Physicochemical and Mechanical Characterization of HDPE and LDPE Films Used in the Postharvest Packaging of Banana (Musa paradisiaca)

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection and Treatment

2.2. Physicochemical Characterization

2.2.1. Atomic Absorption Spectroscopy (AAS)

2.2.2. Differential Scanning Calorimetry (DSC)

2.2.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.2.4. Thermogravimetric Analysis (TGA)

2.3. Mechanical Characterization

Tensile Testing

3. Results

3.1. Atomic Absorption Spectroscopy (AAS)

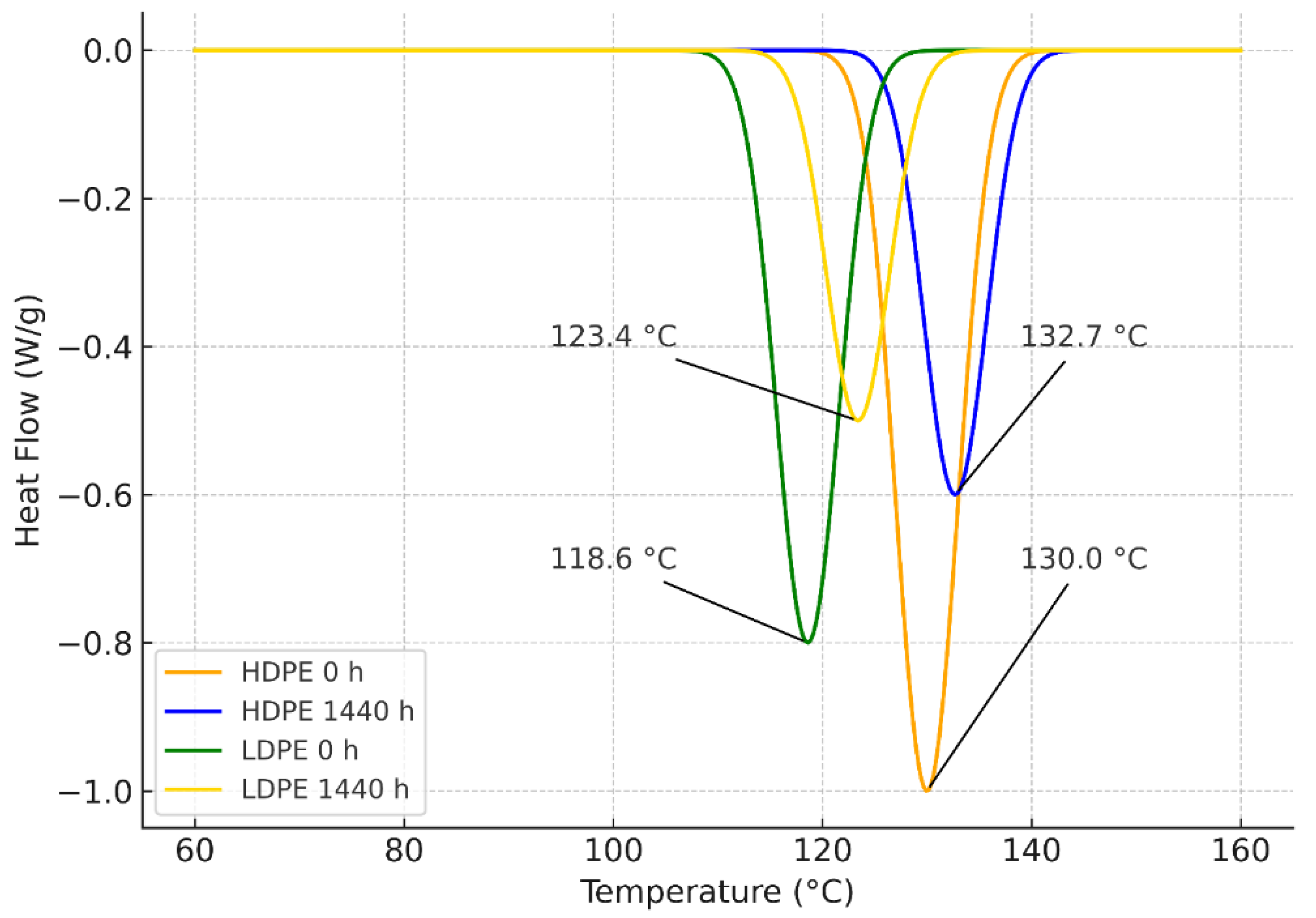

3.2. Differential Scanning Calorimetry (DSC)

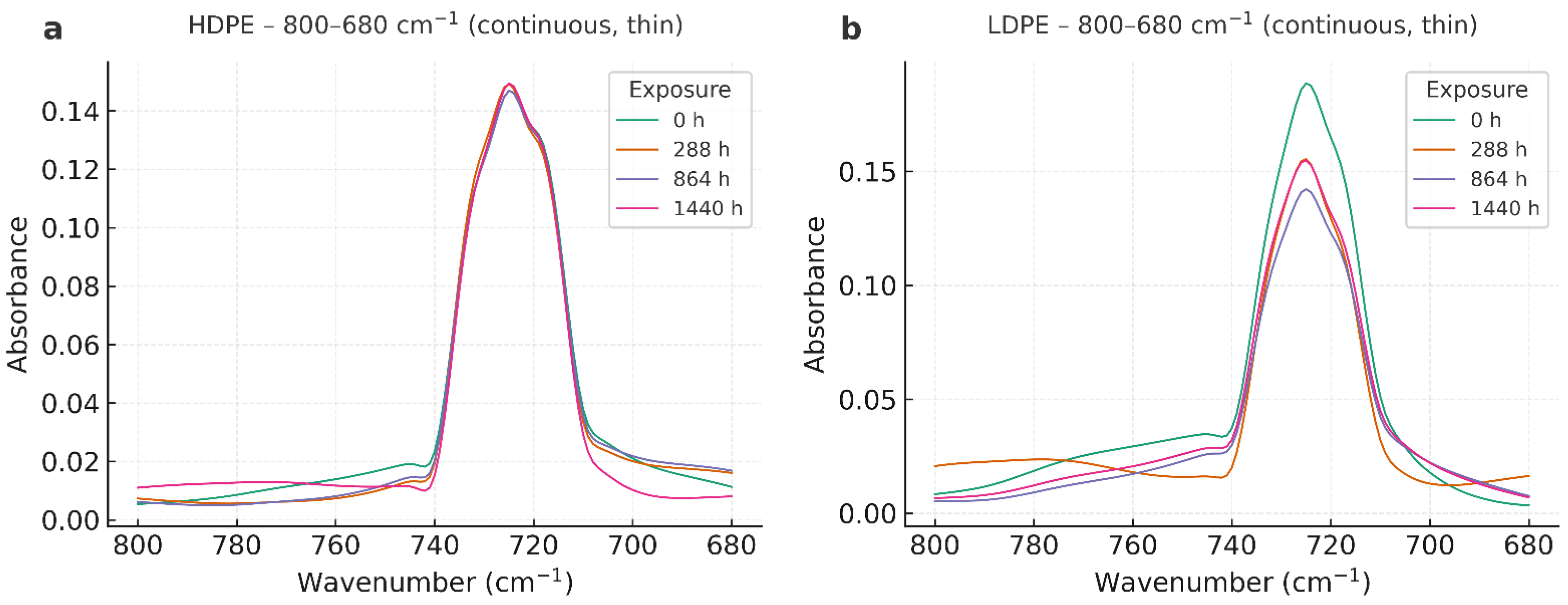

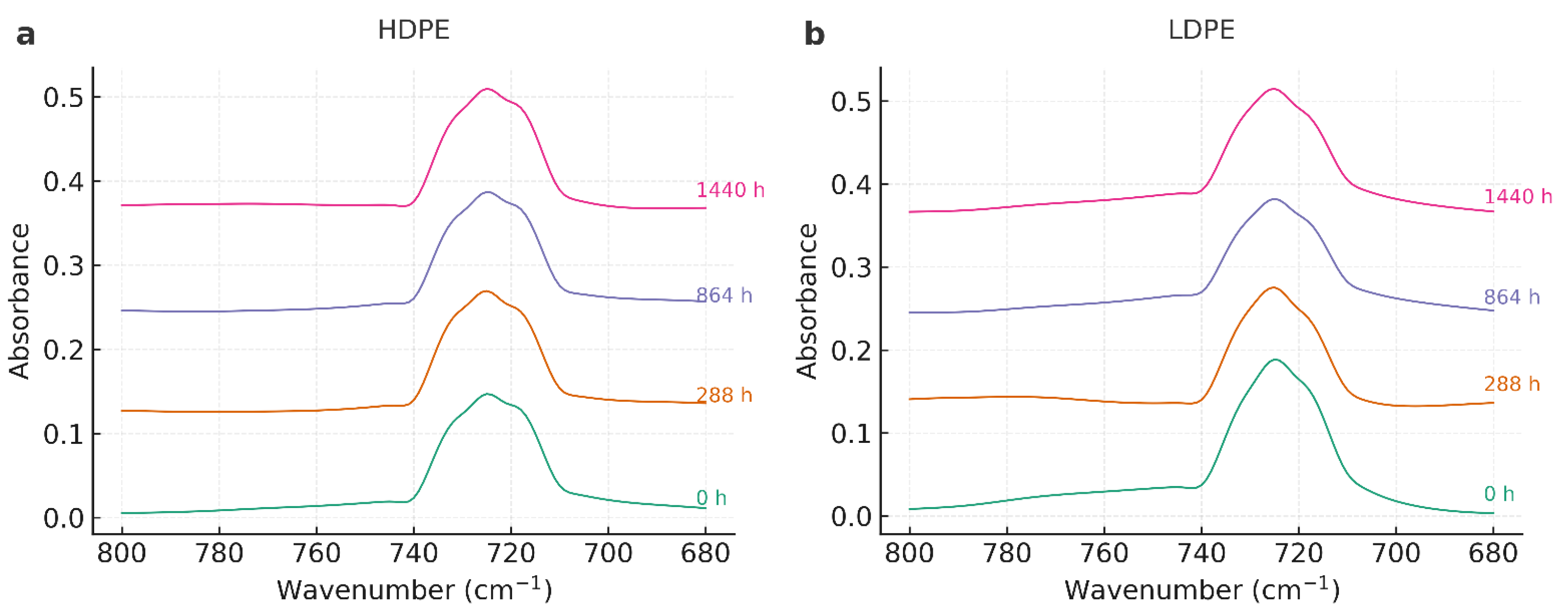

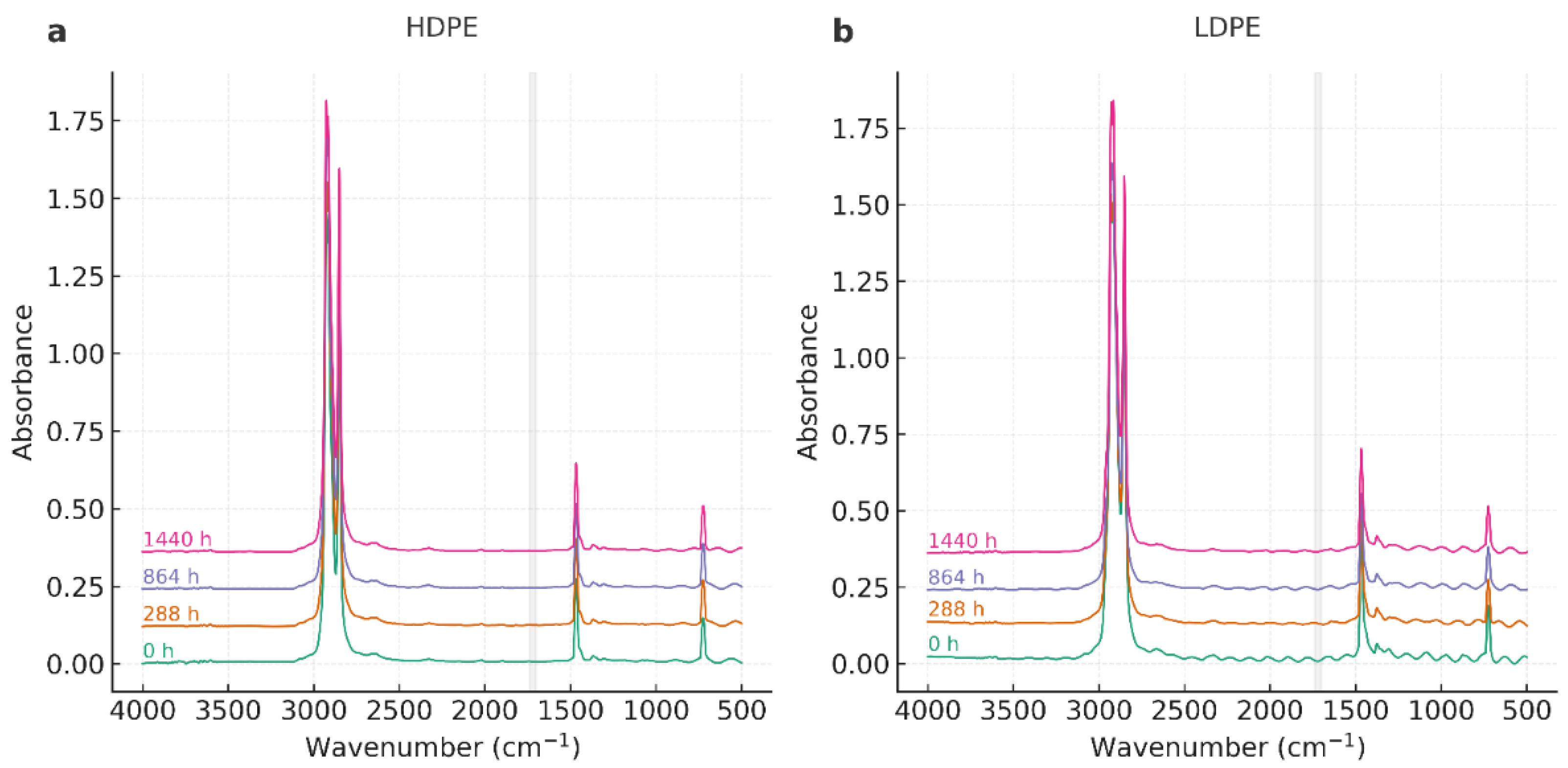

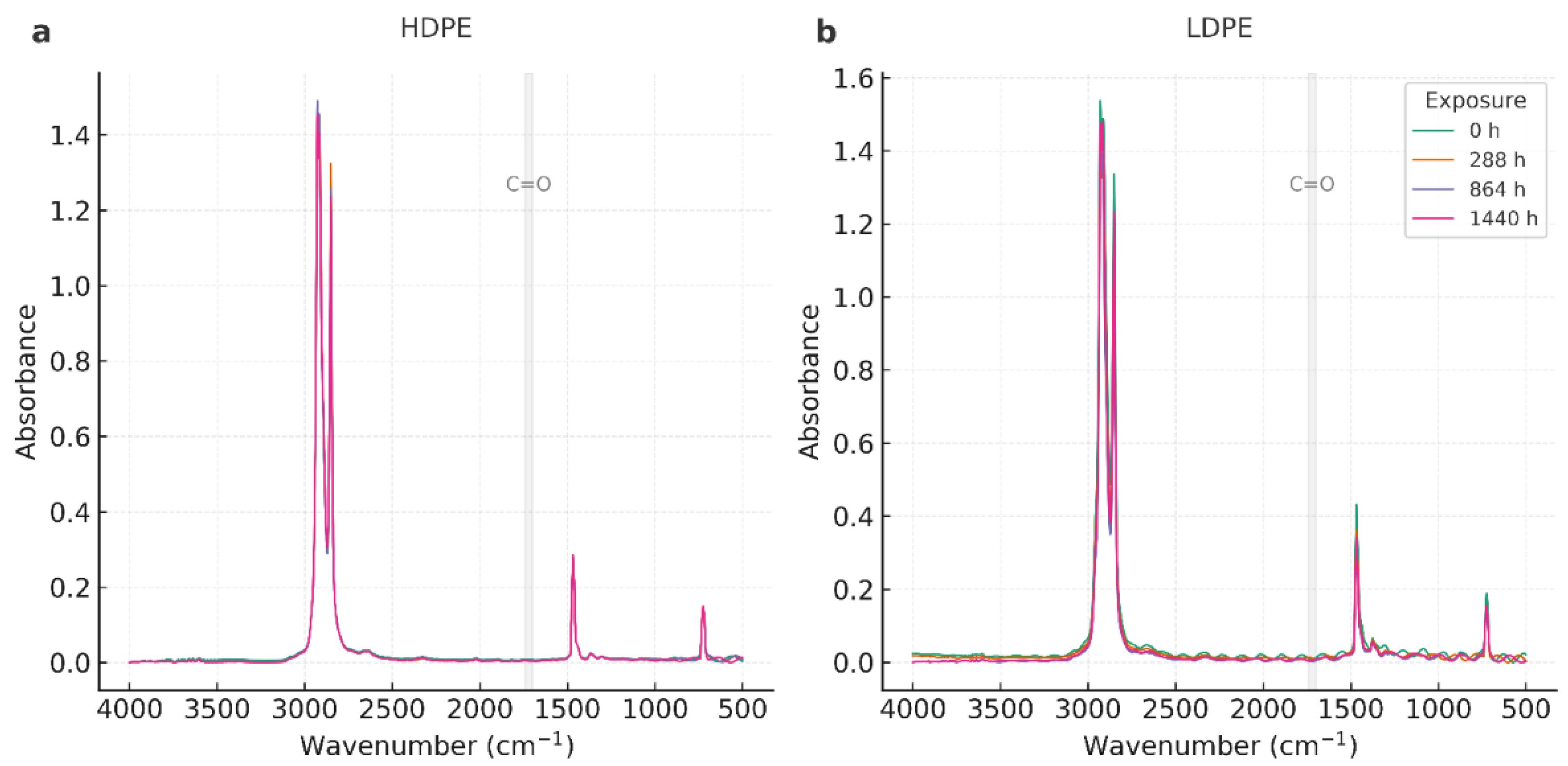

3.3. Fourier Transform Infrared Spectroscopy (FTIR)

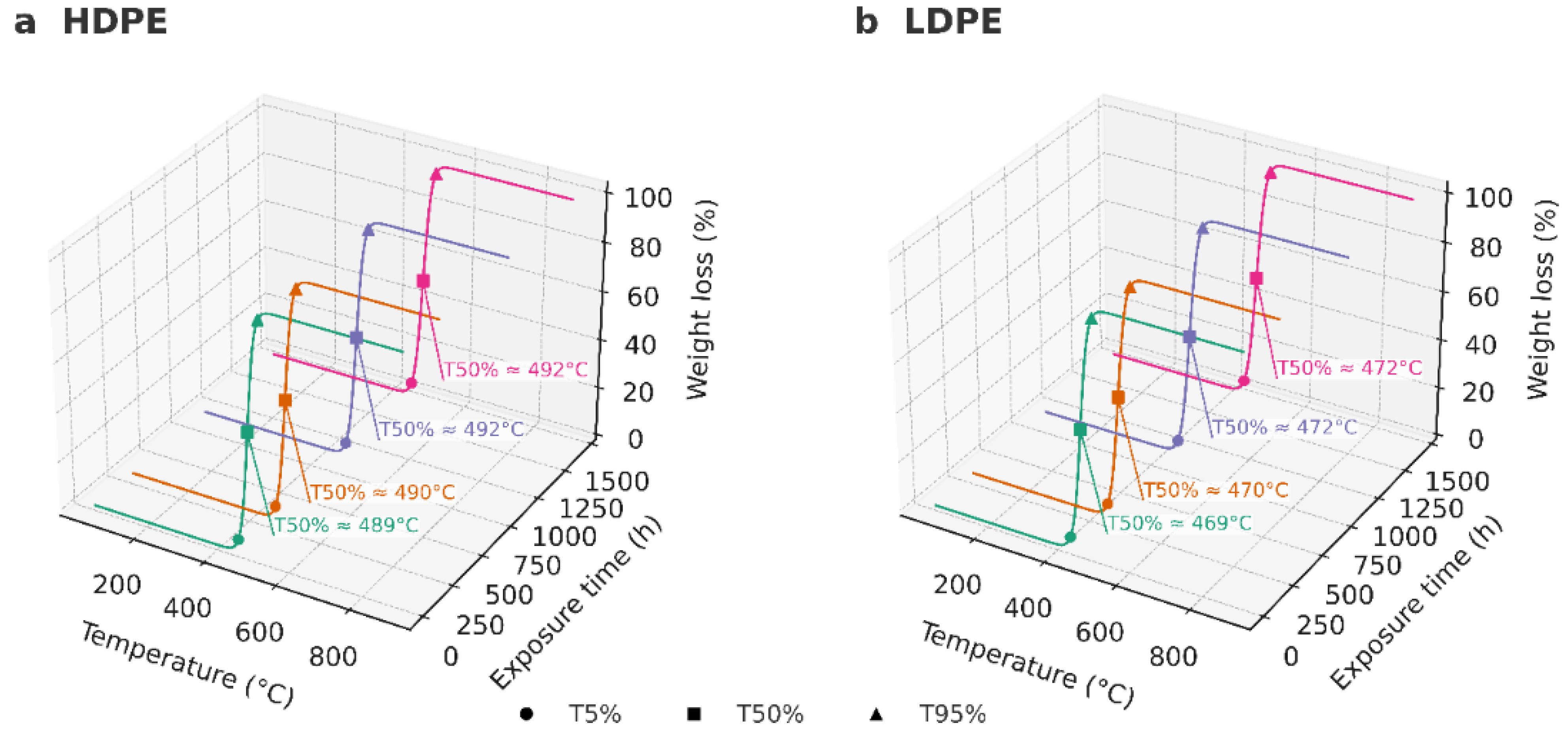

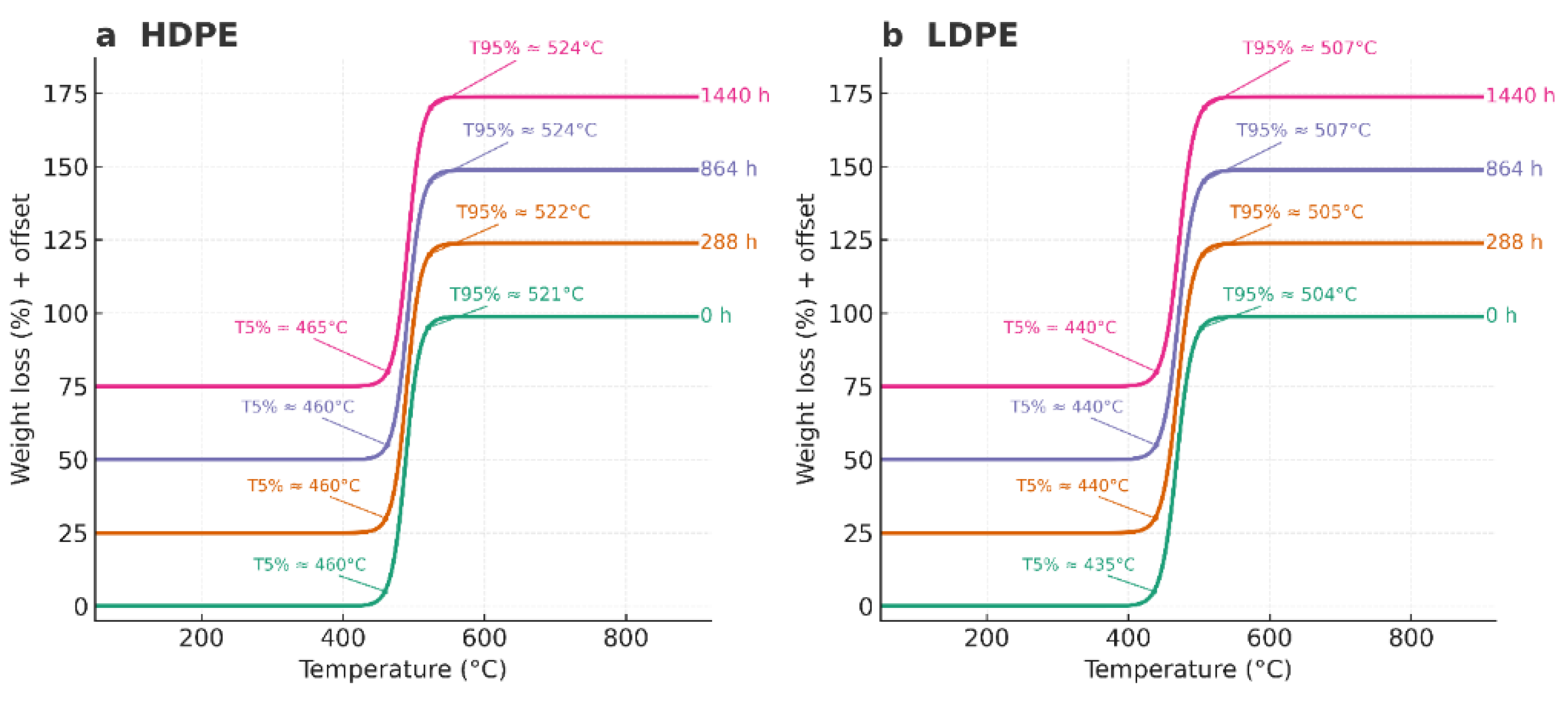

3.4. Thermogravimetric Analysis (TGA)

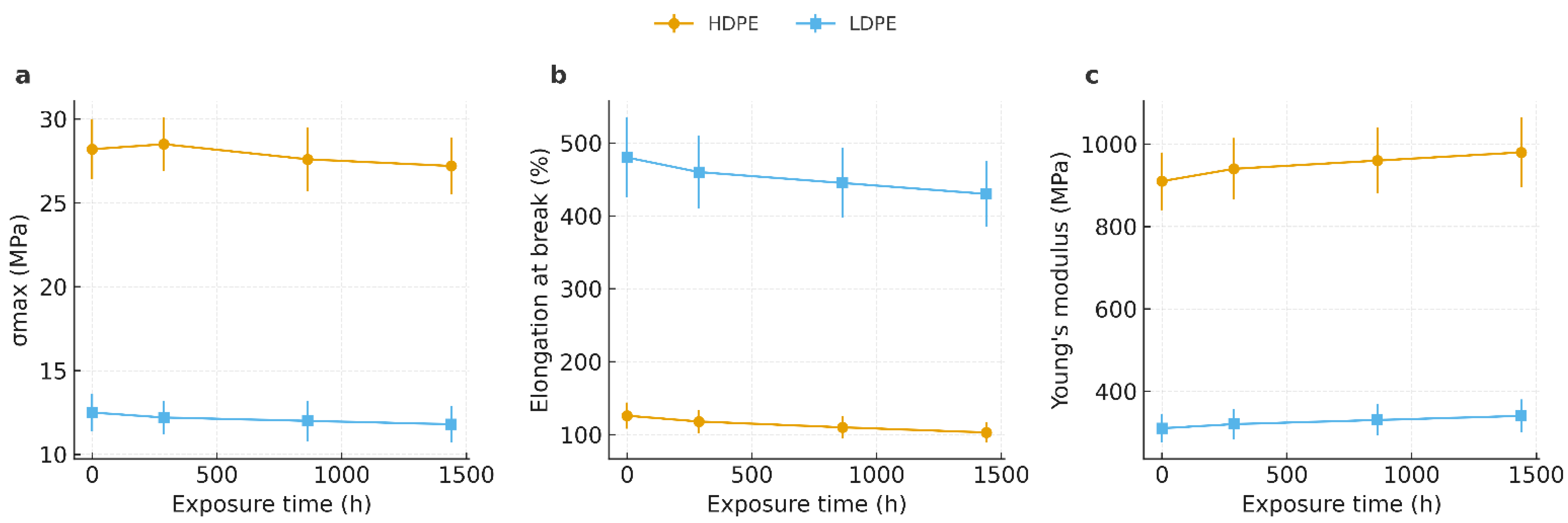

3.5. Tensile Testing

4. Discussion

4.1. Atomic Absorption Spectroscopy (AAS)

4.2. Differential Scanning Calorimetry (DSC)

4.3. Fourier Transform Infrared Spectroscopy (FTIR)

4.4. Thermogravimetric Analysis (TGA)

4.5. Tensile Testing

5. Conclusions

- This study provided an integrated physicochemical and mechanical evaluation of HDPE and LDPE films used in the postharvest packaging of banana (Musa paradisiaca) under controlled storage conditions (13 °C, 95% RH, 0–1440 h). HDPE contained trace levels of Zn (0.82–0.94 mg/100 g), whereas LDPE was zinc-free, highlighting the need to monitor metallic residues in food-contact materials.

- Thermal and spectroscopic analyses confirmed that both polymers preserved their structural integrity, with no carbonyl formation or oxidative degradation. HDPE exhibited higher melting and thermal stability (Tm = 129.8–137.5 °C; Tmax ≈ 492 °C) and partial recrystallization after 1440 h, while LDPE showed lower stability but maintained consistent molecular characteristics.

- Mechanically, HDPE showed greater tensile strength (≈28 MPa) and stiffness (E ≈ 950 MPa), whereas LDPE retained higher ductility (ε_b ≈ 480 → 430%), demonstrating the typical stiffness–flexibility trade-off between both materials. Both films preserved mechanical integrity throughout storage, confirming their suitability for banana postharvest packaging: HDPE is recommended where structural stability and impact resistance are required, while LDPE offers better flexibility for handling and wrapping applications.

- Although this study was performed under inert laboratory conditions, future work should address photo-oxidative aging, additive migration, and the development of recyclable or hybrid PE–biopolymer systems aimed at improving sustainability and performance in tropical fruit export chains.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lennert, J.; Kovács, K.; Koós, B.; Swain, N.; Bálint, C.; Hamza, E.; Király, G.; Rácz, K.; Váradi, M.M.; Kovács, A.D. Climate Change, Pressures, and Adaptation Capacities of Farmers: Empirical Evidence from Hungary. Horticulturae 2024, 10, 56. [Google Scholar] [CrossRef]

- Doyeni, M.O.; Stulpinaite, U.; Baksinskaite, A.; Suproniene, S.; Tilvikiene, V. The Effectiveness of Digestate Use for Fertilization in an Agricultural Cropping System. Plants 2021, 10, 1734. [Google Scholar] [CrossRef] [PubMed]

- Ruiz Medina, M.D.; Ruales, J. Post-Harvest Alternatives in Banana Cultivation. Agronomy 2024, 14, 2109. [Google Scholar] [CrossRef]

- Kikulwe, E.M.; Okurut, S.; Ajambo, S.; Nowakunda, K.; Stoian, D.; Naziri, D. Postharvest Losses and their Determinants: A Challenge to Creating a Sustainable Cooking Banana Value Chain in Uganda. Sustainability 2018, 10, 2381. [Google Scholar] [CrossRef]

- Rodov, V.; Porat, R.; Sabag, A.; Kochanek, B.; Friedman, H. Microperforated Compostable Packaging Extends Shelf Life of Ethylene-Treated Banana Fruit. Foods 2022, 11, 1086. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, Y.; Zheng, X.; Yu, T.; Yan, F. Enhancement of biocontrol efficacy of Kluyveromyces marxianus induced by N-acetylglucosamine against Penicillium expansum. Food Chem. 2023, 404, 134658. [Google Scholar] [CrossRef]

- Shinga, M.H.; Silue, Y.; Fawole, O. Recent Advancements and Trends in Postharvest Application of Edible Coatings on Bananas: A Comprehensive Review. Plants 2025, 14, 581. [Google Scholar] [CrossRef]

- Medina, M.D.R.; Quimbita Yupangui, Y.; Artés-Hernández, F.; Ruales, J. Combined Effect of Antifungal Coating and Polyethylene Packaging on the Quality of Banana During Storage. Agronomy 2025, 15, 2028. [Google Scholar] [CrossRef]

- Bordón, P.; Paz, R.; Peñalva, C.; Vega, G.; Monzón, M.; García, L. Biodegradable Polymer Compounds Reinforced with Banana Fiber for the Production of Protective Bags for Banana Fruits in the Context of Circular Economy. Agronomy 2021, 11, 242. [Google Scholar] [CrossRef]

- Esguerra, E.; Del Carmen, D.; Reyes, R.D.; Lualhati, R.A. Vacuum Packaging Controlled Crown Rot of Organically-Grown Balangon (Musa acuminata AAA Group) Banana. Horticulturae 2017, 3, 14. [Google Scholar] [CrossRef]

- Ruiz Medina, M.D.; Ruales, J. Essential Oils as an Antifungal Alternative to Control Several Species of Fungi Isolated from Musa paradisiaca: Part II. Microorganisms 2025, 13, 2477. [Google Scholar] [CrossRef]

- Xiao, L.; Jiang, X.; Deng, Y.; Xu, K.; Duan, X.; Wan, K.; Tang, X. Study on Characteristics and Lignification Mechanism of Postharvest Banana Fruit During Chilling Injury. Foods 2023, 12, 1097. [Google Scholar] [CrossRef] [PubMed]

- Ruiz Medina, M.D.; Ávila, J.; Ruales, J. Diseño de Un Recubrimiento Comestible Bioactivo Para Aplicarlo en la Frutilla (Fragaria vesca) Como Proceso de Postcosecha. Rev. Iberoam. Tecnol. Postcosecha 2016, 17, 276–287. [Google Scholar]

- Guo, J.; Duan, J.; Yang, Z.; Karkee, M. De-Handing Technologies for Banana Postharvest Operations—Updates and Challenges. Agriculture 2022, 12, 1821. [Google Scholar] [CrossRef]

- Gouda, M.H.B.; Duarte-Sierra, A. An Overview of Low-Cost Approaches for the Postharvest Storage of Fruits and Vegetables for Smallholders, Retailers, and Consumers. Horticulturae 2024, 10, 803. [Google Scholar] [CrossRef]

- Wang, T.; Song, Y.; Lai, L.; Fang, D.; Li, W.; Cao, F.; Su, E. Sustaining freshness: Critical review of physiological and biochemical transformations and storage techniques in postharvest bananas. Food Packag. Shelf Life 2024, 46, 101386. [Google Scholar] [CrossRef]

- Ruiz Medina, M.D.; Quimbita Yupangui, Y.; Ruales, J. Effect of a Protein–Polysaccharide Coating on the Physicochemical Properties of Banana (Musa paradisiaca) During Storage. Coatings 2025, 15, 812. [Google Scholar] [CrossRef]

- Katsarov, P.; Shindova, M.; Lukova, P.; Belcheva, A.; Delattre, C.; Pilicheva, B. Polysaccharide-Based Micro- and Nanosized Drug Delivery Systems for Potential Application in the Pediatric Dentistry. Polymers 2021, 13, 3342. [Google Scholar] [CrossRef]

- Ganvit, V.M.; Patel, V.; Patel, M.; Dharva, A.; Sharma, R.K. Synthesis, physicochemical and thermal properties of urethane-modified polyesteramide films using mahua and castor oil as sustainable resources. J. Appl. Polym. Sci. 2024, 141, e54872. [Google Scholar] [CrossRef]

- Nirere, A.; Sun, J.; Kama, R.; Atindana, V.A.; Nikubwimana, F.D.; Dusabe, K.D.; Zhong, Y. Nondestructive detection of adulterated wolfberry (Lycium chinense) fruits based on hyperspectral imaging technology. J. Food Process Eng. 2023, 46, e14293. [Google Scholar] [CrossRef]

- An, W.; Hu, K.; Wang, T.; Peng, L.; Li, S.; Hu, X. Effects of Overlap Length on Flammability and Fire Hazard of Vertical Polymethyl Methacrylate (PMMA) Plate Array. Polymers 2020, 12, 2826. [Google Scholar] [CrossRef]

- Lin, C.-L.; Cheng, T.-L.; Wu, N.-J. Micropatterned Poly(3,4-ethylenedioxythiophene) Thin Films with Improved Color-Switching Rates and Coloration Efficiency. Polymers 2022, 14, 2951. [Google Scholar] [CrossRef]

- Shourove, J.H.; Islam, G.R.; Eti, S.A.; Rahman, M.M. Migration of heavy metals from disposable food containers to food and potential health risks. J. Food Compos. Anal. 2025, 144, 107686. [Google Scholar] [CrossRef]

- Mustatea, G.; Mocanu, A.L.; Stroe, C.A.; Ungureanu, E.L. Toxic Metals Migration from Plastic Food Contact Materials in Romania: A Health Risk Assessment. Appl. Sci. 2024, 14, 10985. [Google Scholar] [CrossRef]

- Arman Alim, A.A.; Baharum, A.; Mohammad Shirajuddin, S.S.; Anuar, F.H. Blending of Low-Density Polyethylene and Poly(Butylene Succinate) (LDPE/PBS) with Polyethylene–Graft–Maleic Anhydride (PE–g–MA) as a Compatibilizer on the Phase Morphology, Mechanical and Thermal Properties. Polymers 2023, 15, 261. [Google Scholar] [CrossRef] [PubMed]

- Tarani, E.; Pušnik Črešnar, K.; Zemljič, L.F.; Chrissafis, K.; Papageorgiou, G.Z.; Lambropoulou, D.; Zamboulis, A.; Bikiaris, D.N.; Terzopoulou, Z. Cold Crystallization Kinetics and Thermal Degradation of PLA Composites with Metal Oxide Nanofillers. Appl. Sci. 2021, 11, 3004. [Google Scholar] [CrossRef]

- Rubiano-Navarrete, A.F.; Rodríguez Sandoval, P.; Torres Pérez, Y.; Gómez-Pachón, E.Y. Effect of Fiber Loading on Green Composites of Recycled HDPE Reinforced with Banana Short Fiber: Physical, Mechanical and Morphological Properties. Polymers 2024, 16, 3299. [Google Scholar] [CrossRef] [PubMed]

- Lynch, J.M.; Corniuk, R.N.; Brignac, K.C.; Jung, M.R.; Sellona, K.; Marchiani, J.; Weatherford, W. Differential scanning calorimetry (DSC): An important tool for polymer identification and characterization of plastic marine debris. Environ. Pollut. 2024, 346, 123607. [Google Scholar] [CrossRef]

- Leyva, C.; Cruz-Alcantar, P.; Espinoza-Solis, V.; Martínez-Guerra, E.; Piñon-Balderrama, C.; Compean, I.; Saavedra, M. Application of Differential Scanning Calorimetry (DSC) and Modulated Differential Scanning Calorimetry (MDSC) in Food and Drug Industries. Polymers 2020, 12, 5. [Google Scholar] [CrossRef]

- Heimowska, A. Environmental Degradation of Oxo-Biodegradable Polyethylene Bags. Water 2023, 15, 4059. [Google Scholar] [CrossRef]

- Campanale, C.; Savino, I.; Massarelli, C.; Uricchio, V.F. Fourier Transform Infrared Spectroscopy to Assess the Degree of Alteration of Artificially Aged and Environmentally Weathered Microplastics. Polymers 2023, 15, 911. [Google Scholar] [CrossRef]

- Kowalczyk, P.; Kadac-Czapska, K.; Grembecka, M. Polyethylene Packaging as a Source of Microplastics: Current Knowledge and Future Directions on Food Contamination. Foods 2025, 14, 2408. [Google Scholar] [CrossRef]

- Rampazzo, F.; Calace, N.; Formalewicz, M.; Noventa, S.; Gion, C.; Bongiorni, L.; De Lazzari, A.; Causin, V.; Berto, D. An FTIR and EA-IRMS Application to the Degradation Study of Compostable Plastic Bags in the Natural Marine Environment. Appl. Sci. 2023, 13, 10851. [Google Scholar] [CrossRef]

- Henn, A.S.; Frohlich, A.C.; Pedrotti, M.F.; Cauduro, V.H.; Oliveira, M.L.S.; de Flores, E.M.M.; Bizzi, C.A. Microwave-Assisted Solid Sampling Analysis Coupled to Flame Furnace Atomic Absorption Spectrometry for Cd and Pb Determination in Food-Contact Polymers. Sustainability 2022, 14, 291. [Google Scholar] [CrossRef]

- Di Duca, F.; Montuori, P.; de Rosa, E.; de Simone, B.; Scippa, S.; Dadà, G.; Triassi, M. Advancing Analytical Techniques in PET and rPET: Development of an ICP–MS Method for the Analysis of Trace Metals and Rare Earth Elements. Foods 2024, 13, 2716. [Google Scholar] [CrossRef]

- Nhanga, M.C.; Geraldo, D.; Nhapulo, S.L.; João, A.F.; Carneiro, J.; Costa, M.F.M. Evaluation of Heavy Metal Content in Plastic Bags Used as Improvised Food Cooking Covers: A Case Study from the Mozambican Community. Sustainability 2025, 17, 964. [Google Scholar] [CrossRef]

- Shah, Y.A.; Bhatia, S.; Al-Harrasi, A.; Afzaal, M.; Saeed, F.; Anwer, M.K.; Khan, M.R.; Jawad, M.; Akram, N.; Faisal, Z. Mechanical Properties of Protein-Based Food Packaging Materials. Polymers 2023, 15, 1724. [Google Scholar] [CrossRef] [PubMed]

- Ballestar de las Heras, R.; Colom, X.; Cañavate, J. Comparative Analysis of the Effects of Incorporating Post-Industrial Recycled LLDPE and Post-Consumer PE in Films: Macrostructural and Microstructural Perspectives in the Packaging Industry. Polymers 2024, 16, 916. [Google Scholar] [CrossRef] [PubMed]

- Suárez, F.; Conchillo, J.J.; Gálvez, J.C.; Casati, M.J. Macro Photography as an Alternative to the Stereoscopic Microscope in the Standard Test Method for Microscopical Characterisation of the Air-Void System in Hardened Concrete: Equipment and Methodology. Materials 2018, 11, 1515. [Google Scholar] [CrossRef] [PubMed]

- de Souza, A.M.N.; Avila, L.B.; Contessa, C.R.; Valério Filho, A.; de Rosa, G.S.; Moraes, C.C. Biodegradation Study of Food Packaging Materials: Assessment of the Impact of the Use of Different Biopolymers and Soil Characteristics. Polymers 2024, 16, 2940. [Google Scholar] [CrossRef]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-Based Sustainable Food Packaging Materials: Challenges, Solutions, and Applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Fedotova, O.; Myalenko, D.; Pryanichnikova, N.; Yurova, E.; Agarkova, E. Microscopic and Structural Studies of an Antimicrobial Polymer Film Modified with a Natural Filler Based on Triterpenoids. Polymers 2022, 14, 1097. [Google Scholar] [CrossRef]

- Breheny, C.; Colbert, D.M.; Bezerra, G.; Geever, J.; Geever, L.M. Towards Sustainable Food Packaging: Mechanical Recycling Effects on Thermochromic Polymers Performance. Polymers 2025, 17, 1042. [Google Scholar] [CrossRef] [PubMed]

- Yetgin, S.; Ağırsaygın, M.; Yazgan, İ. Smart Food Packaging Films Based on a Poly(lactic acid), Nanomaterials, and a pH Sensitive Dye. Processes 2025, 13, 1105. [Google Scholar] [CrossRef]

- Wang, H.; Liao, Y.; Zhu, G.; Wang, L.; Chen, Z.; Li, X.; Wang, C.; Yu, J.; Song, P. Development of Double-Film Composite Food Packaging with UV Protection and Microbial Protection for Cherry Preservation. Foods 2025, 14, 2283. [Google Scholar] [CrossRef]

- Kao, Y.-C.; Lin, J.-Y.; Chen, W.-C.; Gamal Mohamed, M.; Huang, C.-F.; Chen, J.-H.; Kuo, S.-W. High-Thermal Stable Epoxy Resin Through Blending Nanoarchitectonics with Double-Decker-Shaped Polyhedral Silsesquioxane-Functionalized Benzoxazine Derivatives. Polymers 2024, 16, 112. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Lin, N.; Lan, H.; Li, Q.; Yao, D.; Tang, J. A Review of Degradation and Life Prediction of Polyethylene. Appl. Sci. 2023, 13, 3045. [Google Scholar] [CrossRef]

- Suraci, S.V.; Fabiani, D.; Mazzocchetti, L.; Giorgini, L. Degradation Assessment of Polyethylene-Based Material Through Electrical and Chemical-Physical Analyses. Energies 2020, 13, 650. [Google Scholar] [CrossRef]

- Frigione, M.; Rodríguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Plota, A.; Masek, A. Lifetime Prediction Methods for Degradable Polymeric Materials—A Short Review. Materials 2020, 13, 4507. [Google Scholar] [CrossRef]

- Picuno, C.; Godosi, Z.; Santagata, G.; Picuno, P. Degradation of Low-Density Polyethylene Greenhouse Film Aged in Contact with Agrochemicals. Appl. Sci. 2024, 14, 10809. [Google Scholar] [CrossRef]

- Biale, G.; La Nasa, J.; Mattonai, M.; Corti, A.; Vinciguerra, V.; Castelvetro, V.; Modugno, F. A Systematic Study on the Degradation Products Generated from Artificially Aged Microplastics. Polymers 2021, 13, 1997. [Google Scholar] [CrossRef]

- Wang, X.; Chen, J.; Jia, W.; Huang, K.; Ma, Y. Comparing the Aging Processes of PLA and PE: The Impact of UV Irradiation and Water. Processes 2024, 12, 635. [Google Scholar] [CrossRef]

- Müller, M.; Kolář, V.; Mishra, R.K. Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste. Polymers 2024, 16, 2863. [Google Scholar] [CrossRef] [PubMed]

- Burelo, M.; Hernández-Varela, J.D.; Medina, D.I.; Treviño-Quintanilla, C.D. Recent developments in bio-based polyethylene: Degradation studies, waste management and recycling. Heliyon 2023, 9, e21374. [Google Scholar] [CrossRef] [PubMed]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Yan, H.; Li, W.; Chen, H.; Liao, Q.; Xia, M.; Wu, D.; Liu, C.; Chen, J.; Zou, L.; Peng, L.; et al. Effects of Storage Temperature, Packaging Material and Wash Treatment on Quality and Shelf Life of Tartary Buckwheat Microgreens. Foods 2022, 11, 3630. [Google Scholar] [CrossRef]

- Yang, T.; Skirtach, A.G. Nanoarchitectonics of Sustainable Food Packaging: Materials, Methods, and Environmental Factors. Materials 2025, 18, 1167. [Google Scholar] [CrossRef]

- Ding, J.; Hao, Y.; Liu, B.; Chen, Y.; Li, L. Development and Application of Poly (Lactic Acid)/Poly (Butylene Adipate-Co-Terephthalate)/Thermoplastic Starch Film Containing Salicylic Acid for Banana Preservation. Foods 2023, 12, 3397. [Google Scholar] [CrossRef]

- Kossalbayev, B.D.; Belkozhayev, A.M.; Abaildayev, A.; Kadirshe, D.K.; Tastambek, K.T.; Kurmanbek, A.; Toleutay, G. Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects. Polymers 2025, 17, 2224. [Google Scholar] [CrossRef]

- Panou, A.; Lazaridis, D.G.; Karabagias, I.K. Application of Smart Packaging on the Preservation of Different Types of Perishable Fruits. Foods 2025, 14, 1878. [Google Scholar] [CrossRef] [PubMed]

- Muthu, A.; Nguyen, D.H.H.; Neji, C.; Törős, G.; Ferroudj, A.; Atieh, R.; Prokisch, J.; El-Ramady, H.; Béni, Á. Nanomaterials for Smart and Sustainable Food Packaging: Nano-Sensing Mechanisms, and Regulatory Perspectives. Foods 2025, 14, 2657. [Google Scholar] [CrossRef] [PubMed]

- Clodoveo, M.L.; Crupi, P.; Muraglia, M.; Naeem, M.Y.; Tardugno, R.; Limongelli, F.; Corbo, F. The main phenolic compounds responsible for the antioxidant capacity of sweet cherry (Prunus avium L.) pulp. LWT 2023, 185, 115085. [Google Scholar] [CrossRef]

- Dash, K.K.; Deka, P.; Bangar, S.P.; Chaudhary, V.; Trif, M.; Rusu, A. Applications of Inorganic Nanoparticles in Food Packaging: A Comprehensive Review. Polymers 2022, 14, 521. [Google Scholar] [CrossRef]

- Shankar, V.S.; Thulasiram, R.; Priyankka, A.L.; Nithyasree, S.; Sharma, A.A. Applications of Nanomaterials on a Food Packaging System—A Review. Eng. Proc. 2024, 61, 4. [Google Scholar] [CrossRef]

- Kuan, H.T.N.; Tan, M.Y.; Hassan, M.Z.; Zuhri, M.Y.M. Evaluation of Physico-Mechanical Properties on Oil Extracted Ground Coffee Waste Reinforced Polyethylene Composite. Polymers 2022, 14, 4678. [Google Scholar] [CrossRef]

- Ruiz Medina, M.D.; Ruales, J. Essential Oils as an Antifungal Alternative for the Control of Various Species of Fungi Isolated from Musa paradisiaca: Part I. Microorganisms 2025, 13, 1827. [Google Scholar] [CrossRef]

- Guzmán-Armenteros, T.M.; Echeverría, A.; Ruales, J.; Ruiz-Medina, M.; Ramos-Guerrero, L. Enhancing the Postharvest Stability of Hass Avocado Through Vacuum Impregnation with Antioxidants. Foods 2025, 14, 3633. [Google Scholar] [CrossRef]

- Ruiz Medina, M.D.; Ruales, J. Essential Oils as an Antifungal Alternative to Control Several Species of Fungi Isolated from Musa paradisiaca: Part III. Microorganisms 2025, 13, 1663. [Google Scholar] [CrossRef]

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://store.astm.org/d3418-21.html (accessed on 1 September 2025).

- De las Heras, R.B.; Ayala, S.F.; Salazar, E.M.; Carrillo, F.; Cañavate, J.; Colom, X. Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films After Degradation in Storage Conditions. Polymers 2023, 15, 4154. [Google Scholar] [CrossRef]

| Code | Polyethylene Type | Exposure Time (h) | Condition/Series |

|---|---|---|---|

| T01 | HDPE (high-density) | 0 | Initial control |

| T02 | HDPE (high-density) | 288 | ≈12 days |

| T03 | HDPE (high-density) | 864 | ≈36 days |

| T04 | HDPE (high-density) | 1440 | ≈60 days |

| T05 | LDPE (low-density) | 0 | Initial control |

| T06 | LDPE (low-density) | 288 | ≈12 days |

| T07 | LDPE (low-density) | 864 | ≈36 days |

| T08 | LDPE (low-density) | 1440 | ≈60 days |

| Polyethylene Type | Exposure Time (h) | Condition/Series | Tm (°C) | Tonset (°C) | ΔHf (J/g) | Xc (%) | |

|---|---|---|---|---|---|---|---|

| T01 | HDPE (high-density) | 0 | Initial control | 130.0 ± 1.5 | 128.0 ± 1.0 | 3.20 ± 0.50 | 1.09 ± 0.17 |

| T02 | HDPE (high-density) | 288 | ≈12 days | 129.8 ± 1.2 | 128.5 ± 1.1 | 3.05 ± 0.90 | 1.04 ± 0.31 |

| T03 | HDPE (high-density) | 864 | ≈36 days | 137.5 ± 2.5 | 136.9 ± 2.8 | 0.15 ± 0.08 | 0.05 ± 0.03 |

| T04 | HDPE (high-density) | 1440 | ≈60 days | 132.7 ± 2.1 | 131.1 ± 2.6 | 1.40 ± 0.55 | 0.48 ± 0.19 |

| T05 | LDPE (low-density) | 0 | Initial control | 118.6 ± 2.1 | 116.9 ± 2.0 | 1.40 ± 0.80 | 0.48 ± 0.27 |

| T06 | LDPE (low-density) | 288 | ≈12 days | 123.7 ± 0.9 | 122.3 ± 1.0 | 1.55 ± 0.75 | 0.53 ± 0.25 |

| T07 | LDPE (low-density) | 864 | ≈36 days | 125.4 ± 1.6 | 123.6 ± 1.7 | 2.35 ± 0.95 | 0.80 ± 0.32 |

| T08 | LDPE (low-density) | 1440 | ≈60 days | 123.4 ± 0.8 | 122.0 ± 0.7 | 1.15 ± 0.65 | 0.39 ± 0.22 |

| Wavenumber (cm−1) | Assignment | Observation Across Time |

|---|---|---|

| ~2918, ~2848 | ν_as/ν_s(CH2) | Stable positions and relative intensities in all series. |

| ~1472, ~1463 | δ(CH2) (scissoring) | Stable; used as internal reference for qualitative indices. |

| ~730, ~720 | ρ_r(CH2) (orthorhombic) | Doublet preserved; no systematic loss—consistent with modest crystallinity changes. |

| 1700–1740 | C=O (carbonyl) | Not detected; Carbonyl Index effectively ~0 within noise. |

| 910–990 | =CH2/vinyl | Not evident; no unsaturation growth. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz Medina, M.D.; Ruales, J. Physicochemical and Mechanical Characterization of HDPE and LDPE Films Used in the Postharvest Packaging of Banana (Musa paradisiaca). Polymers 2025, 17, 3268. https://doi.org/10.3390/polym17243268

Ruiz Medina MD, Ruales J. Physicochemical and Mechanical Characterization of HDPE and LDPE Films Used in the Postharvest Packaging of Banana (Musa paradisiaca). Polymers. 2025; 17(24):3268. https://doi.org/10.3390/polym17243268

Chicago/Turabian StyleRuiz Medina, Maritza D., and Jenny Ruales. 2025. "Physicochemical and Mechanical Characterization of HDPE and LDPE Films Used in the Postharvest Packaging of Banana (Musa paradisiaca)" Polymers 17, no. 24: 3268. https://doi.org/10.3390/polym17243268

APA StyleRuiz Medina, M. D., & Ruales, J. (2025). Physicochemical and Mechanical Characterization of HDPE and LDPE Films Used in the Postharvest Packaging of Banana (Musa paradisiaca). Polymers, 17(24), 3268. https://doi.org/10.3390/polym17243268