on determining the impact strength of the new eco-friendly structural composites produced after long-term storage in representative aqueous environments. Also presented are the results of fire response tests of these composites in the context of their disposal by energy recycling. The tests carried out also referred to a well-defined glass fibre-reinforced polymer composite, from which a control slab of the actual product was realistically produced in the form of a representative section of a 34-foot boat hull plate below the waterline. The results of this basic research into these structural composites confirmed the validity of continuing, respectively, application and implementation research, aimed at producing composites dedicated to selected products of the shipbuilding industry.

1. Introduction

Over the past 30 years, there has been significant interest in various industries, for economic and environmental reasons, in the potential use of natural plant fibres (NPFs) in polymer composite materials because of their environmentally friendly impact and global economic sustainability. A significant increase in environmental risk has been observed on our planet, resulting, inter alia, from a faster-than-expected massive increase in waste post-production waste of non-biodegradable plastics used in the chemical and automotive (mainly automotive) industries, as well as hard-to-recycle, end-of-life (EOL), large-scale engineering products (wind turbine blades, recreational vessels and many others), manufactured in dedicated specialised applications from polymer composites [1,2].

The increasing environmental threat has led to research on using NPF as an alternative to synthetic glass fibres (GFs) in polymer composites. Due to the availability of common NPFs in almost all geographical regions of the world and the relative ease with which plant fibres can be extracted from them (sisal, ramie, flax, hemp), the attention of scientists has been particularly focused on these plants. Since the late 1990s, the related specialist literature from around the world has begun to record the results of research work carried out in the area of methods for processing fibres and their modification, with research into the mechanical properties and industrial use of NPFs, and in 2001–2004 in particular, hemp fibres (HFs) as an alternative to GF reinforcement in polymer composites were studied [3,4,5]. From 2006 to 2011, the optimisation of the properties of HFs used as a reinforcement in polymer composites and the properties of these composites were investigated at research and development centres on different continents (North America, Europe, South-East Asia). The properties of polymer composites with HFs were investigated, optimising fibre properties using novel defibring and fibre characterisation methods. A study was conducted on the mechanical treatment of HF-based bast fibres in the use of applied fibre extraction and separation processes for textile-reinforced composites, which caused significant damage to these fibres. The effect of fibre defects on their mechanical properties and their susceptibility to chemical degradation was determined. Systematic and improved methods are presented for the characterisation of surface and fracture of elemental HF using field emission scanning microscopy (FE-SEM), the determination of microfibre angles (MFAs) using advanced microscopy technology, and the study of crystallinity by X-ray diffraction (XRD) and Fourier transform infrared (FTIR) [6,7]. A study on the impact and fatigue behaviour of HF composites was carried out to characterise the post-impact tensile and fatigue properties of a non-woven polyester mat reinforced with HF. In addition, the degradation of the tensile modulus of elasticity during fatigue cycling was investigated [8,9,10]. In 2012, research continued in Europe in the area of the effect of treating natural HFs on the long-term thermal properties of PP/HF (polypropylene/hemp fibre) composites, as well as in the area of predicting the moduli and strength of composites reinforced with these fibres [11,12,13]. Also, in the same year, the flexural properties of HF-reinforced polylactide and unsaturated polyester composites and various chemically treated unsaturated HF-reinforced polyester composites were investigated at research and development centres in Europe, Australia and New Zealand, in the context of the mechanical quantities (Young’s modulus, strength and impact strength), and the dependence of Young’s modulus (E) on HF diameter was investigated by determining interdependent ultrastructural parameters such as cellulose crystallinity and microfibre angles. In addition, factors and conditions affecting the augmentation of the mechanical properties of the components were presented on the basis of subsequent studies [14,15,16,17]. From 2013 to 2021, research in Europe continued to show that HF-reinforced composites with thermoplastic matrices, thermosetting matrices and biodegradable matrices have good mechanical properties, and when used to improve the fibre/matrix interfacial bond, chemical treatments of the HF surface resulted in significant improvements in the mechanical properties of the composites [18,19]. The impact of polypropylene biocomposites reinforced with short HF was investigated, using an impact machine equipped with a camera for the rapid imaging and measurement of macro-crack propagation for mechanical measurements. The impact behaviour was analysed using the finite element method (FEM) [20]. The effects of fibre length and alkali and silane treatments on the mechanical and physical properties of HF-reinforced polypropylene composites were also investigated. A compression moulding technique was used to produce the composite. Longer fibres were shown to increase the mechanical strength of the PP/HF composite [21,22,23]. Composites reinforced with NPF, with a particular emphasis on industrial hemp (Cannabis sativa L.) fibres, is currently a rapidly growing mechanical engineering discipline in the science of structural polymer composites. With respect to the GF used, HF are low-cost, low-density fibres, are biodegradable and exhibit satisfactory specific properties and physical and mechanical parameters. Structural polymer composites based on them are in many respects comparable to common GFRP.

Interest in this issue has also emerged in Poland, particularly in the use of structural polymer composites in shipbuilding and peri-shipyard production [24,25,26,27].

Based on the generally available test results of HFs in relation to type ‘E’ GFs, a comparison of the general properties of these fibres is presented in Table 1.

Table 1.

Comparative table of the general properties of HFs and GFs (own elaboration [27] in combination with [28,29,30,31,32]).

It should be noted that the conclusions in Table 1, resulting from the comparison of the physical–mechanical properties, environmental properties and economic condition of the tested fibres, clearly indicate the many advantages of HFs, which include an approximately 2× lower density (lower weight of the future technical product), the high elasticity of the surface and internal structure of the composite, an ability to absorb impact, and resistance to open cracking. The economic aspect is also important: easy availability and low price of the raw material and low energy required to produce 1 tonne of fibre. What is essential and disproportionately important is the environmental aspect in terms of the possibility of disposal by energy recycling.

Cellulose fibre-based composite materials have remarkable economic and environmental advantages, such as low cost, easy market availability, low density, high strength-to-weight ratio, acceptable strength properties and biodegradability (environmental friendliness).

In order to test and confirm both the advantages and disadvantages of NPF-reinforced composite materials, the first stage of this research focused on carrying out the chemical modification of industrial hemp fibres contained in hemp fabric. Based on an analysis of available scientific publications thematically related to the issue of the chemical modification of HF, it was assumed that the most favourable process would be to refine hemp fibres by alkalisation, using sodium hydroxide (NaOH—r-r-r 22%). The alkalisation of the fibres of the 100% hemp fabric formats consisted of immersing these formats in a tank of solution and applying NaOH to the fabric fibres over a period of 30 min at room temperature (21 ± 0.5 °C). After this time, the alkalisation process was interrupted and the formers were subjected to rinsing at intervals of 10 min in three successive tubs of demineralised water at 21 °C until complete removal of NaOH and reaching pH ~7. The fabric rinsing process was then stopped and the formers were subjected to natural drying (humidity 54 ± 2%, air temperature 19 ± 1 °C) for 72 h. The alkalinisation process removed the cuticle, which is the epidermal (epidermis) layer of the cellulose fibre, facilitating the diffusion and re-reactivity of the cellulose molecules with the chemical modifier. The final effect of NaOH was the modification of HF elemental cells, which, through the chemical process of NaOH permeation into the crystalline areas of the fibre cellulose, resulted in the formation of alkalicellulose and, after washing the unreacted NaOH three times in demineralised water, led to the production of regenerated cellulose. It should be noted that there is a fundamental difference in properties between regenerated and natural cellulose, as there is a far-reaching degradation of the fibre structure during the dissolution process, with the regenerated product tending to be less crystalline. Regenerated cellulose is not soluble in water, and has good mechanical properties and good barrier properties against gases (except water vapour). In order to reduce water vapour permeability, products made from regenerated cellulose are coated with a barrier layer, e.g., vinylester resin, and when used in polymer structural composites, a standard DCPD construction resin (so-called enhanced polyester resin). The second stage of the research focused on the production of new composites using the hand lay-up (HLU) method. The composites, HFRP (hemp fibre-reinforced polymer) and HFRPm (hemp fibre-reinforced polymer with chemically modified hemp fibres), respectively, were prepared using unsaturated polyester DCPD (DiCykloPentaDien) as the matrix and HF and HFm in fabric form as their reinforcement and a GFRP-based composite reinforced with GF.

In the third stage of the study of the new composites, the physical (density and water absorption), mechanical (tensile, flexural, impact) and environmental (fire response tests) properties were determined in the context of the effect of chemical treatment on HF. In order to understand the fibre–matrix interaction in the newly produced composites, the morphology of the fractured surfaces of the composites was investigated using scanning electron microscopy (SEM). The results obtained are presented graphically and, based on the analysis of the results, related issues are clarified [24,25,27]. As HFs have a high environmental resistance, the produced HFRP and HFRPm composites, with respect to the GFRP composite, can be legitimately and purposefully used as biodegradable composites with favourable physical properties in the production of selected structures. In addition, due to their uncomplicated manufacturing process, significantly shorter processing times and lower production costs, these composites can be used as a versatile material in the field of mechanical engineering and manufacturing technology for selected structural products [26,27].

Due to the lack of published results on the impact testing (Charpy method) of manufactured hemp fibre-reinforced polymer composites, a study was undertaken to determine the effect of the content of NaCl [‰] and other trace elements in the respective waters on the transfer of violent dynamic loads by the tested materials, after three months of their storage in aqueous environments with varying degrees of water salinity. In addition, tests were carried out on the reaction-to-fire performance of the HFRP and HFRPm composites vs. the GFRP composite in the context of quasi-complete disposal by energy recycling.

2. Materials and Methods for Producing Composites for Testing

To test the impact performance of the new pro-environmental structural composites, HFRP (series K1–K5) and HFRPm (series Km1–Km5) polymer structural composites were produced after long-term storage in representative aqueous environments. A total of 10 control slabs were produced, reinforced with a variable number of layers of fabric made from 100% HF, a new eco-friendly material envisaged for alternative use in the construction of selected vessels.

Conducting a fire response test of HFRP and HFRPm material vs. GFRP, in the context of their disposal by energy recycling, required the fabrication of an additional GFRP control slab (SE) of a real product in the form of a representative 34ft boat hull plate below the waterline, incorporating GF reinforcement.

2.1. Materials Used in the Study Composite Matrix Material

2.1.1. Matrix Material (Appendix A.1)

- DCPD standard construction resin (so-called improved polyester “yacht” resin);

- Initiator for the copolymerisation;

- Pro-adhesive agent;

- Polymerisation accelerator based on cobalt octanoate 6% (dissolved in xylene).

2.1.2. Composite Reinforcement Material (Appendix A.2)

- A 100% hemp fabric with a 1/1 “plain” weave, produced by weaving from threads made from long-fibre hemp (Cannabis sativa L.);

- GF sewn mats.

2.2. Method of Producing Composites for Testing

Composites in the form of control slabs were made by hand lamination (HLU) by experienced and specialised production staff.

Prior to the fabrication of the control slabs, all GFs as well as the HF and HFm slabs were seasoned under production conditions in a thermal chamber with convection heat circulation at 60 °C for 24 h. Appropriately sorted and labelled format packs were prepared for the manufacture of control slabs (Table 2).

Table 2.

Designation of control slabs/sample series depending on the number of reinforcement layers.

The method of chemical modification of the reinforcement formats (HFms), as well as the production of GFRP, HFRP and HFRPm composites and the preparation of test samples from them is described in detail in [24,27].

Control slabs of structural polymer composites GFRP, HFRP and HFRPm were made in the production hall of TTS (Technologie Tworzyw Sztucznych Sp. z o.o. in Łozienica near Goleniow, Poland—manufacturer of sailing and motor yachts and motor boats), under the supervision of a quality control officer maintaining the conditions according to points 4.2.2–4.2.4 of the Polish Register of Shipping No. 1/1998 [33]. The number of reinforcement layers was based on the assumptions in [24].

In order to determine the format grammage of the reinforcement package (number of reinforcement layers) of the composite material of the specified control slabs, all GFs and the HF and HFm formats were dimensioned, weighed and permanently numbered accordingly: format GF (SE); format HF (K1–K5); HFm (Km1–Km5) (Table 3).

Table 3.

Grammage of the reinforcement package used to make the control slabs.

In addition, in order to test the fire response of the HFRP material and HFRPm vs. GFRP, in the context of their disposal by energy recycling, the thicknesses of the samples produced from the control slabs were measured (Table 4).

Table 4.

Thickness of control slabs.

3. Research Methods and Results

In the literature review of available and published scientific papers, research publications, research reports, etc., worldwide/in Europe/in Poland, no descriptions of previously conducted or completed impact tests of polymer structural composites in various aquatic environments, including composites reinforced with natural plant fibres, in particular hemp fibres, were found. Hence, this initiated the idea of conducting such tests in a natural and real environment for newly produced construction materials reinforced with these fibres for use in the construction of floating units, i.e., in the environment of use of these units manufactured in the shipbuilding sector of the shipbuilding industry. Additionally, the reaction to fire of the HFRP and HFRPm materials vs. GFRP material of the hull of a 34-foot boat was investigated in the context of the disposal of these materials using the energy recycling method.

3.1. Impact Strength Testing (Charpy Method) of Composites in Representative Aqueous Environments

The aim of the study was to determine the ability of new HFRP and HFRPm polymer structural composites to withstand rapid dynamic loads in their natural operating conditions (in waters with different degrees of salinity). The unprotected edges of the samples after cutting out from the control slabs were covered with a micron protective layer of DCPD matrix material. Samples of the tested materials were stored in representative centres: (1)—demineralized water; (2)—fresh water (samples: Lake Miedwie; Poland, Żelewo—geographical coordinates: 53.288862, 14.869285; August 2021); (3)—brackish water—with salinity of 7.8‰ (samples: Baltic Sea; Poland, Dziwnów—geographical coordinates: 54.029464, 14.762658; August 2021); (4)—salty water—with salinity of 38‰ (samples: Adriatic Sea; Croatia, Verudela Beach—geographical coordinates: 44.833609, 13.832109; August 2021) for 3 months [34]. Samples of the new HFRP (K1–K5) and HFRPm (Km1–Km5) material and the GFRP (SE) hull structure material of a 34-foot boat were subjected to Charpy impact testing in accordance with ISO 15314 (Methods of exposure to sea: Method C involving exposure in which the samples are completely immersed in water—five pieces each with dimensions of 80 × 10 × thickness mm) [35]. The tests were carried out on standard unnotched samples using a pendulum hammer manufactured by VEB Werkstoffpruefmaschinen Leipzig-Betrieb des VEB “Fritz Heckert”/German Democratic Republic with a maximum impact energy of up to 50 J and up to 300 J. Conducting a three-month storage test of composites was possible while maintaining appropriate water conditions and quality conditions in these aquatic environments.

The test was conducted in a closed room with a constant temperature of 22 °C and air humidity of 60 ± 1%, in open containers filled with these waters. The samples were completely immersed in separate containers with waters, in which the levels of these waters were replenished every 7 days to their initial state. Each time the level of these waters decreased after this time was the result of surface evaporation of water in the containers. At the end of each passing month, the containers were emptied of water and refilled with “new/fresh” water. This procedure was intended to eliminate water bloom, i.e., a volumetric change in colour in the aquatic environment caused by the mass development of microscopic living organisms that are unrecognisable to the naked eye.

3.2. Analysis of the Results of Impact Tests (Charpy Method) of Materials in Representative Water Environments

The analysis of the impact strength test results (Charpy method) was aimed at determining the effect of the NaCl [‰] content and other trace elements in individual waters on the transfer of sudden dynamic loads by the tested materials, which could be used in potentially exploited composite floating objects.

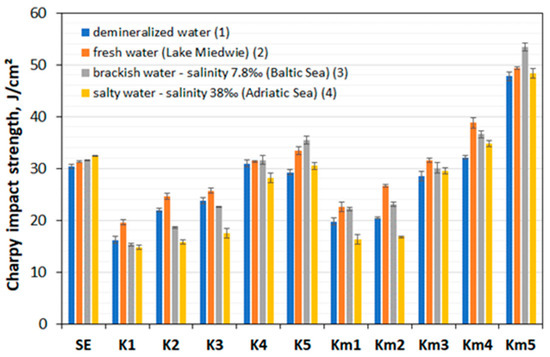

The results of the impact strength tests (Charpy method) of composite samples of individual series K1–K5 and Km1–Km5 vs. series SE material after 3 months of their storage in aqueous environments (1)–(4) are presented in Table 5 and Figure 1.

Table 5.

Average values of impact strength (Charpy method) of HFRP, HFRPm and GFRP composites after 3 months of their storage in representative aqueous environments (1)–(4).

Figure 1.

Charpy impact strength comparison table of HFRP, HFRPm and GFRP composites after 3 months of their storage in representative aqueous environments (1)–(4).

In order to illustrate the analysis of the test results, a comparative graph of the impact strength (Charpy method) of the tested materials is provided (Figure 1).

The storage of the polymer composite samples HFRP and HFRPm in layers, in natural aqueous environments, was as follows: K4–K5 series (9–11) and Km3–Km5 series (7–11) in the environment (2), K4–K5 series (9–13) and Km4–Km5 series (9–11) in the environment (3) and Km4–Km5 series (9–11) in the environment (4); these layers show the higher impact strength values of the composite samples in comparison to the SE series samples of the GFRP composite.

The test results for the SE series GFRP show a consistent slight increase in impact strength (Charpy method) in aqueous environments (1)–(4). Similar test results in aqueous environments (2)–(3) were also obtained by the K1–K5 series of composites. Considering the test results referring to the conditions of individual water environments (2)–(4), i.e., natural environments in which floating objects are operated, a constant increase in impact strength is noticeable: in the water environment (2), the K4 and K5 series at the level of 11% and the Km4–Km5 series at the level of 33% vs. the SE series; similarly, in the water environment (3), the K4 and K5 series at the level of 12% and the Km4–Km5 series at the level of 42%. In the aqueous environment (4), in relation to the SE series, the K4 and K5 series show a decrease in impact strength of 13%, and the Km4–Km5 series show an increase in impact strength of 28%.

It should be noted that the HRFP composites of the K4–K5 series show a steady slight increase in the impact strength of these new materials in the (2) and (3) environments, while the HFRPm composites of the Km3–Km4 series in the (3) environment show an average decrease in impact strength of 6%, and in the (4) environment, a decrease of 7% with respect to the impact strength of these materials in the (2) environment. At this stage of the analysis, the research results confirm the possibilities of using the new HFRP composites of the K4 and K5 series and HFRPm of the Km4 and Km5 series, e.g., in the HLU production of selected products in the shipbuilding sector, meeting the limited requirements for medium- and low-strength floating object components.

3.3. Fire Reaction Tests of New HFRP/HFRPm Polymer Composites

The preliminary tests were carried out in accordance with the research methodology specified in ISO 5660 [36]. The standard specifies a measurement method for the heat release rate and smoke production rate of specimens exposed in the horizontal orientation to irradiance. The heat release rate is determined by measurement of the oxygen consumption derived from the oxygen concentration and the flow rate in the combustion product stream. The time to ignition (sustained flaming) is also measured in this test. The dynamic smoke production rate is calculated from the measurement of the attenuation of a laser light beam by the combustion product stream. Smoke obscuration is recorded for the entire test, regardless of whether the specimen is flaming or not. Horizontally placed samples of 100 mm in width and 100 mm in length and thickness, respectively, for GFRP laminate (7.50 mm), HFRP (13.85 mm) and HFRPm (21.95 mm), were exposed to a 50 kW/m2 irradiance. The ignition of samples was triggered by a spark igniter.

3.4. Analysis of the Results of Fire Reaction Tests of New HFRP/HFRPm Polymer Composites

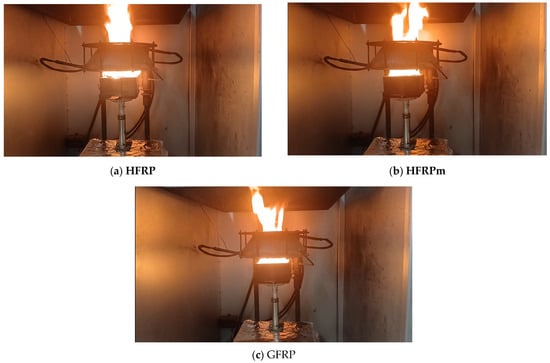

Photos of samples HFRP, HFRPm and GFRP composites in the course of ignition are shown in Figure 2. The obtained results of preliminary tests of the materials are compared in Table 6.

Figure 2.

Photos of samples in the course of ignition: (a) HFRP; (b) HFRPm; (c) GFRP.

Table 6.

Results of fire reaction tests.

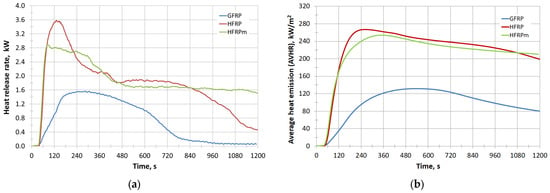

HFRP and HFRPm samples burn longer and more efficiently than GFRP—their combustion is almost complete. HFRP samples burned by approx. 96%, and HFRPm by approx. 83%. This is a significant difference compared to GFRP, whose residues after combustion are approx. 53%, which may cause a greater problem with waste management after subjecting this material to neutralisation through heat recovery. During this process, more heat can be obtained from HFRP and HFRP materials than from GFRP, as indicated by the results of measurements of the heat release rate (Figure 3a), average rate of heat emission (Figure 3b) and total heat release during combustion of the tested materials (Table 6). The most heat during combustion is released by HFRPm (252 MJ/m2), with HFRP at about 239 MJ/m2, and GFRP at only 96.2 MJ/m2.

Figure 3.

(a) Heat release rate with time; (b) average heat emission (AVHR) with time.

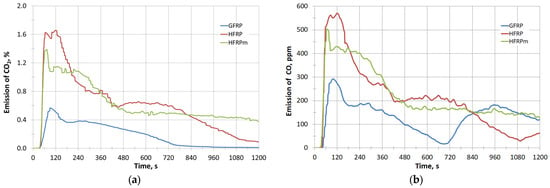

Based on the obtained test results, it can also be stated that HFRP and HFRPm samples emit larger amounts of carbon monoxide and carbon dioxide during combustion compared to GFRP (Figure 4a,b). However, when calculated per unit of material mass, the CO emission values for HFRPm and HFRP are lower than that of GFRP. The specific CO emission values are 0.116, 0.144 and 0.153 kg/kg, respectively.

Figure 4.

(a) Emission of CO2 with time; (b) Emission of CO with time.

4. Conclusions

Impact test results (Charpy method) of new polymer composites of the series K1–K5 and Km1–Km5 vs. series SE, after 3 months of storage in representative aqueous environments (1)–(4), are presented in Table 5.

The results clearly show that the previously commonly used GFRP composite slightly increases its impact strength with growing salinity of the natural aqueous environment (2)–(4). In addition, the series K4–K5 and Km4–Km5 composites, under the same conditions of the aqueous environment with the exception of salt water with a salinity of 38‰ (4), show an increase in impact strength up to 6 and 8%, respectively. Also, it has been noted that the series K4–K5 and Km4–Km5 show an increased impact strength in fresh water (2) and in saline water with salinity of 7.8‰ (3) with respect to the GFRP composite.

The results of the fire response testing of the new polymer composites HFRP and HFRPm compared to GFRP, in light of the need to meet the current sustainability requirements of worldwide economies and to meet increasingly stringent environmental requirements, show that these composites, respectively, can and should be quasi-fully recycled through the method of energy recycling.

The HFRPm composite gives off the most heat during combustion (2.62), while HFRP gives off 2.48 times more heat than GFRP. In addition, it was noted that the waste from controlled combustion (by weight of the composite materials tested) decreased significantly and remained as follows: HFRP—3.7; HFRPm—17.4; GFRP—52.7%. It is therefore advisable to use the waste HFRP/HFRPm materials as an energy fuel and the residue as ash as a full component of effective natural fertilisers. On the basis of the test results obtained, it was also observed that the HFRP and HFRPm emit higher amounts of carbon monoxide (CO) and carbon dioxide (CO2) during combustion compared to GFRP. However, per unit mass of material, the CO emissions for HFRPm and HFRP are lower than that of GFRP (Table 6).

The results of physical, environmental and mechanical properties, with particular emphasis on the impact strength (Charpy method) of the series K1–K5 and Km1–Km5, after 3 months of storage in representative aqueous environments (1)–(4), are presented together with their assessment of their applicability to shipbuilding in Table 7.

Table 7.

Analysis of the physical and mechanical properties of the tested composites and the possibility of using environmentally friendly HFRP and HFRPm composites in the shipbuilding industry.

The experimental results of physical and mechanical tests of the selected HFRP composites of the K4 and K5 series and the HFRPm composites of the Km4 and Km5 series in relation to the GFRP composite of the SE series, collected and presented in a comparative table (Table 7), indicate the validity of the alternative use of HF/HFm reinforcement instead of the commonly used E-type GF reinforcement.

The homogeneity of the geometric shape and the reproducible structure of the GF, ensured by the chemical manufacturing process, results in reproducible physical–mechanical and morphological properties of these fibres. Different in structure, with respect to GF, are the non-uniform geometric shape and uneven wall thickness of NPF of HF, which are characterised by a non-uniform structure (porosity) of the plant material. Despite the use of the same type of matrix (standard DCPD engineering resin) in the structural polymer composites, the demonstrated difference in their strength parameters is derived from the difference in the structure of the NPF in relation to the GF structure.

The reduction in some of the indicated performance values of the tested HFRP and HFRPm composites compared to the GFRP composite allows them to be used in the shipbuilding industry, to a limited extent, in the HLU process for the manufacture of shell components with medium and low strength requirements. The results obtained during this basic research on these structural composites clearly confirmed the need for application research and the desirability of carrying out implementation research to obtain composites dedicated specifically to selected products manufactured in the shipbuilding industry.

The use of new HFRP composite structures (reinforced alternatively with HF only, or with varying amounts of HF and GF or CF (carbon fibres)—so-called hybrid reinforcements)—in the shipbuilding industry for the hull plating of selected vessels appears to be an appropriate alternative to the composite watercraft currently manufactured from GFRP and fits in with the programme for implementing the recommended and EU-required environmentally friendly measures in the production economy of the global shipbuilding industry.

Author Contributions

Conceptualization, M.S., M.U. and A.B.; methodology, M.S. and R.D.; investigation, M.S. and R.D.; data curation, M.U. and A.B.; writing—original draft preparation, M.S. and R.D.; writing—review and editing, M.S., M.U. and A.B; supervision, M.U. and A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Appendix A.1. Matrix Material

- DCPD with the trade name AropolTM M 604 TBR (Safety Data Sheet No. 000000154974—Ashland) manufactured by INEOS Composites/Porvoo/Finland;

- Metox-50WR resin manufactured by Oxytop Sp. z o.o./Antoninek near Steszew, Poland;

- Maleic anhydride (MAH), at a ratio of 3g per 100 g of resin;

- The name BÜFA®-Accelerator Co 6 (prod. No. 742-0600) from BÜFA Composite Systems GmbH & Co. KG, Rastede, Germany.

Appendix A.2. Composite Reinforcement Material

- Its average weight according to the manufacturer, i.e., the company S.C. CAVVAS LIMITED S.R.L., Cluj-Napoca, Romania, was HF = 478 g/m2. At the production stage, the fabric was treated with an impregnating agent named TUBIGUARD 27 (manufactured and selected by BEZEMA AG, Montlingen, Switzerland;

- Manufactured by KROSGLASS S.A., Krosno, Poland, used to produce a representative hull of a selected vessel.

References

- Błędzki, A.; Gorący, K.; Urbaniak, M.; Scheibe, M. Problems connected with utilization of polymer composite products and waste materials Part I. Production volume, utilization of composites with carbon fibres, legislative aspects, industrial recycling. Polimery 2019, 64, 777–787. (In Polish) [Google Scholar] [CrossRef]

- Scheibe, M.; Urbaniak, M.; Gorący, K.; Błędzki, K. Problems connected with utilization of polymer composite products and waste materials Part II. “Scrapping” of composite recreational vessels in the world in the perspective of 2030. Polimery 2019, 64, 788–794. (In Polish) [Google Scholar] [CrossRef]

- Gassan, J.; Chate, A.; Bledzki, A. Calculation of elastic properties of natural fibers. J. Mater. Sci. 2001, 36, 3715–3720. [Google Scholar] [CrossRef]

- Specht, K.; Bledzki, A. Influence of fiber treatment on the thermal longtime behavior of wood and hemp fiber—Polypropylene composites. In Proceedings of the 7th International Conference on Woodfiber-Plastic Composites, Kassel, Germany, 19–20 May 2003. [Google Scholar]

- Bledzki, A.; Fink, H.-P.; Specht, K. Unidirectional hemp and flax EP- and PP-composites: Influence of defined fiber treatments. J. Appl. Polym. Sci. 2004, 93, 2150–2156. [Google Scholar] [CrossRef]

- Rouison, D.; Sain, M.; Couturier, M. Resin transfer molding of hemp fiber composites: Optimization of the process and mechanical properties of the materials. Compos. Sci. Technol. 2006, 66, 895–906. [Google Scholar] [CrossRef]

- Thygesen, A. Properties of Hemp Fibre Polymer Composites—An Optimisation of Fibre Properties Using Novel Defibration Methods and Fibre Characterisation. Ph.D. Thesis, The Royal Agricultural and Veterinary University of Denmark, Roskilde, Denmark, 2006. [Google Scholar]

- Yuanjian, T.; Isaac, D.H. Impact and fatigue behaviour of hemp fibre composites. Compos. Sci. Technol. 2007, 67, 3300–3307. [Google Scholar] [CrossRef]

- Staiger, M.P.; Tucker, N. Natural-Fibre Composites in Structural Applications. In Properties and Performance of Natural Fibre Composite; Pickering, K., Ed.; Woodhead: Boca Raton, FL, USA, 2008; pp. 269–297. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites: A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Hughes, M. Defects in natural fibres: Their origin, characteristics and implications for natural fibre-reinforced composites. J. Mater. Sci. 2012, 47, 599–609. [Google Scholar] [CrossRef]

- Virk, A.; Hall, W.; Summerscales, J. Modulus and strength prediction for natural fibre composites. Mater. Sci. Technol. 2012, 28, 864–871. [Google Scholar] [CrossRef]

- Moyeenuddin, A.S.; Pickering, K.L.; Fernuhough, A. Flexural properties of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. A Appl. Sci. Manuf. 2012, 43, 519–526. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Analysis of mechanical properties of hemp fibre reinforced unsaturated polyester composites. J. Compos. Mater. 2012, 47, 1513–1525. [Google Scholar] [CrossRef]

- Placet, V.; Trivaudey, F.; Cisse, O.; Gucheret-Retel, V.; Boubakar, M.L. Diameter dependence of the apparent tensile modulus of hemp fibres: A morphological, structural, or ultrastructural effect? Compos. A Appl. Sci. Manuf. 2012, 43, 275–287. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Espinach, F.X.; Julián, F.; Torres, L.; Vilaseca, F.; Mutjé, P. Micromechanics of hemp strands in polypropylene composites. Compos. Sci. Technol. 2012, 72, 1209–1213. [Google Scholar] [CrossRef]

- Shahzad, A. A study in physical and mechanical properties of hemp fibres. Adv. Mater. Sci. Eng. 2013, 2013, 325085. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Rfendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Bujanowicz, K.; Kołodziej, J.; Mańkowski, J.; Rojewski, S.; Wesołek, D. Biocomposites Reinforced with Flax and Hemp Fibres as Structural Elements in Land, Water and Air Transport Vehicles and in the Construction Industry; Institute of Natural Fibres and Herb Plants, Ministry of Agriculture and Rural Development: Warsaw, Poland, 2018. (In Polish) [Google Scholar]

- Puech, L.; Ramakrishnan, K.R.; Moigne, N.L.; Corn, S.; Slangen, P.R.; Duc, A.L.; Bouldhani, H.; Bergeret, A. Investigating the impact behaviour of short hemp fibres reinforced polypropylene biocomposites through high speed imaging and finite element modelling. Compos. A Appl. Sci. Manuf. 2018, 109, 428–439. [Google Scholar] [CrossRef]

- Alao, P.F.; Kallakas, H.; Poltimäe, T.; Kers, J. Effect of hemp fibre length on the properties of polypropylene composites. Agron. Res. 2019, 17, 1517–1531. [Google Scholar] [CrossRef]

- Alao, P.F.; Marrot, L.; Kallakas, H.; Just, A.; Poltimäe, T.; Kers, J. Effect of hemp fiber surface treatment on the moisture/water resistance and reaction to fire of reinforced PLA composites. Materials 2021, 14, 4332. [Google Scholar] [CrossRef]

- Scheibe, M. Analysis of the Applicability of Natural Fiber Reinforced Polymer Composites for the Construction of Selected Types of Vessels. Ph.D. Thesis, Maritime University of Szczecin, Szczecin, Poland, 2022. (In Polish). [Google Scholar]

- Scheibe, M.; Urbaniak, M.; Bledzki, A. Application of Natural (Plant) Fibers Particularly Hemp Fiber as Reinforcement in Hybrid Polymer Composites—Part I. Origin of Hemp and Its Coming into Prominence, Cultivation Statistics, and Legal Regulations. J. Nat. Fibers 2023, 20, 2251682. [Google Scholar] [CrossRef]

- Scheibe, M.; Urbaniak, M.; Bledzki, A. Application of Natural (Plant) Fibers Particularly Hemp Fiber as Reinforcement in Hybrid Polymer Composites—Part II. Volume of Hemp Cultivation, Its Application and Sales Marked. J. Nat. Fibers 2023, 20, 2276715. [Google Scholar] [CrossRef]

- Scheibe, M.; Urbaniak, M.; Kukulka, W.; Bledzki, A. Application of Natural (Plant) Fibers Particularly Hemp Fiber as Reinforcement in Hybrid Polymer Composites—Part III. Investigations of Physical and Mechanical Properties of Composites Reinforced with Hemp Fibers. J. Nat. Fibers 2024, 21, 2414194. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Das, H.; Kalita, D. Recent Development of Fiber Reinforced Composite Materials. In Biosensors Nanotechnology; Tiwari, A., Turner, A.P.F., Eds.; Wiley-Scrivener: London, UK, 2014; pp. 441–496. [Google Scholar]

- Tri-Dung, N. Natural Fibers for Sustainable Bio-Composites. In Natural and Artificial Fiber-Reinforced Composites as Renewable Sources; Günay, E., Ed.; InTech: Norderstedt, Germany, 2018; pp. 1201–1278. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Polish Register of Shipping. Rules for the Classification and Construction of Sea-going Yachts. Part II—Hull; Polish Register of Shipping: Gdansk, Poland, 1998. (In Polish) [Google Scholar]

- Polish Register of Shipping. Regulations—Publication 118/P—Requirements for Passenger Ships Constructed of Polymer Composites, Operating in Domestic Shipping; Polish Register of Shipping: Gdansk, Poland, 2018. (In Polish) [Google Scholar]

- ISO 15314:2018; Plastics—Methods for Marine Exposure. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).