Advancing Polymer Science and Energy Storage Solutions Through the Integration of Artificial Intelligence and Machine Learning: A Transformative Approach

Abstract

1. Introduction

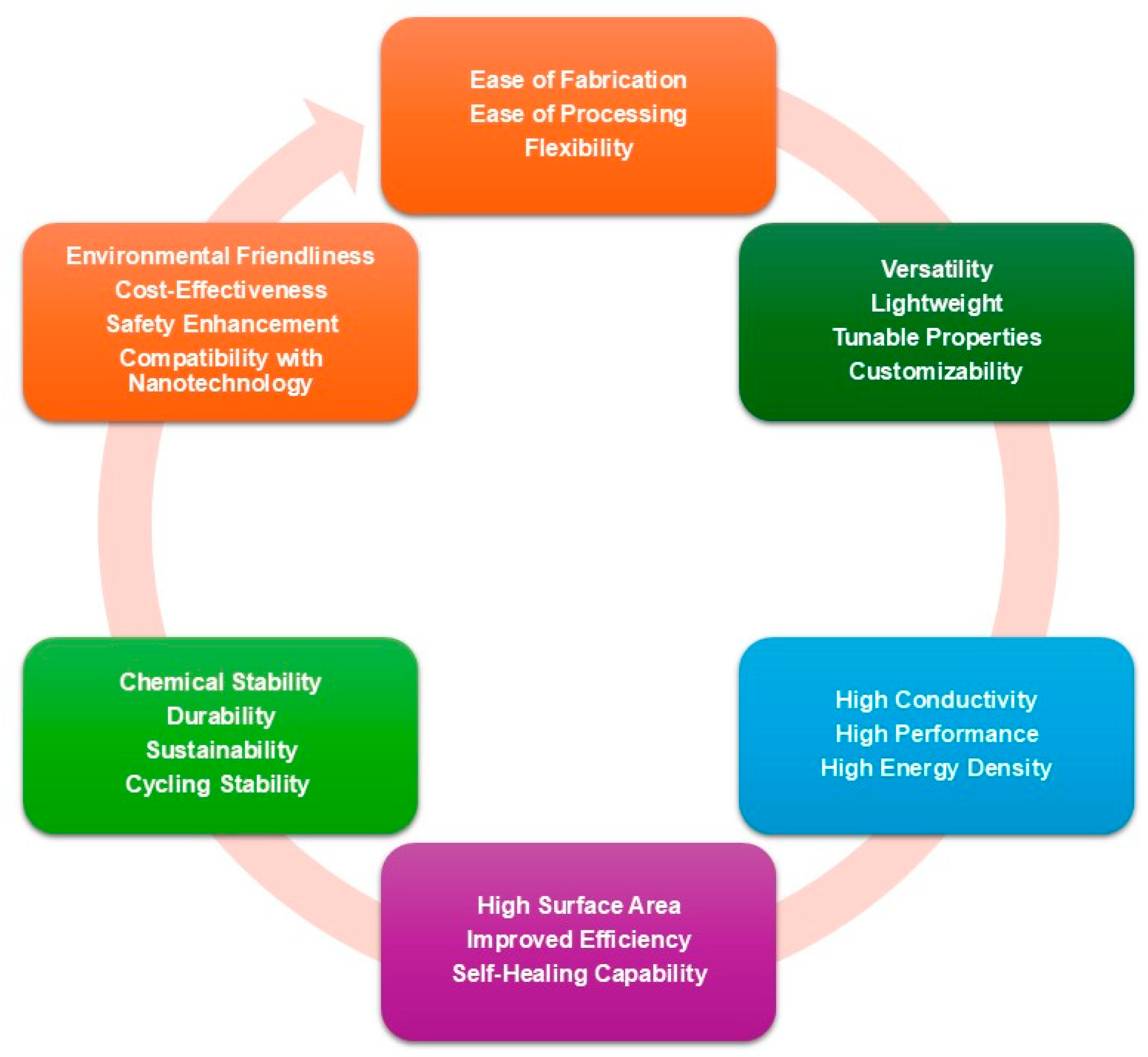

1.1. Exploring the Significance and Characteristics of Polymers in Energy Storage Solutions

1.2. Leveraging Machine Learning and Artificial Intelligence in Polymer Science: Innovations in Polymer Design and Characterization

1.3. Harnessing Artificial Intelligence and Machine Learning for Advancements in Polymer Energy Storage Solutions

1.4. Aim of This Contribution

- The absence of large, high-quality datasets for specific polymer types—such as crosslinked networks and functional polymers such as shape memory polymers (SMPs) and vitrimers—restricts the accuracy and generalizability of ML models.

- Existing structural representation methods, such as BigSMILES, struggle to encapsulate the complex topologies and morphological features of polymer networks, which hinders precise predictions.

- Polymers recommended by AI may often be challenging to synthesize at scale, which limits their practical application.

- The modeling of polymer composites, blends, and formulations remains a significant challenge because of intricate interactions and diverse transport mechanisms.

- Limited or biased datasets may contribute to overfitting, compromising the reliability of predictions.

- The integration of computational and experimental data, as well as the management of varying levels of fidelity, presents a technical obstacle.

- Compared with conventional petroleum-based plastics, AI-designed sustainable polymers, including bioplastics, frequently face cost and scalability challenges.

- The industrial-scale implementation of AI-driven polymer informatics is still in its early stages, facing hurdles in terms of technology transfer and acceptance.

- There is a notable lack of high-quality datasets for specialized applications such as polymer energy storage, particularly concerning properties such as ionic conductivity, dielectric constants, and breakdown strength.

- The mechanisms underlying charge traps and energy storage in polymers are highly intricate, which can lead AI models to oversimplify these phenomena.

- AI models frequently encounter difficulties in generalizing across various polymer systems or in predicting the properties of novel polymers that are not adequately represented in training datasets.

- Many AI models operate as “black boxes,” making it challenging to discern the mechanisms that drive their predictions.

- Current AI models often fail to adequately consider long-term reliability and the environmental factors that impact polymer performance.

- Predictions generated by AI and ML frameworks require extensive experimental validation, which can be both time-consuming and resource-intensive.

- A limited body of research has focused on leveraging AI for the optimization of manufacturing processes, such as crosslinking and blending, to create scalable polymer-based ESSs.

- The study provides a detailed review of the literature on the application of ML and AI in polymer science, polymer design, and characterization, as well as their use in energy storage for polymers. The study identifies the methods utilized in AI and ML and evaluates their contributions to advancing polymer science and energy storage research.

- The work systematically highlights gaps in the literature, such as data limitations, synthetic feasibility challenges, and the lack of integration of physical principles into AI models.

- The manuscript is organized into two distinct parts. The first part focuses on the various ML and AI methodologies applied in polymer science, specifically addressing aspects of polymer design and characterization. In contrast, the second part delves into the unique applications of ML and AI techniques tailored for polymer energy storage solutions. Together, these sections offer a comprehensive exploration of how advanced computational approaches are influencing and enhancing the study and development of polymers.

- The study provides a detailed analysis of the strengths and weaknesses of using AI and ML in polymer science and energy storage, offering insights into their transformative potential and limitations.

- The work proposes actionable future directions to address the identified gaps, such as expanding datasets, integrating physical principles, optimizing manufacturing processes, and fostering interdisciplinary collaboration.

- The study outlines a rigorous methodology for conducting literature reviews, including keyword searches, database selection, and exclusion criteria, ensuring a comprehensive and focused analysis.

- By synthesizing existing knowledge and identifying areas for improvement, the work aims to accelerate advancements in polymer science and energy storage research. It emphasizes the transformative role of AI and ML in enabling efficient, sustainable, and innovative solutions.

2. Methodology

- Conducted an extensive search via keywords such as “polymers + polymer science + polymer design + polymer characterization + artificial intelligence (AI) + machine learning (ML)” and “polymers + energy storage + artificial intelligence (AI) + machine learning (ML)”.

- Multiple databases were utilized for the literature search, including the Web of Science Core Collection, Scopus, and Google Scholar, which focused specifically on the Science Citation Index Expanded (SCIE) database.

- Included articles published between 2016 and 2025 to ensure that the review covers recent advancements.

- The exclusion criteria were as follows: proceedings papers, editorial materials, book chapters, and papers not published in English.

- A rigorous manual examination of the collected articles was conducted to ensure relevance and quality.

- The evaluation of the literature is organized into two distinct parts. Part 1 emphasizes the application of ML and AI in the field of polymer science, specifically addressing polymer design and characterization techniques. In contrast, Part 2 shifts the focus to the role of ML and AI in advancing polymer energy storage solutions. This structured analysis allows for a comprehensive understanding of how these cutting-edge technologies are transforming both the creation and functionality of polymers within different domains.

- Evaluated the AI and ML methods utilized in the reviewed studies. The contributions of these methods to polymer design, characterization, and energy storage research were assessed.

- Analyzed the strengths and weaknesses of using AI and ML in polymer science and energy storage.

- Proposed actionable future directions on the basis of the gaps identified in the literature.

3. Overview of Literature Studies

3.1. Machine Learning Approaches in Polymer Science: Polymer Design and Characterization via AI-ML

3.1.1. Analysis of Review Articles

3.1.2. An In-Depth Analysis of Scholarly Research Contributions

3.2. Artificial Intelligence Machine Learning Approaches for Polymers’ Energy Storage

3.2.1. Comprehensive Review Summary

3.2.2. An In-Depth Analysis of Scholarly Research Contributions

4. Comparative Analysis of Different Methodologies

5. Strengths and Weaknesses

5.1. Strengths and Weaknesses of Using Artificial Intelligence and Machine Learning in Polymer Science, Polymer Discovery, and the Design of Functional and Sustainable Polymers

5.2. Strengths and Weaknesses of Using Artificial Intelligence and Machine Learning for Polymers Energy Storage

6. Future Directions

7. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| AL | Active Learning |

| APIs | Application Programming Interfaces |

| BRR | Bayesian Ridge Regression |

| CGMD | Coarse-Grained Molecular Dynamics |

| CFs | Short-cut Carbon Fibers |

| CNTs | Carbon nanotubes |

| CPs | Conducting polymers |

| cryo-EM | Cryogenic electron microscopy |

| DCs | Dielectric capacitors |

| DFT | Density Functional Theory |

| DL | Deep learning |

| DT | Decision Tree |

| DTR | Decision Tree Regressor |

| D-MPNN | Directed Message Passing Neural Network |

| ECFP | Extended-Connectivity Fingerprints |

| EI | Expected Improvement |

| ELN | Ensemble Learner Network |

| ESDs | Energy storage devices |

| ESSs | Energy storage systems |

| FBS | Frequency-Based Selection |

| GA | Genetic algorithms |

| GAN | Generative Adversarial Networks |

| GB | Gradient Boosting |

| G-BigSMILES | Generative BigSMILES |

| GBR | Gradient Boosting Regressor |

| GNNs | Graph Neural Networks |

| GP | Gaussian Processes |

| GPR | Gaussian Process Regression |

| GPSR | Genetic Programming Symbolic Regression |

| IoT | Internet of Things |

| KDE | Kernel Density Estimation |

| KNN | K-Nearest Neighbor |

| KRR | Kernel Ridge Regression |

| LASSO | Least Absolute Shrinkage and Selection Operator |

| LCA | Life-Cycle Assessment |

| LCPs | Liquid crystalline polymers |

| LHS | Latin Hypercube Sampling |

| LIBs | Lithium-ion batteries |

| LLMs | Large Language Models |

| LR | Linear Regression |

| MDSs | Molecular Dynamics Simulations |

| ML | Machine learning |

| MLE | Mayo-Lewis Equation |

| MLP | Multilayer Perceptron |

| MSE | Mean squared error |

| MT | Multi-Task Learning |

| Mw | Molecular weight |

| MWD | Molecular weight distribution |

| NN | Neural Network |

| PA-12 | Polyamide 12 |

| PANI | Polyaniline |

| ParEGO | Pareto Efficient Global Optimization |

| PCA | Principal Component Analysis |

| PDMS | Polydimethylsiloxane |

| PEDOT | Poly(3,4-ethylenedioxythiophene) |

| PEDOT:PSS | Poly(3,4-ethylenedioxythiophene) doped with poly(4-styrenesulfonate) |

| PEMFC | Proton Exchange Membrane Fuel Cells |

| PENN | Physics-Enforced Neural Networks |

| PLA | Polylactic Acid |

| PNN | Probabilistic Neural Network |

| Ppy | Polypyrrole |

| PTh | Polythiophene |

| PU | Positive and Unlabeled |

| PVC | Polyvinyl chloride |

| R2 | Coefficient of Determination |

| RBFN | Radial Basis Function Network |

| RF | Random Forest |

| RFN | Random Forest Network |

| RFR | Random Forest Regression |

| RL | Reinforcement Learning |

| RSM | Response Surface Methodology |

| RMSE | Root Mean Square Error |

| RR | Ridge Regression |

| sBO | Bayesian Optimization |

| SCs | Supercapacitors |

| SCIE | Science Citation Index Expanded (SCI-Expanded) |

| SEM | Scanning Electron Microscope |

| SGDR | Stochastic Gradient Descent Regression |

| SHAP | SHapley Additive exPlanations |

| SMILES | Simplified molecular-input line-entry system |

| SMPs | Shape Memory Polymers |

| SNOBFIT | Simplex and Stable Noisy Optimization by Branch and Fit |

| SPEs | Solid polymer electrolytes |

| SR | Symbolic Regression |

| SSB | Solid-state battery |

| SVR | Support Vector Regression |

| SVM | Support Vector Machines |

| SVMR | Support Vector Machine Regression |

| TC | Thermal conductivity |

| TS-EMO | Thompson Sampling Efficient Multi-Objective |

| UMAP | Uniform Manifold Approximation and Projection |

| UWG | Underwater Granulation |

| VAE | Variational Autoencoders |

| VFS | Virtual Forward Synthesis |

| wD-MPNN | Weighted directed message passing neural network |

| XGBoost | Extreme Gradient Boosting |

References

- Depren, S.K.; Kartal, M.T.; Çelikdemir, N.Ç.; Depren, Ö. Energy consumption and environmental degradation nexus: A systematic review and meta-analysis of fossil fuel and renewable energy consumption. Ecol. Inform. 2022, 70, 101747. [Google Scholar] [CrossRef]

- Paramati, S.R.; Shahzad, U.; Doğan, B. The role of environmental technology for energy demand and energy efficiency: Evidence from OECD countries. Renew. Sust. Energ. Rev. 2022, 153, 111735. [Google Scholar] [CrossRef]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Pimenow, S.; Pimenowa, O.; Prus, P. Challenges of Artificial Intelligence Development in the Context of Energy Consumption and Impact on Climate Change. Energies 2024, 17, 5965. [Google Scholar] [CrossRef]

- Zheng, J.; Dang, Y.; Assad, U. Household energy consumption, energy efficiency, and household income–Evidence from China. Appl. Energy 2024, 353, 122074. [Google Scholar] [CrossRef]

- Amrouche, S.O.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrogen Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Bocklisch, T. Hybrid energy storage approach for renewable energy applications. J. Energy Storage 2016, 8, 311–319. [Google Scholar] [CrossRef]

- Zheng, B.; Lin, X.; Zhang, X.; Wu, D.; Matyjaszewski, K. Emerging Functional Porous Polymeric and Carbonaceous Materials for Environmental Treatment and Energy Storage. Adv. Funct. Mater. 2020, 30, 1907006. [Google Scholar] [CrossRef]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable Energy and Energy Storage Systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Aghmadi, A.; Mohammed, O.A. Energy Storage Systems: Technologies and High-Power Applications. Batteries 2024, 10, 141. [Google Scholar] [CrossRef]

- Czagany, M.; Hompoth, S.; Keshri, A.K.; Pandit, N.; Galambos, I.; Gacsi, Z.; Baumli, P. Supercapacitors: An Efficient Way for Energy Storage Application. Materials 2024, 17, 702. [Google Scholar] [CrossRef]

- Njema, G.G.; Ouma, R.B.O.; Kibet, J.K. A Review on the Recent Advances in Battery Development and Energy Storage Technologies. J. Renew. Energy 2024, 2024, 2329261. [Google Scholar] [CrossRef]

- Thakkar, P.; Khatri, S.; Dobariya, D.; Patel, D.; Dey, B.; Singh, A.K. Advances in materials and machine learning techniques for energy storage devices: A comprehensive review. J. Energy Storage 2024, 81, 110452. [Google Scholar] [CrossRef]

- Kopac, T. Electrochemical Energy Conversion and Storage Strategies. In Atomically Precise Electrocatalysts for Electrochemical Energy Applications; Gupta, R.K., Ed.; Springer: Cham, Switzerland, 2024; pp. 71–91. [Google Scholar] [CrossRef]

- Kopac, T. Evaluation of recent studies on electrochemical hydrogen storage by graphene-based materials: Impact of modification on overall effectiveness. Int. J. Hydrogen Energy 2024, 69, 777–803. [Google Scholar] [CrossRef]

- Kopac, T. Recent computational insights into hydrogen storage by MXene-based materials and shedding light on the storage mechanism. J. Energy Storage 2024, 97, 112807. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, M.; Huang, Y.; Pei, Z.; Li, H.; Wang, Z.; Xue, Q.; Zhi, C. Multifunctional Energy Storage and Conversion Devices. Adv. Mater. 2016, 28, 8344–8364. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Zhao, D. Mesoporous materials for energy conversion and storage devices. Nat. Rev. Mater. 2016, 1, 16023. [Google Scholar] [CrossRef]

- Wei, H.; Cui, D.; Ma, J.; Chu, L.; Zhao, X.; Song, H.; Liu, H.; Liu, T.; Wang, N.; Guo, Z. Energy conversion technologies towards self-powered electrochemical energy storage systems: The state of the art and perspectives. J. Mater. Chem. A 2017, 5, 1873–1894. [Google Scholar] [CrossRef]

- Abdel Maksoud, M.I.A.; Fahim, R.A.; Shalan, A.E.; Abd Elkodous, M.; Olojede, S.O.; Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.H.; Awed, A.S.; Ashour, A.H.; et al. Advanced materials and technologies for supercapacitors used in energy conversion and storage: A review. Environ. Chem. Lett. 2021, 19, 375–439. [Google Scholar] [CrossRef]

- Kopac, T. Exploring the impact of MXene-based materials on hydrogen storage performance: Experimental insights, applications, and challenges. Mater. Today Sustain. 2025, 31, 101173. [Google Scholar] [CrossRef]

- Nair, S.S.; Mishra, S.K.; Kumar, D. Review—Polymeric materials for energy harvesting and storage applications. Polym. Plast. Technol. Mater. 2021, 60, 626–649. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N. Polymeric Materials in Energy Conversion and Storage. Polymers 2024, 16, 3132. [Google Scholar] [CrossRef]

- Amin, K.; Ashraf, N.; Mao, L.; Faul, C.F.; Wei, Z. Conjugated microporous polymers for energy storage: Recent progress and challenges. Nano Energy 2021, 85, 105958. [Google Scholar] [CrossRef]

- Wu, X.; Chen, X.; Zhang, Q.M.; Tan, D.Q. Advanced dielectric polymers for energy storage. Energy Storage Mater. 2022, 44, 29–47. [Google Scholar] [CrossRef]

- Ismail, K.B.M.; Kumar, M.A.; Mahalingam, S.; Raj, B.; Kim, J. Carbon fiber-reinforced polymers for energy storage applications. J. Energy Storage 2024, 84, 110931. [Google Scholar] [CrossRef]

- Idumah, C.I.; Ezeani, E.O.; Nwuzor, I.C. A review: Advancements in conductive polymers nanocomposites. Polym. Plast. Technol. Mater. 2021, 60, 756–783. [Google Scholar] [CrossRef]

- Sumdani, M.G.; Islam, M.R.; Yahaya, A.N.A.; Safie, S.I. Recent advancements in synthesis, properties, and applications of conductive polymers for electrochemical energy storage devices: A review. Polym. Eng. Sci. 2022, 62, 269. [Google Scholar] [CrossRef]

- Masood, M.; Hussain, S.; Sohail, M.; Rehman, A.; Uzzaman, M.A.; Alnaser, I.A.; Karim, M.R.; Wahab, M.A. Recent Progress, Challenges, and Opportunities of Conducting Polymers for Energy Storage Applications. ChemistrySelect 2024, 9, e202302876. [Google Scholar] [CrossRef]

- Hasan, M.B.; Parvez, M.M.; Abir, A.Y.; Ahmad, M.F. A review on conducting organic polymers: Concepts, applications, and potential environmental benefits. Heliyon 2025, 11, e42375. [Google Scholar] [CrossRef] [PubMed]

- Gurunathan, K.; Murugan, A.V.; Marimuthu, R.; Mulik, U.P.; Amalnerkar, D.P. Electrochemically synthesised conducting polymeric materials for applications towards technology in electronics, optoelectronics and energy storage devices. Mater. Chem. Phys. 1999, 61, 173–191. [Google Scholar] [CrossRef]

- Abdelhamid, M.E.; O’Mullane, A.P.; Snook, G.A. Storing energy in plastics: A review on conducting polymers & their role in electrochemical energy storage. RSC Adv. 2015, 5, 11611–11626. [Google Scholar] [CrossRef]

- Shi, Y.; Peng, L.; Ding, Y.; Zhao, Y.; Yu, G. Nanostructured conductive polymers for advanced energy storage. Chem. Soc. Rev. 2015, 44, 6684–6696. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. Overview on conducting polymer in energy storage and energy conversion system. J. Macromol. Sci. Part A 2017, 54, 640–653. [Google Scholar] [CrossRef]

- Chen, G.; Shen, Z.; Iyer, A.; Ghumman, U.F.; Tang, S.; Bi, J.; Chen, W.; Li, Y. Machine-Learning-Assisted De Novo Design of Organic Molecules and Polymers: Opportunities and Challenges. Polymers 2020, 12, 163. [Google Scholar] [CrossRef]

- Cencer, M.M.; Moore, J.S.; Assary, R.S. Machine learning for polymeric materials: An introduction. Polym. Int. 2022, 71, 537–542. [Google Scholar] [CrossRef]

- Yan, C.; Li, G. The Rise of Machine Learning in Polymer Discovery. Adv. Intell. Syst. 2023, 5, 2200243. [Google Scholar] [CrossRef]

- Nasrin, T.; Pourkamali-Anaraki, F.; Peterson, A.M. Application of machine learning in polymer additive manufacturing: A review. J. Polym. Sci. 2024, 62, 2639. [Google Scholar] [CrossRef]

- Schuett, T.; Endres, P.; Standau, T.; Zechel, S.; Albuquerque, R.Q.; Brütting, C.; Ruckdäschel, H.; Schubert, U.S. Application of Digital Methods in Polymer Science and Engineering. Adv. Funct. Mater. 2024, 34, 2309844. [Google Scholar] [CrossRef]

- Tran, H.; Gurnani, R.; Kim, C.; Pilania, G.; Kwon, H.K.; Lively, R.P.; Ramprasad, R. Design of functional and sustainable polymers assisted by artificial intelligence. Nat. Rev. Mater. 2024, 9, 866–886. [Google Scholar] [CrossRef]

- Raza, Y.; Raza, H.; Ahmed, A.; Quazi, M.M.; Jamshaid, M.; Anwar, M.T.; Bashir, M.N.; Younas, T.; Jafry, A.T.; Soudagar, M.E.M. Integration of response surface methodology (RSM), machine learning (ML), and artificial intelligence (AI) for enhancing properties of polymeric nanocomposites—A review. Polym. Compos. 2025, 46, 13591–13627. [Google Scholar] [CrossRef]

- Xie, C.; Qiu, H.; Liu, L.; You, Y.; Li, H.; Li, Y.; Sun, Z.; Lin, J.; An, L. Machine Learning Approaches in Polymer Science: Progress and Fundamental for a New Paradigm. SmartMat 2025, 6, e1320. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, Y.; Sun, Z.; Yin, H.; Feng, Y. Machine learning in polymer science: A new lens for physical and chemical exploration. Prog. Mater. Sci. 2026, 156, 101544. [Google Scholar] [CrossRef]

- Dutta, R.; Renshaw, D.; Chen, C.; Liang, D. Machine learning based approach for shape memory polymer behavioural characterization. Array 2020, 7, 100036. [Google Scholar] [CrossRef]

- Aldeghi, M.; Coley, C.W. A graph representation of molecular ensembles for polymer property prediction. Chem. Sci. 2022, 13, 10486–10498. [Google Scholar] [CrossRef]

- Huang, X.; Ma, S.; Zhao, C.Y.; Wang, H.; Ju, S. Exploring high thermal conductivity polymers via interpretable machine learning with physical descriptors. npj Comput. Mater. 2023, 9, 191. [Google Scholar] [CrossRef]

- Shah, K.A.; Brütting, C.; Albuquerque, R.Q.; Ruckdäschel, H. Machine learning investigation of polylactic acid bead foam extrusion. J. Appl. Polym. Sci. 2024, 141, e55693. [Google Scholar] [CrossRef]

- Advincula, R.; Ivanov, I.N.; Vasudevan, R.K.; Kumar, R.; Christakopoulos, P.; Tsakinika, M.; Chen, J.; Carrillo, J.M.Y.; Zhu, Q.; Sumpter, B.G. Harnessing Data and Control with AI/ML-driven Polymerization and Copolymerization. Faraday Discuss. 2025; advance article. [Google Scholar] [CrossRef]

- Shah, K.A.; Albuquerque, R.Q.; Brütting, C.; Dippold, M.; Ruckdäschel, H. Low-density polyamide 12 foams using Bayesian optimization and inverse design. Polymer 2025, 320, 128096. [Google Scholar] [CrossRef]

- Wang, C.; Kim, Y.J.; Vriza, A.; Batra, R.; Baskaran, A.; Shan, N.; Li, N.; Darancet, P.; Ward, L.; Liu, Y.; et al. Autonomous platform for solution processing of electronic polymers. Nat. Commun. 2025, 16, 1498. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q.; Dong, B.; He, T.; Sun, Z.; Zhu, J.; Zhang, Z.; Lee, C. Progress in wearable electronics/photonics—Moving toward the era of artificial intelligence and internet of things. InfoMat 2020, 2, 1131–1162. [Google Scholar] [CrossRef]

- Gao, T.; Lu, W. Machine learning toward advanced energy storage devices and systems. iScience 2021, 24, 101936. [Google Scholar] [CrossRef] [PubMed]

- Finegan, D.P.; Squires, I.; Dahari, A.; Kench, S.; Jungjohann, K.L.; Cooper, S.J. Machine-Learning-Driven Advanced Characterization of Battery Electrodes. ACS Energy Lett. 2022, 7, 4368–4378. [Google Scholar] [CrossRef]

- Shen, Z.H.; Liu, H.X.; Shen, Y.; Hu, J.M.; Chen, L.Q.; Nan, C.W. Machine learning in energy storage materials. Interdiscip. Mater. 2022, 1, 175–195. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, T.; Zhang, C.; Shang, Y.; Lei, Q.; Chi, Q. Advances in Polymer Dielectrics with High Energy Storage Performance by Designing Electric Charge Trap Structures. Adv. Mater. 2024, 36, 2310272. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Feng, B.; Huo, J.; Xiao, Y.; Wang, W.; Peng, J.; Li, Z.; Du, C.; Wang, W.; Zou, G.; et al. Artificial Intelligence Meets Flexible Sensors: Emerging Smart Flexible Sensing Systems Driven by Machine Learning and Artificial Synapses. Nano-Micro Lett. 2024, 16, 14. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Song, X.; Xu, H.; Gu, Y.; Fan, J.; Sun, B.; Yu, L. Artificial Intelligence Empowers Solid-State Batteries for Material Screening and Performance Evaluation. Nano-Micro Lett. 2025, 17, 287. [Google Scholar] [CrossRef]

- Mannodi-Kanakkithodi, A.; Pilania, G.; Huan, T.D.; Lookman, T.; Ramprasad, R. Machine Learning Strategy for Accelerated Design of Polymer Dielectrics. Sci. Rep. 2016, 6, 20952. [Google Scholar] [CrossRef]

- Kern, J.; Chen, L.; Kim, C.; Ramprasad, R. Design of polymers for energy storage capacitors using machine learning and evolutionary algorithms. J. Mater. Sci. 2021, 56, 19623–19635. [Google Scholar] [CrossRef]

- Feng, Y.; Tang, W.; Zhang, Y.; Zhang, T.; Shang, Y.; Chi, Q.; Chen, Q.; Lei, Q. Machine learning and microstructure design of polymer nanocomposites for energy storage application. High. Volt. 2022, 7, 242–250. [Google Scholar] [CrossRef]

- Saco, A.; Sundari, P.S.; Karthikeyan, J.; Paul, A. An Optimized Data Analysis on a Real-Time Application of PEM Fuel Cell Design by Using Machine Learning Algorithms. Algorithms 2022, 15, 346. [Google Scholar] [CrossRef]

- Chen, J.; Mohammed, K.J.; Ali, E.; Marzouki, R. Carbon additives to improve polymer performance in energy applications using machine learning. Case Stud. Constr. Mater. 2025, 23, e05099. [Google Scholar] [CrossRef]

- Maeda, H.; Wu, S.; Marui, R.; Yoshida, E.; Hatakeyama-Sato, K.; Nabae, Y.; Nakagawa, S.; Ryu, M.; Ishige, R.; Noguchi, Y.; et al. Discovery of liquid crystalline polymers with high thermal conductivity using machine learning. npj Comput. Mater. 2025, 11, 205. [Google Scholar] [CrossRef]

- Nistane, J.; Datta, R.; Lee, Y.J.; Sahu, H.; Jang, S.S.; Lively, R.; Ramprasad, R. Polymer design for solvent separations by integrating simulations, experiments and known physics via machine learning. npj Comput. Mater. 2025, 11, 187. [Google Scholar] [CrossRef]

| Topic | Methods | Key Insights and Contributions | References |

|---|---|---|---|

| Machine Learning Approaches in Polymer Science: Polymer Design and Characterization by AI-ML | |||

| Development of a ML-based approach for the rapid characterization of SMPs. | Supervised ML, Multiscale Unsupervised Feature Selection Ensemble Learning, BRR, PNN, RBFN, RFN, AdaBoosting Random Subspace Method, Vision-Based Video Analysis | Rapid Characterization of SMP Behavior Data-Driven Modeling Feature Extraction from Thermal Videos Optimization of Material Properties Predictive Modeling for SMP Design Enabling Soft Robotics Applications Benchmarking and Validation AI/ML methods have advanced polymer design and characterization by enabling rapid and accurate modeling of SMP behavior, optimizing material properties, and supporting innovative applications like soft robotics. | Dutta et al. [44] |

| A novel graph-based representation and ML approach for predicting the properties of polymer molecular ensembles, addressing the challenges posed by their stochastic nature. | GNNs, D-MPNN, wD-MPNN, RF Fully Connected NN, Fingerprint Representations Sequence Sampling | Improved Property Prediction Representation of Molecular Ensembles Discrimination Between Polymer Variants Data Efficiency Support for Virtual Screening Application to Experimental Datasets Framework for Polymer Informatics These contributions enable faster and more accurate polymer design and characterization, advancing polymer informatics and supporting the discovery of novel materials for various applications. | Aldeghi and Coley [45] |

| The use of interpretable ML and physical descriptors to efficiently design and predict high thermal conductivity polymers for improved heat dissipation in organic electronics. | RF, XGBoost, MLP, SR SHAP Analysis, PCA, Mol2vec, BO | Efficient Prediction of TC Feature Engineering and Descriptor Optimization Interpretability of ML Models SR for Mathematical Modeling Virtual Screening of Polymer Databases Linking Hierarchical Structures to Thermal Properties Facilitating Experimental Design Integration of AI/ML methods has transformed polymer design from a trial-and-error approach to a systematic, data-driven framework. This accelerates the discovery of high-TC polymers and enhances understanding of structure-property relationships, driving innovation in polymer materials. | Huang et al. [46] |

| Utilizing ML algorithms to analyze the bead foam extrusion process of PLA, focusing on the impact of various processing parameters on bead foam density and melt pressure. | DTR, RF, GBR, LASSO Regressor, SVR, LR | Improved Prediction Accuracy Process Optimization Correlation Analysis Handling Complex Data Advancing Polymer Design Sustainability and Efficiency Feature Selection and Automation Scalability to Other Polymers Use of AI/ML enhances polymer science through accurate predictions, optimized processes, and the design of sustainable materials with tailored properties, representing a significant advancement in material science and engineering. | Shah et al. [47] |

| Optimization of low-density polyamide 12 foams using BO and ML techniques to enhance their properties and reduce experimental trials in the foaming process. | BO, AL Inverse Design ML Models: LR, DT, RF, GBR, GP, LASSO, SGDR, RR Python Framework | Optimization of Processing Parameters Reduction in Experimental Effort Inverse Design for Targeted Properties Enhanced Predictive Capabilities Insights into Process-Property Relationships Characterization of Foam Morphology Sustainability in Polymer Design Scalability and Future Applications AI/ML methods have transformed polymer design and characterization by optimizing processes, minimizing experimental effort, and enhancing understanding of process-property relationships. This leads to sustainable, high-performance polymer materials for various industrial applications. | Shah et al. [49] |

| Integration of AI and ML into polymerization and copolymerization processes to optimize synthesis, manufacturing, and material properties. | ML Algorithms: BO, SNOBFIT, ParEGO, TS-EMO Digital Twins, LLMs Data Analysis and Visualization: PCA, Correlation Matrices Simulation Techniques: CGMD, Kinetic Monte Carlo Simulations Python Scripting and APIs | Optimization of Polymerization Processes Enhanced Predictive Modeling Data-Driven Insights Accelerated Discovery Improved Characterization Scalability and Efficiency Design of Functional Polymers Integration of Theory and Experiment Future Potential AI/ML methods transform polymer design and characterization through precision control, predictive modeling, efficient data analysis, and faster discovery, advancing polymer science. | Advincula et al. [48] |

| Introducing “Polybot,” an AI-driven autonomous laboratory designed to optimize the solution processing of electronic polymer thin films, specifically focusing on PEDOT:PSS. | BO, GPR, Gaussian KDE, SHAP, LHS EI Acquisition Function RFR, UMAP | Efficient Exploration of Complex Parameter Spaces Accelerated Optimization of Polymer Properties Improved Data Quality and Reliability: Interpretability of Polymer Processing-Property Relationships Scalability and Practical Application Unbiased and Systematic Data Generation Advancing Polymer Characterization Generalizable Framework for Polymer Design Integration of AI/ML methods revolutionizes polymer design and characterization through high-throughput, data-driven optimization, enhancing insights into processing-property relationships and speeding up the development of high-performance materials. This represents a significant shift in materials science, leading to smarter, more efficient polymer manufacturing. | Wang et al. [50] |

| Artificial Intelligence Machine Learning Approaches for Polymers Energy Storage | |||

| Developing a Ml-based framework to accelerate the design and discovery of polymer dielectrics. | KRR, GA | Accelerated Property Prediction Efficient Polymer Design Expansion of Polymer Options Guidance for Experimental Synthesis AI/ML methods have accelerated the discovery of advanced polymer dielectrics, meeting the demand for high-performance materials in energy storage. | Mannodi-Kanakkithodi et al. [58] |

| Using ML techniques to design and optimize the microstructure of polymer nanocomposites for enhanced energy storage applications. | RF, SVM, NN | Prediction of Energy Storage Density Optimization of Experimental Design Descriptor Weight Analysis Exploration of Effective Filler Structures Reliability Verification AI/ML methods have enhanced the design of polymer nanocomposites, boosting efficiency and innovation in energy storage materials. | Feng et al. [60] |

| The design of polymers for energy storage capacitors using ML and GA to identify candidates that can withstand high temperatures and electric fields. | ML Property Predictors, GPR models GA, Clamping Fitness Function, Duplication Checking, Chemical Screening Rules, FBS, Functional Group Screening Polymer Retrosynthesis Algorithm | Accelerated Polymer Discovery Targeted Property Optimization Enhanced Search Efficiency Synthetic Feasibility Assessment Customization for Specific Applications Public Accessibility AI/ML methods have streamlined polymer design, enhancing speed, efficiency, and precision in creating advanced materials for energy storage capacitors. | Kern et al. [59] |

| Optimization of data analysis for the design of PEMFC using ML algorithms to enhance performance and efficiency. | SVMR, LR, KNN | Optimization of PEMFC Performance Reduction of Computational Complexity Data-Driven Insights Validation Against Numerical Methods Scalability and Design Optimization AI/ML methods have greatly advanced the design, analysis, and optimization of PEMFCs, essential for energy storage and renewable energy systems. | Saco et al. [61] |

| Design of high-performance polymer membranes for organic solvent separations, utilizing a combination of ML, simulations, and experimental data to enhance solvent diffusivity predictions and identify optimal membranes. | MT PENN (PENN-1, PENN-2) GPR, NN Data Augmentation Polymer Genome Fingerprinting | Enhanced Predictive Accuracy Generalizability in Data-Limited Scenarios Physics-Based Modeling Screening Large Chemical Spaces Data-Driven Design The study on solvent separations showcases AI/ML methods that can also speed up the discovery and optimization of polymers for energy storage technologies like batteries, SCs, and dielectric materials. | Nistane et al. [64] |

| Development and optimization of polymer nanocomposites enhanced with carbon-based additives, specifically CNTs and CFs, for energy applications. | Hybrid Model Structure: combining RFR and SVR Dataset, Model Training and Validation Performance Metrics, Feature Importance Analysis Simulation and Design Optimization | Enhanced Predictive Accuracy Optimization of Material Properties Reduction in Experimental Effort Insights into Structure-Property Relationships Simulation of Untested Scenarios Improved Energy Storage Performance Error Mitigation and Data Quality Control Scalable Framework for Future Applications ML methods significantly enhance the design, performance, and development of polymer-based energy storage systems, improving their efficiency and scalability for practical use. | Chen et al. [62] |

| The discovery of LCPs with high TC using ML. | Supervised Learning, PU Learning High-Throughput Virtual Screening Descriptor Encoding, Optimization Clustering, Dimensionality Reduction | Predictive Modeling Data-Driven Design High-Throughput Screening Improved TC Molecular Orientation Analysis Phase Transition Insights ML enables the design of advanced polymers with high thermal conductivity, crucial for enhancing ESS performance and reliability. | Maeda et al. [63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopac, T. Advancing Polymer Science and Energy Storage Solutions Through the Integration of Artificial Intelligence and Machine Learning: A Transformative Approach. Polymers 2025, 17, 3267. https://doi.org/10.3390/polym17243267

Kopac T. Advancing Polymer Science and Energy Storage Solutions Through the Integration of Artificial Intelligence and Machine Learning: A Transformative Approach. Polymers. 2025; 17(24):3267. https://doi.org/10.3390/polym17243267

Chicago/Turabian StyleKopac, Turkan. 2025. "Advancing Polymer Science and Energy Storage Solutions Through the Integration of Artificial Intelligence and Machine Learning: A Transformative Approach" Polymers 17, no. 24: 3267. https://doi.org/10.3390/polym17243267

APA StyleKopac, T. (2025). Advancing Polymer Science and Energy Storage Solutions Through the Integration of Artificial Intelligence and Machine Learning: A Transformative Approach. Polymers, 17(24), 3267. https://doi.org/10.3390/polym17243267