The Influence of Fiber-Form Waste Tire Aggregates on the Flexural Strength, Ductility, and Energy Dissipation of Pultruded GFRP–Rubberized Concrete Hybrid Beams

Abstract

1. Introduction

Aim of This Study

- Decreased compressive strength due to rubber addition;

- Increased ductility due to rubber addition;

- The constraint effect arising from the GFRP profile are simultaneously investigated under a bending load.

2. Materials and Methods

Materials

3. Results

3.1. Microstructure Analysis (SEM)

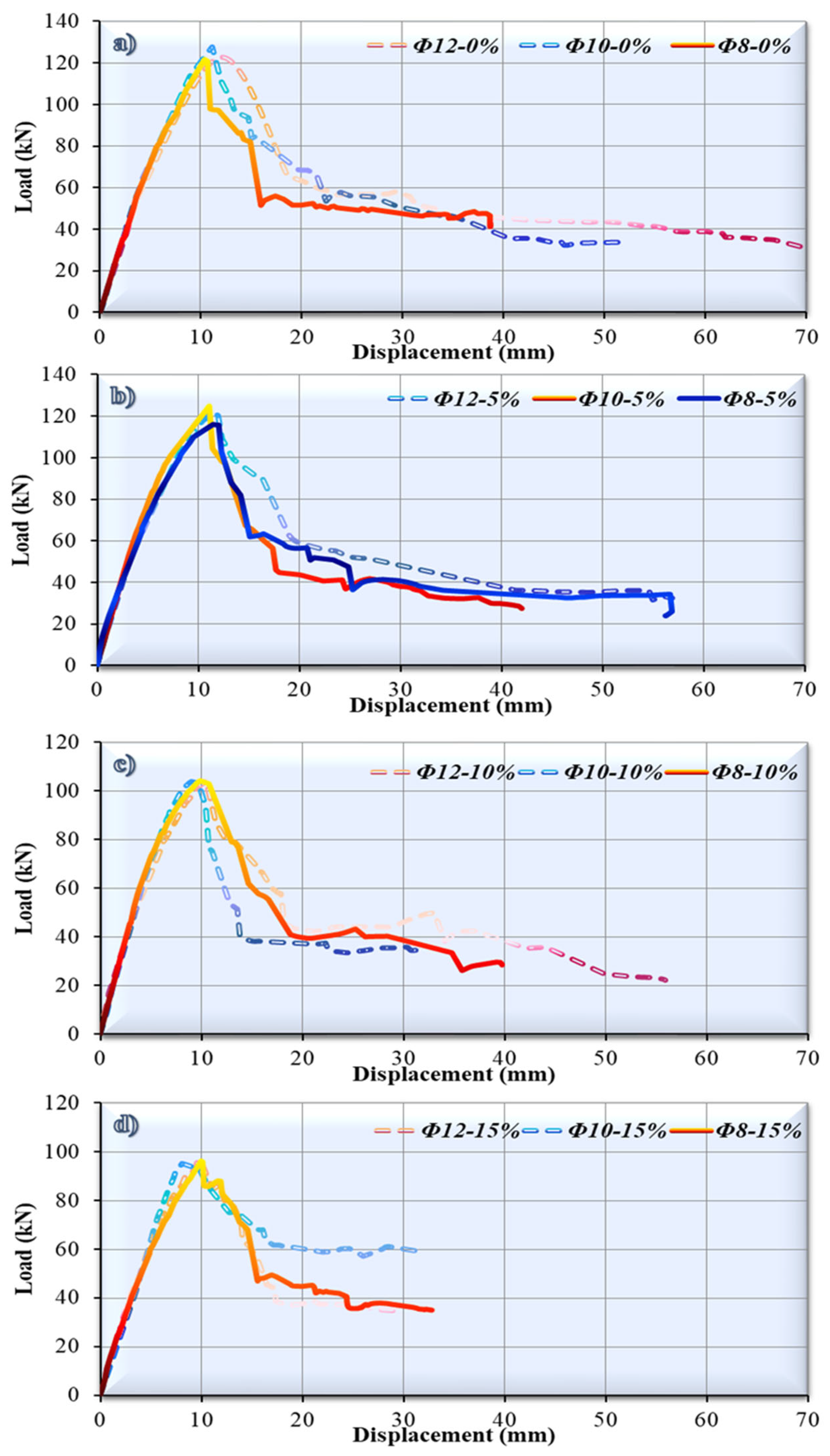

3.2. Effects of Varying Proportions of Waste Rubber Aggregates

3.3. Variations in the Effect of the Tension Reinforcement Proportion on Waste Rubber Aggregates

4. Conclusions

- Firstly, cube, cylinder, and flexural tests were carried out in this study. With the use of the 15% waste rubber aggregate, cube compressive strength, cylinder tensile strength, and flexural strength decreased by 27.5%, 50%, and 47.6%, respectively, compared to the reference specimens.

- As a result of the four-point bending tests on the beams, the inclusion of waste rubber aggregates in the concrete mixtures at the rates of 10% and 15% affected the mechanical properties of the concrete and significantly reduced the maximum load-carrying capacity. However, it was determined that there was an improvement in terms of ductility compared to the reference beams.

- It is understood that the best balance between strength and ductility is achieved, and the performance closest to the reference beams is realized when the waste rubber aggregate ratio is 5%. It can be said that the Ø10-5% specimen shows better performance in terms of both strength and yield stiffness.

- As a result of the tests, it was determined that the beams with the Ø10 reinforcement had both higher load-carrying capacity and higher yield stiffness when using concrete with 5% waste rubber aggregate.

- When the ratio of the waste rubber aggregate is 15%, although the maximum load-carrying capacity decreases with increasing longitudinal reinforcement ratios (Ø12-15% > Ø10-15% > Ø8-15%), the approximate load-carrying capacities of the specimens are similar (Ø12-15% = 96.72 kN > Ø10-15% = 95.28 kN > Ø8-15% = 96.39 kN).

- It was observed that the overall energy consumption capacities for all tested beams generally decreased with the increase in the proportion of waste rubber aggregates. This can be explained by the fact that shear damage in the beam occurs more quickly, and the area under the load–displacement curve decreases with the increase in the amount of waste rubber aggregates.

- It was evaluated within the scope of this experimental study that waste rubber aggregates to be used in reinforced concrete beams can provide environmental and economic benefits at certain ratios (especially at the 5% level).

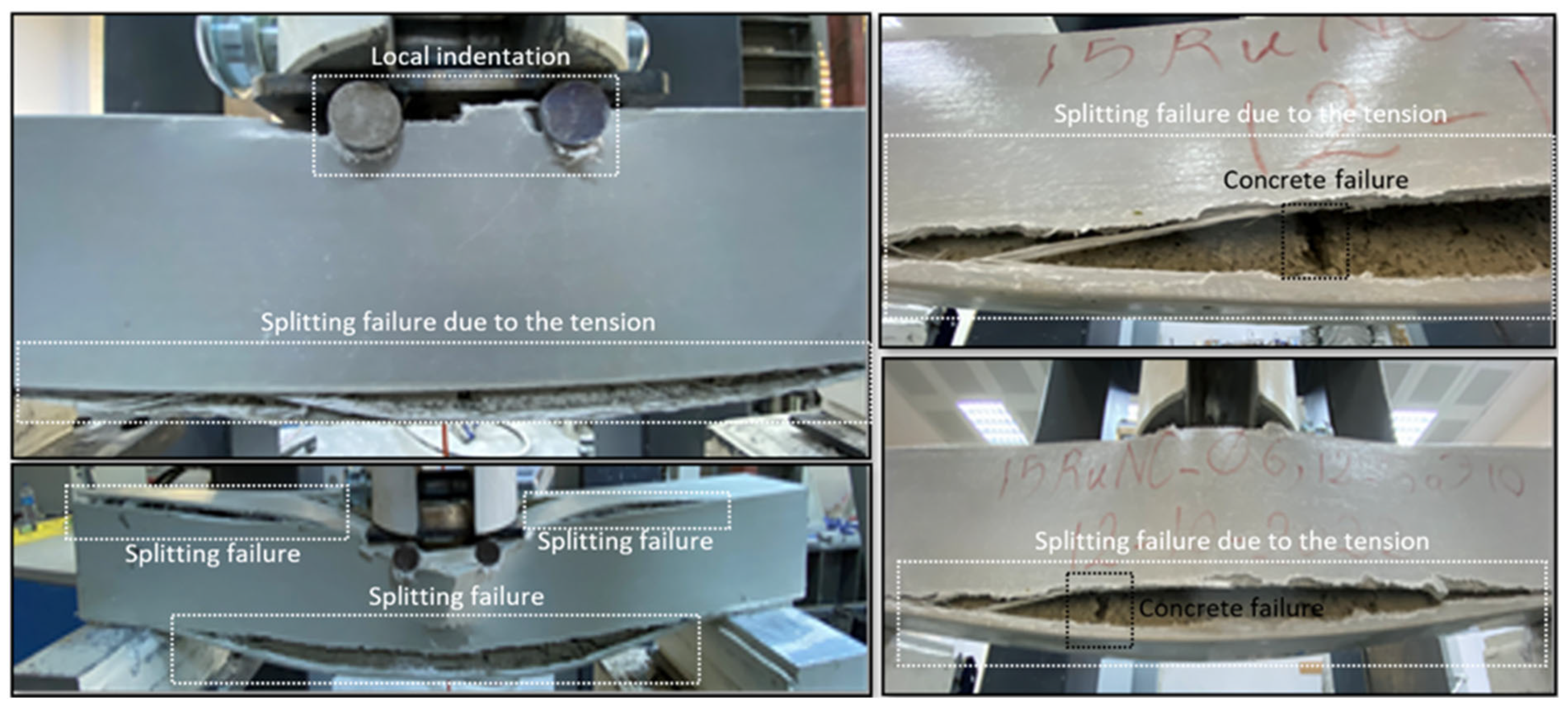

- Common failures observed in pultruded GFRPs were splitting at the beam’s loading point, web-flange separation, and local notch failure.

- The 5% hybrid ratio is shown to produce the most advantageous overall response, according to a quantitative synthesis of many measures, including strength, ductility, and energy. Ratios exceeding 5% alter the response profile, inducing increased stiffness, reduced deformability, and earlier onset of localization. Consequently, in line with the planned hybrid design goal, the 5% arrangement offers the best balance between strength gain and deformation capacity.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, F.; Meng, L.-Y.; Ning, G.-F.; Li, L.-J. Fatigue performance of rubber-modified recycled aggregate concrete (RRAC) for pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete—A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A. Use of metakaolin on enhancing the mechanical properties of self-consolidating concrete containing high percentages of crumb rubber. J. Clean. Prod. 2016, 125, 282–295. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Topcu, I.B. The properties of rubberized concretes. Cem. Concr. Res. 1995, 25, 304–310. [Google Scholar] [CrossRef]

- Shahjalal, M.; Islam, K.; Rahman, J.; Ahmed, K.S.; Karim, M.R.; Billah, A.M. Flexural response of fiber reinforced concrete beams with waste tires rubber and recycled aggregate. J. Clean. Prod. 2021, 278, 123842. [Google Scholar] [CrossRef]

- Vadivel, T.S.; Thenmozhi, R.; Doddurani, M. Experimental study on waste tyre rubber reinforced concrete. J. Struct. Eng. 2012, 39, 291–299. [Google Scholar]

- Chan, C.W.; Yu, T.; Zhang, S.; Xu, Q. Compressive behaviour of FRP-confined rubber concrete. Constr. Build. Mater. 2019, 211, 416–426. [Google Scholar] [CrossRef]

- Li, G.; Pang, S.-S.; Ibekwe, S.I. FRP tube encased rubberized concrete cylinders. Mater. Struct. 2011, 44, 233–243. [Google Scholar] [CrossRef]

- Elshazly, F.A.; Mustafa, S.A.; Fawzy, H.M. Rubberized concrete properties and its structural engineering applications–an overview. Egypt. Int. J. Eng. Sci. Technol. 2020, 30, 1–11. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Hosseini, S.-A.; Ozbakkaloglu, T. The combined effect of crumb rubber aggregates and steel fibers on shear behavior of GFRP bar-reinforced high-strength concrete beams. J. Build. Eng. 2021, 44, 102981. [Google Scholar] [CrossRef]

- Adday, A.A.; Ali, A.S. Flexural Behavior of Rubber-Filled Reinforced Concrete Beams Strengthening with CFRP Sheets. In Proceedings of the E3S Web of Conferences: EDP Sciences, Online, 13 September 2023; p. 02021. [Google Scholar]

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.S.; Zhuge, Y.; Mohammed, A.A.; Bai, Y.; Aravinthan, T.; Schubel, P. Bending and shear behaviour of waste rubber concrete-filled FRP tubes with external flanges. Polymers 2021, 13, 2500. [Google Scholar] [CrossRef] [PubMed]

- Batayneh, M.K.; Marie, I.; Asi, I. Promoting the use of crumb rubber concrete in developing countries. Waste Manag. 2008, 28, 2171–2176. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Mehra, P.; Kumar, S. Performance of high strength rubberized concrete in aggressive environment. Constr. Build. Mater. 2015, 83, 320–326. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Qiao, P.; Davalos, J.F.; Barbero, E.J.; Troutman, D. Step-by-Step Engineering Desing Equations for FRP Structural Beams. In Proceedings of the International Composites EXPO’99, Cincinnati, OH, USA, 10–13 May 1999; pp. 1–7. [Google Scholar]

- Madenci, E.; Özkiliç, Y.O.; Lokman, G. Theoretical investigation on static analysis of pultruded GFRP composite beams. Acad. Platf.-J. Eng. Sci. 2020, 8, 483–490. [Google Scholar]

- Estep, D.D.; GangaRao, H.V.; Dittenber, D.B.; Qureshi, M.A. Response of pultruded glass composite box beams under bending and shear. Compos. Part B Eng. 2016, 88, 150–161. [Google Scholar] [CrossRef]

- Karalar, M.; Ozturk, H.; Ozkilic, Y.O. Experimental and numerical investigation on flexural response of reinforced rubberized concrete beams using waste tire rubber. Steel Compos. Struct. 2023, 48, 43–57. [Google Scholar]

- Zeng, J.-J.; Zeng, W.-B.; Ye, Y.-Y.; Liao, J.; Zhuge, Y.; Fan, T.-H. Flexural behavior of FRP grid reinforced ultra-high-performance concrete composite plates with different types of fibers. Eng. Struct. 2022, 272, 115020. [Google Scholar] [CrossRef]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Gorji, M.; Mehdikhani, H.; Movahedi Rad, M. Shear bond strength in stone-clad Façades: Effect of polypropylene fibers, curing, and Mechanical Anchorage. Polymers 2024, 16, 2975. [Google Scholar] [CrossRef]

- Sun, H.-Q.; Zeng, J.-J.; Hong, G.-Y.; Zhuge, Y.; Liu, Y.; Zhang, Y. 3D-printed functionally graded concrete plates: Concept and bending behavior. Eng. Struct. 2025, 327, 119551. [Google Scholar] [CrossRef]

- Kevin, B.; Sarker, P.K.; Madhavan, M.K. Performance assessment and microstructural characterization of combined surface, chemical and polymer treated crumb rubber concrete. Sci. Rep. 2025, 15, 15853. [Google Scholar] [CrossRef]

- Huang, W.; Huang, X.; Xing, Q.; Zhou, Z. Strength reduction factor of crumb rubber as fine aggregate replacement in concrete. J. Build. Eng. 2020, 32, 101346. [Google Scholar] [CrossRef]

| Chemical Properties | Obtained Values | TS EN 197-1 | |

|---|---|---|---|

| Most | |||

| Loss on Ignition (%) | 2.76 | 5.00 | |

| Insoluble Residue (%) | 0.35 | 5.00 | |

| Sulfur trioxide (SO3) (%) | 3.4 | 4.00 | |

| Chloride (Cl) (%) | 0.028 | 0.10 | |

| K2O (%) | 0.64 | ||

| Na2O (%) | 0.34 | ||

| Physical Properties | Obtained values | TS EN 197-1 | |

| Least | Most | ||

| 2-Day Compressive Strength (MPa) | 27.2 | 20 | |

| 28-Day Compressive Strength (MPa) | 49.7 | 42.5 | 62.5 |

| Initial Setting Time (min) | 135 | 60 | |

| Volume Expansion (mm) | 1 | 10 | |

| Mix | Slump (cm) | Splitting Tensile Strength (MPa) | Average Splitting Tensile Strength (MPa) | Bending Load (kN) | Bending Strength (MPa) | Average Bending Strength (MPa) | Compressive Strength (MPa) | Compressive Strength Average (MPa) |

|---|---|---|---|---|---|---|---|---|

| RuNC | 19 | 2.24 | 2.31 | 14.06 | 8.44 | 8.270 | 22.442 | 22.86 |

| 2.51 | 13.84 | 8.30 | 23.288 | |||||

| 2.20 | 13.46 | 8.07 | 22.836 | |||||

| 5RuNC | 15 | 1.41 | 1.58 | 7.85 | 4.71 | 5.257 | 12.751 | 12.65 |

| 1.55 | 9.16 | 5.49 | 12.250 | |||||

| 1.79 | 9.28 | 5.57 | 12.938 | |||||

| 10RuNC | 14 | 1.23 | 1.24 | 6.42 | 3.85 | 6.013 | 8.179 | 8.42 |

| 1.23 | 12.35 | 7.41 | 8.258 | |||||

| 1.27 | 11.30 | 6.78 | 8.824 | |||||

| 15RuNC | 11 | 1.06 | 1.18 | 10.09 | 6.05 | 4.330 | 6.100 | 6.32 |

| 1.22 | 6.02 | 3.61 | 6.337 | |||||

| 1.27 | 5.55 | 3.33 | 6.516 |

| Test Specimens | Pmax (kN) | Displacement at Pmax (mm) | Stiffness at (Pmax) (kN/mm) | Pu (0.85 Pmax) (kN) | Displacement at Yield δy (mm) | Stiffness at Yield (0.85 Pmax) (kN/mm) | δu (mm) | Ductility Ratio |

|---|---|---|---|---|---|---|---|---|

| Ø8-0 | 122.035 | 10.400 | 11.729 | 103.730 | 8.562 | 12.115 | 10.958 | 1.280 |

| Ø8-5 | 116.314 | 11.517 | 10.099 | 98.867 | 7.878 | 12.550 | 13.310 | 1.690 |

| Ø8-10 | 104.348 | 9.92 | 10.519 | 88.696 | 6.603 | 13.433 | 10.790 | 1.634 |

| Ø8-15 | 96.392 | 9.994 | 9.646 | 81.934 | 7.322 | 11.191 | 12.067 | 1.648 |

| Ø10-0 | 127.729 | 11.149 | 11.457 | 108.570 | 8.892 | 12.210 | 12.024 | 1.352 |

| Ø10-5 | 125.108 | 11.114 | 11.257 | 106.342 | 7.244 | 14.680 | 11.436 | 1.579 |

| Ø10-10 | 103.903 | 9.0664 | 11.460 | 88.318 | 6.708 | 13.166 | 10.467 | 1.560 |

| Ø10-15 | 95.280 | 8.108 | 11.751 | 80.988 | 6.311 | 12.833 | 10.910 | 1.729 |

| Ø12-0 | 123.000 | 12.000 | 10.250 | 104.550 | 9.730 | 10.745 | 14.150 | 1.454 |

| Ø12-5 | 122.122 | 11.604 | 10.524 | 103.804 | 8.230 | 12.613 | 13.483 | 1.638 |

| Ø12-10 | 104.244 | 10.504 | 9.924 | 88.607 | 7.463 | 11.873 | 11.471 | 1,537 |

| Ø12-15 | 96.721 | 9.877 | 9.792 | 82.213 | 7.300 | 11.262 | 12.342 | 1.691 |

| Test Specimens | Maximum Displacement (mm) | Energy Dissipation at Pmax (kJ) | Energy Dissipation at 0.85 Pmax (kJ) | Plastic Energy Dissipation (kJ) | Total Energy Dissipation (kJ) | Ductility Level Sufficient/ Deficient |

|---|---|---|---|---|---|---|

| Ø8-0 | 38.738 | 0.720 | 0.509 | 1.032 | 1.541 | Deficient |

| Ø8-5 | 56.942 | 0.841 | 0.444 | 1.730 | 2.174 | Deficient |

| Ø8-10 | 39.819 | 0.639 | 0.318 | 1.160 | 1.479 | Deficient |

| Ø8-15 | 32.752 | 0.557 | 0.322 | 0.794 | 1.116 | Deficient |

| Ø10-0 | 51.552 | 0.825 | 0.553 | 1.604 | 2.156 | Deficient |

| Ø10-5 | 41.980 | 0.844 | 0.407 | 1.273 | 1.680 | Deficient |

| Ø10-10 | 31.511 | 0.050 | 0.318 | 0.684 | 1.003 | Deficient |

| Ø10-15 | 31.787 | 0.406 | 0.247 | 0.810 | 1.057 | Deficient |

| Ø12-0 | 71.638 | 0.840 | 0.518 | 2.338 | 2.857 | Deficient |

| Ø12-5 | 56.880 | 0.853 | 0.470 | 1.763 | 2.233 | Deficient |

| Ø12-10 | 55.974 | 0.669 | 0.374 | 1.669 | 2.043 | Deficient |

| Ø12-15 | 30.000 | 0.561 | 0.331 | 0.703 | 1.034 | Deficient |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ecemis, A.S.; Karalar, M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Aksoylu, C.; Madenci, E.; Özkılıç, Y.O. The Influence of Fiber-Form Waste Tire Aggregates on the Flexural Strength, Ductility, and Energy Dissipation of Pultruded GFRP–Rubberized Concrete Hybrid Beams. Polymers 2025, 17, 3274. https://doi.org/10.3390/polym17243274

Ecemis AS, Karalar M, Beskopylny AN, Stel’makh SA, Shcherban’ EM, Aksoylu C, Madenci E, Özkılıç YO. The Influence of Fiber-Form Waste Tire Aggregates on the Flexural Strength, Ductility, and Energy Dissipation of Pultruded GFRP–Rubberized Concrete Hybrid Beams. Polymers. 2025; 17(24):3274. https://doi.org/10.3390/polym17243274

Chicago/Turabian StyleEcemis, Ali Serdar, Memduh Karalar, Alexey N. Beskopylny, Sergey A. Stel’makh, Evgenii M. Shcherban’, Ceyhun Aksoylu, Emrah Madenci, and Yasin Onuralp Özkılıç. 2025. "The Influence of Fiber-Form Waste Tire Aggregates on the Flexural Strength, Ductility, and Energy Dissipation of Pultruded GFRP–Rubberized Concrete Hybrid Beams" Polymers 17, no. 24: 3274. https://doi.org/10.3390/polym17243274

APA StyleEcemis, A. S., Karalar, M., Beskopylny, A. N., Stel’makh, S. A., Shcherban’, E. M., Aksoylu, C., Madenci, E., & Özkılıç, Y. O. (2025). The Influence of Fiber-Form Waste Tire Aggregates on the Flexural Strength, Ductility, and Energy Dissipation of Pultruded GFRP–Rubberized Concrete Hybrid Beams. Polymers, 17(24), 3274. https://doi.org/10.3390/polym17243274